Large vacuum annealing furnace

A vacuum annealing furnace, a large-scale technology, applied in the direction of furnace, furnace type, lighting and heating equipment, etc., can solve the problems of affecting the annealing production efficiency and quality, not all of the process requirements, difficult to drive in and out of the furnace, etc. Crystal structure and mechanical properties, significant economic and social benefits, and the effect of improving the quality of annealing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

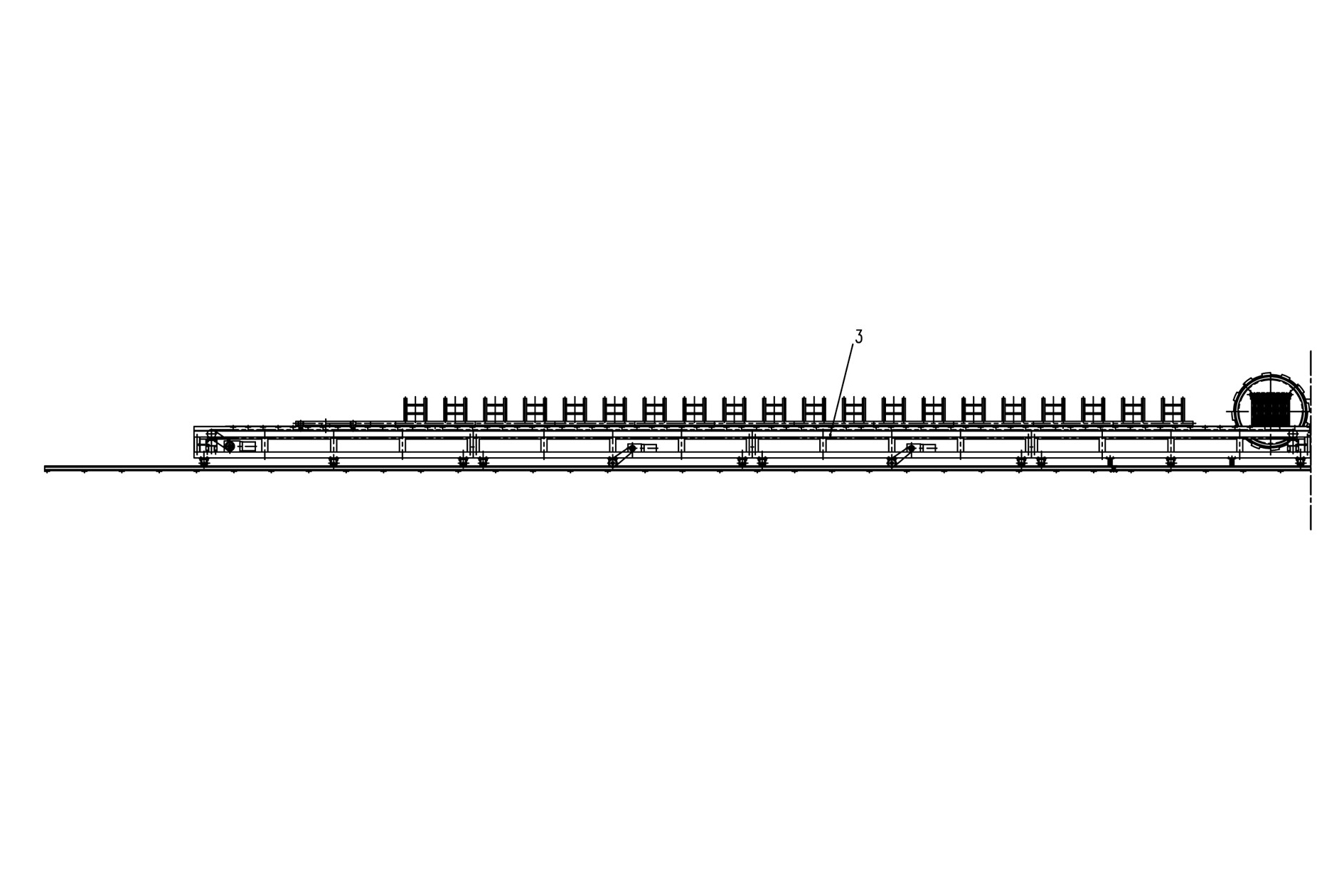

