Patents

Literature

35results about How to "Improve grain refinement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

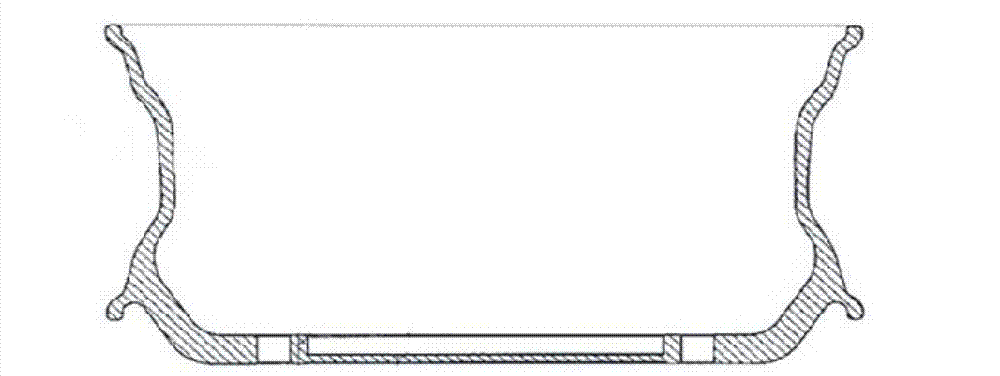

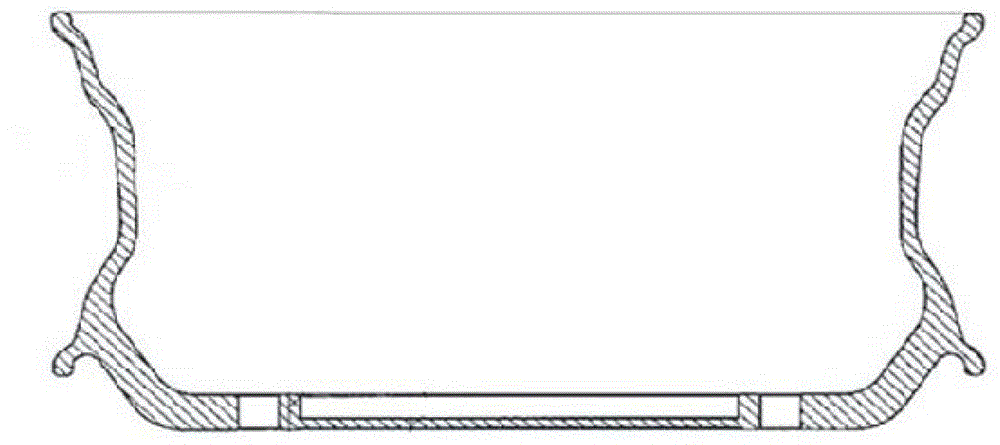

Large-diameter moderately-strong heat-resisting magnesium alloy thick-wall barrel-shaped piece forming process

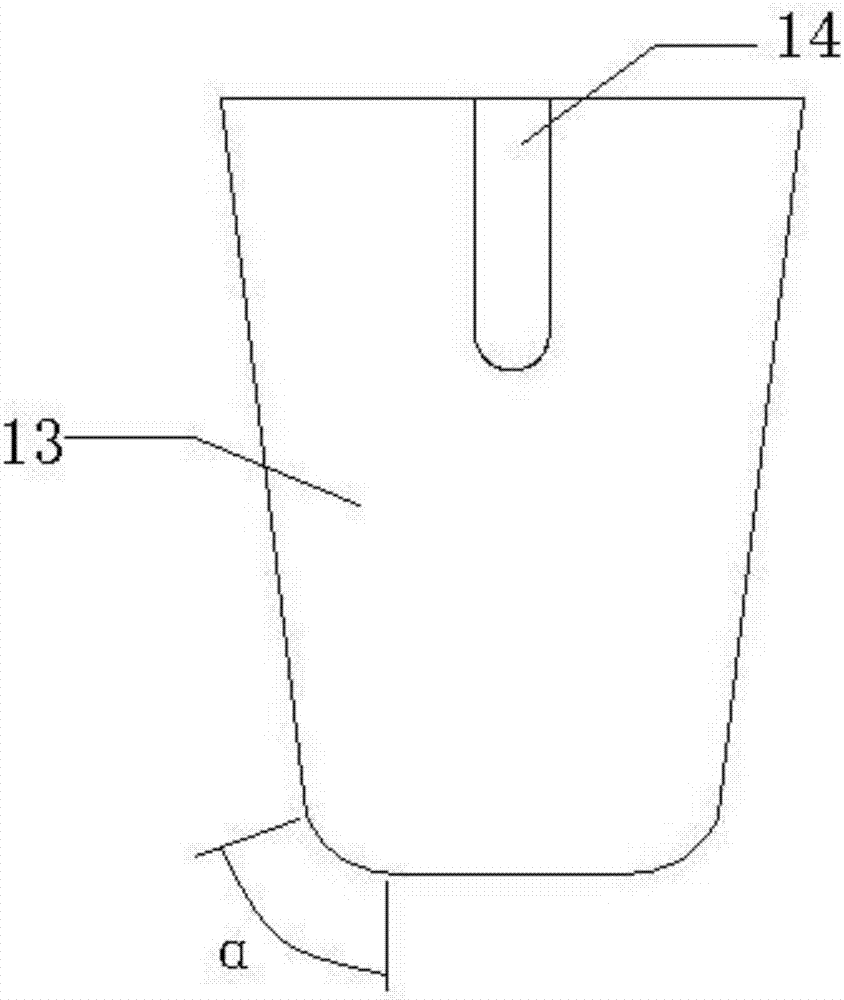

The invention discloses a large-diameter moderately-strong heat-resisting magnesium alloy thick-wall barrel-shaped piece forming process. The process includes the steps of large-furnace smelting, semi-continuous casting, homogenizing annealing, varying-temperature multi-direction forging, mechanical punching, ring rolling forming and aging treatment. The varying-temperature multi-direction forging is conducted on an oil press, pressing speed is 200-400mm / min, upsetting reduction in pass is 30-40%, drawing down reduction in pass is 5-10%, blank before ring rolling forming is kept at the temperature of 380-400 DEG C for 4-8 hours, and rolling deformation is 60-80%. The thick-wall barrel-shaped piece 700-1100mm in outer diameter, 50-100mm in wall thickness and 300-700mm in height is manufactured. The thick-wall barrel-shaped piece is high in strength and good in heat resistance and meets size and performance requirements of structural parts in the aerospace field.

