Patents

Literature

62results about How to "Satisfy process needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

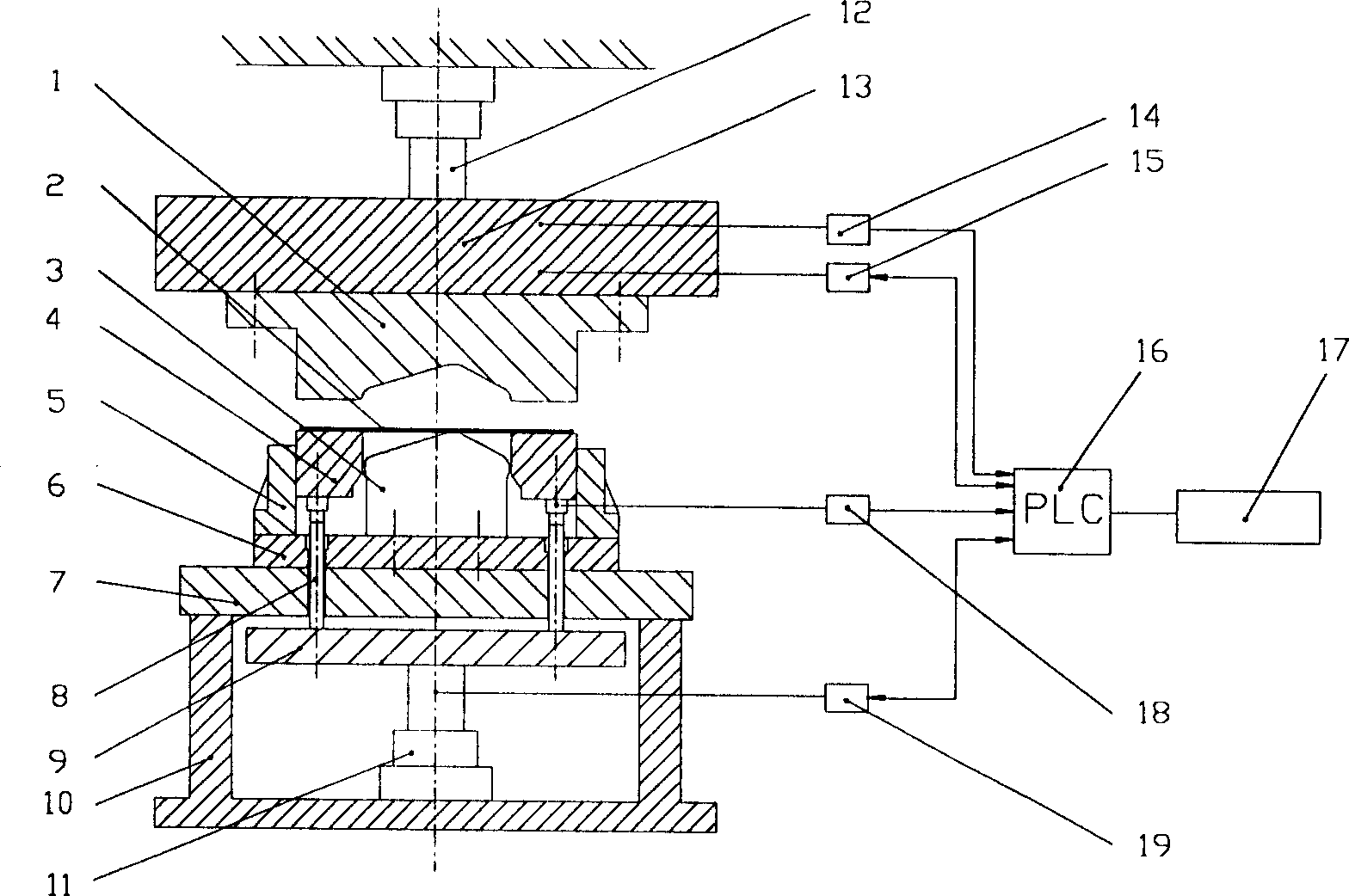

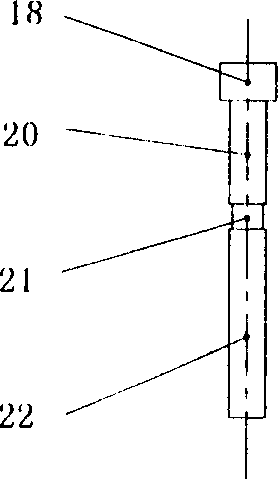

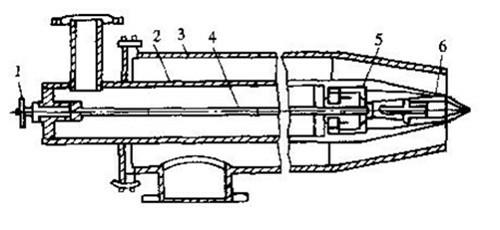

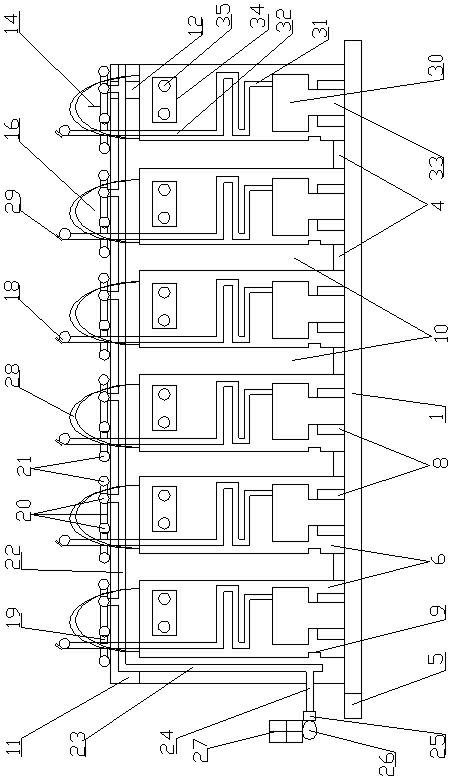

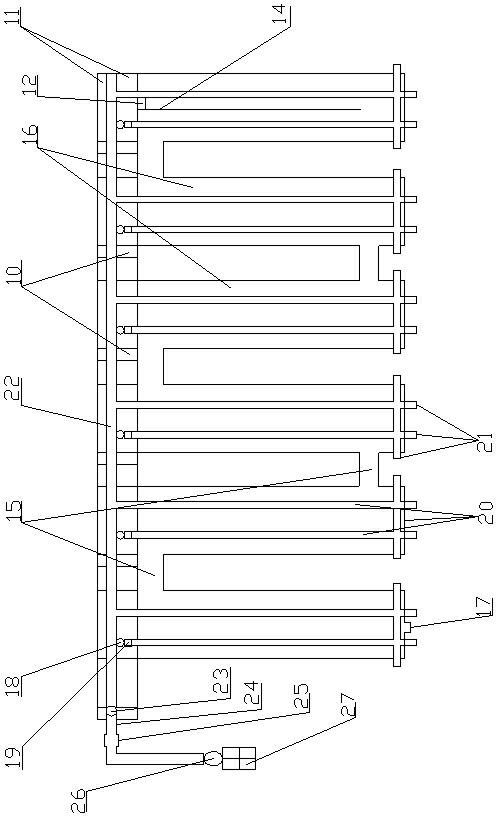

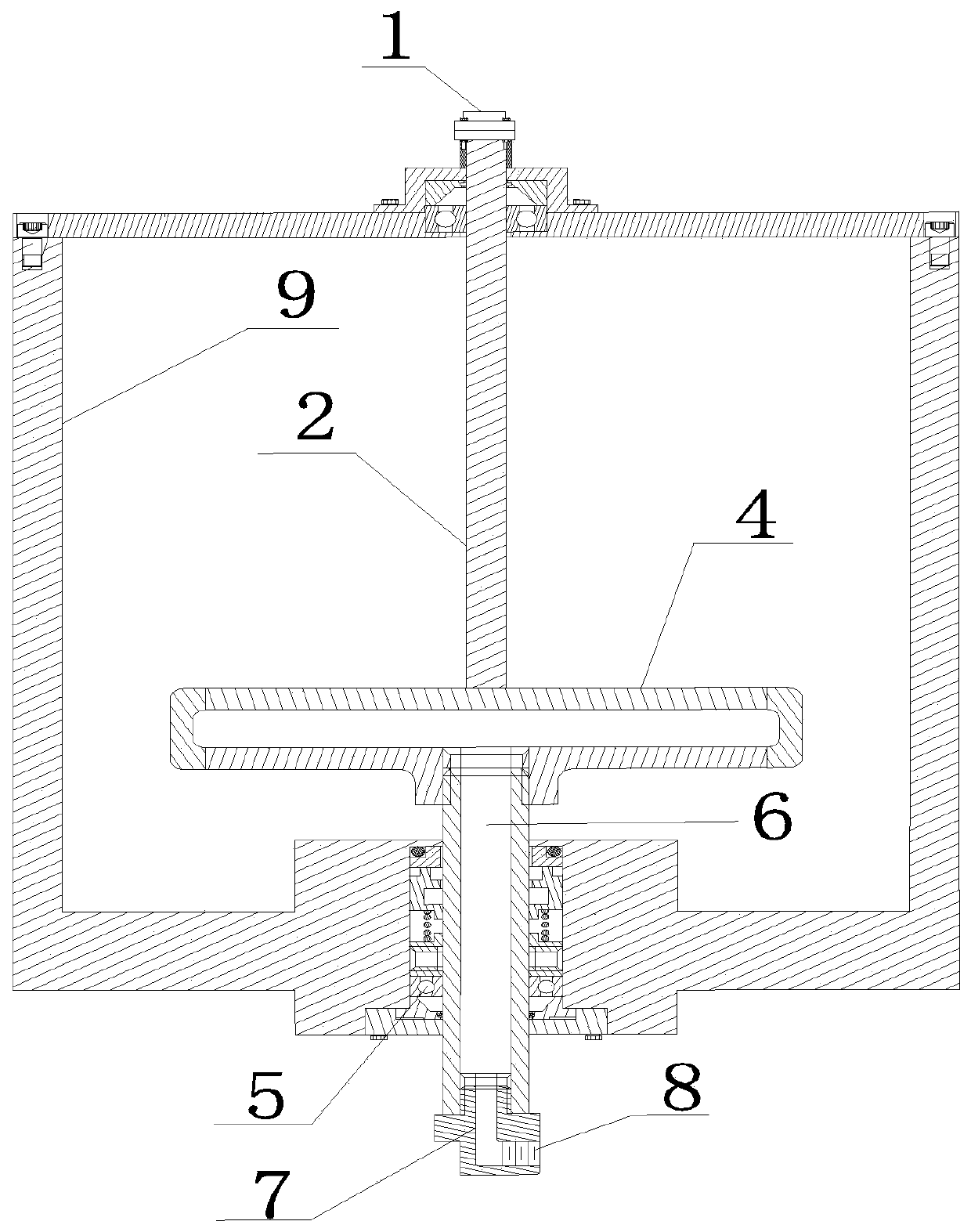

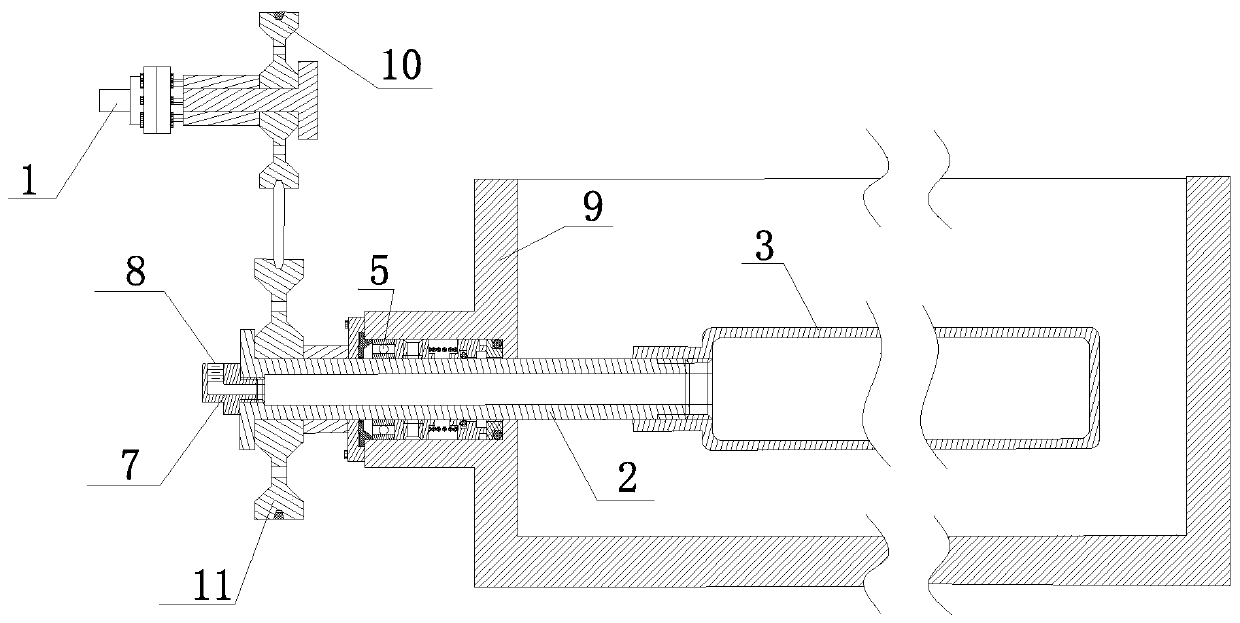

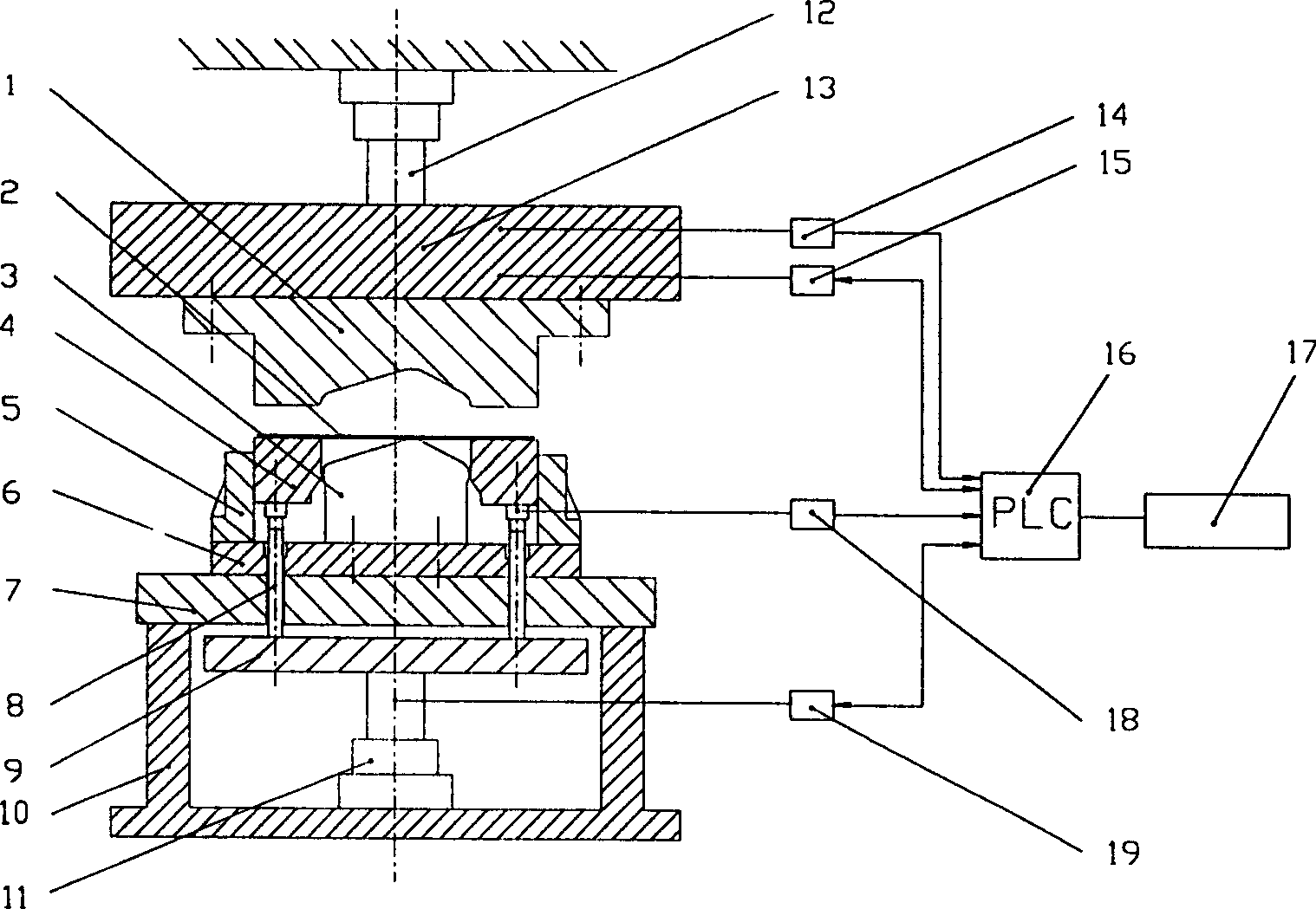

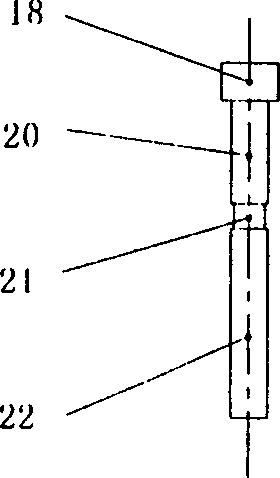

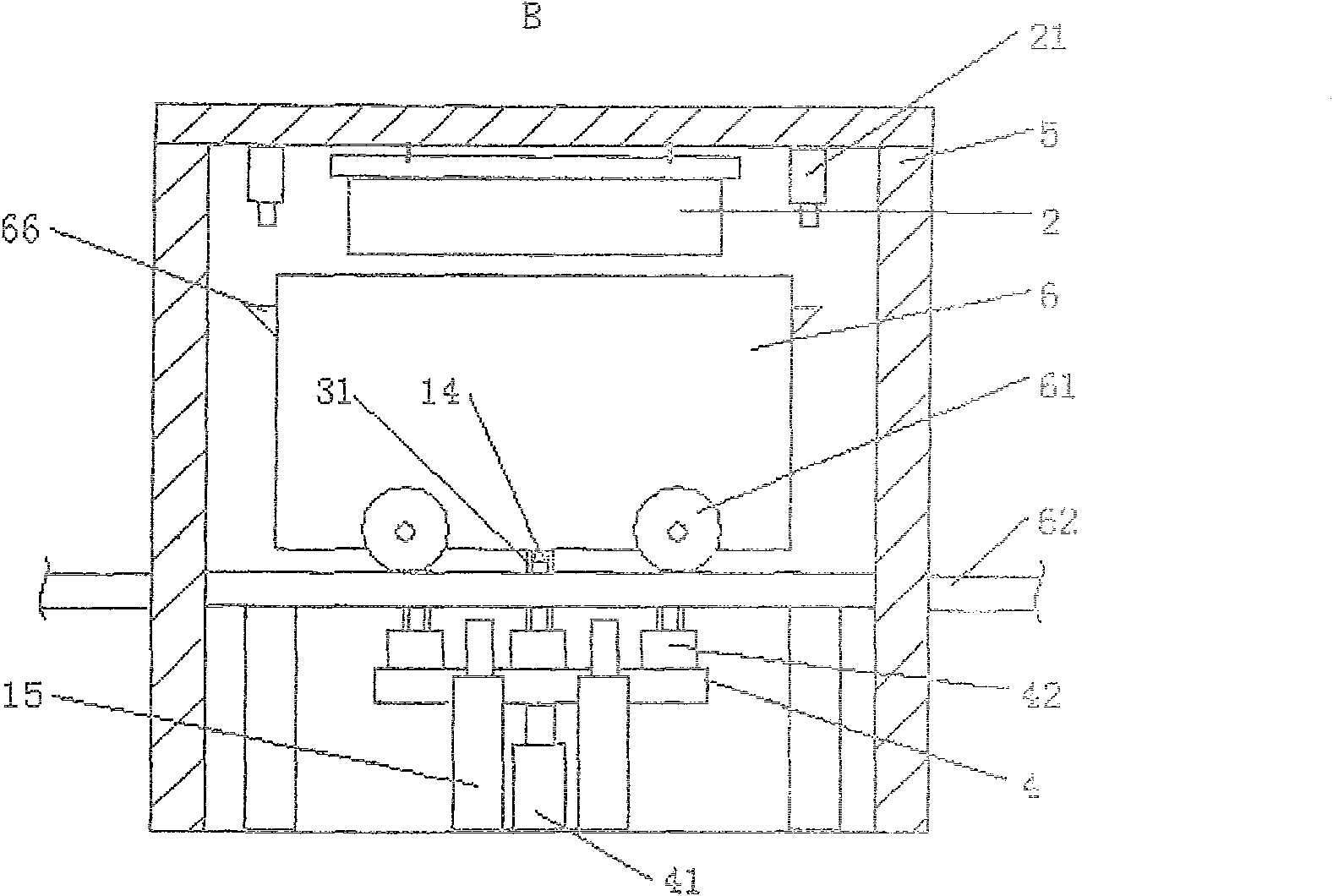

Edge pressing force and punching speed changeable single moving sheet hydraulic test machine

InactiveCN1434282AChange the total blank holder forceExcellent drawing performanceMaterial strength using tensile/compressive forcesLoop controlSheet steel

The invention is a single-acting sheet hydraulic test machine of variable border pressing force and press speed. It uses the displacement of the top slide block as the independent variable, accordingto the present working curve, uses the pressure and speed sensor to real-timely sample the pressure and speed data provide for the PLC to make close-loop control, which realize the continual variation of the border-pressing force within 150KN-1250KN and the adjustment of the press speed within 4-20 mm / s.

