Patents

Literature

150results about How to "Consistent deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

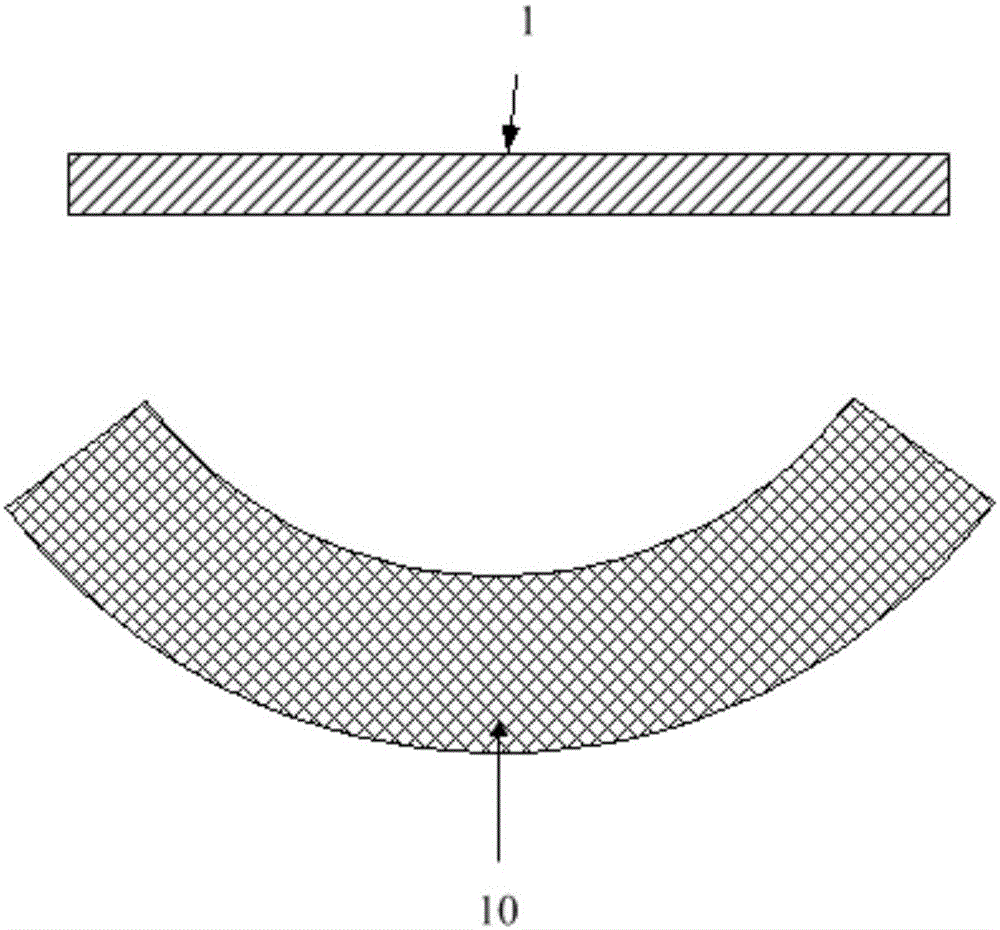

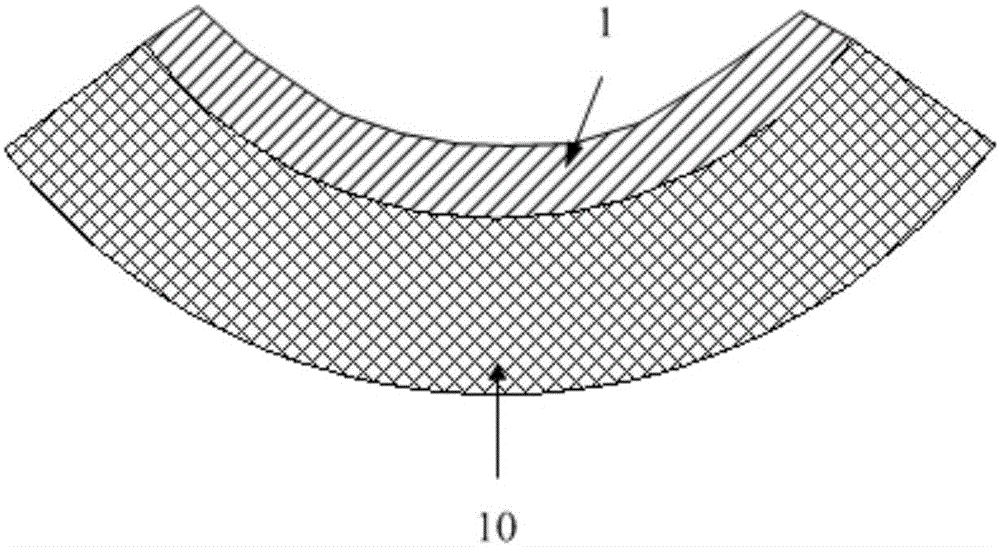

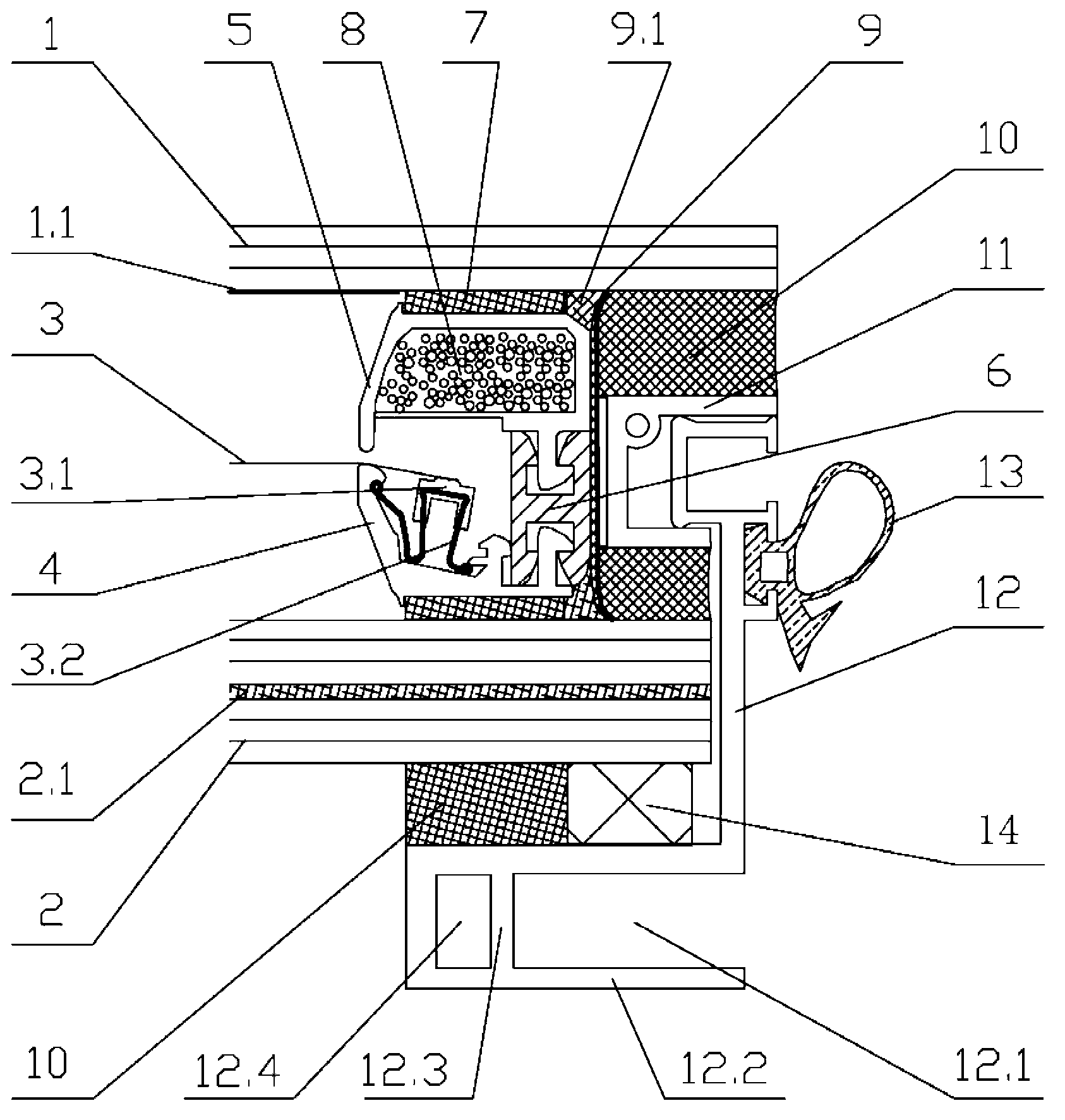

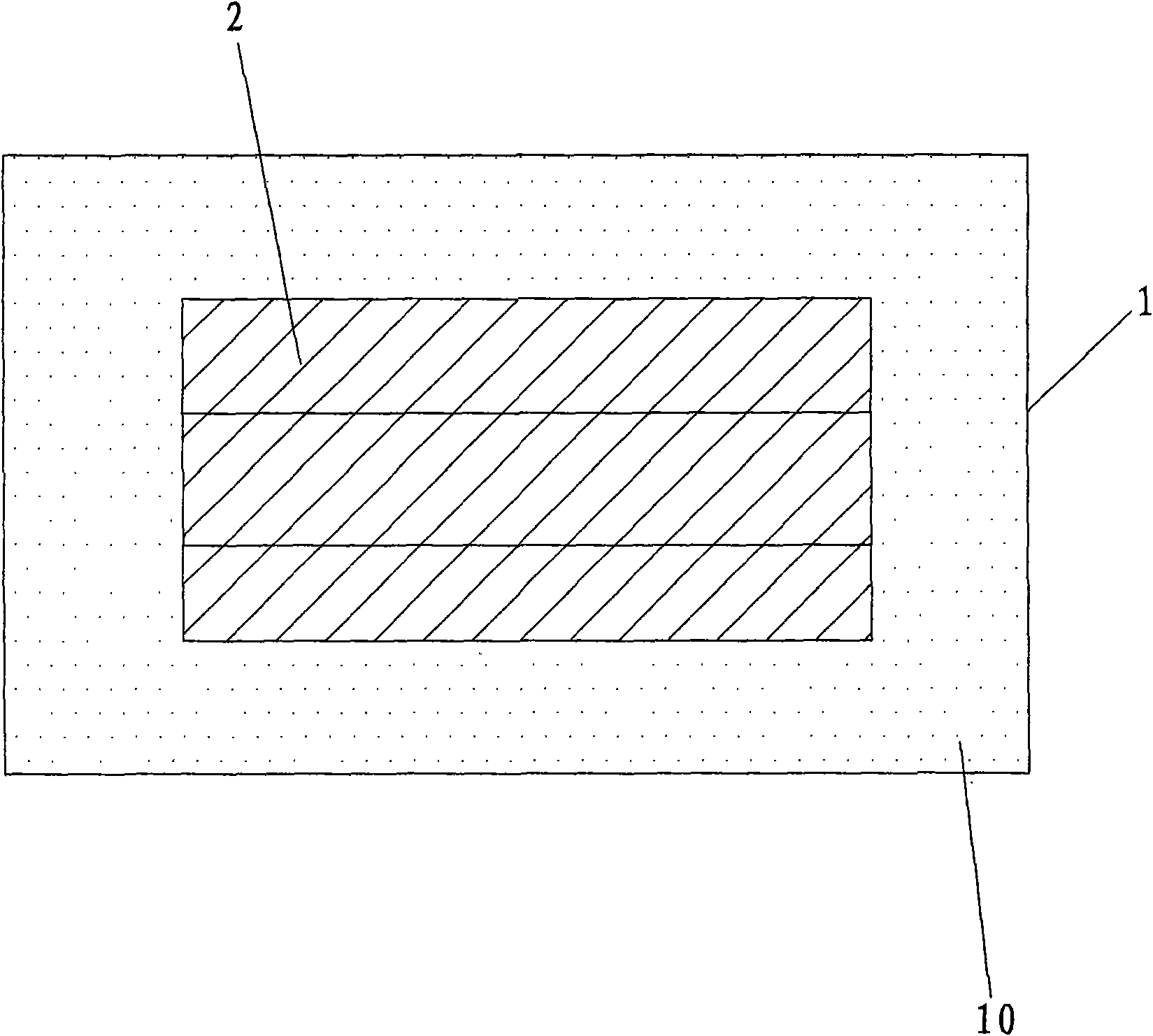

Display apparatus

ActiveCN105044957AFlexible adjustment of curvatureImprove performanceCasings with display/control unitsNon-linear opticsDisplay deviceEngineering

The invention belongs to the technical field of display and concretely relates to a display apparatus comprising a display screen and a back plate mechanism arranged on a non-displaying side of the display screen. The back plate mechanism comprises a plurality of straight supporting plates; two adjacent straight supporting plates are connected and form an included angle; the display screen is arranged between the two adjacent straight supporting plates and tangent to the same; and the display screen forms a curved surface structure by the plurality of straight supporting plates. The back plate mechanism of the display apparatus can be easily manufactured, possesses even resilience and can further possesses various curvature; and a curved display device having great consist curvature can be achieved.

Owner:BOE TECH GRP CO LTD

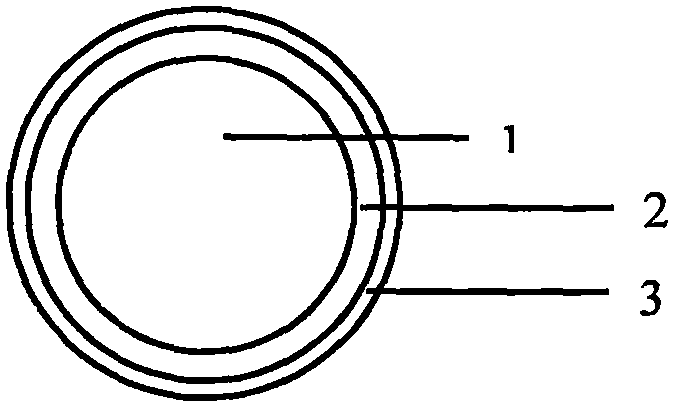

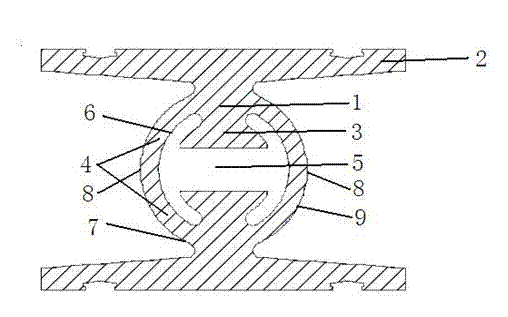

Surface palladium-plated bonding brass wire

ActiveCN102130067AGood ultimate plastic deformation abilityConsistent deformationSemiconductor/solid-state device detailsSolid-state devicesCost performanceBrass

The invention discloses a surface palladium-plated bonding brass wire comprising a brass core taking brass as a main component and a palladium layer formed by plating on the brass core. The surface palladium-plated bonding brass wire is characterized in that trace metal for improving the extension performance is added in the brass core taking the brass as the main component; a single crystal is smelt and drawn to form a brass alloy core wire; the palladium is plated on the surface of the brass alloy core wire; and the surface palladium-plated bonding brass wire is formed in a superfine drawing manner. Compared with the prior art, the invention has the benefits that the surface palladium-plated bonding brass wire has better final plasticity deformation capability in the subsequent superfine drawing process without intermediate annealing; the percentage elongation of the surface palladium-plated bonding brass wire is at least 11 percent; the deformation of a palladium-plated layer in the pressure processing flow is consistent; the surface of the surface palladium-plated bonding brass wire is uniform, compact and complete, which is especially beneficial to full deformation during welding bonding, and thus the pulling strength and the reliability are improved. In addition, the cost of products can be controlled to be about 6 yuan / 100 meters and the products have high cost performance.

