Wall formwork infilled wall of cast-in-place reinforced concrete without support and construction method thereof and wall formwork veneer and production method of non-bearing infilled wall

A technology of reinforced concrete and infill wall, applied in the direction of walls, building components, buildings, etc., can solve the problem of high cost and achieve the effect of low cost, short construction period and firm installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

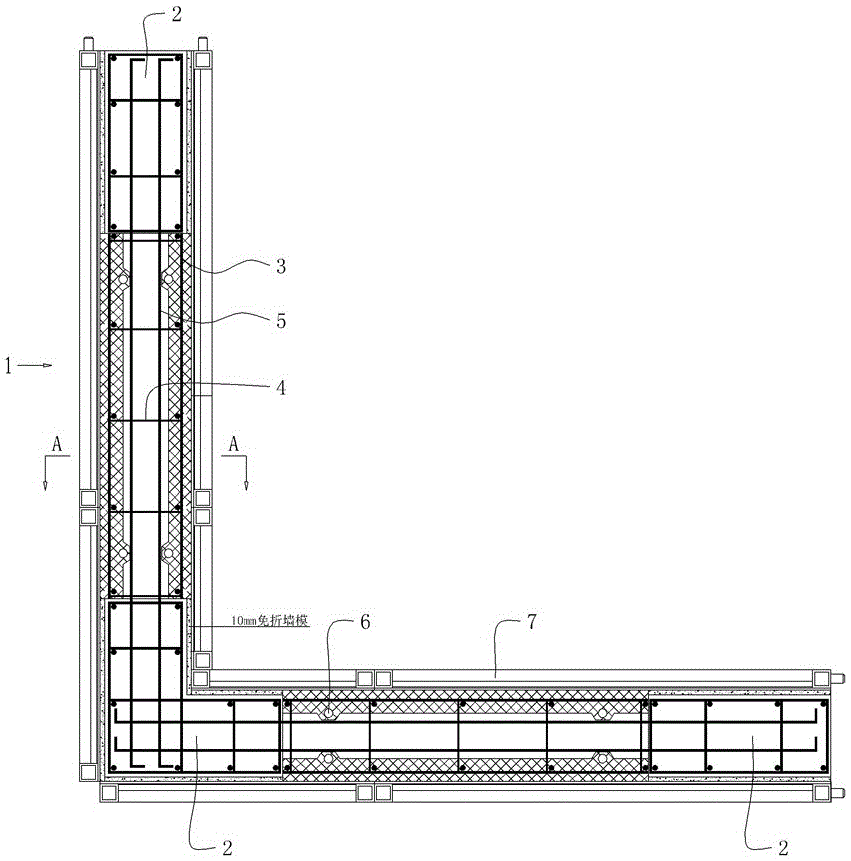

[0050] The cast-in-place reinforced concrete wall mold filling wall free of support of the present embodiment, as figure 1 with figure 2 As shown, it includes a wall form 1 and a special-shaped column reinforcement cage 2 fixed at one or two ends of the wall form and used to connect adjacent wall forms.

[0051] The wall formwork 1 includes a wall formwork reinforcement cage 5 composed of two oppositely arranged reinforcement mesh sheets 3 and tie bars 4 connecting and fixing the two reinforcement mesh sheets.

[0052] Adjusting rods are all fixed on the side of the wall form reinforcement cage 5 and the special-shaped column reinforcement cage 2. The upper and lower ends of the wall formwork reinforcement cage 5 and the special-shaped column reinforcement cage 2 are respectively fixed with inserting parts 6 for aligning with the adjacent upper and lower wall formwork reinforcement cages 5 and the special-shaped column reinforcement cage 2 . The plug-in part 6 is a ferrule ...

Embodiment 2

[0059] The support-free cast-in-place reinforced concrete wall form filling wall of this embodiment is an improvement on the basis of the first embodiment, and the difference from the first embodiment is that it includes a wall form 1 and is fixed on one or two ends of the wall form and used for Special-shaped column reinforcement cages or non-load-bearing infill walls connecting adjacent wall forms9.