Owner:JIANGSU UNIV

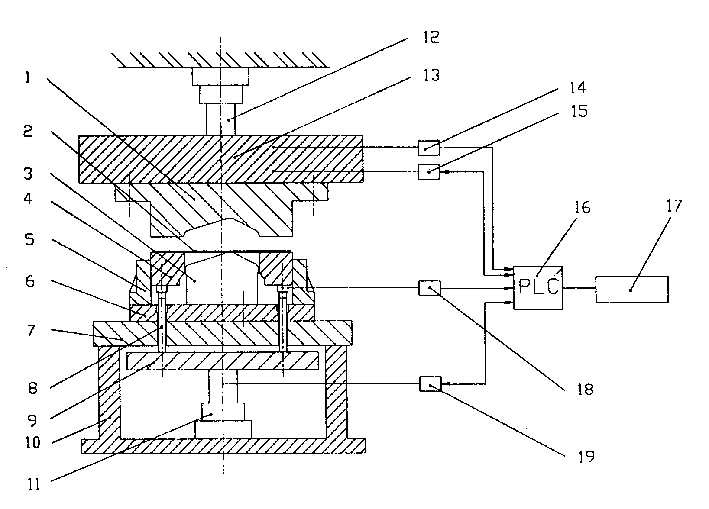

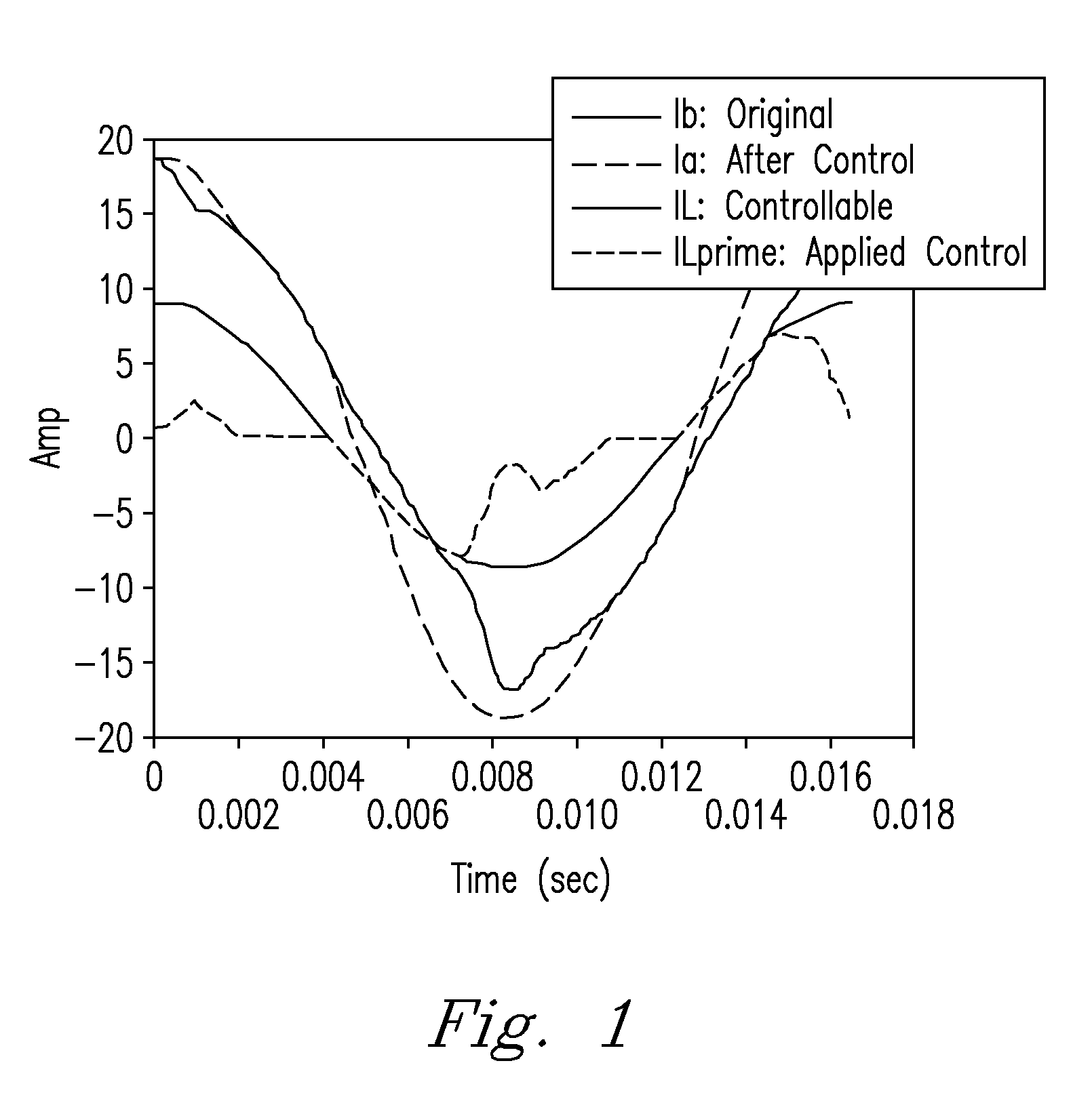

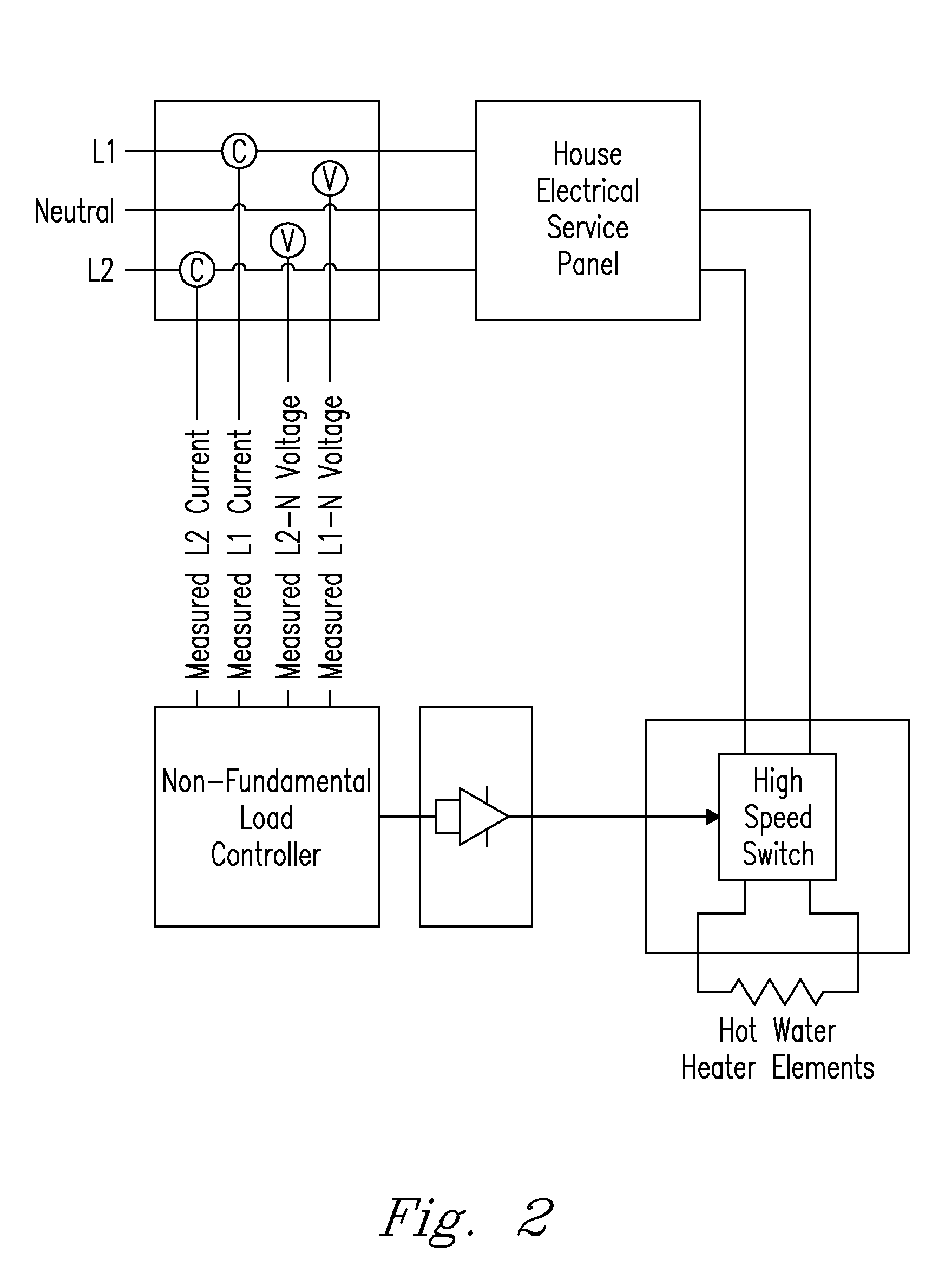

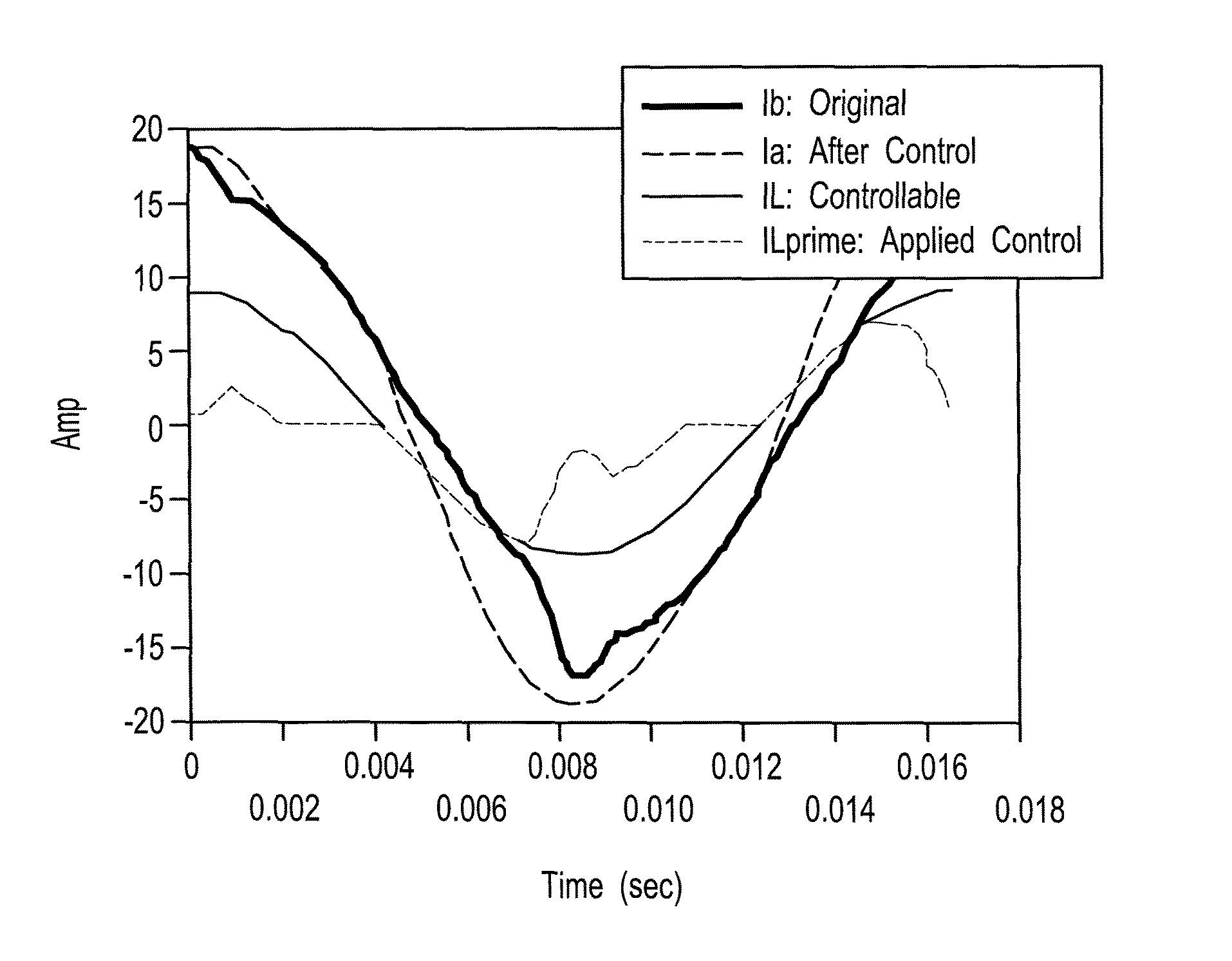

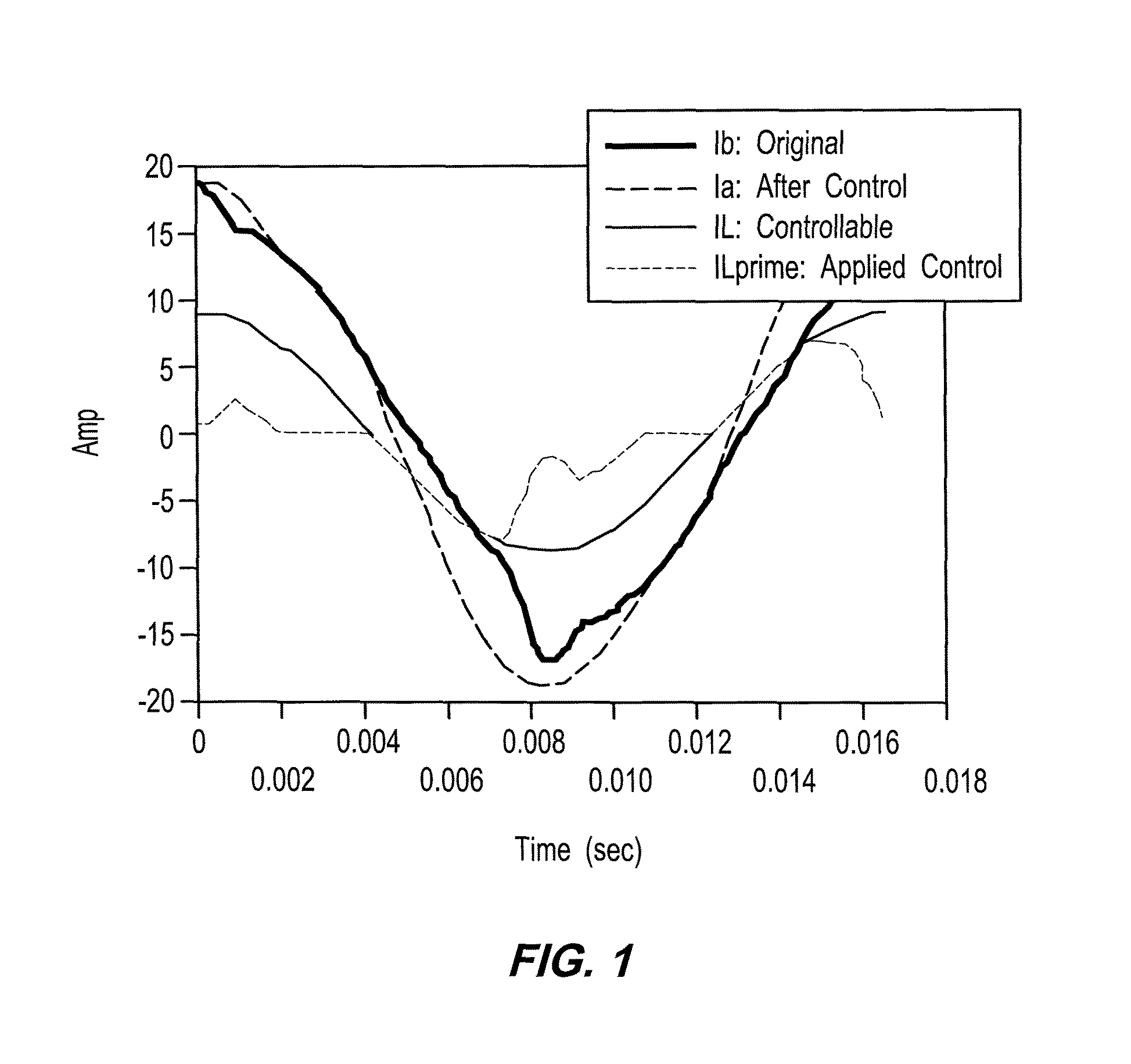

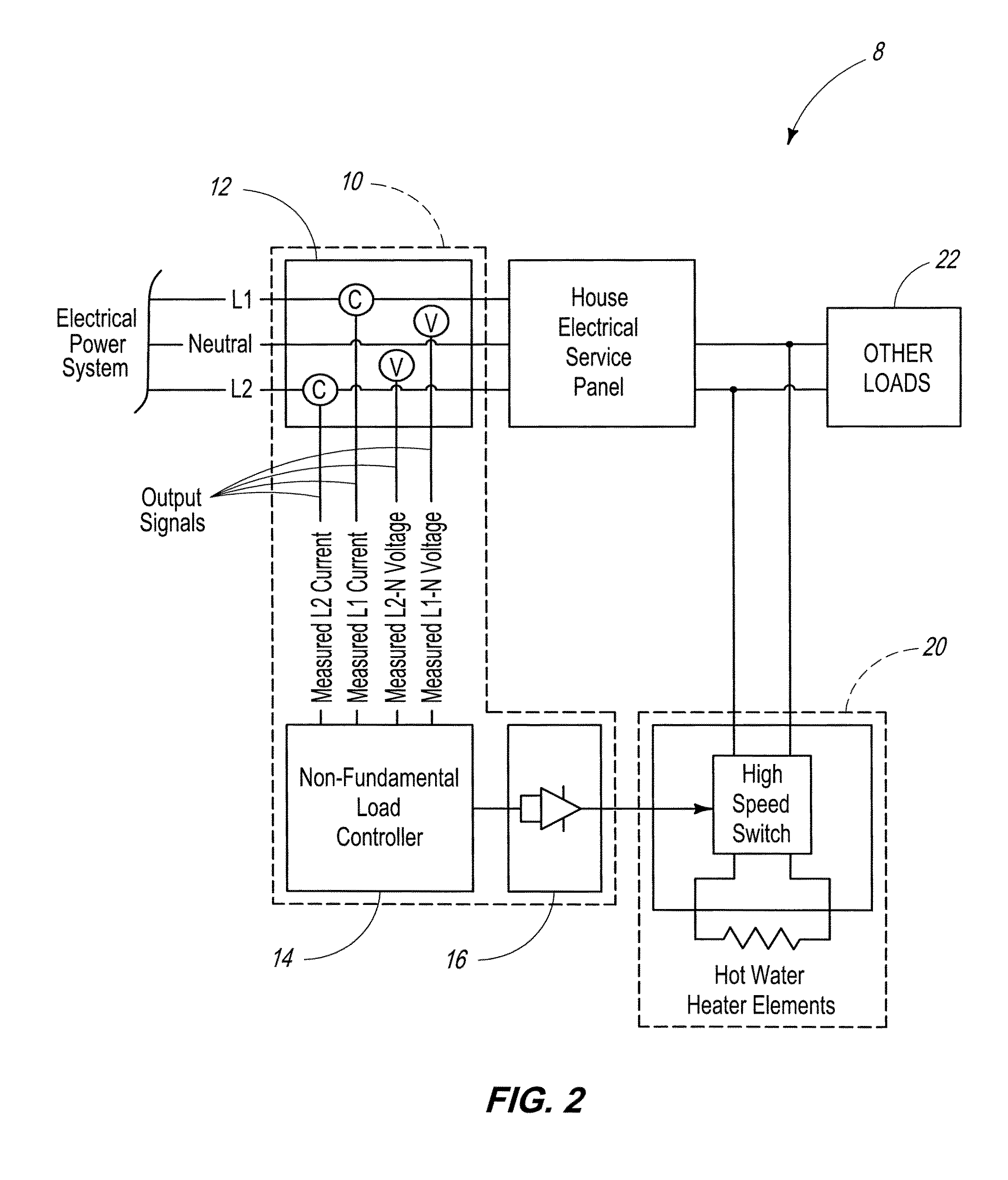

Device, method, and system for improving electrical power factor and harmonic power quality through active control of power quality improving electrical appliances

ActiveUS20090033296A1Improve electrical power factorImprove harmonic qualityBatteries circuit arrangementsEfficient power electronics conversionElectricityPower quality

A system, method and device for controlling and modifying the current drawn by an electrical load in a way that will improve the electrical power factor and harmonic quality of at least a portion of an electrical power system. In one embodiment of the invention, the invention includes a controller device that monitors the electrical current entering a site and modifies or corrects power quality of the current by directing how power will be consumed by the appliances at a site to improve the harmonic and power factor qualities of the electrical current entering the site.

Owner:BATTELLE MEMORIAL INST

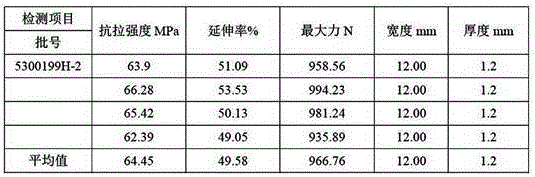

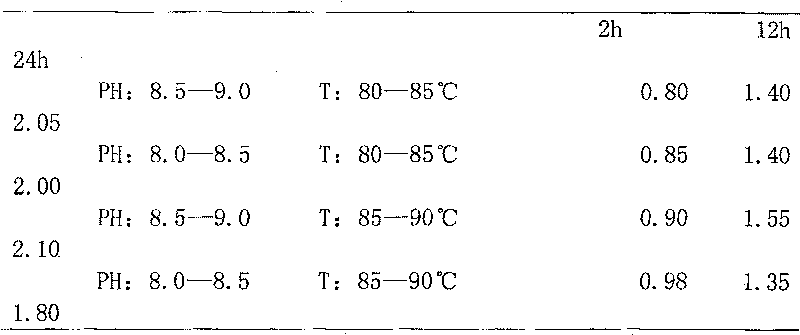

Process for fabricating low nitrogen furan resin for steel casting

ActiveCN101199983AHigh strengthReduce nitrogen contentFoundry mouldsFoundry coresFuranManufacturing technology

The invention relates to a manufacture method of furan resin used for steelcasting, in particular to a manufacture technology of low nitrogen furan resin used for steelcasting. The optimum formula is: 8 to 9 shares of formaldehyde (36.5 percent ), 3 to 5 shares of carbamide, no less than 85 shares of furfuryl alcohol, 40 percent of NaOH solution, 10 percent of hydrochloric acid solution, 0.2 percent of silane coupling agent; the invention comprises the following steps: feeding material, increasing temperature by heating, dehydration, synthesizing, discharging material, packing and warehousing; the invention uses the unique technology to achieve good performances that free formaldehyde of low nitrogen furan resin used for steelcasting is less than 0.1 percent, the tensile strength for 24 hours is more than 2.2MPa, the using time is more than 30 minutes, and the nitrogen content is less than 1.4 percent.

Owner:共享新材料(山东)有限公司

Electrical energy consumption control apparatuses and electrical energy consumption control methods

ActiveUS8258761B2Improve factor and harmonic qualityImprove harmonic and power factor qualityBatteries circuit arrangementsEfficient power electronics conversionElectric power systemElectrical current