Owner:CENT SOUTH UNIV

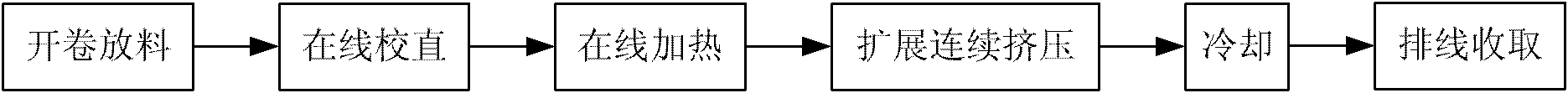

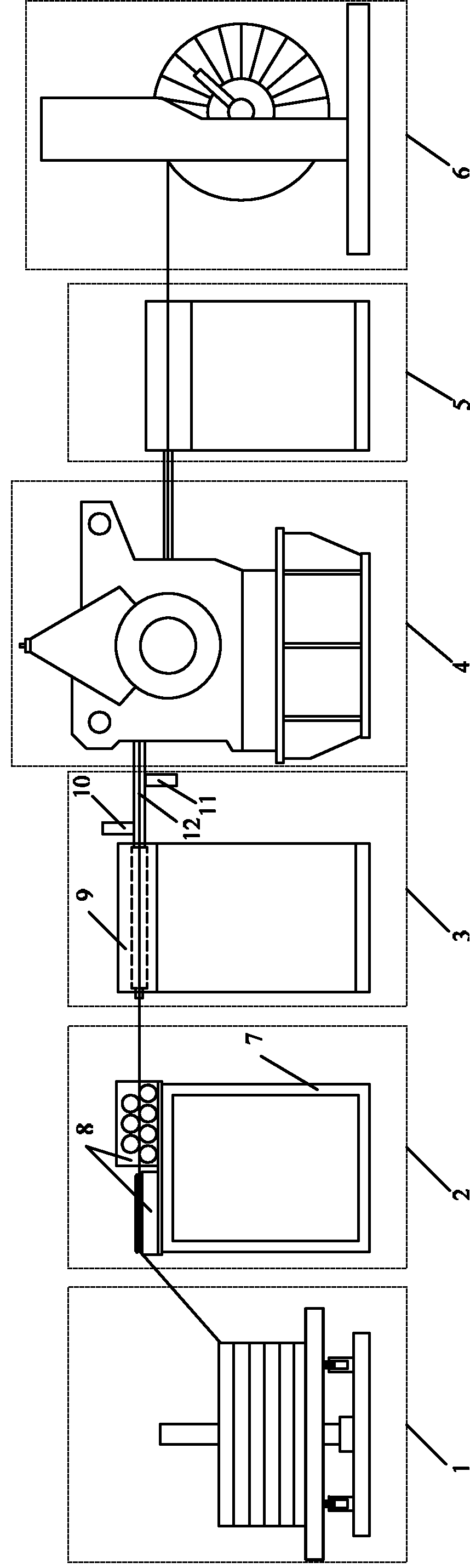

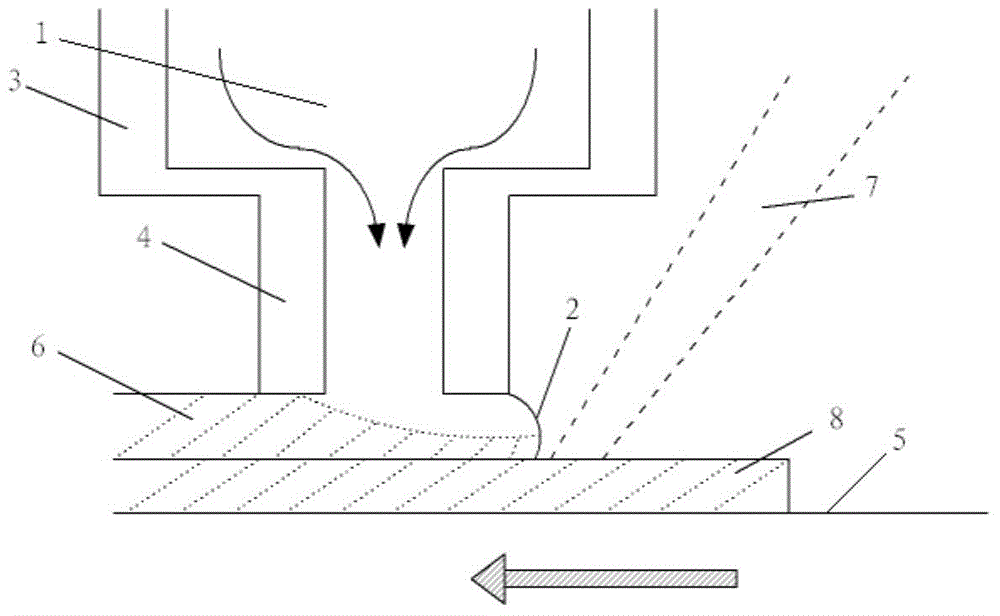

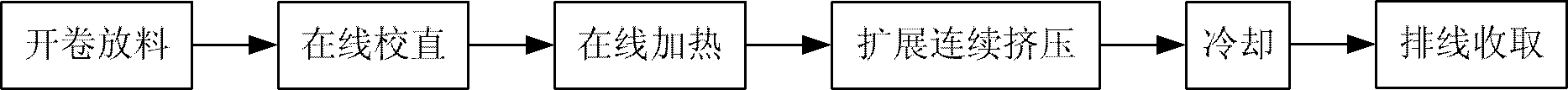

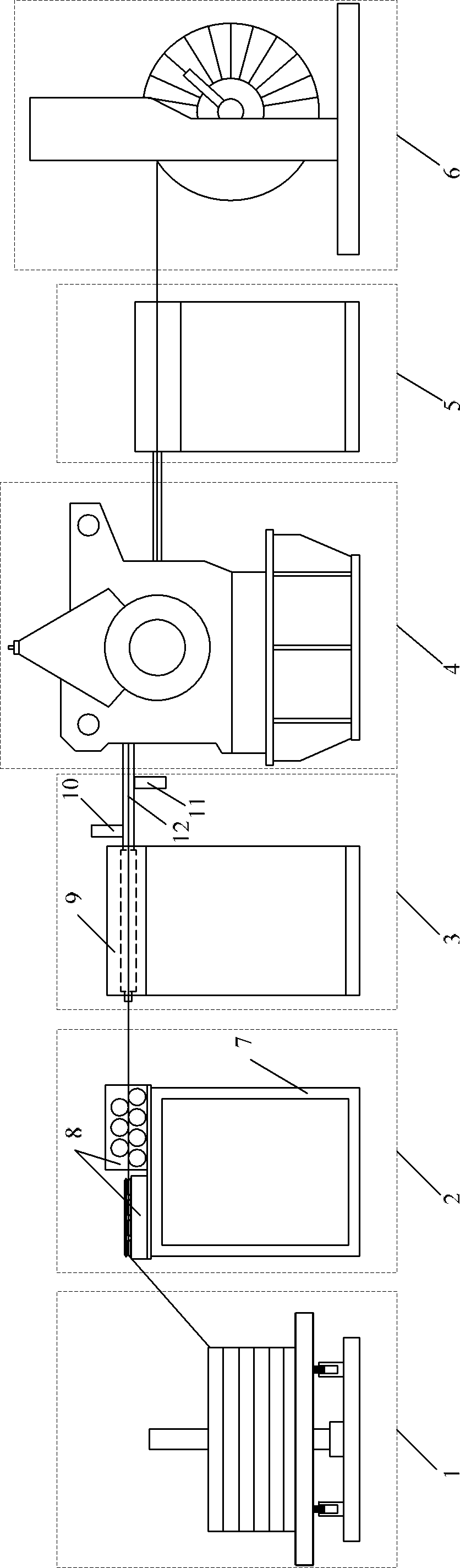

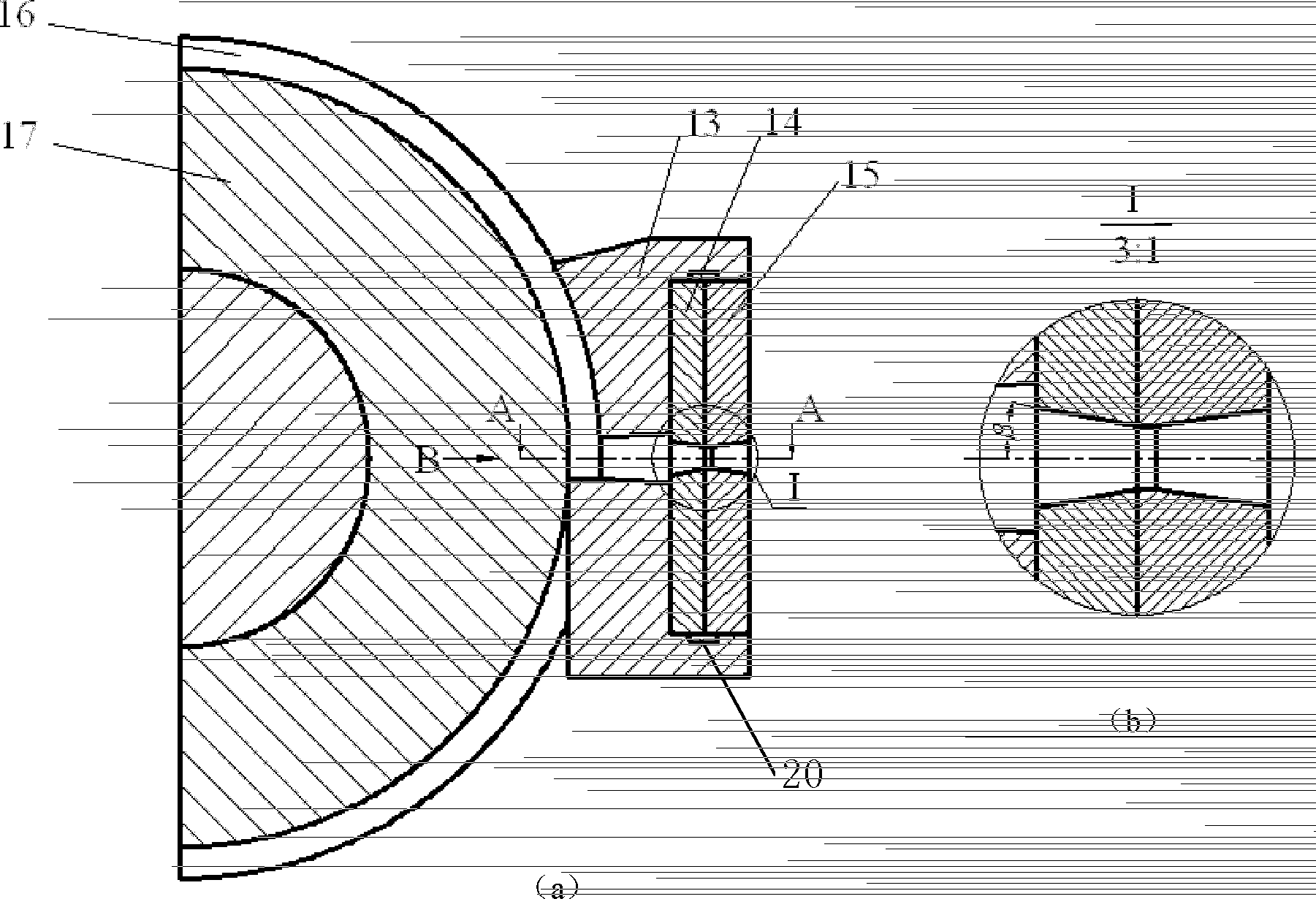

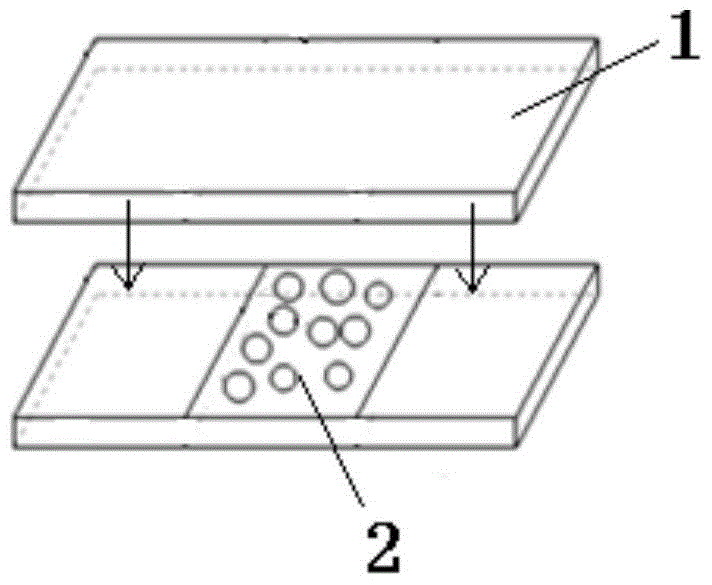

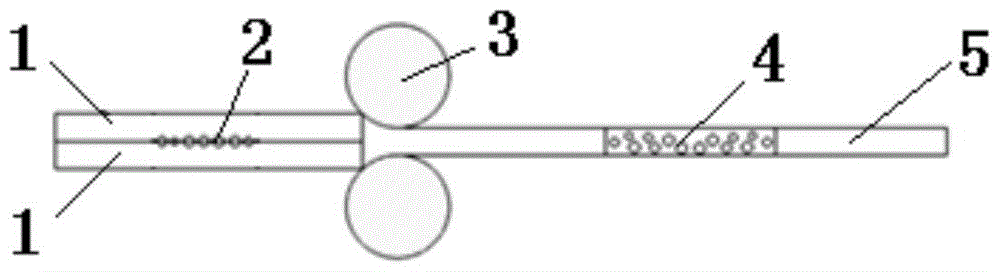

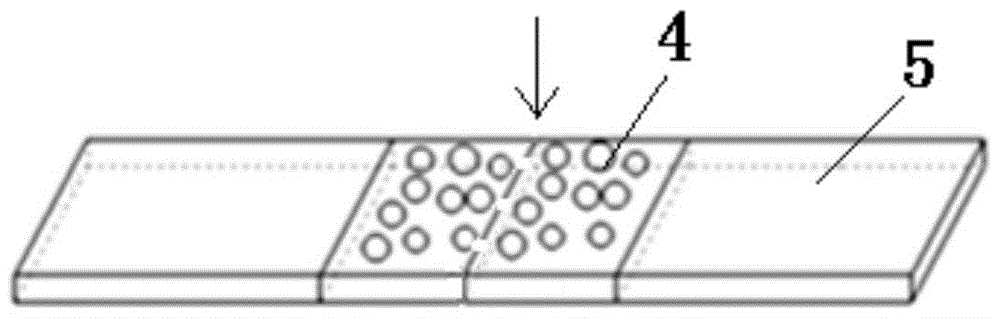

System and method for continuous extrusion production of fine-grain magnesium alloy strip

ActiveCN102688907AShort processIncrease productivityExtrusion control devicesProduction lineLine heating

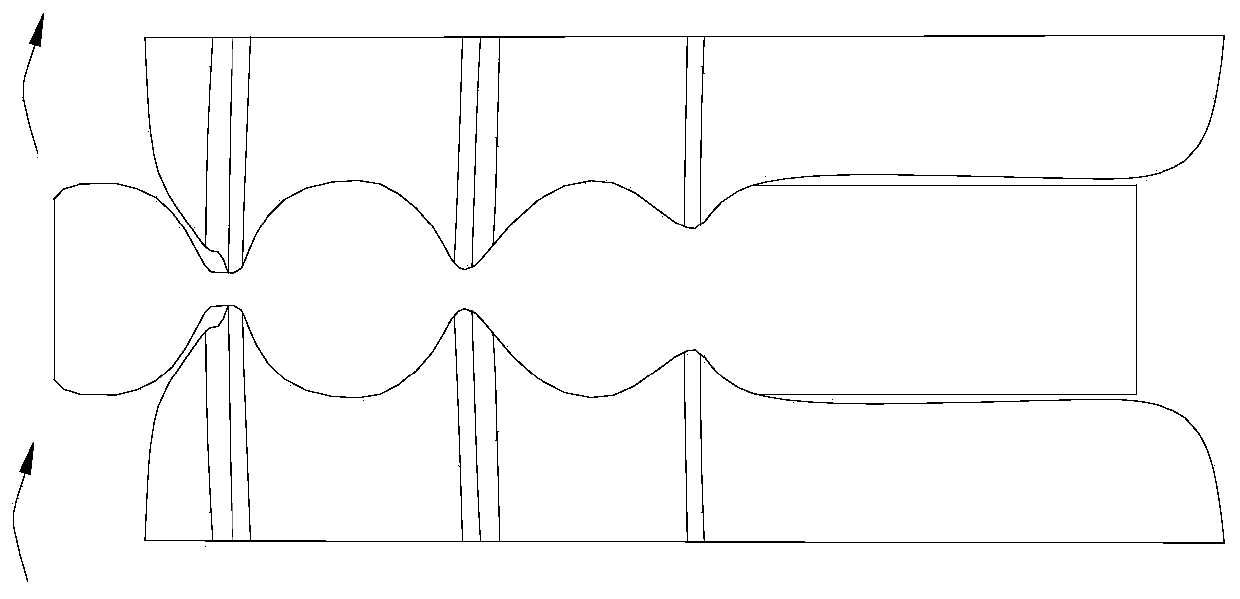

The invention discloses a system and a method for continuous extrusion production of a fine-grain magnesium alloy strip. The system comprises a decoiling emptying device, an on-line straightening device, an on-line heating device, a continuous extrusion device, a cooling device and a winding displacement collection device. Through control of a temperature of a rod, a good extrusion driving force is produced between the rod and an extrusion wheel groove. Through an expansion mold cavity and a flow-blocking mold, magnesium alloy expansion flowing in a width direction is realized. In order to extrude a plate having larger width, the system adopts a two / three rod feeding-type extrusion mode so that joining and intermetallic welding of multiple rods in a corresponding multi-rod mold cavity are realized. The system and the method have the advantages that a process route is short; production efficiency is high; a grain refinement degree of a product microstructure is high; plate formability is good; and a continuous production line provided by the invention is suitable for industrial application.