Owner:SICHUAN WINNER SPECIAL ELECTRONICS MATERIALS

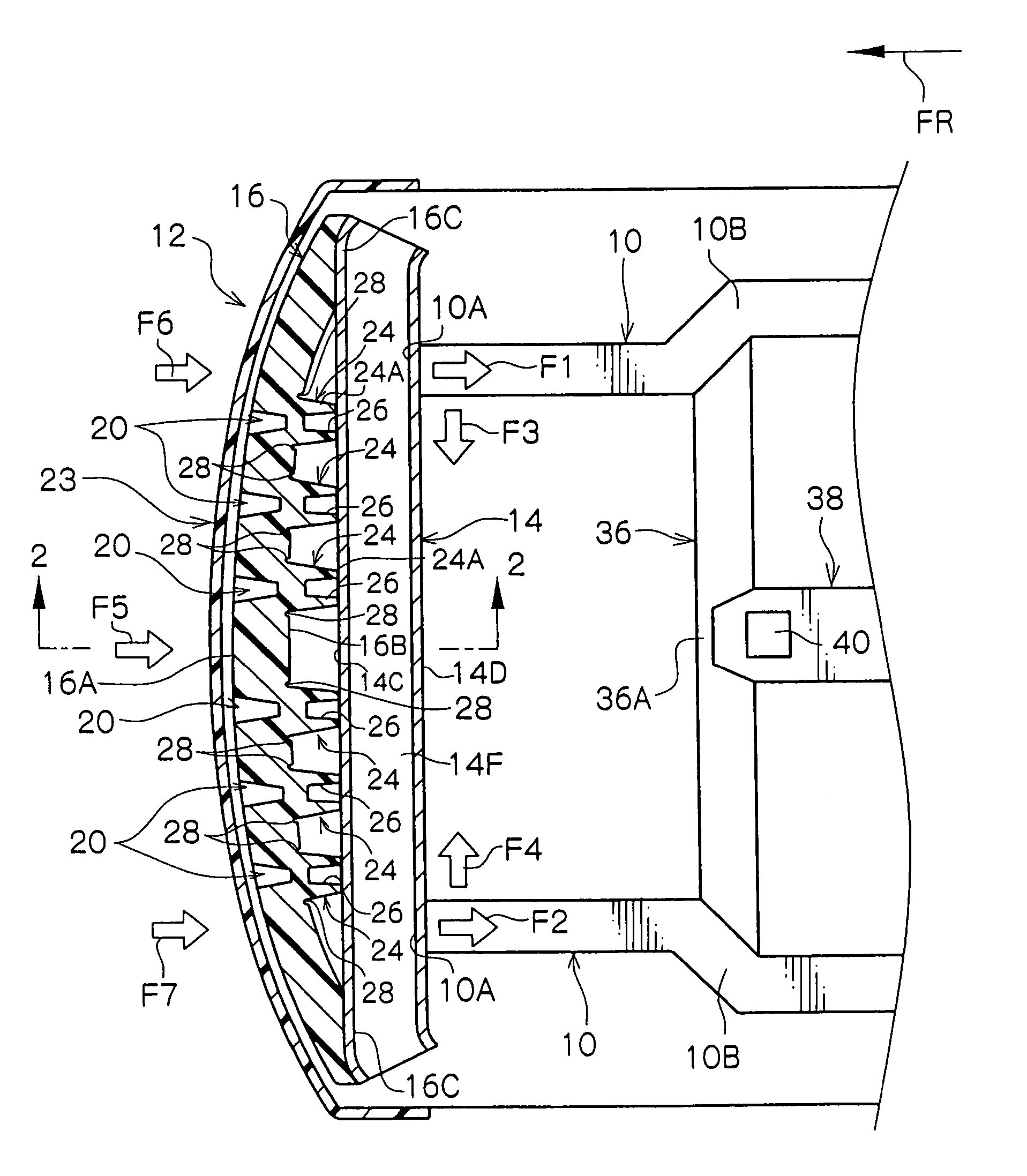

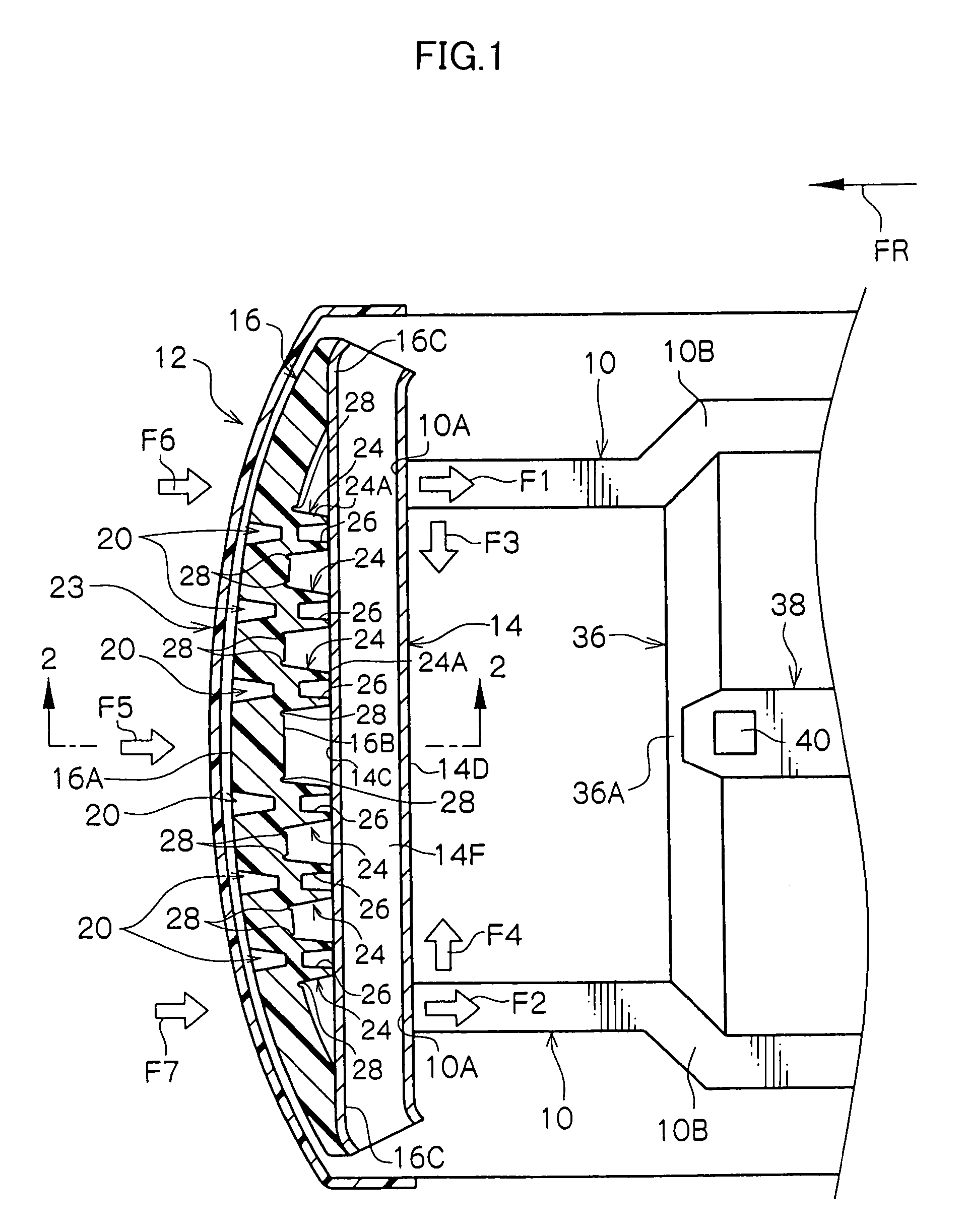

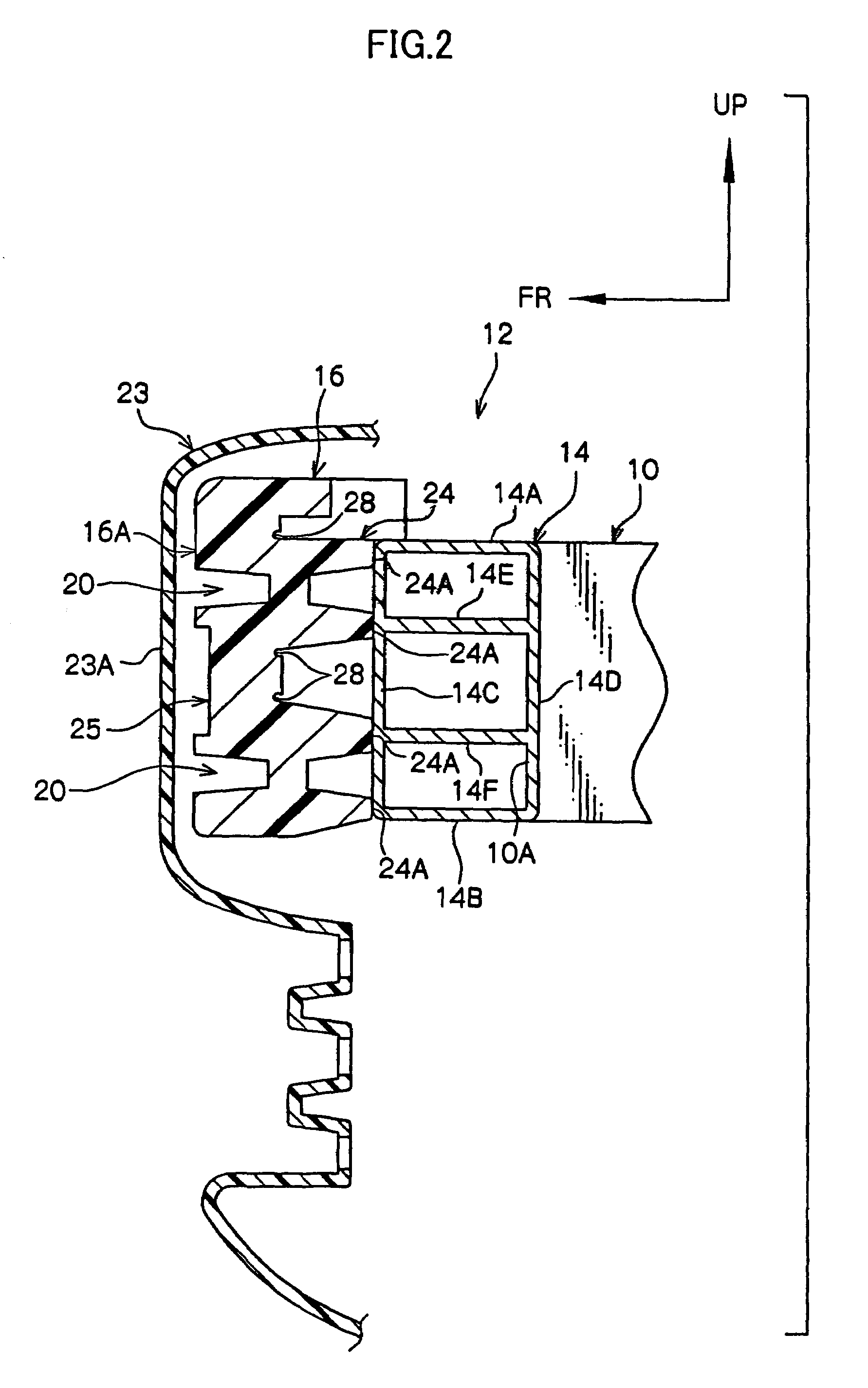

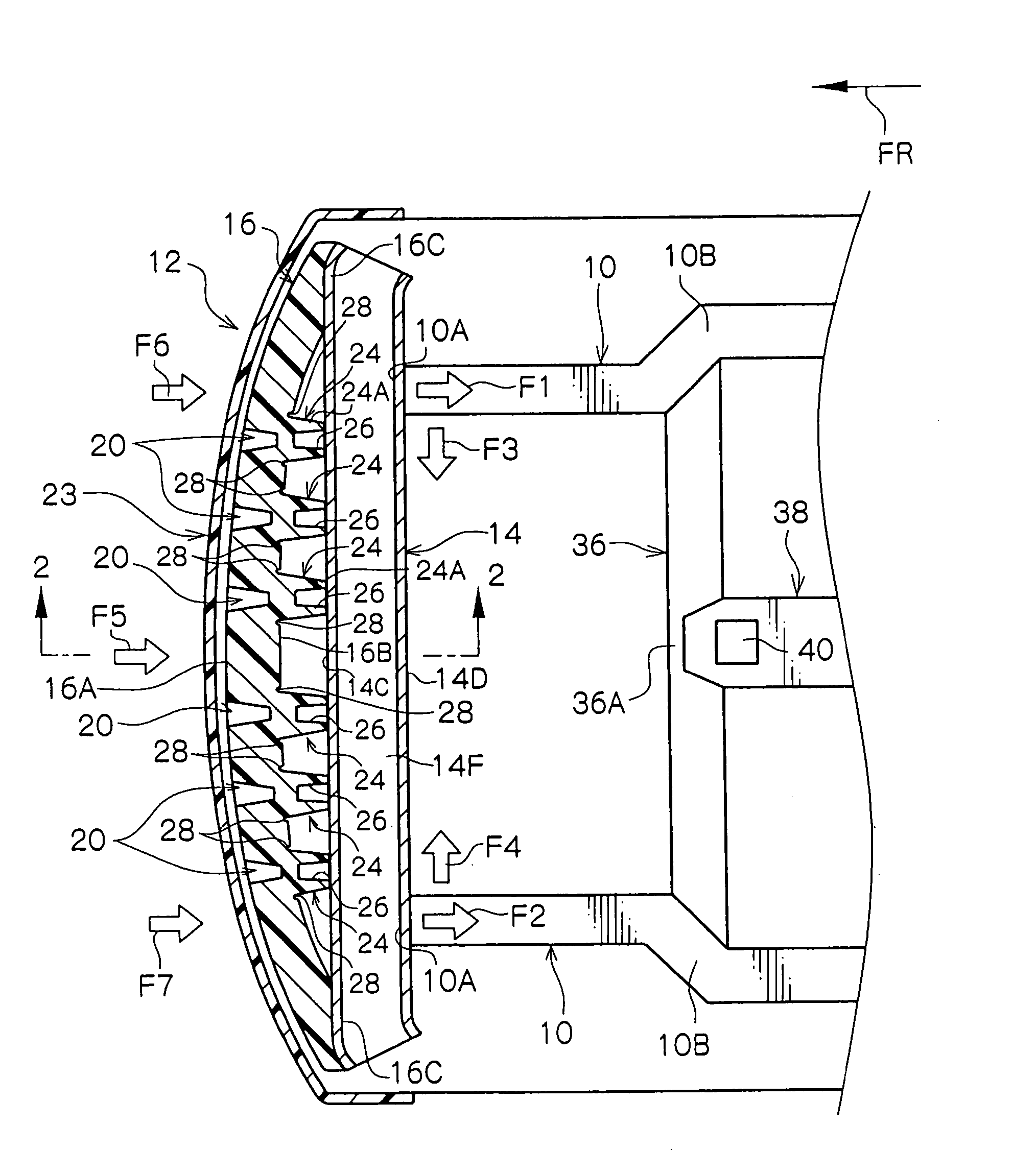

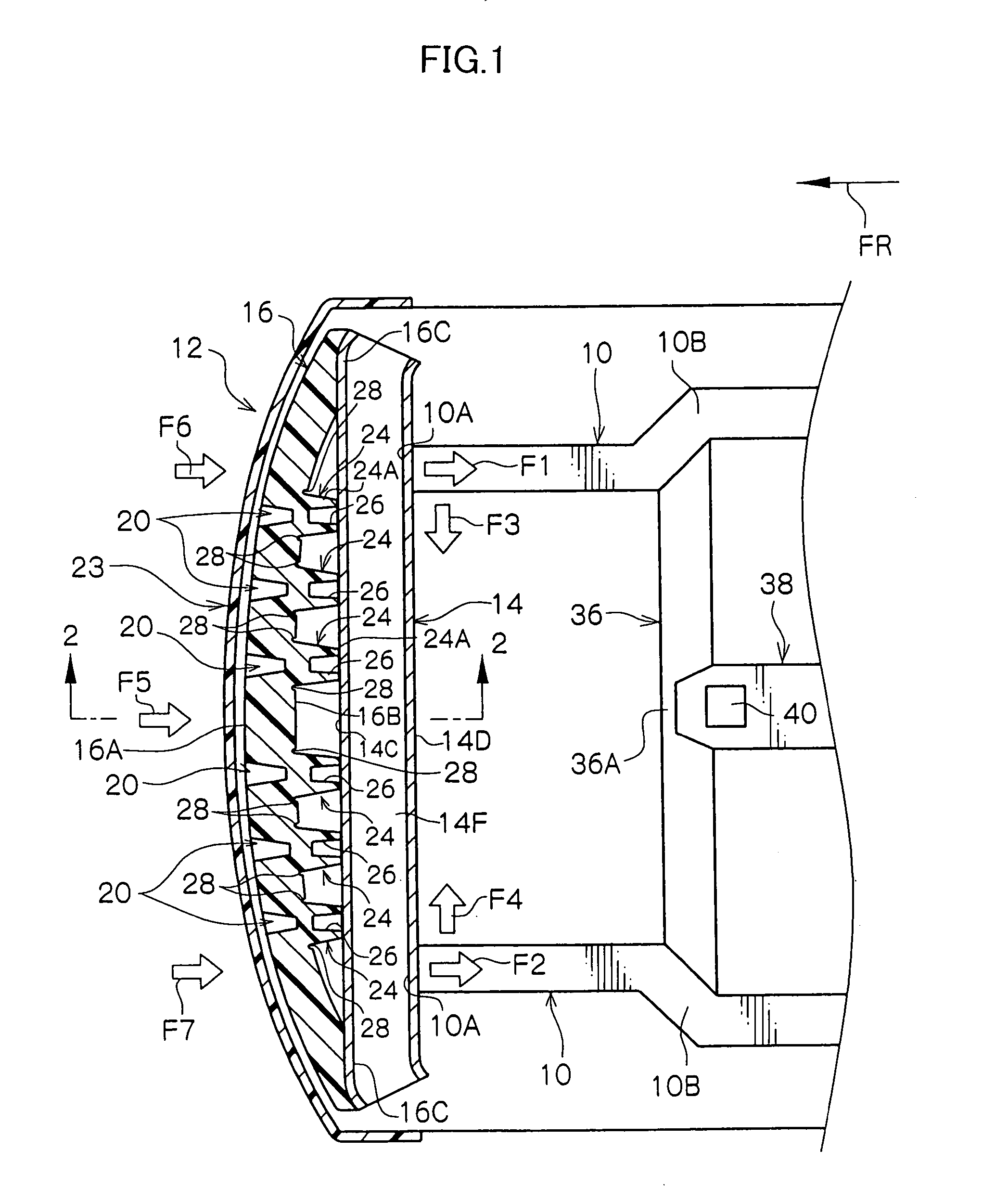

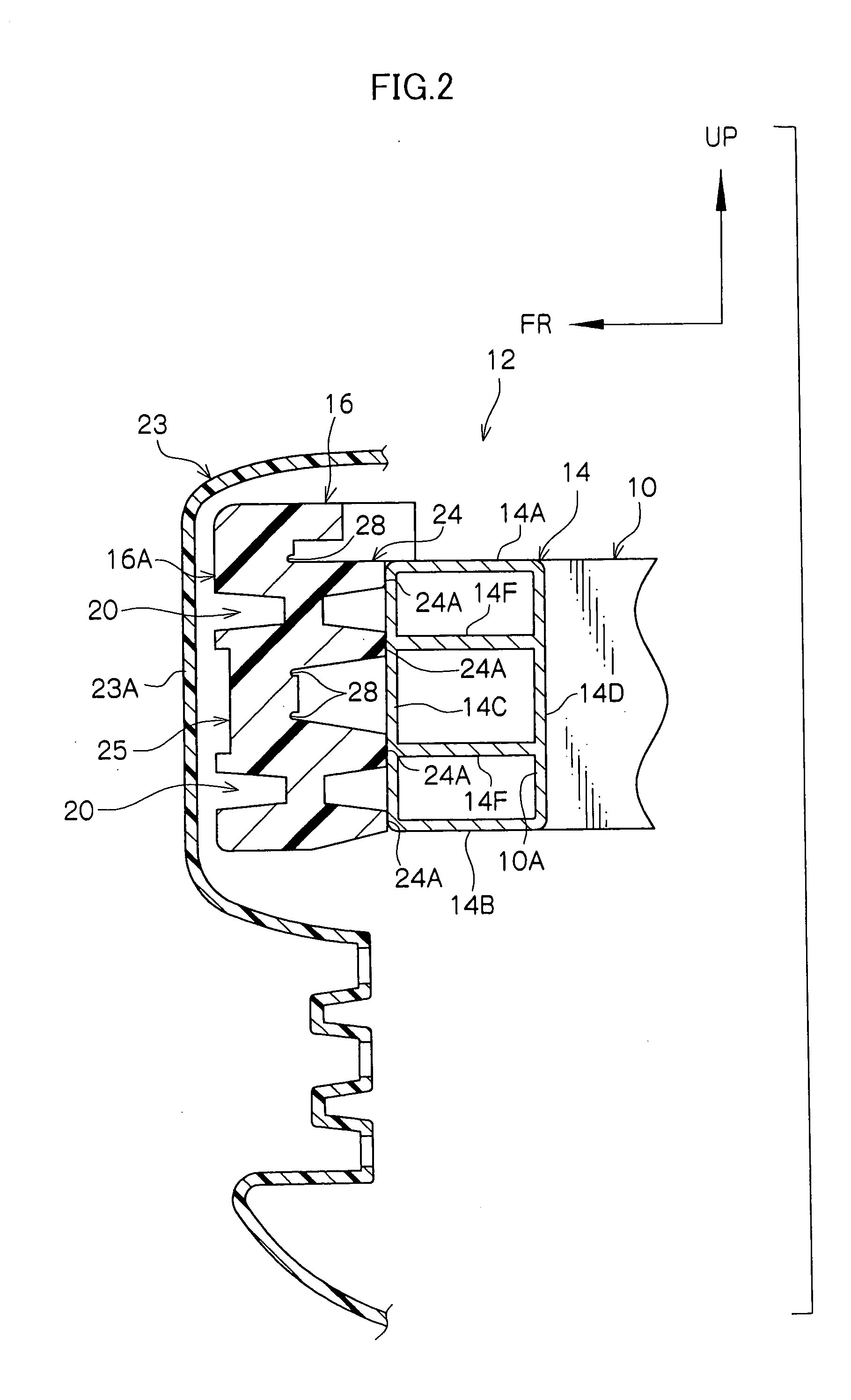

Vehicle bumper structure

An impact-absorbing system and method which assures speed dependency of loads generated in side members at times of frontal collisions, and reduces repair costs at times of low-speed collisions. A reinforcing member spans along a vehicle width direction in a substantially linear form between front ends of a pair of side members. A region of a rear wall portion of an impact-absorbing member, which region is disposed so as to connect between end portions of the side members, is provided with a plurality of protrusion portions which are spaced by a predetermined interval in the vehicle width direction, and includes grooves at outer peripheries of base portions of the protrusion portions. Peak portions of the protrusion portions include hole portions along a length axis of the vehicle.

