System and method for continuous extrusion production of fine-grain magnesium alloy strip

A magnesium alloy plate and production system technology, applied in metal extrusion, metal extrusion control equipment, metal processing equipment, etc., can solve the problem of not considering metal expansion deformation, etc. The effect of short process and improved specification range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

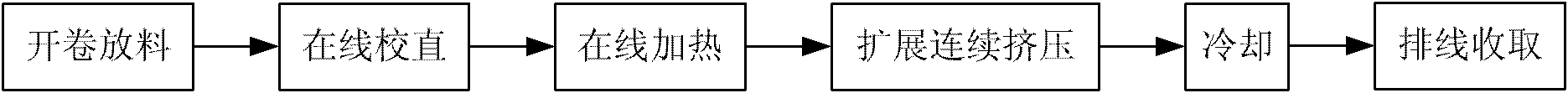

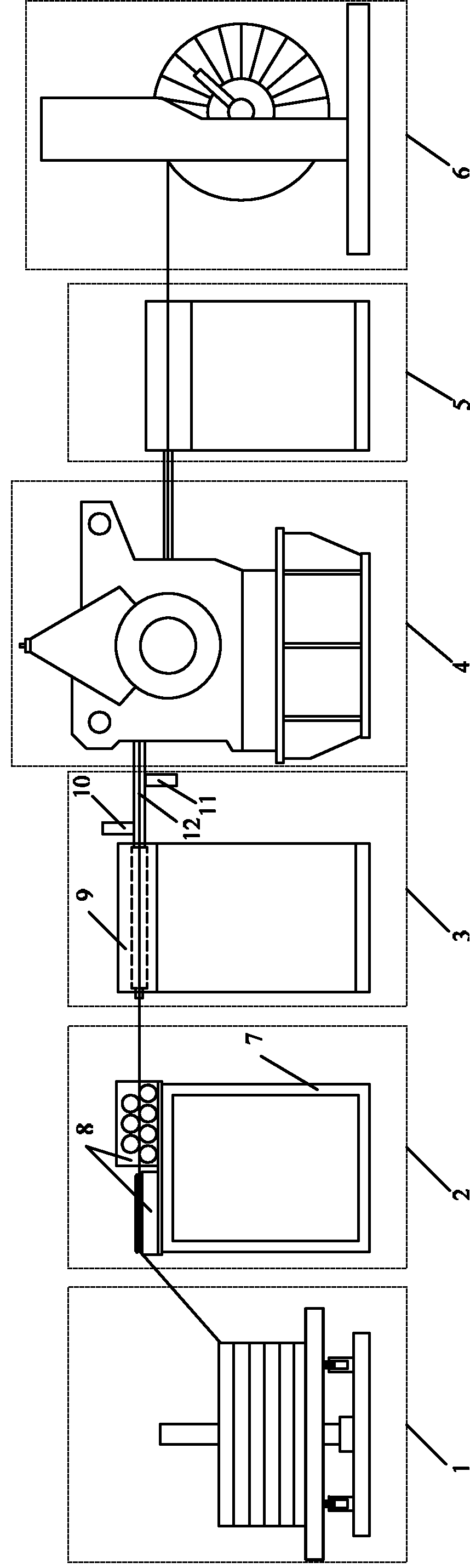

[0040] Single-rod-single-slot continuous extrusion production system, including uncoiling and unwinding device 1, online straightening device 2, online heating device 3, continuous extrusion device 4, cooling device 5 and cable take-up device 6;

[0041] The online straightening device 2 is composed of a frame 7 and a set of straightening units 8 fixed on the frame. The straightening unit is composed of two straightening devices whose straightening direction is 90 degrees. The straightening rollers on the straightening device There are straightening grooves on the wheel surface;

[0042] The online heating device 3 is composed of an electric heating device 9, a temperature detector 10, a speed detector 11 and an anti-oxidation protection tube 12; both ends of the anti-oxidation protection tube 12 are respectively connected with the electric heating device 9 and the continuous extrusion device 4; The temperature detector 10 and the speed detector 11 are arranged on the anti-oxi...

