Laser tailor-welded high-strength steel warm forming preparation method

A technology of laser tailor welding and warm forming, which is applied in the field of material processing, can solve the problems affecting the welding performance of boron steel, the low plasticity of hot-formed boron steel, and poor mechanical properties, etc., so as to save process costs, reduce forming temperature, and excellent Effect of Mechanical Properties and Surface Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method for warm forming of high-strength steel by laser tailor welding, comprising the following steps:

[0027]S1. Select 22MnB5 steel plate as Tailored Welded Sheet I, with a thickness between 1.2mm-1.8mm. The chemical composition weight percentage of the 22MnB5 steel plate is: C: 0.21-0.25%; Mn: 1.2-1.4%; Cr: 0.11- 0.25%; Si: 0.2-0.3%; B: 0.002-0.005%; Al: 0.02-0.05%; P≤0.015%; S≤0.005%; the balance is Fe and unavoidable impurities;

[0028] The medium manganese steel plate is selected as the second tailored welded sheet, the thickness is between 1.2mm-1.8mm, and the chemical composition weight percentage of the medium manganese steel plate is: C: 0.05-0.50%; Mn: 4.0-6.0%; P≤0.015% ; S≤0.02%, the balance is Fe and unavoidable impurities; wherein, the 22MnB5 steel plate and the medium manganese steel plate can be of equal thickness or unequal thickness; weight can be added on the basis of the chemical composition of the medium manganese steel plate One ...

Embodiment 1

[0033] 22MnB5 steel and medium manganese steel are selected, and their chemical compositions are respectively by weight percentage:

[0034] 22MnB5 steel is C: 0.225%; Mn: 1.25%; Cr: 0.18%; Si: 0.22%; B: 0.003%; Al: 0.025%; P: 0.013%; S: 0.003%; impurities;

[0035] Medium manganese steel is C: 0.1%; Mn: 5%; P: 0.013%; S: 0.01%; the balance is Fe and unavoidable impurities.

[0036] The preparation method comprises the following steps:

[0037] S1, making the two high-strength steels of the above composition into steel parts for use;

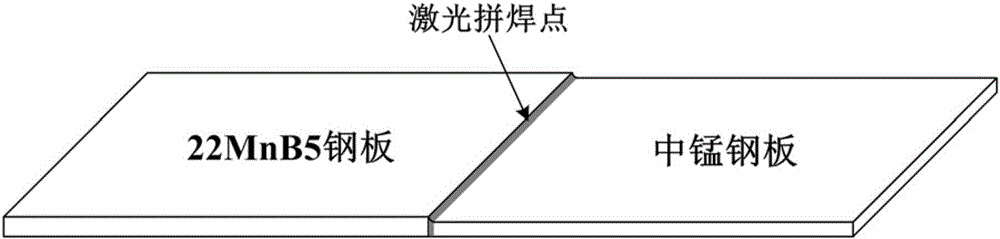

[0038] S2. Perform laser tailor welding on the two steel pieces; in this embodiment, the 22MnB5 steel plate is selected to be 1.5 mm, and the medium manganese steel plate is selected to be 1.2 mm. The size of the two steel plates is 40cm*30cm, the schematic diagram of laser tailor welding, as shown in image 3 shown. When real auto parts are subjected to laser tailor welding and warm forming according to this patent, the dimensions of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com