Patents

Literature

332results about How to "Squeeze evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

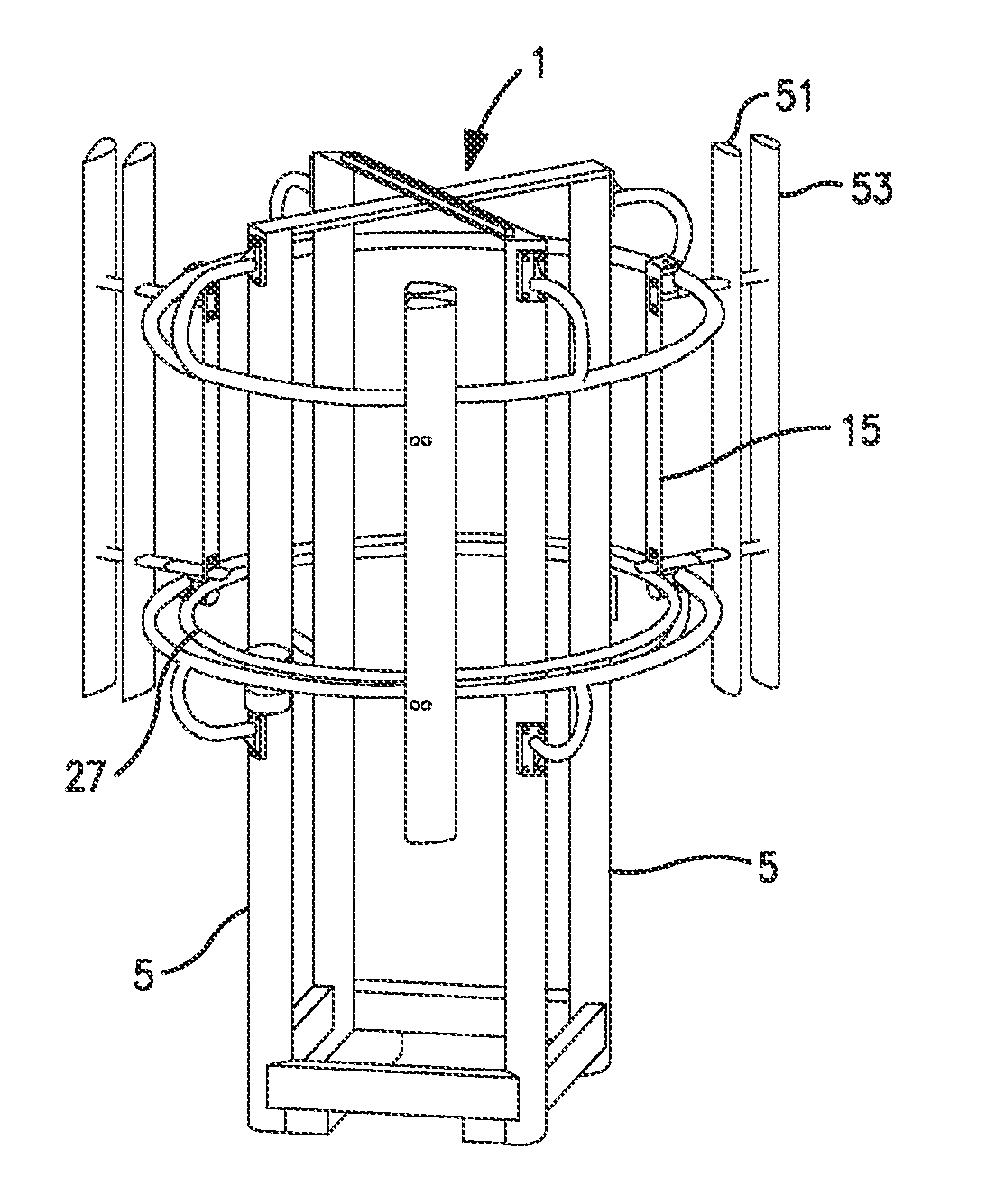

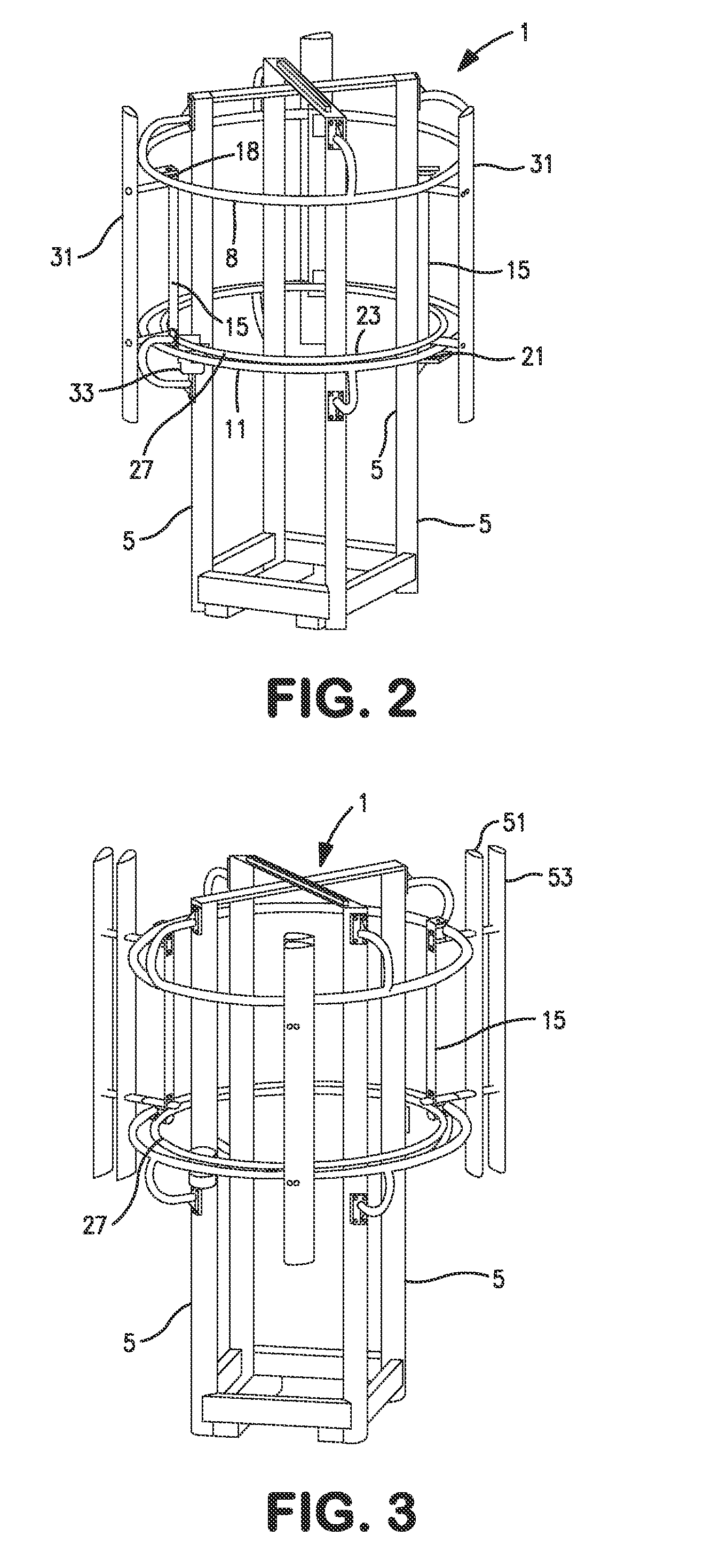

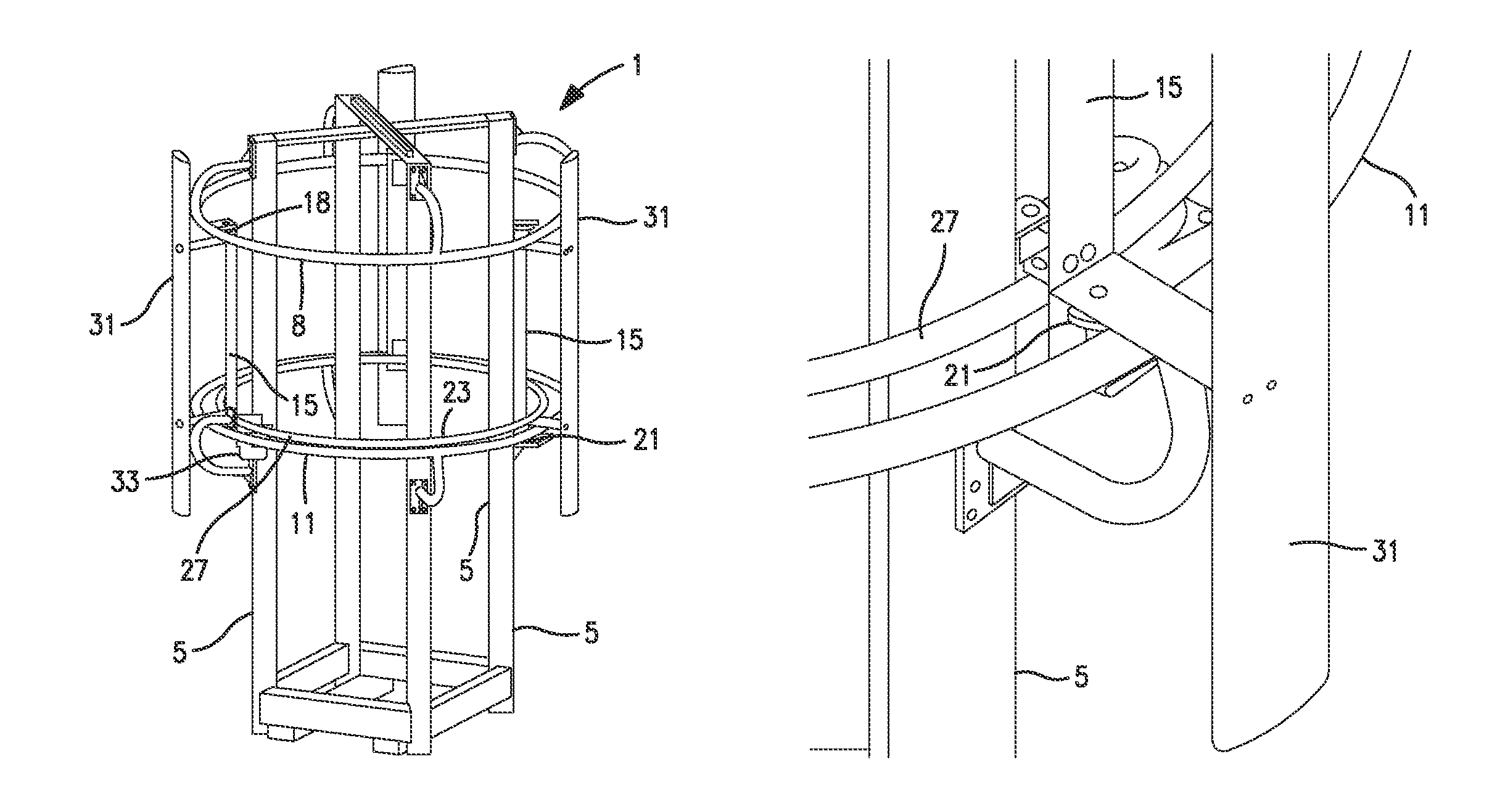

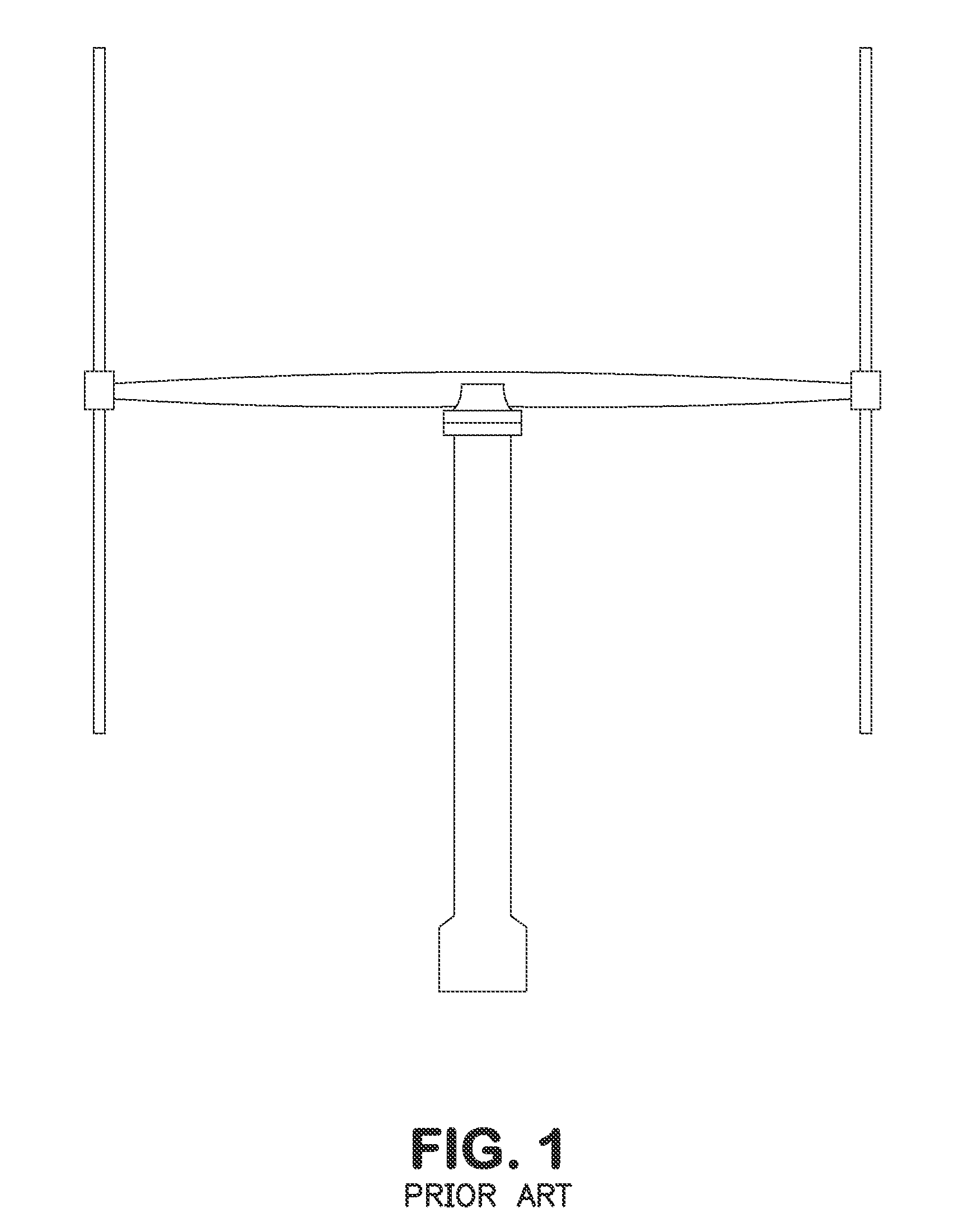

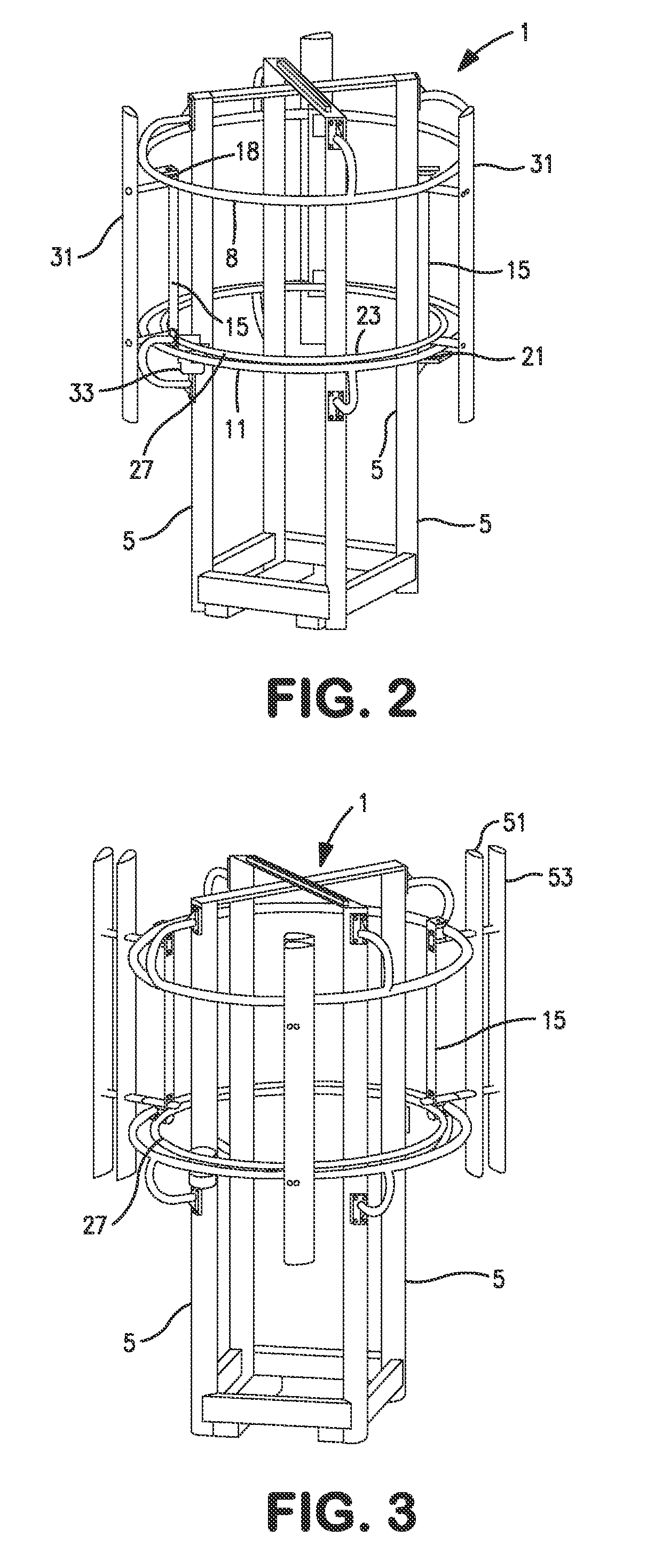

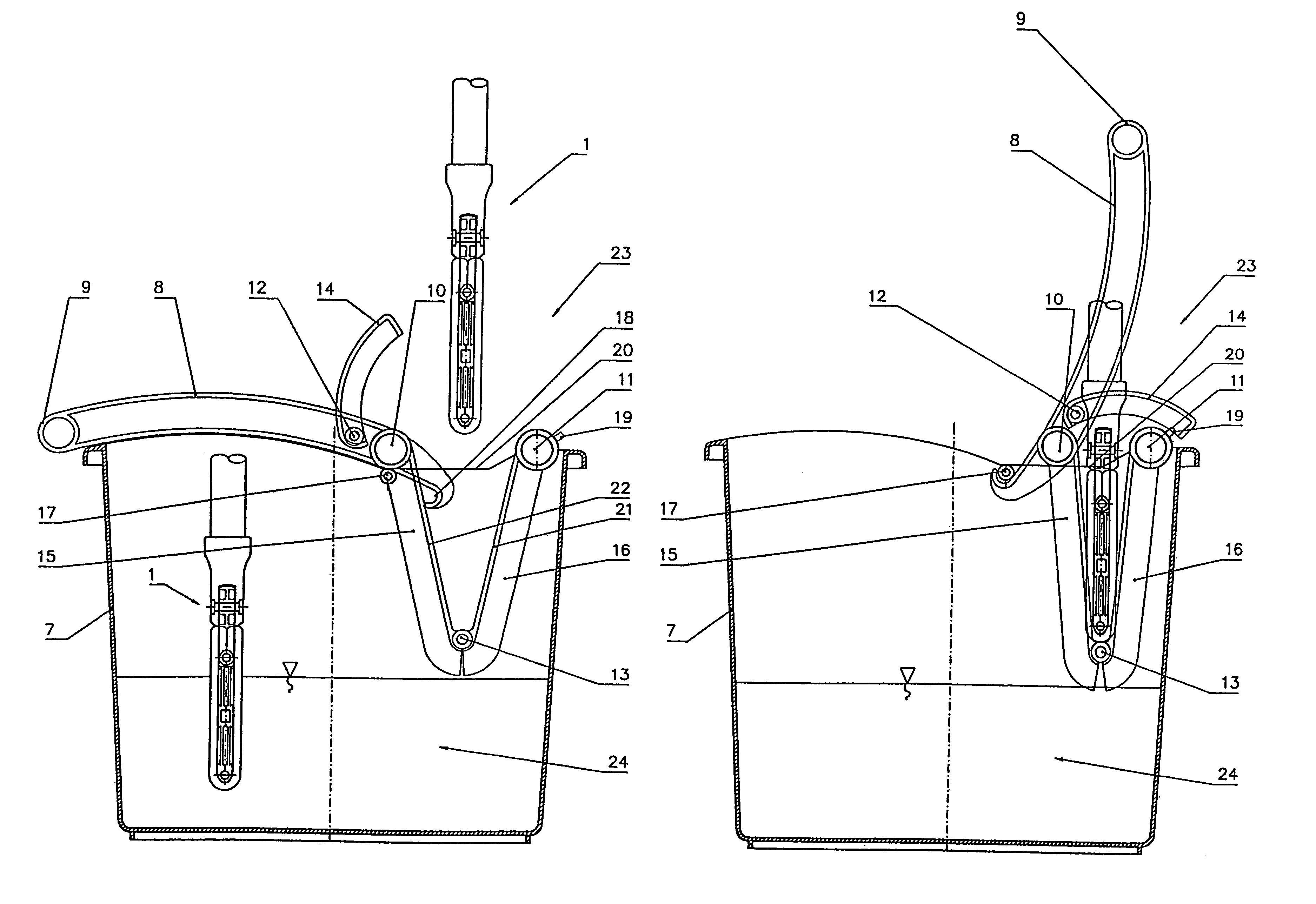

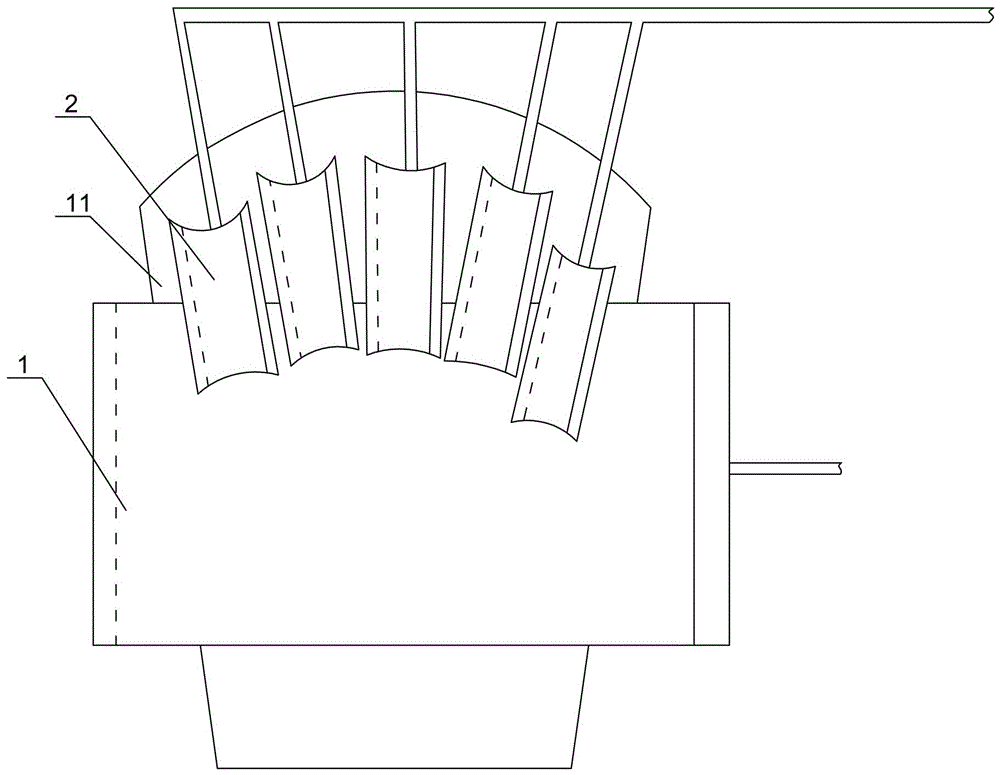

Orbital Track Wind Turbine

An orbital track wind turbine for generation of electrical energy from wind power is provided. The wind turbine includes a plurality of spaced vertical supports to which at least two parallel spaced circular tracks are fixedly secured. These circular tracks are coaxial with one another and are positioned in parallel horizontal planes. A plurality of trucks extend between the circular tracks, the trucks having at least two grooved rollers which partially surround the circular tracks and operate in rolling engagement therewith. A circular power takeoff ring is coaxial with said circular tracks, and the power takeoff ring is attached to the truck which is rotatable in a horizontal plane about its central axis. A plurality of vertical airfoils extends around the circular power takeoff ring, with each of the airfoils being attached to a truck and the power takeoff ring. One or more generators are connected to the power takeoff ring, thereby converting wind generated rotation of the power takeoff ring to electrical energy.