Electrical energy consumption control apparatuses and electrical energy consumption control methods are described. According to one aspect, an electrical energy consumption control apparatus includes processing circuitry configured to receive a signal which is indicative of current of electrical energy which is consumed by a plurality of loads at a site, to compare the signal which is indicative of current of electrical energy which is consumed by the plurality of loads at the site with a desired substantially sinusoidal waveform of current of electrical energy which is received at the site from an electrical power system, and to use the comparison to control an amount of the electrical energy which is consumed by at least one of the loads of the site.

Owner:BATTELLE MEMORIAL INST

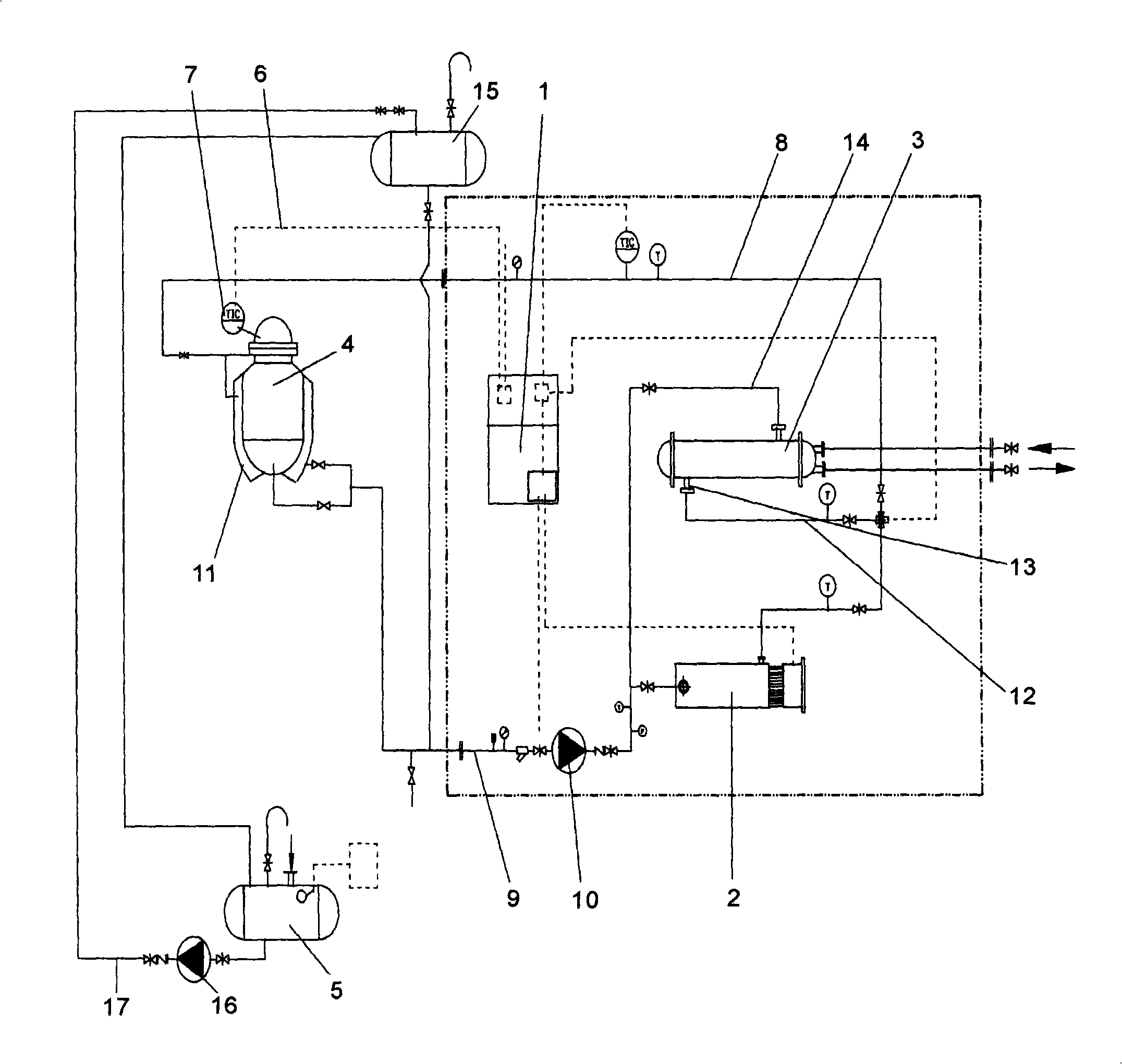

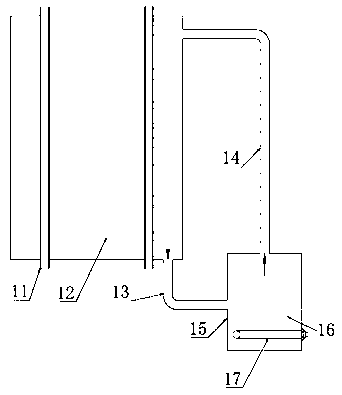

Temperature device for controlling heating or cooling of reaction kettle

InactiveCN101537335ASatisfy process needsTemperature control without auxillary powerChemical/physical/physico-chemical processesElectrical controlProcedural approach

The invention relates to a temperature device for controlling the heating or the cooling of a reaction kettle, which is characterized in that a signal conducting wire of an electrical control cabinet is connected with a temperature sensor of a reaction kettle body, a switch cabinet and a three-way valve of a heating system and oil pumps of an oil delivery pipe and an oil return pipe; the electrical control cabinet is connected with a power supply; the oil delivery pipe output by the heating system is connected with an oil pipe output by a cooler through the three-way valve; an outlet of the three-way converging valve is connected with an oil inlet pipe of the reaction kettle through a pipeline; a circulating oil pump is arranged on the oil return pipe; and a slippage pump of the circulating oil pump is arranged on an oil supplementing pipeline positioned between an oil storage tank and an expanding oil tank. When materials inside the reaction kettle are heated to certain temperature by oil which flows to a clamping sleeve of the reaction kettle, the temperature sensor which is embedded into the reaction kettle body sends signals back to the electrical control cabinet, and the electrical control cabinet sends a command to the heating system to adjust heating power or stop heating or partly start a cooling loop of the three-way valve so as to enable the reaction kettle to internally keep preset temperature. The whole temperature device is controlled by procedures, thereby meeting a requirement for automated management of factories.