Embodiment 2

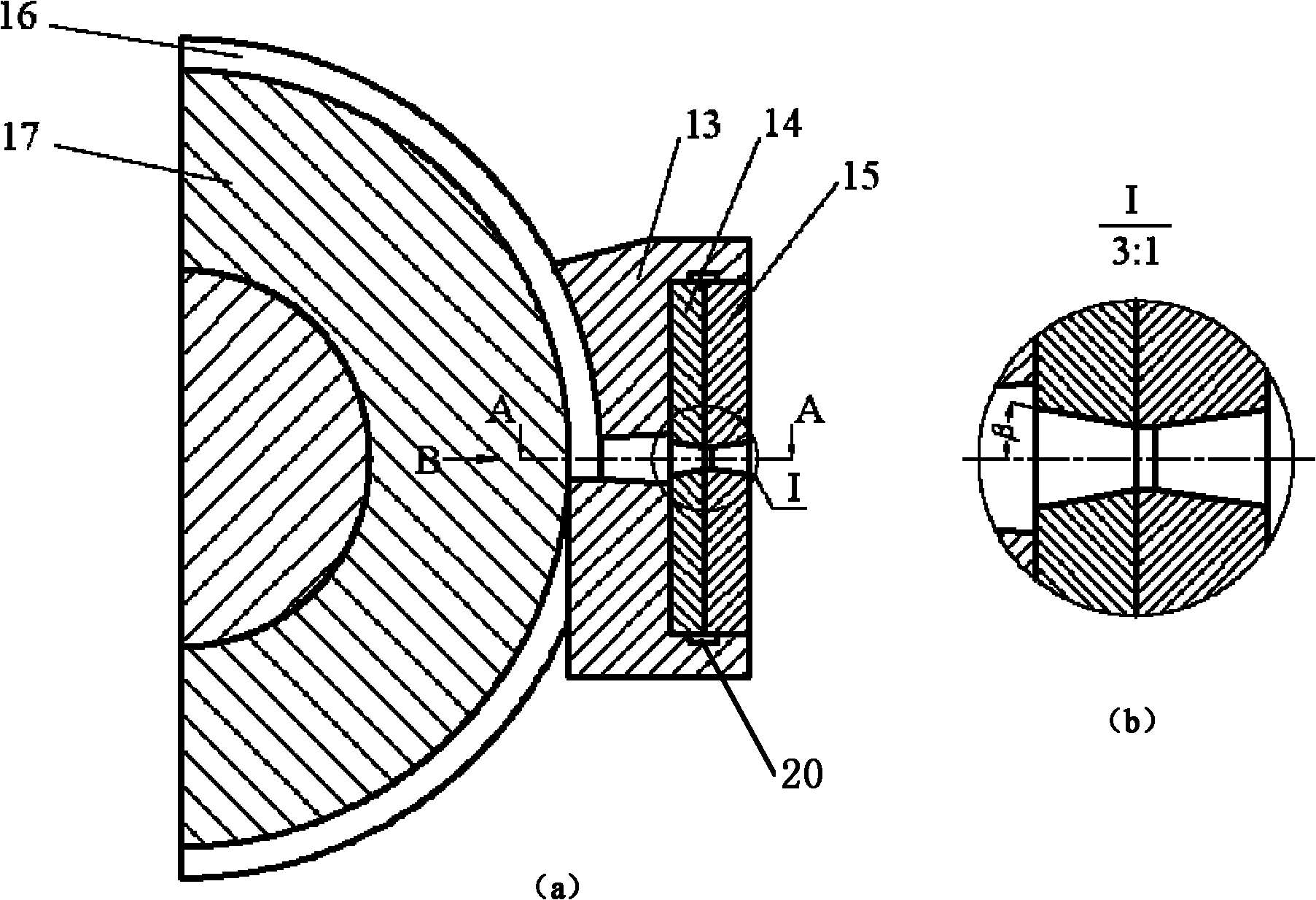

[0046] The method for producing fine-grained magnesium alloy plates and strips using the single-rod-single-groove continuous extrusion system of Embodiment 1, after the extruded AZ31 magnesium alloy rod material with a circular cross section and a diameter of 30 mm is discharged through the uncoiling discharge device 1, Enter the online straightening device 2 for straightening, and then enter the online heating device 3 to heat the rod material to 400-450°C. The rod material enters the extrusion wheel groove 16 of the extrusion wheel 17 through the entrance of the continuous extrusion device 4, and the rod material The circular movement of the material at the front edge of the stop block of the expansion cavity 13 is blocked, and the required temperature and pressure are generated under the action of friction to press the rod material into the expansion cavity feed port 18, and reach the expansion cavity after expanding in the width direction. Cavity outlet 19, the rod material...

Embodiment 3

[0049] A double-rod-double-groove continuous extrusion production system, including 2 sets of uncoiling and unwinding devices 1, an online straightening device 2 and an online heating device 3 with the same structure as that of the embodiment 1;

[0050] Also includes a double-groove continuous extrusion device 4, the continuous extrusion device 4 includes extrusion wheels 17, double grooves 16, expansion die cavity 13 and choke die 14; said expansion die cavity 13 is provided with two Expansion die cavity inlet 18 (as Figure 5-2 shown) and 1 expansion die cavity discharge port 19, the mold 15 is installed below the discharge port 19; One side of the expansion cavity; 2 expansion cavity feed openings 18 widths are 22mm, expansion cavity discharge opening 19 width is 310mm, expansion angle α is 130 °, and flow blocking angle β is 2 °; the expansion cavity 13 Equipped with a circulating cooling channel 20 with a data transmission interface; the outlet of the continuous extrusi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com