Owner:EXQUADRUM

Orbital track wind turbine

InactiveUS8164213B2Easy to captureFacilitate initiationWind motor controlWind motor combinationsTurbineTruck

An orbital track wind turbine for generation of electrical energy from wind power is provided. The wind turbine includes a plurality of spaced vertical supports to which at least two parallel spaced circular tracks are fixedly secured. These circular tracks are coaxial with one another and are positioned in parallel horizontal planes. A plurality of trucks extend between the circular tracks, the trucks having at least two grooved rollers which partially surround the circular tracks and operate in rolling engagement therewith. A circular power takeoff ring is coaxial with said circular tracks, and the power takeoff ring is attached to the truck which is rotatable in a horizontal plane about its central axis. A plurality of vertical airfoils extends around the circular power takeoff ring, with each of the airfoils being attached to a truck and the power takeoff ring. One or more generators are connected to the power takeoff ring, thereby converting wind generated rotation of the power takeoff ring to electrical energy.

Owner:EXQUADRUM

Pure titanium two-step plastic deformation processing method

The invention relates to a pure titanium two-step plastic deformation processing method in the technical field of metallic material plastic deformation; the method comprises the following steps: level-3 industrial pure titanium block is taken as the raw material, after being coated with graphite lubricant, the material is extruded on a 300KN hydraulic pressure universal experimental machine and then is subjected to rolling treatment at liquid nitrogen temperature to carry out deformation treatment on submicron crystal industrially pure titanium block, thus obtaining the superfine crystal pure titanium. The superfine crystal pure titanium of the invention features a tensile strength of 1218MPa and a specific elongation of 12.6%.

Owner:SHANGHAI JIAO TONG UNIV

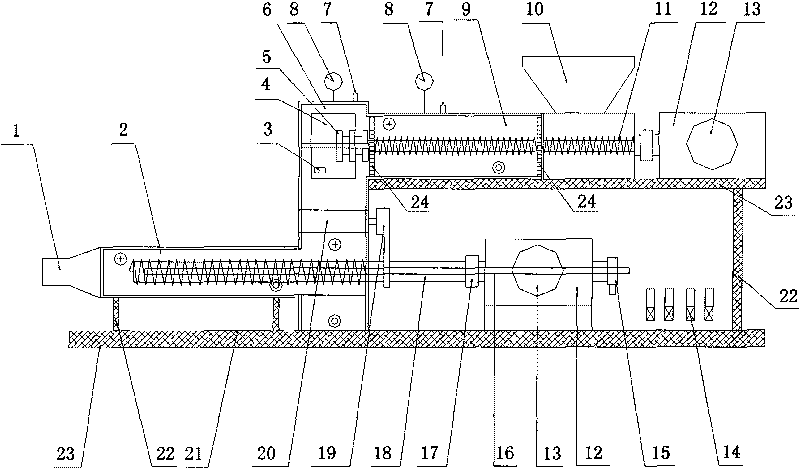

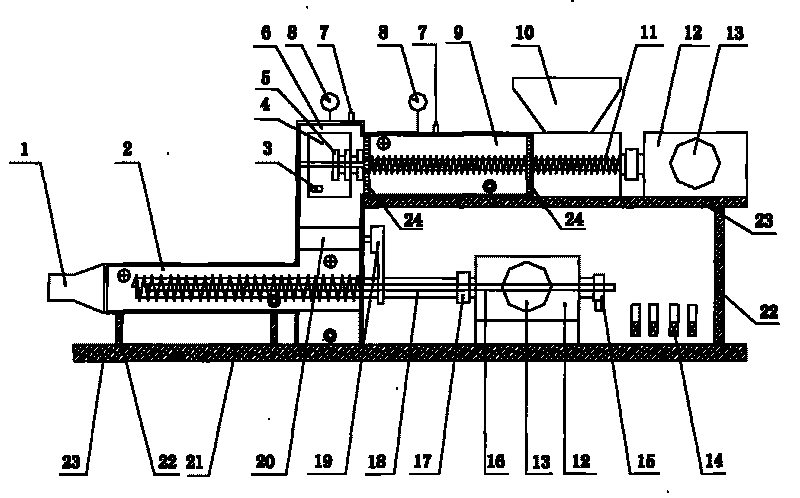

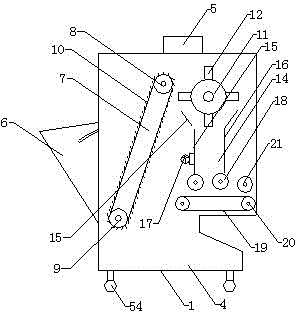

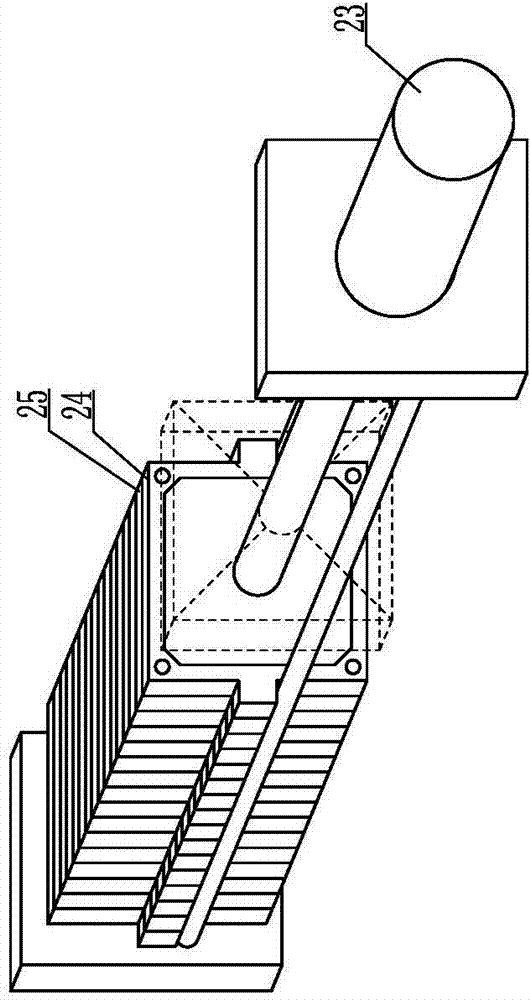

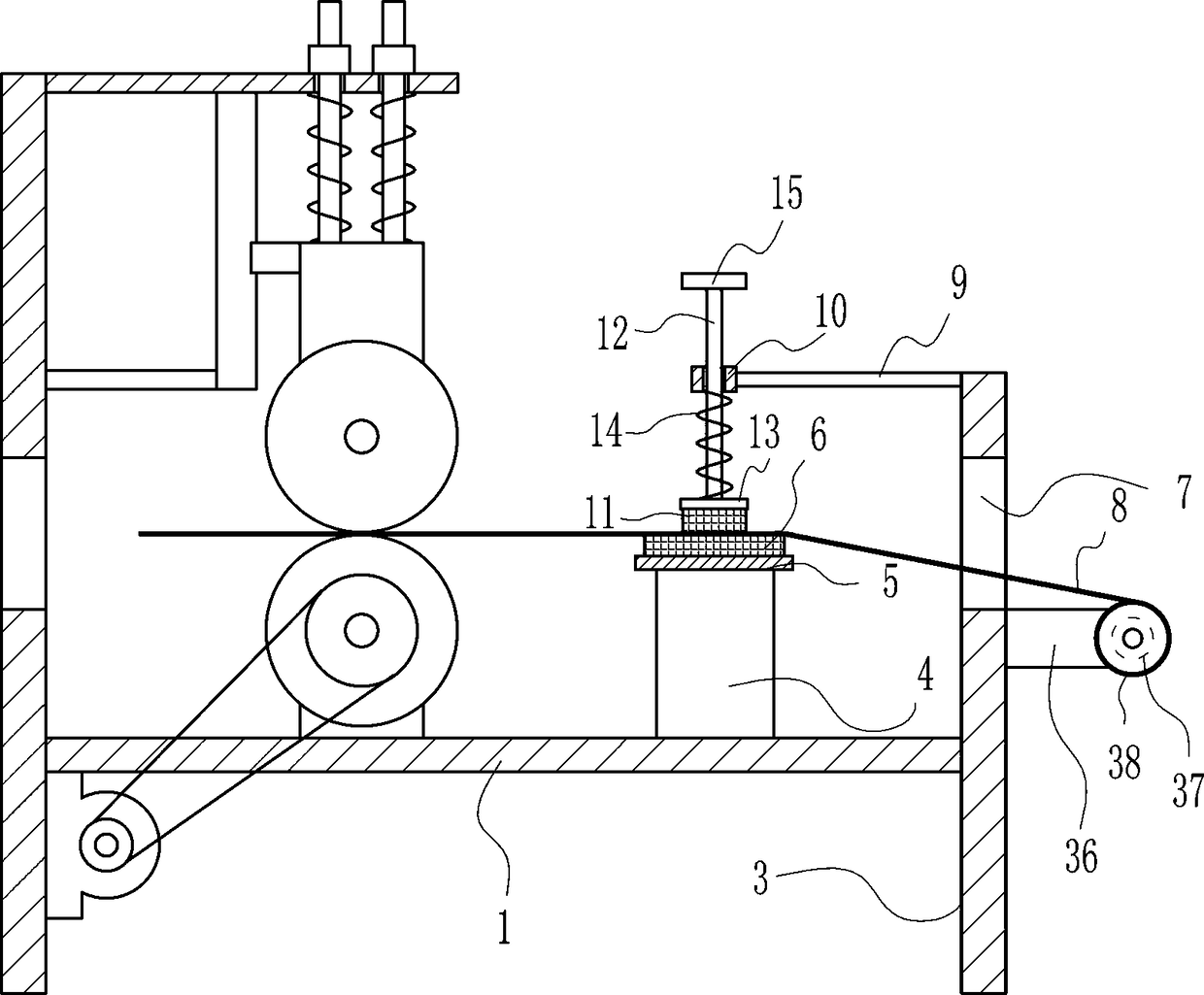

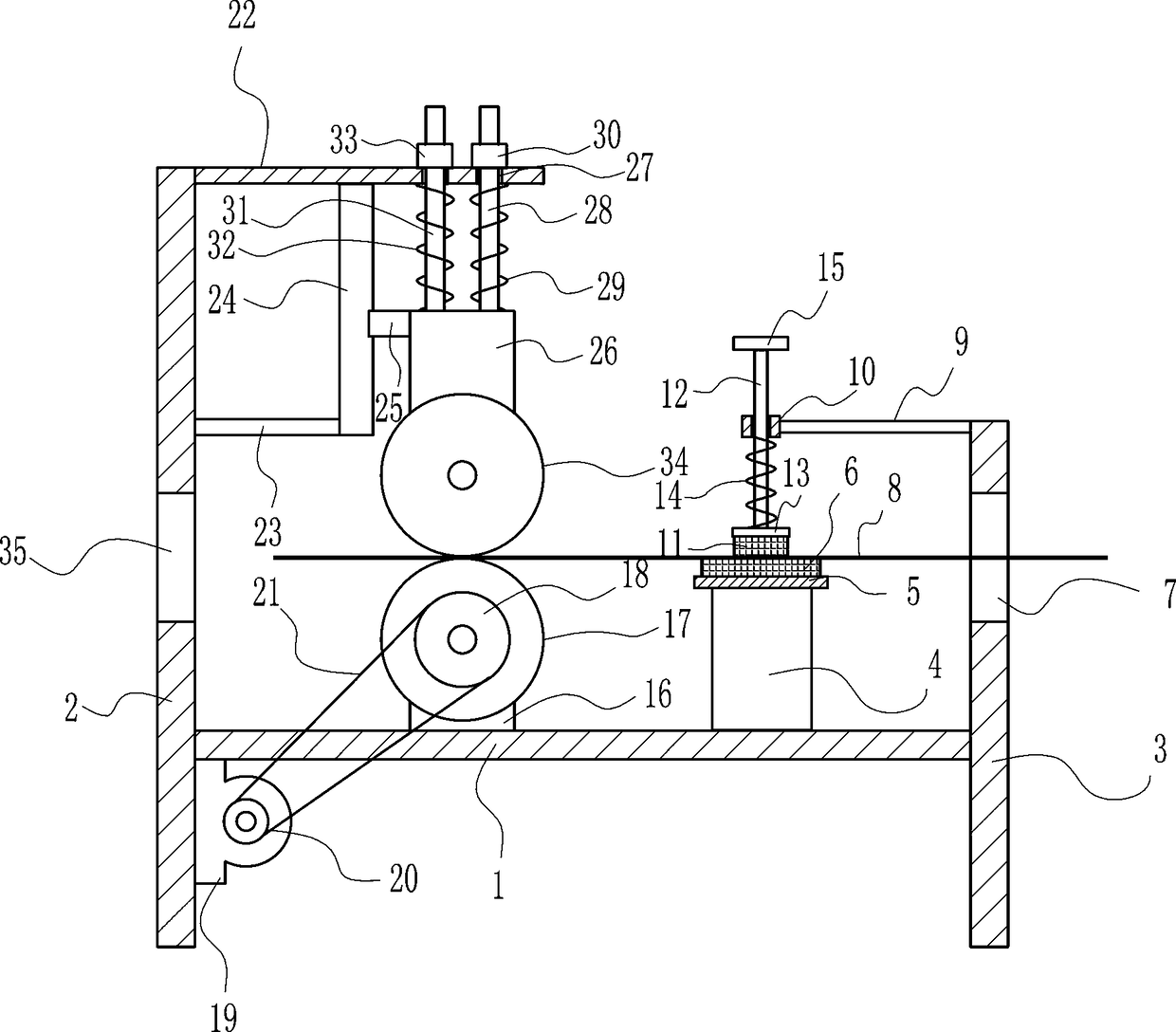

Honeycombed ceramic slurry water cooling vacuum refiner

The invention provides a honeycombed ceramic slurry water cooling vacuum refiner, comprising a slurry feed cylinder, slurry stirring shafts with helical blades, a vacuum chamber, a pumping hole, two kneading rollers, a photoelectric control device, a transmission mechanism, a hollow extruding shaft with helical blades, a slurry discharge cylinder, a fence which has section area close to and slightly smaller than the slurry feed cylinder, a cooling water device, a frame, a speed reducer and a variable-frequency motor, wherein the front end of the slurry stirring shafts with helical blades is provided with a slurry scraping knife. The slurry feed cylinder consists of two cylinders which are communicated, the section plane of the slurry feed cylinder is in a shape of a lying 8, and is communicated in the middle; the outlet end of the slurry feed cylinder is provided with the fence and the pumping port to form primary vacuum area; one slurry stirring shaft with the helical blade extends into each single cylinder, and is supported by a bearing with a seal ring; a bearing at the front end of the slurry stirring shaft is provided with a plurality of slurry scraping knives consisting of crossed blades; the fence is arranged at the outlet of the slurry feed cylinder; the upper end of the vacuum chamber is provided with the pumping port to ensure the vacuum chamber and the slurry discharge cylinder to form a secondary vacuum area; the lower part of the vacuum chamber is provided with two kneading rollers which are engaged with each other; the slurry outlet on the front part of the slurry discharge cylinder is a cone with narrowing opening.