Owner:TOYOTA JIDOSHA KK

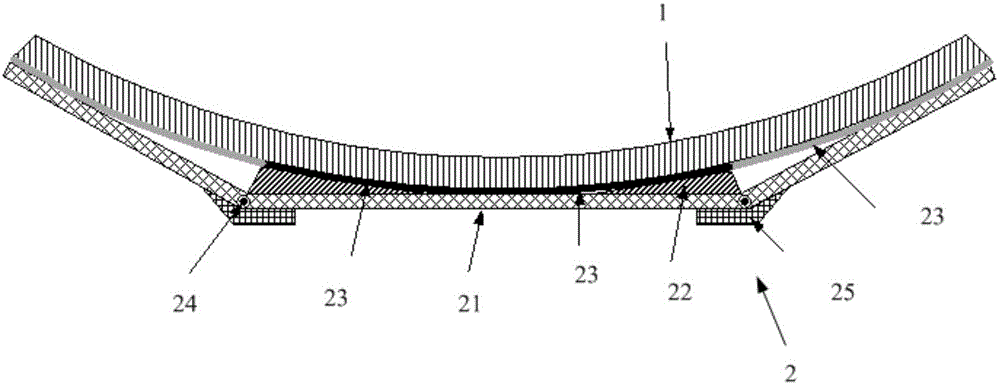

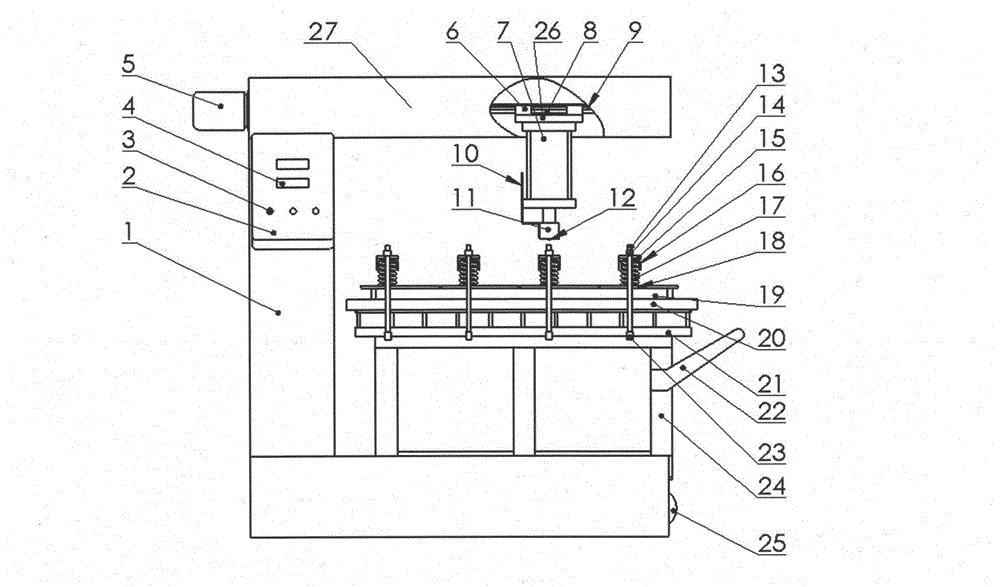

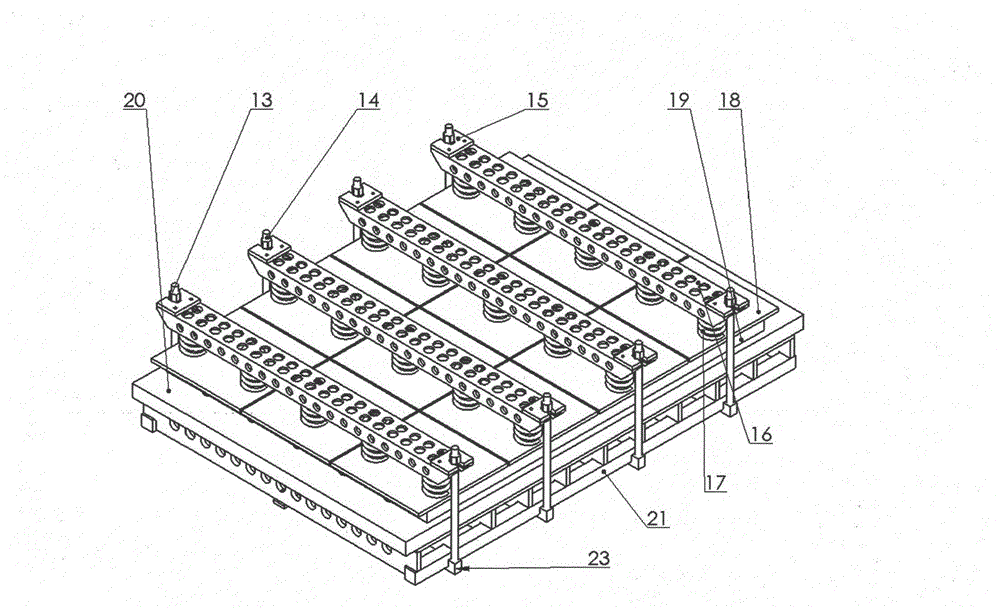

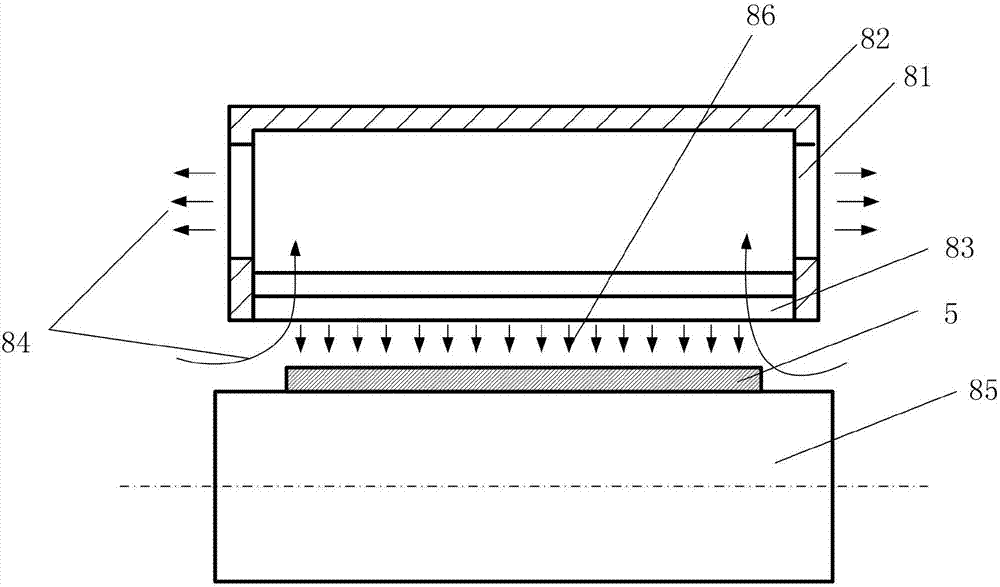

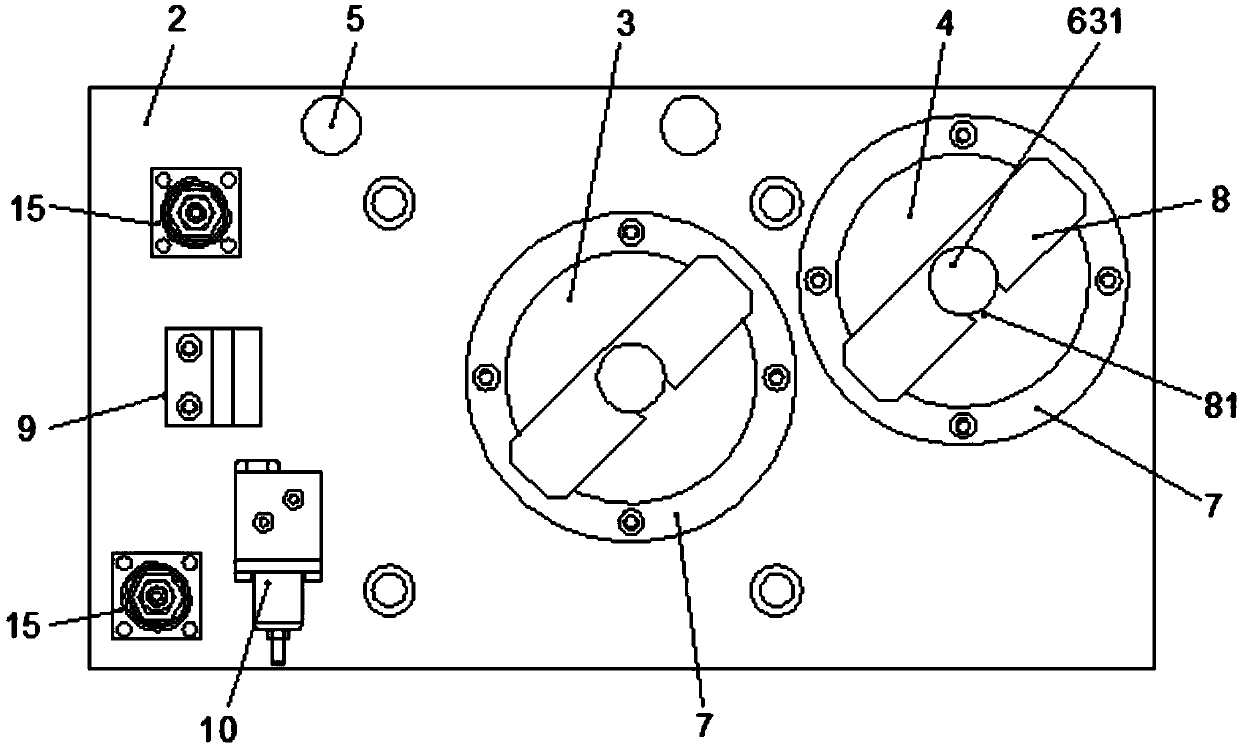

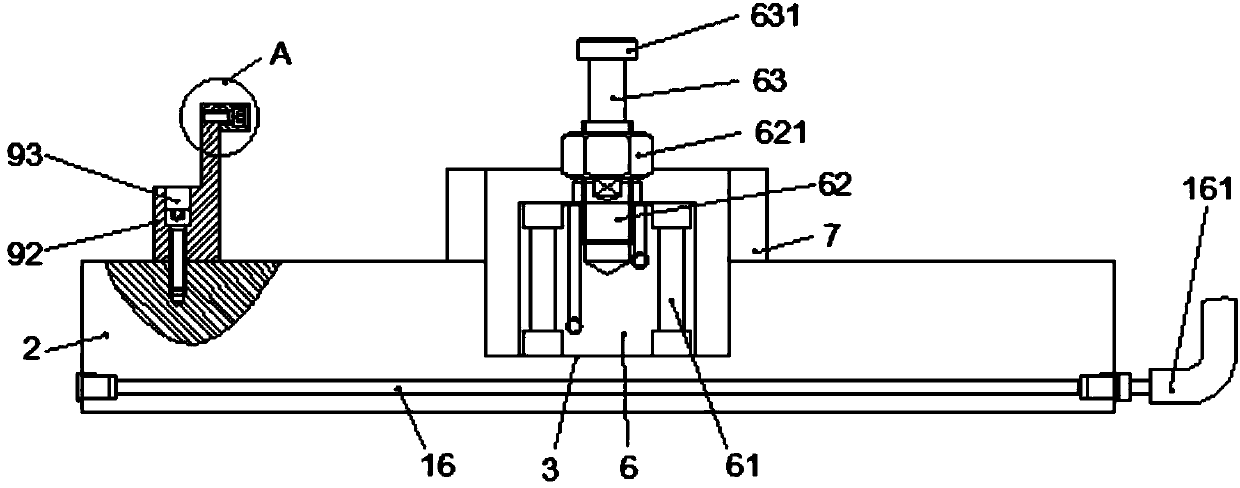

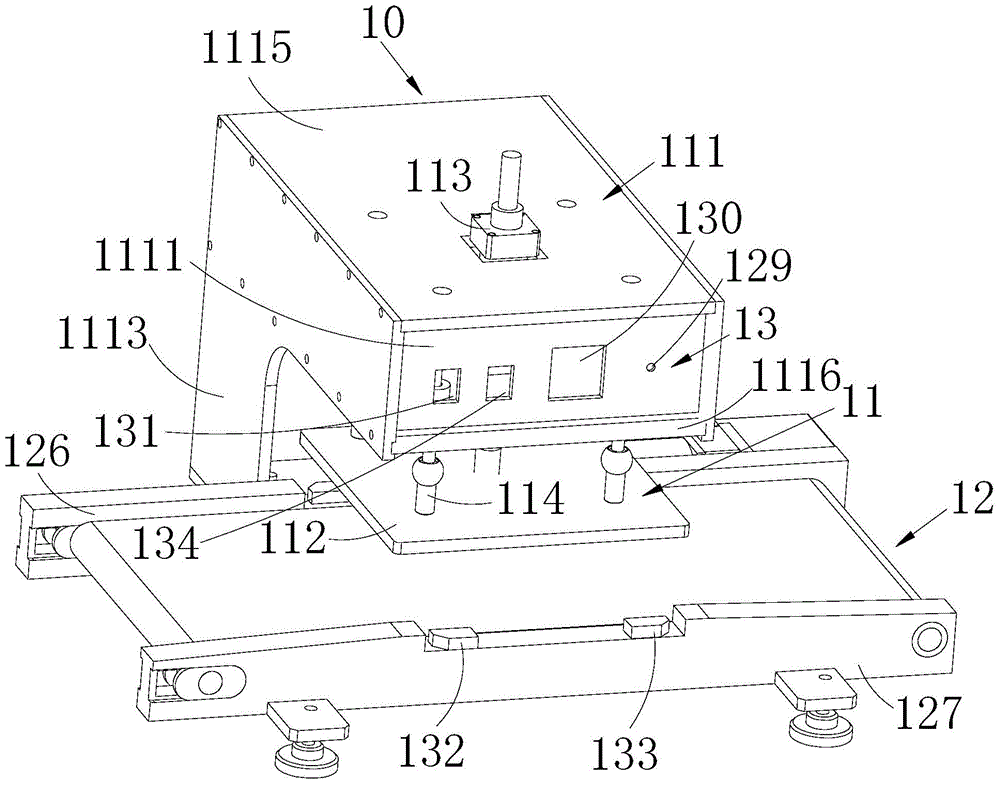

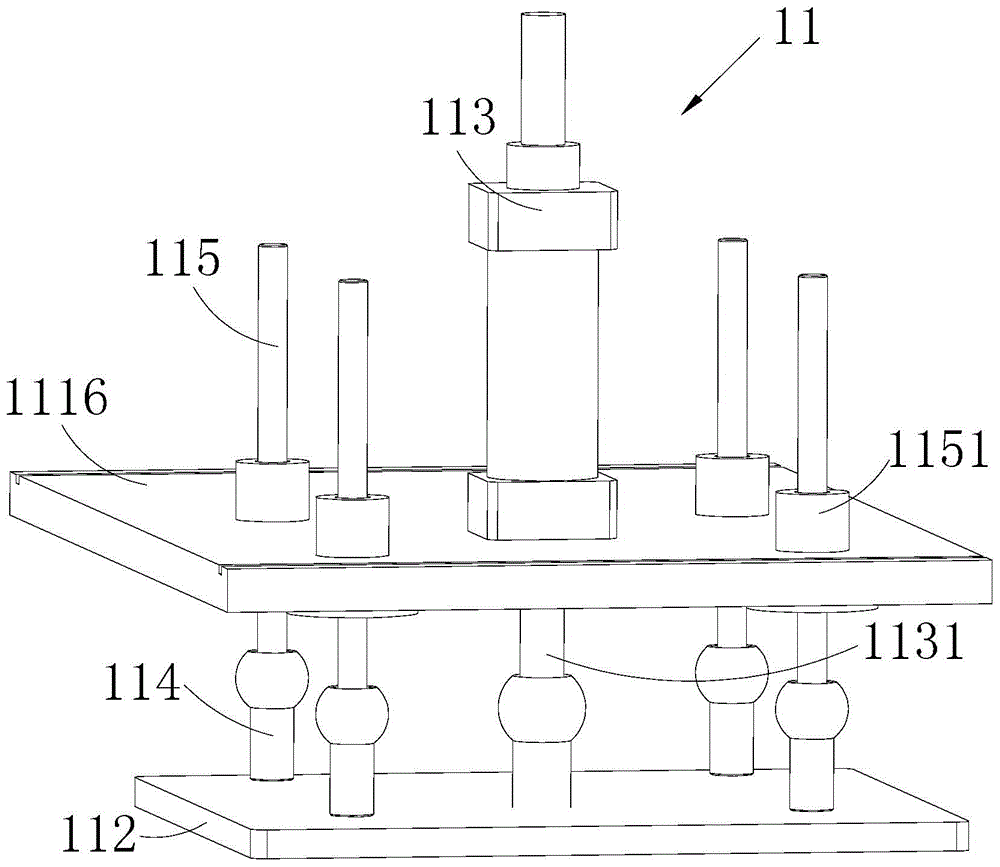

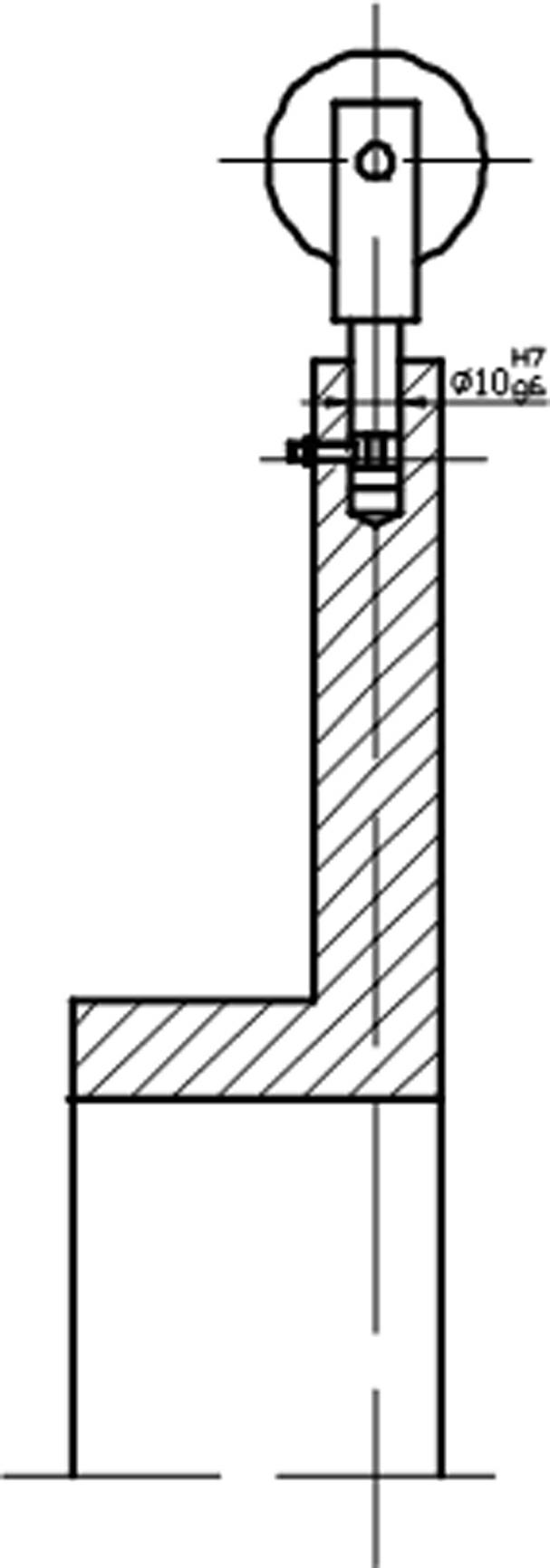

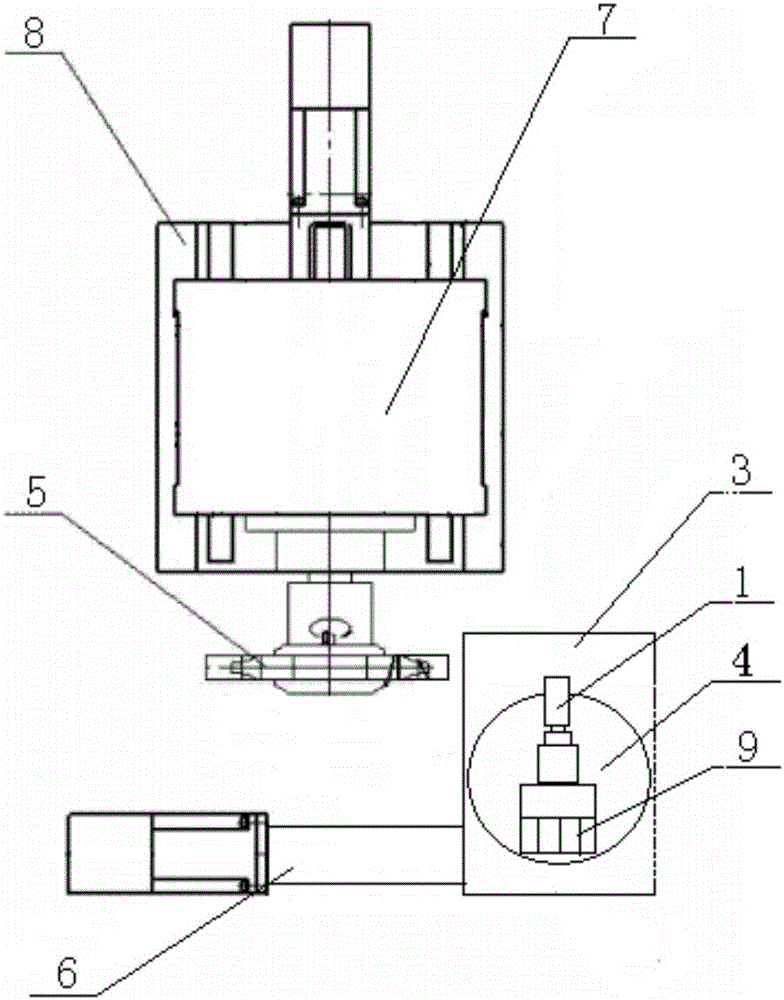

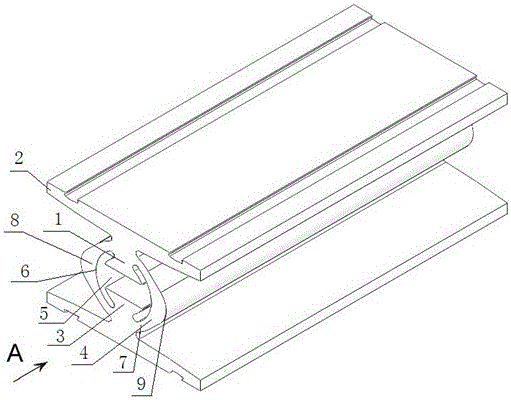

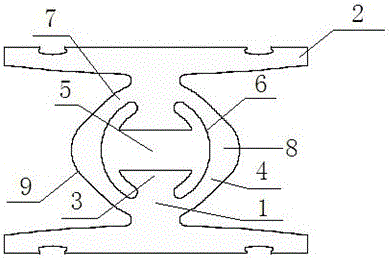

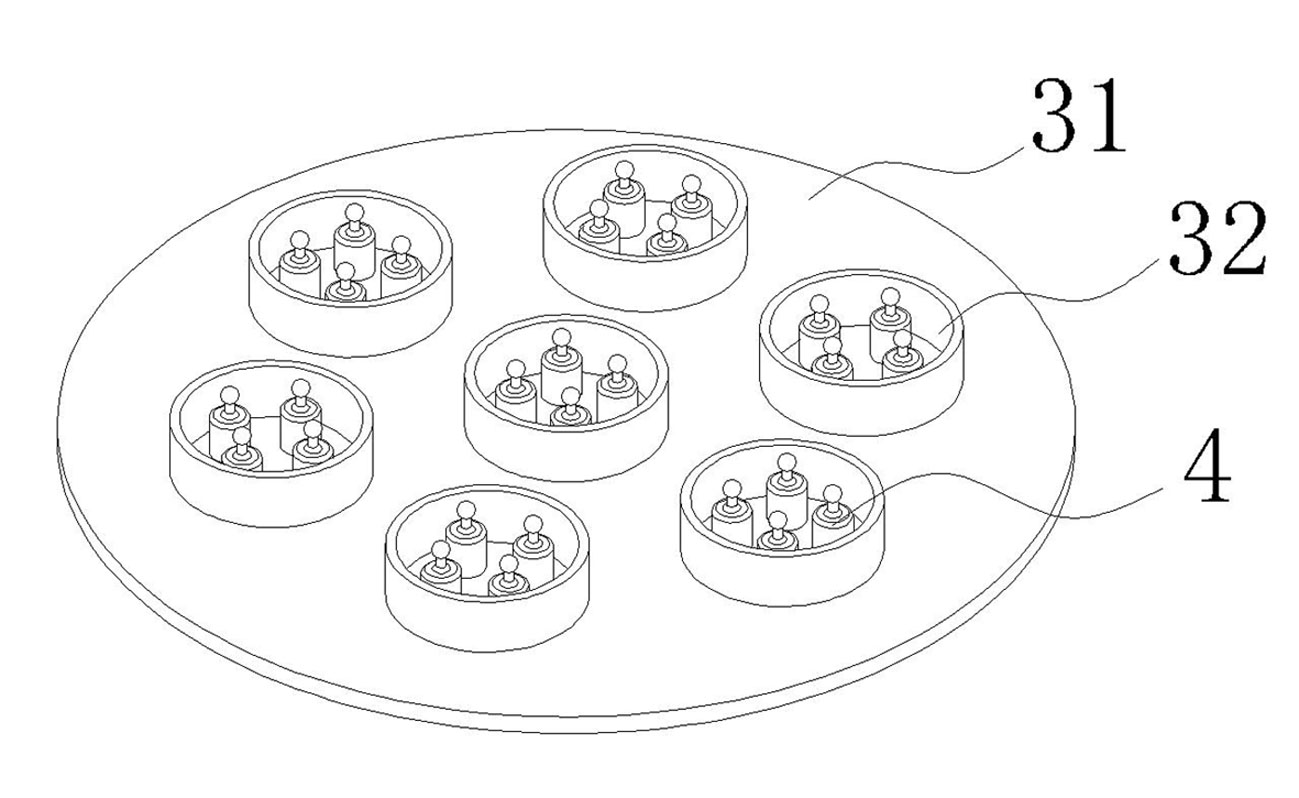

Vacuum brazing tool for water-cooling plate

InactiveCN102873491APrecisely control the total pressing forcePrecisely control the pressing forceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringInternal radiation

The invention discloses a vacuum brazing tool for a water-cooling plate. The vacuum brazing tool comprises a movable trolley, wherein a clamping device is arranged on the movable trolley and comprises a bottom board, a cover plate and at least one group of clamping device, wherein the bottom board and the cover plate are vertically superposed; and the vacuum brazing tool is characterized by further comprising a C-shaped main frame, wherein a suspension beam is arranged on the upper part of the C-shaped main frame, a vertical moving device which can move along the direction of the suspension beam is arranged on the lower side of the suspension beam, a pressing block is arranged on the bottom end of the vertical moving device, and at least one load sensor is arranged on the bottom of the pressing block. According to the tool, total press fitting force on the water-cooling plate can be accurately controlled, the press fitting force on each part of the water-cooling plate is basically consistent, and thus, the deformation of each clamp is slight and consistent, the service life of each clamp is prolonged, round hole structures of parts such as the bottom board and a pressing board are beneficial to the internal radiation heat adsorption and heat dissipation of a product in a vacuum brazing furnace, so that the brazing efficiency is improved, after the tool is adopted to weld the water-cooling plate, the once finished product rate can reach above 90%, and the tool can be widely applied to the assembling of the water-cooling plate before the vacuum brazing.

Owner:SHANGHAI EAGTOP ELECTRONICS TECH

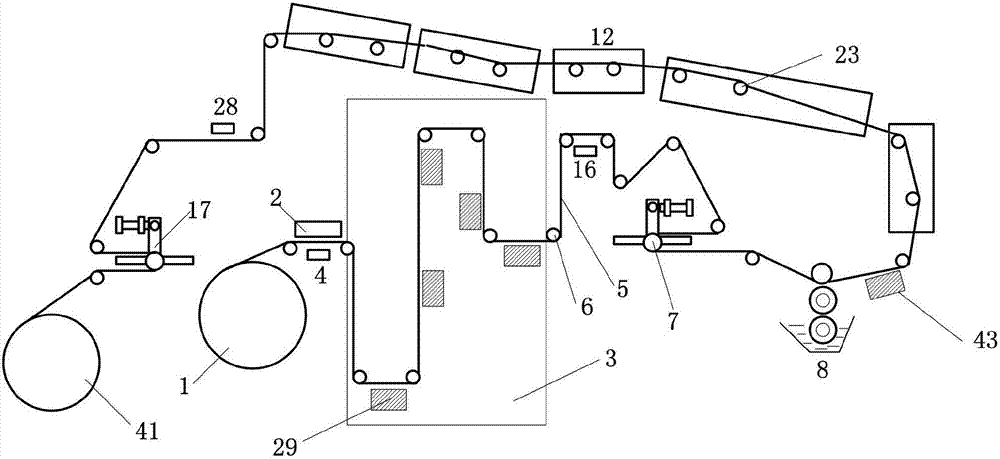

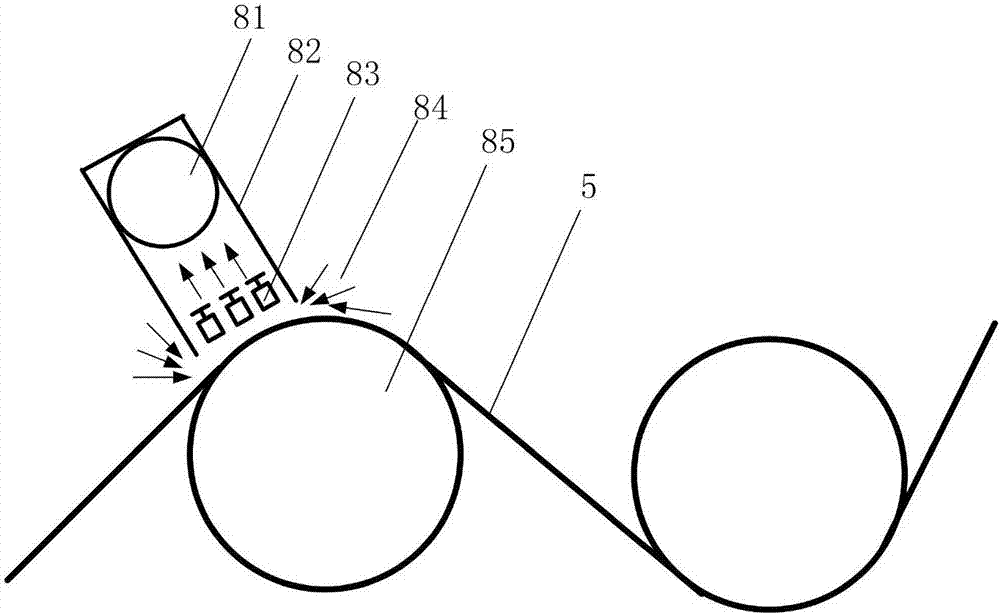

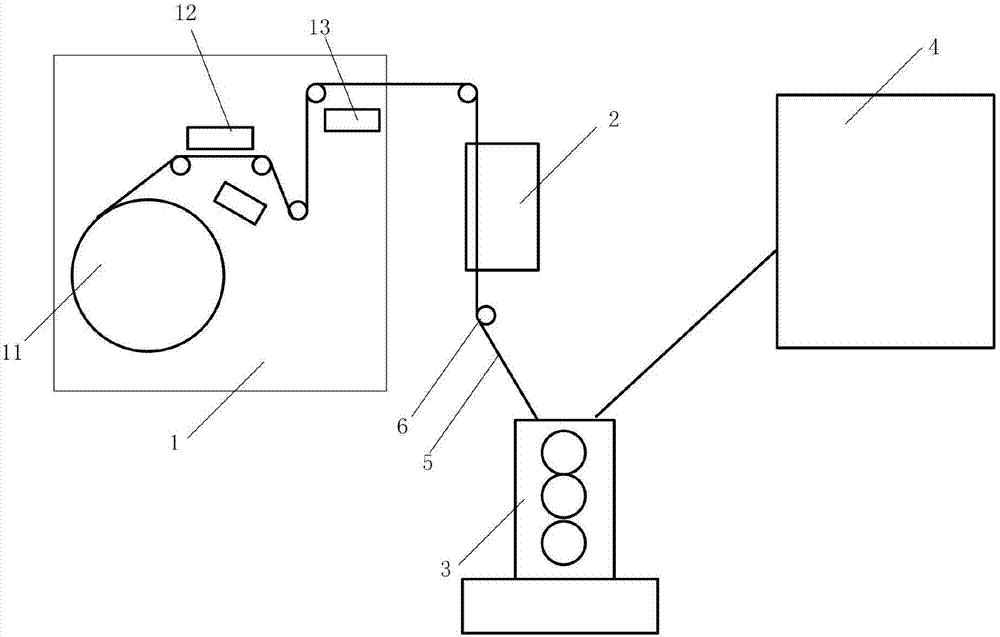

Device for coating graphene on surfaces of metal foils

ActiveCN107457141AThe glue layer is thin and uniformStrong adhesionPretreated surfacesCoatingsMetal foilCopper foil

The invention discloses a device for coating graphene on surfaces of metal foils. The device comprises a control unit, and an unwinding unit, a coating printing device, a baking unit and a winding unit arranged in sequence in a moving direction of the metal foils; the metal foils are aluminum foils or copper foils; the coating printing device comprises a pressing roller, a driving silica gel roller and a driving steel roller laminated from top to bottom; the driving silica gel roller and the driving steel roller are rotated in opposite directions by keeping a micron gap; the driving steel roller is dipped in a colloid pool with viscous materials; and a substrate is arranged between the pressing roller and the driving silica gel roller. The device realizes uniform spraying of materials with submicron thicknesses and thinner layers on the surface of the substrate to meet the thickness requirements of the graphene coated on the metal foils, and achieves excellent adhesion to effectively reduce the contact resistance between carbon particles and the metal foils.

Owner:陕西浩合机械有限责任公司

Vehicle bumper structure

An impact-absorbing system and method which assures speed dependency of loads generated in side members at times of frontal collisions, and reduces repair costs at times of low-speed collisions. A reinforcing member spans along a vehicle width direction in a substantially linear form between front ends of a pair of side members. A region of a rear wall portion of an impact-absorbing member, which region is disposed so as to connect between end portions of the side members, is provided with a plurality of protrusion portions which are spaced by a predetermined interval in the vehicle width direction, and includes grooves at outer peripheries of base portions of the protrusion portions. Peak portions of the protrusion portions include hole portions along a length axis of the vehicle.

