Sheathing and extruding preparation method for titanium aluminum alloy rods

A titanium-aluminum alloy and sheathing technology, which is applied in the field of alloy materials and its preparation, can solve problems such as cracking, achieve the effects of preventing cracks, suppressing cracks, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Taking the preparation of Ti48Al2Cr2Nb alloy rods as an example, the preparation steps are as follows:

[0042] Step 1: Prepare Ti48Al2Cr2Nb alloy ingots by vacuum consumable arc melting method. The first two meltings are smelted by conventional methods, and the cooling water temperature is controlled at 45°C for the third smelting, and the cooling time is 1h. To room temperature, the prepared Ti48Al2Cr2Nb alloy ingot size is Φ210mm.

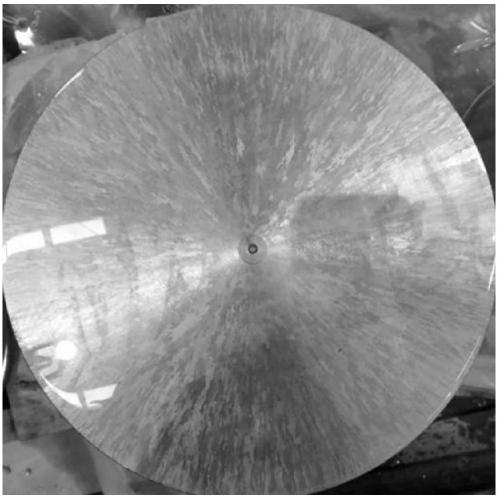

[0043] Step 2: Cut off the head and tail of the ingot prepared in step 1 by 100mm and peel it to Φ200mm. The surface roughness of the ingot is ≤1.6μm. Cut a length of 250mm from the ingot as an extrusion billet, see figure 1 .

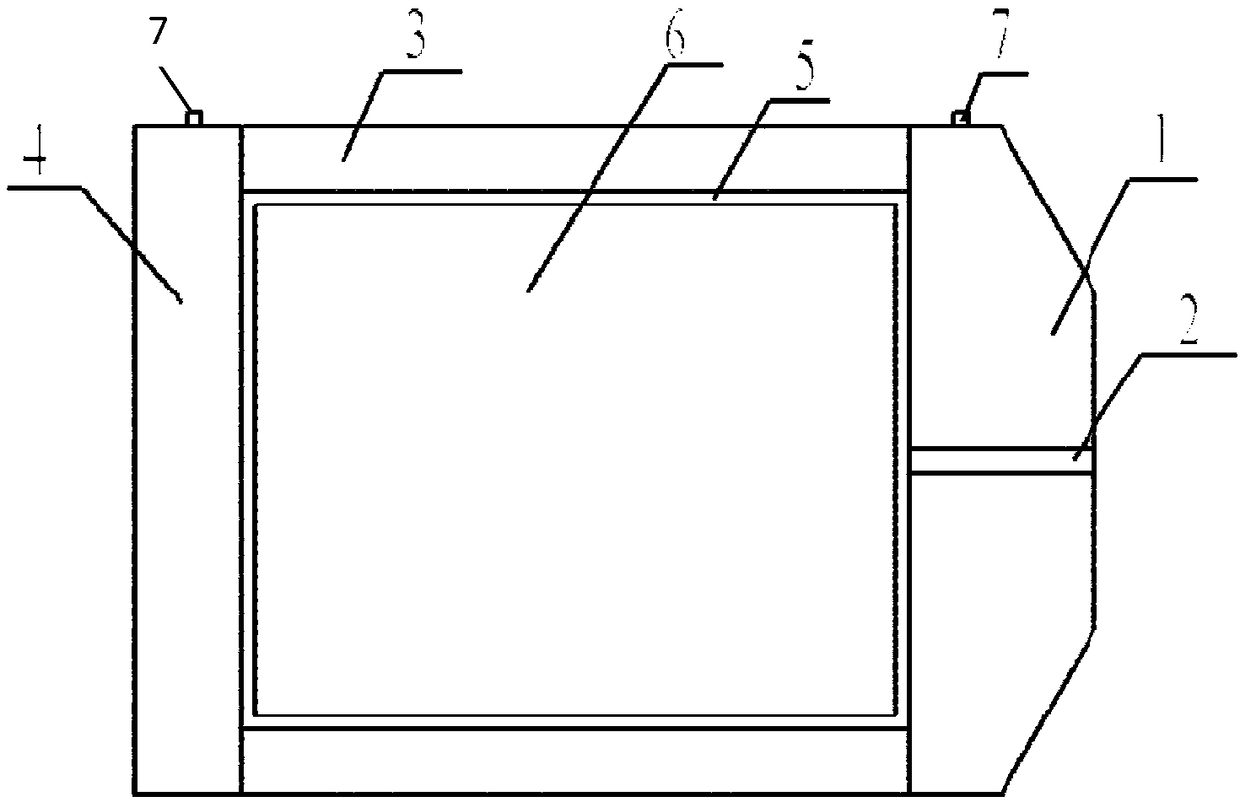

[0044] Step 3: Make the bag, see figure 2 , package sleeve body 3 specifications: outer diameter the inside diameter of Height 251mm; top cover 1 specification: thickness 70mm, diameter of the upper end of the vertebral body 125mm, taper 120 degrees, diameter of the lower end 250mm, center opening Hole; ...

Embodiment 2

[0050] Taking the preparation of Ti47Al2Cr2Nb alloy rods as an example, the preparation steps are as follows:

[0051] Step 1: Prepare Ti47Al2Cr2Nb alloy ingots by vacuum consumable arc melting method. The first two meltings are smelted by conventional methods. The cooling water temperature is controlled at 45°C for the third smelting, and the cooling time is 1h. To room temperature, the prepared Ti47Al2Cr2Nb alloy ingot size is Φ120mm.

[0052] Step 2: Cut off the head and tail of the ingot prepared in step 1 by 100mm and peel off the skin to Φ110mm. The surface roughness of the ingot is ≤1.6μm. Check the low-magnification structure of the head and tail. A length of 250 mm was cut from the ingot as an extrusion billet.

[0053] Step 3: Make the bag, cylinder specification: outer diameter the inside diameter of Height 251mm; top cover specifications: thickness 70mm, diameter of the upper end of the vertebral body 85mm, taper 120 degrees, diameter of the lower end 150mm, c...

Embodiment 3

[0059] Taking the preparation of Ti47.5Al2.5V1Cr alloy rods as an example, the preparation steps are as follows:

[0060] Step 1: Prepare Ti47.5Al2.5V1Cr alloy ingots by vacuum consumable arc melting. The first two smeltings are smelted by conventional methods. During the third smelting, the cooling water temperature is controlled at 40°C, and the cooling time is 1h. Wrap it with insulation cotton and cool it to room temperature, and the specification of the prepared Ti47.5Al2.5V1Cr alloy ingot is Φ160mm.

[0061] Step 2: Cut off the head and tail of the ingot prepared in step 1 by 100mm and peel off the skin to Φ150mm. The surface roughness of the ingot is ≤1.6μm. Check the low-magnification structure of the head and tail end surfaces. A length of 250 mm was cut from the ingot as an extrusion billet.

[0062] Step 3: Make the bag, cylinder specification: outer diameter the inside diameter of Height 251mm; top cover specifications: thickness 70mm, diameter of the upper en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com