Owner:NANJING KERUI SPECIAL CERAMICS +1

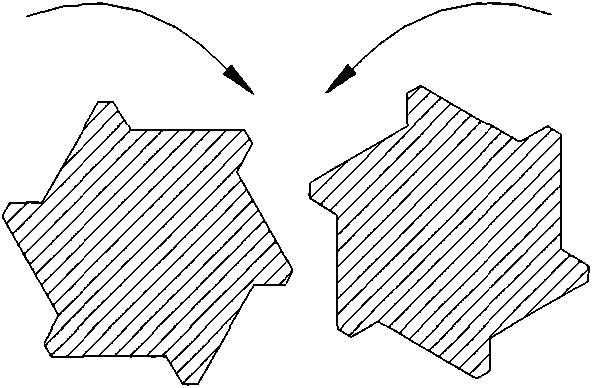

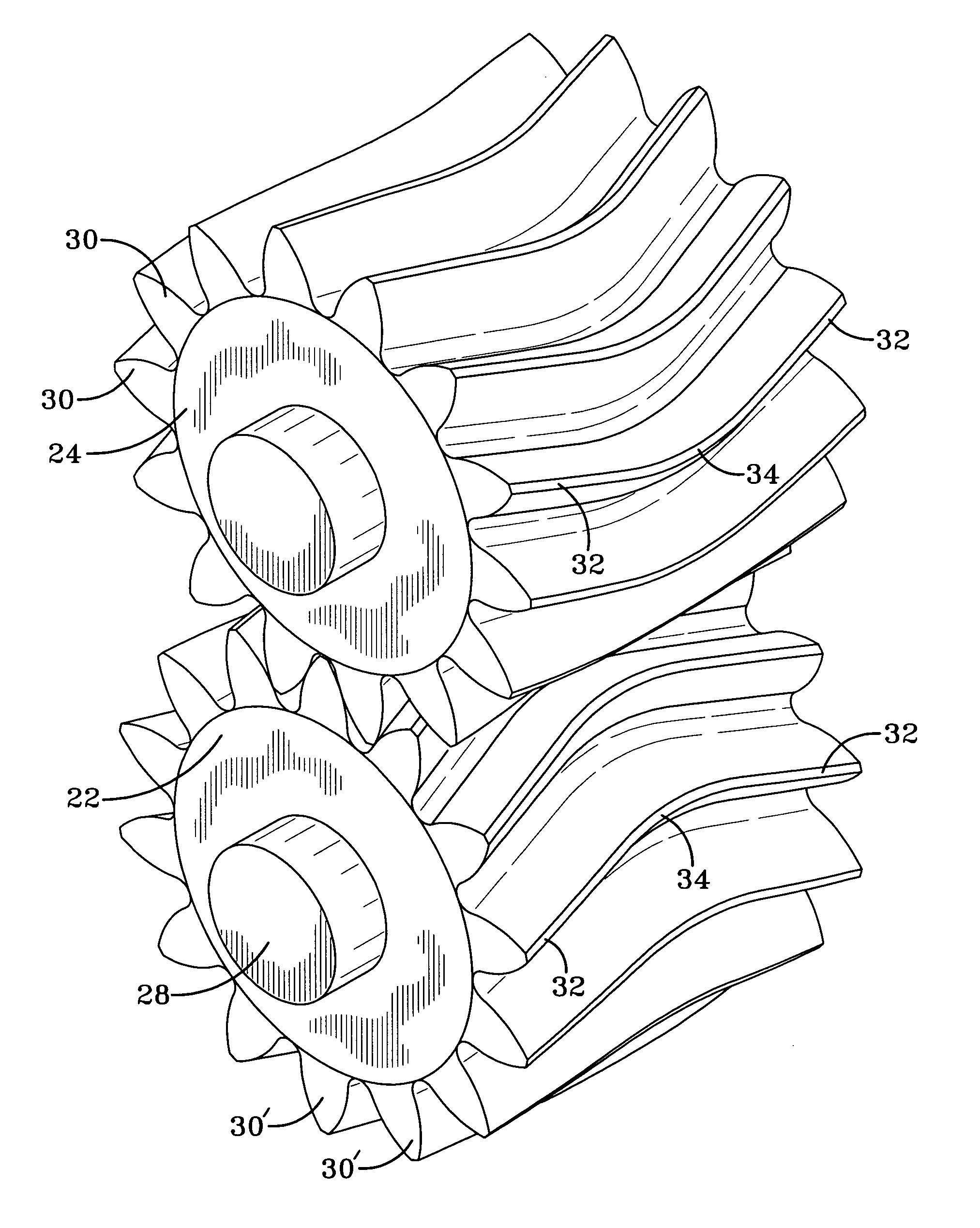

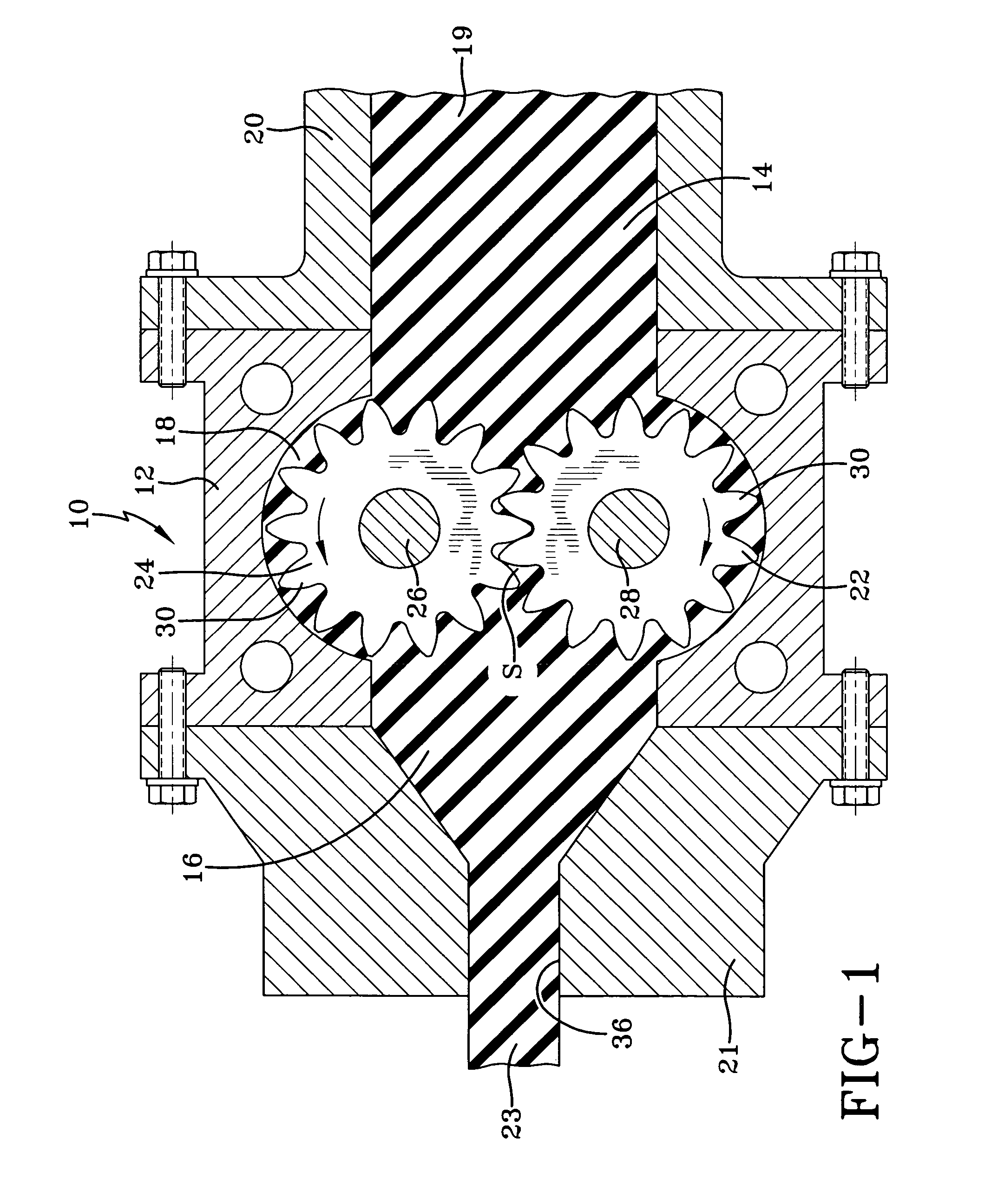

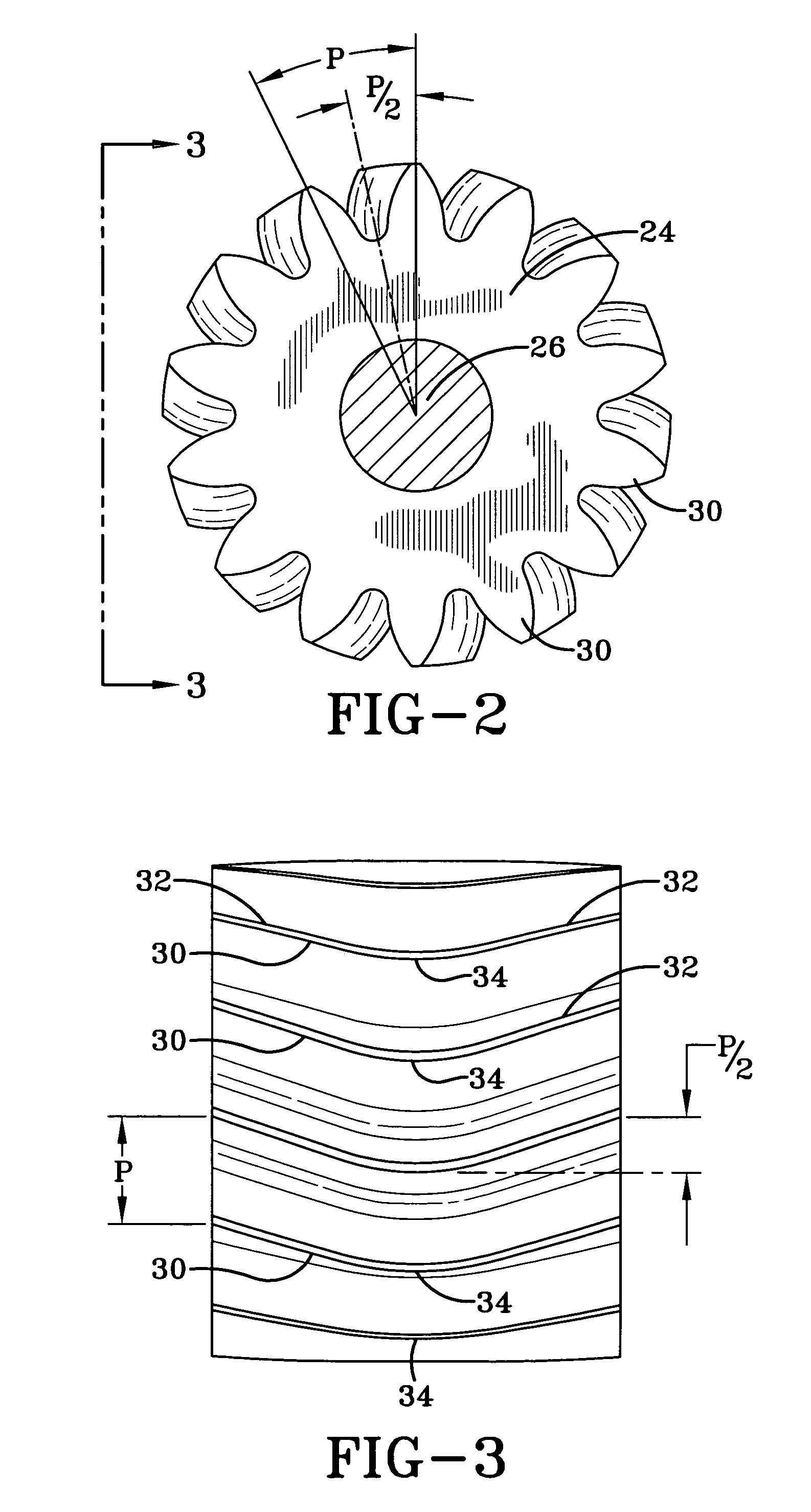

Gear pump with gears having curved teeth and method of feeding elastomeric material

InactiveUS7040870B2Minimizes flow of materialSqueeze evenlyOscillating piston enginesFlexible member pumpsGear pumpHerringbone gear

A gear pump and method for pumping elastomeric material having two gears with meshing herringbone gear teeth. Each of the gear teeth has helical side portions and a curved central portion which extends circumferentially of the gear a distance equal to at least one half the pitch of the gear teeth to provide a continuous squeezing contact between the teeth of the two gears for pumping a uniform strip of elastomeric material from the gear pump.

Owner:THE GOODYEAR TIRE & RUBBER CO

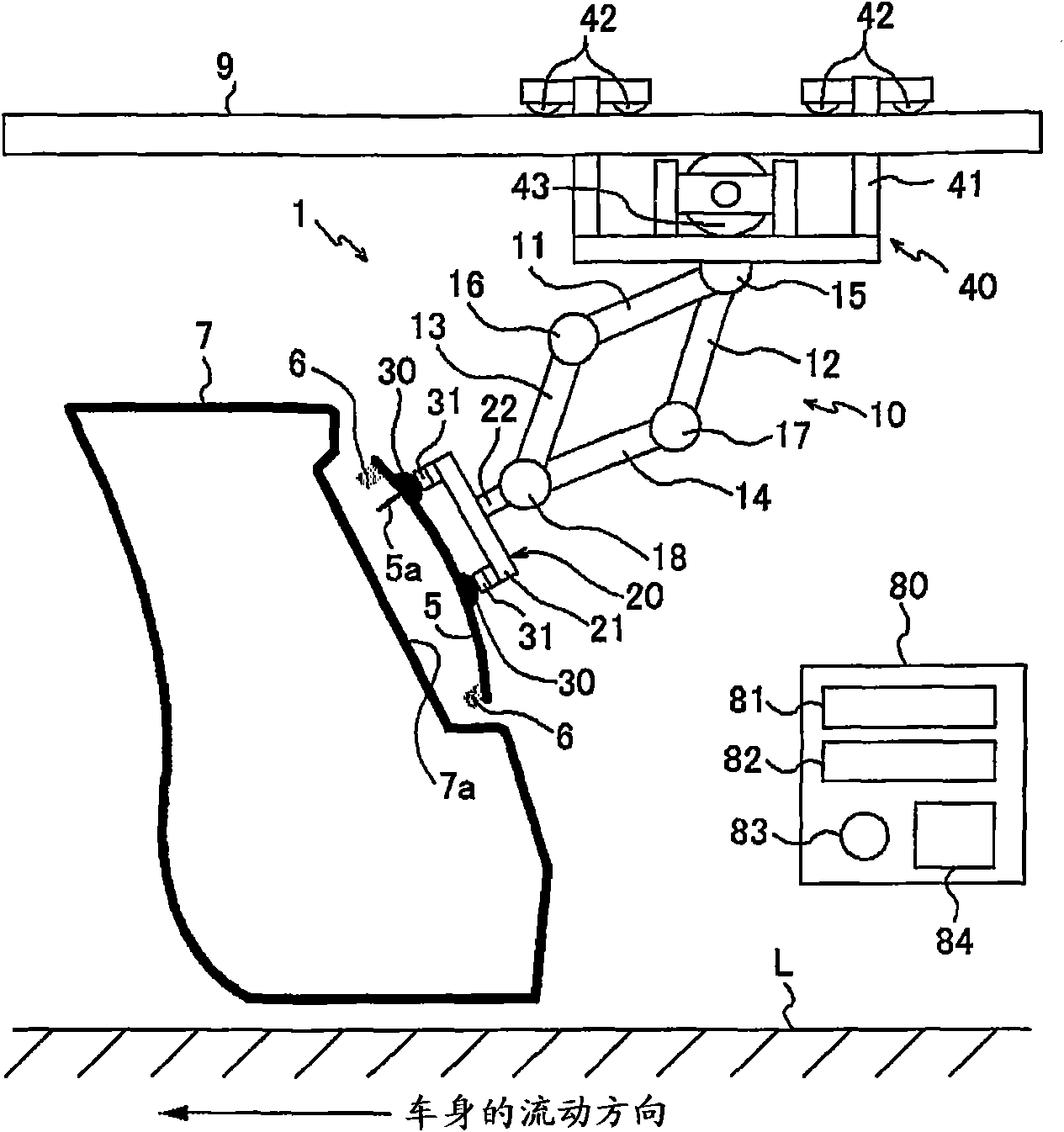

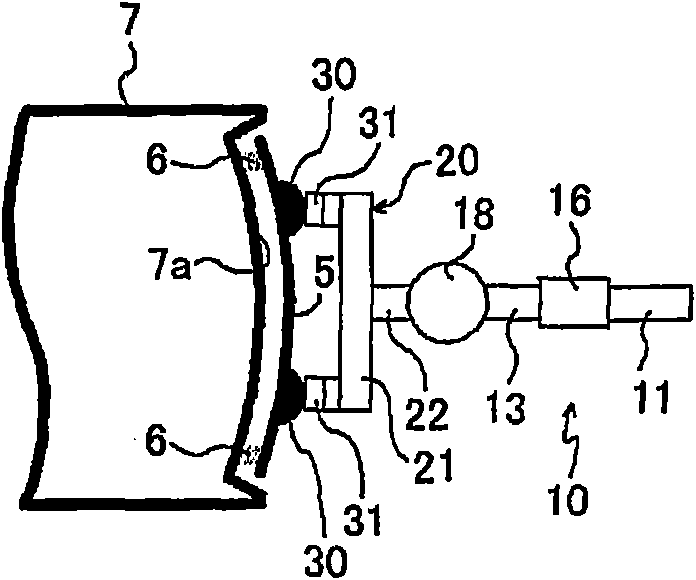

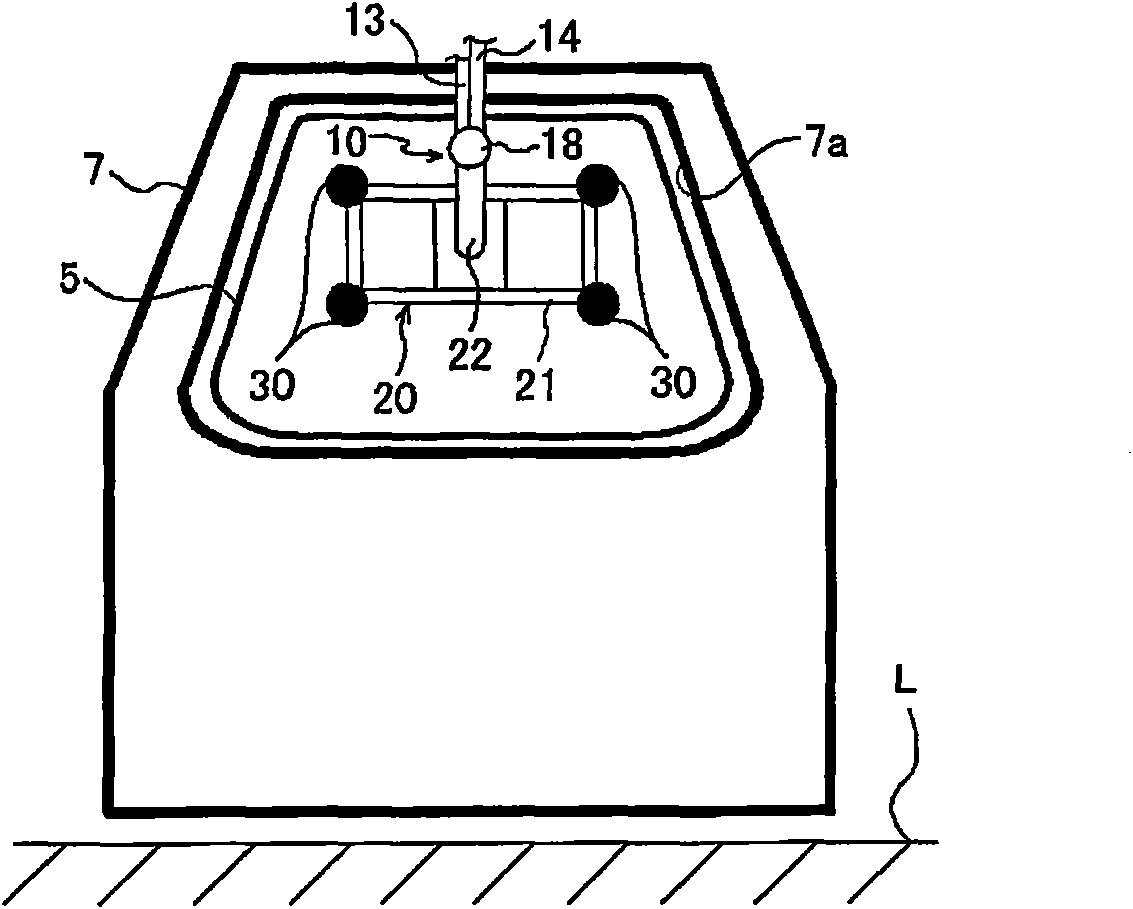

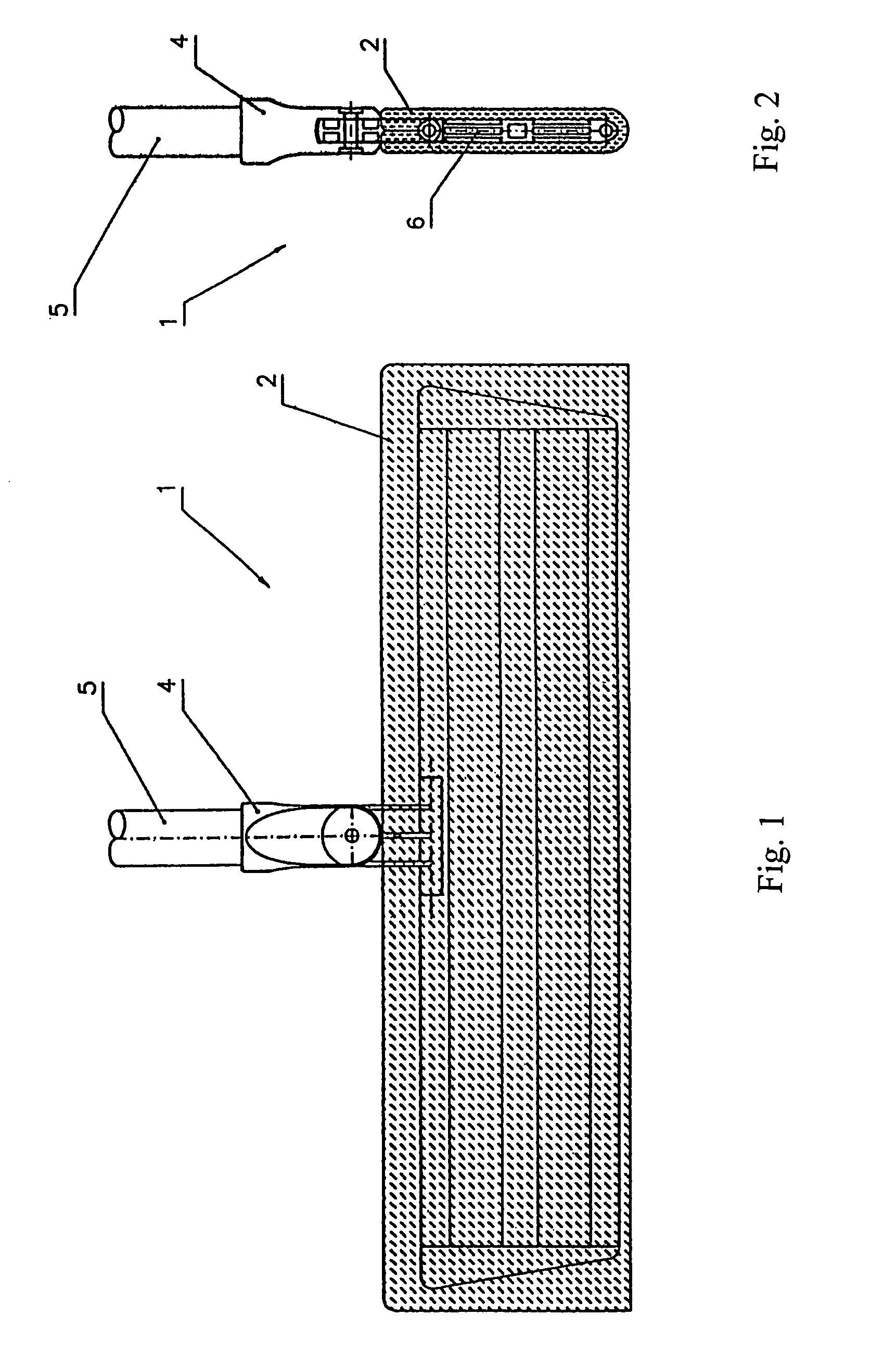

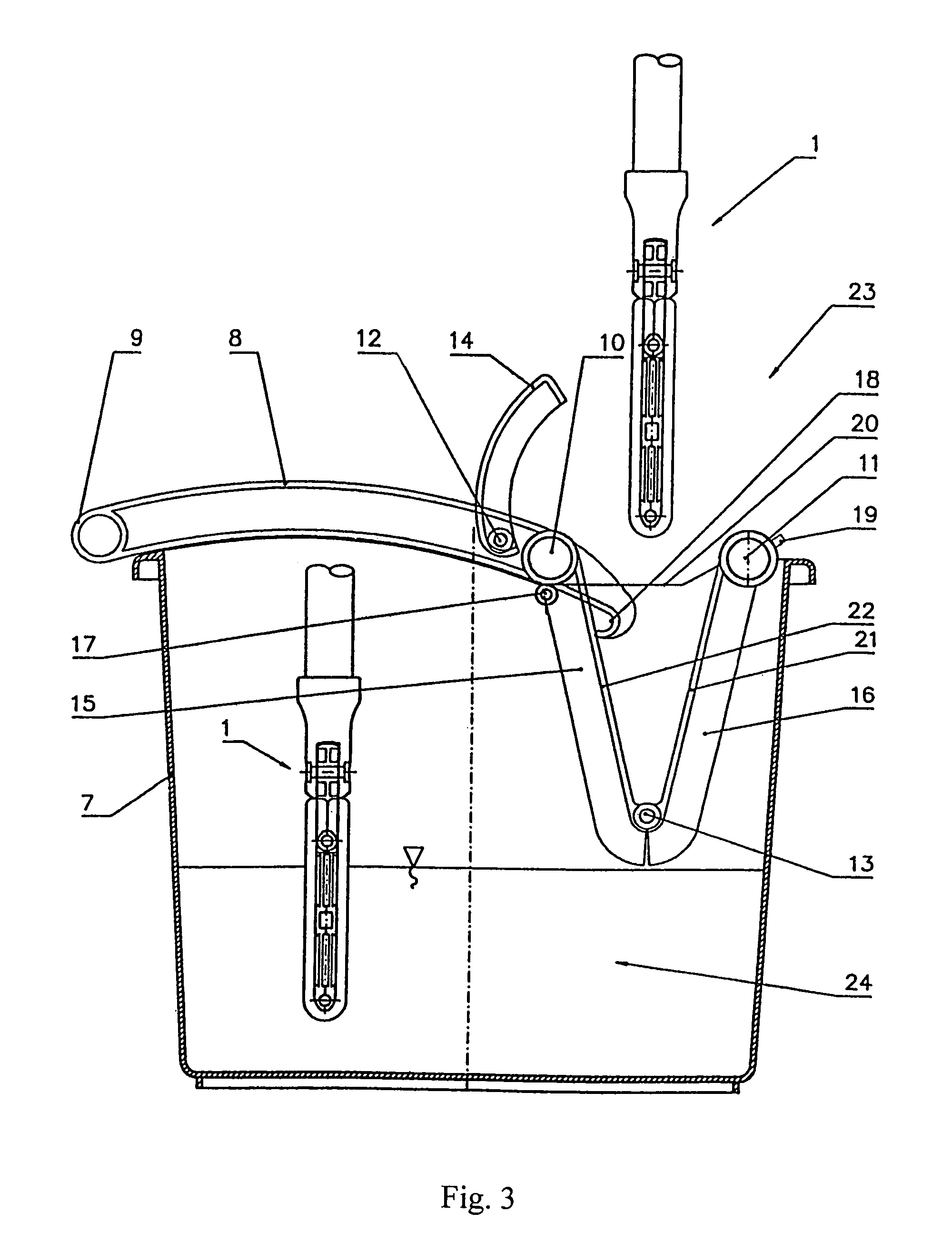

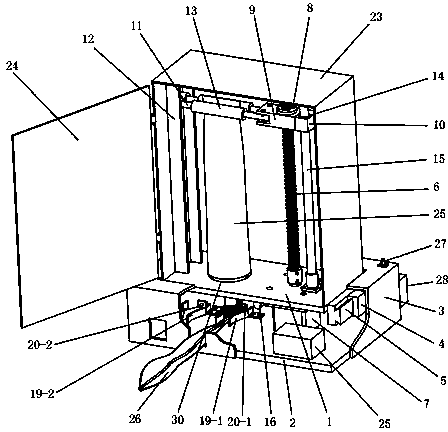

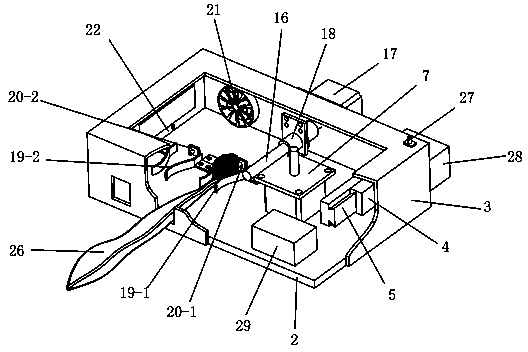

Work transfer apparatus, and work mounting method

InactiveCN101772402AImprove setting accuracySqueeze evenlyProgramme-controlled manipulatorGripping headsEngineeringAdhesion strength

According to a work mounting method by the work transfer apparatus of the prior art, a glass plate or a work may fail to abut against a window frame homogeneously at its peripheral edge portion, and the adhesion strength or the sealing property between the glass plate and the window frame may not be retained all over the periphery of the adhered portion. Provided is a work transfer apparatus (1),which grips a rear glass (5) by its gripping member (20) and mounts the rear glass (5) while pushing the gripped rear glass (5) onto the window frame (7a) of a car body (7) by the action of a supporting arm (10). The work transfer apparatus (1) comprises a control device (80), and each of absorption pads (30) of the gripping member (20) includes a force detecting sensor (31) for detecting the force to be applied to the absorption pads (30). The control device (80) controls, when it uses the work transfer apparatus (1) to mount the rear glass (5) on the window frame (7a), the actions of the supporting arm (10) on the basis of the magnitude of the detected value of the force detecting sensor (31) of each absorption pad (30).