Owner:TOYOTA JIDOSHA KK

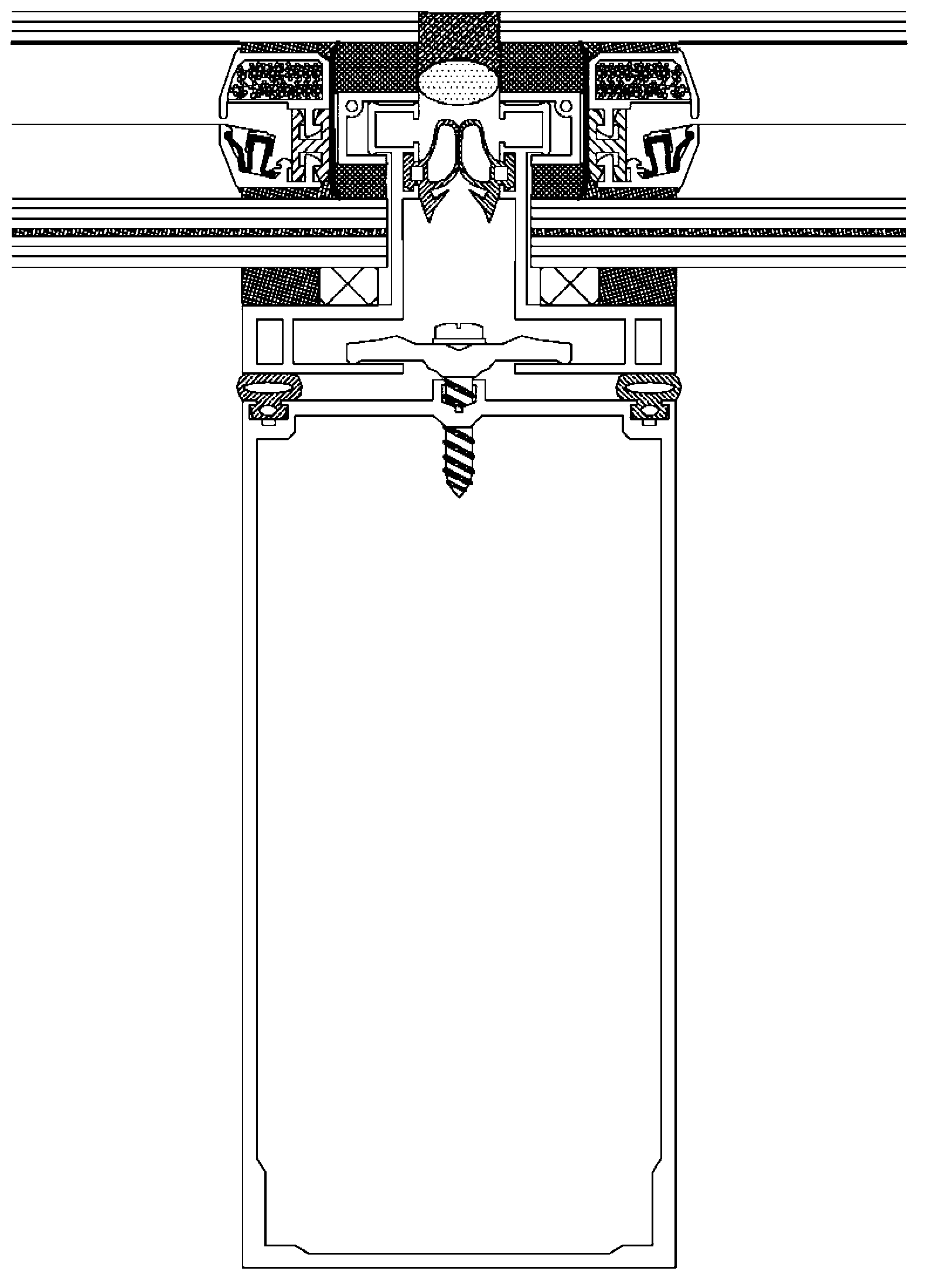

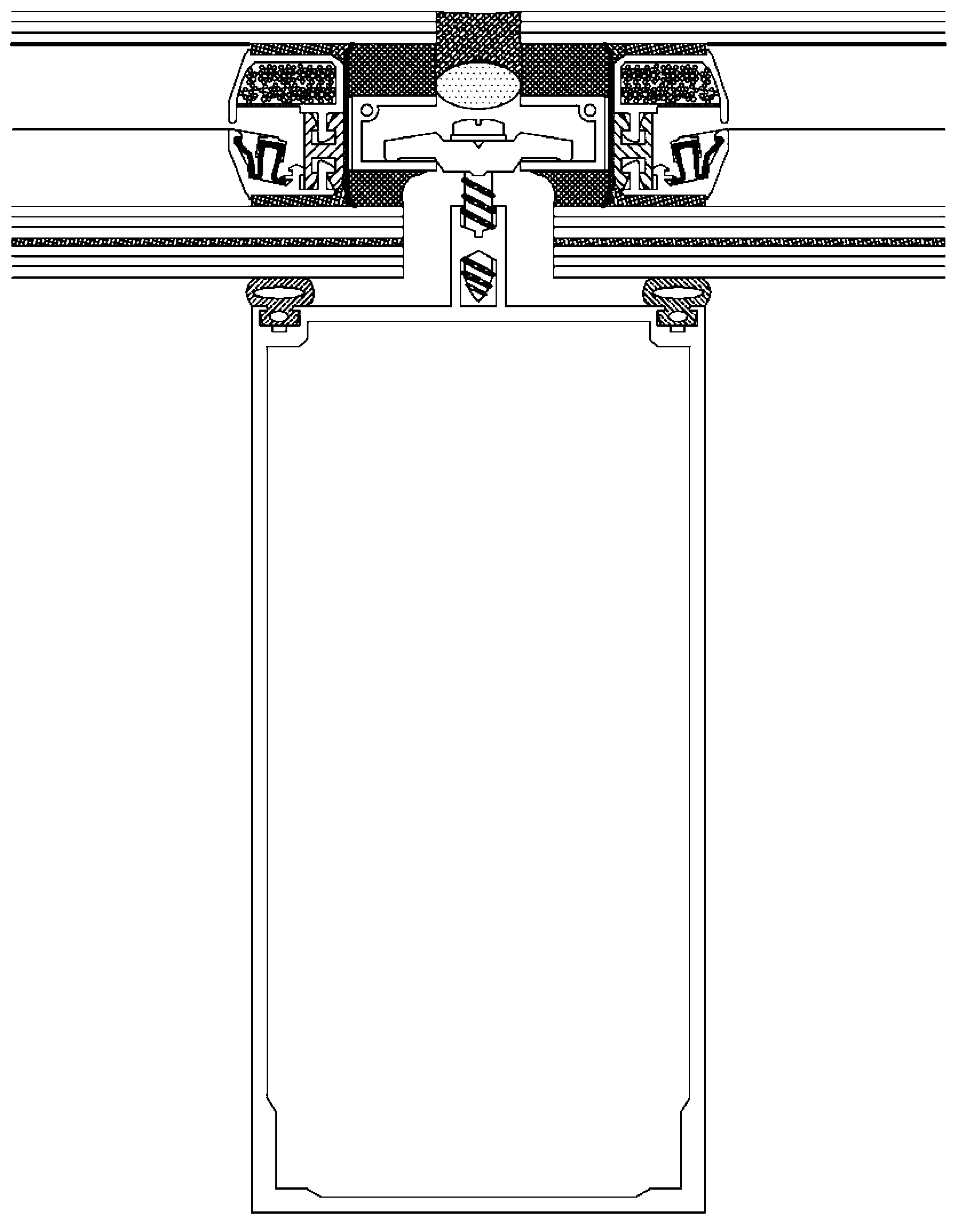

Double-hollow glass ceiling module with film suspended therein

ActiveCN103074966AConvenient lightingImprove heat insulationRoof covering using slabs/sheetsWallsMoisture condensationThermal deformation

The invention discloses a double-hollow glass ceiling module with a film suspended therein. An optical control film serves as a middle layer, and an internally suspended film structure frame, a mounting structure frame, a reinforcing separating strip and glass are sealed into an integral double-hollow glass plate. An inner structure frame and an outer structure frame are made from a novel heat-isolating material with a coefficient of thermal expansion similar to that of the glass. The internally suspended film structure frame is structurally connected through a heat-isolating bridge. A butyl rubber tape on the outer surface of the internally suspended film structure frame serves as a first sealing layer. A second sealing layer consists of the external reinforcing separating strip and a silicone structural sealant, the whole structure is always consistent to the thermal deformation of the glass, so that the sealing capability of the whole system is more reliable, and the heat-isolating property, the moisture condensation-preventing property, the sound-isolating property and the like are greatly improved. Dirt is not easily accumulated on the outer surface of a mounted ceiling, so that the ceiling is convenient to clean and maintain. The double-hollow glass ceiling module has a flexible assembling and mounting way, and can be applied to different vertical surfaces of an outer building rail.

Owner:伟视幕墙(淮安)有限公司

Production technology of gold and palladium-plated bonding copper wire for encapsulation

InactiveCN106086962AAvoid breakingConsistent deformationSolid-state devicesSemiconductor/solid-state device manufacturingCopper wireGold layer

The invention discloses a production technology of a gold and palladium-plated bonding copper wire for the field of semiconductor integrated circuit encapsulation. The production technology comprises the technological process of carrying out coarse drawing, annealing, palladium layer electroplating, fine drawing, annealing, gold layer electroplating and cleaning on a microelement-added central copper rod treated through a continuous casting technology, so as to prepare the gold and palladium-plated bonding copper wire excellent in physical and chemical property. The technological process is characterized in that only one-time coarse drawing and one-time fine drawing are carried out, and a gold plating technology is carried out after a target wire diameter is achieved through the fine drawing. According to the gold and palladium-plated bonding copper wire produced through the technology, the wire breakage rate during the drawing process is relatively low, the combination property of a palladium-plated layer and a gold-plate layer is good, and the binding reliability and stability of the bonding wire are greatly improved.

Owner:上海铭沣科技股份有限公司

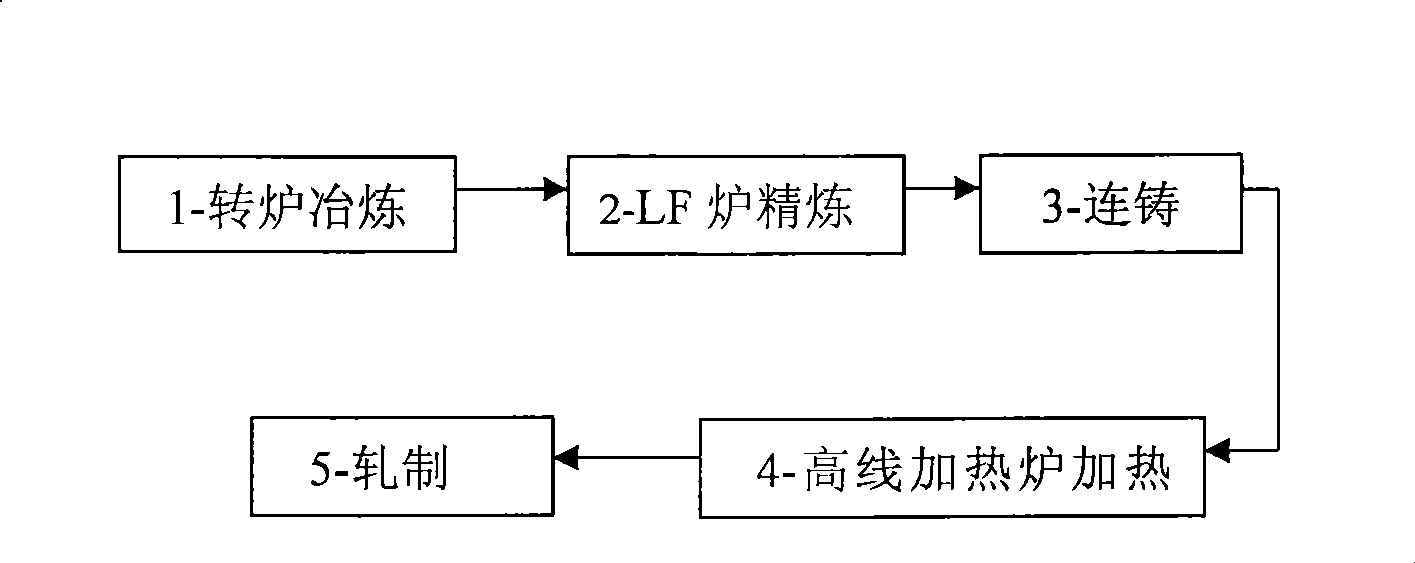

Production method of low-carbon free-cutting steel

InactiveCN101417384AUniform mechanical propertiesUniform tissueTemperature control deviceWork treatment devicesSulfideHeating furnace

The invention provides a production method of low-carbon free-cutting steel and is characterized in that when the free-cutting steel is rolled, the range of sensitive temperature of sulfide embrittlement is escaped in the heating temperature; the first heating temperature of a heating furnace of steel billets is 1050 to 1150 DEG C, the second heating temperature is 1150 to 1250 DEG C, the holding zone is provided with the temperature of 1180 to 1240 DEG C, the initial rolling temperature is 1120 to 1150 DEG C the spinning temperature is 860 to 900 DEG C and the time in the furnace is controlled to be equal to or more than 130 minutes; and delayed cooling is adopted and both a fan and a heat holding cover are shut down. The invention solves the phenomena of easy head cracking, collaring and slipping, difficult gripping, great operational difficulty, and the like in the rolling of S-system free-cutting steel, and has good cutting and processing performance.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

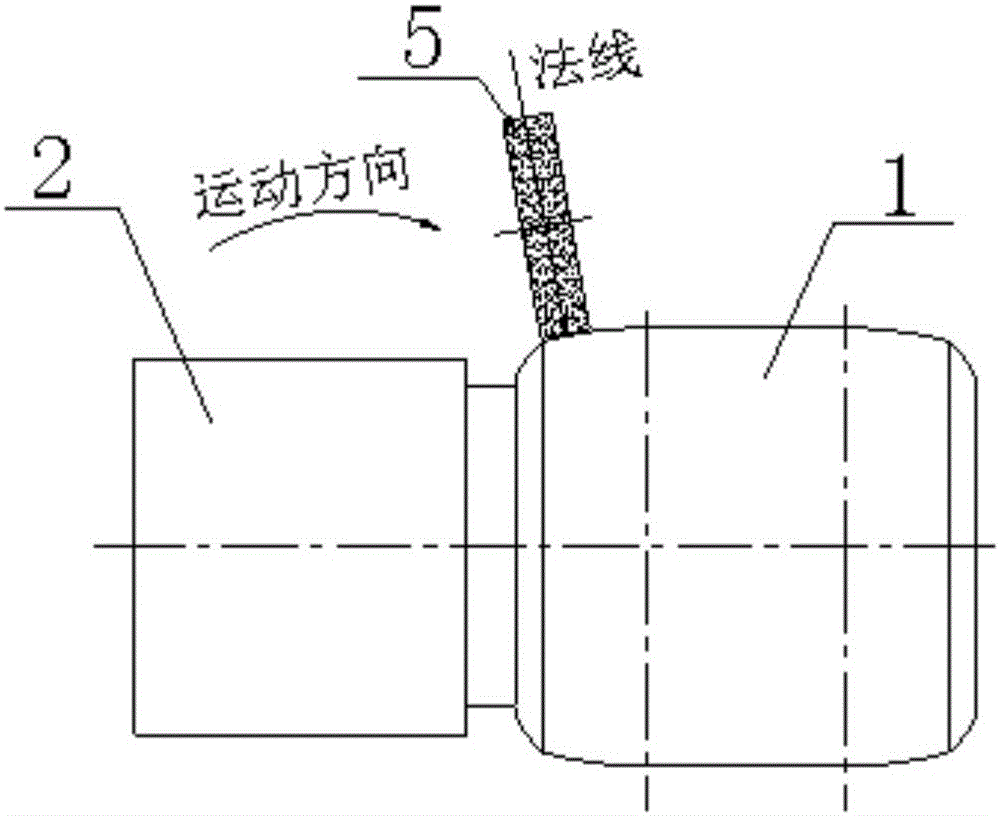

Grinding wheel normal tracing method during complex curve grinding process

InactiveCN1699020AImplement automatic normal trackingImplement normal trackingAutomatic grinding controlMathematical modelEngineering

This invention relates to an abrasive wheel normal tracing method in complex curve grind process, which is used in curve fine grinding field. The method comprises the following steps: a) adding a spinnig axis of bench sliding seat to the digital control shaft, which makes the work-piece outline alterable relative to the abrasive wheel axial cord; b) setting up mathematical model of normal tracing, computing the separation angle theta i between the outline normal line in grinding point and the radical admission shaft; c) making the bench sliding seat deflecting a certain angle with C axis, and making the abrasive wheel axial cord coincidence with the normal line of grinding point according to the theta i of each grinding point. The invention can remain the cutting status of abrasive wheel, and the abrasive wheel is forced evenly, which can avoid the interference from abrasive wheel and work-piece.

Owner:RAYMOND BEIJING VALVE MFG

Three-roller coating printing unit for continuously coating surface of base material with viscous material

ActiveCN107350121AThin and uniform glue layerReduce usageLiquid surface applicatorsCoatingsEngineeringCoating

The invention discloses a three-roller coating printing unit for continuously coating the surface of a base material with a viscous material. The unit comprises a pressing roller, a driving silica gel roller and a driving steel roller which are stacked from top to bottom. The driving silica gel roller and the driving steel roller rotate in opposite directions, and a micron order gap is kept; the driving steel roller is soaked with a colloid pond containing the viscous material, the base material is arranged between the pressing roller and the driving silica gel roller, and the base material is supported on the supporting roller and moves in the centrifugal force direction of the top vertex of the driving silica gel roller under power traction. Under the effect that the viscous material is extruded, stretched and extended through rotating rollers with the two different rotating speeds and the opposite directions, a rubber layer of the certain thickness is formed on the surface of the rubber covered roller, the material is transferred to the surface of the continuously running base material by means of the pressing roller, the thin and uniform coating is formed, and materials of the micro order and submicron order thickness and thinner materials can be uniformly sprayed to the surface of the base material.

Owner:陕西浩合机械有限责任公司

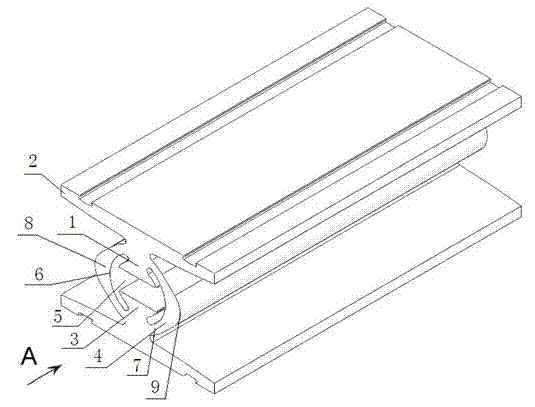

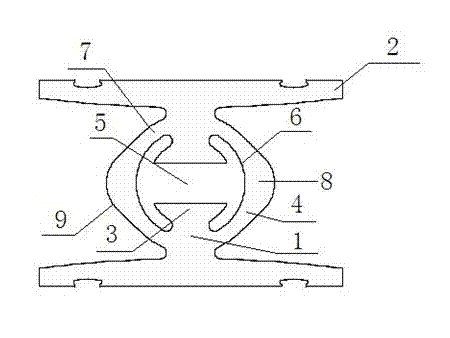

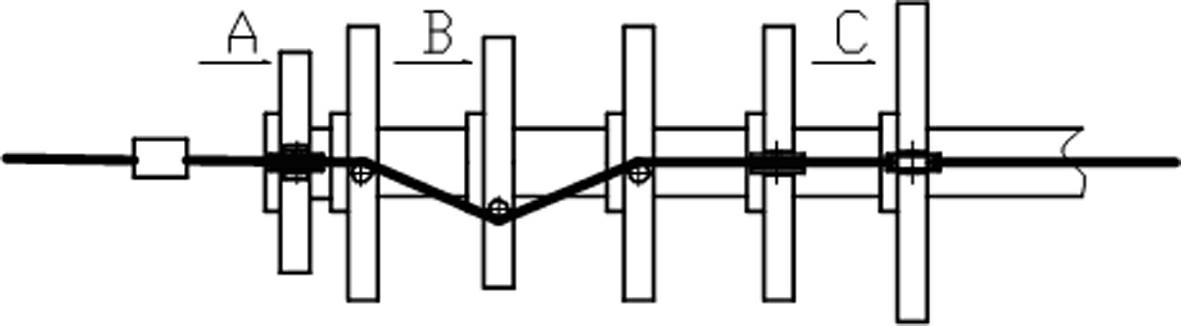

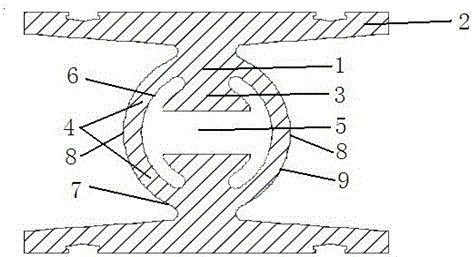

Structural member of sensor

ActiveCN102928005ASolve assembly problemsLarge deformationMeasurement apparatus componentsWeighing apparatus detailsEngineeringFlange

The invention relates to the field of a sensor, specifically to a structural member of a sensor. The structural member of the sensor is in an I-beam structure; the I-beam structurally comprises two parallel flanges, and a web which connects the two flanges, wherein the web is provided with two side walls which are located on left and right sides respectively; a hollow through hole which is parallel to the flanges is arranged in the cross section of the web; the hollow through hole is used for setting the sensor; the inner surfaces of the side walls are cambered surfaces; the curvature radiuses of the cambered surfaces of the inner surfaces of the side walls are the same; the distances between a central point of the hollow through hole and one point and between the central point of the hollow through hole and any other point on the inner surfaces are the same, wherein each side wall of the web is provided with a root part and an end part, wherein the end part is the axle wire position of the web; the end part of each side wall of the web is thicker than the root part; the thicknesses of the two side walls are symmetrical. The structure provided by the invention is characterized in that the web deformation and variation of height of the restorable through hole are increased in multiples, thus the assembly accuracy is improved and the assembly difficulty is reduced.

Owner:SICHUAN XINGDA MINKO ELECTR MECHANICAL ENG

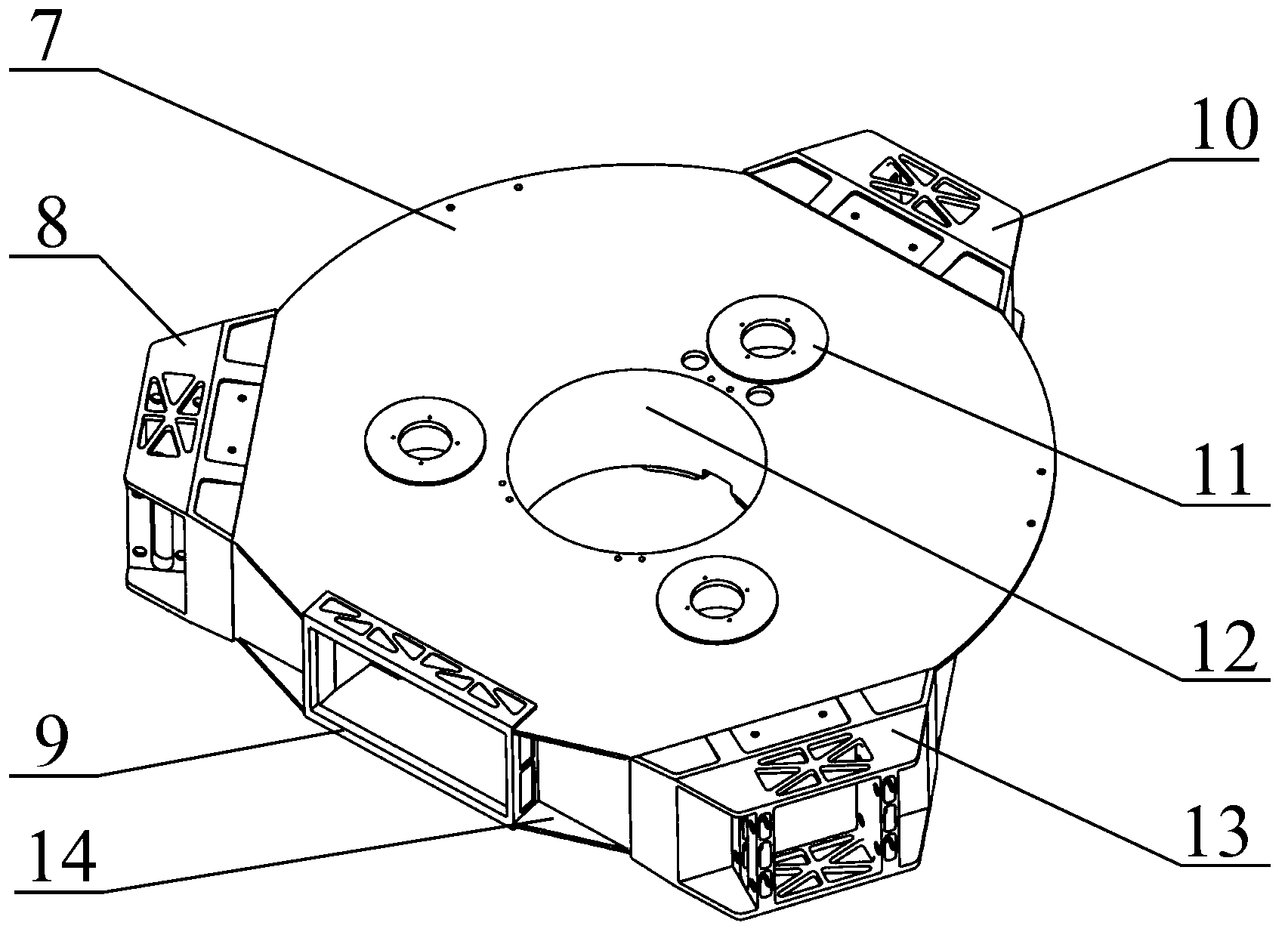

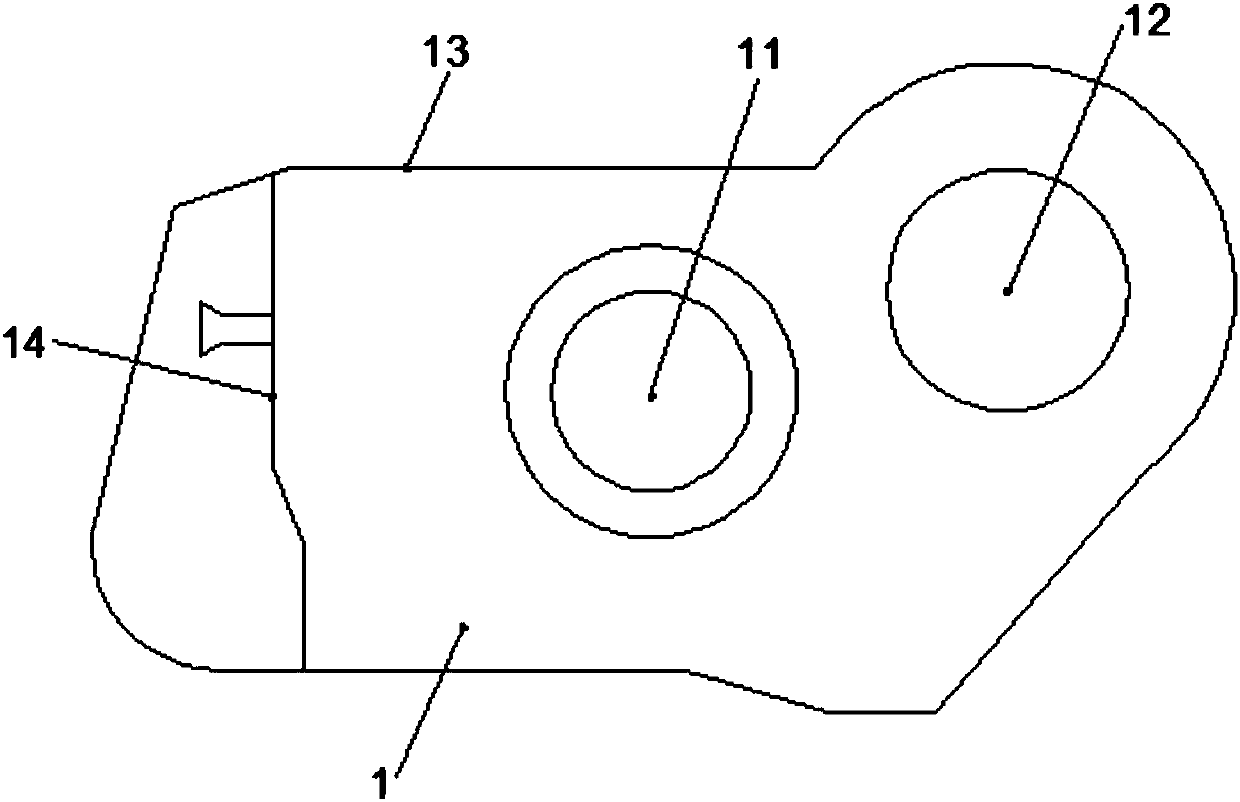

Space optical remote sensor main bearing plate structure adopting embedded part

ActiveCN102798960AImprove structural rigidityImprove structural strengthMountingsEmbedded systemMain bearing

The invention discloses a space optical remote sensor main bearing plate structure adopting an embedded part, and belongs to the technical field of space optical remote sensing, and relates to a main bearing plate structure of the embedded part. The technical problem to be solves is to provide a space optical remote sensor main bearing plate structure adopting an embedded part. The technical scheme is as follows: the structure comprises a main bearing plate front panel, a first truss embedded block, a second truss embedded block, a third truss embedded block, a three-mirror embedded block, a main mirror embedded block, a main bearing plate central hole, a main bearing plate back panel, a folded mirror embedded block, a bias current embedded block, a main mirror embedded block socket, a longitudinal bar groove, a transverse bar groove, a transverse bar and a longitudinal bar. By virtue of the embedded blocks on the main bearing plate, the corresponding mirror assemblies and the other supporting structure assemblies are mounted and located to form a main structure of the space optical remote sensor. The transverse bar and the longitudinal bar are arranged on a contact surface between each embedded block and the bearing plate, so that the effective contact area with a carbon fiber composite material is enhanced; the structure rigidity is reinforced; and the structure reliability is improved.

