Steel die forging piston heat treatment adjustable temperature control furnace with energy saving and emission reduction effects and heat treatment process method thereof

A technology of energy saving, emission reduction, heat treatment device, applied in heat treatment furnace, heat treatment process control, waste heat treatment and other directions, can solve the problems of unstable internal quality of steel die forging piston, difficult temperature control, waste of heat energy, etc., to achieve easy equipment Automatic production, good heat insulation effect, good furnace temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

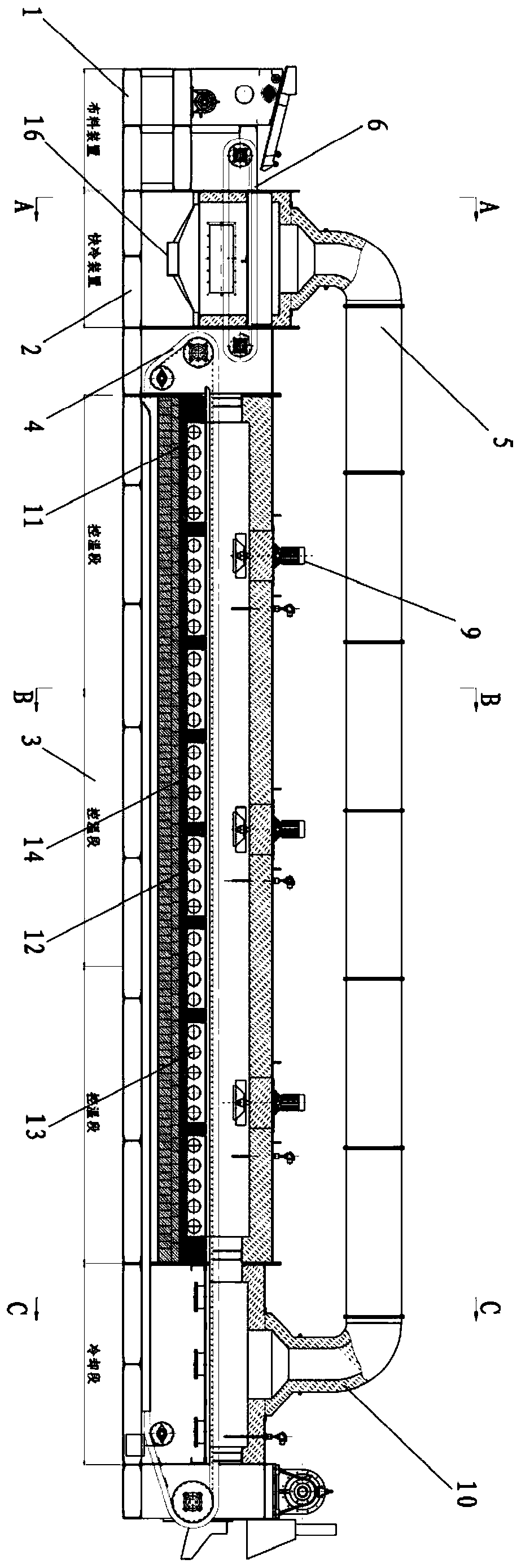

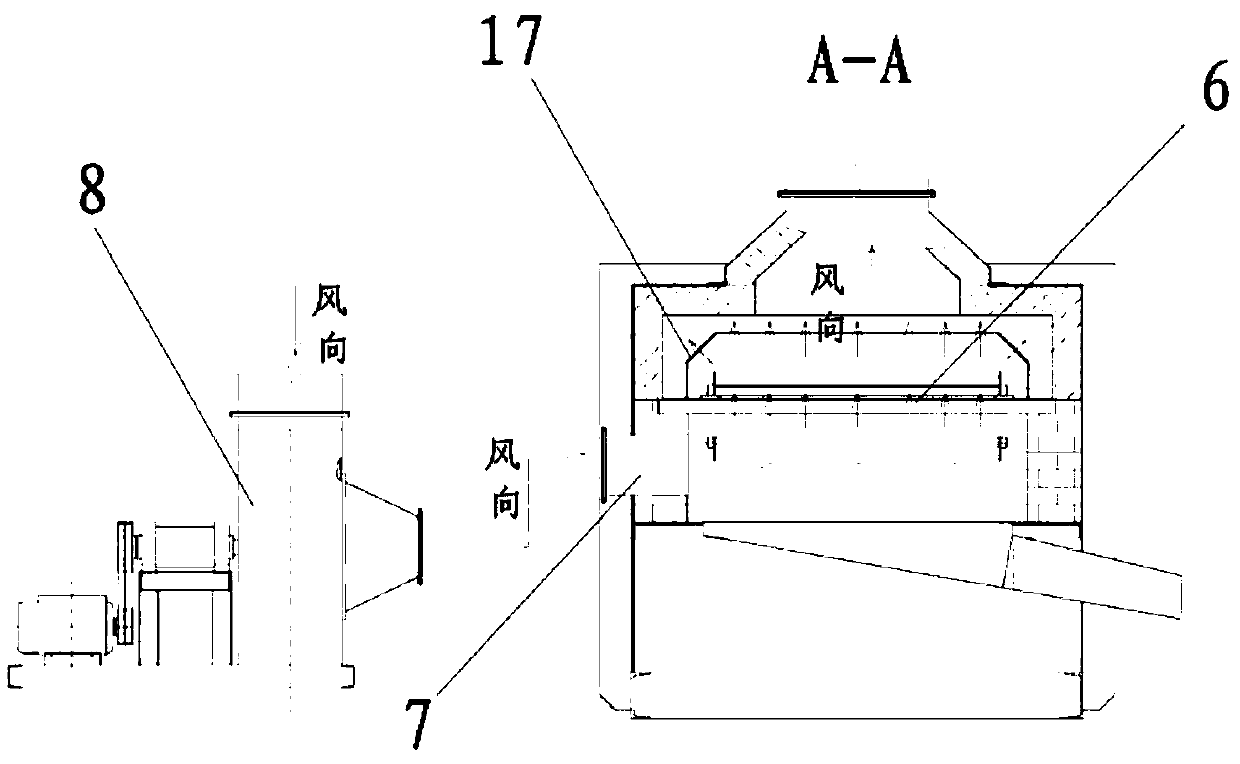

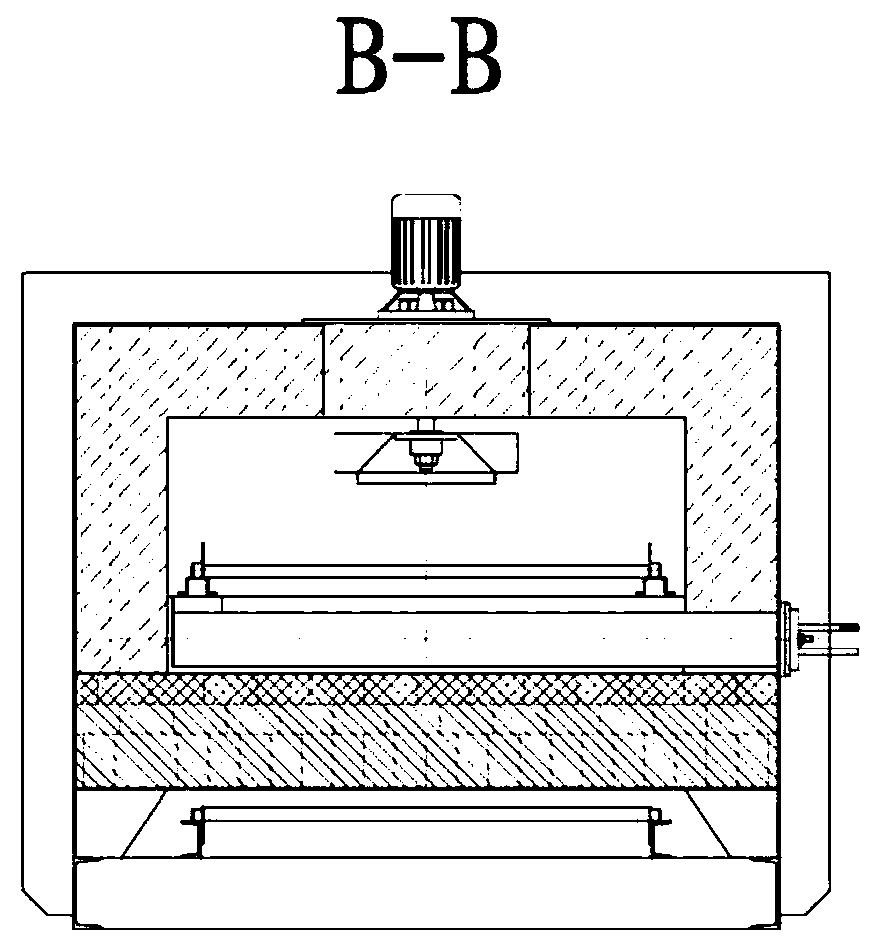

[0035] like figure 1 , figure 2 , image 3 and Figure 4 As shown, a steel die forging piston heat treatment adjustable temperature furnace with energy-saving and emission-reducing effects according to the present invention includes a material distribution device 1, a fast cooling device 2 and a heat treatment device 3, and the material distribution device 1 is a traditional transmission component. The discharge port of the device 1 is located above the conveyor belt 6 of the quick cooling device 2 , and the distributing device 1 slides the steel die forging piston pretreatment parts circulated in the previous process to the quick cooling device 2 through its slideway and buffer chain. The conveyor belt 6 of the quick cooling devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com