Well-type vacuum furnace

A vacuum furnace and well-type technology, applied in the field of well-type vacuum furnaces, to achieve the effects of long service life, good furnace temperature uniformity and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

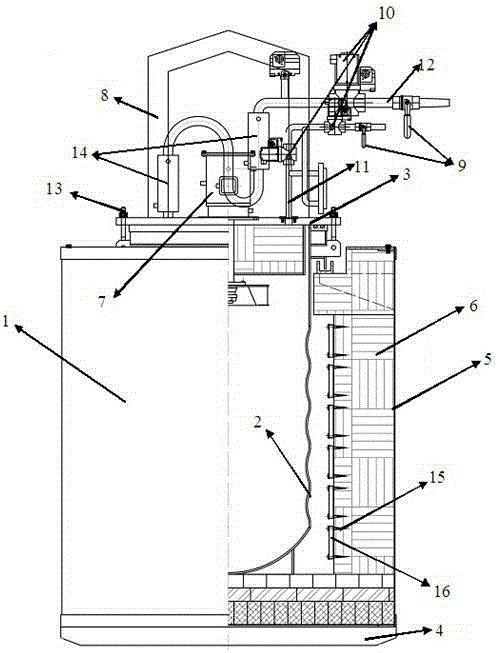

[0012] Depend on figure 1 Known, a pit-type vacuum furnace is composed of a furnace body 1, an inner tank 2 and a furnace cover 3, the furnace body 1 includes a furnace base 4, a furnace shell 5 and a furnace lining 6, and the furnace shell 5 is fixed on the furnace base 4 Above, the furnace shell 5 has a furnace surrounded by a furnace lining 6, and the inner tank 2 is arranged in the furnace. The bottom of the furnace is fixed with refractory bricks, and a barrel-shaped stainless steel inner tank 2 is fixed on the refractory bricks. The inner tank 2 opens toward In general, high-strength refractory bricks have sufficient strength to withstand pressure and have good high-temperature resistance. The furnace cover 3 is fixedly equipped with a fan device 7, a hanger 8, a manual valve 9, a protective gas pipe 11, and a vacuum tube 12. For opening and closing the furnace cover 3 and the furnace body 1, a sealing ring is provided between the furnace cover 3 and the inner tank 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com