Three-roller coating printing unit for continuously coating surface of base material with viscous material

A substrate surface and printing unit technology, which is applied in the coating printing unit and the device field of spraying a thin layer of viscous material on the substrate, can solve the problems that the uniform coating of the thin surface adhesive layer cannot be achieved, and it is difficult to meet special application requirements. Achieve the effects of reducing thermal effects, improving overall performance, and suppressing polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

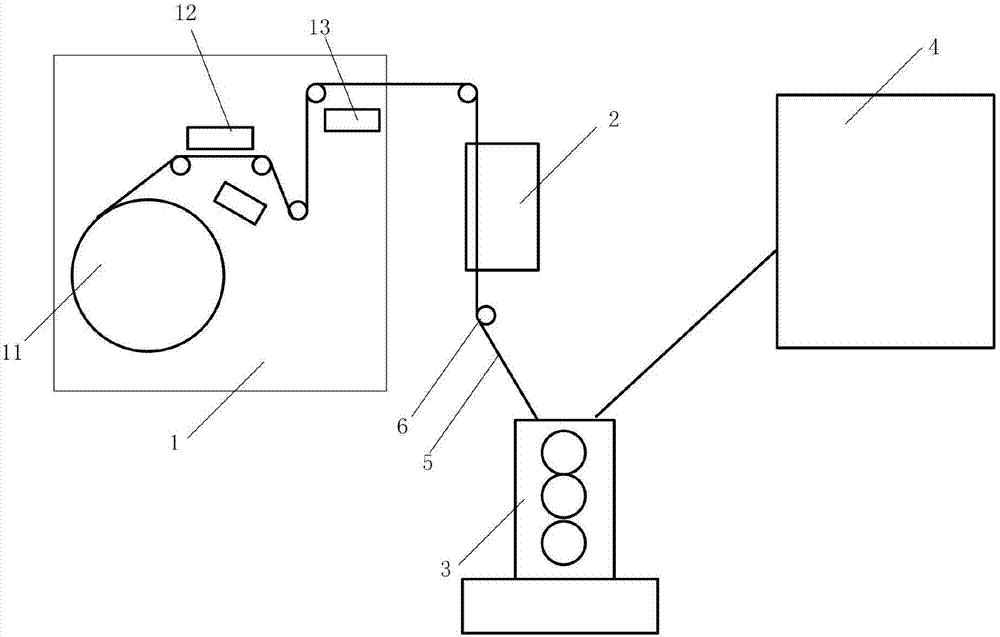

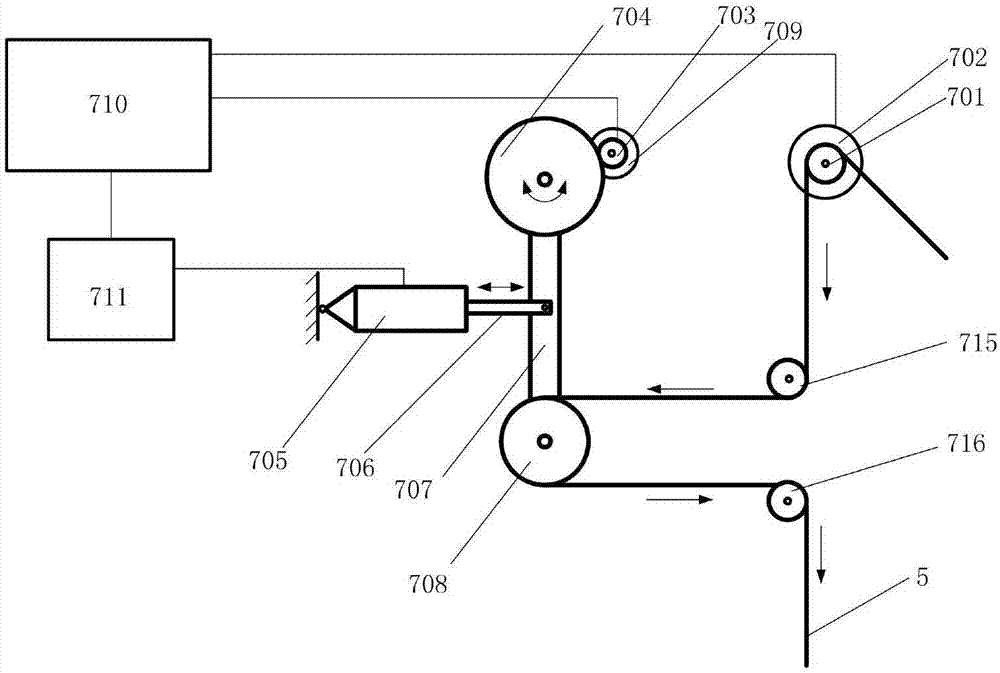

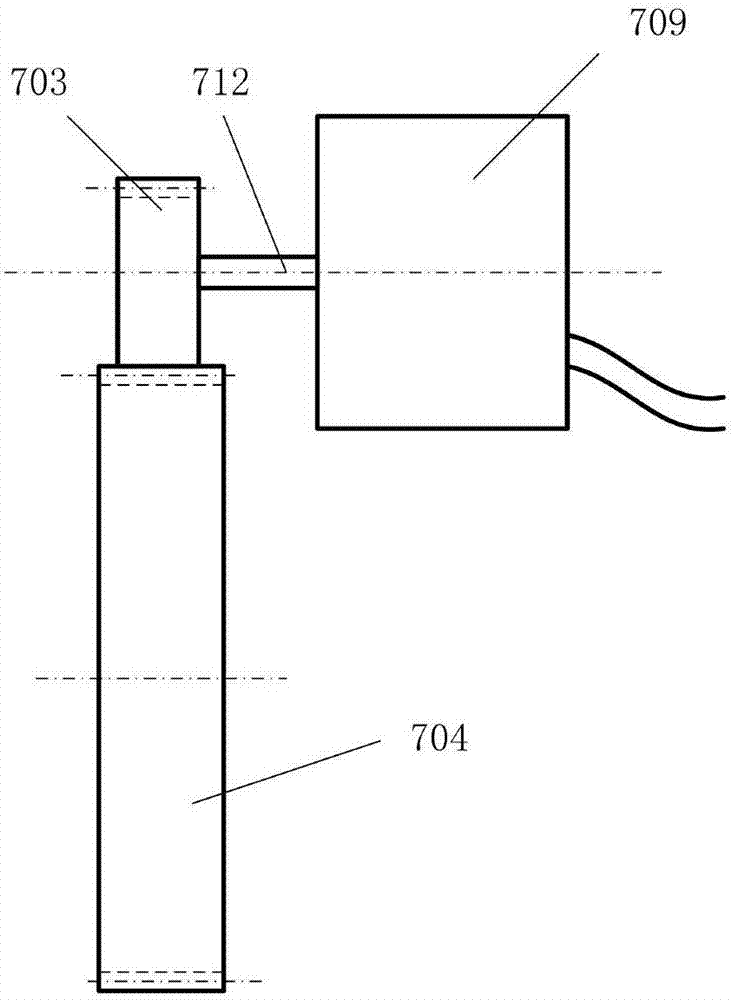

[0028] Such as figure 1 As shown, the device for coating liquid viscous materials of the present invention includes a control unit and an unwinding unit 1 , a tension control unit 2 , a coating and printing unit 3 and a follow-up unit 4 arranged in sequence along the moving direction of the substrate 5 .

[0029] 1. Unwinding unit

[0030] The unwinding unit 1 includes an unwinding wheel 11, a tension control sensor 12, a deviation correction device 13, and several rollers 6. The power unit drives the unwinding wheel 11 under the action of a magnetic powder brake, so that the base material 5 is unrolled, and the base material 5 is provided with The tension sensor 12, the tension controller 12 and the magnetic powder brake of the unwinding unit 1 form a closed-loop control to ensure that the tension of the base material 5 remains constant, and can be regarded as set. A deviation correcting device 13 is also provided at the position of the unwinding unit 1 of the base material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com