Owner:王颖

An adjustable flame burner

The invention discloses an adjustable flame burner, comprising a handwheel, a gas pipe, an air pipe and a pull rod. The air pipe is provided with a gas pipe, the gas pipe is provided with a pull rod, and the pull rod is provided with a hand The wheel includes a throttle ring and a gas distributor, the throttle ring is mounted on the tie rod, and the gas distributor is connected with the tie rod. The invention can make the pull rod drive the gas distributor to move forward or backward by rotating the handwheel, so as to change the gas spraying condition to adjust the length and luminosity of the artillery, so as to meet the technological requirements of the heated object.

Owner:大连经济技术开发区水国燃烧器有限公司

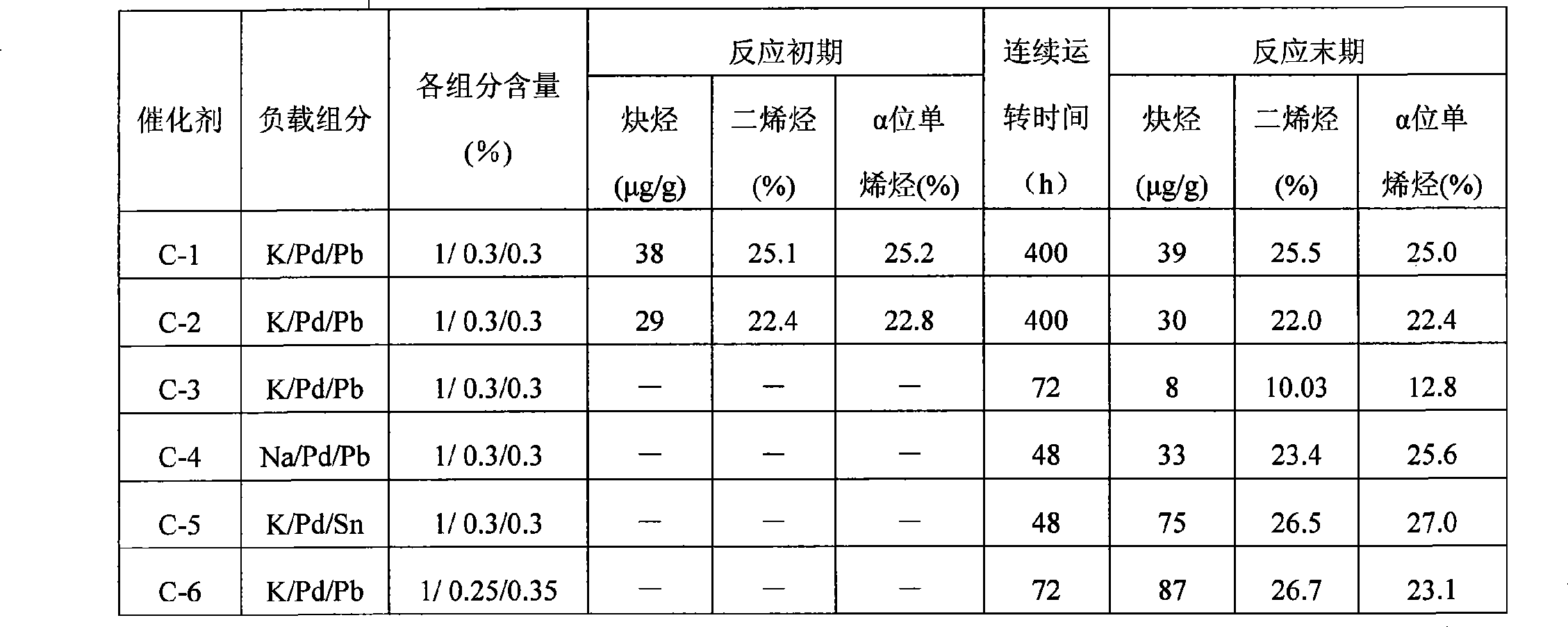

Selective hydrogenation catalyst for carbon five fraction and preparation and use thereof

ActiveCN101380590AImprove catalytic performanceExtended service lifeMolecular sieve catalystsHydrocarbon by hydrogenationMolecular sieveNitrate

The invention provides a selective hydrogenation catalyst for C5 fraction. The catalyst takes a compound of alumina and molecular sieves as a carrier and takes metals in the IA or IIA group, the VIII group, the IVA group and the IB group as active components. The compound carrier is soaked in aqueous solution of metallic compound in the IA / IIA group and is soaked in water soluble salt solution of the metals in the VIII group, nitrate solution of the metals in the IVA group and nitrate solution of the metals in the IB group by one step or multiple steps; after being soaked by one step, the compound carrier is dried for 12-20h at the temperature of 80-200 DEG.C, and then is calcined for 1-12 hours at the temperature of 350-650 DEG C. When the selective hydrogenation is carried out on unsaturated compounds in the C5 fraction by the catalyst, the transformation ratio of alkyne hydrogenation is more than or equal to 45%, the transformation ratio of dialkene is 15-35%, the content of alpha position olefin after hydrogenation is more than or equal to 15% and can meet the need of producing alpha-resin with high quality in the process of subsequent production, thus improving the quality of the alpha-resin products.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

Magnesium-iron-carbon brick used for vanadium-extracting converter and preparation method thereof

ActiveCN103387396AImproved thermal shock resistance and corrosion resistanceMaintain high temperature strengthMagnesiteFixed carbon

The invention relates to a magnesium-iron-carbon brick used for a vanadium-extracting converter and a preparation method thereof, and belongs to the technical field of refractory materials. The brick comprises, by weight, 62-84% of fused magnesite clinker, 10-18% of flaky graphite, 5-12% of iron powder, 1-3% of netted fixed carbon and 0-5% of an anti-oxidant. The preparation method comprises (1) a step of mixing the fused magnesite clinker, the flaky graphite, the iron powder and an organic binding agent, adding or not adding the anti-oxidant, and mixing uniformly to obtain a mixture; (2) a step of subjecting the mixture to compression moulding under a pressure of 200-250 MPa to prepare an unburned brick; and (3) a step of subjecting the unburned brick to heat treatment at 150-250 DEG C for 12-32 h to obtain the magnesium-iron-carbon brick. The brick provided by the invention has good practical performances and the simple preparation method, and has a good application prospect.

Owner:NORTHEASTERN UNIV

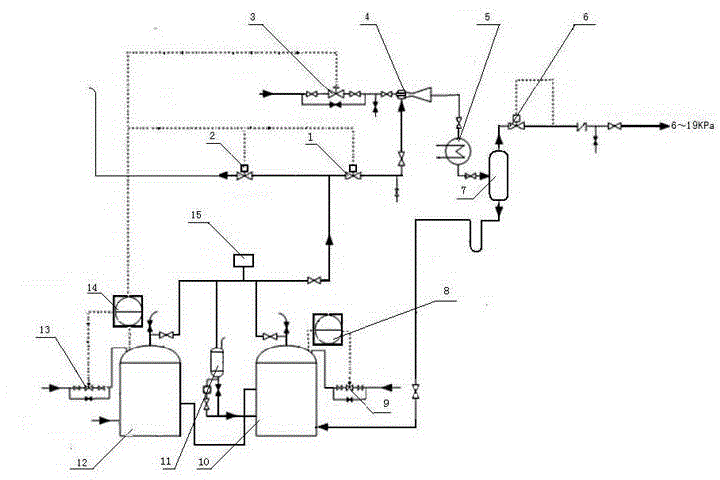

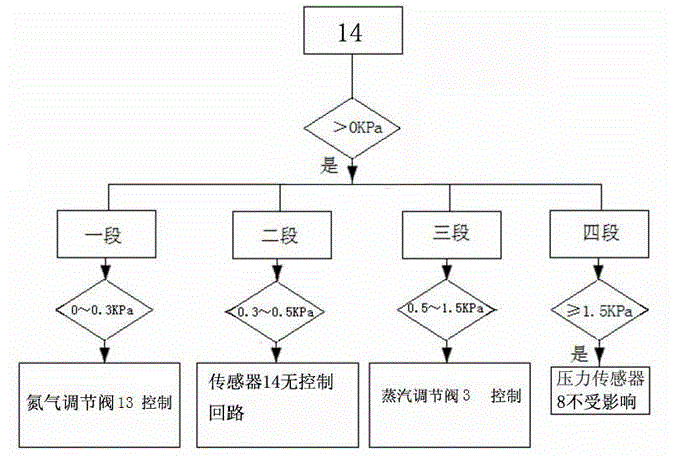

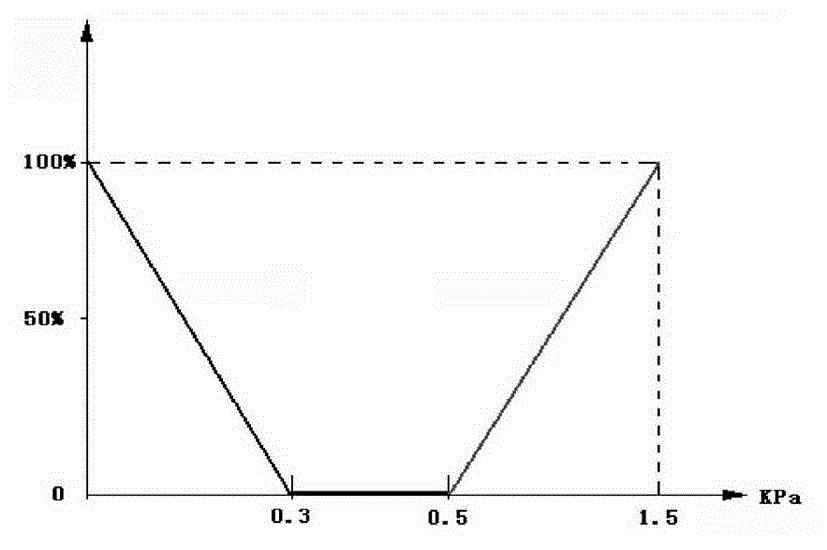

Sealed recovery and operation pressure stabilizing control method for tank top tail gas of refinery enterprise atmospheric storage tank

ActiveCN105668064AGuaranteed uptimeSolve the difficult problem of airtight recyclingLarge containersNitrogenSewage

The invention relates to a sealed recovery and operation pressure stabilizing control method for tank top tail gas of a refinery enterprise atmospheric storage tank. The sealed recovery and operation pressure stabilizing control method for the tank top tail gas of the refinery enterprise atmospheric storage tank is suitable for production requirements of a refinery enterprise and comprises the steps that the tank top tail gas in a steam jet compressor is subjected to gas-steam on-line supercharging and then conveyed to a cooler to be cooled to 45 DEG C; after the tank top tail gas is subjected to gas-liquid separation, non-condensable gas enters a refinery low-pressure gas flare system, and condensate liquid reflows to a sewage storage tank through self pressure. Normal operation of the sealed recovery and operation pressure stabilizing control method is controlled in a segmented mode, when the tank top pressure is 0-0.3 kPa, a nitrogen adjusting valve is opened, and a steam adjusting valve is closed; when the tank top pressure is 0.3-0.5 kPa, the nitrogen adjusting valve is closed, and the steam adjusting valve is closed; when the tank top pressure is 0.5-1.5 kPa, the nitrogen adjusting valve is closed, and the steam adjusting valve is opened; and when the tank top pressure is greater than or equal to 1.5 kPa, a control brake valve is opened. According to the sealed recovery and operation pressure stabilizing control method for the tank top tail gas of the refinery enterprise atmospheric storage tank, the tank top tail gas of the atmospheric storage tank is led into the refinery low-pressure gas flare system after being supercharged, the zero emission purpose is achieved, and the problem that the atmospheric storage tank is low in operation pressure is solved.

Owner:CHINA PETROLEUM & CHEM CORP

Low-carbon dense baking system for modulating cured tobacco

InactiveCN102090707ASatisfy process needsReduce energy consumptionTobacco preparationSolar heat devicesSystems designTrapping

The invention relates to a low-carbon dense baking system for modulating cured tobacco, comprising a group of dense curing barns; a double-arch film tent is arranged above each dense curing barn; a double-arch film heat-collecting and heat-trapping room is arranged below each double-arch film tent; the double-arch film heat-collecting and heat-trapping room is communicated with a hot air shared passage; a single-pit hot air personal passage communicated with a dense curing barn heating room is arranged on the hot air shared passage; a high-temperature smoke radiation pipe communicated with a heating furnace chimney through a smoke on-off machine is arranged in the double-arch film heat-collecting and heat-trapping room; the high-temperature smoke radiation pipe is communicated with a smoke interconnecting passage; and the smoke interconnecting passage is communicated with a smoke devulcanizer; and the smoke devulcanizer is communicated with a desulphurization reaction settling pond. The system is reasonable in design, thereby reducing the energy consumption of the tobacco modulation by more than 40% and reducing the discharge of pollutants by more than 60%.

Owner:河南省烟草公司平顶山市公司 +1

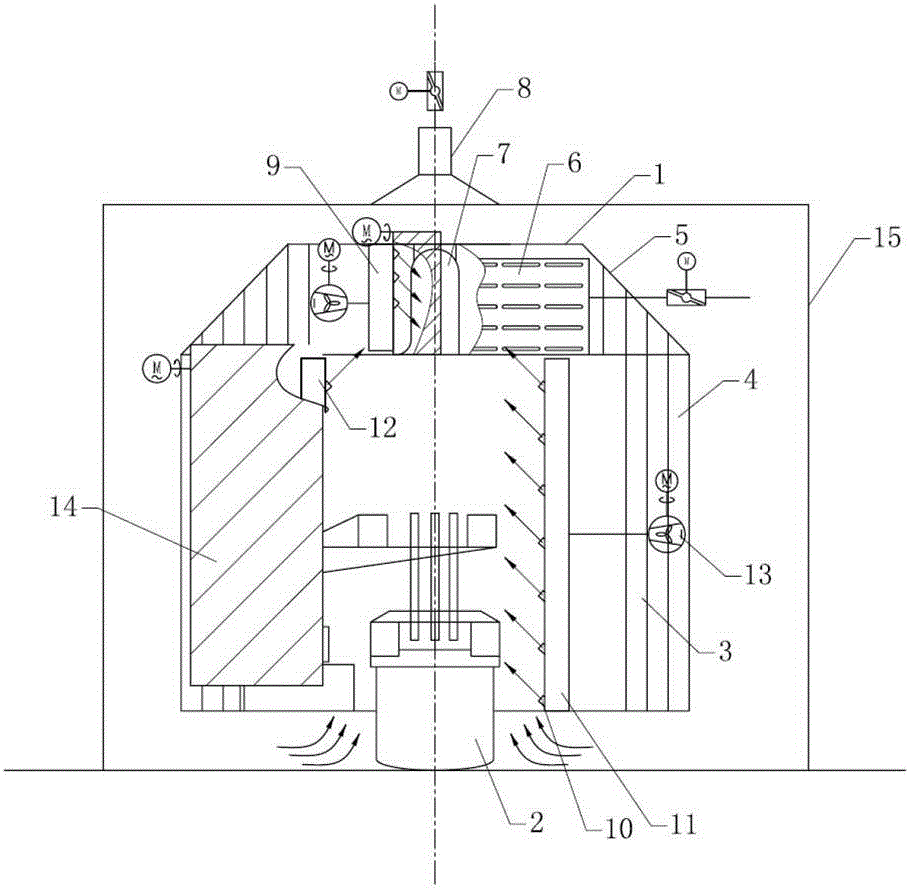

Micro bubble generation method and micro bubble generator

PendingCN110354705AHigh speedAvoid resistanceRotary stirring mixersTransportation and packagingPorosityMicro bubble

The invention belongs to the technical field of water treatment and relates to a micro bubble generation method and a micro bubble generator. The micro bubble generator comprises a microporous device,a hollow pipe, a rotating joint, a motor, a power output shaft, a driving shaft and an air pump, wherein the motor is connected with the microporous device through the power output shaft and the driving shaft in sequence and drives the microporous device to rotate around the axial direction of the driving device; the air pump is communicated with the microporous device through the rotating jointand the hollow pipe in sequence and inputs gases into the microporous device; the surface of the microporous device is provided with micropores of which the porosity is not lower than 28 percent; thesize of the micropores is 0.01 to 2 mu m; the gases entering the microporous device overflow from the micropores on the surface of the microporous device to form bubbles with particle size of 5 to 100mu m. The invention provides the micro bubble generation method and the micro bubble generator, which have the advantages of low energy consumption, simple structure and capability of stably producing a large amount of high-density micro bubbles with uniform particle size in liquid phase for a long term.