Owner:DALIAN JIAOTONG UNIVERSITY

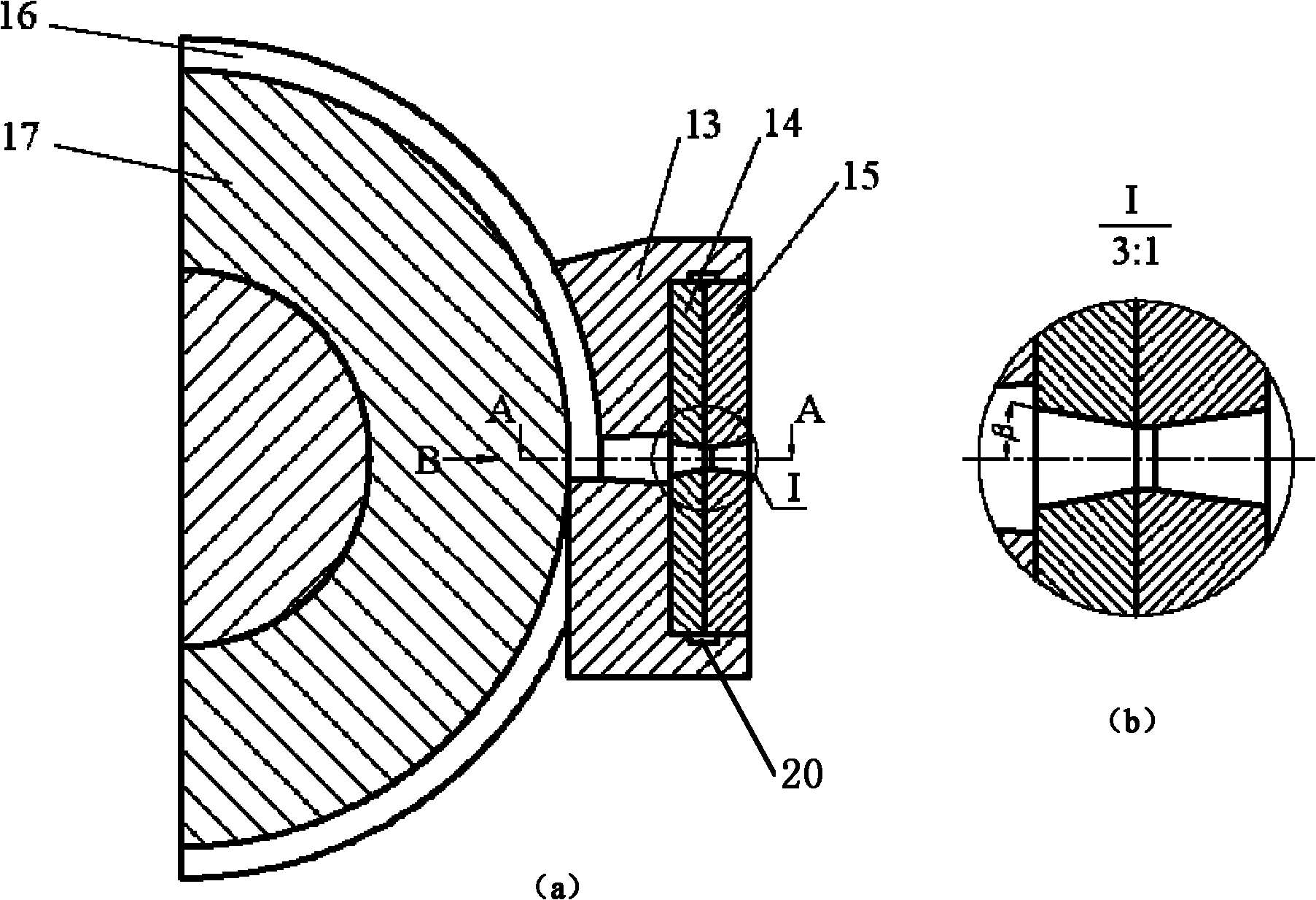

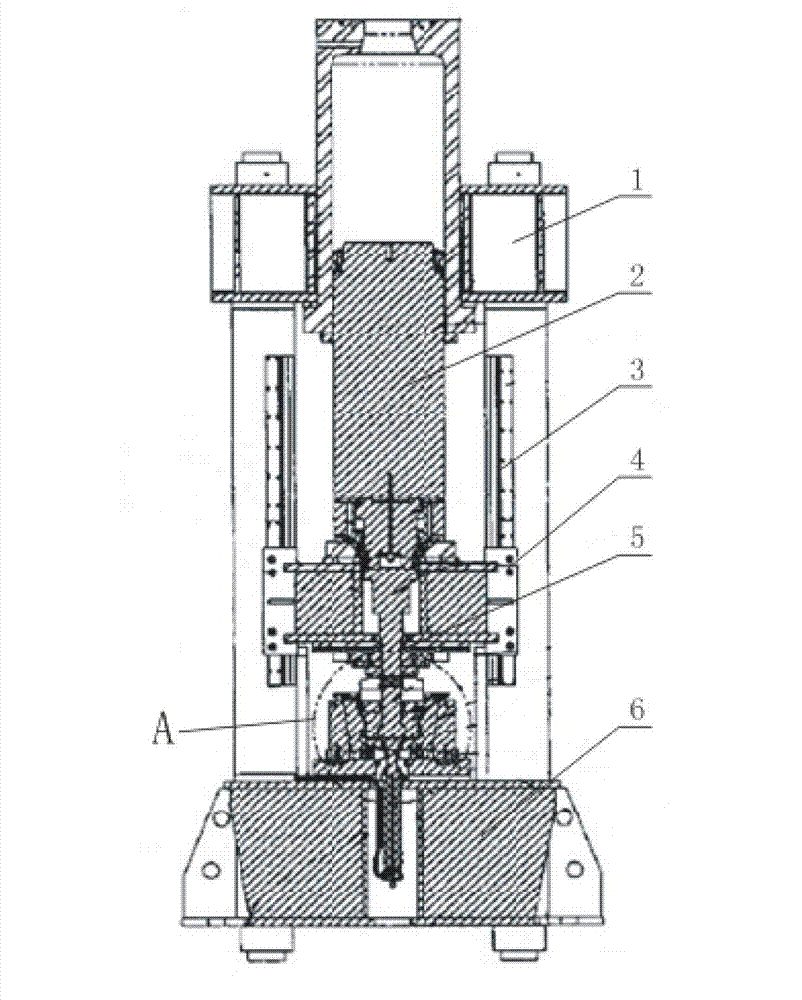

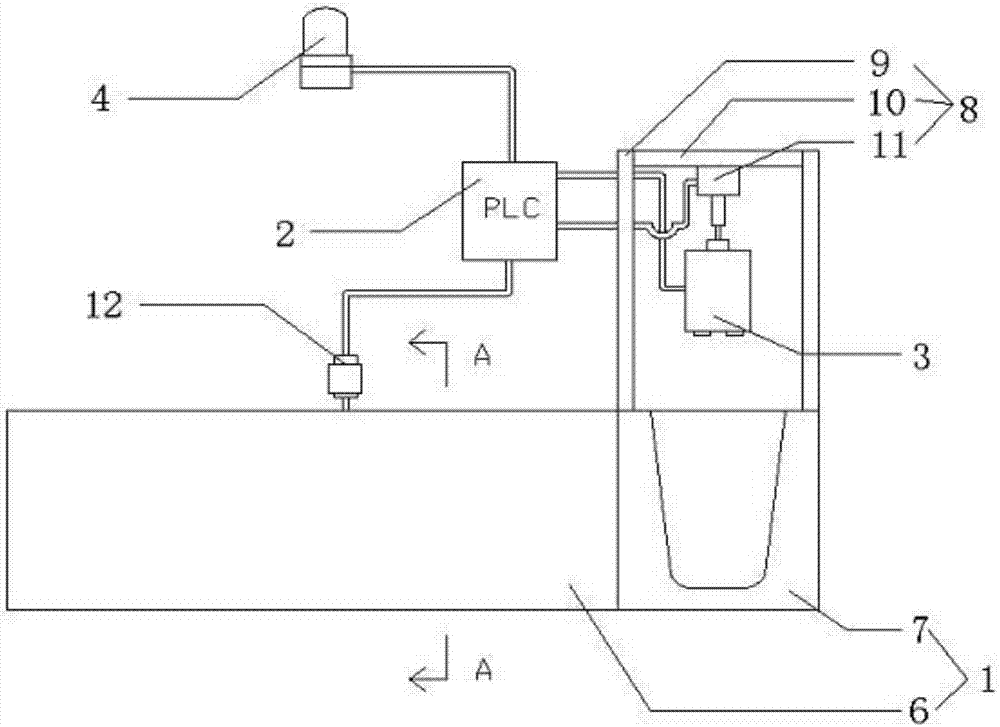

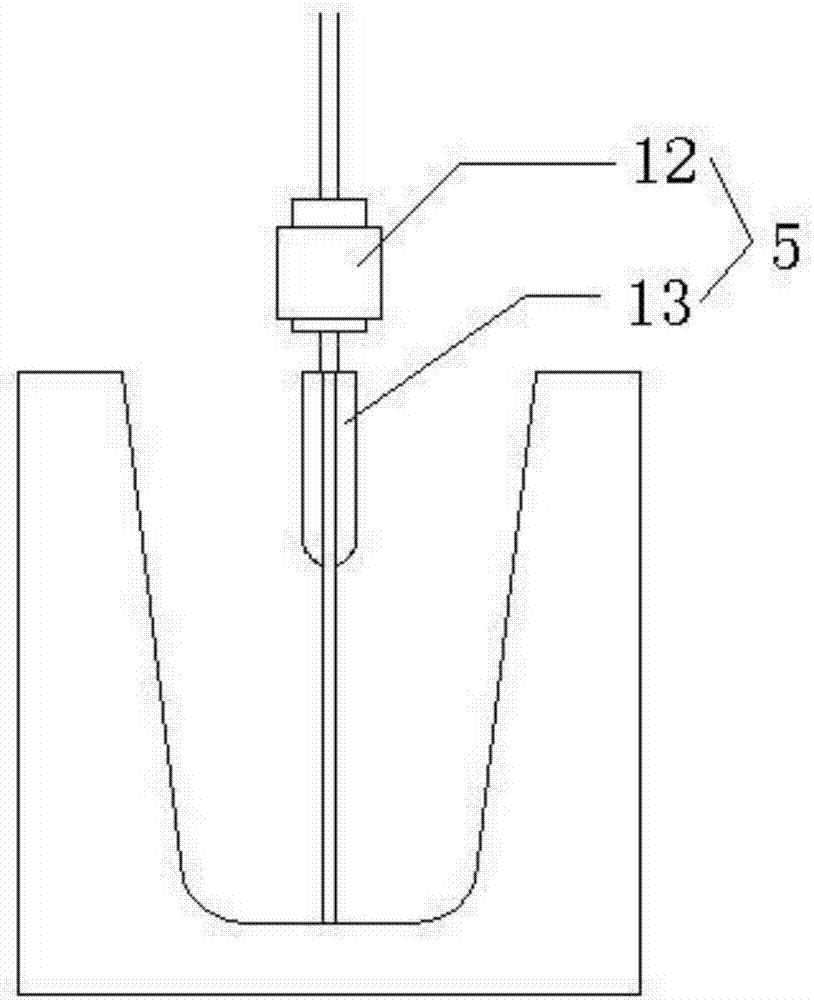

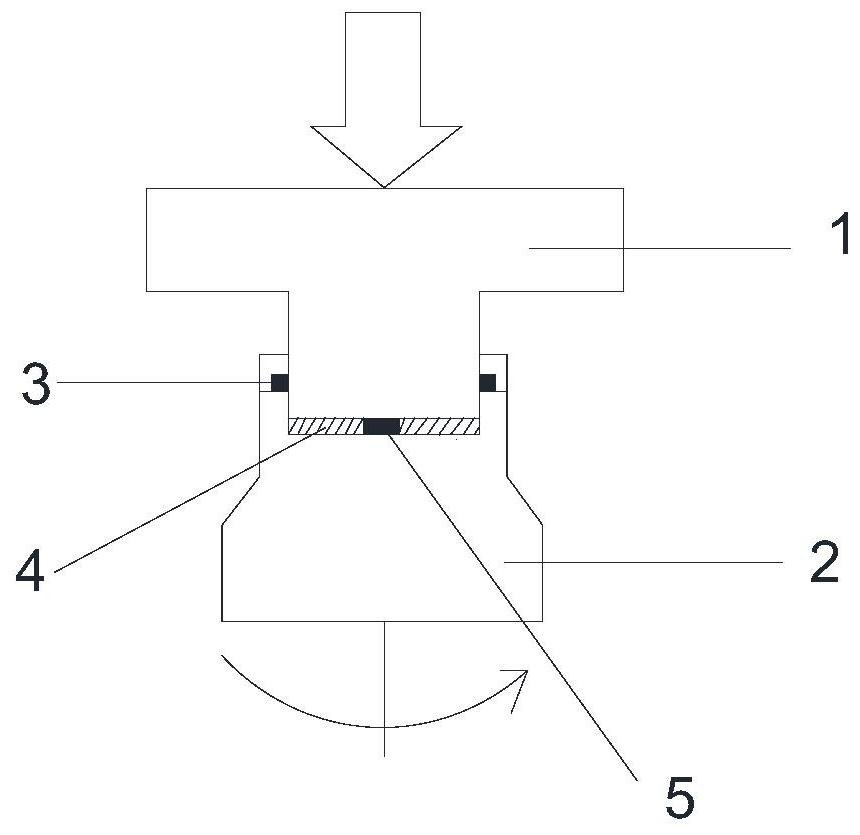

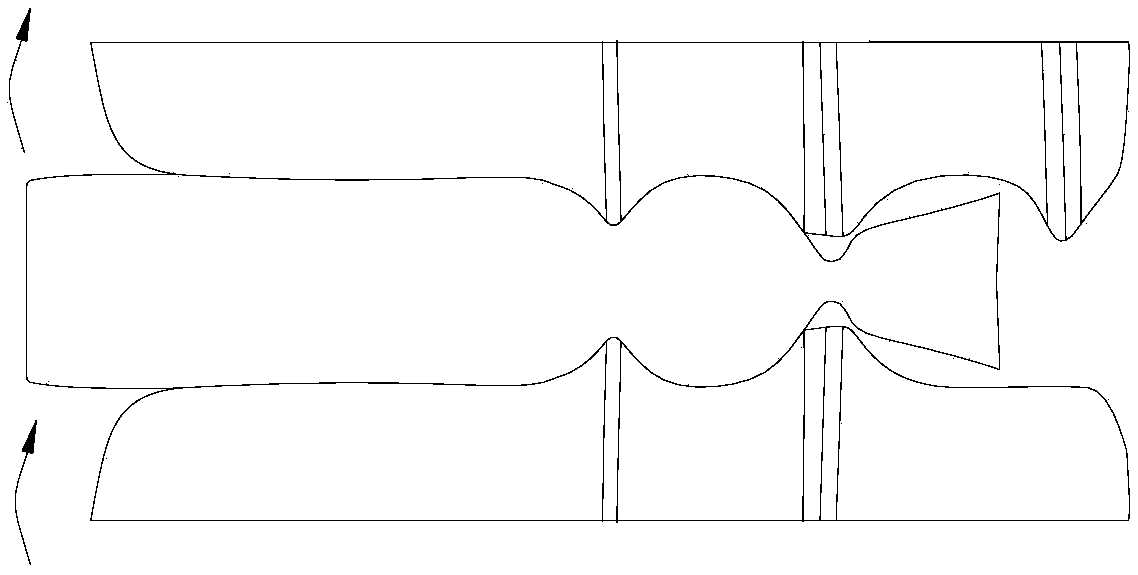

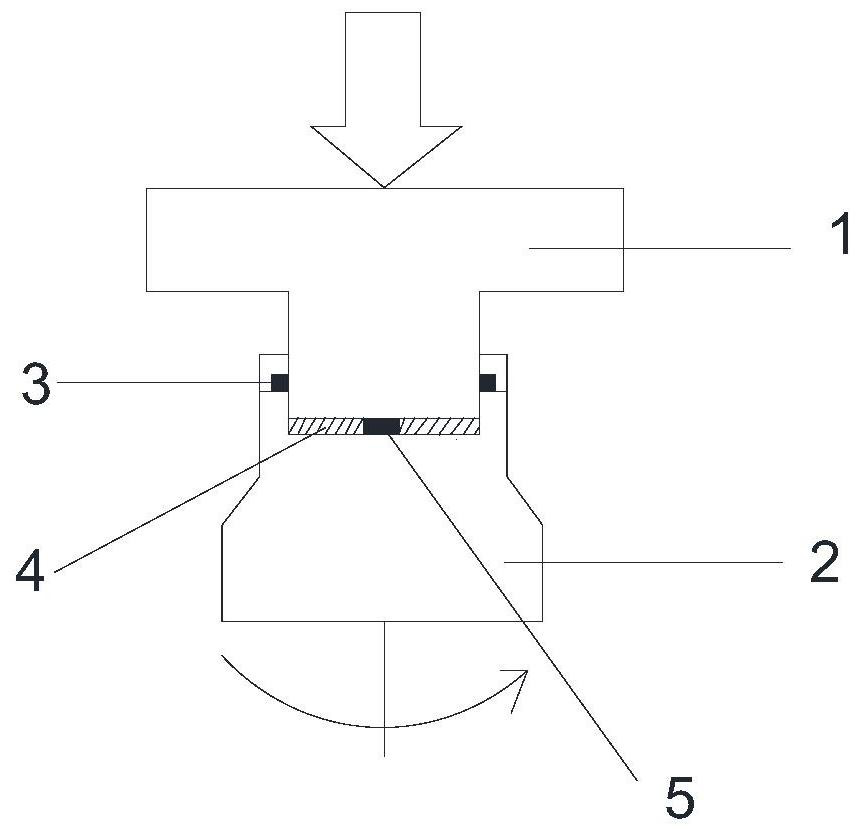

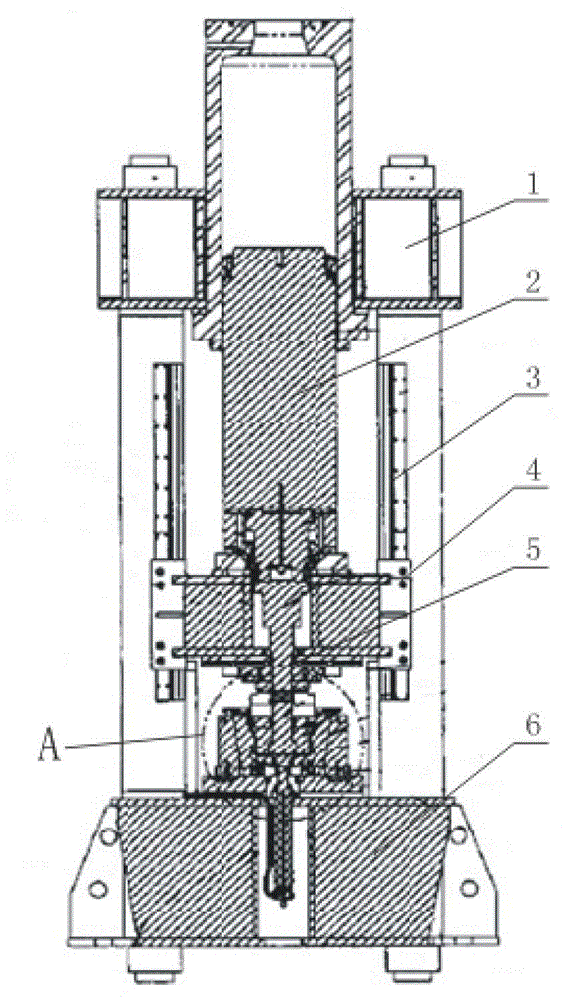

Grain refinement method and device thereof

The invention provides a grain refinement method, comprising the steps of carrying out equal-channel angular pressing on blanks and simultaneously subjecting the blanks to ultrasonic wave actions to obtain an ultrafine grain material. A grain refinement device is further provided, which comprises an equal-channel angular pressing mold and is characterized by further comprising an ultrasonic wave system, the distance between the output end of the ultrasonic wave system and the outlet of the equal-channel angular pressing mould is 0-500mm, and the output end of the ultrasonic wave system and the outlet of the equal-channel angular pressing mould are located on the same horizontal plane. Compared with the traditional equal-channel angular pressing model, by adopting the ultrasonic wave system, the invention ensures that a grain boundary is caused to vibrate violently and break under the action of ultrasonic waves when a material passes through the corner of the equal-channel angular pressing mould and is subjected to violent hearing deformation, thereby obviously improving the effect on fining grains and being particularly suitable for the preparation of large radial dimension nanocrystalline materials.

Owner:WUHAN UNIV OF TECH

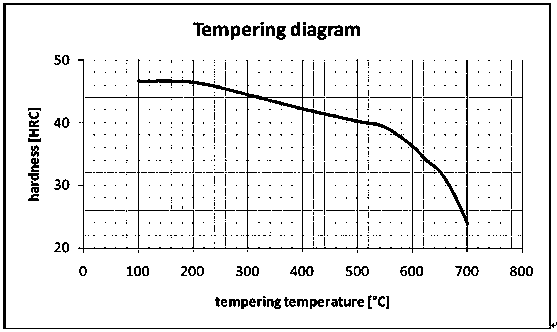

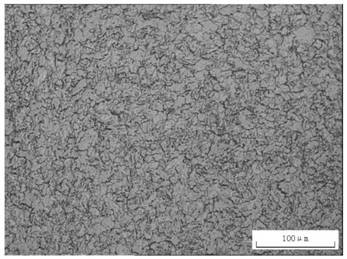

Highly-polished prehardened die steel, and preparation method thereof

The invention relates to a highly-polished prehardened die steel, and a preparation method thereof. The highly-polished prehardened die steel is composed of, by mass, 0.21 to 0.25% of C, Si<=0.30%, 1.40 to 2.00% of Mn, 1.30 to 1.70% of Cr, 0.60 to 1.00% of Ni, 0.40 to 0.60% of Mo, V<=0.10%, P<0.015%, S<0.005%, 0.02 to 0.04% of Nb, and the balance Fe. The preparation method comprises following steps: material blending, smelting, casting, and hot charging; high temperature diffusion heat treatment, multi-directional forging heat processing, after-forging heat treatment, and sawing; and hardeningand tempering heat treatment. The hardness of the obtained tempered martensite structure ranges from 38 to 42HRC. The advantages of the highly-polished prehardened die steel are that: cost is low, hardenability and hardness are high, and polishing properties and cleavage line etching performance are excellent.

Owner:ZHANGJIAGANG CITY GUANGDA MACHINERY FORGING

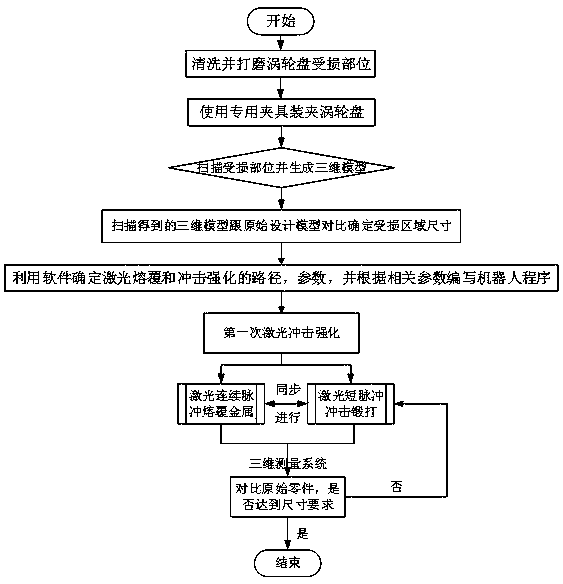

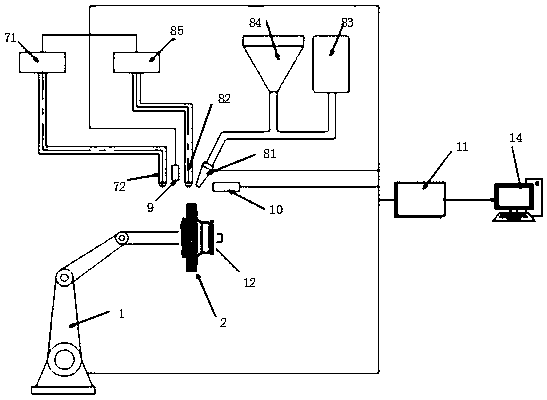

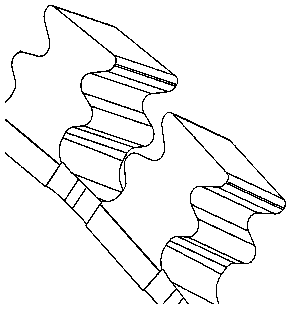

Double-laser forging remanufacturing and repairing device for damaged mortises of high-temperature alloy small-size structure turbine disc and application method thereof