Owner:TOYOTA JIDOSHA KK

Device for squeezing liquid-absorbing wiper bodies

InactiveUS6996873B2Little strengthSqueeze evenlyCarpet cleanersFloor cleanersEngineeringMechanical engineering

Owner:VERMOP SALMON

Micro fine-grained titanium-nickel-niobium shape memory alloy block material preparing method

The invention is a manufacturing method for a kind of micron tiny crystal titanium nickel-niobium shape memorizing alloy block materials, 45%-50% titanium, 40%-45% nickel, 5%-10% niobium are melted and produced into titanium nickel-niobium alloy cast ingot, and cuts the titanium nickel-niobium alloy block material into blank, and carries on surface finish process, and paints with glass lubricate, uses isometric curved squeezing mould with 90-120 degrees channel angle, the mould cavity surface is painted with black lead lubricate, the blank and mould are heated and carries on temperature reservation, and takes them out to be squeezed at the same time, finally gets the product. The invention solves the problem that the bad plastic property of titanium nickel-niobium shape memorizing alloy in room temperature, enhances the alloy mechanical performance, and lowers the cost.

Owner:SHANGHAI JIAO TONG UNIV

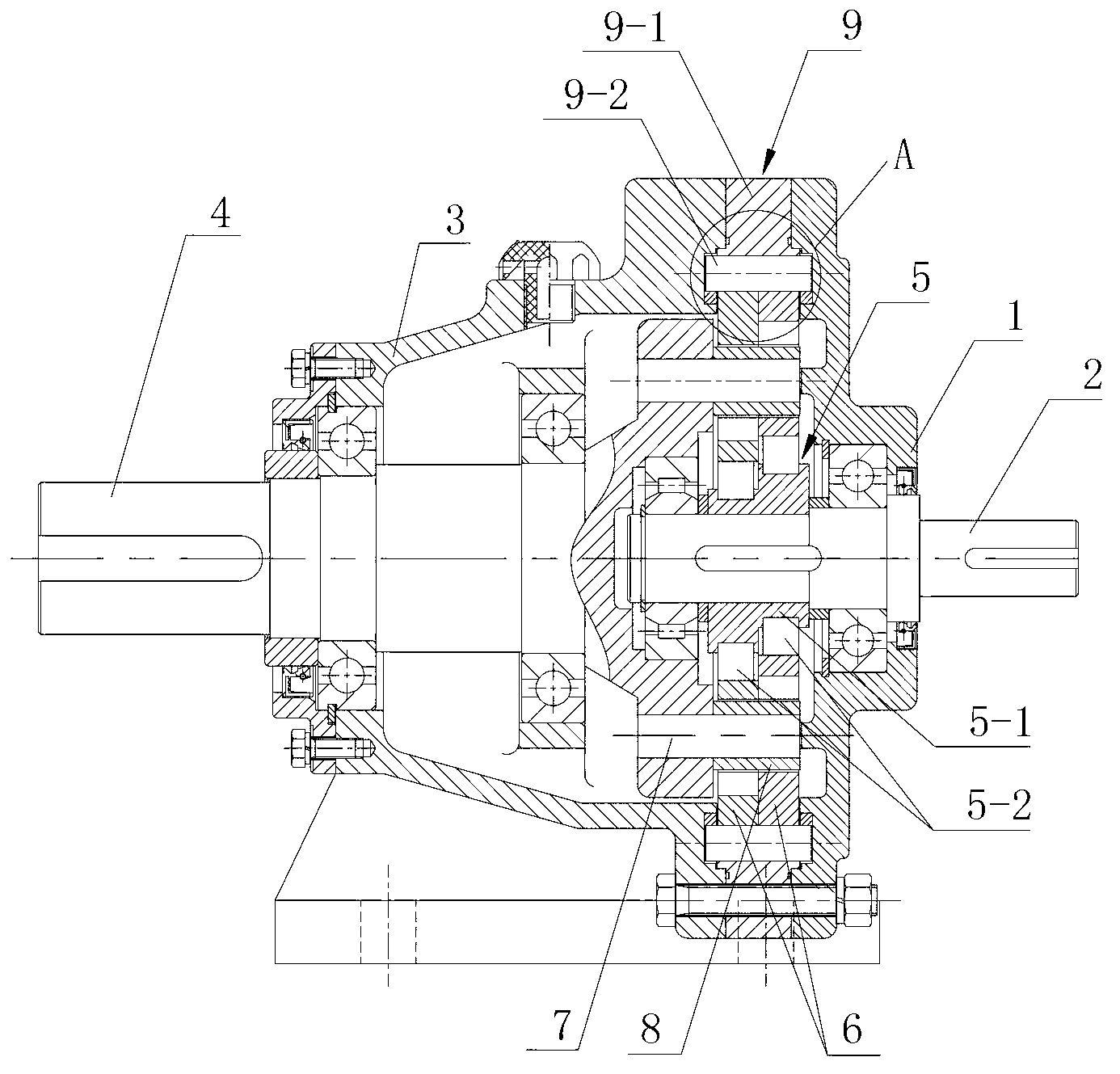

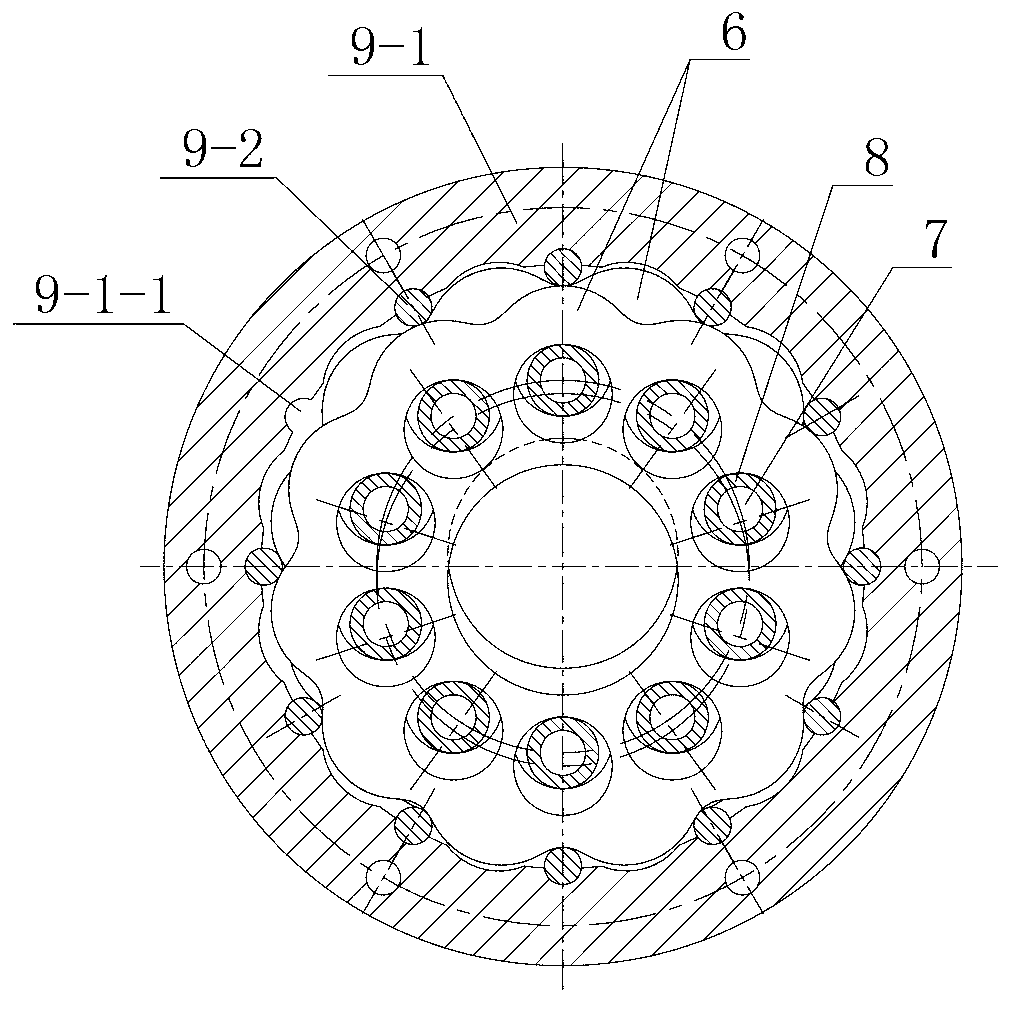

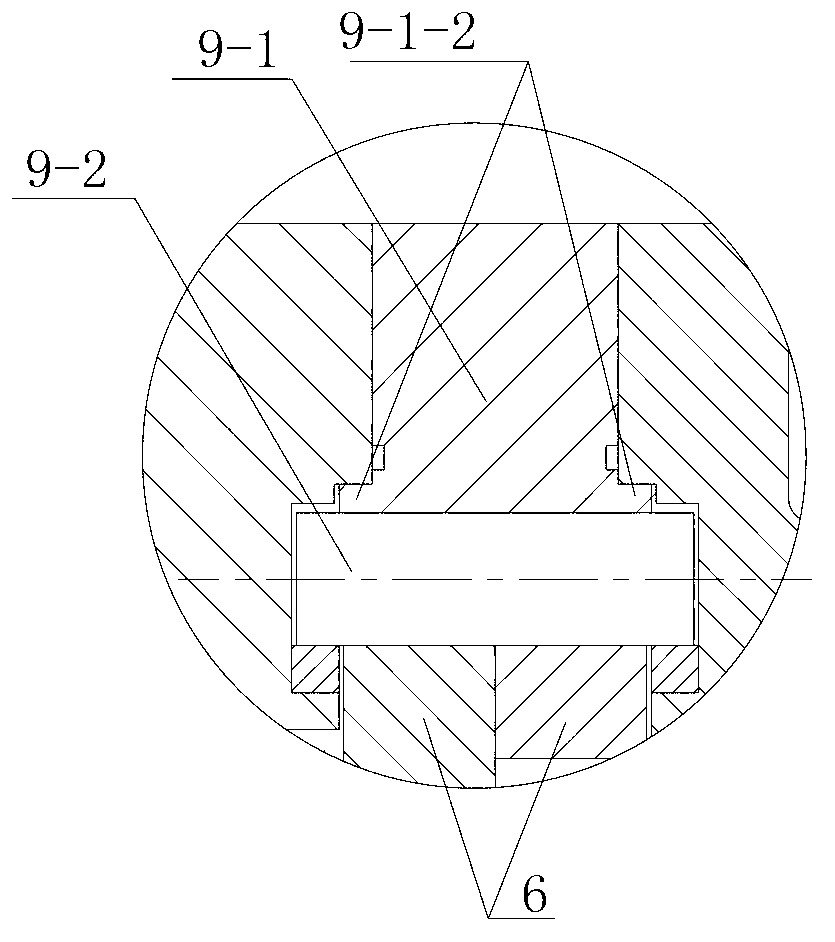

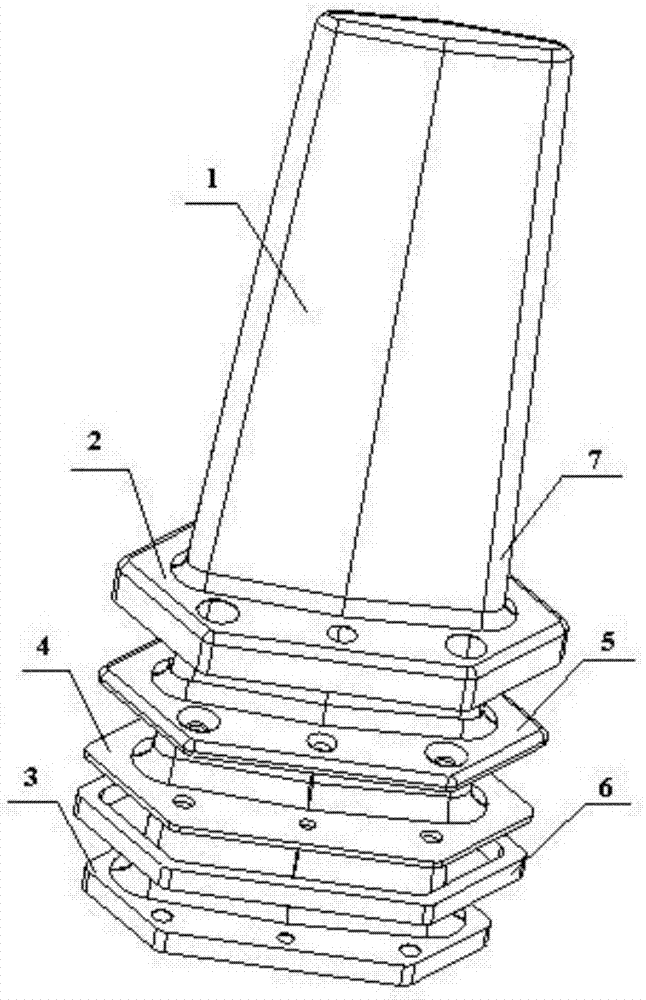

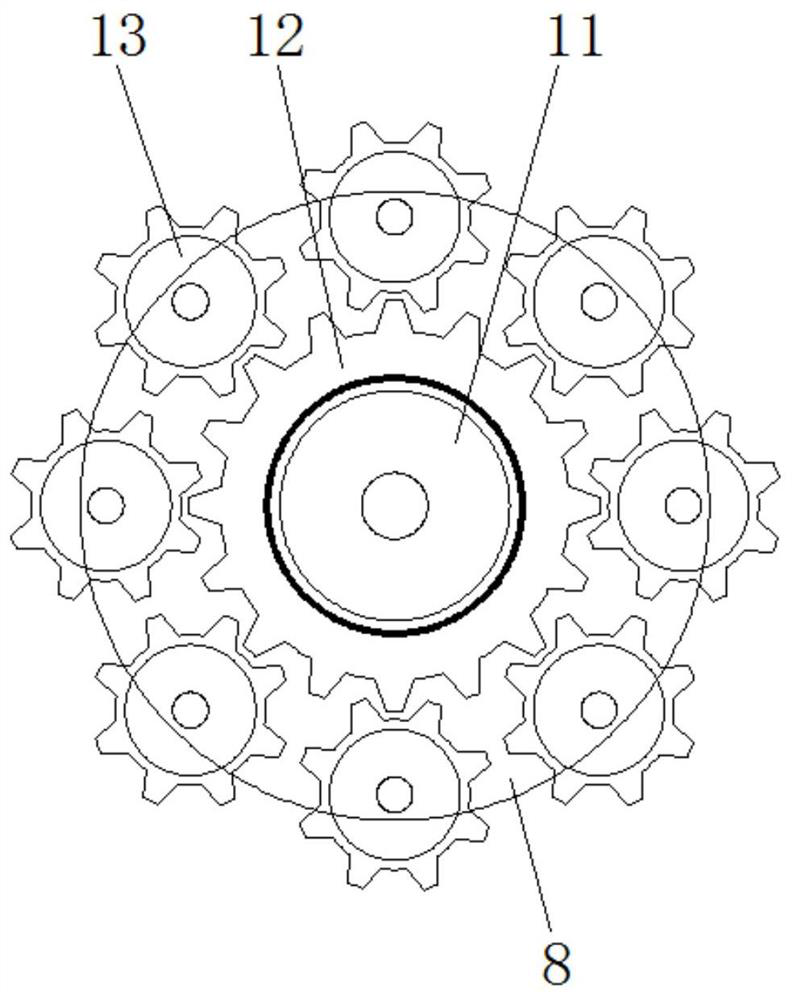

High-bearing-capacity cycloidal pin wheel speed reducer

The invention relates to a high-bearing-capacity cycloidal pin wheel speed reducer. The high-bearing-capacity cycloidal pin wheel speed reducer comprises an input portion, a speed reduction portion and an output portion, wherein the input portion comprises a flange plate and an input shaft; the output portion comprises an engine seat and an output shaft; and the speed reduction portion comprises a 180-degree-staggered double-eccentric support member, two cycloidal wheels and a plurality of pin shafts, a pin sleeve and a pin gear assembly, wherein the pin shafts and the pin sleeve are connected with the cycloidal wheels and the output shaft. The high-bearing-capacity cycloidal pin wheel speed reducer is characterized in that the pin gear assembly consists of a pin gear housing and a plurality of gear pins; two end surfaces of the pin gear housing are respectively compressed with the inner end surfaces of the flange plate and the engine seat, and the pin gear housing, the flange plate and the engine seat are fixedly connected by bolts; and arc-shaped grooves are uniformly formed in the inner circle of the pin gear housing, and the gear pins are mounted in the arc-shaped grooves one by one. By utilizing the technical scheme, the contact areas between the gear pins and the pin gear housing are increased; and compared with the conventional structure, for the high-bearing-capacity cycloidal pin wheel speed reducer, the gear pins are uniformly extruded on the whole axial length, so that the rigidity of the gear pins is substantially increased, the deformation of the gear pins is avoided when an input torque is properly increased, the noise and the temperature rise caused by the deformation are reduced, and finally the bearing capacity of the whole speed reducer is improved.

Owner:天津百利天星传动有限公司

Constant diameter right-angle extruding production of micro/nanometer crustal industrial pure titanium block

An isometric angle squeezing technology for preparing micron / nano-crystal industrial-purity Ti block includes such steps as providing an industrial-purity Ti block, annealing, holding its temp, cutting it to become blanks, polishing the surface of blank, coating glass lubricant, coating graphite lubricant on the inner surface of an isometric angle squeezing die with a squeezing channel angle of 90-120 deg, heating said blank and die, and isometric angle squeezing. Its product has high strength, plasticity, biocompatibility and anticorrosion nature, the elastic modulus similar to that of bone, and low cost.

Owner:SHANGHAI JIAO TONG UNIV

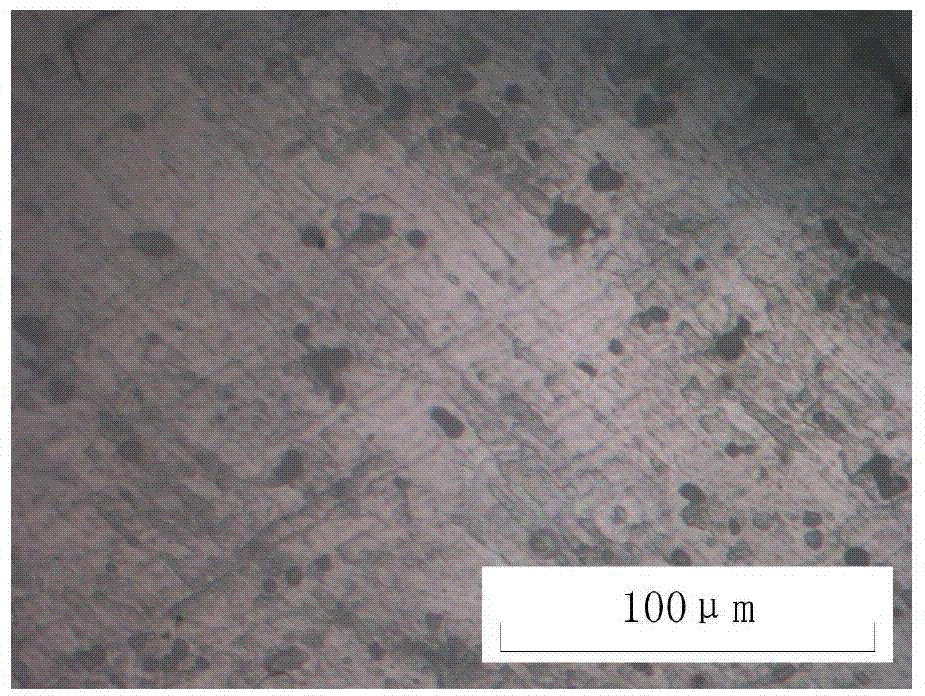

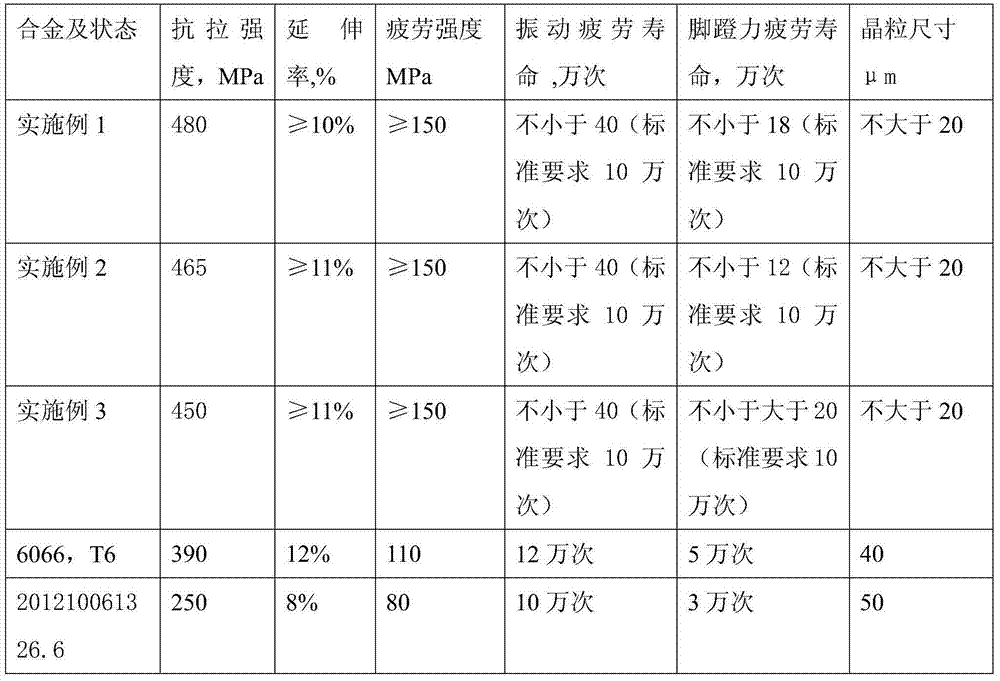

Aluminum alloy for bicycle frame tube and preparation method thereof

The invention discloses an aluminum alloy for a bicycle frame tube and a preparation method thereof, wherein the aluminum alloy aims at solving the technical problems that the intensity of the existing aluminum alloy which is used for manufacturing the bicycle frame tube is not good or the welding process property is not good or the safe reliability is not good. The aluminum alloy comprises the following components according to weight percentage 0.8-1.6% of Mg, 0.8-1.8% of Si, 0.7-1.2% of Cu, 0.6-1.4% of Mn, 0.10-0.30% of Cr, 0.1-0.6% of Er, 0.08-0.20% of Zr, and the balance Al and inevitable impurities. The aluminum alloy provided by the invention have the beneficial effects that the intensity of the aluminum alloy is good, the plasticity is good, the light weight of a bicycle is realized, the intensity of the bicycle frame tube which is made of the aluminum alloy is greater than 450MPa, and the extending ratio can be kept to be more than 10%; the welding property and the extrusion property are excellent, the welding requirements on the extrusion moulding of the bicycle frame tube and a frame are met, and the aluminum alloy can smoothly pass the European standard safety test.