Owner:湖南亿纳环保科技有限公司

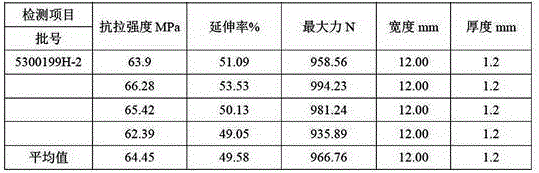

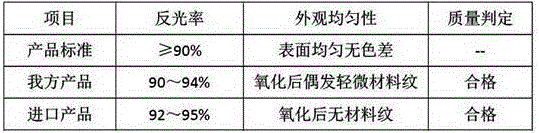

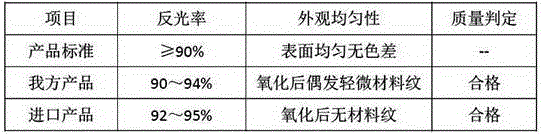

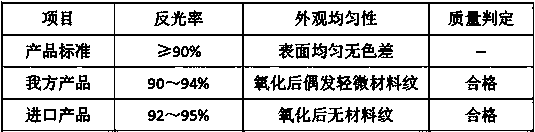

Hot rolling process for aluminum alloy for anodic oxidation

ActiveCN106694548ASimple methodSatisfy process needsMetal rolling arrangementsAnodic oxidationAfter treatment

The invention discloses a hot rolling process for aluminum alloy for anodic oxidation. The hot rolling process comprises the following steps that (1) homogenization heat preservation is conducted on an aluminum alloy plate ingot under the temperature of 450-490 DEG C; (2) after homogenization, rolling starting is conducted at the temperature of 410-460 DEG C with an equal rolling reduction distribution principle; (3) hot rolling is conducted till the temperature of the plate ingot is 350-390 DEG C, small-rolling-reduction rolling with the reduction rate of 7% is conducted once first, and then over-rolling-reduction rolling with the reduction rate of 45% is conducted once; and (4) after treatment of the step (3), rolling continues to be conducted with the equal rolling reduction distribution principle, and the finish rolling temperature is controlled to 235-270 DEG C. Through the hot rolling process, the forming ability of products machined by a common single-rack hot mill can completely reach the effect of a multi-rack hot continuous rolling mill, the hot rolling process is wide in practicability, the production and control difficulty and the cost are low, the product market competitiveness is obvious, and economic benefit is remarkable.

Owner:XINJIANG JOINWORLD CO LTD

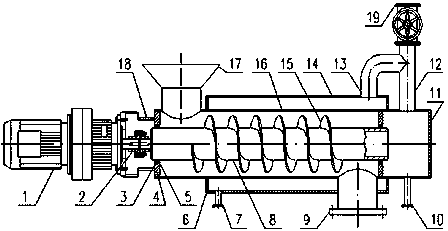

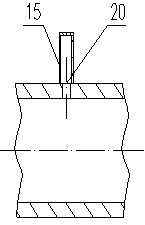

High-concentration solution or solid material conveying device with heat exchange function

PendingCN111422569AReduce sensitivityIncrease contact surfaceSteam/vapor condensersPipeline systemsMotor speedFrequency conversion

The invention discloses a high-concentration solution or solid particle material conveying device with a heat exchange function. The device comprises a frequency conversion motor speed reducer drivinga guide vane shaft to rotate, a shell, a material inlet, a material outlet, a spiral-shaped conveying guide vane arranged in the shell, a shaft used for fixing a guide vane and a bearing used for fixing the guide vane shaft. By means of the device, a heating cavity is formed in the outer portion of the shell, the interiors of the guide vane shaft and the interior of the guide vane are cavities, the cavity of the guide vane shaft is provided with a heating medium input end and a cooling medium output end in a communication manner, and the starting end and the terminal of the cavity of the guide vane are provided with channels to communicate with the cavity of the guide vane shaft. The high-concentration solution or solid material conveying device can also be used as an independent and complete device for conveying high-concentration solutions or solid fluid materials, meanwhile, the materials are heated or cooled, the technology requirements are met, the productivity can be greatly increased, and the work efficiency is improved.

Owner:张培洲 +1

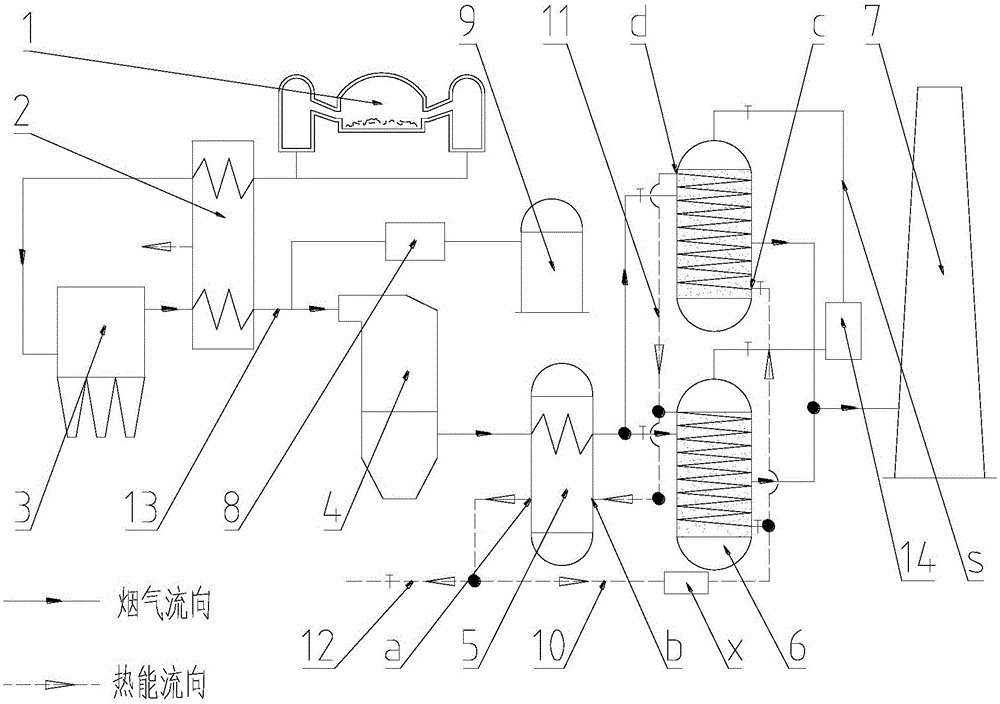

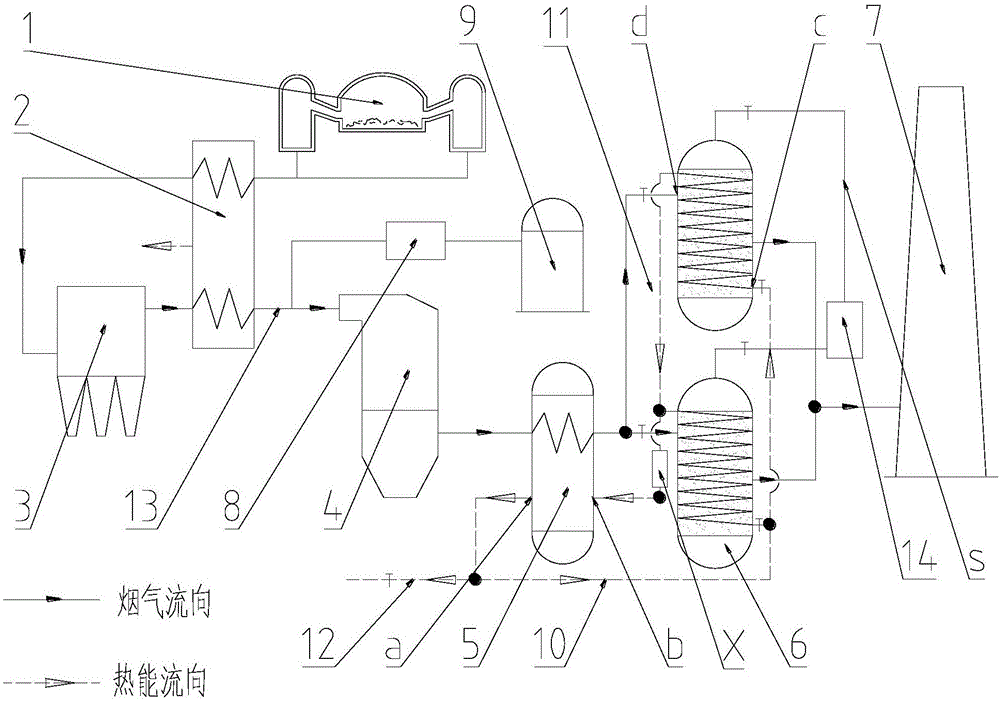

Glass high-temperature kiln flue gas energy conservation and emission reduction purification system and method

ActiveCN106139900ASuitable temperatureMeet environmental protection requirementsGas treatmentDispersed particle separationChemistryNH3 compound

The invention discloses a glass high-temperature kiln flue gas energy conservation and emission reduction purification system and method. The system comprises a glass kiln, a catalytic reaction tower and an adsorption system which are sequentially connected through flue gas pipelines, and an ammonia adding device is connected to the catalytic reaction tower. The glass high-temperature kiln flue gas energy conservation and emission reduction purification system and method have the advantages that flue gas from the glass kiln needs to be subjected to dedusting treatment, impurities in the flue gas can be prevented from plugging devices and catalysts in subsequent process sections; the flue gas which is too high in temperature can affect normal operation of a dedusting device, and the flue gas which is too low in temperature is not beneficial for subsequent desulfurization and denitrification treatment; according to the technical scheme, the characteristic of the flue gas itself is utilized, heat exchange is conducted on cooled flue gas and high-temperature flue gas, the technological requirement is met, heat energy contained in the flue gas is fully utilized, two adsorption towers are used for secondary adsorption purification in a one in service and one in standby mode, that is to say, one adsorption tower is used for purification treatment, the other adsorption tower is used for regeneration operation, when regeneration operation is conducted, heat energy is provided by the high-temperature flue gas, energy conservation and environment protection are achieved, and the sustainable development requirement is met.

Owner:CHONGQING TAIKE ENVIRONMENTAL PROTECTION TECH CO LTD

Edge pressing force and punching speed changeable method for forming sheets and device thereof

InactiveCN1181332CSatisfy process needsChange the total blank holder forceMaterial strength using tensile/compressive forcesSheet steelLoop control

Owner:JIANGSU UNIV

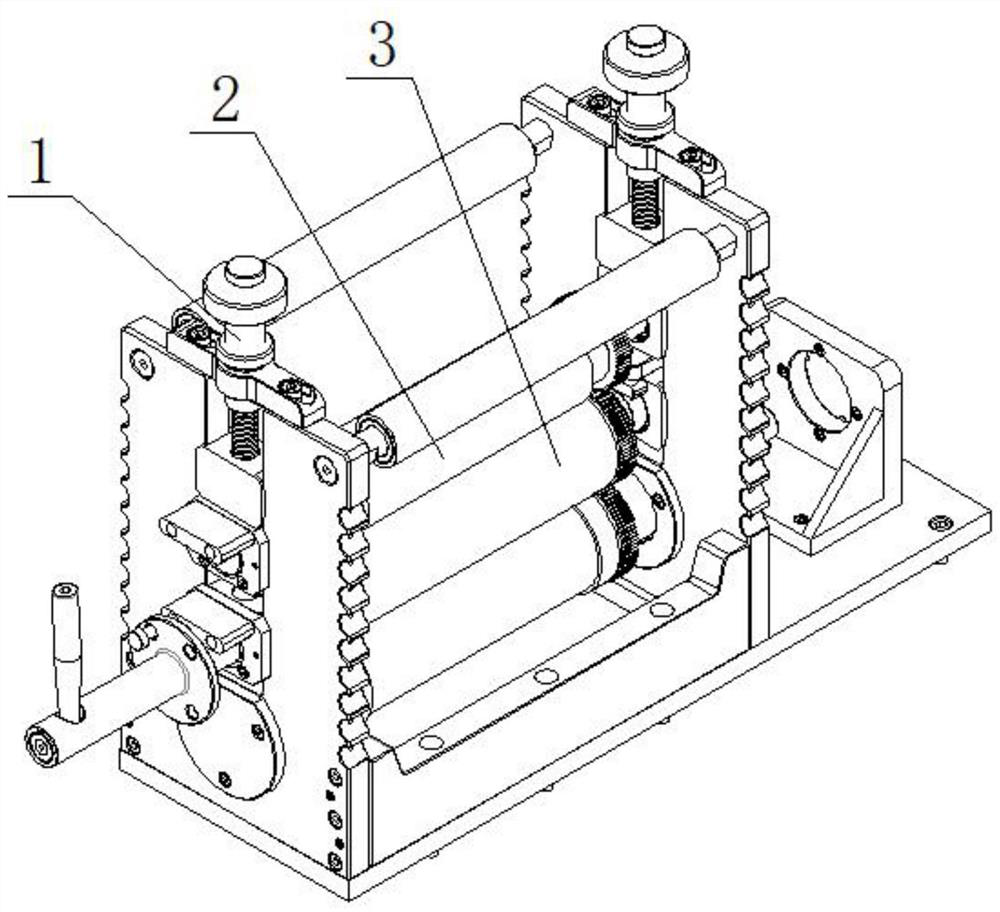

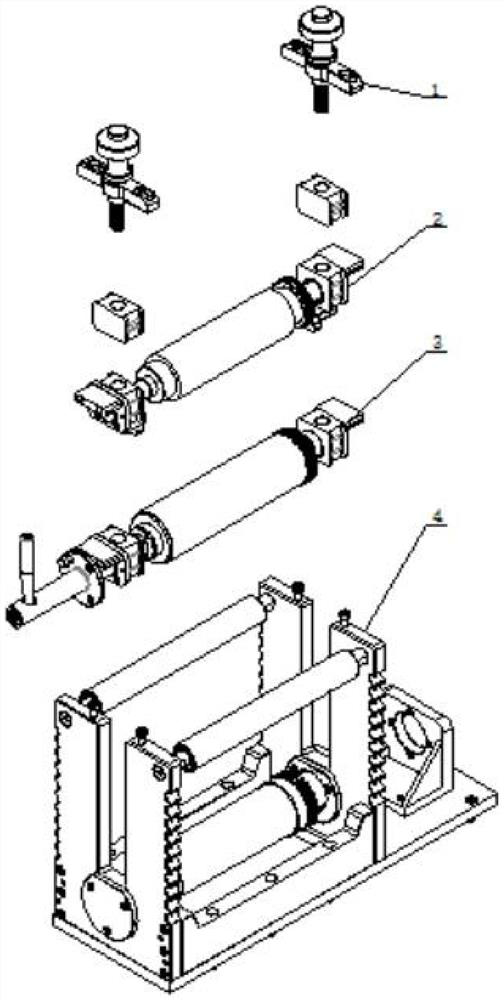

Manual cam elastic adjusting device for circular knife machine

PendingCN112720695AAchieve regulationLow experience requirementMetal working apparatusEngineeringMachine

The invention relates to a manual cam elastic adjusting device for a circular knife machine. The manual cam elastic adjusting device comprises a machine base, a bottom roller is mounted on the machine base, and a pressing roller is in pressure joint to the bottom roller. The manual cam elastic adjusting device further comprises pressure adjusting mechanisms, the pressure adjusting mechanisms acting on the two sides of the pressing roller are arranged on the machine base, and each pressure adjusting mechanism is composed of a spring supporting core, a rotating sleeve, a standby nut, a fixed block and a rectangular spring. The manual cam elastic adjusting device for the circular knife machine is scientific and reasonable in design, has the advantages of being convenient to operate, capable of saving time and labor, capable of improving the die cutting efficiency and reducing the rejection rate, high in adjusting accuracy and easy to implement, and has high innovativeness.

Owner:中融飞腾(北京)科技有限公司

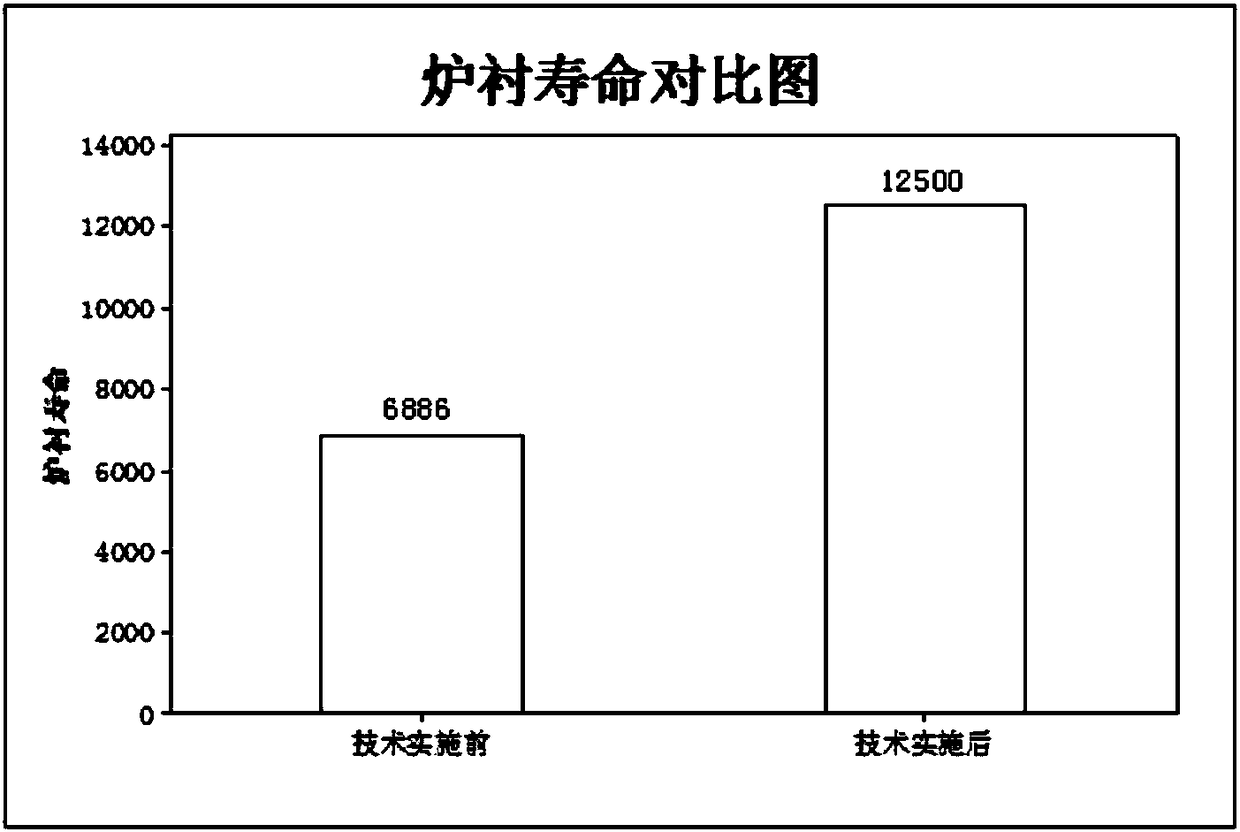

Method for cooling and secondary blowing-in of converter

ActiveCN108660276AReduce the cost of converter refractoriesLow costManufacturing convertersSteelmakingBrick

The invention relates to a method for cooling and secondary blowing-in of a converter. The method comprises blowing-out of the converter, blowing-out of the converter for maintenance, converter dryingand blowing-in processing for secondary blowing-in of the converter, and smelting processing after secondary blowing-in of the converter. According to the invention, during blowing-out of the converter, no brick in a converter lining is exposed; no slag in the blown-out converter is subjected to slagging; the converter is naturally cooled at a room temperature, so converter lining bricks are slowly cooled; during cooling of the converter, water is prohibited from leaking into the converter; when the converter is shut down, a tap hole cannot be exchanged; and after the converter is shut down,different damaged parts of the converter lining are repaired by adopting different repair materials and repair manners. With the method provided by the invention, under the situation that the converter with a magnesia carbon brick lining has shut down for 72 hours or more or the temperature of the converter drops to an environment temperature, the converter lining bricks are not removed or re-built, and the converter is started again through secondary drying of the converter. Thus, under the premises of guaranteeing safe production and meeting process demands, the refractory material cost of the converter in a steelmaking plant is reduced; production capacity can be dynamically adjusted at any time; and the converter in the steelmaking plant can be started and shut down at any time according to market situations.