ActiveCN108754490AImprove bindingExtended service lifeMetallic material coating processesNumerical modelsSuperalloy

The invention relates to the technical field of remanufacturing and repairing of aeronautical parts, in particular to a double-laser forging remanufacturing and repairing device for damaged mortises of a high-temperature alloy small-size structure turbine disc and an application method thereof. Firstly, the damaged surface of the turbine disc is cleared, and damaged residues and the like are removed; a numerical model is generated by scanning the surface of a component point by point, then a complete component three-dimensional model is generated on a computer through three-dimensional software, the complete component three-dimensional module is compared with an original three-dimensional model, and the positions of all points and the related sizes are determined; a short-pulse laser is utilized to conduct impact strengthening processing on notch parts firstly, so that material structures at the notch parts are refined, and the bondability of notches is improved; and then, double laserbeams are utilized to repair the damaged parts, wherein the first-beam continuous pulse laser serves as heat source molten metal powder to repair the damaged parts such as tenon teeth of the turbinedisc, and the second-beam short pulse laser directly acts on the surface of high-temperature laser cladding metal. The pulse width is changed according to the variable section size of the repaired mortises, and macroscopic deformation is controlled.

Owner:GUANGDONG UNIV OF TECH

Aluminum alloy material, preparation method and application of aluminum alloy material in solar energy photovoltaic support

InactiveCN108165845AHigh strengthHigh tensile strengthPhotovoltaic supportsPhotovoltaic energy generationAlloyImpurity

The invention belongs to the field of chemical materials and particularly relates to an aluminum alloy material, a preparation method and application of the aluminum alloy material in a solar energy photovoltaic support. The aluminum alloy material is composed of the following components of, by mass, 0.2%-0.4% of Si, 0.08%-0.20% of Cu, 0.6%-0.8% of Mg, 0.15%-0.25% of Zr, 0.15%-0.25% of Ti, 0.01%-0.15% of Mn and the balance aluminum and inevitable impurities. According to the designed aluminum alloy material, by adding metal elements of Si, Cu, Mg, Zr, Ti, Mn and the like, the grain refinementdegree is improved by a large margin, and the effect in the aspect of promoting the comprehensive properties such as tensile strength, the elongation and the corrosion-resistant property of the aluminum alloy material is significant. The aluminum alloy material is used for preparing a solar energy photovoltaic support profile, so that the corrosion-resistant property of the photovoltaic support prepared from the aluminum alloy material is better than that of a traditional aluminum alloy photovoltaic support component.

