PVC wide seamless wall cloth and manufacturing method thereof

A manufacturing method and seamless technology, applied in the field of veneer decoration materials, can solve the problems that the embossed pattern cannot be aligned with the printed pattern, cannot be seamlessly paved on the wall, aggravated, etc., so as to achieve the consistent pattern and design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

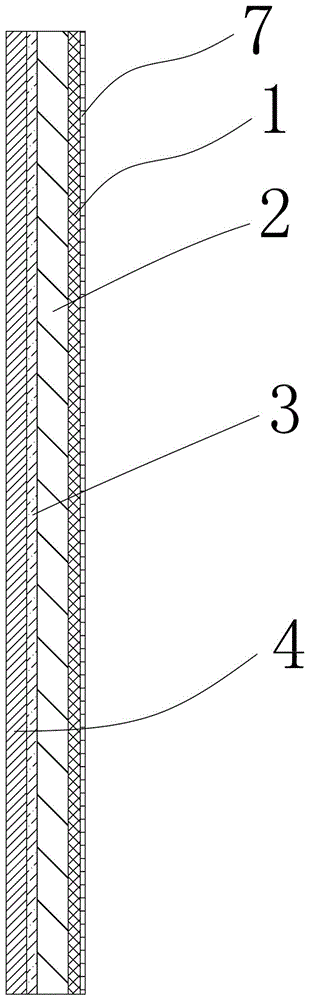

[0038] like figure 1 A PVC wide-width seamless wall covering is shown, comprising a polyester cloth layer 2; a wallpaper base paper layer 4 completely covering the back of the polyester cloth layer 2; a water-based adhesive layer 3 between the back of the polyester cloth layer and the wallpaper base paper layer; The PVC foam coating 1 coated on the front side of the polyester cloth is provided with a surface printing coating 7 on the surface of the PVC foam coating 1 . The surface printing coating 7 is a printing layer and an embossing structure, and the pattern and embossing of the printing layer are arranged in pairs.

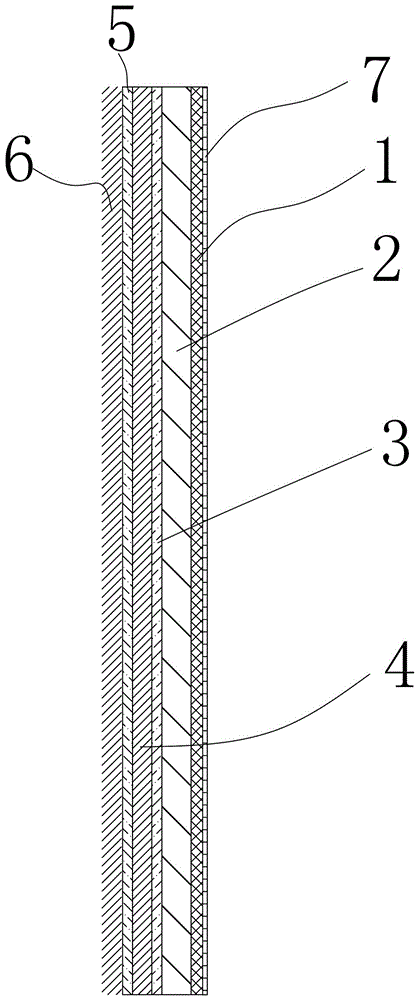

[0039] like figure 2 As shown, when the PVC wall covering of the present invention is pasted, after the leveled wall surface is coated with cold glue, the base paper layer of the wallpaper is combined with the cold glue, and the wall is smoothed out. The upper and lower directions and the circumferential direction of the body surface are continuously paved...

Embodiment 2

[0048] like figure 1 A PVC wide-width seamless wall covering is shown, comprising a polyester cloth layer 2; a wallpaper base paper layer 4 completely covering the back of the polyester cloth layer 2; a water-based adhesive layer 3 between the back of the polyester cloth layer and the wallpaper base paper layer; The PVC foam coating 1 coated on the front side of the polyester cloth is provided with a surface printing coating 7 on the surface of the PVC foam coating 1 . The surface printing coating 7 is a printing layer and an embossing structure, and the pattern and embossing of the printing layer are arranged in pairs.

[0049] like figure 2 As shown, when the PVC wall covering of the present invention is pasted, after the leveled wall surface is coated with cold glue, the base paper layer of the wallpaper is combined with the cold glue, and the wall is smoothed out. The upper and lower directions and the circumferential direction of the body surface are continuously paved...

Embodiment 3

[0058] like figure 1 A PVC wide-width seamless wall covering is shown, comprising a polyester cloth layer 2; a wallpaper base paper layer 4 completely covering the back of the polyester cloth layer 2; a water-based adhesive layer 3 between the back of the polyester cloth layer and the wallpaper base paper layer; The PVC coating 1 coated on the front side of the polyester cloth is provided with a surface printing coating 7 on the surface of the PVC foam coating 1 . The surface printing coating 7 is a printing layer and an embossing structure, and the patterns and embossings of the printing layer are not arranged in alignment.

[0059] like figure 2 As shown, when the PVC wall covering of the present invention is pasted, after the leveled wall surface is coated with cold glue, the base paper layer of the wallpaper is combined with the cold glue, and the wall is smoothed out. The upper and lower directions and the circumferential direction of the body surface are continuously ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com