Owner:ANGANG STEEL CO LTD

Hot rolling process of hard aluminum alloy for anodic oxidation

ActiveCN106694547ASimple methodSatisfy process needsMetal rolling arrangementsEconomic benefitsReduction ratio

The invention discloses a hot rolling process of a hard aluminum alloy for anodic oxidation. The hot rolling process comprises the following steps that (1) a hard aluminum alloy plate ingot is subjected to homogenized heat preservation at the temperature of 490 DEG C for 8 hours; (2) after homogenizing is conducted, rolling is started at the temperature of 440-460 DEG C according to the equal rolling reduction allocation principle; (3) hot rolling is conducted till the temperature of the plate ingot is 370-390 DEG C, one time of low reduction rolling with the rolling reduction ratio being 7% is conducted at first, and then, one time of ultra-high reduction rolling with the rolling reduction ratio being 45% is conducted; and (4) after the plate ingot is treated through the step (3), rolling continues to be carried out according to the equal rolling reduction allocation principle, and the final rolling temperature is controlled to be 250-270 DEG C. By means of the hot rolling process, the forming capacity of a product machined by a common single-rack hot rolling mill can completely achieve the effect of a product machined by a multi-rack hot continuous rolling mill. According to the hot rolling process, practicality is high, the production and control difficulty and the cost are low, the product market competitiveness is obvious, and economic benefits are remarkable.

Owner:XINJIANG JOINWORLD CO LTD

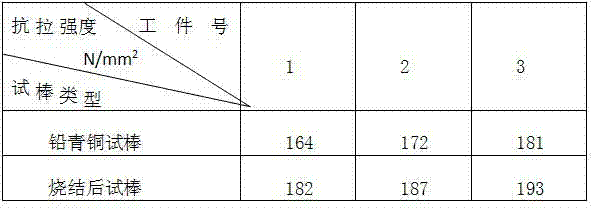

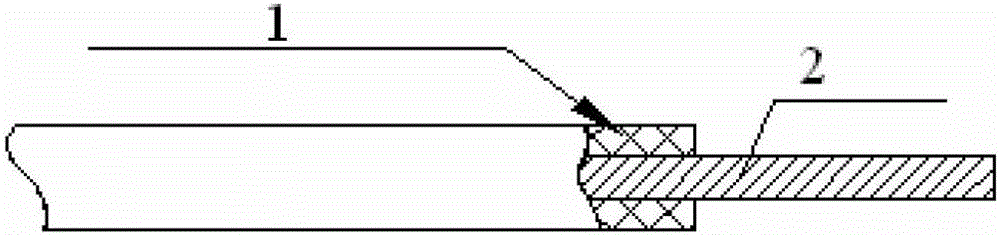

Bimetallic sintering process of spheroidal graphite cast iron and copper

ActiveCN102390005ASolve the strength problemSolve associativityLaminationLamination apparatusDuctile ironCleansing Agents

The invention relates to a bimetallic sintering process of spheroidal graphite cast iron and copper. The bimetallic sintering process comprises the following steps of: selection of raw materials: QT700 is adopted for a spheroidal graphite cast iron base body and lead bronze is selected for a copper rod; ultrasonic cleaning: before sintering, a water-based cleaning liquid is adopted for cleaning the spheroidal graphite cast iron and the lead-bronze copper rod thoroughly; vacuum cleaning: under the condition of vacuum negative pressure, a carbon-hydrogen cleaning agent is utilized for further circulatory cleaning of the spheroidal graphite cast iron and the lead-bronze copper rod; coating of a fluxing agent: a layer of fluxing agent with the thickness of 0.5mm-1.5mm is coated on the surfaceof the spheroidal graphite cast iron; treatment of the copper rod: a coating for preventing the copper rod from generating air holes on the surface of the spheroidal graphite cast iron in the processof heating and melting is sprayed on the surface of the copper rod, and then the treated copper rod is placed on the spheroidal graphite cast iron; and sintering. The bimetallic sintering process canbe used for solving the problems such as poor combining strength and mixing of the air holes on the combined surface in the bimetallic sintering technology of the spheroidal graphite cast iron and the copper rod.

Owner:SHANDONG CCHC HYDRAULICS

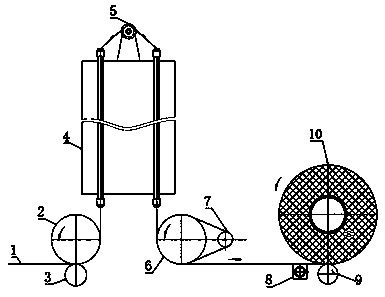

Densification drying device for polyacrylonitrile filaments

The invention discloses a densification drying device for polyacrylonitrile filaments. The densification drying device comprises a feeding roller, a heat box, a heat roller, a sliver divider and a bobbin. Slivers which need to be processed sequentially pass through the feeding roller, the heat box, the heat roller and the sliver divider and then are wound around the bobbin; a pressing roller is mounted on the feeding roller, and the slivers pass through the gap between the feeding roller and the pressing roller; two heat pipes are mounted in the heat box, a sliver guider is mounted on the topof the heat box, and the slivers sequentially pass through the heat pipe on the left side, the sliver guider and the heat pipe on the right side; the heat box is connected with a biphenyl stove, an input pipe and a recovery pipe are connected between the biphenyl stove and the heat box, and an electric heating rod is mounted in the biphenyl stove. The heat roller consists of a fixing base, a second motor, an iron core and a sliver guide roller. In this way, the densification drying device for polyacrylonitrile filaments can meet the technical demands of slivers different in strand density.

Owner:CHANGSHU XIANGYING SPECIAL FIBER

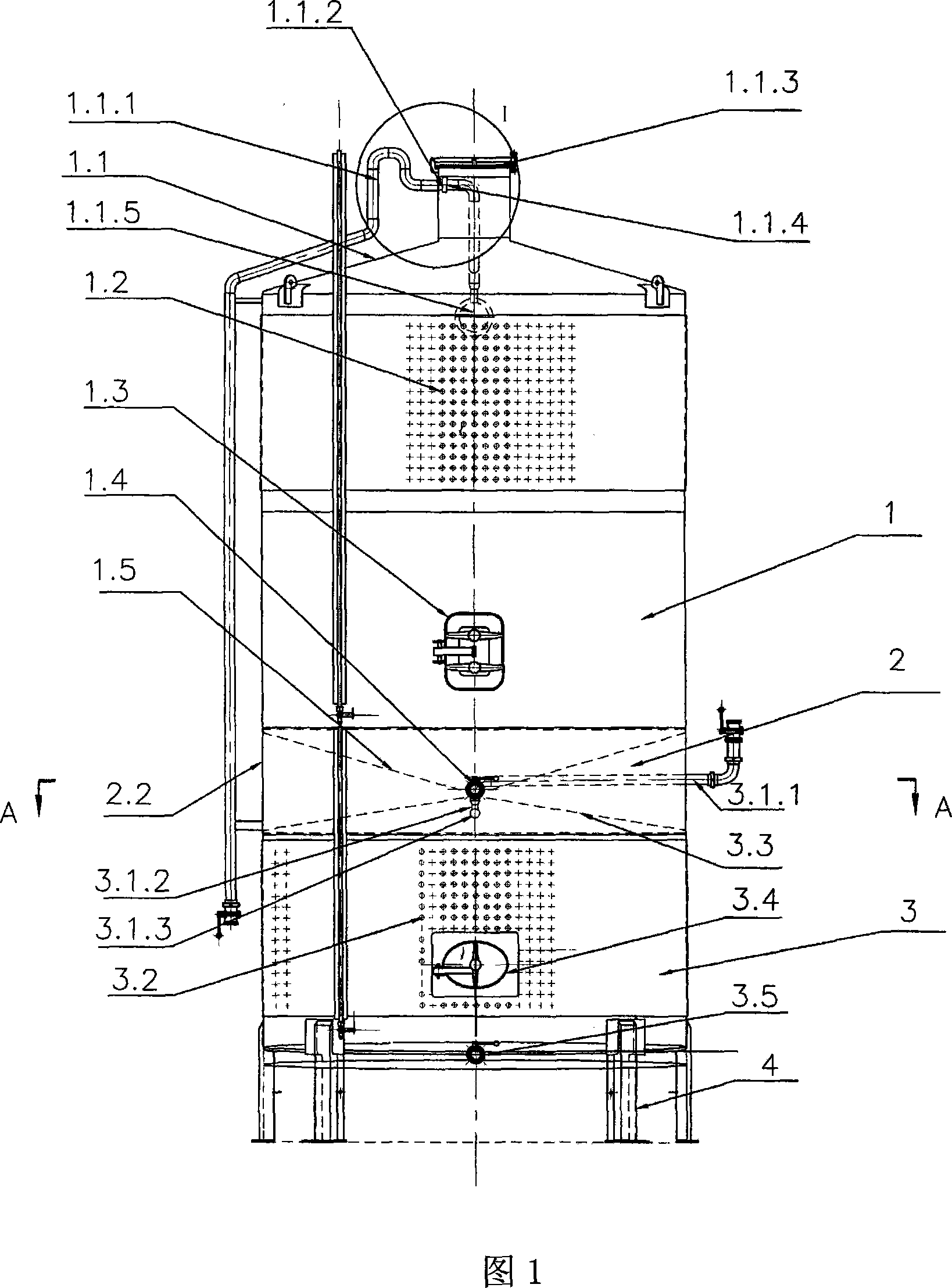

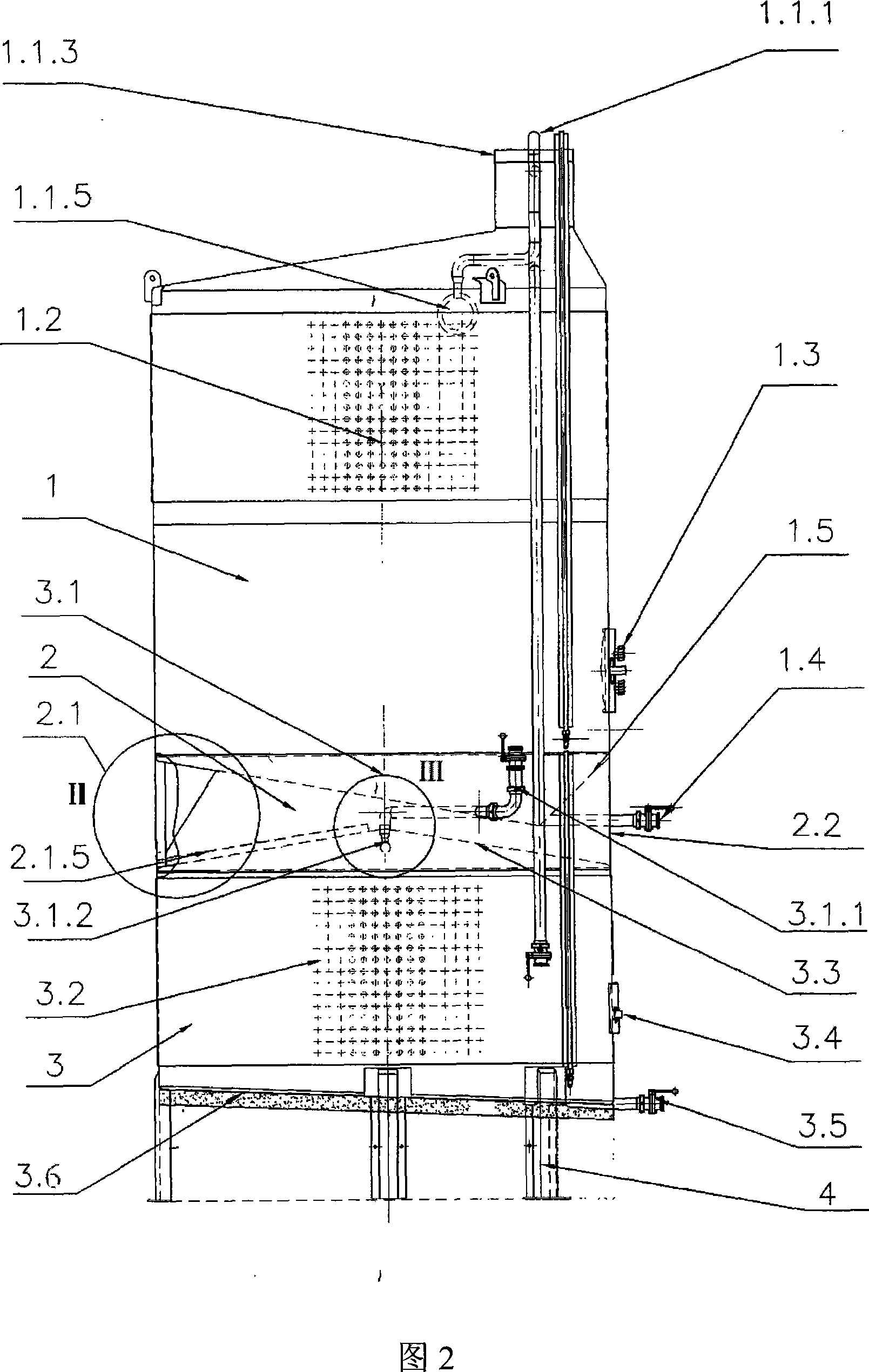

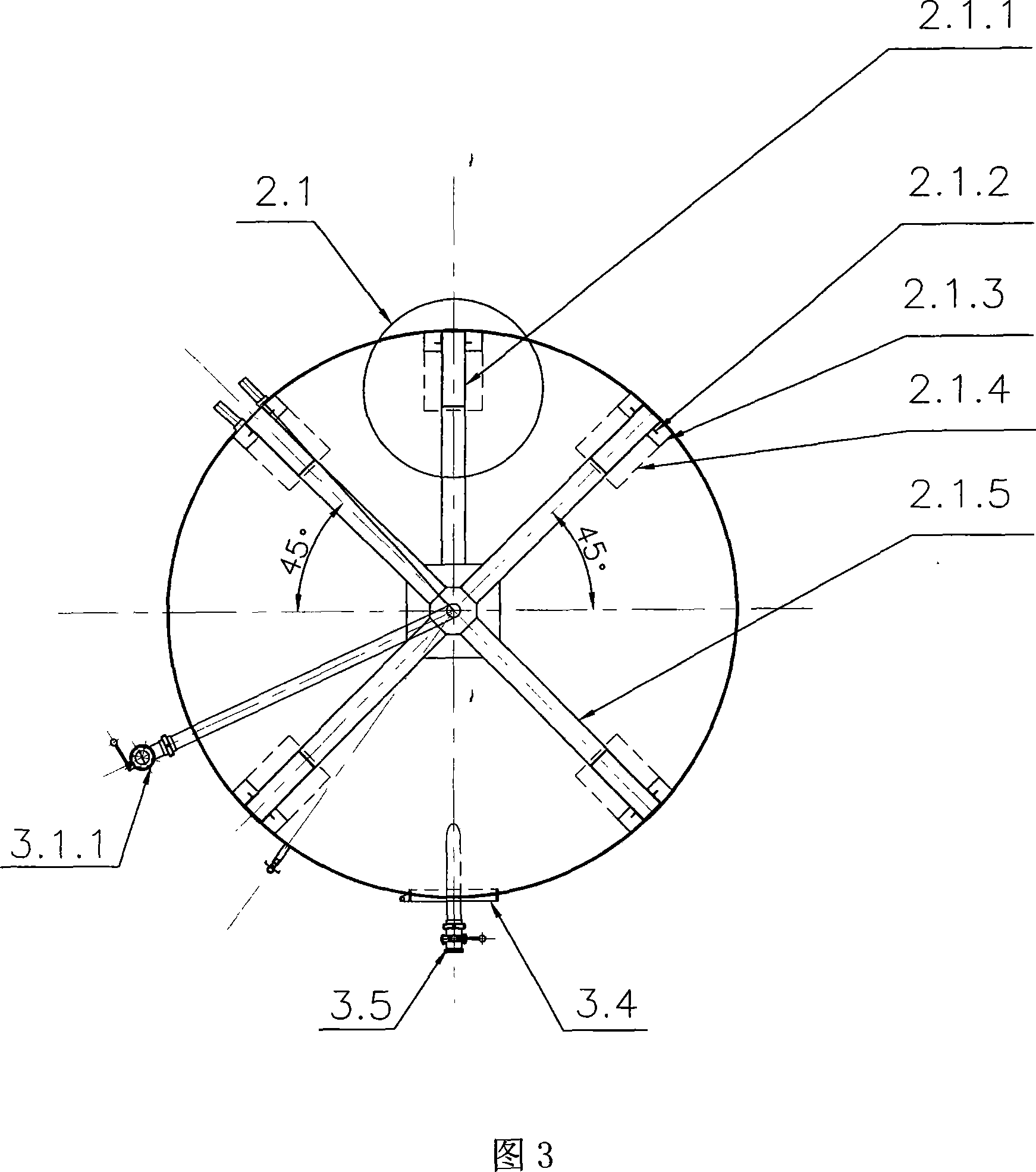

Double-layer wine storage pot

InactiveCN101224816BPrevent oxidationReduce the use of areaLarge containersBackflow prevention deviceHoneycomb