Owner:柏涛涛

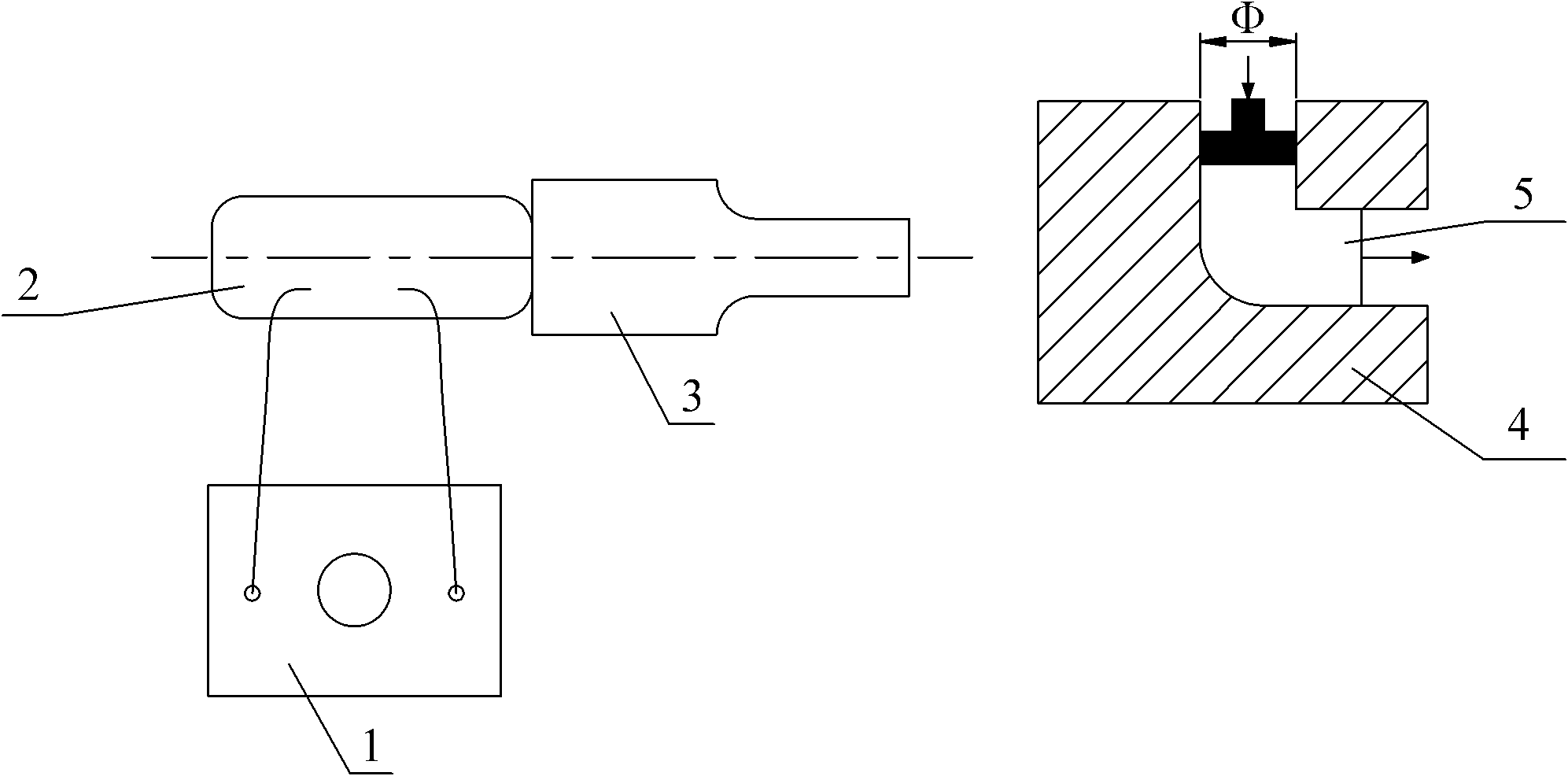

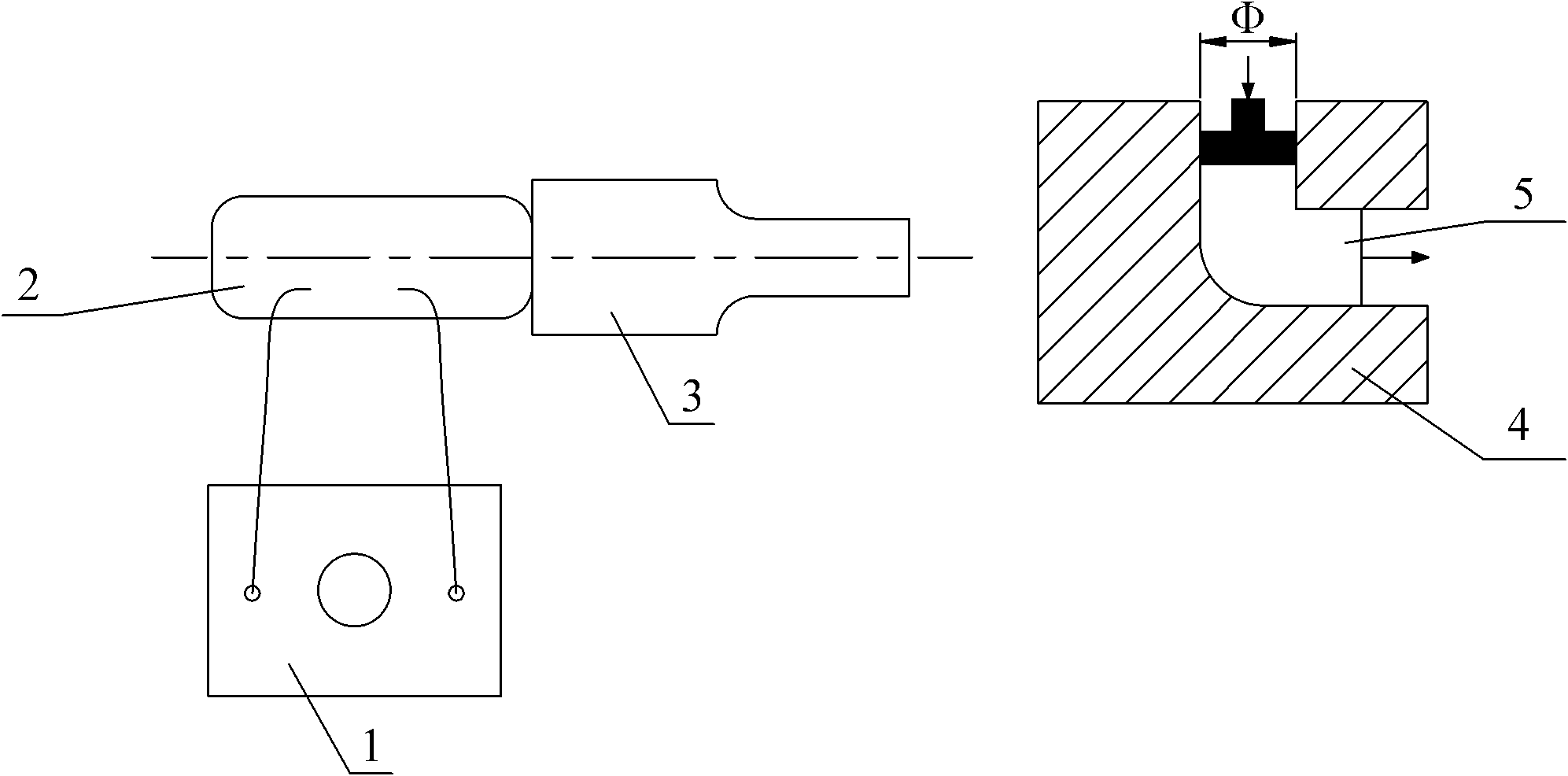

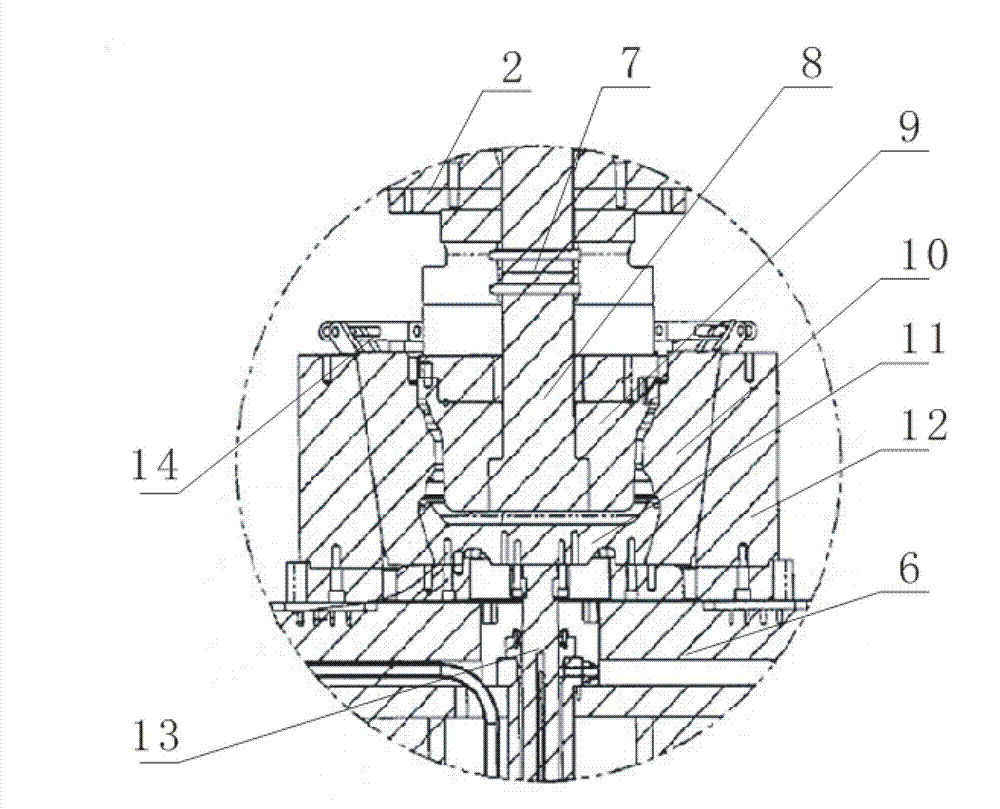

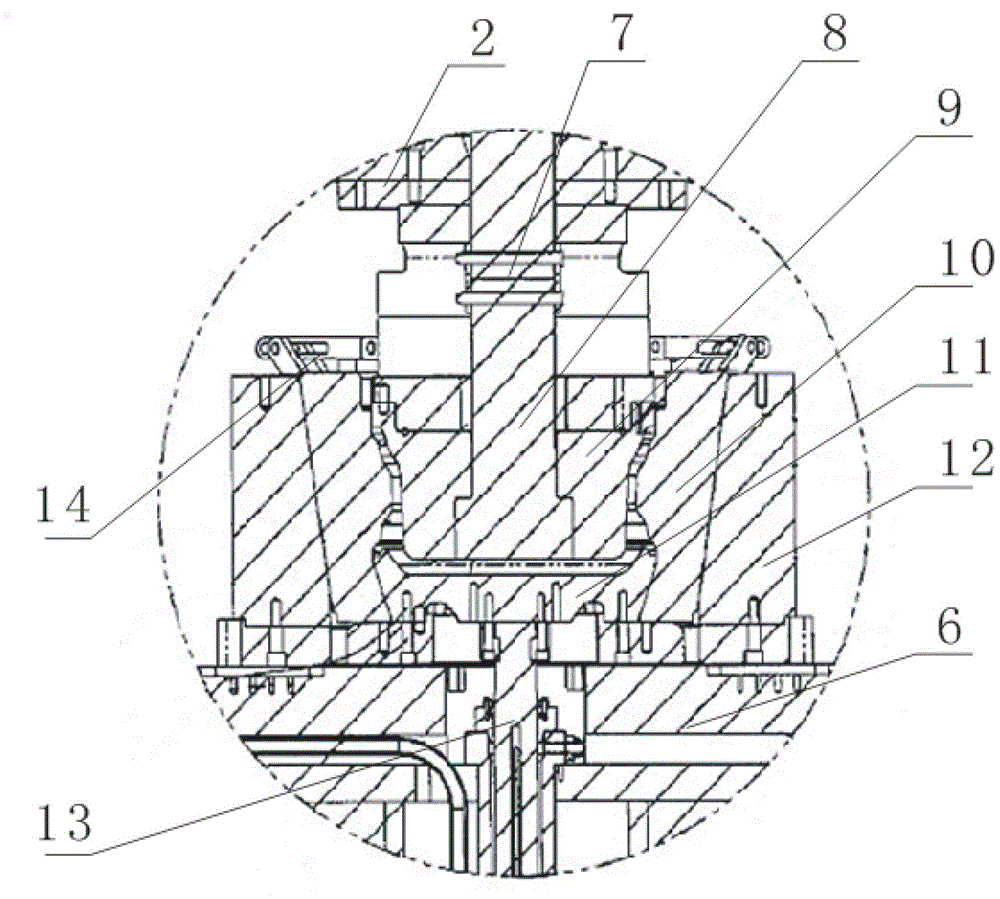

Molten soup forging method and die thereof

ActiveCN103084560AAvoid damageMeet mechanical performance requirementsMechanical propertyRefined grains

The invention relates to a molten soup forging method and a molten soup forging die. The molten soup forging method and the molten soup forging die comprise an upper die, a lower die and side dies, to-be-produced wheel-shaped die cavity is formed among the upper die, the lower die and the side dies, wherein the molten soup forging method and the molten soup forging die are characterized in that a lower die assembly formed by coaxially enclosing the plurality of side dies and the lower die is coaxially embedded in a pressure bearing die sleeve, and a hydraulic pressure lifting mechanism which is vertically upward and used for lifting products is coaxially arranged at the lower end of the lower die. The molten soup forging method and the molten soup forging die have the advantages of improving product quality, reducing molten soup dosage, improving inner structure refined grain of metals, improving product mechanical property, tensile property and other overall properties, shortening product production time, reducing equipment maintenance cost, increasing output, improving production efficiency and prolonging die service life.

