Low-carbon dense baking system for modulating cured tobacco

A technology of dense baking and dense baking rooms, applied in the field of energy-saving and emission-reducing baking systems, can solve the problems of poor application effect, aggravated pollution, simple structure, etc., and achieve reduced resource utilization, reduced pollutant emissions, and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

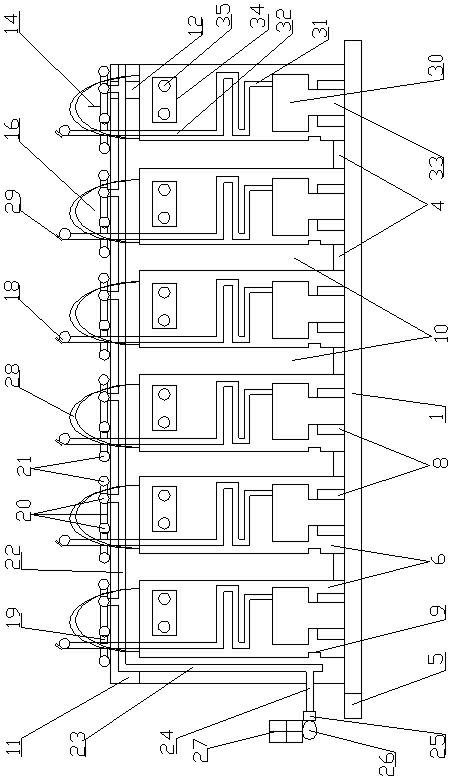

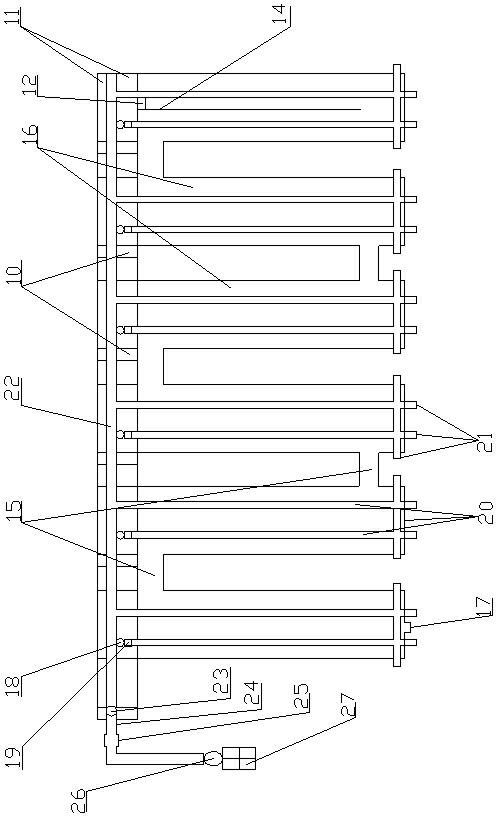

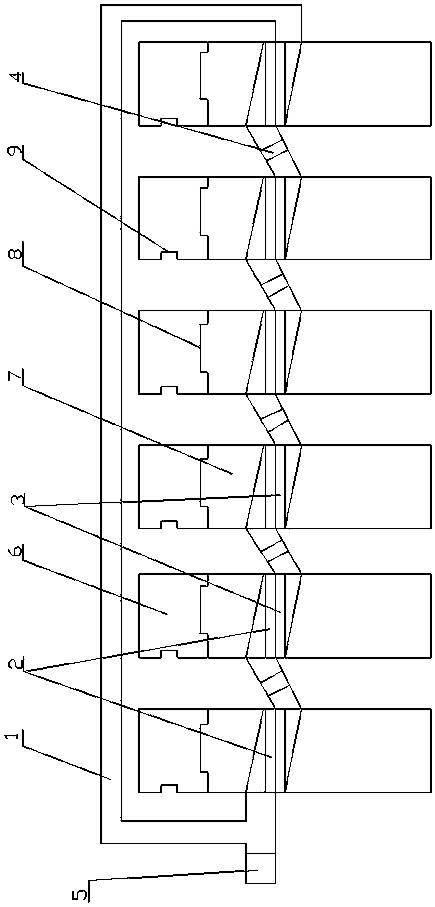

[0018] Embodiment 1: as figure 1 , 2 As shown, as long as the temperature is required for the modulation process of roasting high-quality and characteristic tobacco leaves in a dense tobacco barn, the barn controller installed outside sends instructions to the dust remover and desulfurizer 26 through wires, and the induced draft fan and negative pressure on the dust remover 26 The system composed of stabilizer 25 and smoke breaker 19 provides the heating furnace with the required oxygen for the combustion of coal, the coal in the combustion chamber 30 of the heating furnace starts to burn, the radiator 31 of the heating furnace starts to dissipate heat, and the circulation fan 35 in the intensive baking room The heat is transported from the heating chamber 6 of the dense curing barn to the tobacco loading room 7 of the dense curing barn, and is absorbed and utilized by the tobacco leaves in the tobacco charging room 7 of the dense curing barn, and most of the energy is dissipa...

Embodiment 2

[0019] Embodiment 2: as figure 1 , 3 As shown, when the modulation process of baking high-quality characteristic tobacco leaves in the highest-energy tobacco-leaf-intensive barn requires dehumidification, the hot air in the double-arch film heat-collecting and intercepting chamber 16 enters the barn supplementary air door 9 through the hot air common channel 11 and then enters the intensive The heating chamber 6 of the curing barn is heated by the radiator 31 of the heating furnace and then enters the tobacco loading room 7 of the intensive curing barn under the action of the circulation fan 35 in the intensive curing barn. The exhaust port 3 of the shared channel enters the waste heat circulation shared channel 1, and when it passes through the bottom of the next dense barn, the waste heat sharing channel displaces the air inlet 2 and enters the dense barn smoke chamber of the dense barn. The energy is recycled and circulated in turn Utilize until the lowest energy-intensive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com