Owner:TIANJIN GOLDEN WHEEL BICYCLE GRP +1

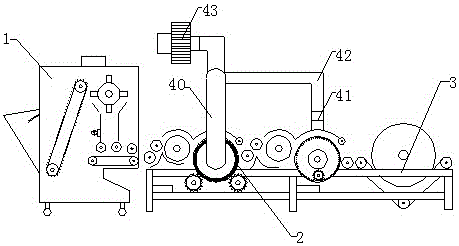

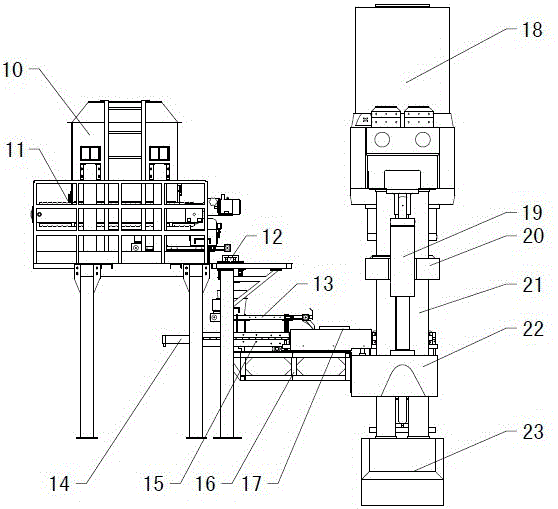

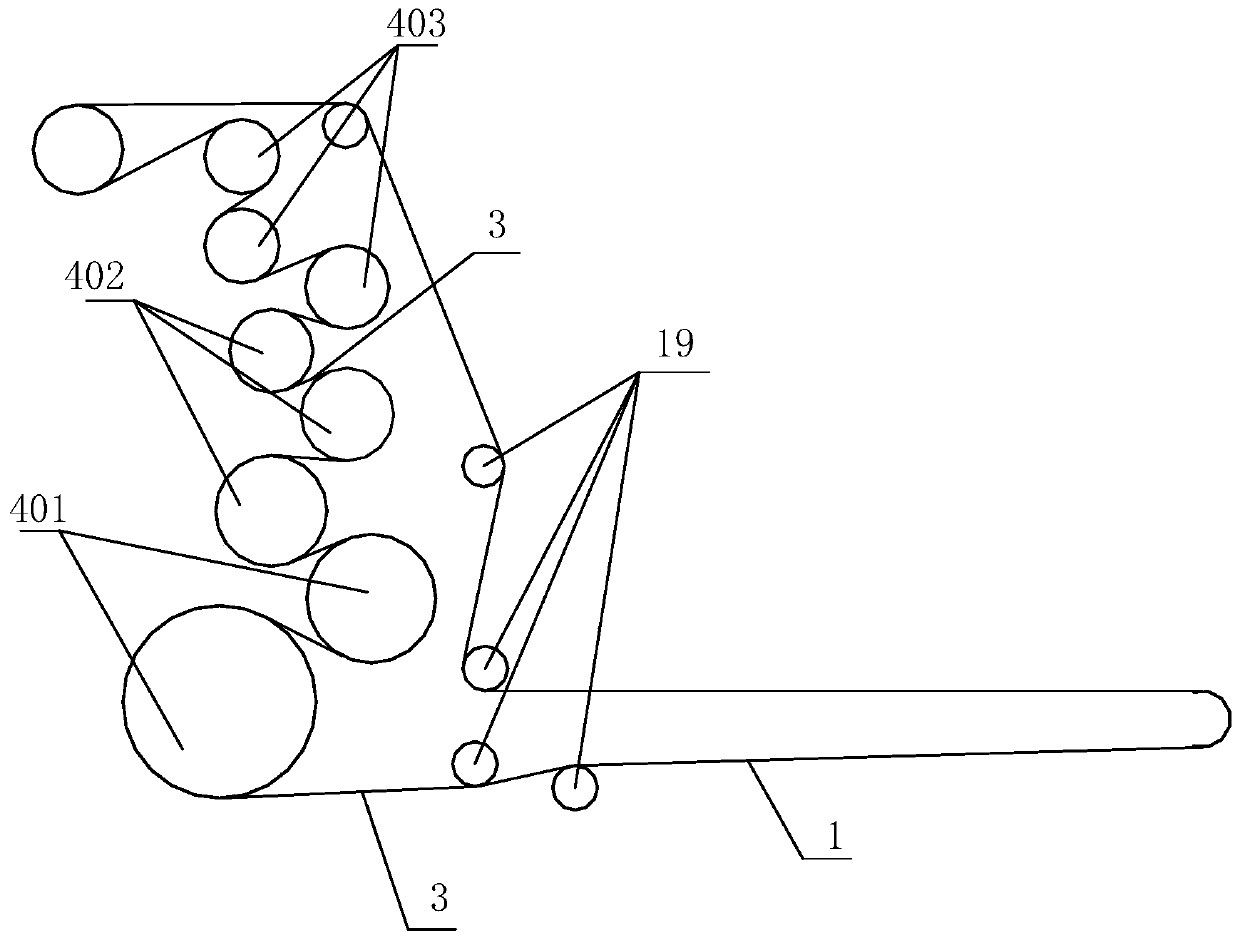

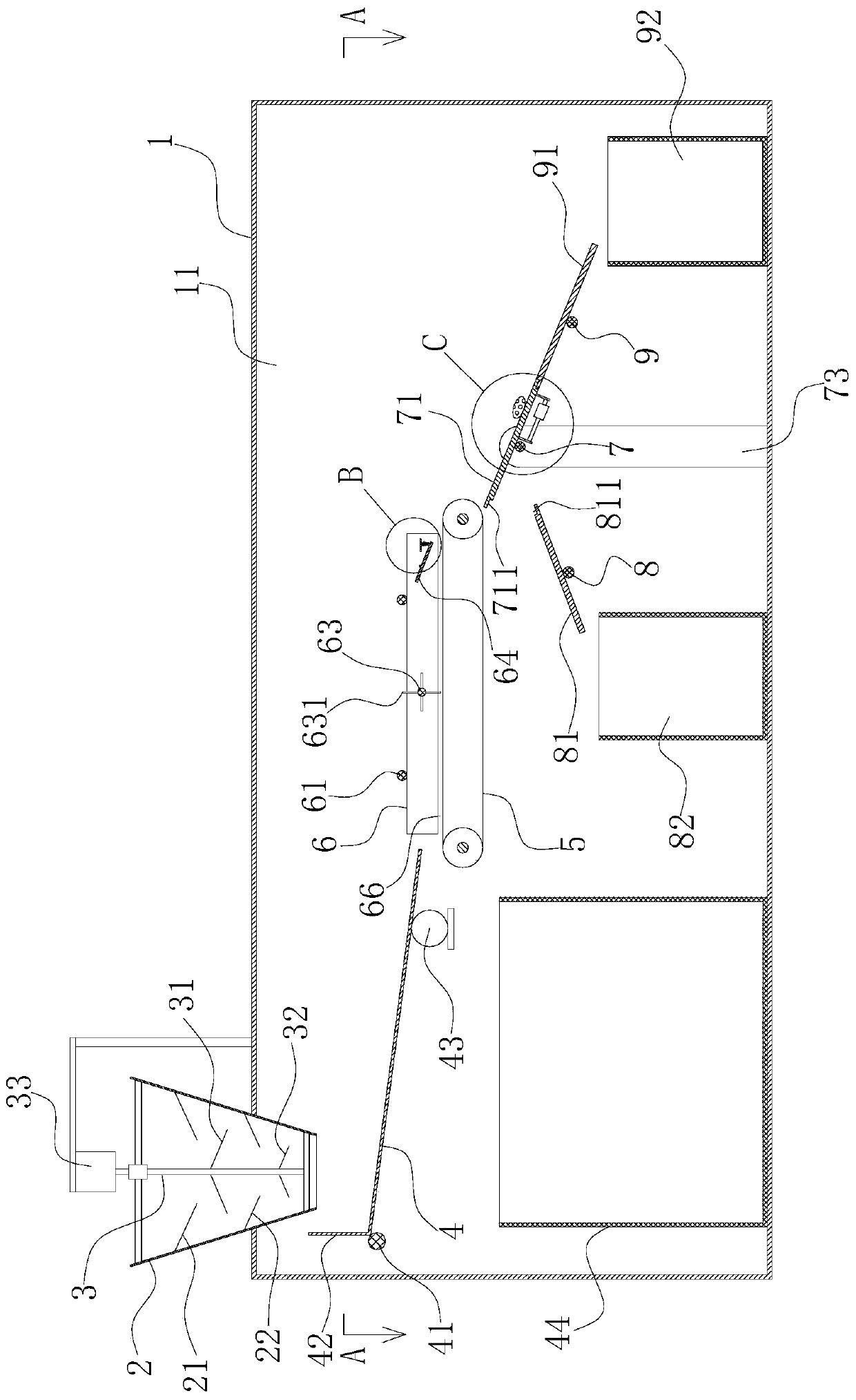

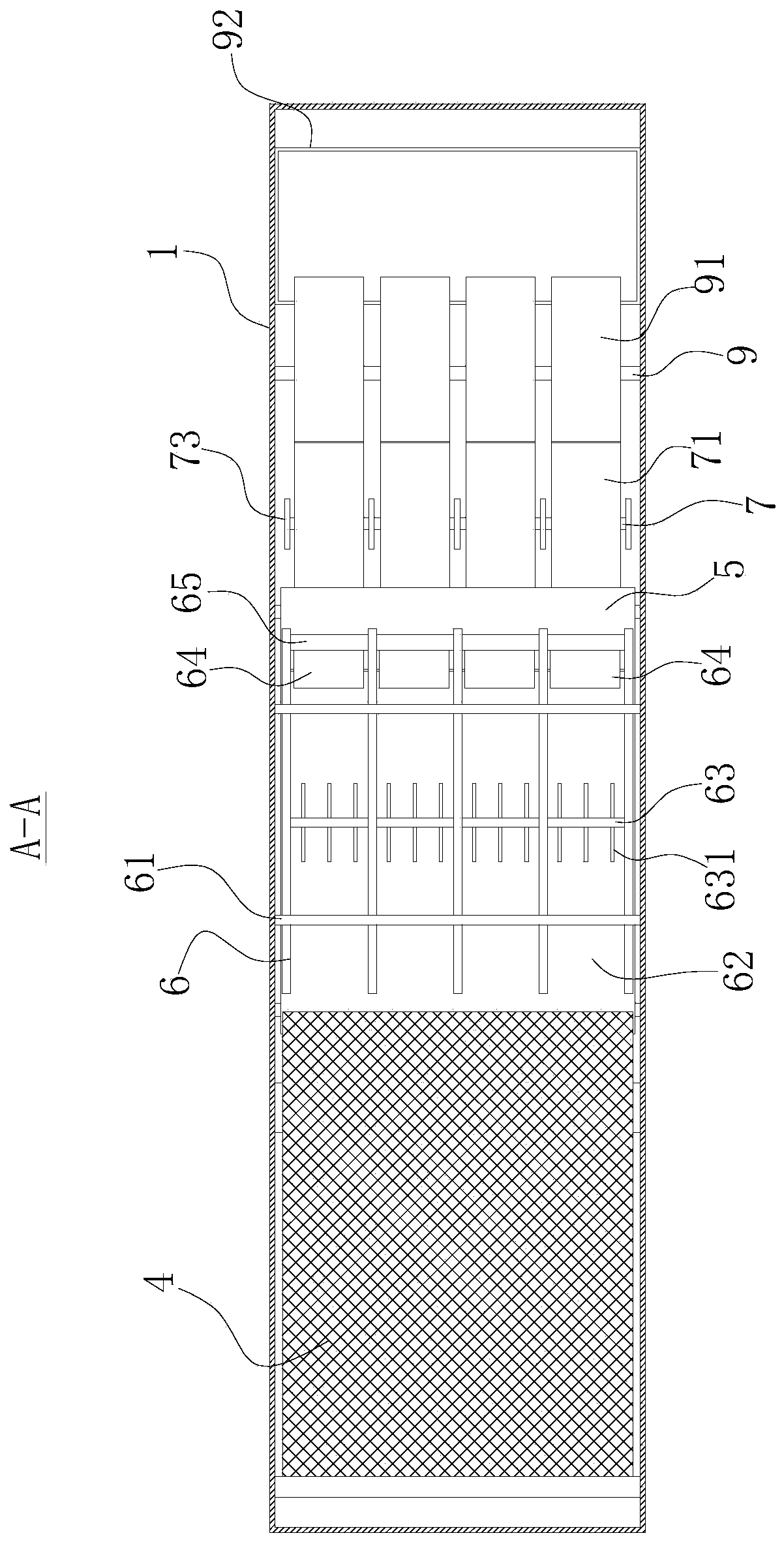

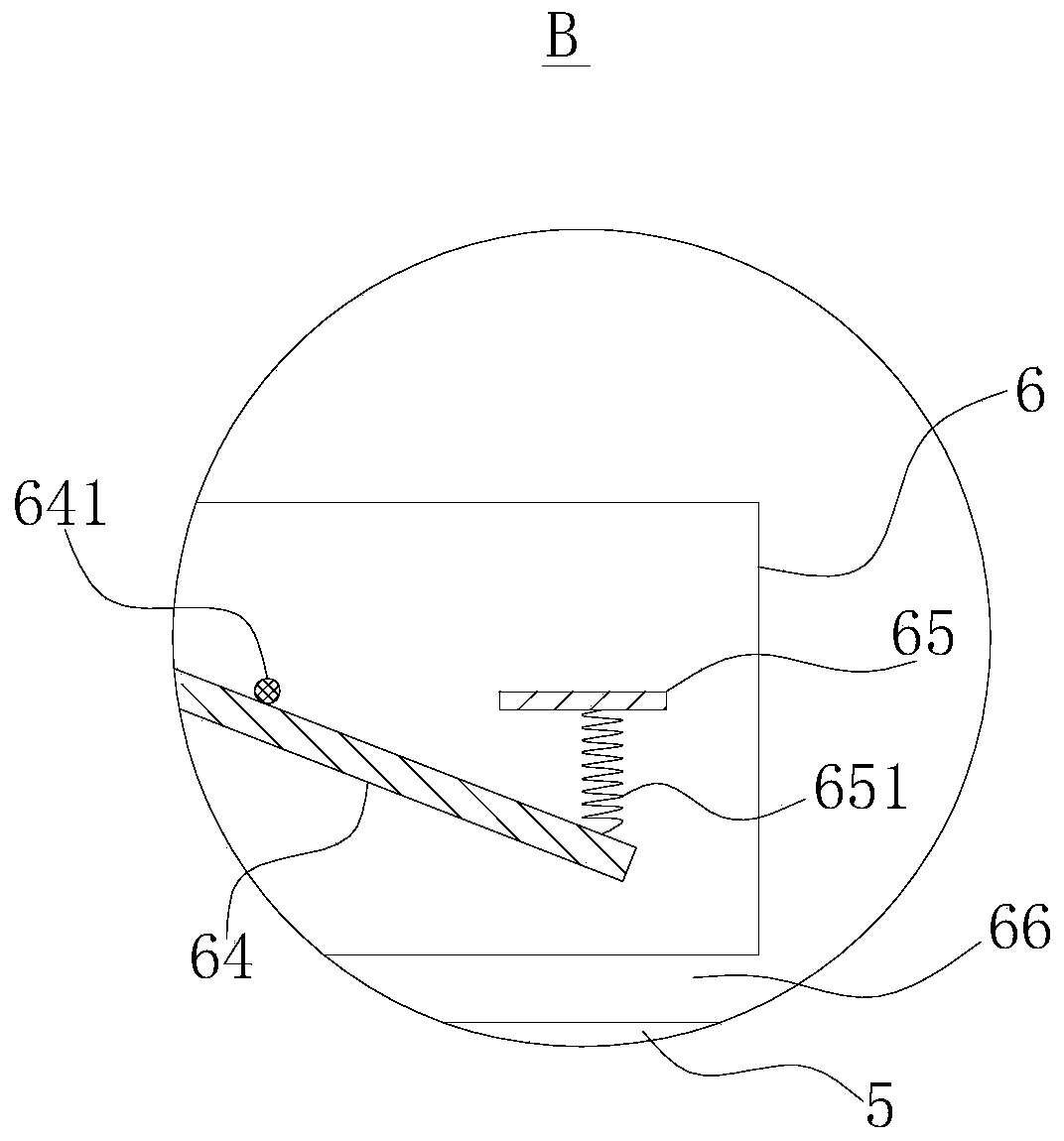

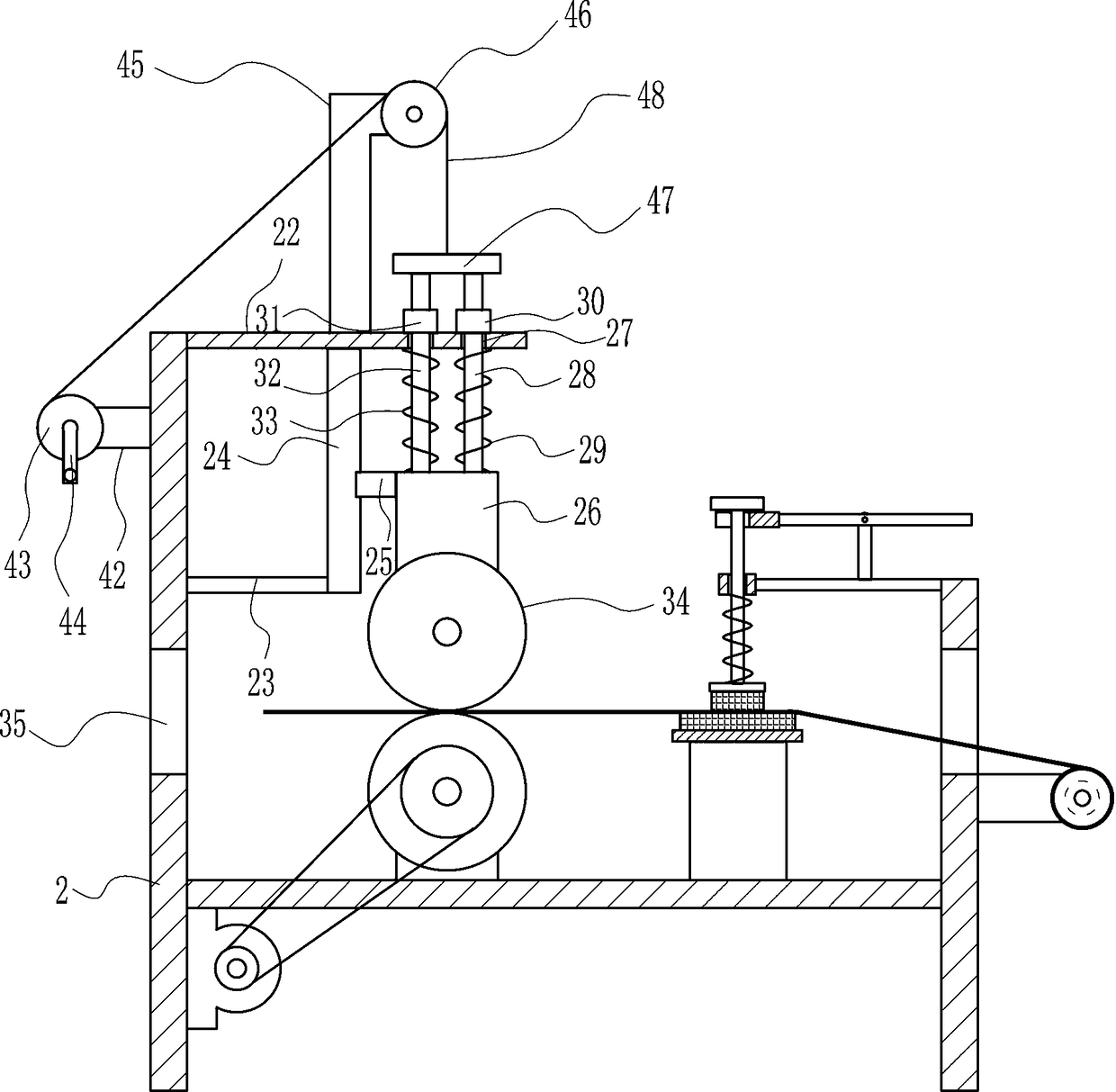

Highly-efficient cotton fluffer

InactiveCN105040169AGuaranteed cleanlinessEnsure cleanlinessFibre cleaning/opening by toothed membersFibre cleaning/opening machinesAgricultural engineeringAgricultural science

The invention belongs to the technical field of textile equipment and relates to a highly-efficient cotton fluffer. The highly-efficient cotton fluffer comprises an automatic cotton-feeding device, a cotton-carding device and a cotton-collecting device. Compared with a conventional cotton-feeding device, the automatic cotton-feeding device is more mechanized so that input of manual power is greatly reduced and helps to ensure personal safety of operators and achieve automated cotton-feeding with great safety factor. The automatic cotton-feeding device is connected with the cotton-carding device in order to realize synchronous drive. Double licker-in roller devices and double dust cage devices are employed by the cotton-carding device and used for carding cotton and dedusting twice in one process in order to satisfy requirements for high quality and high cleanliness. The cotton-collecting device located at the tail end adopts a cotton-accumulating drum to automatically collect cotton under drive of a driving belt so that cotton collection without manual labor is realized, thereby greatly saving manpower of a company. Additionally, cost of production and manufacture of the company is decreased. As a whole, the highly-efficient cotton fluffer is advantaged by being reasonable in structure layout, high in working efficiency, great in safety factor of manufacture and production and in cotton cleanliness and few in input of manpower.

Owner:HENAN XINPUFENG COTTON GIN TECH CO LTD

Micron fine-grained titanium-nickel alloy block material isodiametric corner extrusion preparing method

InactiveCN1528940AReduce temperature dropReduce sliding frictional resistanceMechanical propertyNickel based

The invention is an isometric angle squeezing producing method for a kind of micron tiny crystal titanium nickel alloy block materials. Titanium and nickel whose atom percentage are 45%-52% and 48%-55% are melted in vacuum, produces the titanium nickel base alloy cast ingot, cuts the block materials into blanks, and carries on surface finish process, and paints with glass lubricate, uses squeezing mould with 90-120 degrees angle, the surface of mould cavity is painted with black lead lubricate, the blank, mould are heated, and they are taken out from the stove and carried on with angle squeezing, finally acquires the titanium nickel base alloy block materials with excellent intensity and plasticity. The invention enhances the mechanical property of alloy, and reduces the cost.