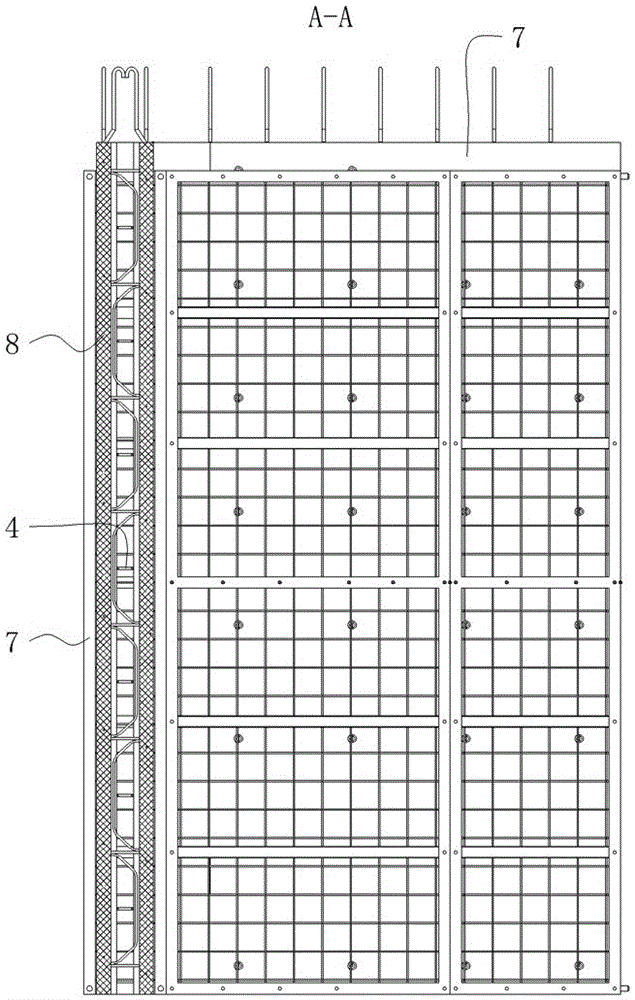

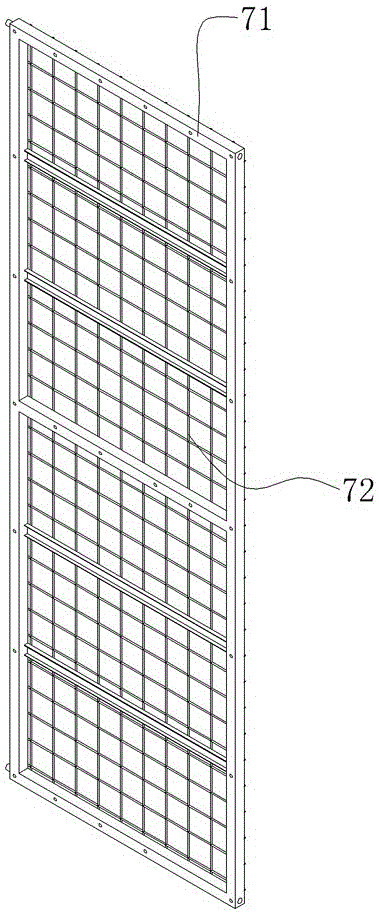

[0060] The wall formwork 1 includes two wall formwork veneers 8 oppositely arranged and a hollow layer arranged between the two wall formwork veneers 8 . The wall formwork veneer 8 is prefabricated by fixing the steel grid sheet 3 in concrete. The wall form veneer 8 is provided with a reserved through hole, and the diameter of the reserved through hole is 20-80mm.

[0061] A tie bar 4 is arranged in the hollow layer. The tie bars 4 extend into the reserved through holes of the two wall formwork veneers 8 and are connected and fixed with the reinforcement grid sheet 3 in the w...

Embodiment 3

[0066] The construction method of the support-free cast-in-place reinforced concrete wall form filling wall of the present embodiment adopts the support-free cast-in-place reinforced concrete wall form filling wall of embodiment one and embodiment two to carry out construction, comprising the following steps:

[0067] 1) Before hoisting the wall formwork 1, special-shaped column reinforcement cage 2 or non-load-bearing filling wall 9, hang the segment frame 7 on the assembled wall formwork 1, special-shaped column reinforcement cage 2 or non-load-bearing filling wall 9 (such as Figure 4 with Figure 5 shown) on both outer sides,

[0068] 2) Install wall formwork 1 with special-shaped column reinforcement cage 2 on the first floor:

[0069] Fix the convex shaft or ferrule on the foundation according to the set distance, then hoist the wall formwork 1 with the special-shaped column reinforcement cage 2 in sequence, and connect the two adjacent wall formworks 1 through the spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com