The invention relates to a double layer wine-storing tank, which includes an accessed nitrogen flushing system; the wine-storing tank is composed of two tanks with one superposes on the other, the volume of the upper wine-storing tank is larger than that of the lower wine-storing tank, and reinforcing structure is arranged between the two wine-storing tanks; the upper wine-storing tank and the lower wine-storing tank are respectively provided with an upper tank nitrogen-flushing pipeline and a lower tank nitrogen-flushing pipeline which have the pipeline function of charging and discharging nitrogen and the function of cleaning the tank; the nitrogen-flushing pipeline at the top of the upper wine-storing tank has a backflow prevention device used for preventing the wine flowing back to the pipeline so as to cause the bacterial infection; the upper tank and the lower tank respectively have an upper cooling honeycomb panel and a lower cooling honeycomb panel to increase the rigidity of the wine-storing tank. The invention has the advantages that the double layer wine fermentation tank can meet the technique requirement for the production of high-quality red wine, thus filling the domestic blankness; the using area of the workshop can be saved; the rigidity and stability of the wine tank can be guaranteed; the invention is convenient for the worker to operate and disassemble.

Owner:SINO FRENCH JOINT VENTURE DYNASTY WINERY

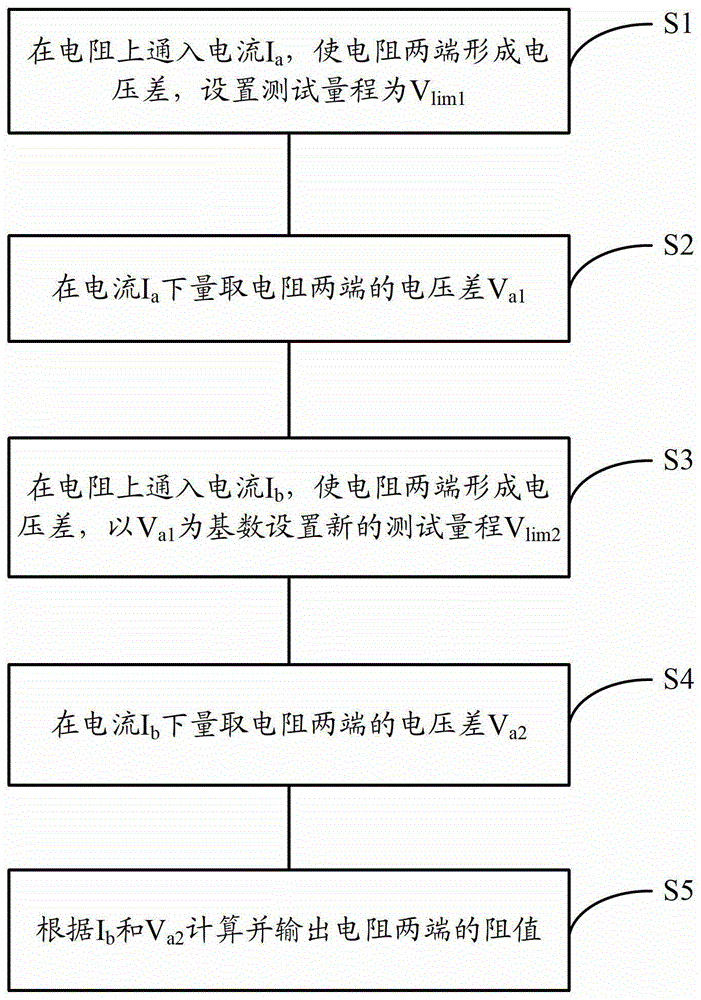

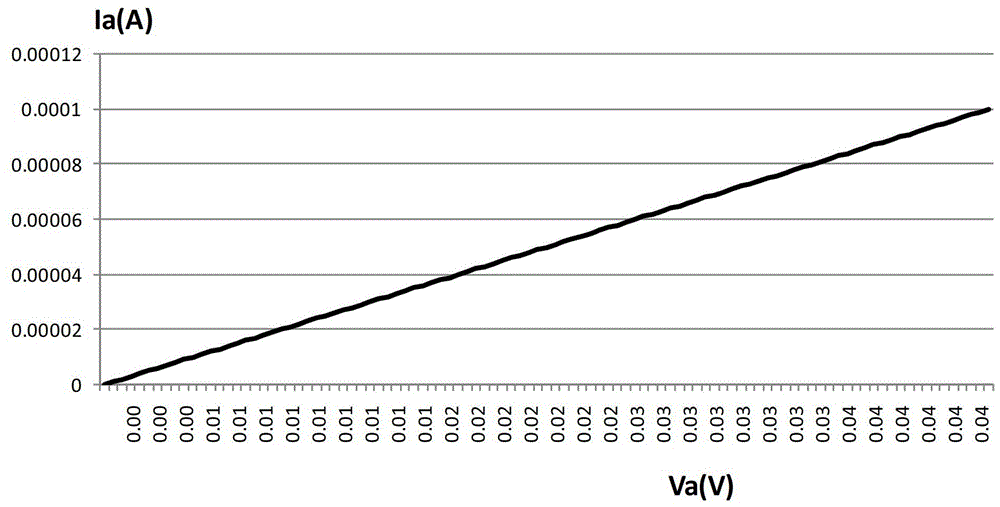

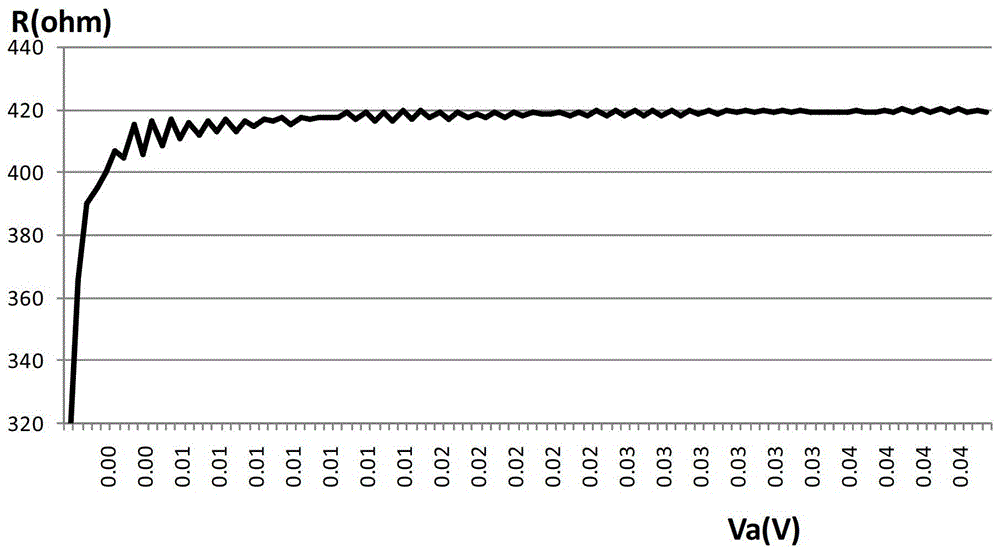

Adaptive Range Resistance Test Method

ActiveCN103792430BHigh measurement accuracyReduce test errorResistance/reactance/impedenceElectrical resistance and conductanceImage resolution

The invention discloses a self-adaptive range resistance test method comprising the following steps: S1. current Ia is piped onto a resistor so that voltage difference is formed on the two ends of the resistor, and a test range is arranged to be Vlim1; S2. voltage difference Va1 of the two ends of the resistor is measured under the current Ia; S3. current Ib is piped onto the resistor so that voltage difference is formed on the two ends of the resistor, and a new test range Vlim2 is arranged with Va1 as a base number, wherein Va1, Ib, Va1 and Ia meet that Vlim2 / Ib > / = Va1 / Ia; S4. voltage difference Va2 of the two ends of the resistor is measured under the current Ib; and S5. a resistance value of the two ends of the resistor is calculated and outputted according to Ib and Va2. Under the situation that voltage is ensured not to surpass the range, resolution in voltage measurement is enhanced, resistance measurement precision is enhanced, an error in a resistance test is reduced and technology demands are met.

Owner:CSMC TECH FAB2 CO LTD

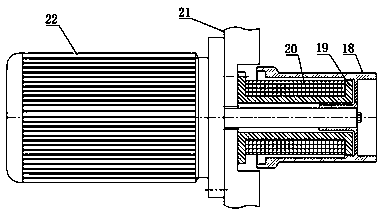

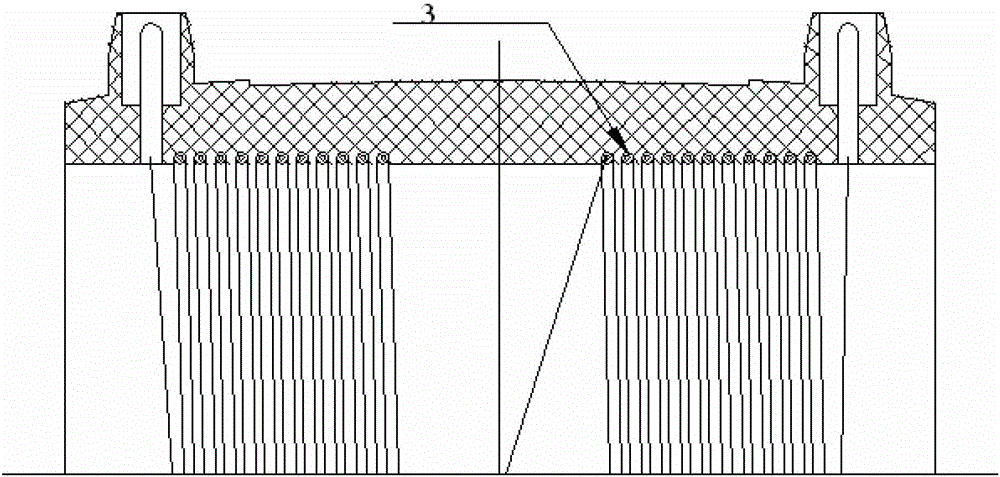

Plastic pipe electrofusion connector with mesh structure electric heating element and preparation method thereof

ActiveCN103527885BGuaranteed safe operationStable structurePipe connection arrangementsSiphonsElectrical resistance and conductanceElectricity

The invention discloses a plastic pipeline electric smelting connecting piece of an electric heating element with a mesh structure and a preparing method of the connecting piece. The drum-shaped electric heating element is arranged in the connecting piece. The connecting piece is formed by resistance material strips and plastic strips with the same materials, and the resistance material strips and the plastic strips are arranged at equal space distance along the inner wall of the electric smelting connecting piece and are arrayed in a continuous n shape along the drum wall. The preparing method of the connecting piece comprises the following steps that 1) the resistance material strips of the mesh structure are prepared; 2) the surfaces of the resistance material strips of the mesh structure prepared in the step 1) are fixedly connected with the plastic strips with the same materials, the strips are rolled to form the drum-shaped electric heating element; 3) the drum-shaped electric heating element prepared in the step 2) is inserted into an injection mould, and injection moulding is carried out according to a conventional injection moulding technology to obtain a finished product. The electric heating element structure of the connecting piece is stable, according to the preparing method, conventional mechanical equipment is used, multi-specification pipeline connecting pieces can be prepared, a technology platform is provided for manufacturing an electric smelting connecting piece with the extra-large aperture, the welding temperature of the connecting piece can be kept at the needed temperature, and short circuits and disconnection are avoided.

Owner:NINGBO HENGYUAN PRECISION VALVES TECH

Molten steel heat preservation covering agent capable of achieving heat supplementing

ActiveCN113337670ASatisfy process needsCost controlProcess efficiency improvementSteelmakingLithium oxide

The invention discloses a molten steel heat preservation covering agent capable of achieving heat supplementing. The covering agent is a first-layer covering agent or comprises the first-layer covering agent and a second-layer covering agent at the same time, wherein the first-layer covering agent is composed of one or more of dry quenching furnace fly ash, blast furnace fly ash or coke screen underflow, and further comprises expanded perlite, expanded vermiculite, aluminum silicate fibers, dolomite and ferrosilicon powder; and the second-layer covering agent is composed of one or more of light-burned dolomite, lime, lithium peroxide or sodium peroxide, boron nitride, magnesium hydroxide or magnesium borate. The covering agent for hot metal ladles, steel ladles and tundishes is provided to overcome the limitation that due to the fact that an existing covering agent is poor in heat preservation performance, the temperature of molten iron and molten steel is greatly reduced, and the surfaces are prone to crusting; and the requirement of the steelmaking technology is met.

Owner:武汉钢铁有限公司

Smoke gathering device used for electric arc furnace and refining furnace and smoke gathering method

ActiveCN105806088APrevent spillageQuickly sucked awayWaste heat treatmentElectric arc furnaceProcess engineering

The invention discloses a smoke gathering device used for an electric arc furnace and a refining furnace. The smoke gathering device comprises a sealing chamber, the sealing chamber seals and surrounds equipment generating smoke, an opening is formed in the sealing chamber, and is provided with a sealing door, the sealing door achieves opening and closing, and therefore the opening is opened and sealed; and the opening forms an air curtain; and a dust suction cover is arranged on the top of the sealing chamber, and the dust suction cover is used for gathering the smoke. Meanwhile, the invention discloses a smoke gathering method achieved through the smoke gathering device used for the electric arc furnace and the refining furnace. The device and method are high in smoke gathering rate, low in noise, easy to operate, safe, reliable and high in automation degree.

Owner:尼欧迪克(青岛)环保科技有限公司

A kind of hot rolling process of hard aluminum alloy for anodic oxidation

ActiveCN106694547BSimple methodSatisfy process needsMetal rolling arrangementsAnodizingReduction ratio

The invention discloses a hot rolling process of a hard aluminum alloy for anodic oxidation. The hot rolling process comprises the following steps that (1) a hard aluminum alloy plate ingot is subjected to homogenized heat preservation at the temperature of 490 DEG C for 8 hours; (2) after homogenizing is conducted, rolling is started at the temperature of 440-460 DEG C according to the equal rolling reduction allocation principle; (3) hot rolling is conducted till the temperature of the plate ingot is 370-390 DEG C, one time of low reduction rolling with the rolling reduction ratio being 7% is conducted at first, and then, one time of ultra-high reduction rolling with the rolling reduction ratio being 45% is conducted; and (4) after the plate ingot is treated through the step (3), rolling continues to be carried out according to the equal rolling reduction allocation principle, and the final rolling temperature is controlled to be 250-270 DEG C. By means of the hot rolling process, the forming capacity of a product machined by a common single-rack hot rolling mill can completely achieve the effect of a product machined by a multi-rack hot continuous rolling mill. According to the hot rolling process, practicality is high, the production and control difficulty and the cost are low, the product market competitiveness is obvious, and economic benefits are remarkable.

Owner:XINJIANG JOINWORLD CO LTD

Hot rolling process for soft-state aluminum alloy for anodic oxidation

The invention discloses a hot rolling process for a soft-state aluminum alloy for anodic oxidation. The hot rolling process comprises the following steps that 1, homogenized heat preservation is conducted on a soft-state aluminum alloy plate ingot for 8 hours at the temperature of 450 DEG C; 2, after homogenization is completed, rolling is conducted at the temperature of 410-430 DEG C on the basis of the allocation principle of the equal rolling reduction amount; 3, when hot rolling is conducted to the extent that the temperature of the plate ingot reaches 350-370 DEG C, small-reduction rolling with the reduction rate being 7% is conducted once in the first place, and subsequently, super-reduction rolling with the reduction rate being 45% is conducted once; and 4, after treatment as specified in step 3 is completed, rolling is conducted continuously on the basis of the allocation principle of the equal rolling reduction amount, and the finishing rolling temperature is controlled within the range of 235-250 DEG C. By means of the method, molding capacity of a product machined through a common single-rack hot rolling mill can completely achieve the effect of a multi-rack hot rolling mill; the hot rolling process is wide in practicability and low in production difficulty, control difficulty and cost; the product is obvious in market competitiveness; and remarkable economic benefits are achieved.