Owner:CHANGGUANG SATELLITE TECH CO LTD

Novel ball bearing groove curvature coefficient designing method

InactiveCN104794257AEasy to useConsistent changeSpecial data processing applicationsThree dimensional simulationBall bearing

The invention discloses a novel ball bearing groove curvature coefficient designing method. The method comprises the following steps that firstly, according to the working environment, a three-dimensional model is established by UG NX three-dimensional software; secondly, a working condition is loaded, the kinetic simulated analysis is carried out, and the rolling ball bearing load is measured; thirdly, a three-dimensional simulation model is established by the UG NX three-dimensional software, one quarter of the three-dimensional simulation model is taken to be as a finite element simulation model; fourthly, grids are divided; fifthly, a boundary loading mode and a constraint condition are carried out; sixthly, contact setting is carried out; seventhly, a solution scheme is set; eighthly, a simulation result is analyzed, the consensus of the strain of an inner ring and an outer ring of a ball bearing is guaranteed, and meanwhile structural optimizing is carried out. According to the technical scheme, the consensus of the deformation of the inner ring and the outer ring of the ball bearing is effectively guaranteed, the condition that the structural parameter is deviated from the ideal position is maximally lowered, the reliability of the performance and service life is guaranteed, and meanwhile the same service life design of bearing components is achieved.

Owner:LUOYANG INST OF SCI & TECH

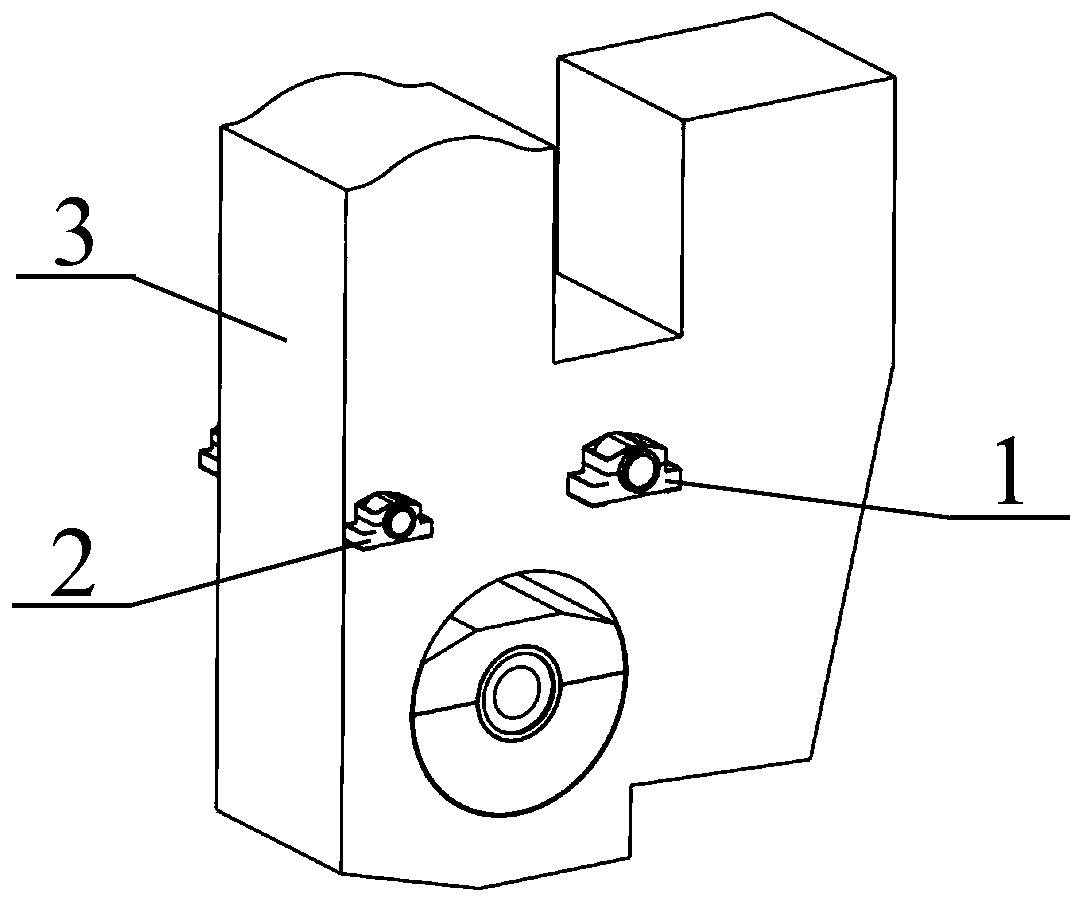

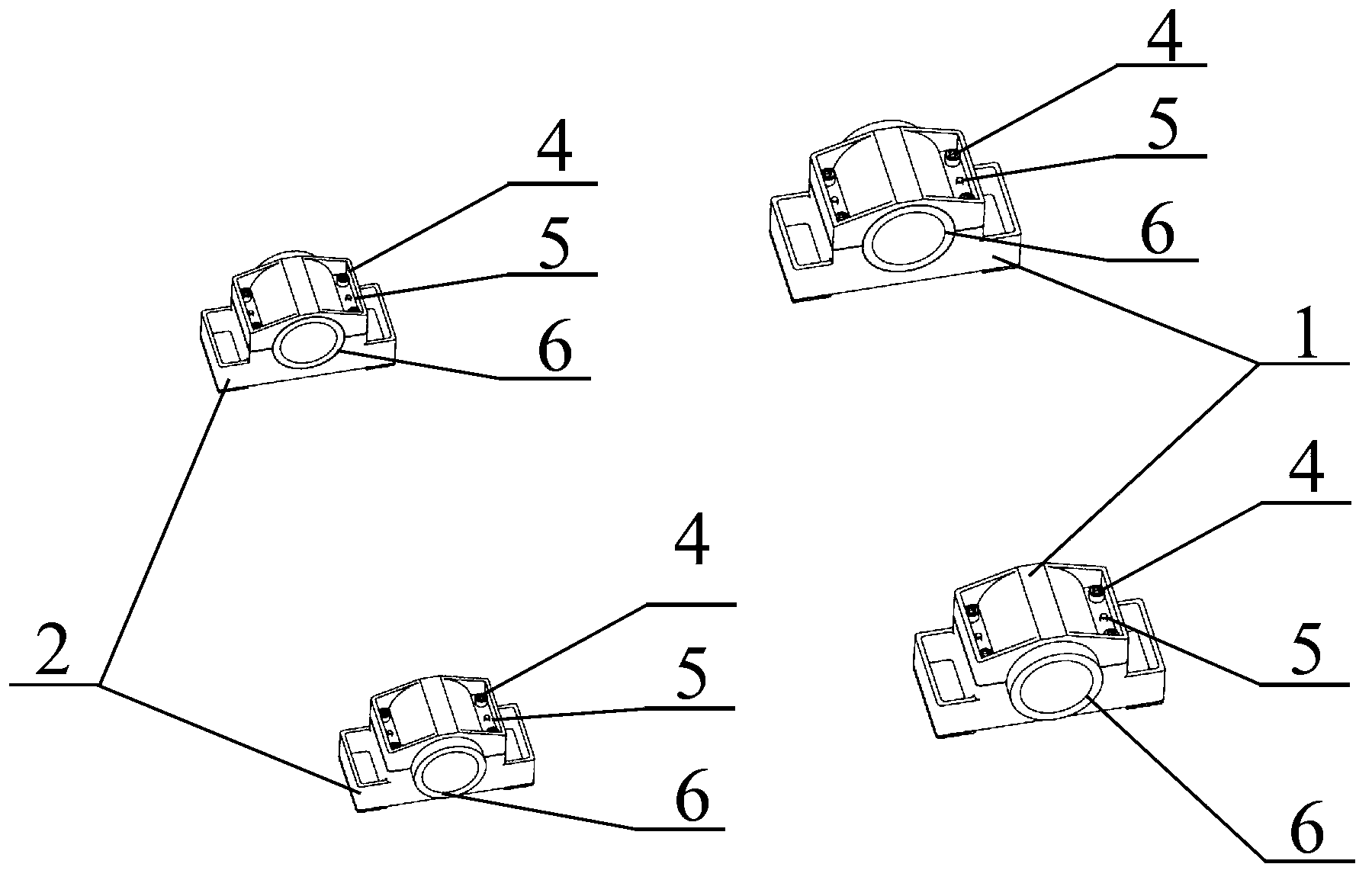

Clamp for milling joint face of gearbox shell and use method of clamp

PendingCN107791066AGuaranteed machining accuracyReduce labor intensityPositioning apparatusMetal-working holdersMachining processProcessing accuracy

The invention provides a clamp for a milling joint face of a gearbox shell and a use method of the clamp. The clamp comprises a bottom plate. Countersinks corresponding to assembling holes in the shell in position are formed in the bottom plate. A pressing device is arranged on each countersink. Fixed pressing force can be set on each pressing device. A stop dog device clamped to the turning faceof the shell and a support device with the height adjusting and height self-locking functions are arranged on the bottom plate. The use method of the clamp comprises the steps that (1), a workpiece isclamped; (2), the workpiece is tensioned by oil cylinders; and (3), the workpiece is abutted by the support device and locked. The clamp and the use method have the beneficial effects that the degreeof automation is high, the clamping pressure is fixed, the problems of tool vibration, extremely-poor flatness and the like existing in the clamping and machining processes of the thin wall shell aresolved, and the machining accuracy of the milling joint face of the gear shell is guaranteed.

Owner:CHUZHOU YUEDA IND

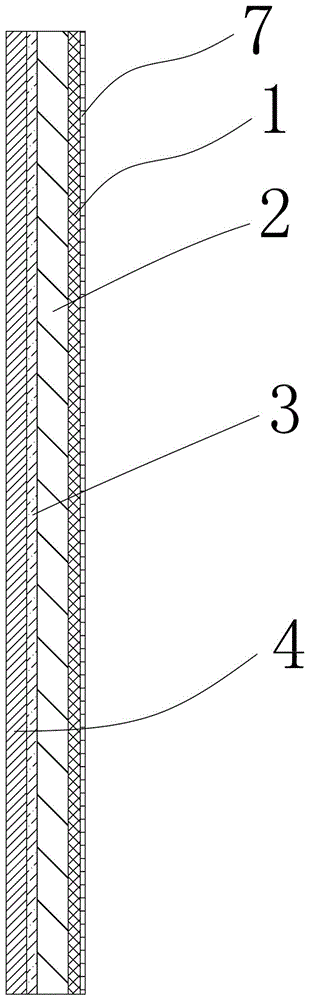

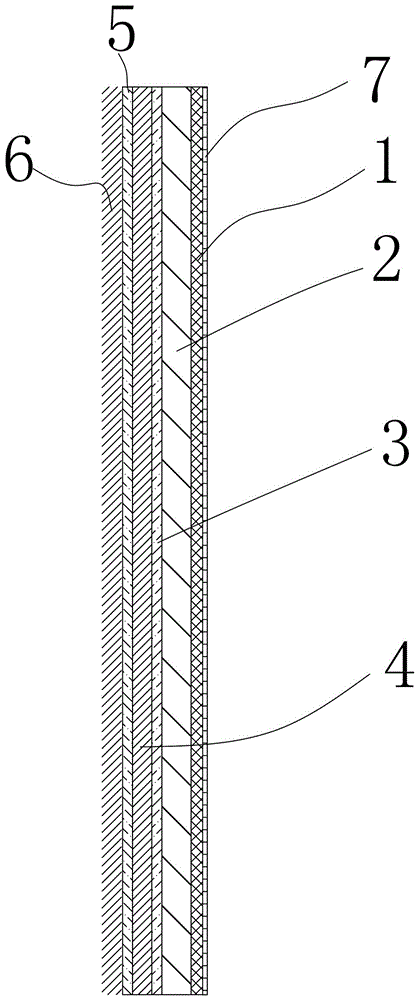

PVC wide seamless wall cloth and manufacturing method thereof

ActiveCN106758280AConsistent deformationRealize multi-color overprintLamination ancillary operationsSynthetic resin layered productsCoated surfacePolyester

The invention belongs to the technical field of veneer decorative materials and in particular relates to PVC wide seamless wall cloth and a manufacturing method thereof. The technical scheme for solving the technical problem is as follows: the cloth comprises a polyester fabric layer, a wallpaper original paper layer which fully covers the back surface of the polyester fabric layer, an aqueous glue layer between the back surface of the polyester fabric layer and the wall paper original paper layer, a PVC foamed coating coated to the front surface of the back surface of the polyester fabric and a surface printing coating arranged on the surface of the PVC foamed coating. The PVC wide seamless wall cloth provided by the invention can manufacture the PVC wall cloth in a wide manner, the width reaching 2.7-3.2m. According to demands, the width can be also made greater, or even 5-10m, continuous production of the whole batch of cloth can be made in the length direction to integrally realize the requirement of seamless width, so that seamless paving in the upper and lower directions and the peripheral direction of a decorative space is realized.

Owner:ZHEJIANG LIANXIANG EMBROIDERY CO LTD

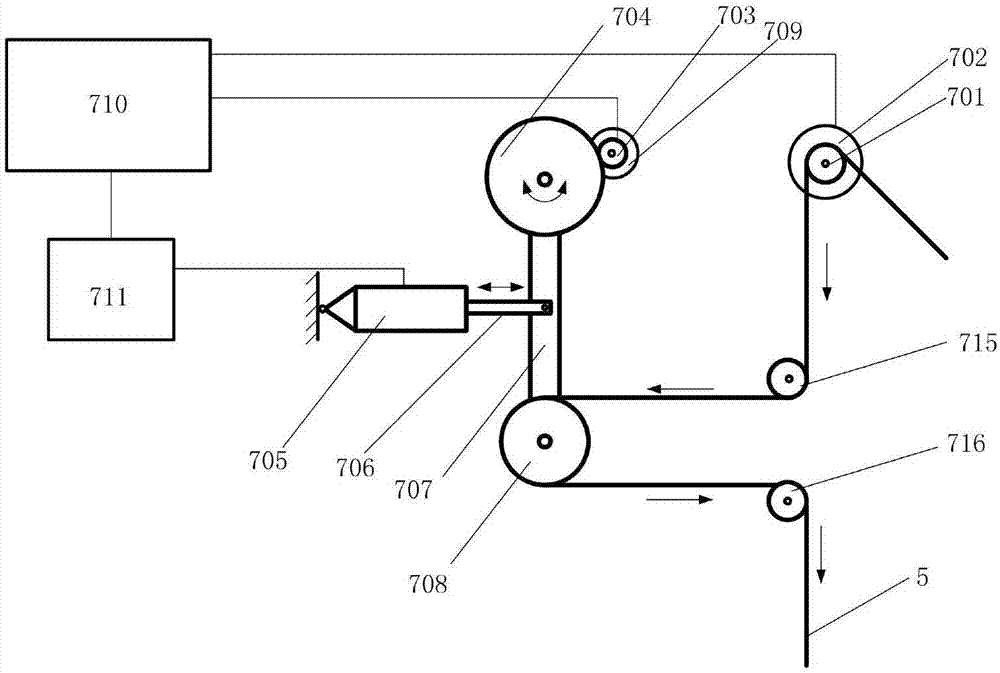

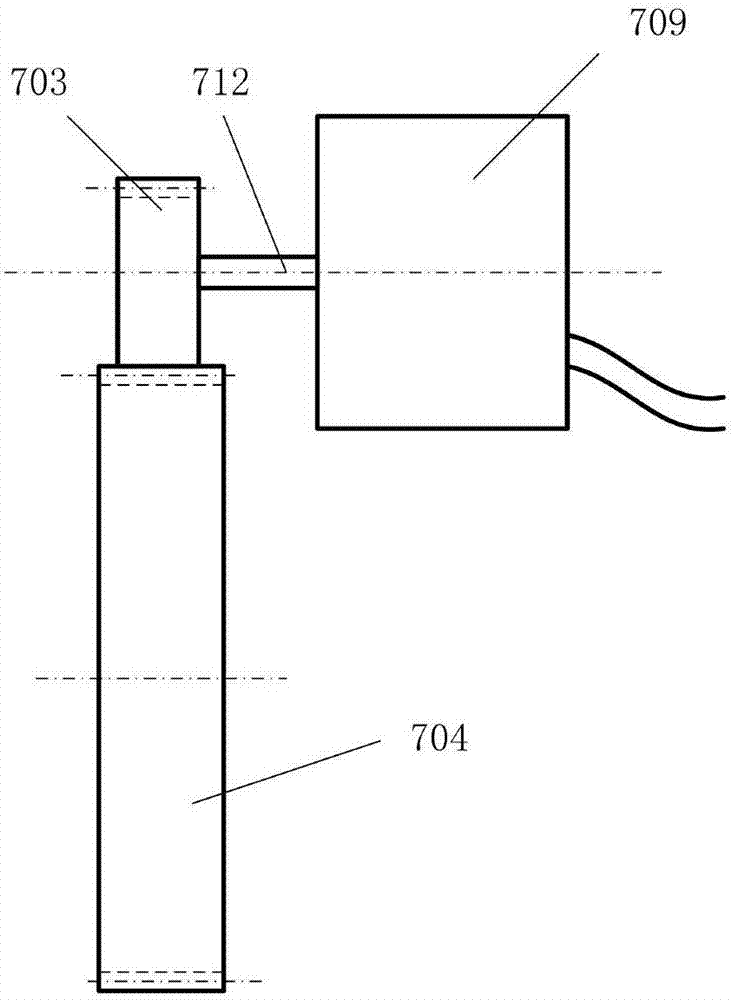

Automatic foot pad pressing machine

ActiveCN104440031AConsistent deformationUniform downforceMetal working apparatusMechanical engineeringEngineering

The invention relates to the technical field of electronic product production equipment, and provides an automatic foot pad pressing machine. The automatic foot pad pressing machine comprises a pressing mechanism, a conveying mechanism and an electronic control module. The pressing mechanism comprises a support. A pressing plate and a driving component are arranged on the support. Guide rods are arranged on the support. The guide rods are connected with the pressing plate through knuckle bearings respectively. The knuckle bearings are sleeved with balance pressure springs. The conveying mechanism is adopted to convey foot pads to the position below the pressing plate, and the driving component drives the pressing plate to press the foot pads downwards under the control of the electronic control module. The balance pressure springs can automatically adjust deformation to adapt to the different foot pads whether the surfaces of the foot pads are planes or inclined faces. In this way, the automatic food pad pressing machine is simple in structure, easy to operate, convenient to maintain, stable in work, high in reliability, small in labor intensity and high in production efficiency, and the pressing-in effect of the foot pads and the product quality are ensured.

Owner:SHENZHEN GONGJIN ELECTRONICS CO LTD

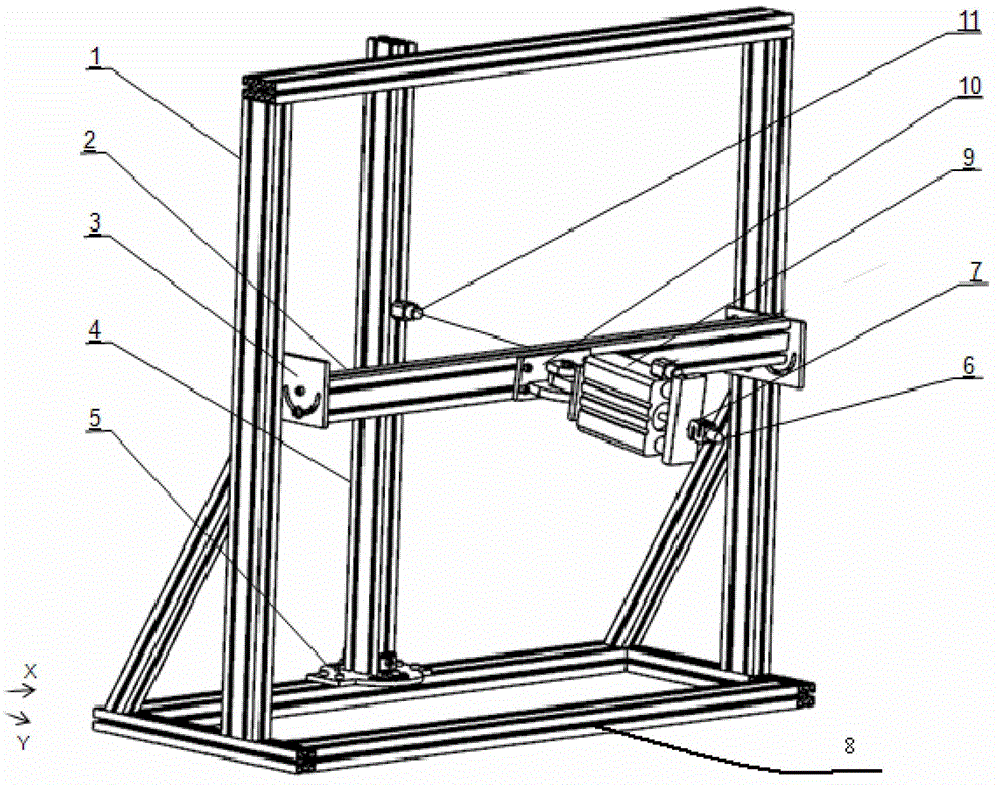

Rack for testing anti-sinking rigidity of side surface of vehicle body

InactiveCN102944469AEliminate the effects ofImprove test accuracyInvestigating material hardnessEngineeringActuator

The invention provides a rack for testing the anti-sinking rigidity of the side surface of a vehicle body. The rack comprises a chassis, and a vertical frame and an upright post which are fixedly connected with the chassis, wherein transverse beam mounting plates are connected with the vertical frame; two ends of a transverse beam are connected with the vertical frame through the transverse beam mounting plates; an actuator mounting seat is connected with the transverse beam in manner of adjusting the relative position; the actuator mounting seat comprises a fixing seat, a movable seat and a hinge pin; the fixing seat is fixedly connected with the transverse beam; the fixing seat is hinged with one end of the movable seat and can be fixedly connected with the movable seat; the other end of the movable seat is fixedly connected with an actuator; the actuator is connected with a test head; a force sensor is arranged between the test head and the actuator; and a transverse beam transformation displacement sensor is arranged between the upright post and the transverse beam and is used for testing the deformation of the transverse beam during a rigidity test. The rack is simple in structure, easy to operate, high in adaptability and low in cost, and can effectively test the anti-sinking rigidity of the side surface of the vehicle body.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

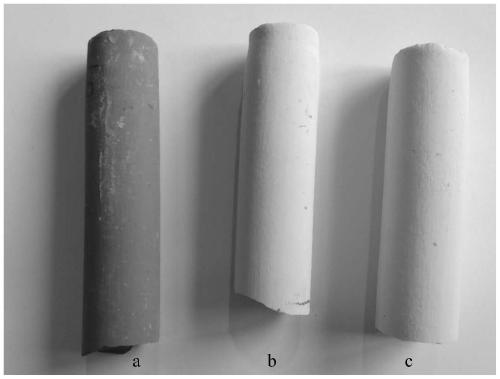

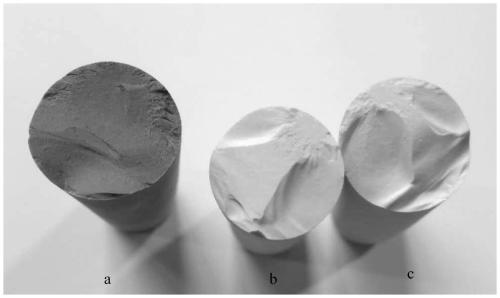

Formula for producing post porcelain insulator by using industrial alumina powder instead of high-quality alumina powder by dry method and preparation method and application thereof

The invention relates to a formula for producing a post porcelain insulator by using industrial alumina powder instead of high-quality alumina powder by a dry method and a preparation method and application thereof, and belongs to the technical field of insulators. The formula for producing the post porcelain insulator by using the industrial alumina powder instead of the high-quality alumina powder in the dry method comprises, by weight, 12-16% of the industrial alumina powder, 28-36% of kaolin, 28-36% of flux mineral, 18-22% of elutriation soil, 0.5-3% of an additional mineralizer and 0.15-0.4% of a dispersant, wherein the mineralizer is one or more of barium salt, magnesium salt or talc. By the adoption of the formula for producing the post porcelain insulator by using the industrial alumina powder instead of the high-quality alumina powder by the dry method, the design is simple and scientific; a prepared product has small intensity dispersibility and high intensity; a formed blankis uniform in density and low in internal stress; and meanwhile, the invention provides the simple and convenient preparation method and application.