Owner:TIANJIN NANUO MACHINERY MFG

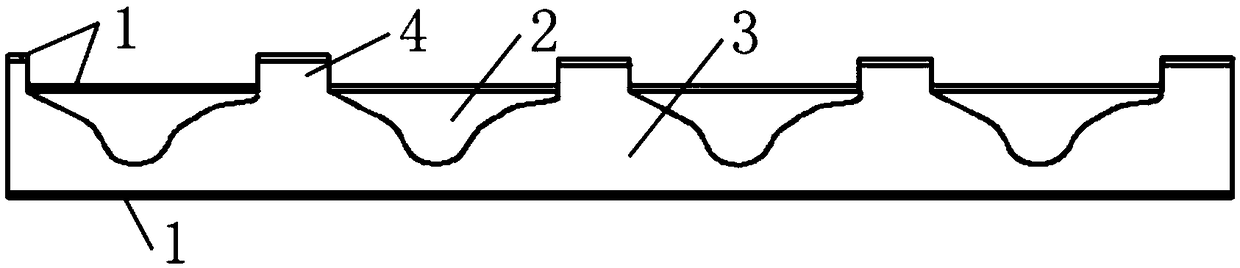

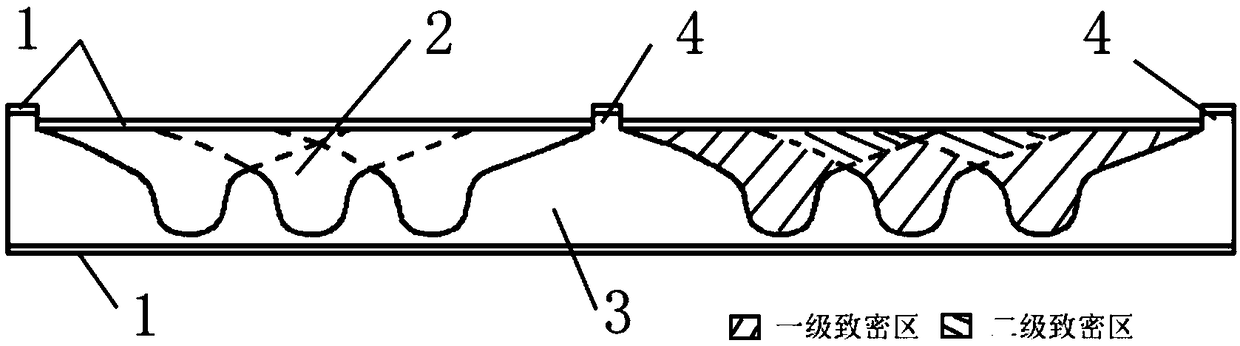

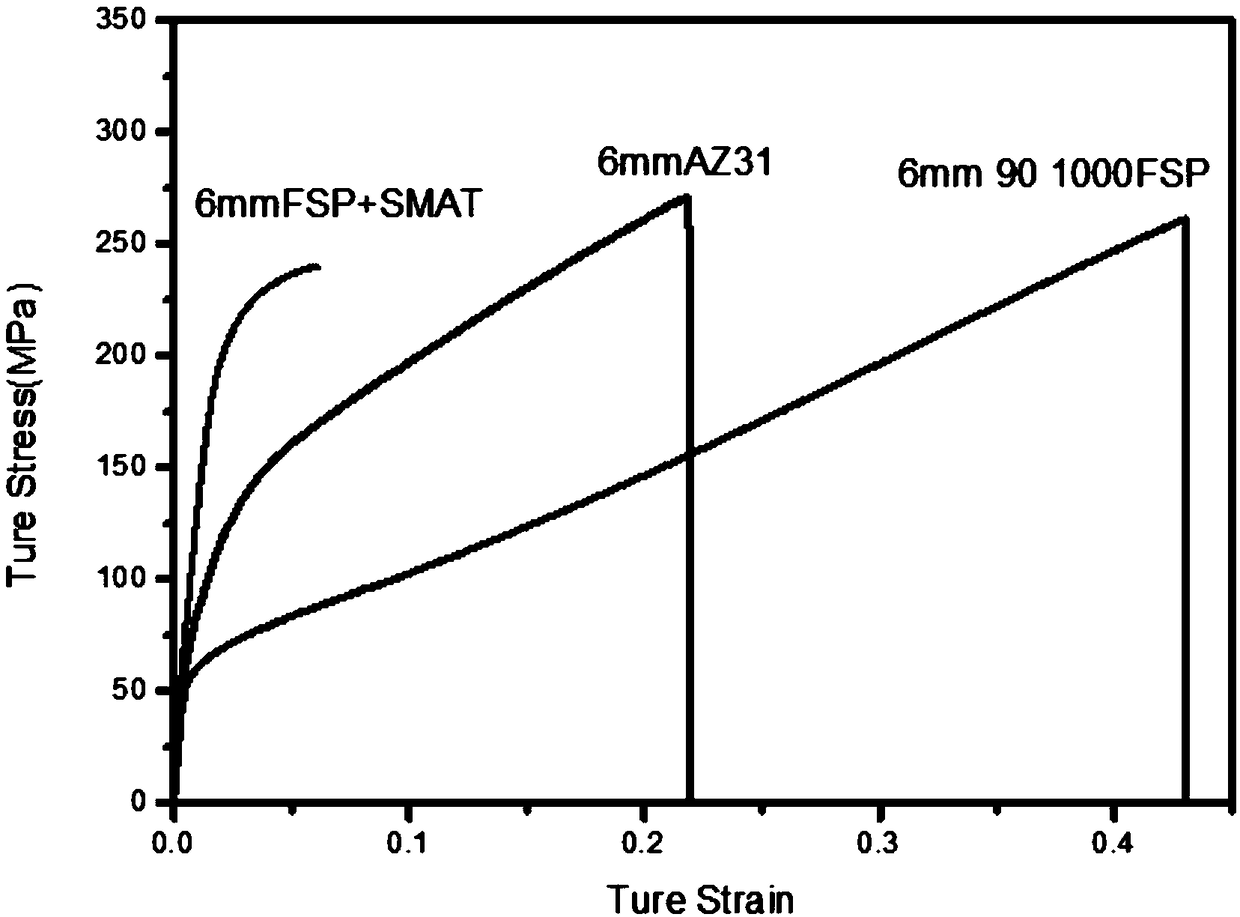

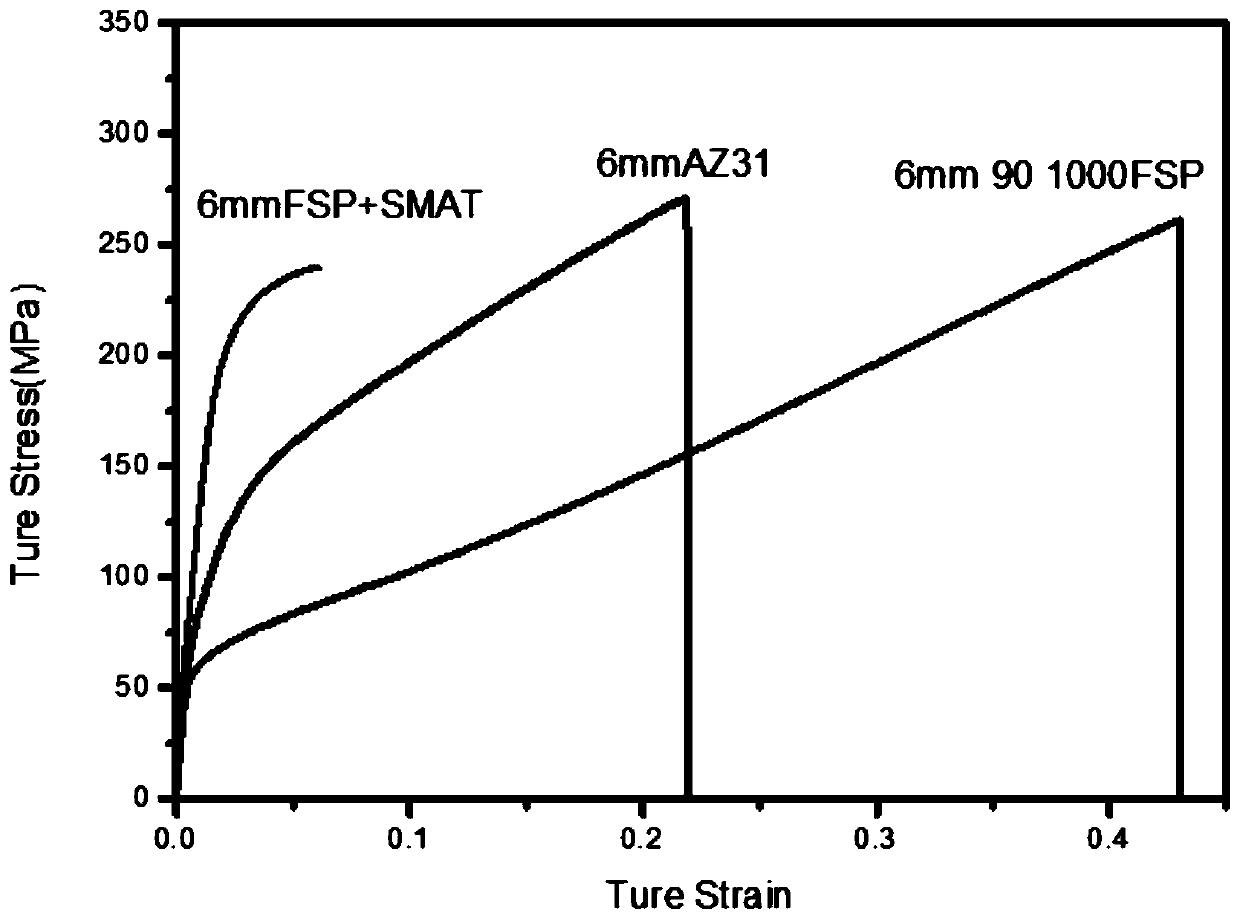

High-intensity and high-plasticity magnesium alloy composite plate and preparation method thereof

The invention provides a high-intensity and high-plasticity magnesium alloy composite plate and a preparation method thereof. The magnesium alloy plate is prepared from Mg, Al, Zn, Mn, Si, Cu and Fe,and is excellent in mechanical properties such as intensity, plasticity and the like; the room temperature ductility of the plate is not less than 21 percent; the surface vickers microhardness is notless than 126 Hv; and the tensile strength is not less than 270.9 MPa. According to the method provided by the invention, a product with good mechanical properties is finally achieved by steps of stirring and friction processing treatment, surface peening and the like. The raw materials of the composite plate adopt magnesium alloy industry-level rolled plates; the production process is relativelysimple, and the overall performance of the plate is obviously improved.

Owner:HEFEI UNIV OF TECH

High-impact-toughness foamed aluminum based on A356 aluminum alloy and production process of high-impact-toughness foamed aluminum

The invention relates to a foamed aluminum material, in particular to high-impact-toughness foamed aluminum based on A356 aluminum alloy and a production process of the high-impact-toughness foamed aluminum. The production process comprises the steps that (1) 12-20 parts, by weight, of a foaming agent is ground and screened through a sieve with 100-180 meshes; (2) 100 parts, by weight, of A356 aluminum alloy ingots are crushed, ground into particles and then evenly mixed with 8-15 parts, by weight, of inorganic nano-whiskers and 10-12 parts, by weight, carbon nano-tubes, then a mixture is placed into a smelting furnace and completely molten in an inert gas atmosphere, afterwards, the foaming agent is sucked in to the smelting furnace under negative pressure, and a molten aluminum mixture is obtained after uniform mixing; (3) the molten aluminum mixture obtained in the step (2) is poured into a mold, the mold is then pushed into a foaming furnace, and heat preservation is conducted for1-2h at the temperature of 680-700 DEG C; and (4) the mold enters a cooling system to be cooled, and thus the foamed aluminum is obtained. According to the high-impact-toughness foamed aluminum basedon the A356 aluminum alloy and the production process of the high-impact-toughness foamed aluminum, the mixture of the inorganic nano-whiskers and the carbon nano-tubes is added in the forming processof the foamed aluminum, and thus the impact toughness of the aluminum is remarkably improved.

