Processing method of pure-zirconium wide sheet

A processing method and wide-width technology, which is applied in the field of processing pure zirconium wide-width thin plates, can solve the problems of undeveloped technology and stable production technology for wide-width pure zirconium thin plates, and achieve uniform and anisotropic horizontal and vertical mechanical properties. Small, good surface quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

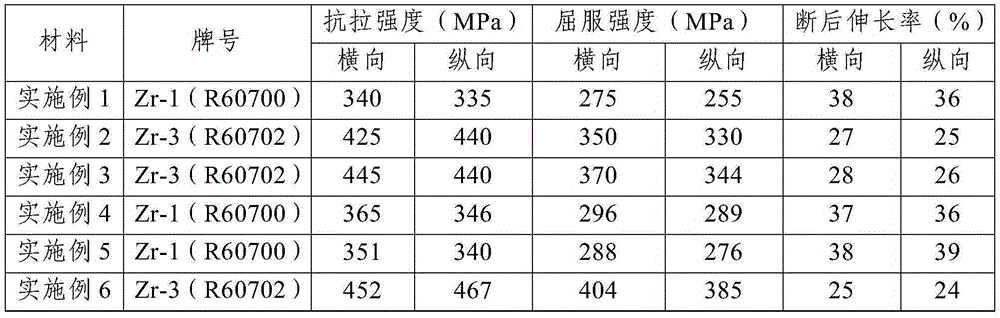

Examples

Embodiment 1

[0027] This embodiment includes the following steps:

[0028] Step 1. Put a pure zirconium slab with a size of 150mm (thickness) × 800mm (width) × 1100mm (length) in a heating furnace for heating, so that the temperature of the pure zirconium slab is raised to 740 ° C and kept for 120 minutes, and then sent to hot rolling The first rolling is carried out in the machine to obtain the first semi-finished slab with a size of 27.5mm (thick) × 800mm (width) × 6000mm (long); the first rolling is unidirectional rolling, and the first rolling The total deformation is 81.67%, and the first rolling is divided into 8 passes to complete, and the pass deformation rates of each rolling pass are: 10.00%, 16.30%, 22.12%, 22.73%, 26.47%, 24.00 %, 18.42% and 11.29%, the grade of the pure zirconium slab is Zr-1 (R60700);

[0029] Step 2: Cut the first semi-finished slab described in step 1 to a size of 27.5mm (thickness) × 800mm (width) × 1000mm (length), and then place the cut first semi-finis...

Embodiment 2

[0035] This embodiment includes the following steps:

[0036] Step 1. Put a pure zirconium slab with a size of 200mm (thickness) × 1000mm (width) × 1200mm (length) in a heating furnace for heating, so that the temperature of the pure zirconium slab is raised to 800°C and kept for 160 minutes, and then sent to hot rolling Carry out the first rolling in the machine, obtain the size and be 32mm (thick) * 1000mm (width) * 7500mm (long) the first semi-finished slab; The first rolling is unidirectional rolling, and the first rolling The total deformation amount is 84.00%, and the first rolling is divided into 9 passes to complete, and the pass deformation rates of each rolling pass are: 10.50%, 14.53%, 18.30%, 20.00%, 22.00%, 23.08% , 20.00%, 20.83% and 15.79%, the grade of the pure zirconium slab is Zr-3 (R60702);

[0037] Step 2. Cut the first semi-finished slab described in step 1 to a size of 32mm (thickness)×1000mm (width)×1500mm (length), and then place the cut first semi-fin...

Embodiment 3

[0043] This embodiment includes the following steps:

[0044] Step 1. Put a pure zirconium slab with a size of 140mm (thickness) × 1000mm (width) × 1170mm (length) in a heating furnace for heating, so that the temperature of the pure zirconium slab is raised to 770°C and kept for 80 minutes, and then sent to hot rolling The first rolling is carried out in the machine to obtain the first semi-finished slab with a size of 21mm (thick) × 1000mm (width) × 7800mm (long); the first rolling is unidirectional rolling, and the first rolling The total deformation is 85.00%, and the first rolling is divided into 8 passes to complete, and the pass deformation rates of each rolling pass are: 14.29%, 16.67%, 30.00%, 27.14%, 25.49%, 23.68% , 17.24% and 12.50%, the grade of the pure zirconium slab is Zr-3 (R60702);

[0045] Step 2. Cut the first semi-finished slab described in step 1 to a size of 21 mm (thickness) × 1000 mm (width) × 1300 mm (length), and then place the cut first semi-finish...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com