Owner:SINOMA JIANGXI ELECTRICAL PORCELAIN ELECTRIC CO LTD

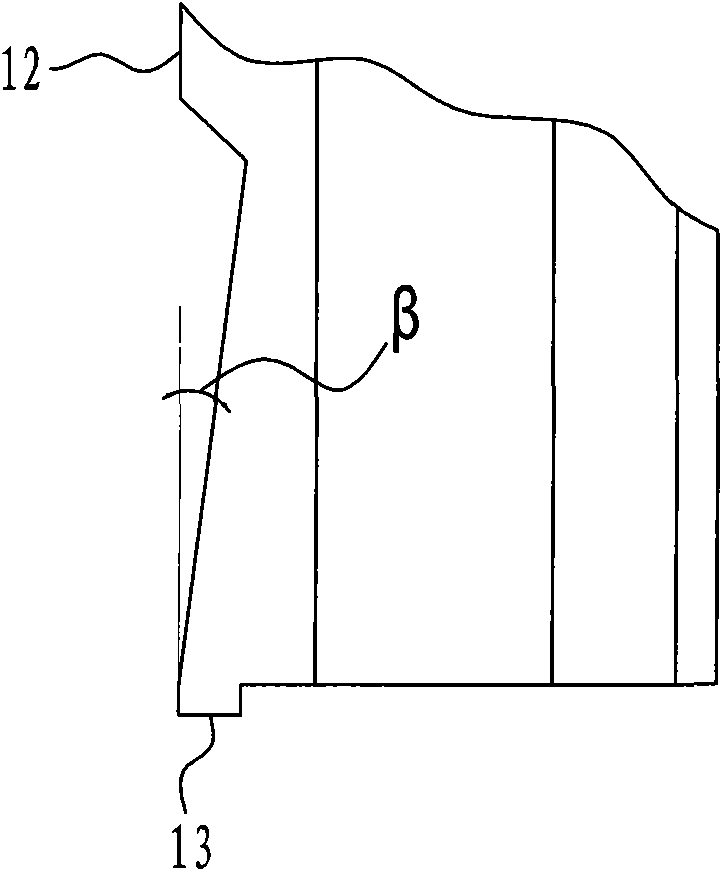

Ultra thin reed forming die

InactiveCN101569909AControl Geometric AccuracyControl Geometric ToleranceShaping toolsVertical planeStress point

The invention relates to an ultra thin reed forming die, comprising an upper die and a lower die which are connected and are provided with a plurality of upper cores and lower cores; the upper die and the lower die are provided with connected reed support positioning surfaces which are configured mutually and are vertical to the moving direction of the upper core and the lower core; the lower end of the front vertical plane of the upper core is provided with a springback angle beta which is inclined inwards along the moving direction; the bottom surface of the upper core is provided with a springback surface which is vertical to the moving direction; the upper end of the rear vertical plane of the lower core is provided with a prebending angle alpha which is inclined outwards along the moving direction; the rear vertical plane of the lower core and the front vertical plane of the upper core correspond; the cross section of the upper core is set as a section with arc rectangles at the front side and the rear side; and the springback angle beta and the springback surface are arranged at the front side of the arc section. The invention has the advantages of being capable of greatly improving geometric accuracy and geometric tolerance of the reed in the process of bending and pressing, and being capable of realizing the accordance of stress points and deformation amount of a plurality of reeds between the upper die and the lower die, thus being capable of greatly improving qualification rate of products and reducing the cost of products.

Owner:NINGBO JCT ELECTRONICS

Inorganic adhesive for concrete interface

The inorganic concrete interface binder consists of mainly active powder material, cement and surfactant, the active powder material is one or the composite of slag, zeolite powder, flyash, silicon powder and other active material; the surfactant is one or the composite of lignin, naphthalene, resin, molasses, chlorine salt, sulfate and organic amine; and cement used is high strength cement. The binder adheres new and old concrete parts into one integral, and the interface between the new and old concrete parts has tensile strength greater than that of the concrete itself. The binder has the same deformation as concrete, good endurance, easy construction, low cost, no toxicity and other features. It may be used widely in the interface between new and old concrete.

Owner:WUHAN UNIV

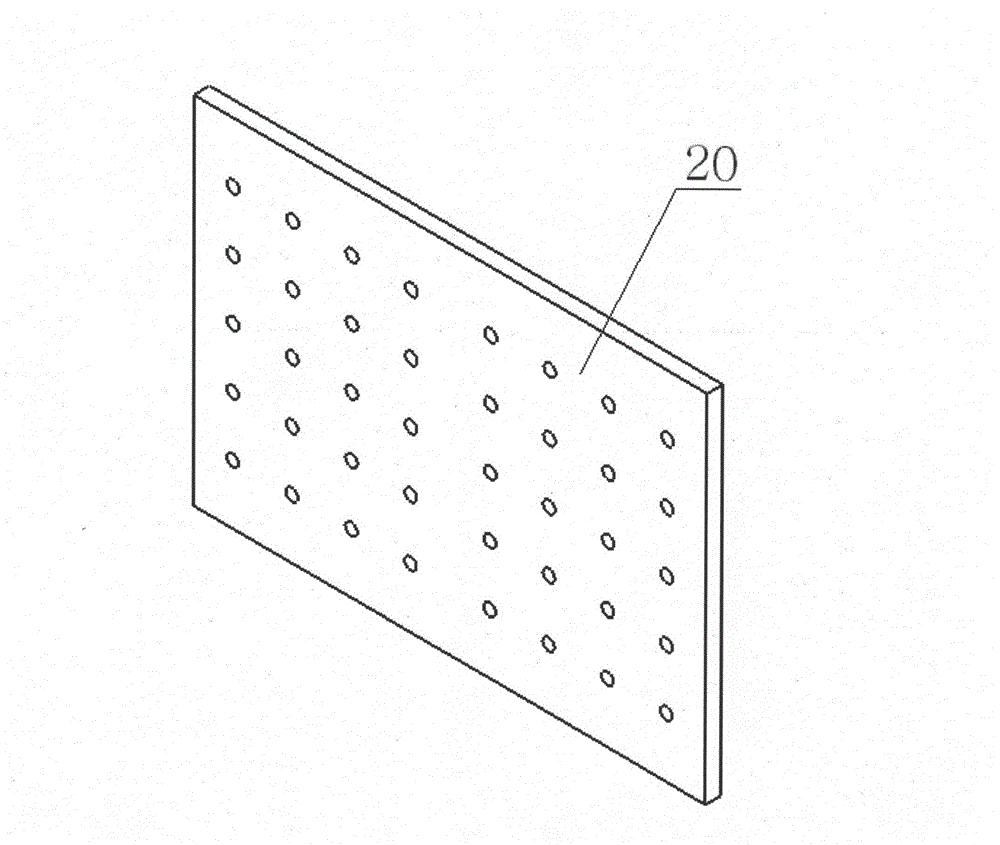

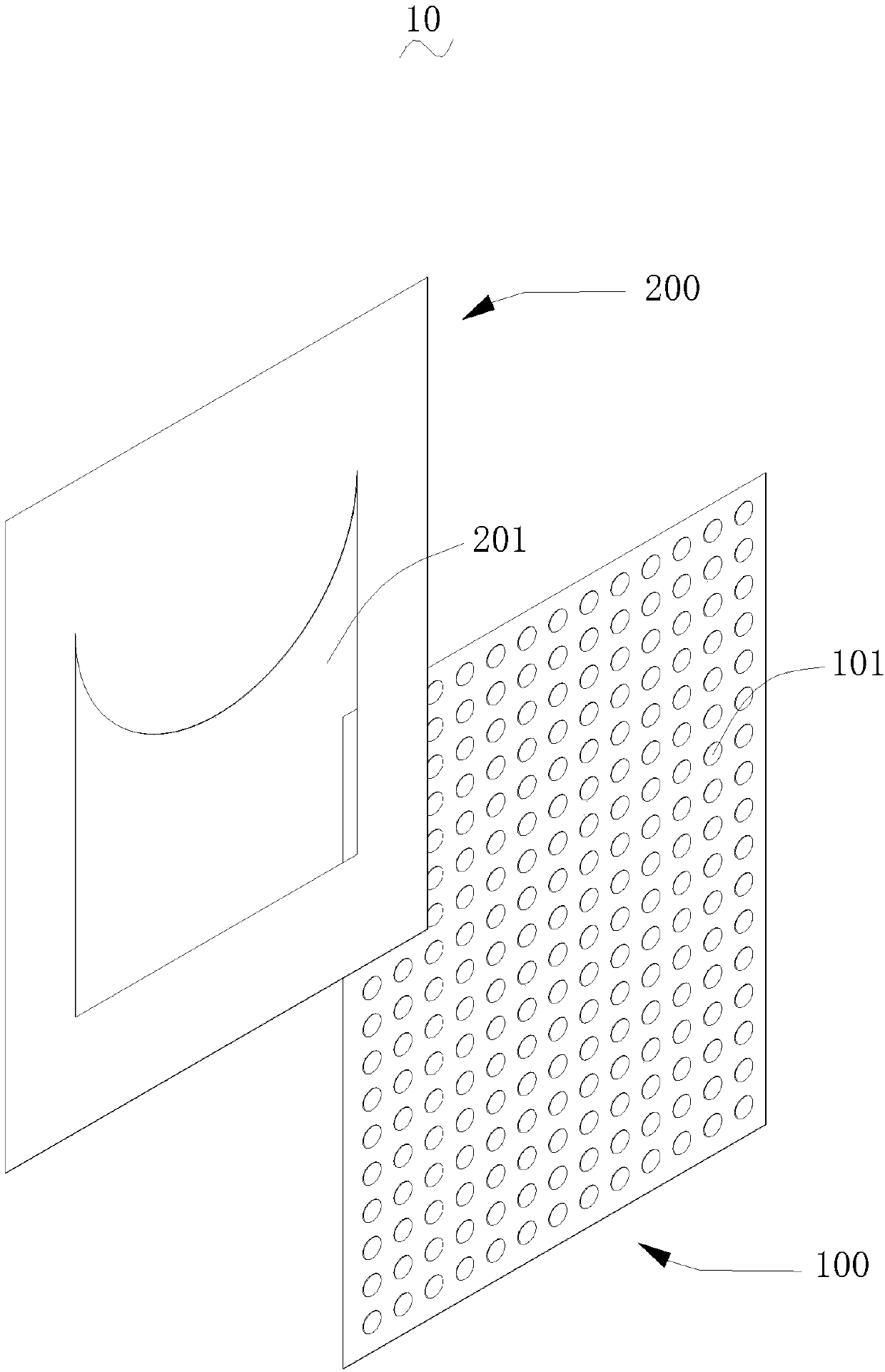

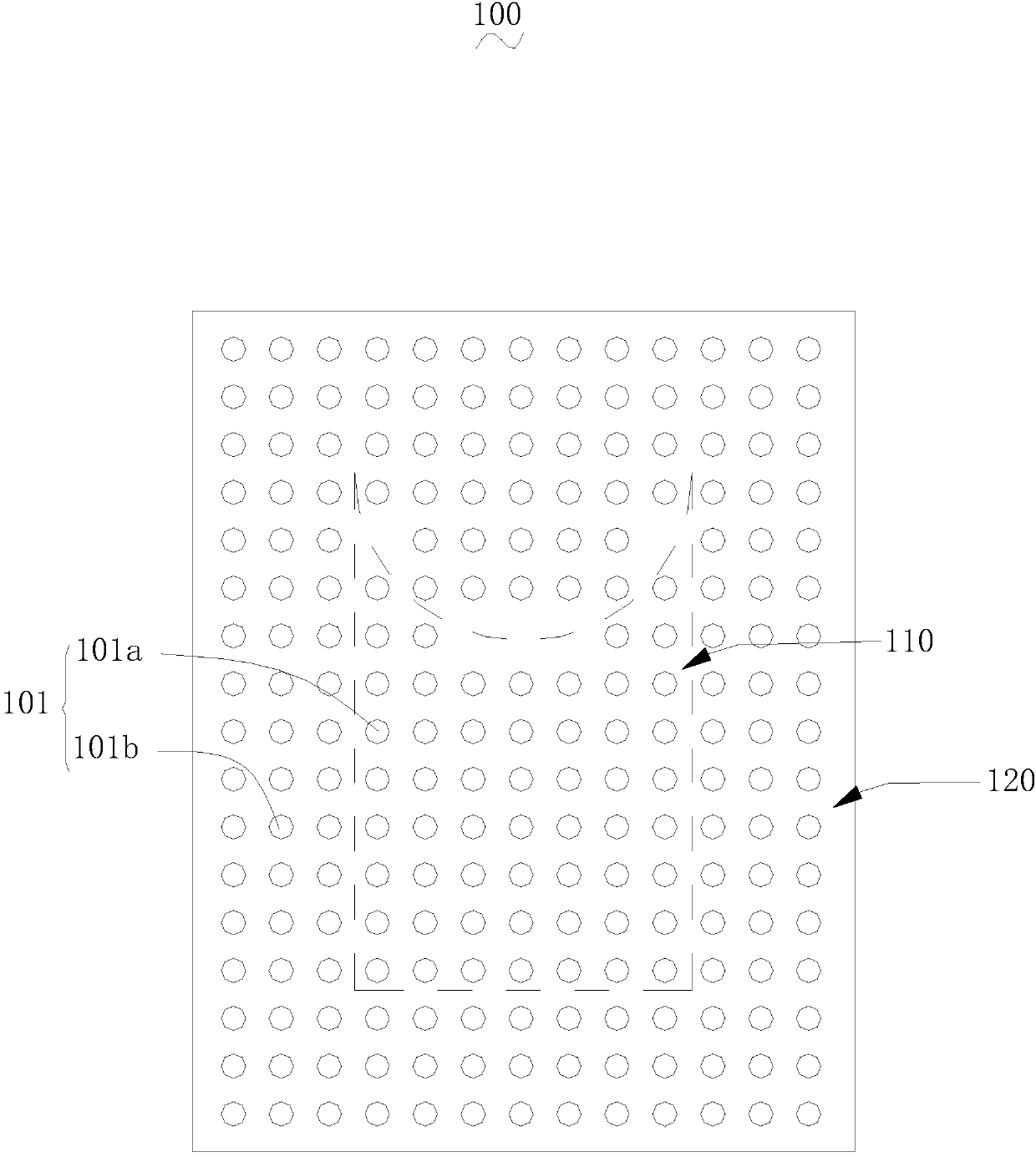

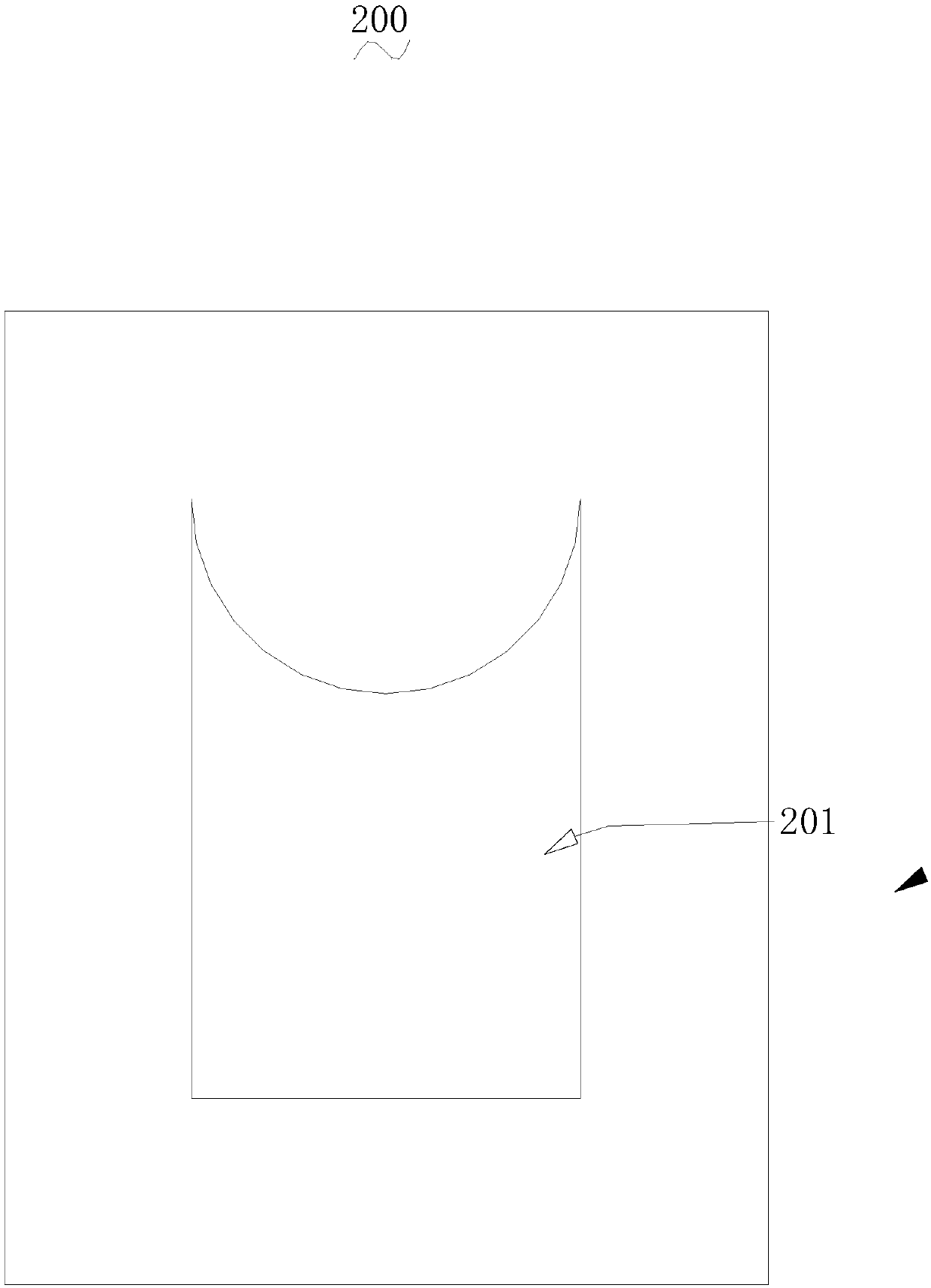

Mask device

InactiveCN107808936ASame mechanical propertiesConsistent deformationSolid-state devicesVacuum evaporation coatingEngineeringMechanical property

The invention relates to a mask device comprising a mask plate and a shielding member. The mask plate is evenly provided with multiple through holes. The shielding member is connected with the mast plate in an abutting way. The shielding member is provided with a port of which the shape is irregular. The port is aligned with a part of through holes on the mask plate and the port is communicated with all the aligned through holes. The shielding member is arranged on the rest part of through holes on the mask plate in a shielding way. The mask plate is evenly provided with the through holes so that all parts of the mask plate are enabled to have the same mechanical property, the overall deformation of the mask plate is enabled to be consistent and wrinkling can be avoided. Besides, the irregularly shaped port of the shielding member is adaptive to the special-shaped AA region of the display screen, the organic material can be vapor-deposited on the substrate through the port and the through holes aligned with the port in turn and the through holes shielded by the shielding member can effectively shield the organic material so that the special-shaped AA region of irregular shape can be formed on the substrate and the vapor deposition effect of the display screen equipped with the special-shaped display region is enabled to be better.