Owner:SHANGHAI JIAO TONG UNIV

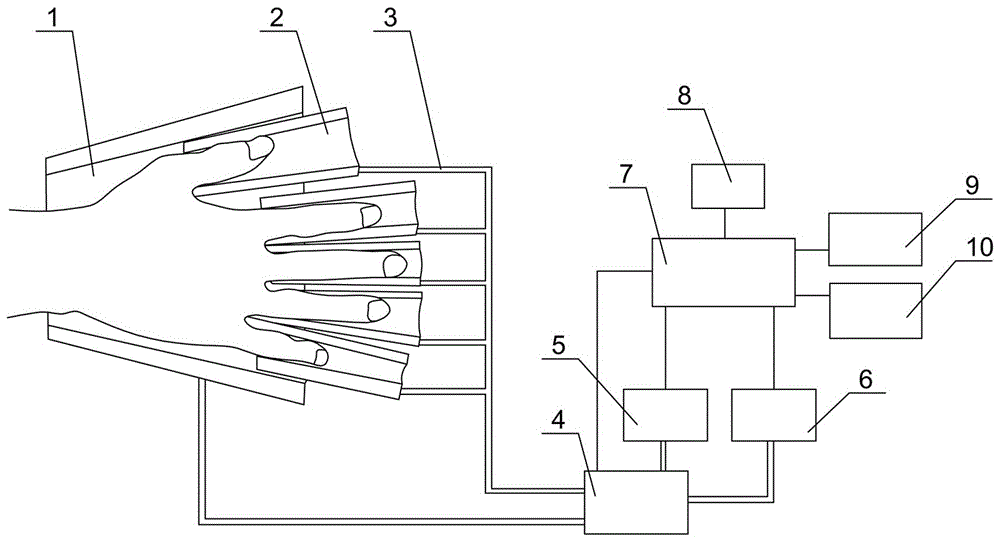

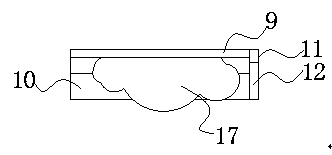

Rehabilitation device for treating hand edema of stroke patient

The invention relates to a medical rehabilitation device, in particular to a rehabilitation device for treating hand edema of a stroke patient. The medical rehabilitation device comprises an extrusion system and a control system, wherein the extrusion system comprises an outer covering air bag, five finger air bags, inflating tubes, an electromagnetic valve group and an air pump, wherein the outer covering air bag and the finger air bags are all of open structures; the unfolding shapes are rectangular shapes; connecting elements are arranged at the two ends of each rectangular shape; each rectangular shape is connected through the connecting elements to from a tubular shape; the outer covering air bag is sequentially connected with the electromagnetic valve group and the air pump through the air inflating tube; the five finger air bags are communicated through the inflating tubes and are then sequentially connected with the electromagnetic valve group and the air pump; the control system comprises an air pressure sensor, a CPU (Central Processing Unit) control circuit, a power supply module, an input module and an output module; the CPU control circuit is respectively connected with the electromagnetic valve group, the air pump, the air pressure sensor, the power supply module, the input module and the output module; and the air pressure sensor is connected with the electromagnetic valve group arranged in the extrusion system.

Owner:刘志成

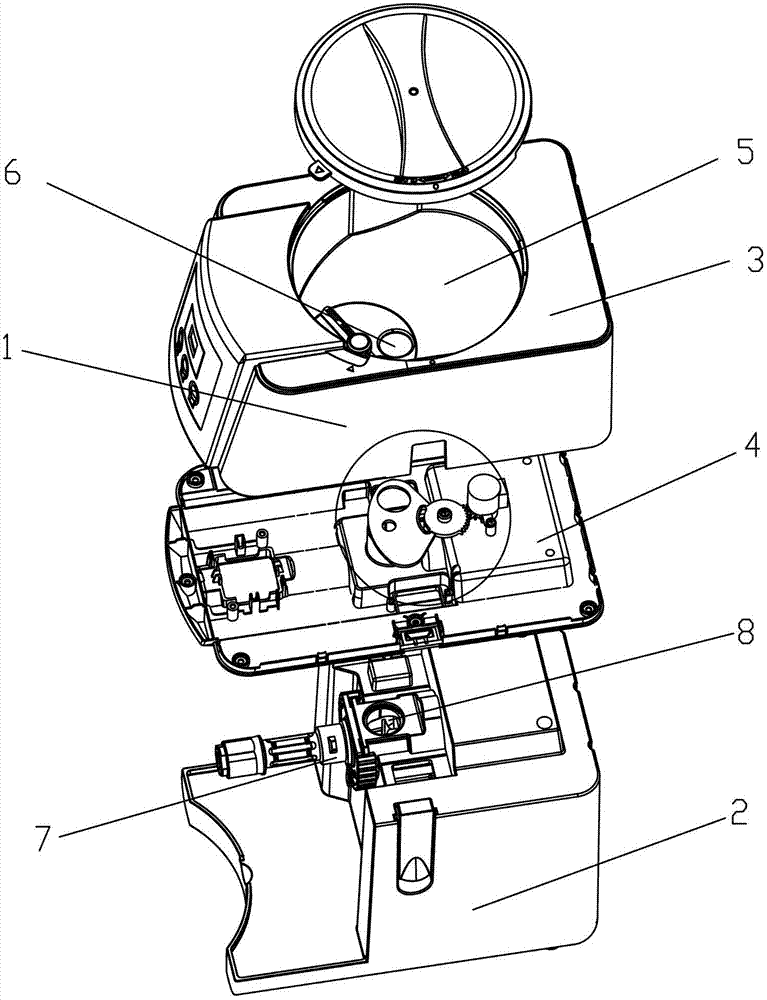

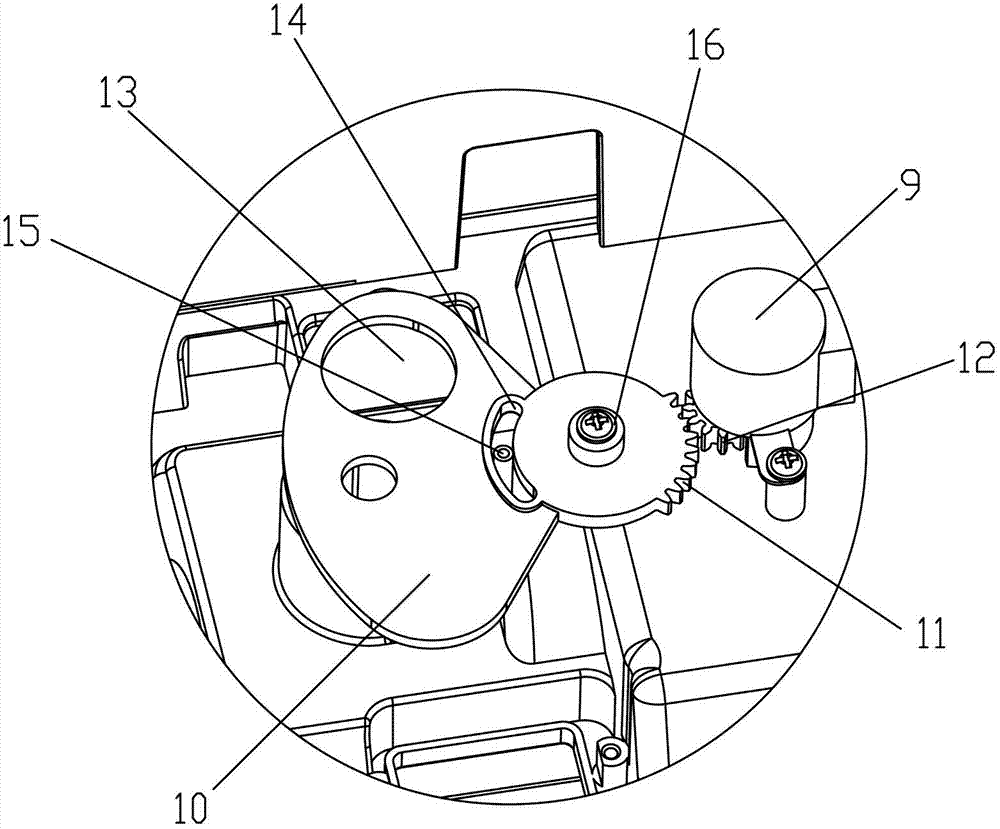

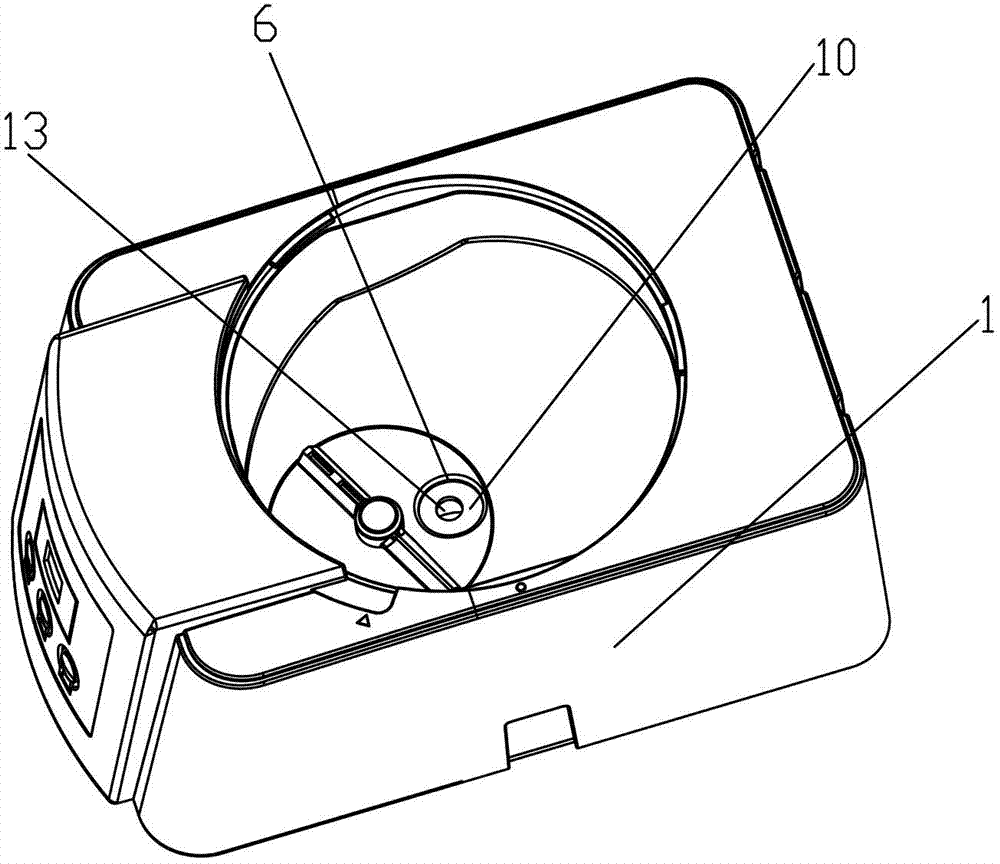

Domestic oil press with blanking control mechanism

The invention discloses a domestic oil press with a blanking control mechanism. The domestic oil press comprises an upper machine base and a lower machine base. The upper machine base comprises a casing and a bottom plate, the casing is provided with a material storage cavity, a discharge hole is arranged in the material storage cavity, the discharge hole is communicated with a feed port of a pressing mechanism on the lower machine base, the blanking control mechanism is arranged on the bottom plate, the blanking control mechanism comprises a motor and a rotation stopping sheet, a motor shaft and the rotation stopping sheet are in transmission through a gear, the rotation stopping sheet is tightly attached to the lower portion of the discharge hole, and the discharge hole can be shielded or opened. When the pressing mechanism breaks down, the rotation stopping sheet is rotated to shield the discharge hole, and materials cannot enter the pressing mechanism so as to avoid blocking. When the upper machine base needs to be removed for inspection and maintenance, residual materials cannot fall from the discharge hole. When blanking ports of different sizes are arranged on the rotation stopping sheet, large-particle materials or small-particle materials are pressed, the blanking ports of different sizes can be selected to correspond to the discharge hole, blanking amount is appropriate, smooth pressing is guaranteed, and generality of the oil press is enhanced.

Owner:江门市贝尔斯顿电器有限公司

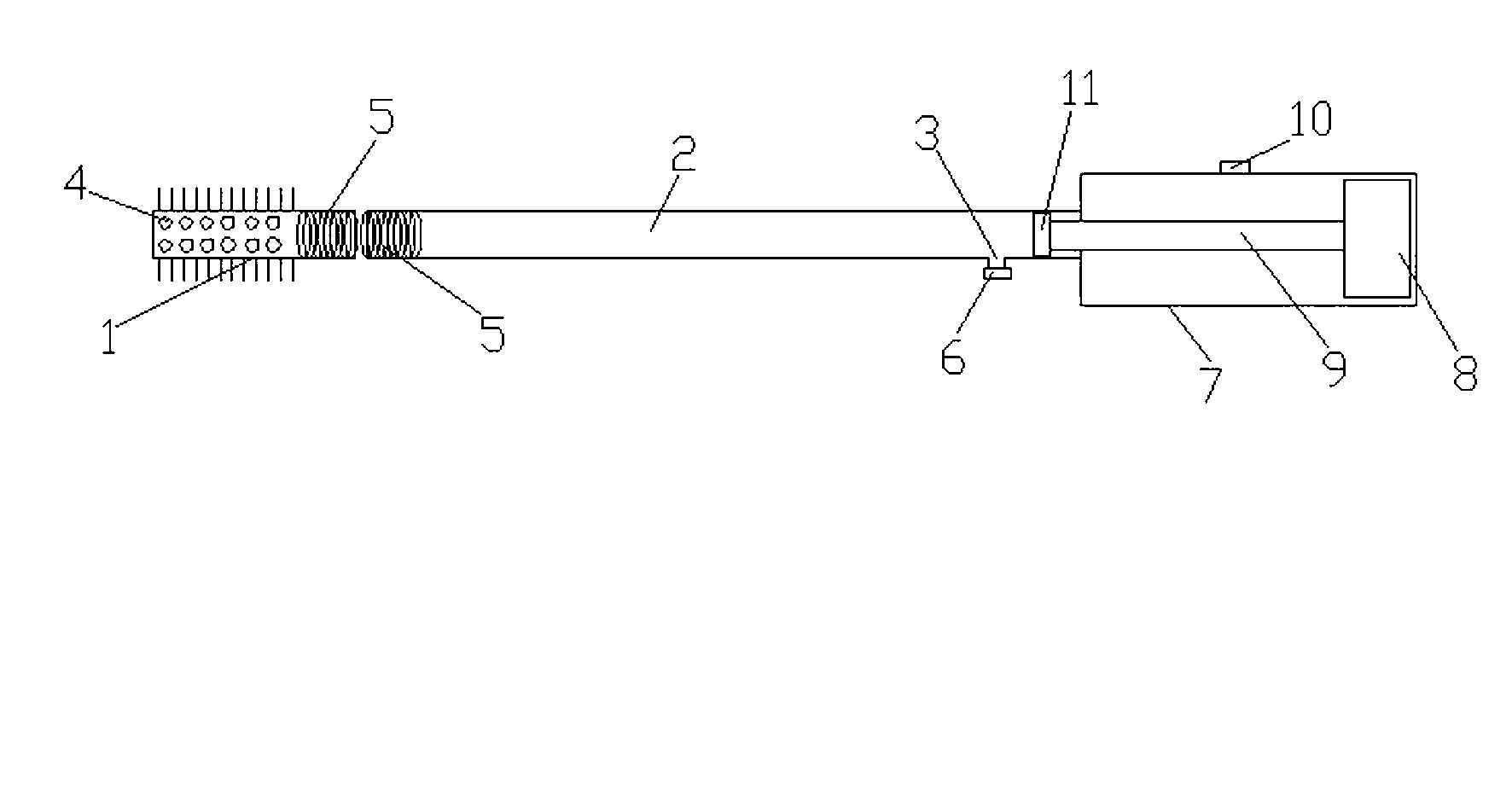

Novel electric lash curler

The invention relates to a novel electric lash curler which comprises a brush head, a brush rod, a material feeding hole, material discharging holes, threads, a piston, a power output box, a small motor, a rotating shaft, a switch and a pressure plug. The novel electric lash curler is characterized in that the threads are arranged between the brush head and the brush rod, so that the brush head can be detached from the brush rod; the material feeding hole is formed in the part, which is close to the power output box, on the brush rod; the brush head and the brush rod are hollow; eye black is poured into the lash curler through the material feeding hole; when the eye black is fully filled in the lash curler, the material feeding hole can be plugged by the piston; a plurality of material discharging holes are uniformly formed in the brush head; the small motor, the switch and the rotating shaft are arranged in the power output box; the tail end of the rotating shaft is connected with the pressure plug; and when the switch is turned on, the pressure plug can rotatably compress the eye black in the brush rod under the action of the rotating shaft, so that the eye black can be uniformly extruded from the material discharging holes. The novel electric lash curler is simple in structure and easy to manufacture.

Owner:殷秀芝

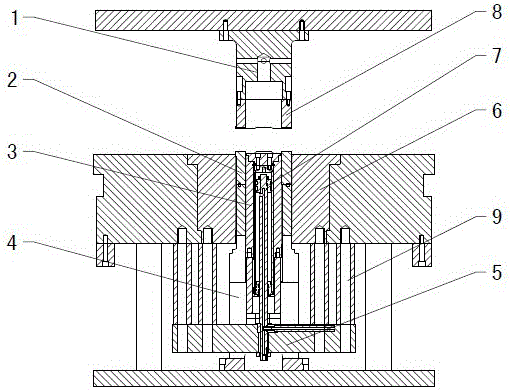

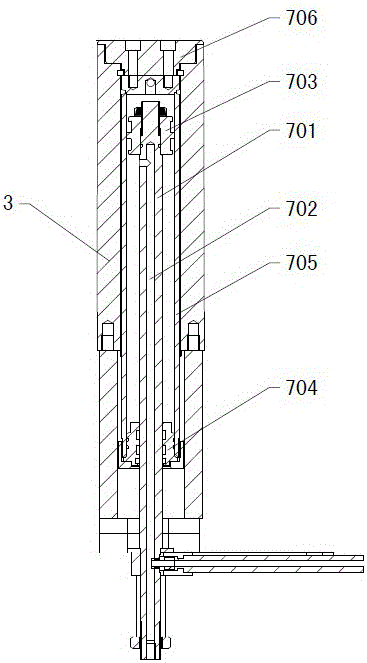

Automatic pressing machine mold for cylindrical refractory bricks, fully-automatic hydraulic brick pressing machine and brick pressing process

ActiveCN105690550AReduced die wearExtended service lifeDischarging arrangementMouldsMaterials scienceRefractory

The invention provides an automatic pressing machine mold for cylindrical refractory bricks, a fully-automatic hydraulic brick pressing machine and a brick pressing process and belongs to the field of refractory brick production equipment. The automatic pressing machine mold comprises an upper mold plate, a lower mold plate and a middle frame. The middle frame comprises a central spindle and a side plate. The central spindle is arranged on the inner side of the lower mold plate. The side plate is arranged on the outer side of the lower mold plate. The middle frame and the lower mold plate relatively ascend and descend to form an annular mold cavity. The side plate is connected with a side plate lifting connecting part for driving the side plate to ascend and descend. The side plate lifting connecting part is movably arranged relative to the central spindle and can push the central spindle to ascend. The central spindle is connected with a central spindle demolding mechanism for driving the central spindle to descend. According to the automatic pressing machine mold for the cylindrical refractory bricks, a material uniformizing device is fixed to a material distribution trolley; the middle frame is connected with a floating mold frame and ascends and descends along with the floating mold frame; it is required that an auxiliary oil cylinder relieves pressure in the pressing molding process in the pressing process, and the floating mold frame is in the floating state; and the automatic pressing machine mold has the beneficial effects that the draft angle is small, the quality of the pressed refractory bricks is good, and continuous working can be achieved.