Owner:JIESHOU JINGHUA TECH INFORMATION CONSULTING SERVICE CO LTD +1

Solar photovoltaic support aluminum alloy material

InactiveCN108165846AImprove corrosion resistanceImprove protectionPhotovoltaic supportsPhotovoltaic energy generationAramidImpurity

The invention belongs to the field of chemical materials, and particularly relates to a solar photovoltaic support aluminum alloy material. The solar photovoltaic support aluminum alloy material includes a core die and a fiber reinforcing layer which is arranged at the outer surface of the core die in a wrapping mode, and the core die is made of aluminum alloy which comprises, by mass, 0.1-0.5% ofSi, 0.05-0.25% of Cu, 0.5-0.85% of Mg, 0.1-0.3% of Zr, 0.1-0.25% of Ti, 0.01-0.15% of Mn, and the balance Al and inevitable impurities; and the fiber reinforcing layer is fiber reinforcing plastic. The solar photovoltaic support aluminum alloy material is produced by aramid fiber cloth reinforcing materials pasting on the surface of an aluminum alloy core die, the existence of the fiber reinforcing materials can support fine protection for the aluminum alloy core die, so that a photovoltaic support produced by the solar photovoltaic support aluminum alloy material has better anti-corrosion performance compared with a traditional aluminum alloy photovoltaic support component.

Owner:柏涛涛

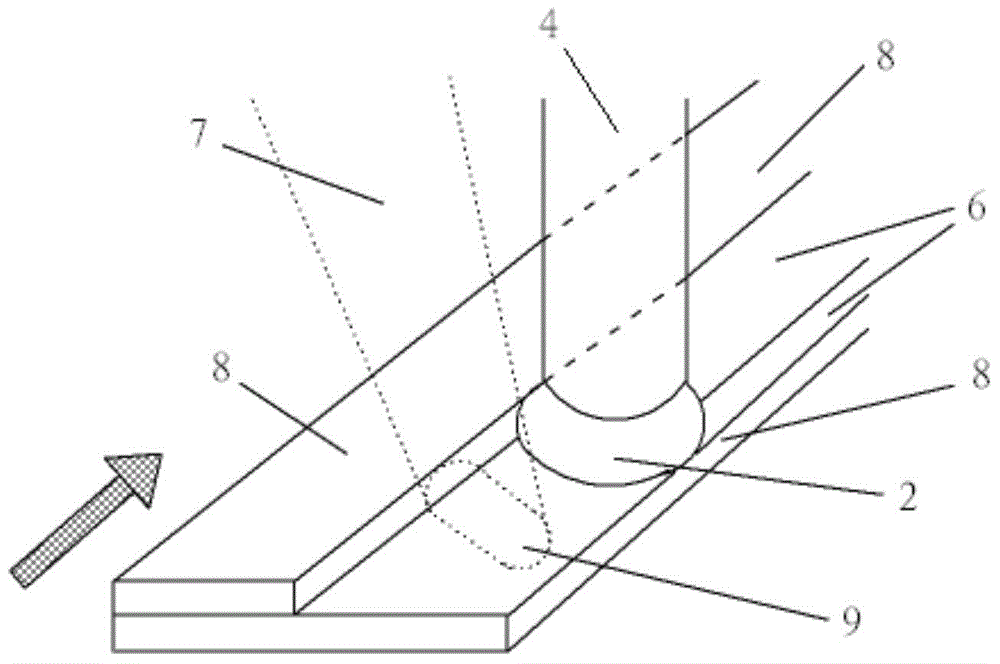

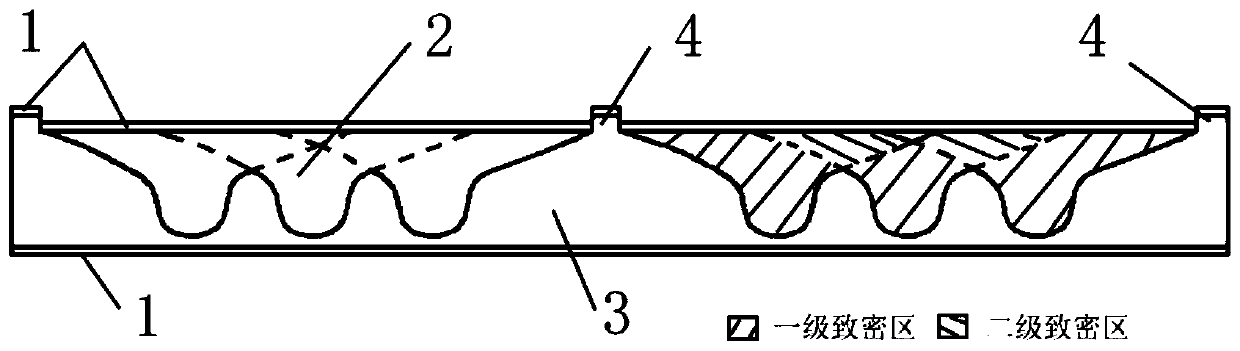

Laser-assisted liquid metal synchronously-casting mould-free forming method

ActiveCN105057628AImprove grain refinementAvoid the disadvantages of grain growthAdditive manufacturing apparatusLaser assistedControl software

The invention relates to a laser-assisted liquid metal synchronously-casting mould-free forming method. The laser-assisted liquid metal synchronously-casting mould-free forming method comprises the steps that (1) a laser device is made to aim at a movement front area to be covered with a melt, the time when the laser device is started and the time when the laser device is stopped are set to be synchronous with the time when a base plate starts to move and the time when the base plate stops moving in control software, a laser device power source is started, the parameters of the laser device are adjusted, and the preparation is made for light emitting; (2) a movement switch is turned on, the melt is squeezed out of a crucible under pressure and falls onto the base plate below an outlet of the crucible, and laser light is irradiated onto the movement front area, of the melt, on the base plate at the same time; and (3) forming is ended, the movement switch is turned off, pressurizing of the melt in the crucible is stopped, the melt stops flowing, and laser light irradiation is stopped at the same time. According to metal formed through cast rolling according to the method, the fineness of grains is high, and the compact degree approximates to or reaches the rolling level or the forging level; meanwhile, metallurgical bonding of interlayer interfaces can be well achieved, and the quality of formed products is high.

Owner:广东空天科技研究院

Improved CTP plate base aluminum alloy strip based on 1052# aluminum alloy

The invention discloses an improved CTP plate base aluminum alloy strip based on a 1052# aluminum alloy. The improved CTP plate base aluminum alloy strip is manufactured through the procedures of melting, refining, cast rolling, finish rolling, stretch bending and straightening. To save the production time and improve the production efficacy, a 1052# aluminum alloy strip is directly selected as araw material, the excellent physical and mechanical performance is reserved, meanwhile, an Al-Ti-B wire and a titanium-magnesium alloy strip are selected in a grain refining agent, the integral feeding amount of the titanium element is increased, and the grain refining degree is improved; due to the mixed magnesium element, the electrolysis quality is better improved, a sand mesh layer can be better finely and evenly improved, the sand mesh value Ra is greatly improved, and the CTP plate base quality requirement is completely met; and through the improvement on a runner, the feeding frequencyof aluminum molten liquid is improved, and rolling efficiency and quality improving is ensured as well. As a whole, the product CTP plate base aluminum alloy strip completely meets the CTP plate basequality requirement, and meanwhile the beneficial effects of the simple technology and the high production efficiency are achieved.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

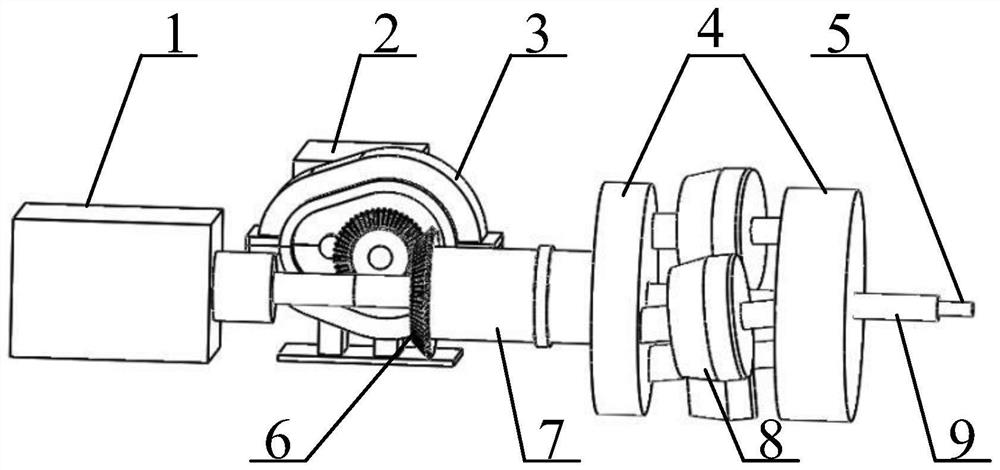

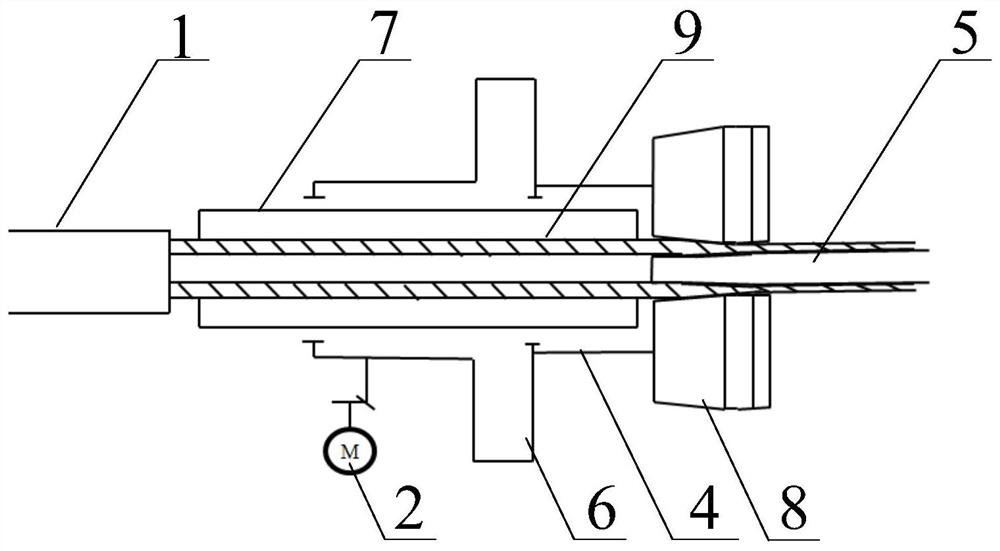

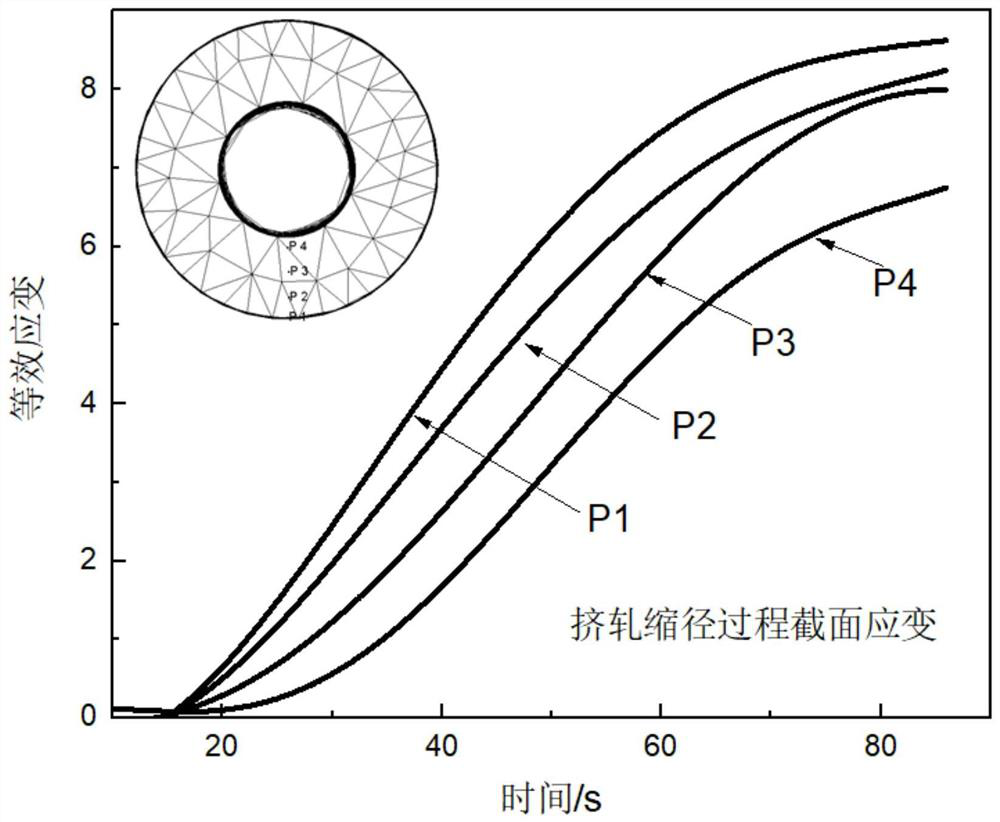

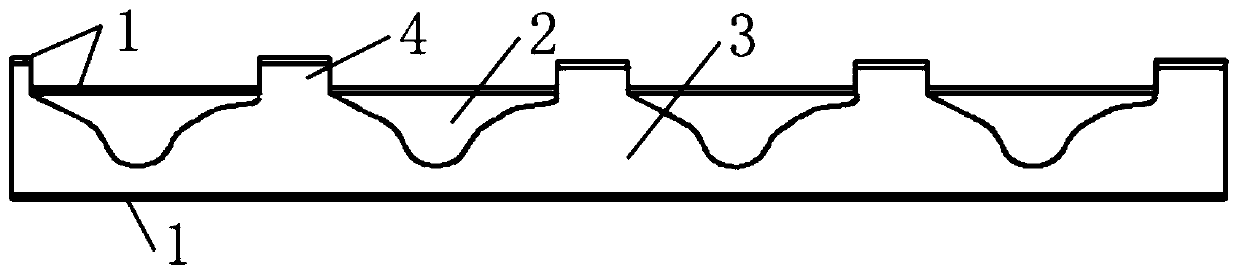

Quick extruding and rolling reduction forming device and method for titanium alloy tube blank