Owner:TRULY HUIZHOU SMART DISPLAY

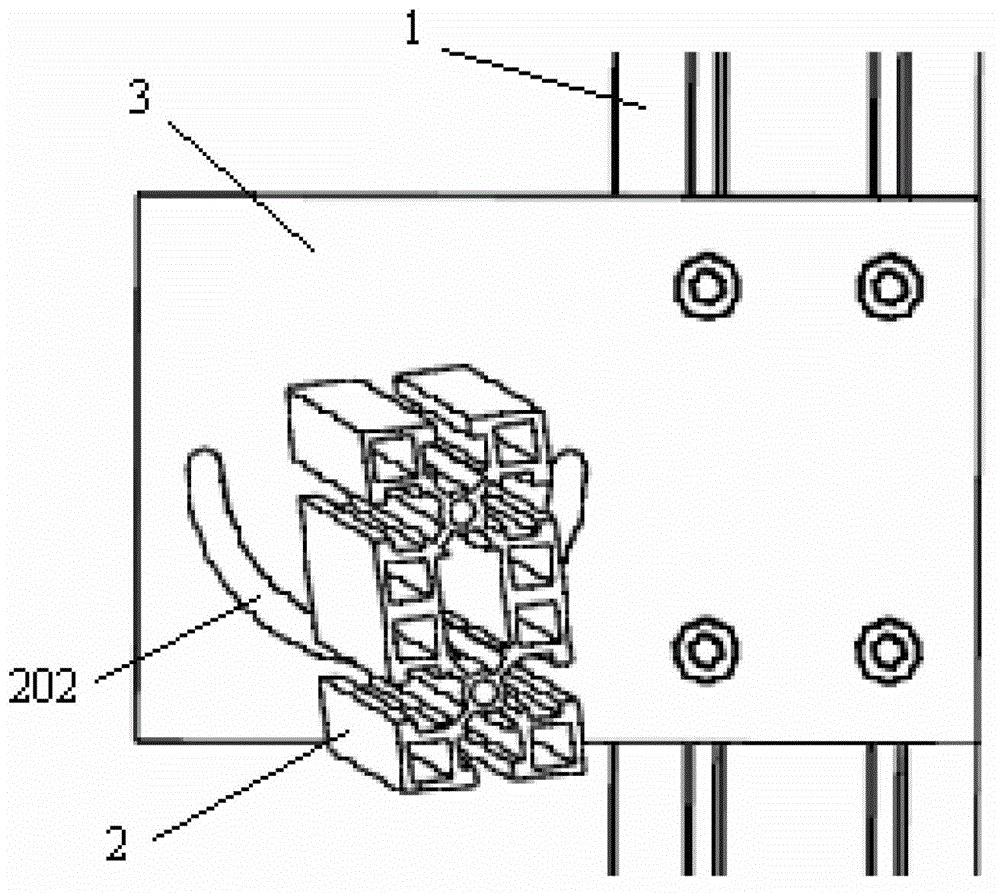

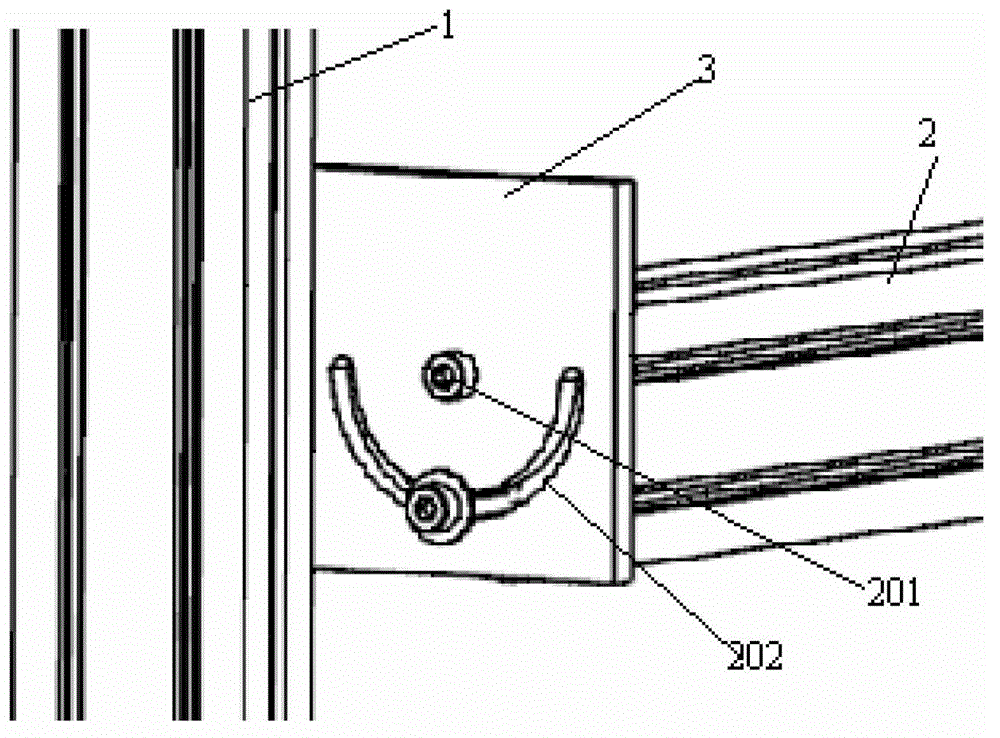

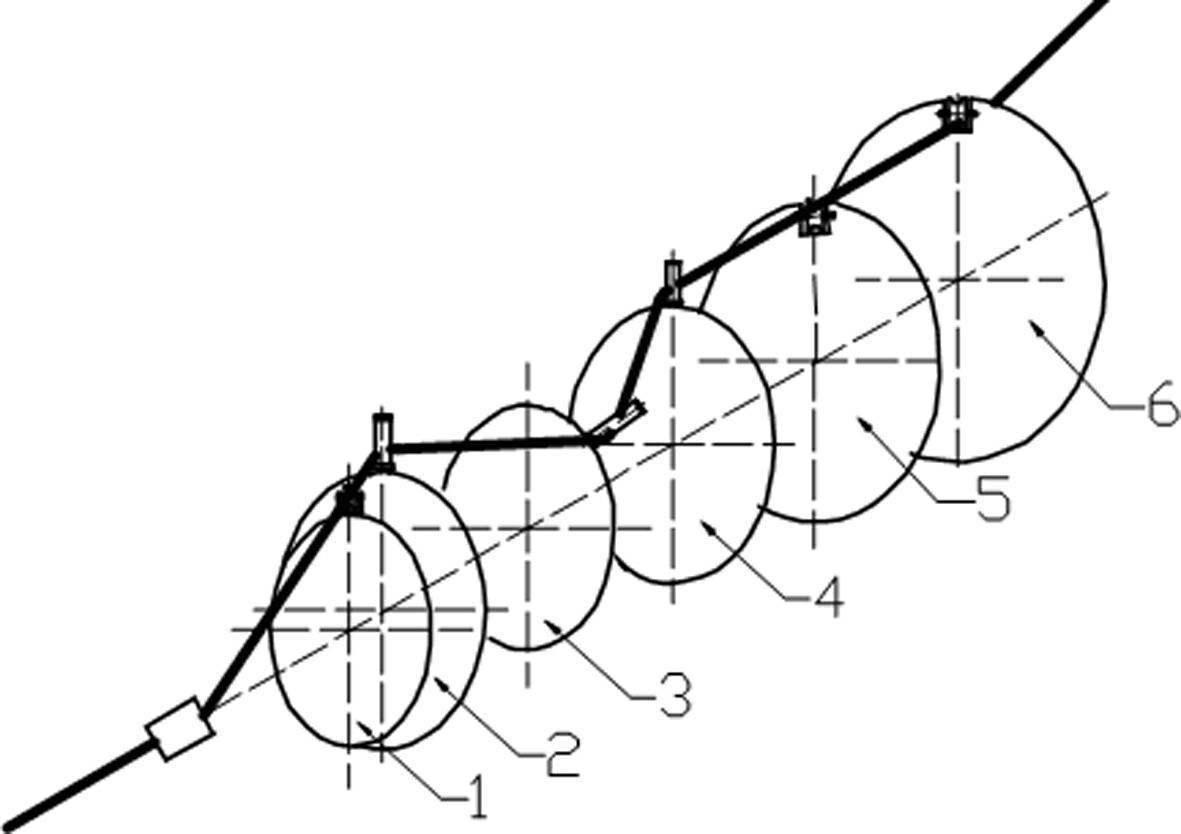

Horizontal adjustment stranded wire pre-twisting device and method thereof

ActiveCN102682930AAdvanced technologySimple structureCable/conductor manufactureClassical mechanicsStructural engineering

Owner:武汉电缆有限公司

Lithium-ion battery

InactiveCN101562262ASuppress local deformationSuppresses thickness variationFinal product manufactureSecondary cellsPolyvinylidene fluorideLithium electrode

The invention discloses a lithium-ion battery which is provided with a shell and an electrolyte and an electric core that are wrapped in the shell; the electric core consists of one or more monomer cores; the monomer core consists of two or more complexes; the complex is prepared by the superposed arrangement and pressing of a positive plate, a diaphragm paper and a negative plate; two sides of the diaphragm paper are provided with a bonding layer respectively; and the bonding layer uses polycarboxylic tetrafluoroethylene or polyvinylidene fluoride as preparation material. The lithium-ion battery has the advantages of being not easy to deform when in use.

Owner:深圳市普天通数码实业有限公司

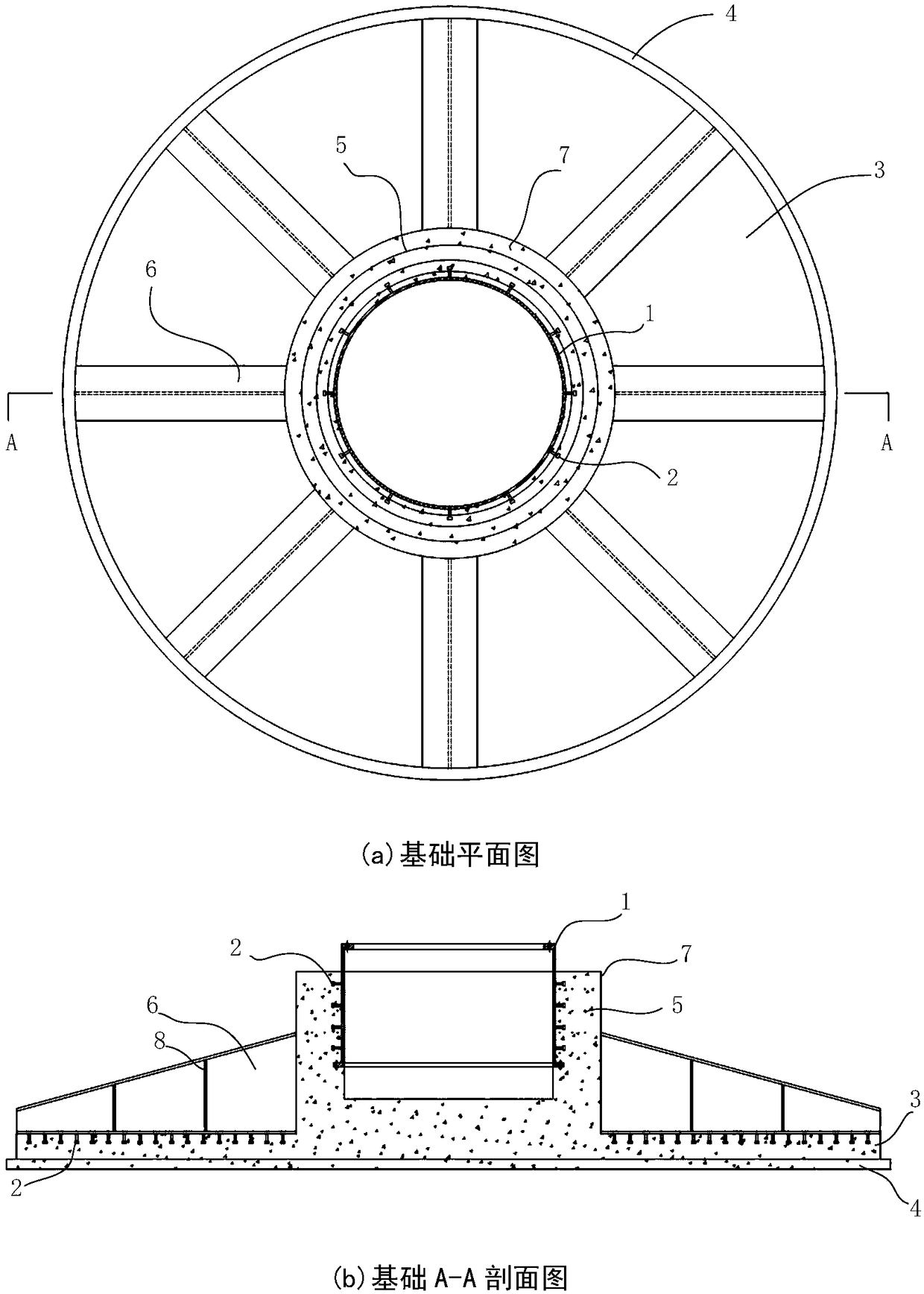

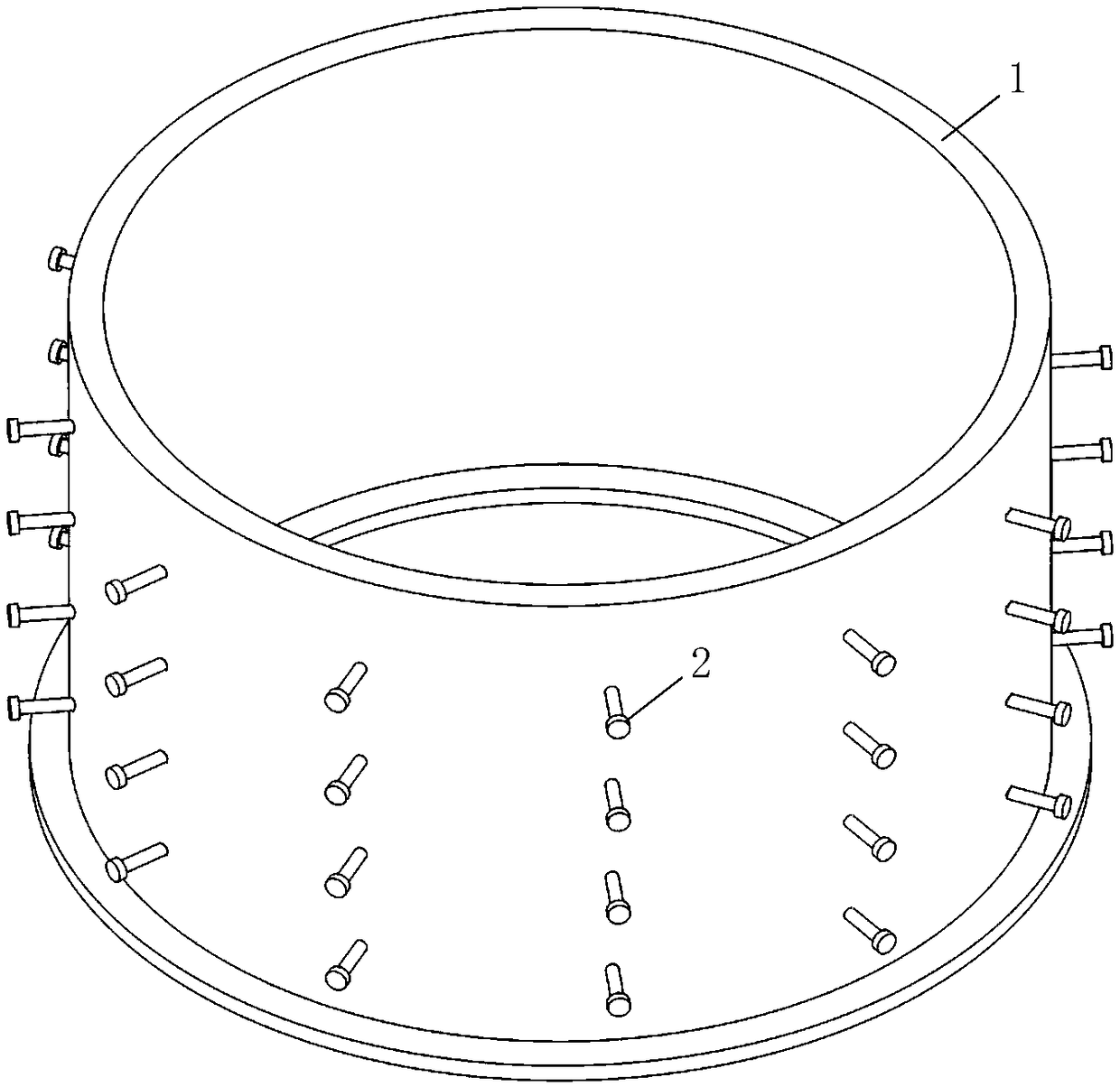

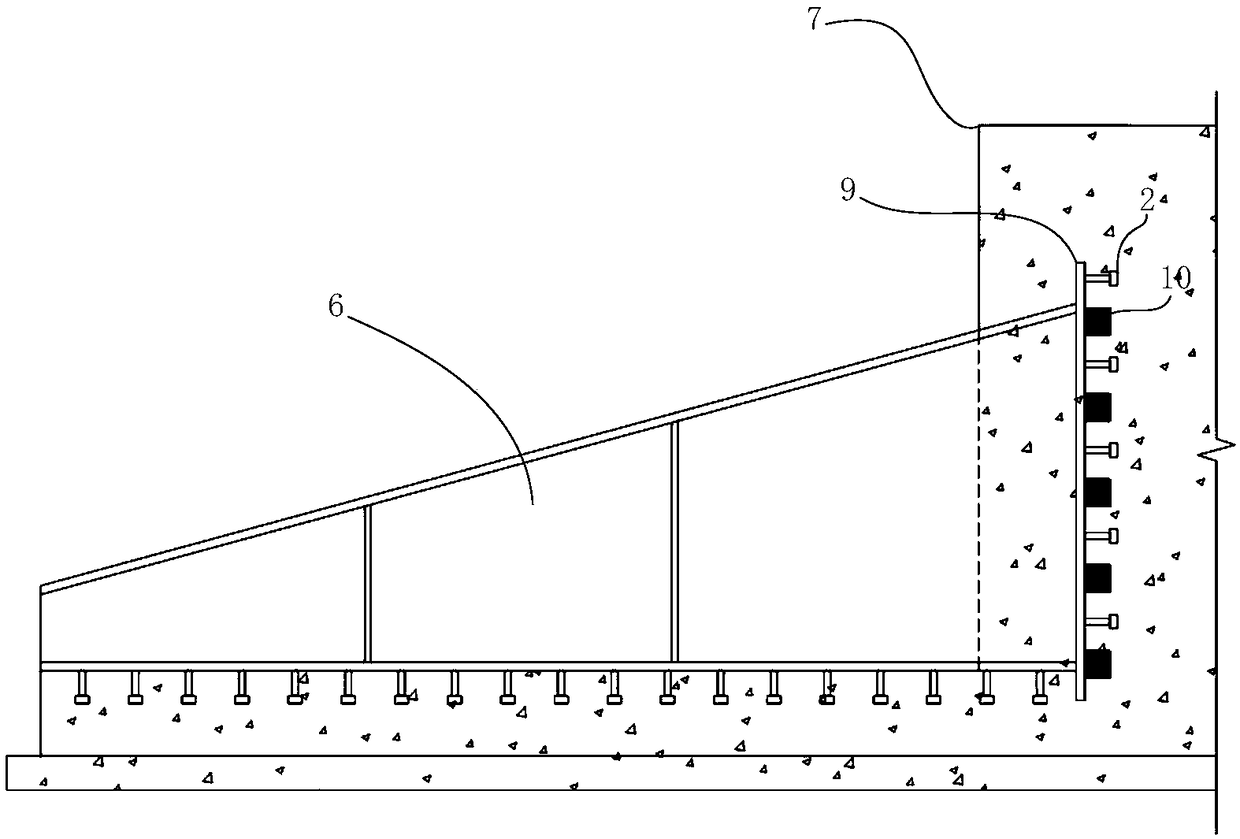

Wind power tower drum foundation ring ribbed beam type foundation based on combined structure

The invention discloses a wind power tower drum foundation ring ribbed beam type foundation based on a combined structure, and relates to the technical field of onshore wind power generation. The system comprises a foundation ring, a circular concrete floor, a variable-cross-section H-shaped steel rib beam, a hollow concrete pillar, a toggle pin and a square steel shear connector. The foundation ring is connected with a wind power tower drum on the upper part, and a perforation reinforcing steel bar required by a traditional basic ring is removed and replaced with the prefabricated welding toggle pin, so that the basic ring and a foundation concrete form effective connection by utilizing favorable shearing resistance and pulling resistance of the toggle pin, and the construction difficultyin reinforcing steel bar perforating on site is remarkably reduced. The variable-cross-section H-shaped steel rib beam is connected with a foundation slab and the pillar through the shear connector so as to form a combined structure stress system, so that the mechanical characteristics of two materials are fully played, and larger internal force produced by the upper load can be resisted. The foundation system can be applied to a circular bearing platform of a circular spread foundation or a pile foundation, and is high in on-site construction efficiency and material-saving so as to have a good engineering application prospect.

Owner:CHONGQING UNIV

Machining method for aviation high-precision bearing roller

InactiveCN106181678AEasy to tilt and swivelImprove balanceGrinding drivesGrinding machinesAviationStress conditions

The invention discloses a method for processing aviation high-precision bearing rollers, which is characterized in that a clamping position is set at the end of the roller, a swinging part is set on the workbench, the roller is installed on the swinging part through the clamping position, and the swinging part The rotation makes the roller axially inclined, and the rotation direction of the grinding wheel always coincides with the normal direction at the grinding point of the sinking contour of the roller, ensuring that the grinding wheel and the roller are always in point contact. In the method for processing aviation high-precision bearing rollers described in the present invention, a clamping position is set at the end of the roller, which is convenient for clamping the roller to make it tilt and rotate, and the grinding wheel and the surface of the roller are ground by point contact, and the grinding force And the grinding heat is small, the force of the grinding wheel is consistent, the deformation is consistent, the machining accuracy is effectively improved, and the error distribution on the surface of the roller is evenly distributed to ensure that the roller has a good balance when it rotates at a high speed.

Owner:成都芬尼克兹机电设备有限公司

A sensor structure

ActiveCN102928005BSolve assembly problemsLarge deformationMeasurement apparatus componentsWeighing apparatus detailsEngineeringFlange

The invention relates to the field of a sensor, specifically to a structural member of a sensor. The structural member of the sensor is in an I-beam structure; the I-beam structurally comprises two parallel flanges, and a web which connects the two flanges, wherein the web is provided with two side walls which are located on left and right sides respectively; a hollow through hole which is parallel to the flanges is arranged in the cross section of the web; the hollow through hole is used for setting the sensor; the inner surfaces of the side walls are cambered surfaces; the curvature radiuses of the cambered surfaces of the inner surfaces of the side walls are the same; the distances between a central point of the hollow through hole and one point and between the central point of the hollow through hole and any other point on the inner surfaces are the same, wherein each side wall of the web is provided with a root part and an end part, wherein the end part is the axle wire position of the web; the end part of each side wall of the web is thicker than the root part; the thicknesses of the two side walls are symmetrical. The structure provided by the invention is characterized in that the web deformation and variation of height of the restorable through hole are increased in multiples, thus the assembly accuracy is improved and the assembly difficulty is reduced.