Owner:XINJIANG JOINWORLD CO LTD

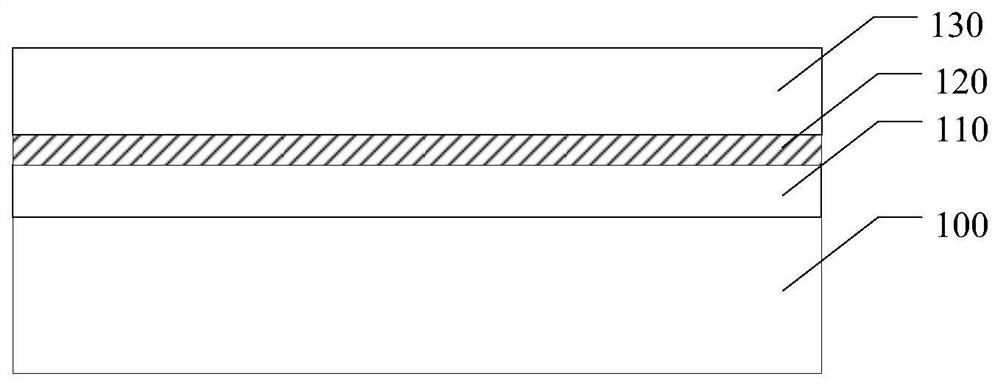

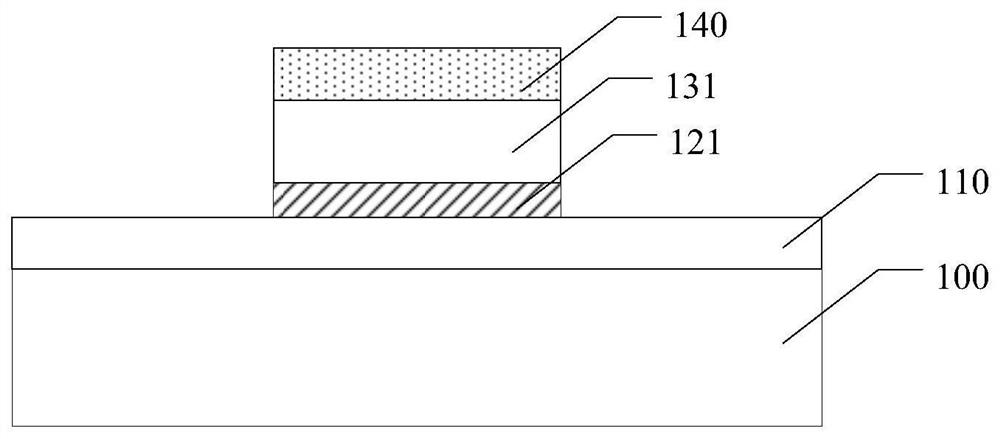

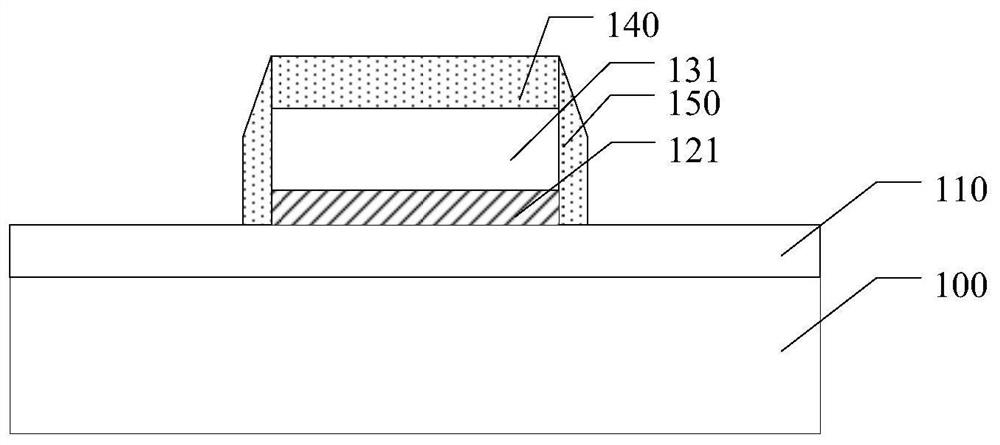

Semiconductor structure and forming method thereof

ActiveCN112531103AImprove performanceGood vertical shapeMagnetic-field-controlled resistorsSolid-state devicesSemiconductor structureMembrane surface

The invention discloses a semiconductor structure and a forming method thereof. The method comprises the following steps: providing a substrate; forming a first electromagnetic film on the substrate,wherein the surface of a part of the first electromagnetic film is provided with a tunnel layer and a second electromagnetic layer located on the surface of the tunnel layer; forming a first dielectric film on the surface of the first electromagnetic film, the surface of the side wall of the tunnel layer, and the surfaces of the side wall and the top of the second electromagnetic layer; forming asecond dielectric layer on the surface of the first dielectric film located at the top of the second electromagnetic layer; etching back the first dielectric film by using a first etching process until the surface of the first electromagnetic film is exposed, and forming a first dielectric layer on the surface of the side wall of the tunnel layer and the surfaces of the top and the side wall of the second electromagnetic layer, wherein the etching rate of the first etching process on the first dielectric film is higher than the etching rate of the first etching process on the second dielectriclayer; and etching the first electromagnetic film by taking the first dielectric layer and the second dielectric layer as masks until the surface of the substrate is exposed, thereby forming a firstelectromagnetic layer. The semiconductor structure formed by the method is good in performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Process for fabricating low nitrogen furan resin for steel casting

ActiveCN101199983BReduce nitrogen contentReduce dosageFoundry mouldsFoundry coresFuranManufacturing technology

The invention relates to a manufacture method of furan resin used for steelcasting, in particular to a manufacture technology of low nitrogen furan resin used for steelcasting. The optimum formula is: 8 to 9 shares of formaldehyde (36.5 percent ), 3 to 5 shares of carbamide, no less than 85 shares of furfuryl alcohol, 40 percent of NaOH solution, 10 percent of hydrochloric acid solution, 0.2 percent of silane coupling agent; the invention comprises the following steps: feeding material, increasing temperature by heating, dehydration, synthesizing, discharging material, packing and warehousing; the invention uses the unique technology to achieve good performances that free formaldehyde of low nitrogen furan resin used for steelcasting is less than 0.1 percent, the tensile strength for 24hours is more than 2.2MPa, the using time is more than 30 minutes, and the nitrogen content is less than 1.4 percent.

Owner:共享新材料(山东)有限公司

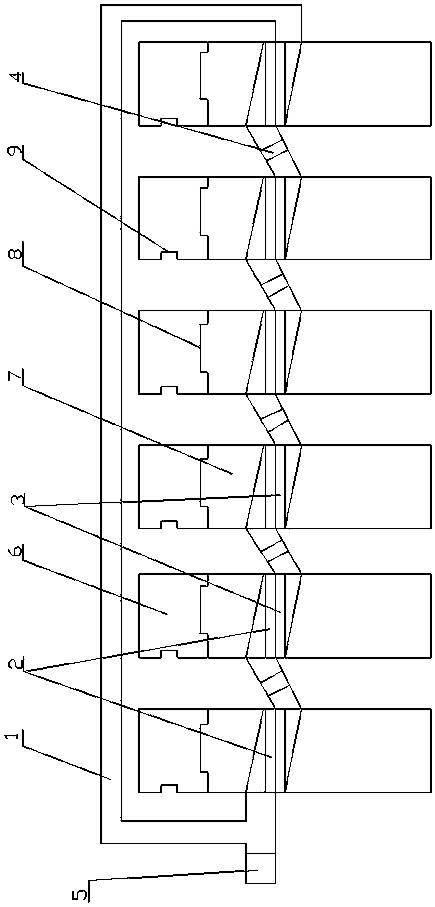

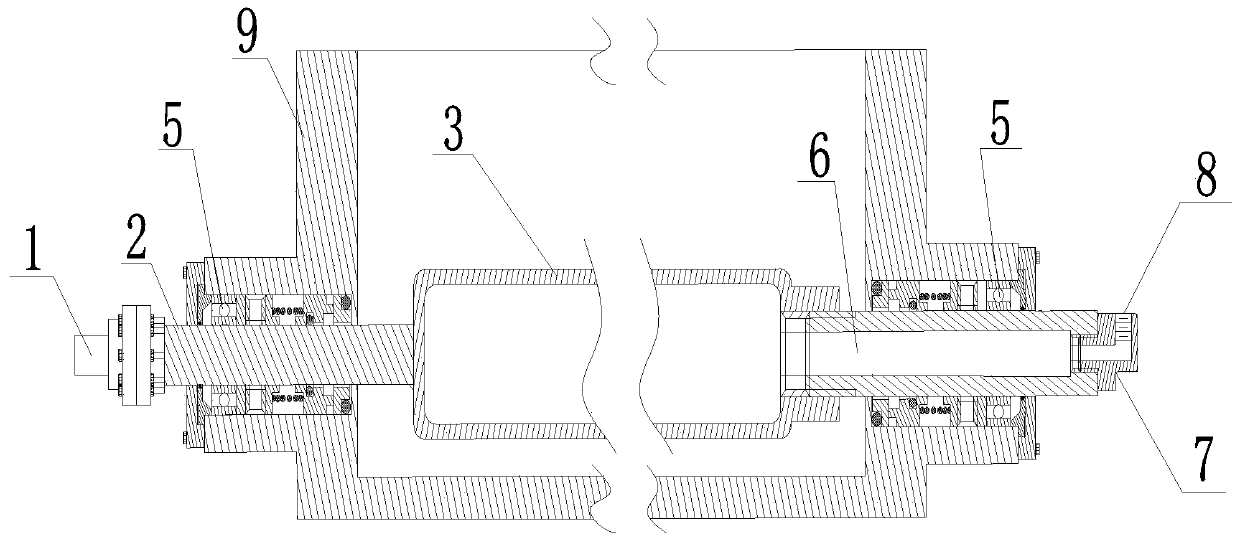

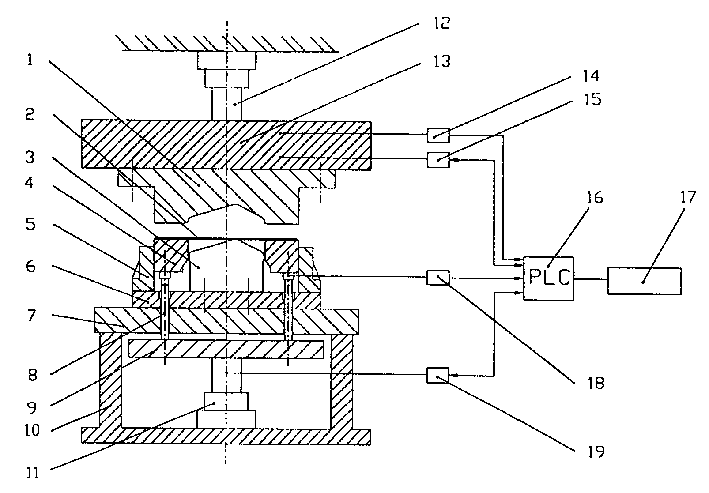

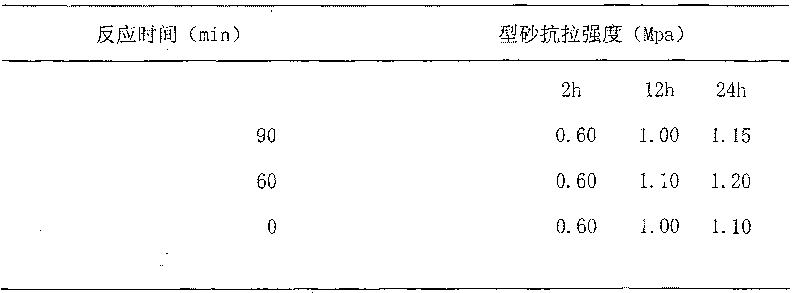

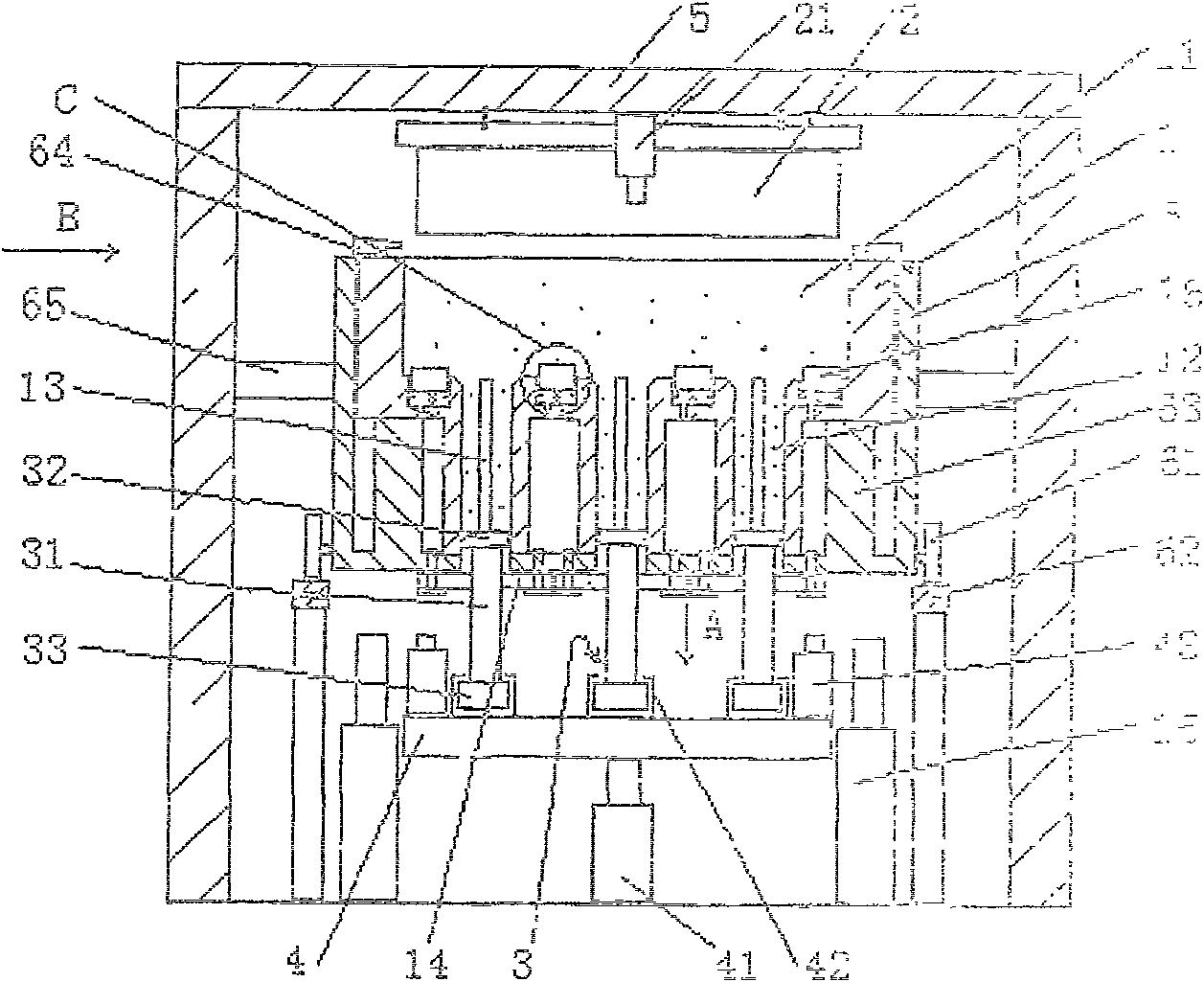

Special-purpose equipment for plant fibre tray bidirectional extrusion forming method

InactiveCN100575023CImprove bearing capacitySqueeze evenlyFlat articlesDomestic articlesPlant fibreEngineering

The present invention discloses a bidirectional extrusion forming method of a plant fiber pallet and a dedicated device thereof. The bidirectional extrusion forming method of the plant fiber pallet includes the following steps: after a mold cavity is loaded with material, a female mold is jacked up by an oil cylinder, so that an upper mold punch can be pressed into the pallet plate molding cavity of the female mold, a lower mold punch is then jacked up by an oil cylinder to move into the supporting foot molding cavity of the female mold, pressing is stopped after a designed pressure is reached, and after heat preservation and solidification, demoulding is carried out. The dedicated device is composed of the female mold, the upper mold punch, the upper mold punch, a movable frame, a frame and a hydraulic power device. The present invention has the advantages of uniform compaction, little damage ratio, low production cost, great bearing capacity of the finished products, etc. The upper surface of the pressed pallet can be flat or concavo-convex, and the pallet can be adapted to the transportation requirements of various products.

Owner:张翠兰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com