Owner:ZIBO YUANHE ELECTRICAL & MECHANICAL ENG CO LTD

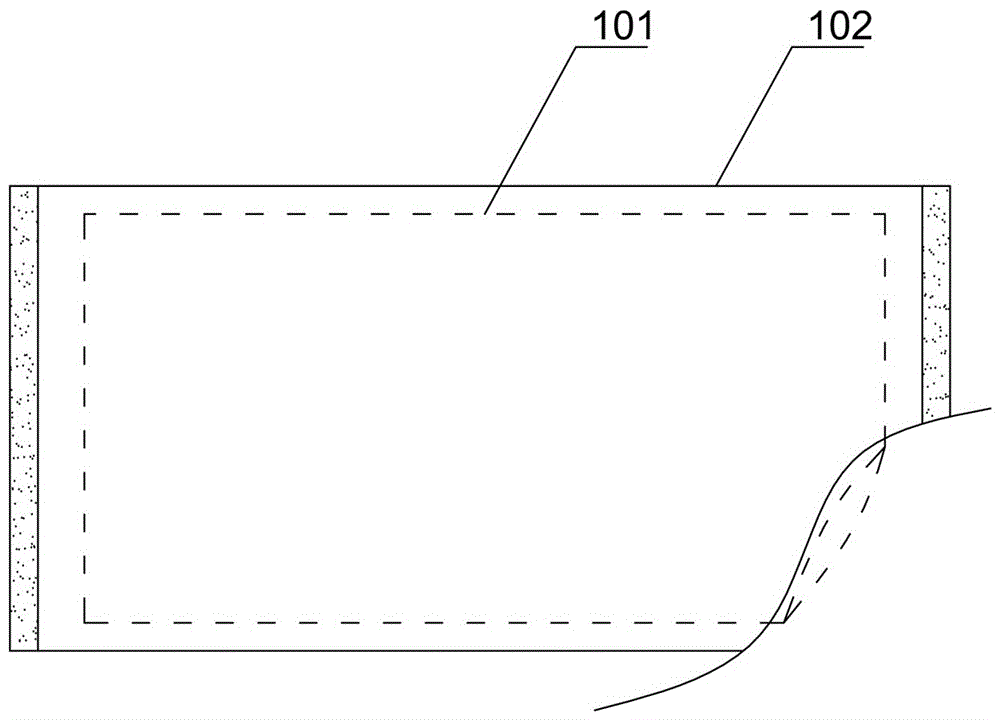

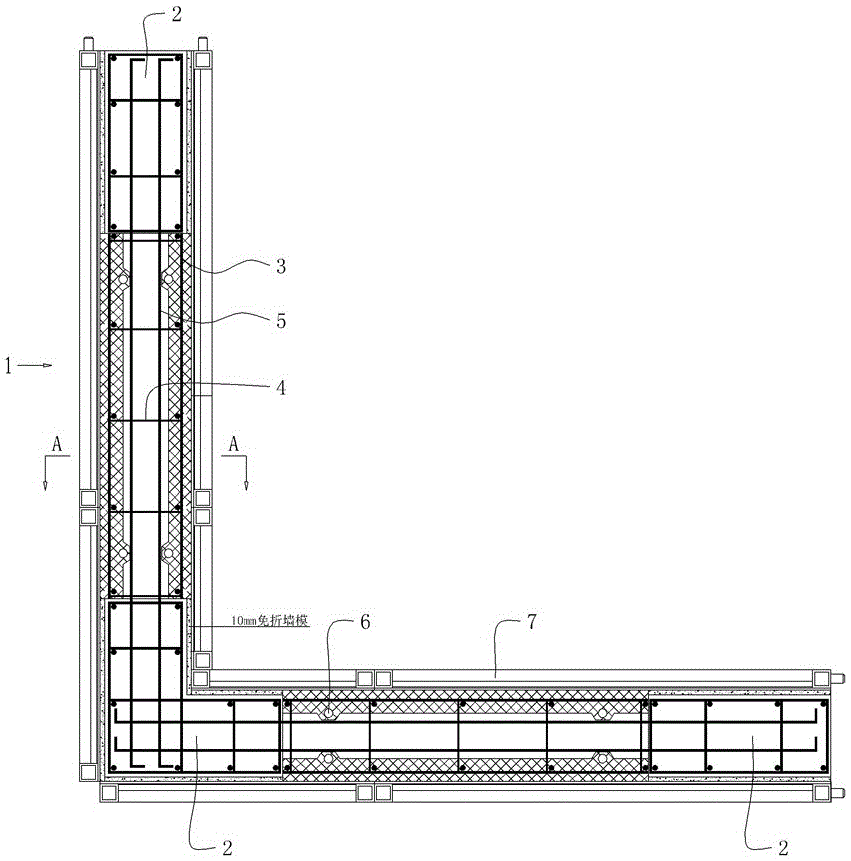

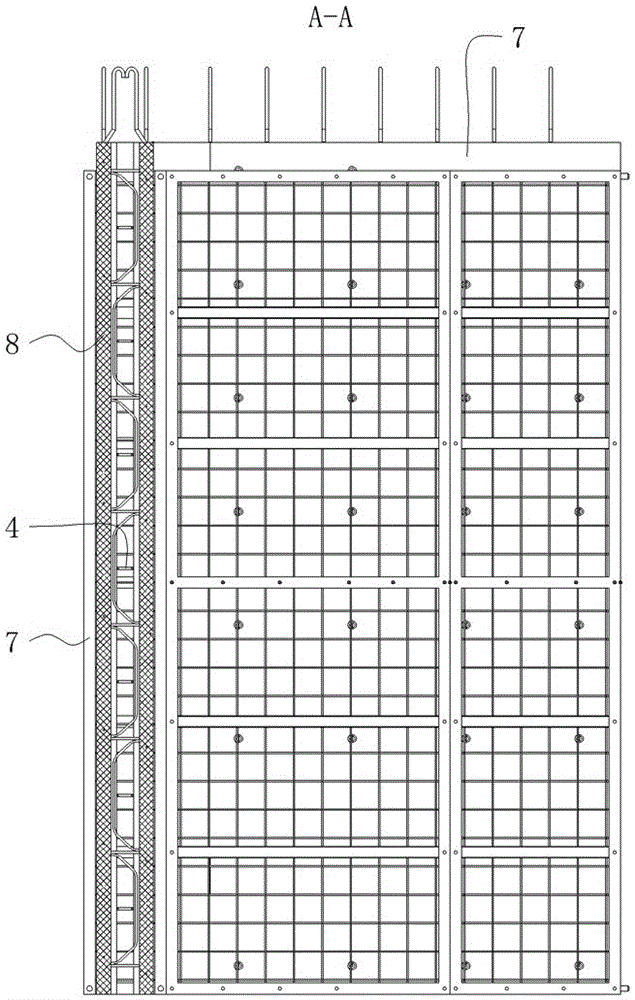

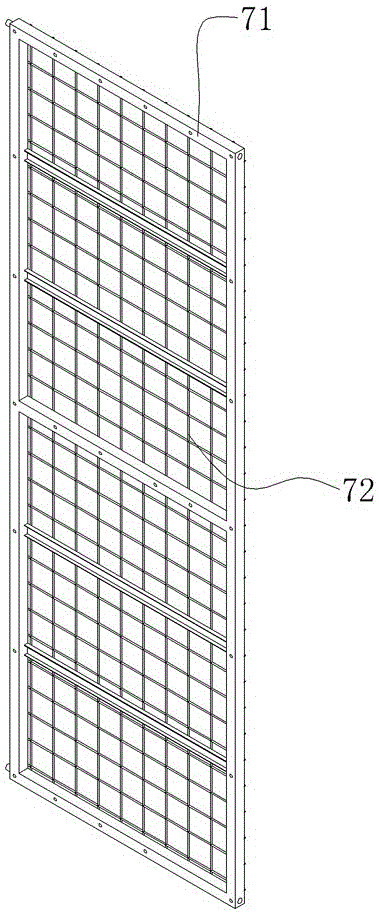

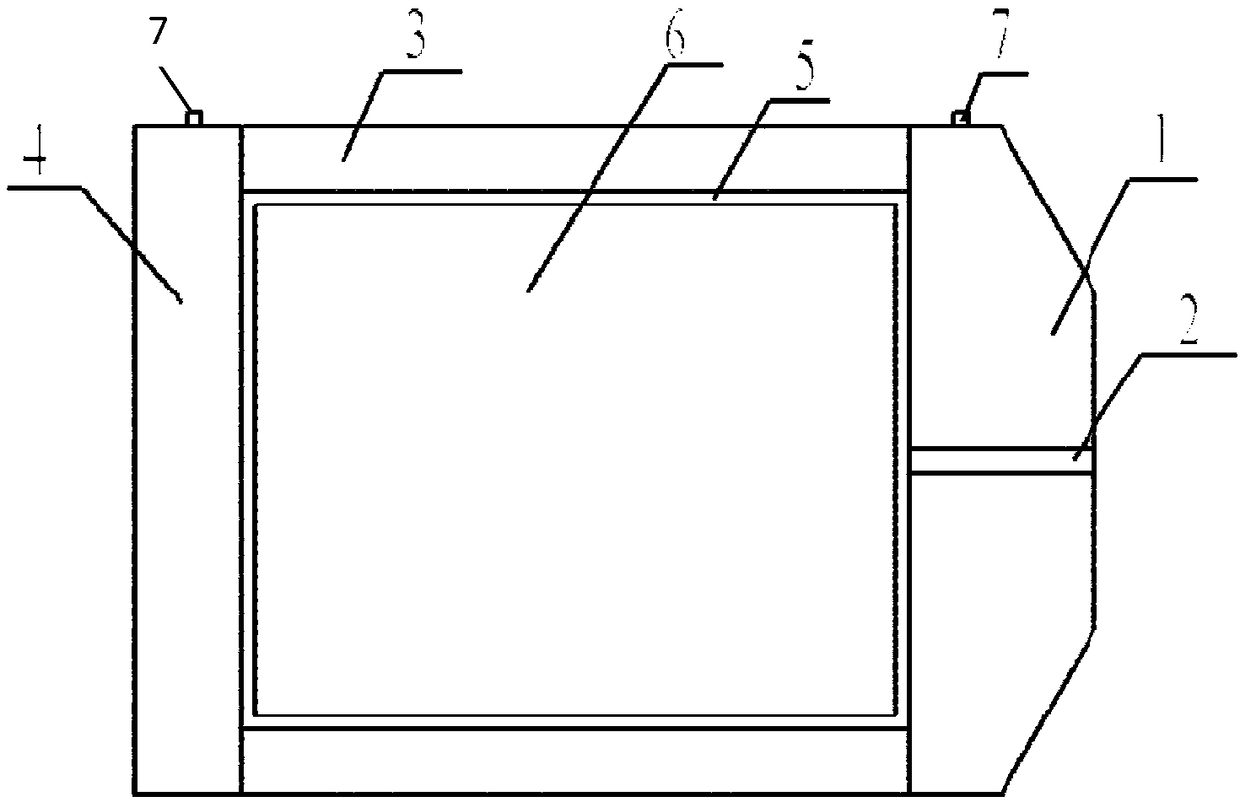

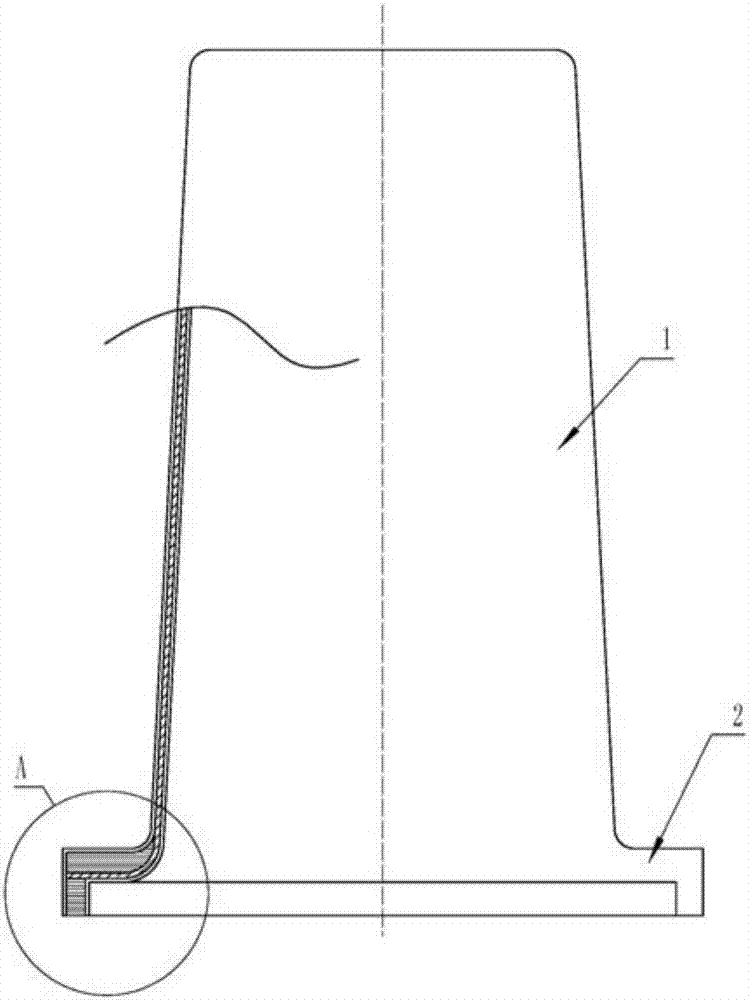

Wall formwork infilled wall of cast-in-place reinforced concrete without support and construction method thereof and wall formwork veneer and production method of non-bearing infilled wall

The invention relates to a wall formwork infilled wall of cast-in-place reinforced concrete without support and construction method thereof and wall formwork veneer and production method of non-bearing infilled wall, and belongs to the wall technical fields. The wall formwork infilled wall comprises a wall formwork, a special-shaped column steel reinforcement cage, the wall formwork comprises a wall formwork steel reinforcement cage, and the regulating stem and the removable segment frame are fixedly arranged on the flanks of the wall formwork steel reinforcement cage and the special-shaped column steel reinforcement cage, the up and down sides both of the wall formwork steel reinforcement cage and the special-shaped column steel reinforcement cage are each fixedly provided with insert fitting, the segment frame comprises a frame, a panel and a template, and the template borders upon the wall formwork steel reinforcement cage and the special-shaped column steel reinforcement cage, the regulating stem crosses via the frame and is provided with adjustable regulating part with fixed segment frame, the wall formwork steel reinforcement cage and the special-shaped column steel reinforcement cage both have cast-in-place concrete inside. The wall formwork infilled wall of cast-in-place reinforced concrete without support and construction method thereof and wall formwork veneer and production method of non-bearing infilled wall has the advantages of being short in the time limit for a project and low in cost.

Owner:史世英

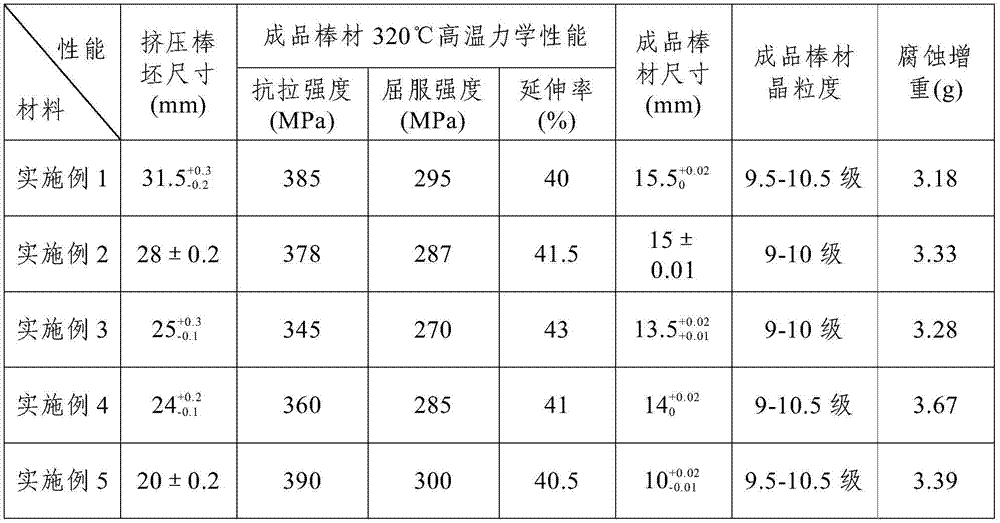

Sheathing and extruding preparation method for titanium aluminum alloy rods

Disclosed is a sheathing and extruding preparation method for titanium aluminum alloy rods. The method comprises the steps that the head and tail of a titanium aluminum alloy cast ingot are cut off, then the surface and the head and tail end faces of the cast ingot are polished on a lathe, and the titanium aluminum alloy cast ingot is wrapped with high silicon oxide cloth and then put into a sheath to obtain a sheathing and extruding billet; after the sheathing and extruding billet is heated, the billet is put into a glass protective lubricant for even adhesion, extruding and cooling are conducted, and the titanium aluminum alloy rods are obtained after the sheath is removed. Due to the high heating temperature, an extruding lubricating material is difficult to withstand the high temperature, rolling application of the lubricating material glass protective lubricant is conducted after heating is completed, and the lubricating effect in the extruding process is ensured; in addition, thesheathing material is also cooled, so that the deformation resistance of the sheathing material and titanium aluminum alloy is kept consistent, and it is ensured that the subsequent extruding processis smoothly carried out. The titanium aluminum alloy cast ingot is wrapped in the middle of the sheathing material, the cast ingot and the sheathing material are both under the compressive stress inthe extruding deformation process, the plasticity of the material can be fully exerted in the stress state, and the generation of cracks is inhibited.

Owner:XIAN SUPERCRYSYAL SCI TECH DEV CO LTD

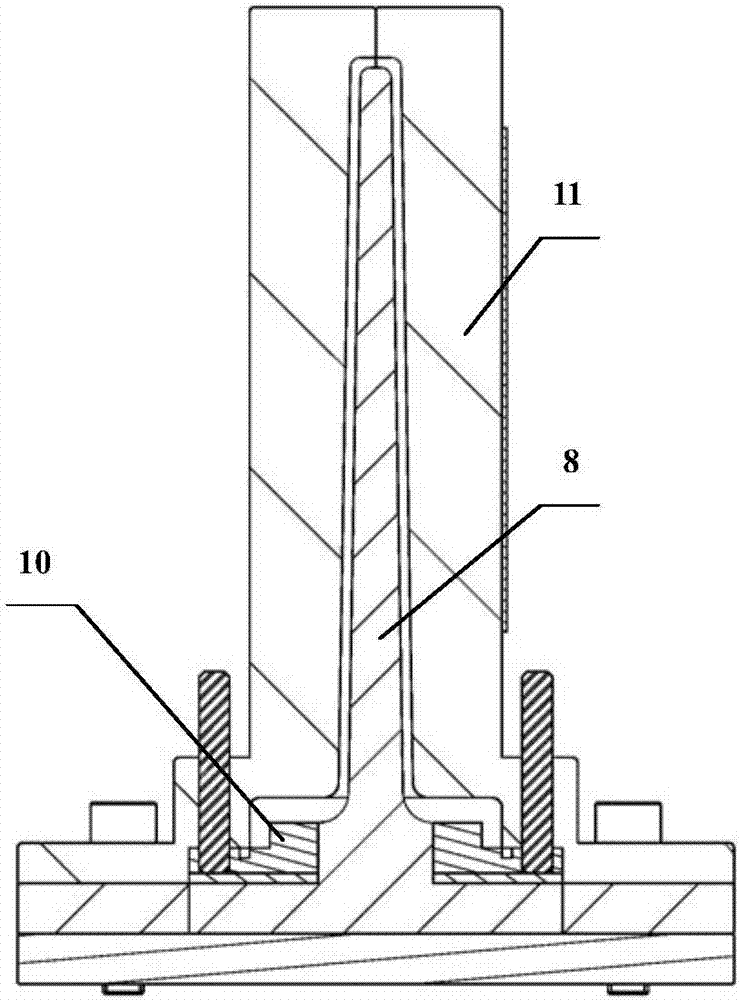

Vehicle-mounted knife-type antenna cover and precise manufacturing method thereof

ActiveCN106921031AAchieve broadband characteristicsImprove electrical performance indicatorsAntenna adaptation in movable bodiesRadiating element housingsGlass fiberSurface layer

The invention discloses a vehicle-mounted knife-type antenna cover and a precise manufacturing method thereof. The antenna cover is formed by combining an inner surface layer, a functional layer, a bottom plane layer, a stop opening layer and an outer surface layer. The inner surface layer, the bottom plane layer, the stop opening layer and the outer surface layer are made of different specifications of high-intensity glass fiber prepregs. The functional layer is made of different materials of high-intensity glass fiber prepreg, a metal array and a nomex honey comb, thereby satisfying different functions of wide frequency, high wave transparency and invisibility. The inner surface layer, the stop opening layer, the functional layer, the bottom plane layer and the outer surface layer are successively laid on a core die sequentially, an outer die is assembled and a vacuum bag is used for sealing, and through a vacuum system and an oven, heating and solidification are achieved to form a whole body. A layering method and laying sequence are set, so high speed discharging and precise prefabrication of different layers can be achieved. By combining a metal outer die and a silicone rubber core die, the size precision of the antenna cover is ensured and the technique cost is reduced.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP +1

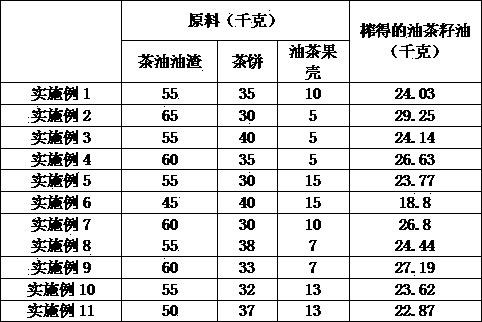

Method for manufacturing oil by using tea oil residues

ActiveCN103421612AReduce total usageDoes not affect reuseFatty oils/acids recovery from wasteFatty substance recoveryCamellia oleiferaOrganic chemistry

The invention discloses a method for manufacturing oil by using tea oil residues. The method includes the following steps: step 1, raw material preparation: preparing raw materials according to the following proportion, by mass, 45-65 parts of tea oil residues, 30-40 parts of tea cakes and 5-15 parts of tea oil husks, step 2, crushing and stirring: crushing the obtained tea cakes and tea oil husks, and then, mixing and evenly stirring the crushed tea cakes and tea oil husks with the tea oil residues to obtain a compound raw material, step 3, water supplement: evenly stirring the evenly-stirred compound raw material through water supplement, enabling the water content of the compound raw material to be 7-10% by mass, and obtaining a semi-finished product, and step 4, squeezing: placing the semi-finished product into an oil press to squeeze the semi-finished product to obtain camellia oleosa seed oil. The method is high in oil yield and simple in process, auxiliary materials are cheap and easy to obtain, and the obtained tea cakes can be reused as fodder and the like.

Owner:HUNAN DASANXIANG TEA OIL CO LTD

Preparation method of aluminum alloy with excellent comprehensive property

InactiveCN103060730AImprove mechanical propertiesImprove tribological performanceMechanical propertyLubricant

The invention discloses a preparation method of an aluminum alloy with excellent comprehensive properties. The preparation method comprises the following steps of cutting the aluminum alloy in the cast state, rolled state or forged state into a blank, wherein the cross section of the blank can be cut into a circular shape or a square shape according to practical demands; carrying out surface machining treatment on the blank; coating a lubricant on the surface of the blank; carrying out equal channel corner extrusion treatment by using an equal channel corner extruding die which is accordant to the cross section of the blank in shape; after each extrusion treatment, carrying out the surface machining treatment again on the surface of the blank; after more than four times of the equal channel corner extrusion treatment, cleaning the surface of the blank; carrying out surface laser fusing treatment, wherein working parameters in the surface treatment can be changed through the laser fusing treatment according to practical application demands; and finally obtaining the aluminum alloy block material of which a substrate has high mechanical property and the surface has high friction property. By utilizing the preparation method, the mechanical property and the friction property of the aluminum alloy can be remarkably improved, the application range of the alloy is widened, and the requirements of practical production on the high-performance aluminum alloy are met better.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