Owner:SICHUAN XINGDA MINKO ELECTR MECHANICAL ENG

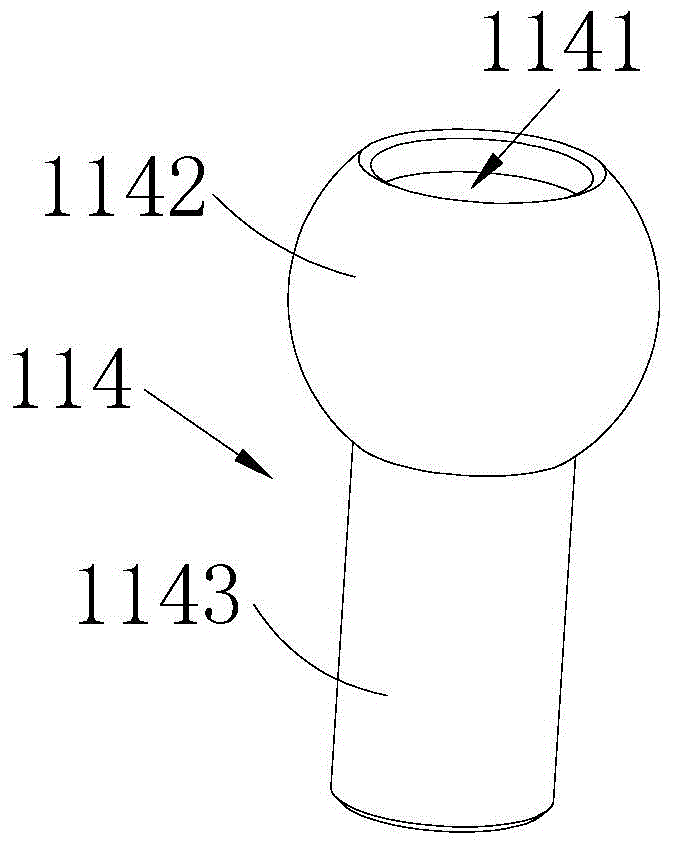

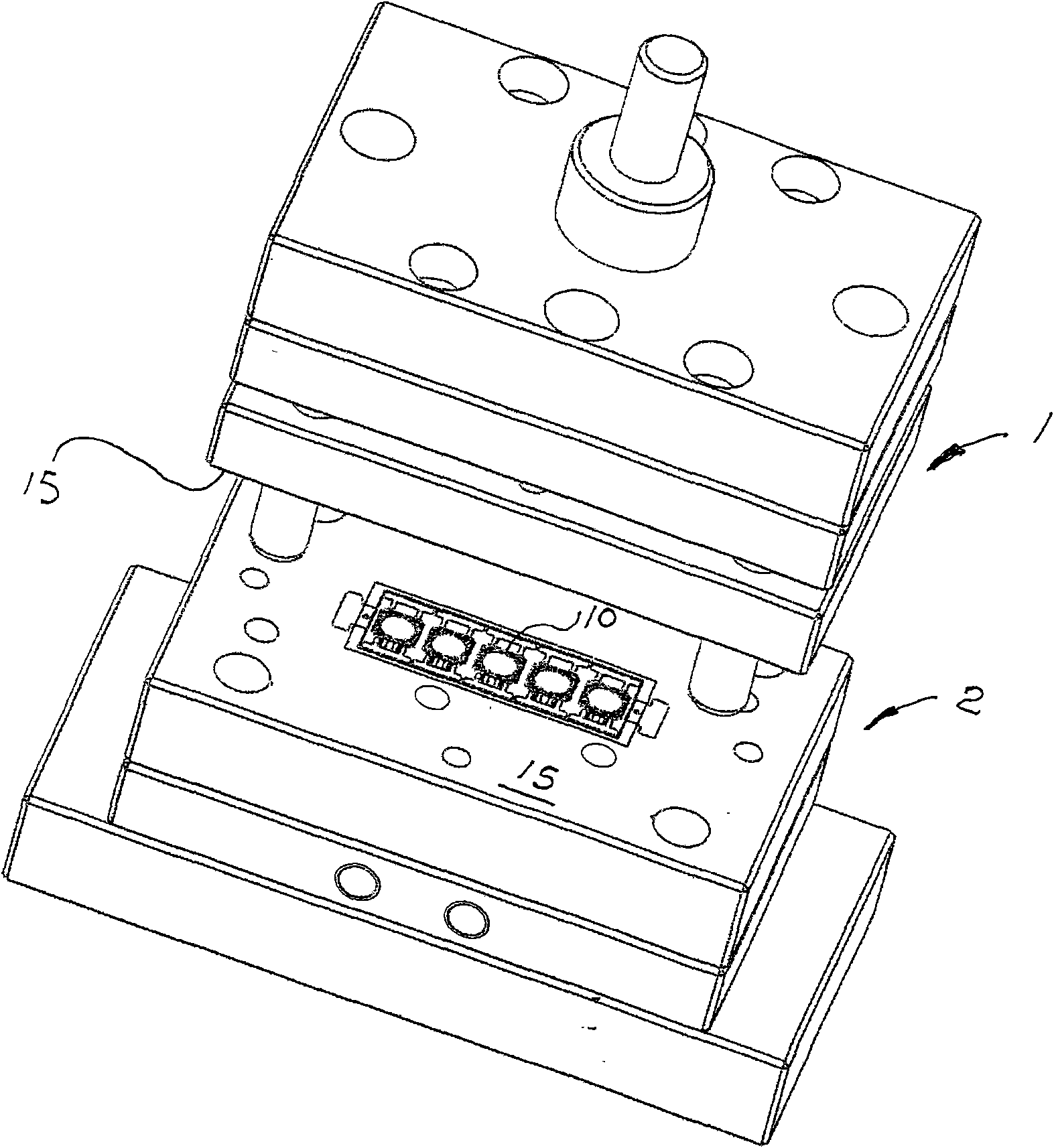

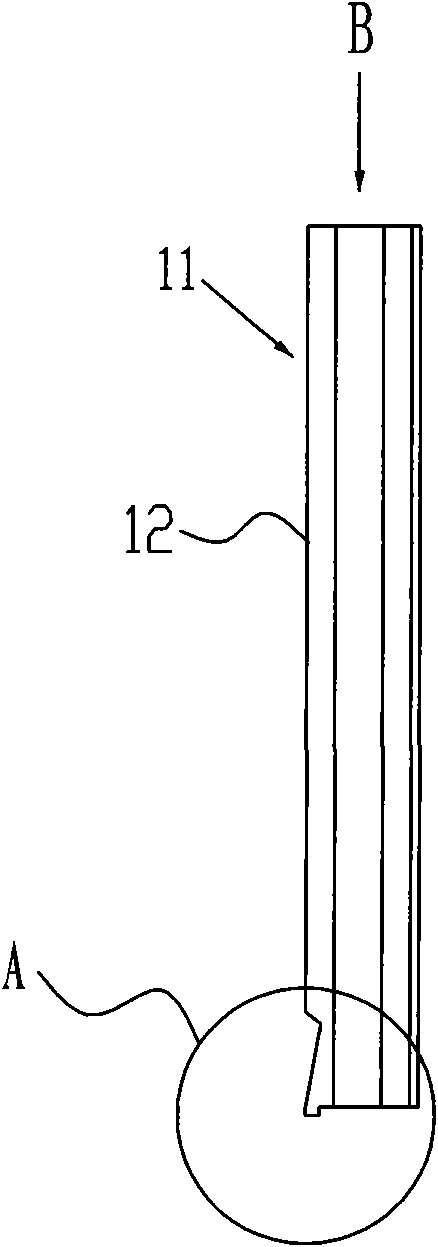

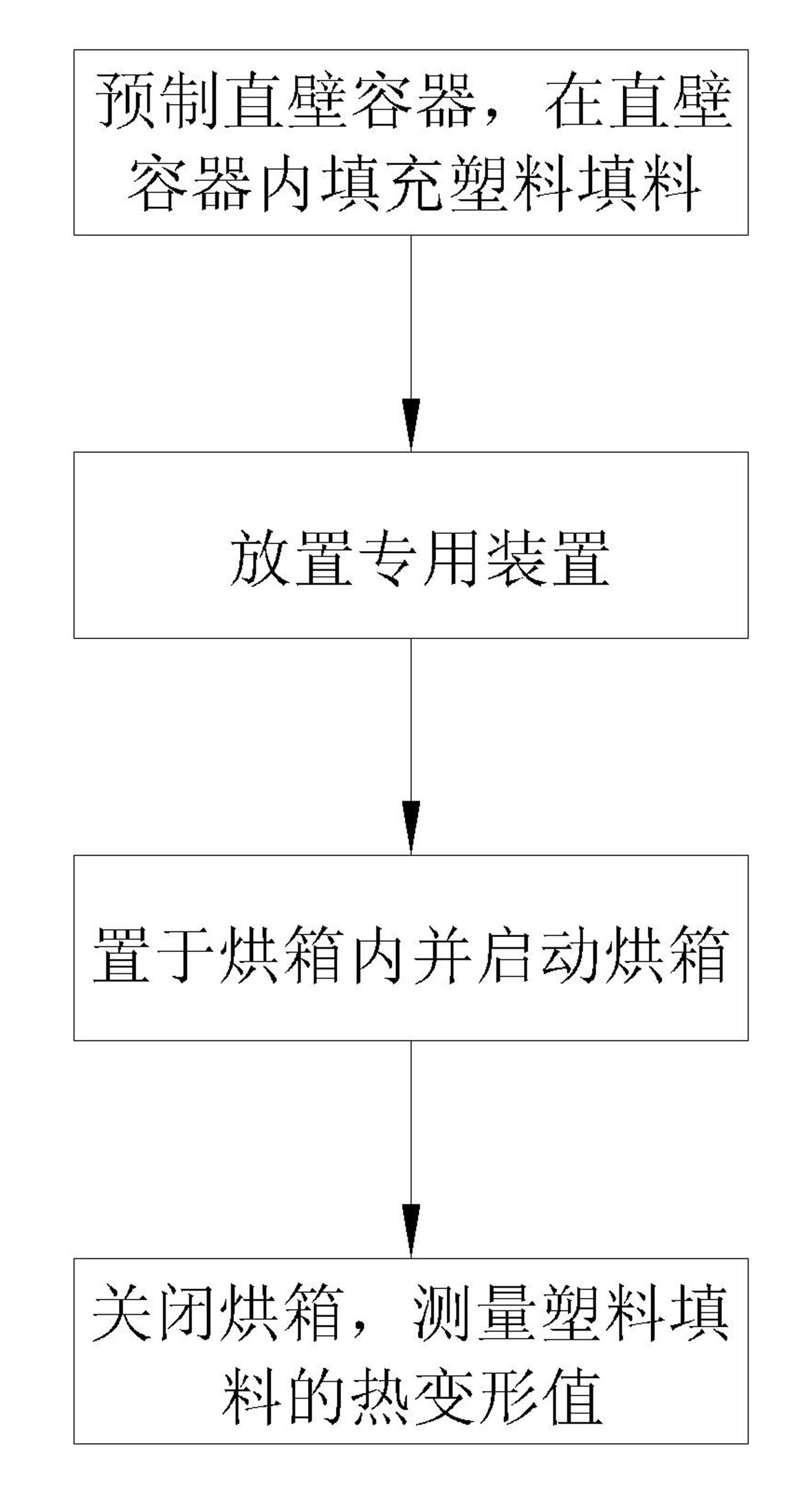

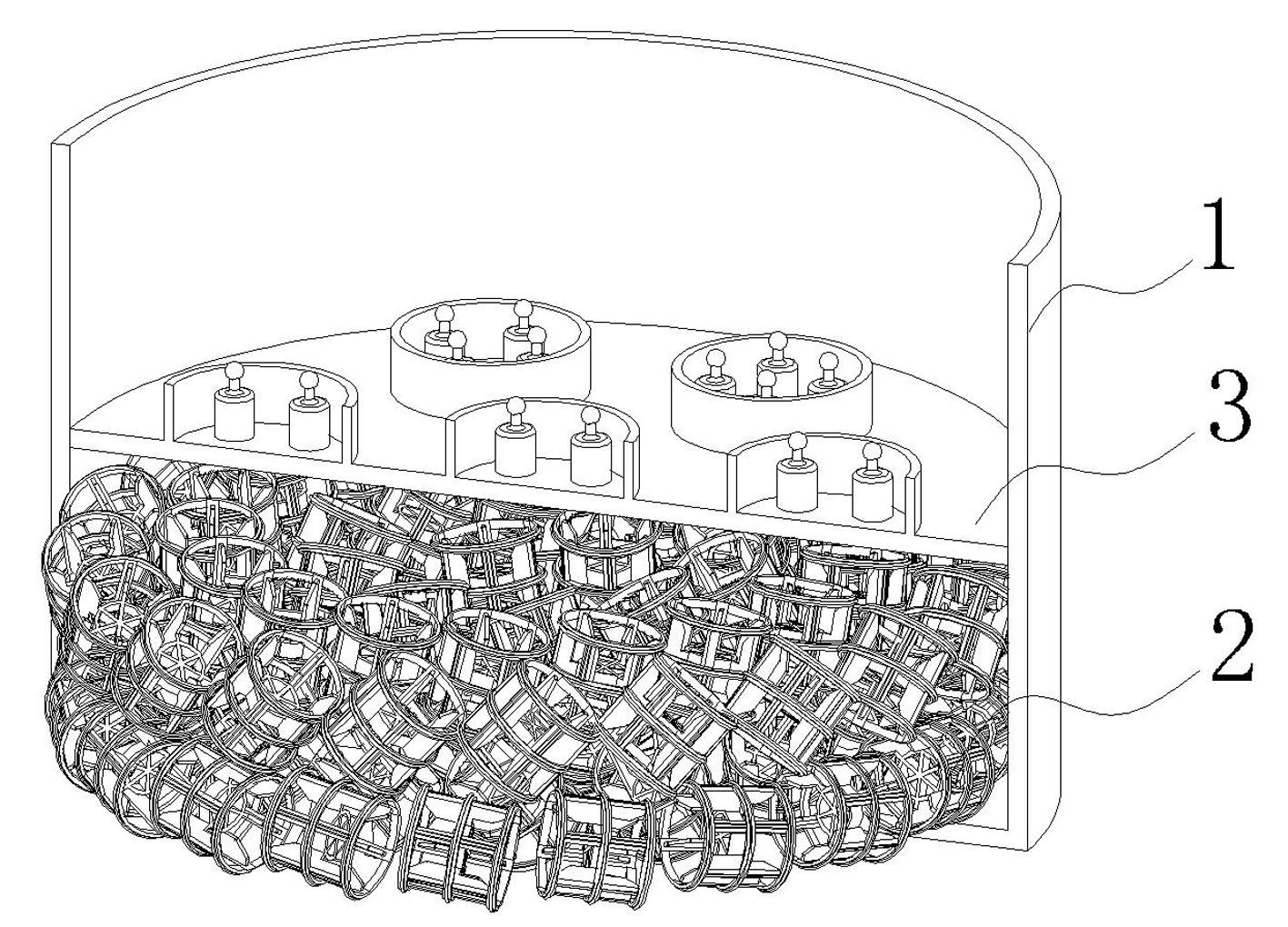

Method for simulating work environment for testing high-temperature stability of plastic filler and special device thereof

InactiveCN102072915AThe amount of deformation is real and reliableConsistent deformationMaterial thermal analysisThermal deformationWorking environment

The invention discloses a method for simulating a work environment for testing the high-temperature stability of plastic filler and a special device thereof, and provides a method capable of simulating the work environment for testing the high-temperature deformation amount of the plastic filler, which has the advantages of simple structure and use method, and a special device thereof. The invention solves the technical problems of large bed layer resistance, thermal-mass exchange effect reduction and the like directly caused by the fact that the detected deformation value of the plastic filler is not consistent with the actual value because only the thermal deformation value of a single plastic filler under no bearing can be detected in the prior art. The course of the method provided by the invention roughly comprises the following steps: firstly, filling an upright container with vertical walls with the plastic filler at a certain height, thereby maintaining the level surface of the plastic filler; then, selecting the special device, wherein the weight of the special device is the same as the weight of the bed layer borne by the plastic filler to be detected at the bottom of a tower after weighing; placing the special device in parallel on the surface of the plastic filler; simultaneously placing the special device, the bed layer and the plastic filler into a baking oven to be baked; and taking out the plastic filler after the baking to measure the deformation amount.

Owner:LINDE ENG HANGZHOU

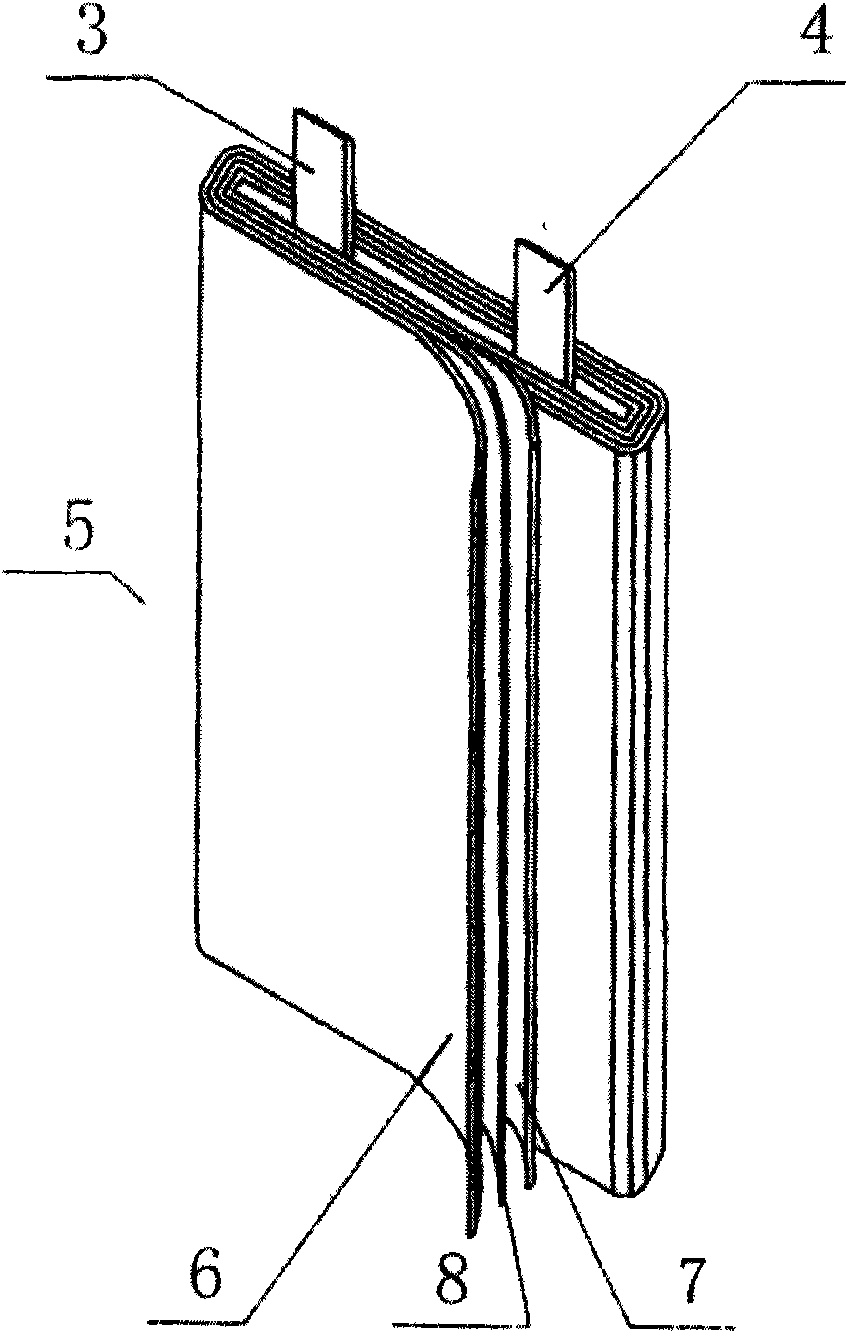

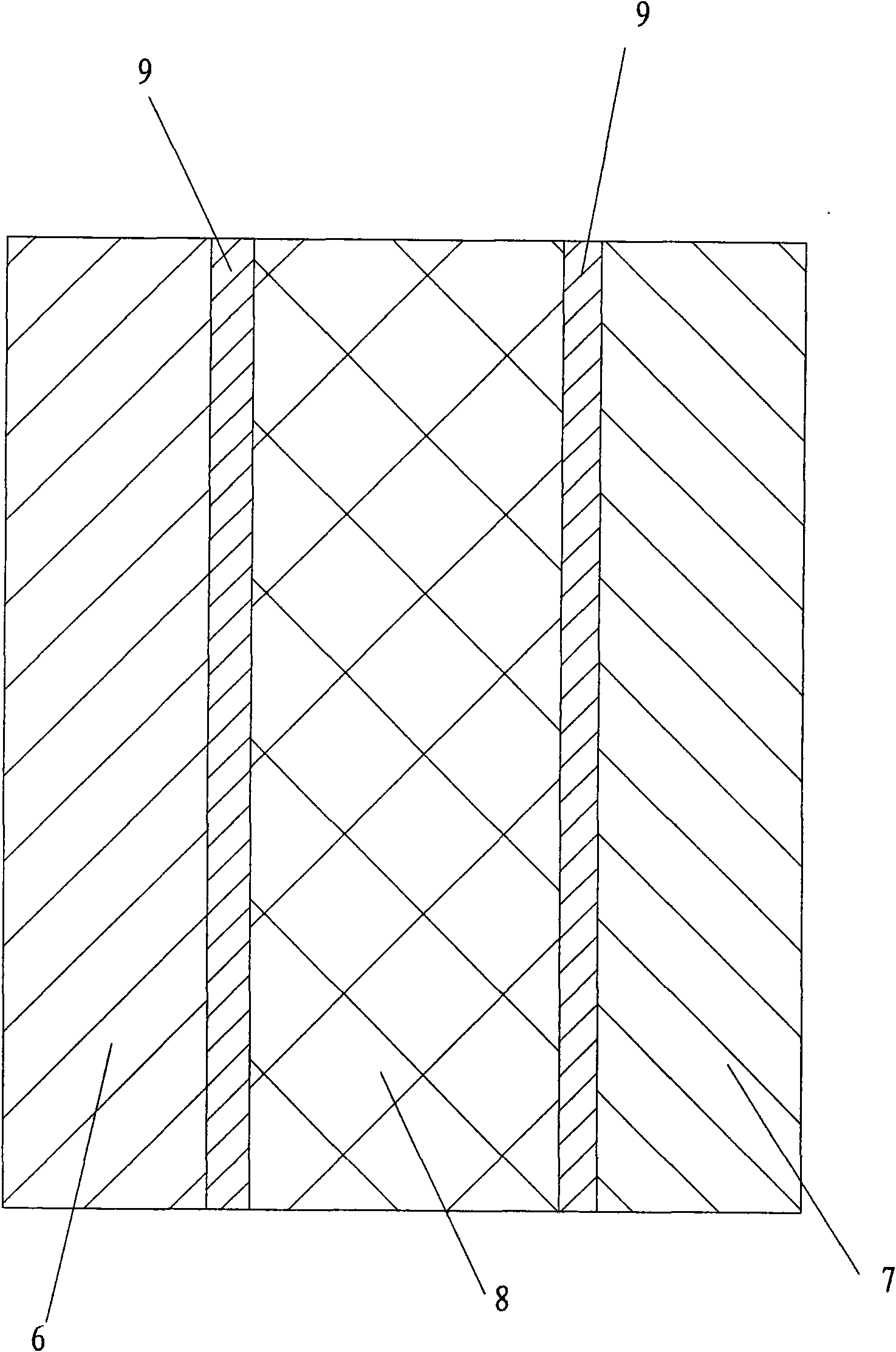

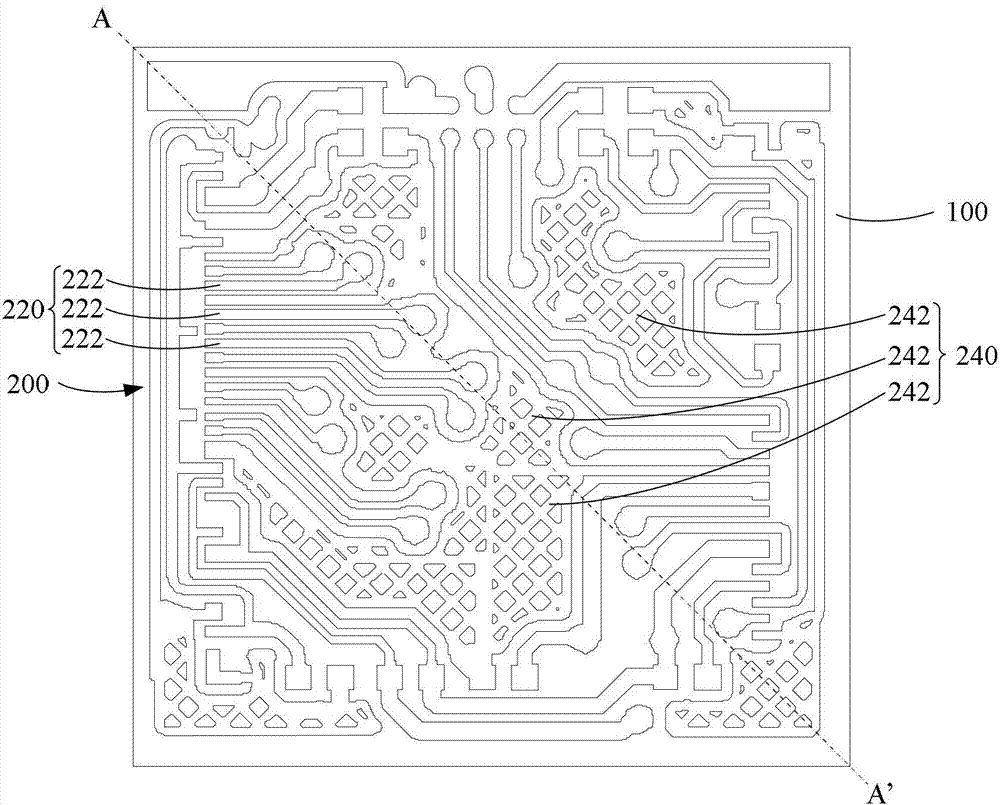

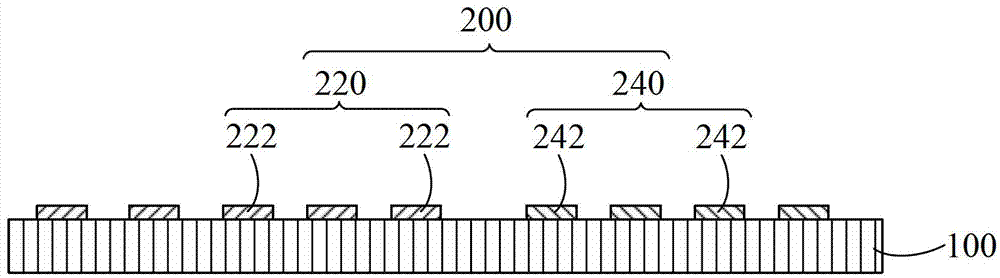

Flexible printed circuit board and manufacturing method thereof

InactiveCN103402303AConsistent deformationLow surface roughnessPrinted circuit manufactureElectrical connection printed elementsManufacturing technologyEngineering

The invention discloses a flexible printed circuit board and a manufacturing method thereof. A routing part of a conductive layer comprises a plurality of conductive traces which are arranged at intervals; and a non-routing part is formed by intercrossing conductive wires which are arranged at intervals. The non-routing part is designed to be formed by intercrossing the conductive wires which are arranged at intervals, so that the phenomenon that a region, which is used for holding the non-routing part, of a base material layer is completely covered by the non-routing part is avoided. In a subsequent manufacturing technology, when the flexible printed circuit board is baked or passes through a furnace after being erected with other components and is then deformed, stress produced in the flexible printed circuit board is uniformly distributed, and parts of the flexible printed circuit board are deformed consistently; and the reduction of the surface flatness of the flexible printed circuit board is avoided.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD +3

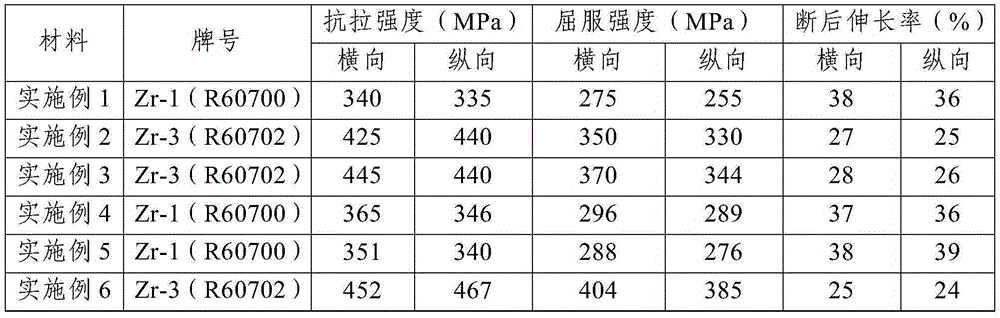

Processing method of pure-zirconium wide sheet

ActiveCN105414181AReduce anisotropyThe deformation is close to the sameTemperature control deviceMetal rolling arrangementsMechanical propertyVacuum annealing

The invention discloses a processing method of a pure-zirconium wide sheet. The processing method of the pure-zirconium wide sheet comprises the steps that firstly, primary rolling is conducted on a pure-zirconium slab after the pure-zirconium slab is heated, so that a first semi-finished slab is obtained; secondly, secondary rolling is conducted on the first semi-finished slab after the first semi-finished slab is heated, so that a second semi-finished slab is obtained; thirdly, intermediate annealing is conducted on the second semi-finished slab after the second semi-finished slab is sheared, so that a third semi-finished slab is obtained; fourthly, shot blasting and spraying type acid pickling are conducted on the third semi-finished slab, so that a fourth semi-finished slab is obtained after oxide skin on the surface is removed; fifthly, cold rolling is conducted on the fourth semi-finished slab, so that a fifth semi-finished slab is obtained; and sixthly, deoiling, finished product vacuum annealing and leveling are conducted on the fifth semi-finished slab, so that the pure-zirconium wide sheet with the thickness being 0.4-4 mm and the width being 1000-1600 mm is obtained. By the adoption of the processing method, the pure-zirconium wide sheet which is good in surface quality, smooth in sheet shape, uniform in structure and transverse and longitudinal mechanical property and small in aeolotropy can be obtained.

Owner:WESTERN TITANIUM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com