Bottom lifting type resistance heating annealing furnace

A resistance heating, lifting technology, applied in the field of annealing furnace, can solve the problem of high scrap rate, achieve the effect of high degree of automation and meet the needs of heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

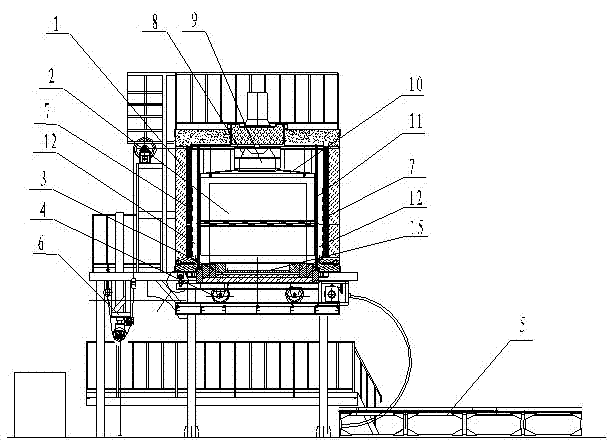

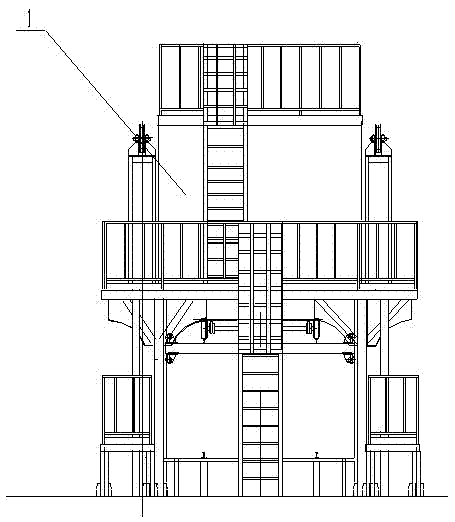

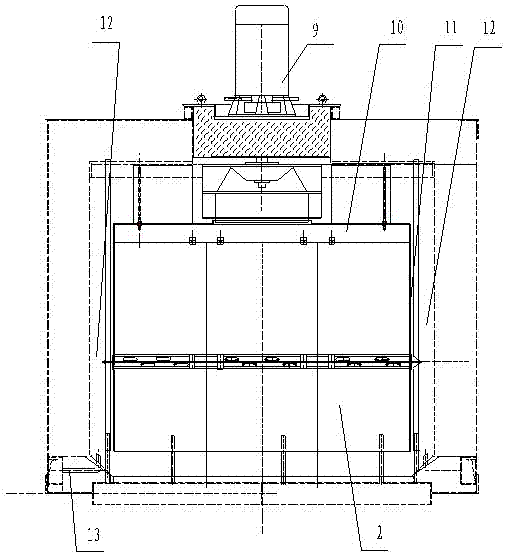

[0019] The bottom lifting type resistance heating annealing furnace of the present invention includes a furnace body 1, a furnace hearth 2 and a control device. The furnace body 1 is composed of a metal furnace shell on the surface and a heat-resistant furnace lining inside, and the cavity inside the furnace body 1 forms a furnace hearth 2 , as the area where the workpiece to be heat treated is placed; the bottom surface of the furnace body 1 is a furnace bottom cover 3 that is movable. The track 5 cooperates and can move on the track 5 (under the action of the self-contained or external driving device); the furnace bottom cover 3 can rise or fall under the drive of the lifting device 6, and after rising, it can be sealed with the furnace body 1 (sealed furnace The furnace mouth on the bottom surface of the body 1) forms the working bottom surface of the furnace 2, falls on the matching track 5 after falling, and moves on the track 5 through the running wheel 4. In the figure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com