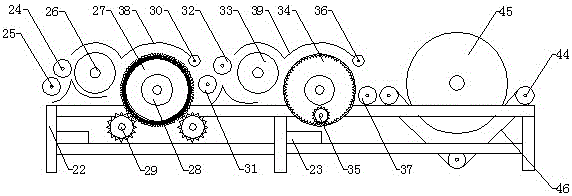

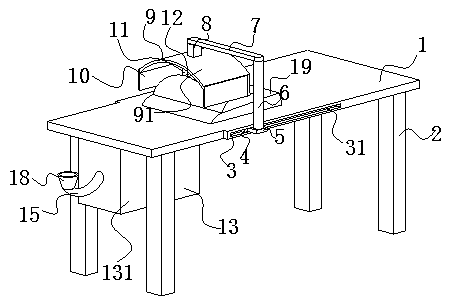

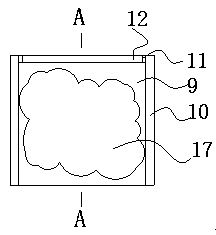

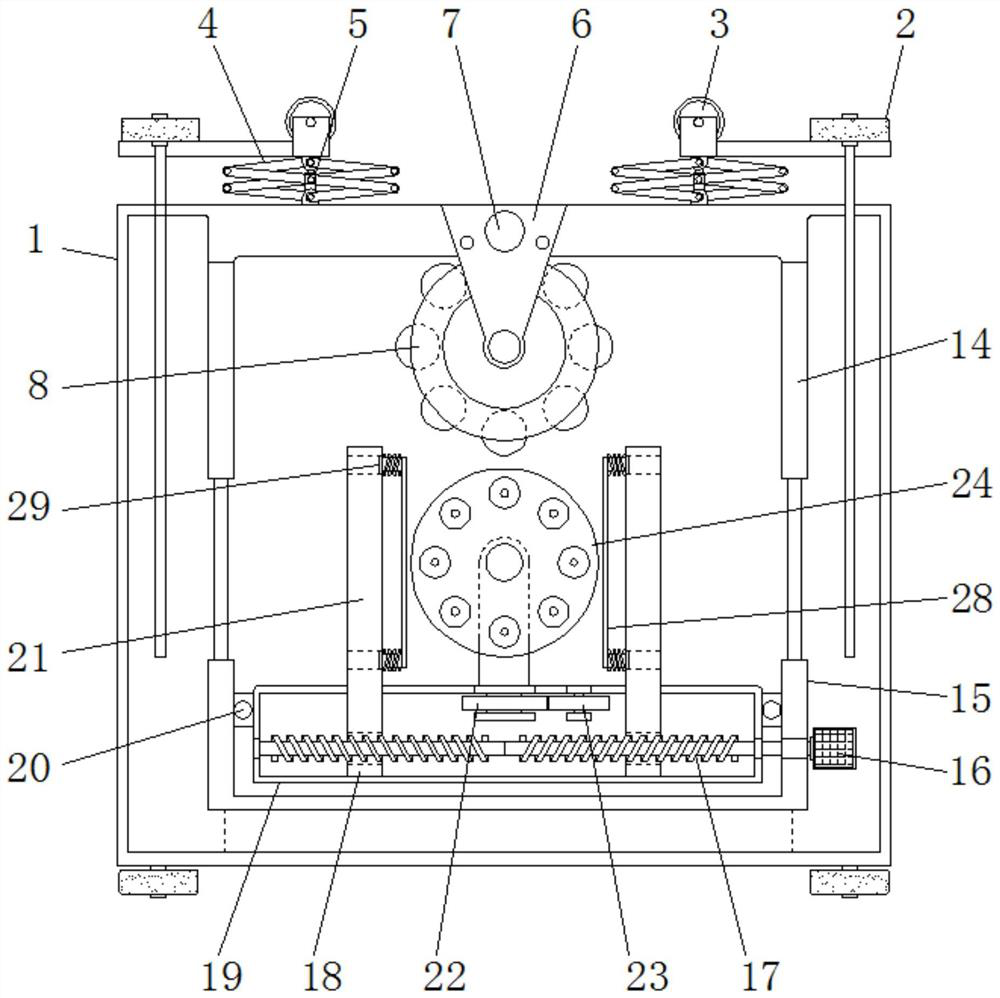

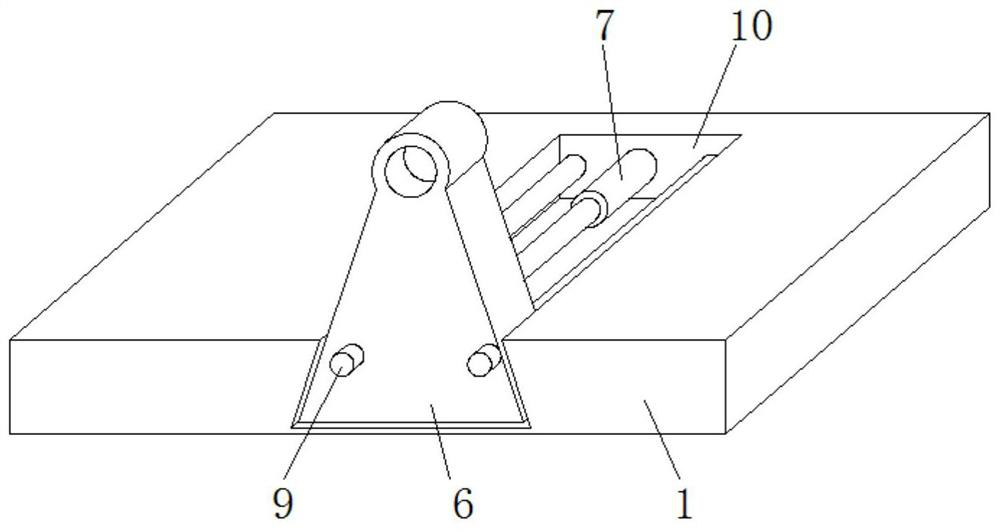

Automatic toothpaste squeezing machine

InactiveCN103922002ASqueeze evenlyEasy to useHolders and dispensersArticle unpackingToothpasteEngineering

The invention discloses an automatic toothpaste squeezing machine which comprises a lower cover. A lower base plate is fixedly connected with the bottom of the lower cover, guide rail grooves are fixedly formed in the two inner side walls of the lower cover, guide rails are movably arranged in the guide rail grooves, the two guide rails are fixedly connected with the two ends of an upper base plate respectively, and the upper base plate is connected with a horizontal transmission device and a vertical transmission device. A toothpaste hole is formed in the upper base plate and located below two idler wheels. When a toothpaste pipe is clamped between the two idler wheels, the squeezing effect can be achieved on the toothpaste pipe through the idler wheels in the process that horizontal rolling shafts move downwards. According to the automatic toothpaste squeezing machine, toothpaste can be stably and evenly squeezed to the head of a toothbrush through the cooperation effect of the horizontal transmission device and the vertical transmission device.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

High-quantity hafnium rod manufacturing method

ActiveCN105436232AOvercome scourOvercome uniformity issuesTemperature control deviceMetal rolling arrangementsHafniumOxide coating

The invention discloses a high-quantity hafnium rod manufacturing method. The method includes the steps that a hafnium rod blank is wrapped with a steel pipe, then the steel pipe is wrapped with a copper pipe, and the double-wrapped hafnium rod blank is obtained; secondly, the double-wrapped hafnium rod blank is extruded after the rod blank is heated and the temperature is kept, and the extruded rod blank is obtained; thirdly, the copper pipe and the steel pipe wrapping the extruded rod blank are removed, and then the extruded rod blank is subjected to vacuum annealing treatment; fourthly, under the condition that the extruded rod blank is heated continuously in the atmosphere, the extruded rod blank is rolled through a heat pipe rolling machine; fifthly, oxide coatings are removed, then the extruded rod blank is straightened, ground and polished in sequence, and a semi-finished hafnium rod is obtained; and sixthly, vacuum annealing treatment is conducted, and a finished high-quality hafnium rod is obtained. By the high-quantity hafnium rod manufacturing method, the hafnium rod blank is double-wrapped before being extruded, and the hafnium rod blank is rolled through the heat pipe rolling machine under the condition that the extruded rod blank is heated continuously in the atmosphere, and the hafnium rod with the dimensional deviation ranging from -0.02 mm to 0.02 mm, the ovality smaller than or equal to 0.02 mm and excellent mechanical property and corrosion resistance and of an even structure can be obtained.

Owner:西安诺博尔稀贵金属材料股份有限公司

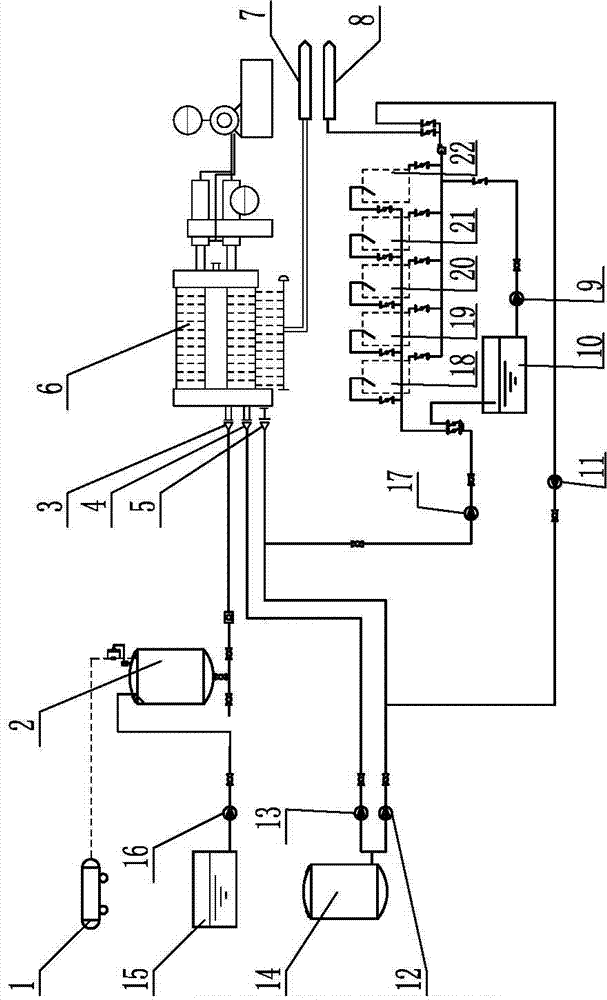

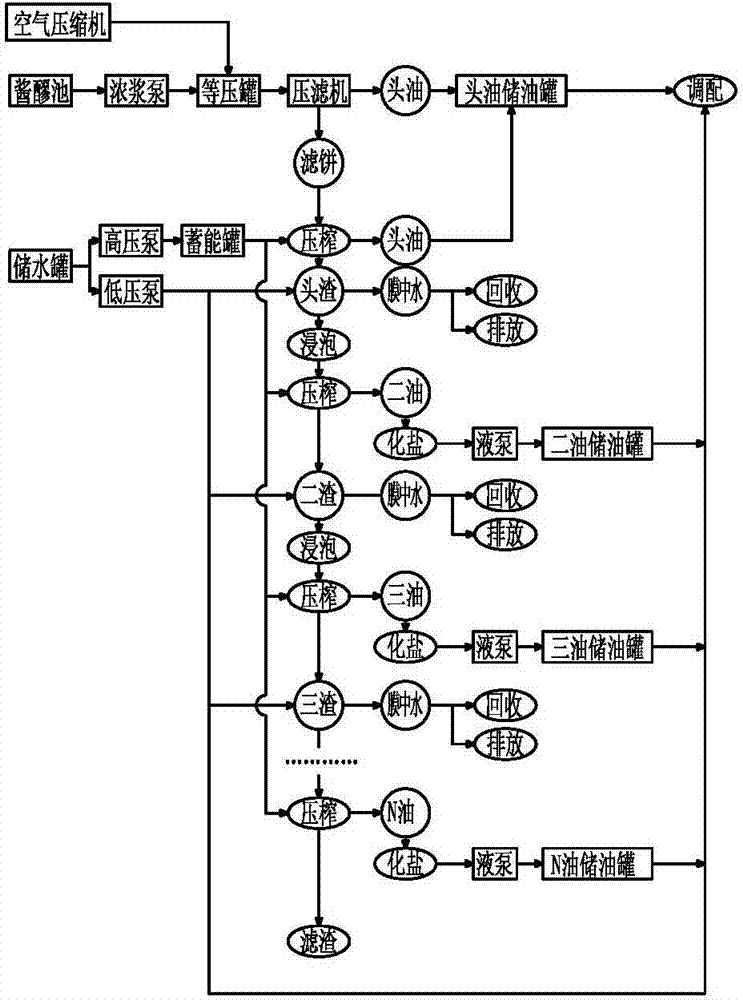

Squeezing system and squeezing process for high-salt liquid sauce

ActiveCN104757502ALess stickyReduce particle damage and other phenomenaFood preparationWater storageWater storage tank

The invention provides a squeezing system and squeezing process for a high-salt liquid sauce, belonging to the field of squeezing of sauces. The squeezing system is characterized by comprising a sauce mash squeezing system, a pneumatic system and a water-circulating pipe system, wherein the sauce mash squeezing system is connected with a feed inlet of an isobaric tank through an underflow pump, a discharge outlet of the isobaric tank is connected with a feed inlet of a membrane plate-type filter press, discharge outlets of the membrane plate-type filter press are separately connected with a salt dissolving pond and an oil storage tank, the salt dissolving pond is connected with the oil storage tank through a material pump, an air compressor of the pneumatic system is connected with the air inlet of the isobaric tank, water storage tanks of the water-circulating pipe system are separately connected with a high-pressure pump and a low-pressure pump, the high-pressure pump is connected with a membrane plate water filling port of the membrane plate-type filter press, and the low-pressure pump is connected with the discharge outlet of the membrane plate-type filter press. The squeezing system provided by the invention needs low investment; the squeezing process is excellent; high production efficiency and high crude oil removal quality are obtained; and labor intensity of workers is low.

Owner:山东玉兔食品股份有限公司

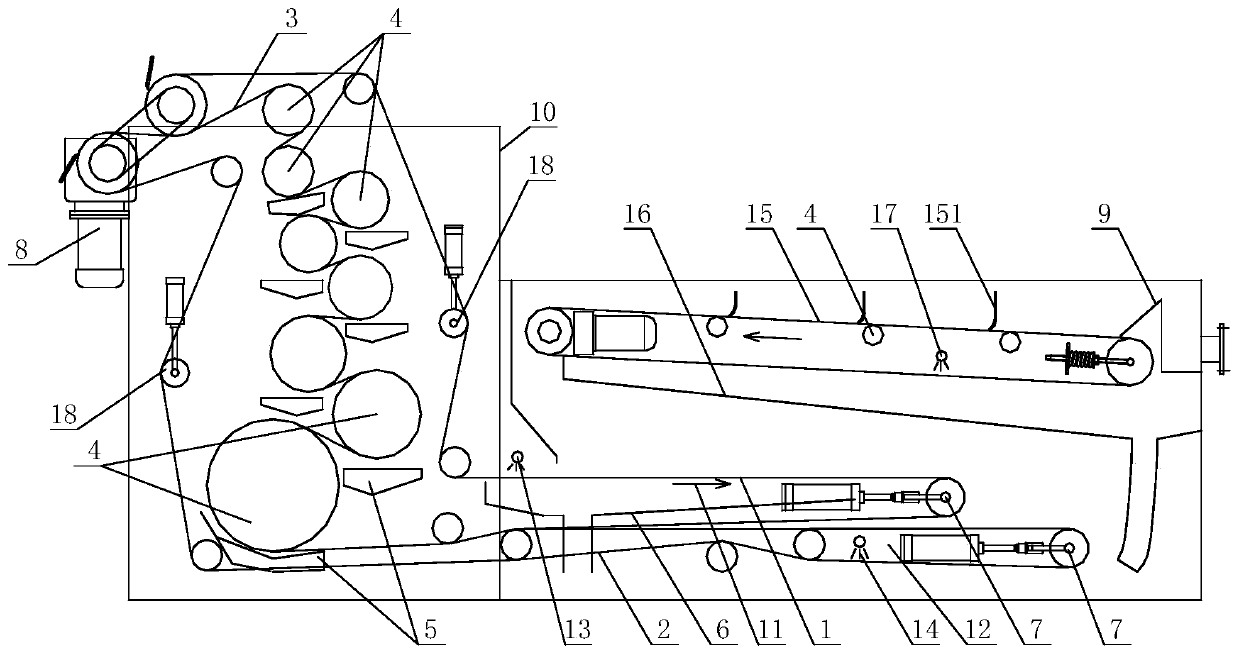

Filter press and filter pressing method

PendingCN110372170AHigh efficiency filter pressCompress usage amount and volumeSludge treatment by de-watering/drying/thickeningEngineeringMechanical engineering

The invention relates to a filter press and a filter pressing method, and belongs to the technical field of water removing equipment. The filter press comprises a first filter pressing system and a second filter pressing system, the first filter pressing system internally comprises a first filter belt, the second filter pressing system internally comprises a second filter belt, a section of an overlapping part formed by mutual attaching is arranged between the first filter belt and the second filter belt, pressing rollers are arranged on one side of the overlapping part, the pressing rollers extrude the overlapping part, thus objects to be subjected to filter pressing between the first filter belt and the second filter belt are extruded to filter liquid out; and the two or more pressing rollers are arranged, and the diameters of the pressing rollers located on the front filter pressing position are larger than the diameters of the pressing rollers located on the rear filter pressing position. The multiple pressing rollers with the diameters being decreased progressively are adopted to sequentially conduct pressure progressive increase type filter pressing on the overlapping part, the pressing rollers located on the front filter pressing position become the basis of further filter pressing of the pressing rollers located on the rear filter pressing position, high-efficiency filter pressing of overall filter pressing equipment is achieved, and the water outlet proportion of the objects, to be subjected to filter pressing, such as sludge and impurities is increased.

Owner:CHINA TIESIJU CIVIL ENG GROUP +1

Shell screening device

PendingCN110732486AEasy to operateSimple structureSievingScreeningElectric machineryStructural engineering

The invention provides a shell screening device, and belongs to the technical field of shell screening equipment. The shell screening device comprises a device body, a feeding pipe, a filter net, a conveying belt, a guiding mechanism and a weight screening mechanism. An installing cavity is formed in the device body. The feeding pipe is arranged on the top of the device body, and the lower end ofthe feeding pipe communicates with the installing cavity. The filter net is hinged into the installing cavity through a hinge shaft. A vibration motor is fixedly arranged in the installing cavity andfixedly connected with the lower side face of the filter net. The conveying belt is horizontally arranged in the installing cavity, and the left end of the conveying belt is located below the right side edge of the filter net. The guiding mechanism can divide shells on the conveying belt into a plurality of rows, the shells are sequentially moved to the right end of the conveying belt one by one,and the weight screening mechanism can classify the shells moved to the right end of the conveying belt according to the weight. By means of the shell screening device, screening can be conducted according to the weight of the shells, and operation is simple.

Owner:ZHEJIANG OCEAN UNIV

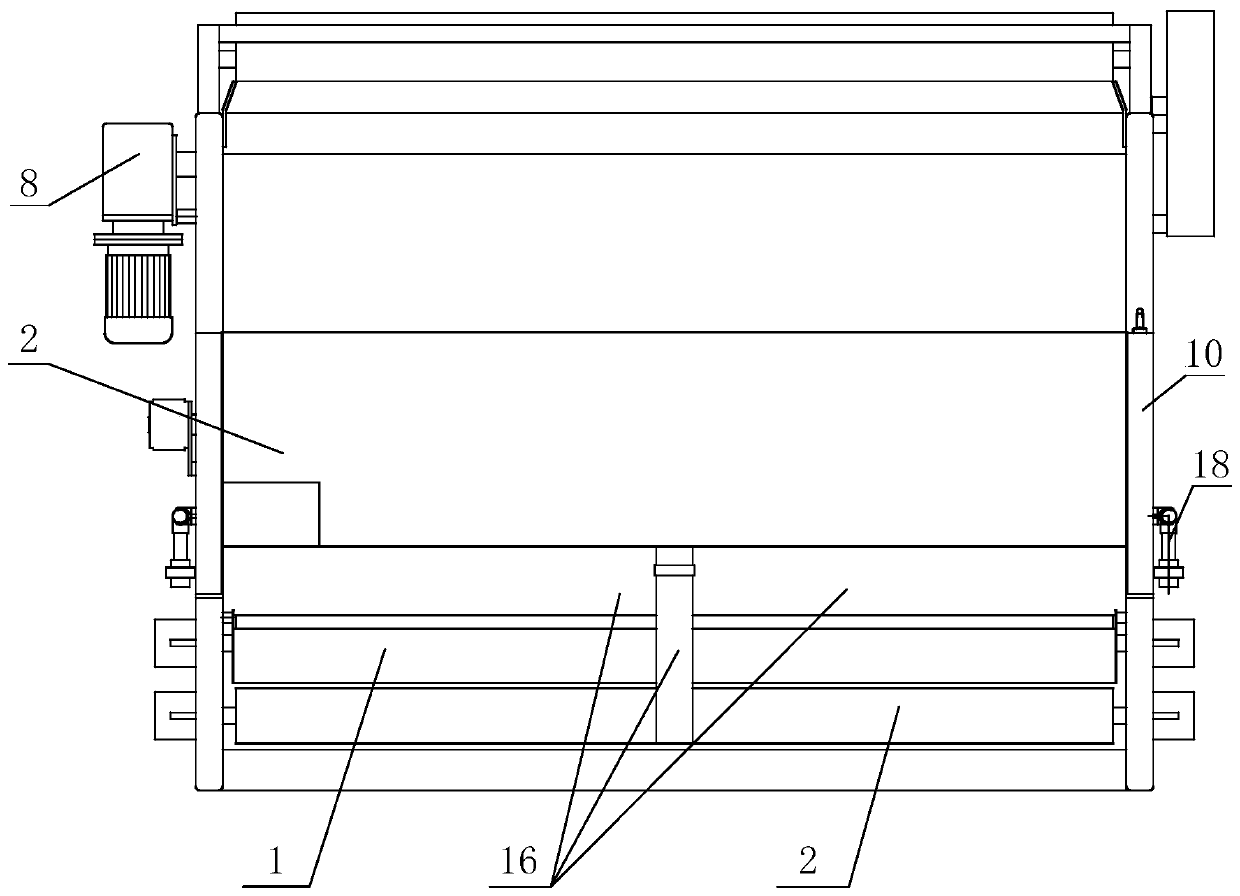

Flattening and dust removal device for lithium battery copper foil

The invention relates to a flattening and dust removal device, in particular to the flattening and dust removal device for a lithium battery copper foil. The flattening and dust removal device for thelithium battery copper foil has a mature flattening technology, high efficiency, convenience and simple operation. According to the technical scheme, the flattening and dust removal device for the lithium battery copper foil comprises a base, a first bracket, a second bracket, a first fixing plate, a second fixing plate and the like, wherein the first bracket is fixedly connected to the left endof the base, the second bracket is fixedly connected to the right end of the base, the first fixing plate is fixedly connected to the right side above the base, and the second fixing plate is fixedlyconnected to upper portion of the first fixing plate. The flattening and dust removal device for the lithium battery copper foil which is developed specially has the function of extruding and dust removing to the copper foil, not only is the effect of uniform extrusion realized, but also the effect of rapid dust removal is realized. The flattening and dust removal device for the lithium battery copper foil has the characteristics of convenient use, safe use, simple operation and the like.

Owner:温岭市中天自动化设备有限公司

Obstetric apparatus for obstetrical department

ActiveCN109528425AConvenient midwifery operationReduce damageOperating tablesObstetrical instrumentsInjury causeObstetric history

The invention provides an obstetric apparatus for the obstetrical department, and relates to the field of obstetrics and gynecology. The obstetric apparatus comprises a bed board, supporting legs, anadjusting device, a bionic press obstetric device and a negative pressure adsorption device, wherein the bottom of the bed board and the supporting legs are fixed by welding; the adjusting device comprises a transverse slide rail slot, a slide rail block, a welding block, a supporting rod, a connecting cross rod and a connecting block; the transverse slide rail groove is formed in the side face ofthe bed board; and the rail inner wall of the transverse slide rail groove is in sliding connection with the slide rail block. According to the obstetric apparatus, air exhausted in the process of generating negative pressure with a sucker can be used for inflating the bionic press obstetric device through the connection of an exhaust hose and a bionic press air bag, the inflated and plumped bionic press air bag directly acts on the abdomen of a mother body, and the obstetric operation on an infant can be performed effectively and conveniently through the extruding force on the mother body generated by plumping the air bag and matched use of the air bag and the sucker, and occurrence of infant body injury caused by directly drawing the infant with a sucker can be reduced.

Owner:RIZHAO HOSPITAL OF TCM

Floor tile paving device capable of reducing hollowing and for building construction

The invention discloses a floor tile paving device capable of reducing hollowing and for building construction. The device comprises a shell, a second telescopic rod, a first motor, third telescopic rods, a third motor and an electric push rod, wherein idler wheels are mounted at corners of the shell, an adjusting rod is connected between a limiting wheel and the shell through a hinge, a sliding groove is formed in the inner wall of the front end of the shell, an extrusion disc is fixedly connected to the lower end of a supporting plate, a main rubber disc is fixedly connected to an output endof the first motor, the third telescopic rods are fixedly connected to the left side and the right side of the inner wall of the shell, and a fourth telescopic rod is fixedly installed on the inner wall of an adjusting frame. According to the floor tile paving device capable of reducing hollowing and for building construction, tiles can be conveniently paved flatly, skewing is avoided, meanwhile,the tiles can be conveniently and evenly extruded, hollowing is reduced, connecting joints between the tiles can be conveniently buckled, loosening is prevented, gaps are prevented from being large and small, and attractiveness is prevented from being affected.

Owner:天长市千盛建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com