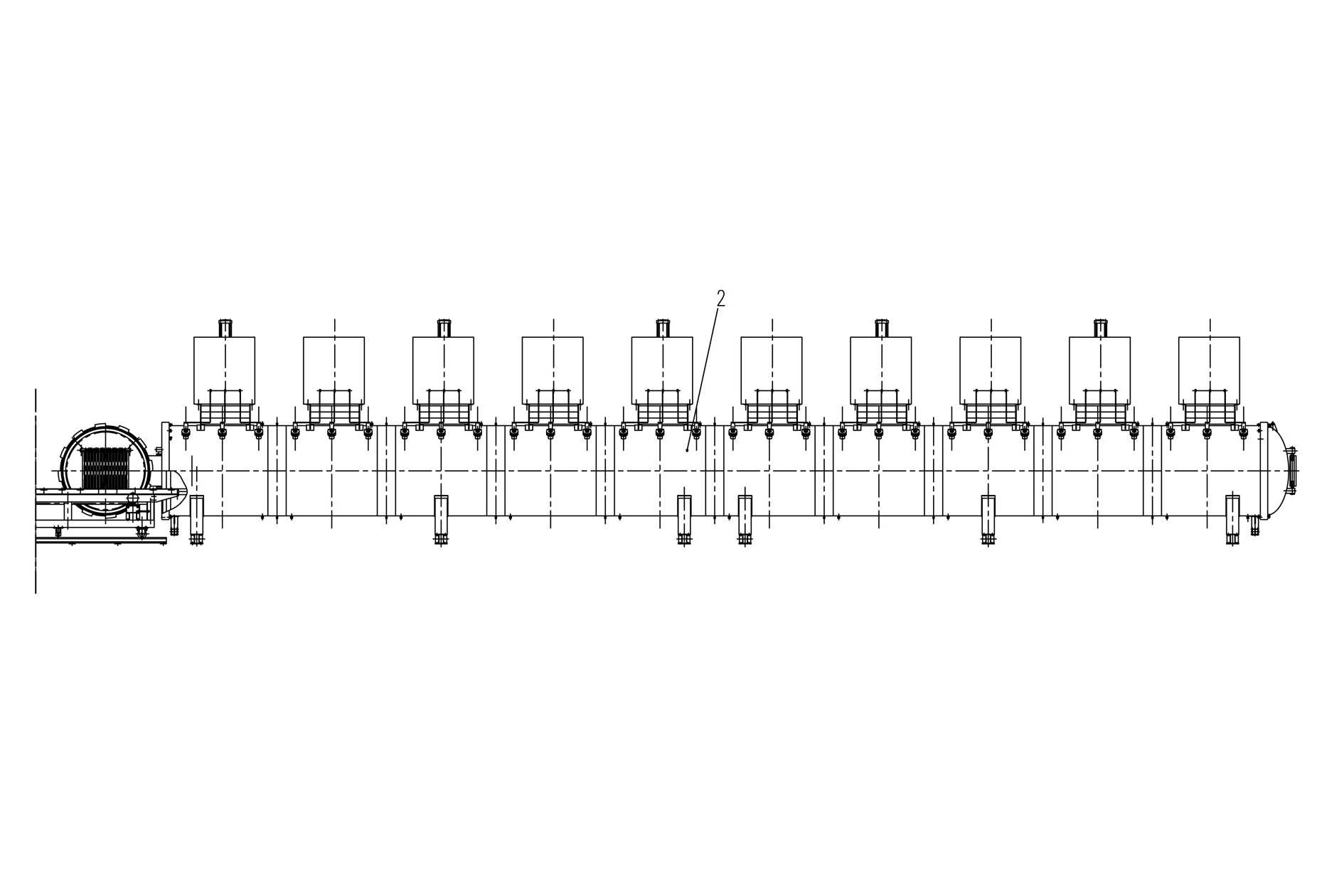

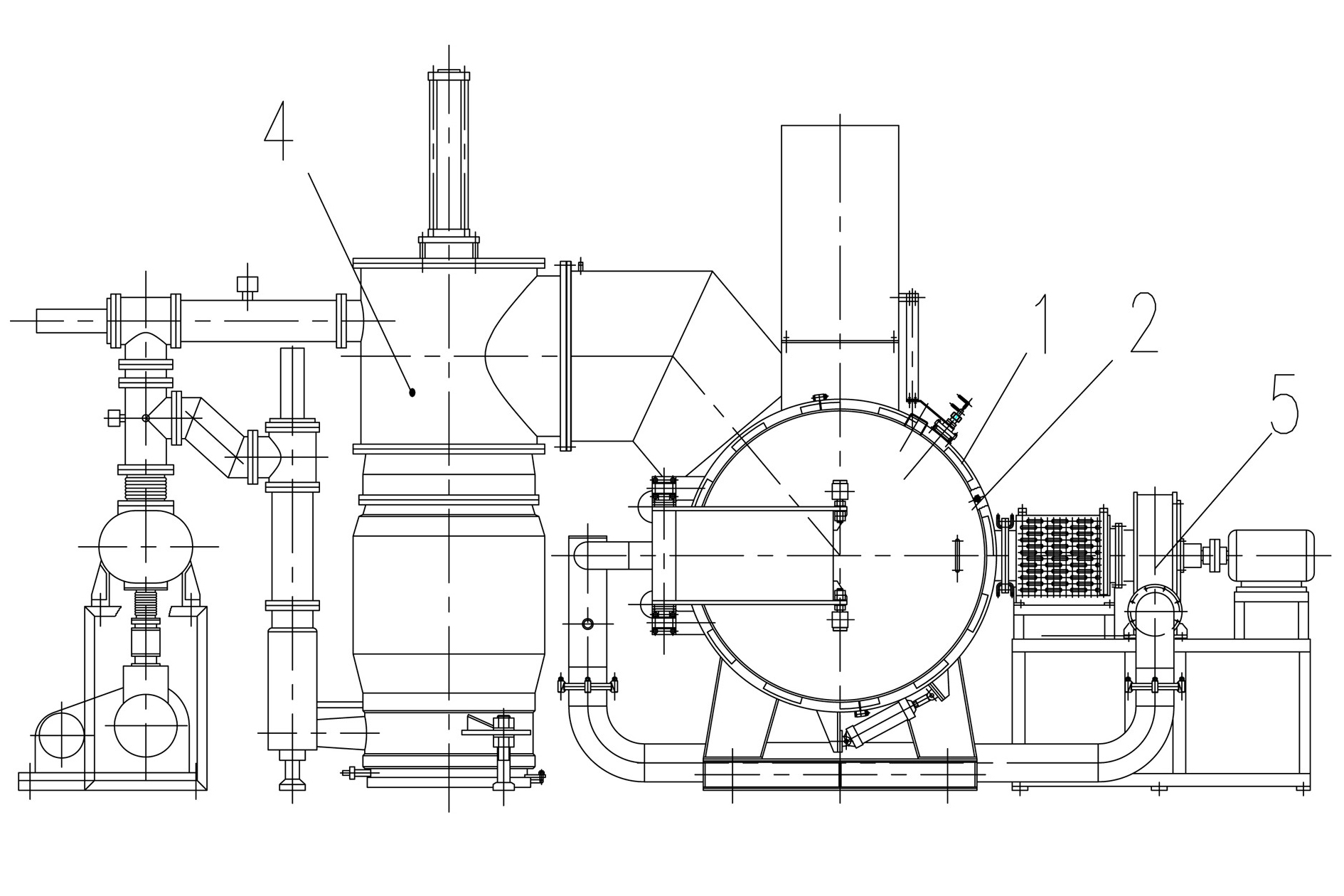

[0040] refer to figure 1 , figure 2 and image 3 As shown, the large-scale vacuum annealing furnace of the present invention adopts a single-chamber, internally heated horizontal structure, and is composed of a furnace body 1, a heating device 2, a feeding system 3, a vacuum system 4, a cooling system 5 and an electric control system.

[0041] The furnace body 1 includes a shell, a heating chamber, a front furnace door and a rear furnace door. The furnace body can be a horizontal cylindrical double-layer water-cooled structure. The front and rear doors are opened, and the front door is loaded with materials. The furnace door can be opened and closed automatically by using a cylinder push-pull structure. The rubber sealing ring is used between the furnace door and the flange of the furnace body to meet the high vacuum sealing requirements, and the sealing is stable and reliable. It is also equipped with inflation interface and valve, air release valve, temperature standar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com