A kind of composite plate rolling method

A composite plate and composite billet technology, which is applied in metal rolling, metal rolling, manufacturing tools, etc., can solve problems such as warped buckles and buckles, and achieve the effects of low heating temperature, low energy consumption, and low heat preservation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

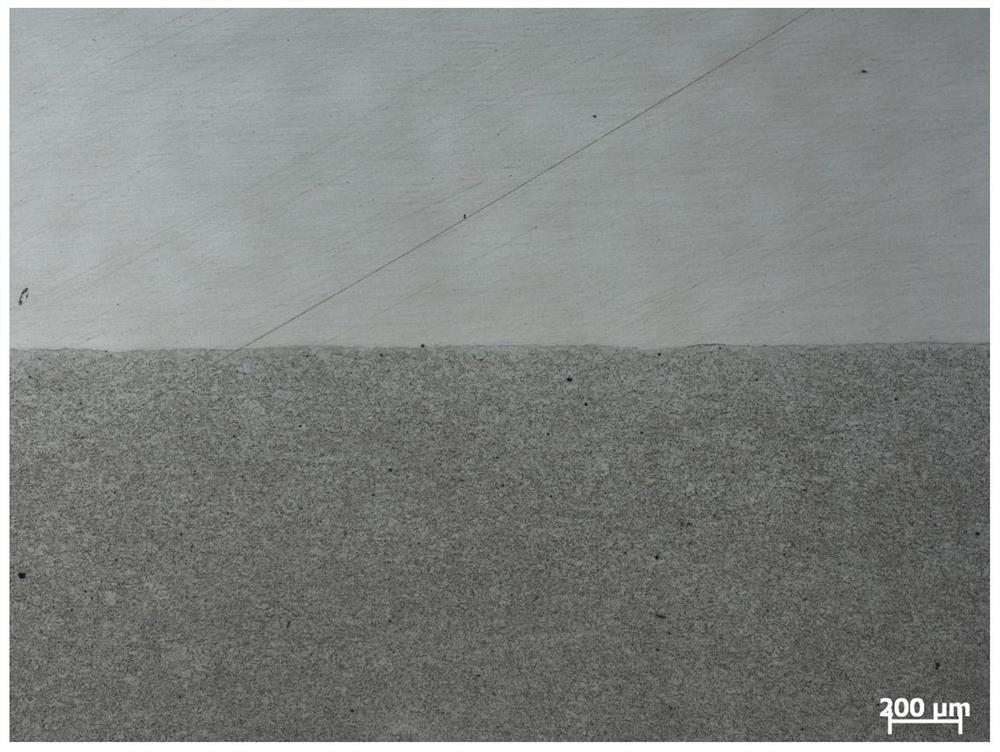

Image

Examples

Embodiment 1

[0028] 1. The composite blank is TA1 / Q235B, the thickness of the composite layer TA1 is 6mm, the thickness of the base layer Q235B is 74mm, and the total thickness is 80mm.

[0029] 2. The composite billet TA1 / Q235B is heated in a heating furnace, the heating temperature is 880-900°C, and the heating and holding time is ≥1.3min / mm;

[0030] 3. The composite billet TA1 / Q235B is subjected to conventional rolling, and a total of 7 passes are rolled. When heating and rolling, the composite layer of the composite billet is on top. Before the first rolling pass, the composite billet enters the instant cooling device at a speed of 2m / s for cooling. Only the cooling water on the upper surface of the instant cooling device is turned on to cool the titanium layer. The carbon steel layer is not cooled and is cooled once. Then rolling the first pass and the second pass, the pass reduction is less than 25mm, and the pass reduction rate is less than 12%;

[0031] 4. Between the second pas...

Embodiment 2

[0034] 1. The composite blank is TA1 / Q345B, the thickness of the composite layer TA1 is 6mm, the thickness of the base layer Q345B is 74mm, and the total thickness is 80mm.

[0035] 2. The composite billet TA1 / Q345B is heated in a heating furnace, the heating temperature is 880-900°C, and the heating and holding time is ≥1.3min / mm;

[0036] 3. The composite billet TA1 / Q345B is subjected to conventional rolling, with a total of 9 passes. When heating and rolling, the composite layer of the composite billet is on top. Before the first rolling pass, the composite billet enters the instant cooling device at a speed of 4m / s for cooling, only the cooling water on the upper surface of the immediate cooling device is turned on to cool the titanium layer, and the carbon steel layer is not cooled, and a single cooling is performed. Then rolling the first pass and the second pass, the pass reduction is less than 25mm, and the pass reduction rate is less than 12%;

[0037] 4. Between the ...

Embodiment 3

[0042] 1. The composite blank is TA2 / Q345B, the thickness of the composite layer TA2 is 4mm, the thickness of the base layer Q345B is 60mm, and the total thickness is 64mm.

[0043] 2. The composite billet TA2 / Q345B is heated in a heating furnace, the heating temperature is 880-900°C, and the heating and holding time is ≥1.3min / mm;

[0044] 3. The composite billet TA2 / Q345B is conventionally rolled, with a total of 7 passes. When heating and rolling, the composite layer of the composite billet is on top. Before the first rolling pass, the composite billet enters the instant cooling device at a speed of 4m / s for cooling, only the cooling water on the upper surface of the immediate cooling device is turned on to cool the titanium layer, and the carbon steel layer is not cooled, and a single cooling is performed. Then rolling the first pass and the second pass, the pass reduction is less than 25mm, and the pass reduction rate is less than 12%;

[0045] 4. Between the second pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com