ActiveCN111644466AImprove grain refinementImprove the overall performance of the productMetal rolling stand detailsMandrelsMoulding deviceStructural engineering

The invention provides a quick extruding and rolling reduction forming device and method for a titanium alloy tube blank. The device comprises a hydraulic cylinder, a sleeve assembly, a fixed rack, arotary turnplate and a mandrel which are successively arranged in a horizontal direction. By means of reasonable design and arrangement of a roll profile curve of a roller and a mandrel structure, thecross diameter of an oblique roller is decreased from middle to two sides, so that the roller has a certain feeding angle, a relatively large inlet taper angle and a relatively small outlet taper angle. Three oblique rollers fixed to the rotary turnplate are matched with the mandrel, so that an extruding and rolling reduction process of the tube blank is achieved. The device integrates the structural and movable characteristics of oblique rolling perforation, planetary rolling and extrusion, so that the preparation period can be shortened greatly, large plastic deformation of the metal tube blank is achieved, and a complex stress state needed by grain crushing and dynamic recrystallized grain refining is established, and therefore, the comprehensive performance of the tubular product is further improved.

Owner:SHANGI INST FOR ADVANCED MATERIALSNANJING CO LTD

Treatment technique of aluminum alloy profiles for photovoltaic assembly supports

ActiveCN108179292AHigh strengthHigh tensile strengthHot-dipping/immersion processesUltimate tensile strengthMetal

The invention belongs to the field of chemical engineering materials and particularly discloses a treatment technique of aluminum alloy profiles for photovoltaic assembly supports. The technique comprises the steps of preparation of alloy raw materials, fused mixing of the alloy raw materials, refining and deslagging of molten aluminum, pouring of the molten aluminum, acid pickling of castings, plating assisting of the castings, and passivating treatment of the surfaces of the castings. According to the treatment technique, aiming at existing aluminum alloy materials, by adding metal elementssuch as Mn, Cu, Si, Mg and Ta and through reasonable formula design, the alloy strength is effectively improved, the grain refinement extent is greatly increased, and the effects on improvement of comprehensive properties such as the tensile strength, the elongation and the anti-corrosion property of aluminum alloys and the firm forming quality of oxidation films are remarkable.

Owner:NANJING UNIV OF SCI & TECH

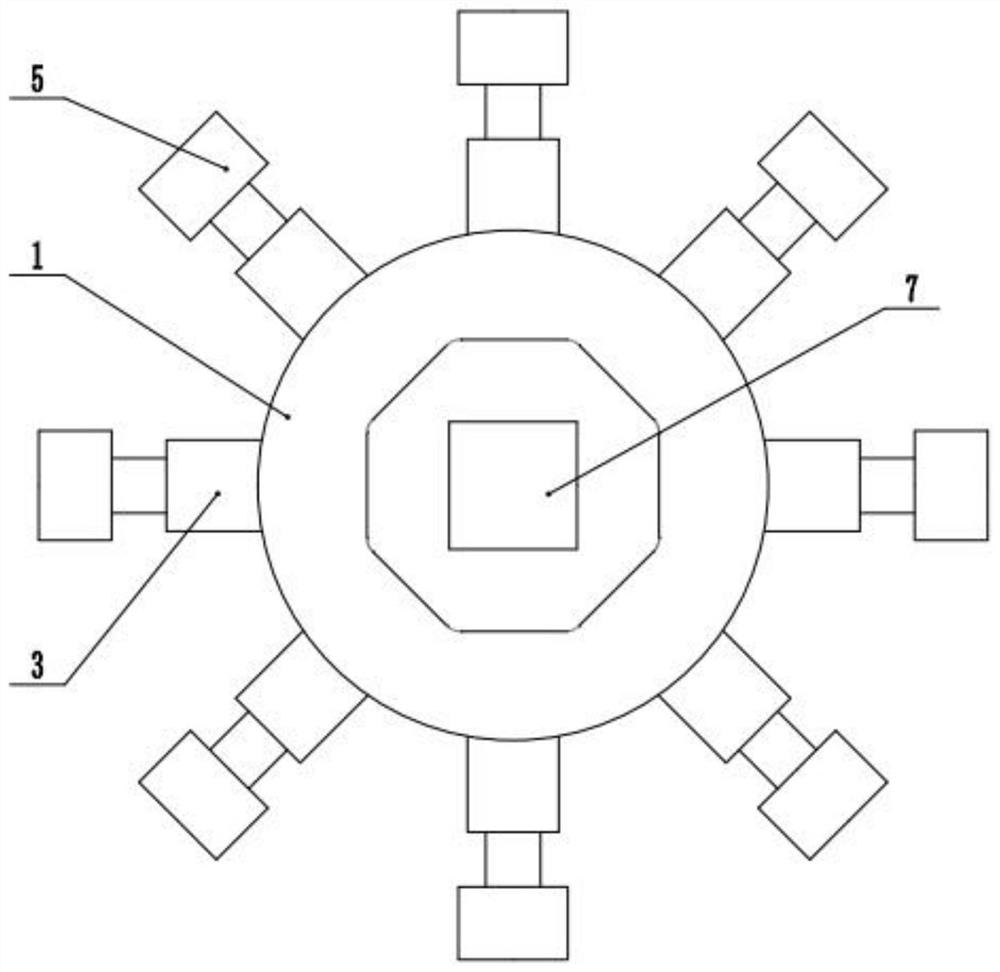

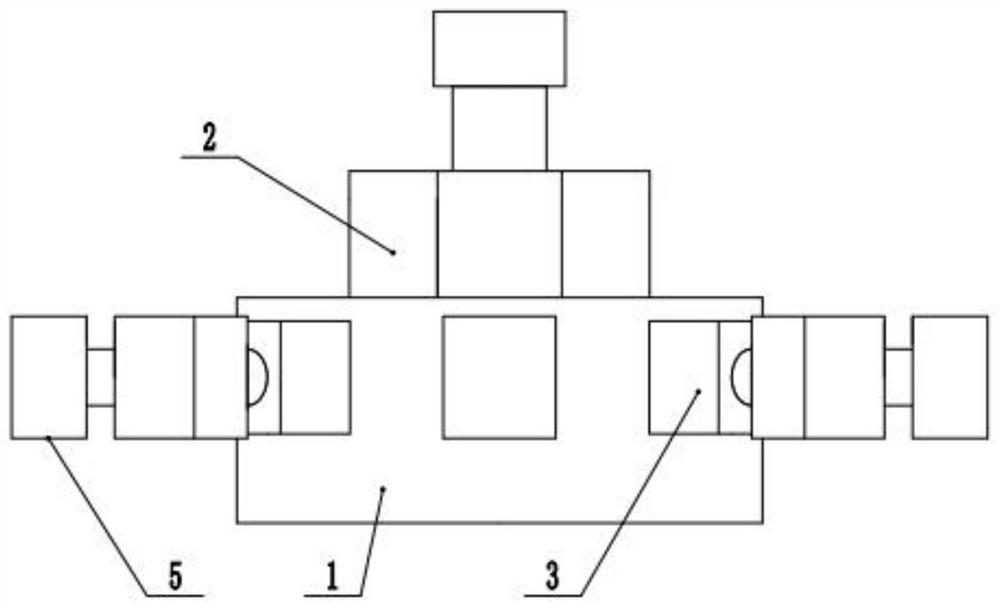

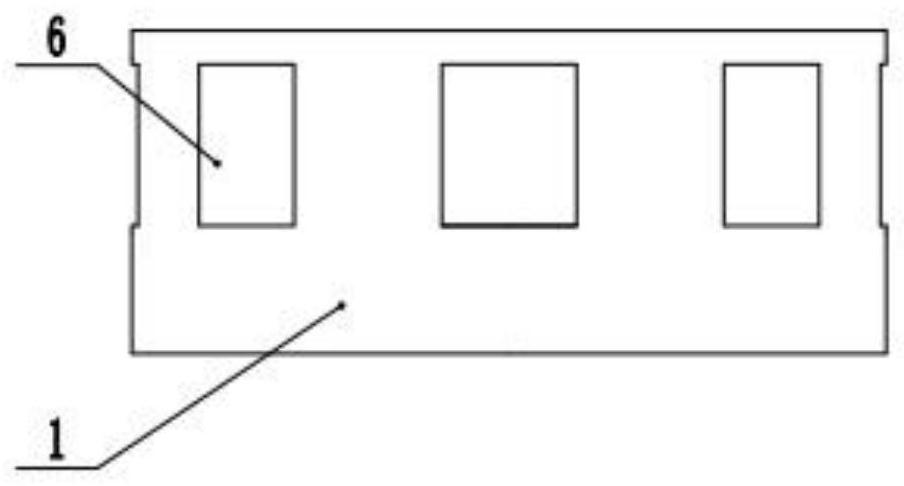

Multi-directional extrusion strong deformation die and process

The invention discloses a multi-directional extrusion strong deformation die. The multi-directional extrusion strong deformation die comprises a female die, an upper die pressure head and side pressure heads; and the female die is provided with a female die cavity. The invention further provides a multi-directional extrusion strong deformation process. The upper die pressure head moves downwards to extrude a blank; then the blank is extruded through four of the side pressure heads at intervals, and moving is stopped when the four pressure heads are connected in an abutted mode; and the blank continues being extruded through the other four side pressure heads at intervals till the four side pressure heads are connected in an abutted mode, and the extruding step is repeated till deformationis completed. The blank is synergistically extruded in multiple directions through the upper die pressure head and the multiple side pressure heads, the evenly-distributed excellent structure with thehigh grain refinement degree can be obtained, and the comprehensive performance of materials is remarkably improved; and the eight side pressure heads provide deformation in the eight loading directions, the problem that manual overturning is needed between times of a tradition process is solved, and because of the special process setting, the uniformity of structure refinement of all parts of the block materials is also improved.

Owner:YANSHAN UNIV

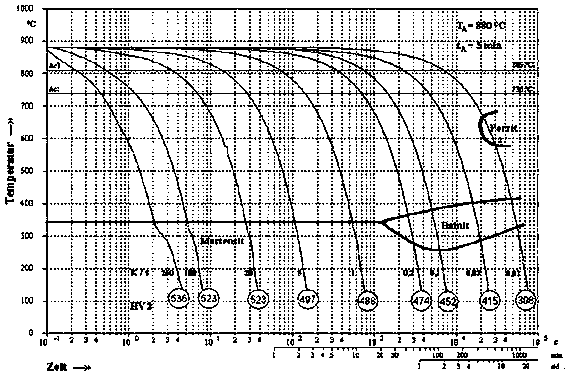

Martensitic steel copious cooling and high-pressure twisting mold and method

ActiveCN111621628ALower recrystallization activation energyReduce the amount of retained austeniteCryogenic treatmentUltimate tensile strength

The invention discloses a martensitic steel copious cooling and high-pressure twisting mold and method, and relates to the technical field of high-strength steel fine grain treatment. A mold with a groove formed in a lower mold is adopted, a USIBOR1500 martensitic high-strength steel plate is contained in liquid nitrogen in the groove of the lower mold, an upper mold descends to be pressed on theplate, the groove of the lower mold is filled with liquid nitrogen, then the upper mold and the lower mold are sealed, copious cooling treatment is carried out on a sample, and the treatment time is 20 min or 30 min; after copious cooling treatment, high-pressure twisting is carried out under the pressure being 4 GPa or 5 GPa, and the twisting angle is 360 degrees; and the USIBOR1500 martensitic high-strength steel plate subjected to copious cooling treatment of different processes and high-pressure twisting is subjected to vacuum electric field assisted recrystallization annealing treatment,the temperature is 750 DEG C, the soaking time is 20 min, and air cooling is carried out after heat preservation is finished. Grains of finally-prepared USIBOR1500 martensitic high-strength steel areeven tiny martensitic grains, and the yield strength, tensile strength and ductility of the steel are all improved to a certain degree by being compared with steel before treatment.

Owner:YANSHAN UNIV

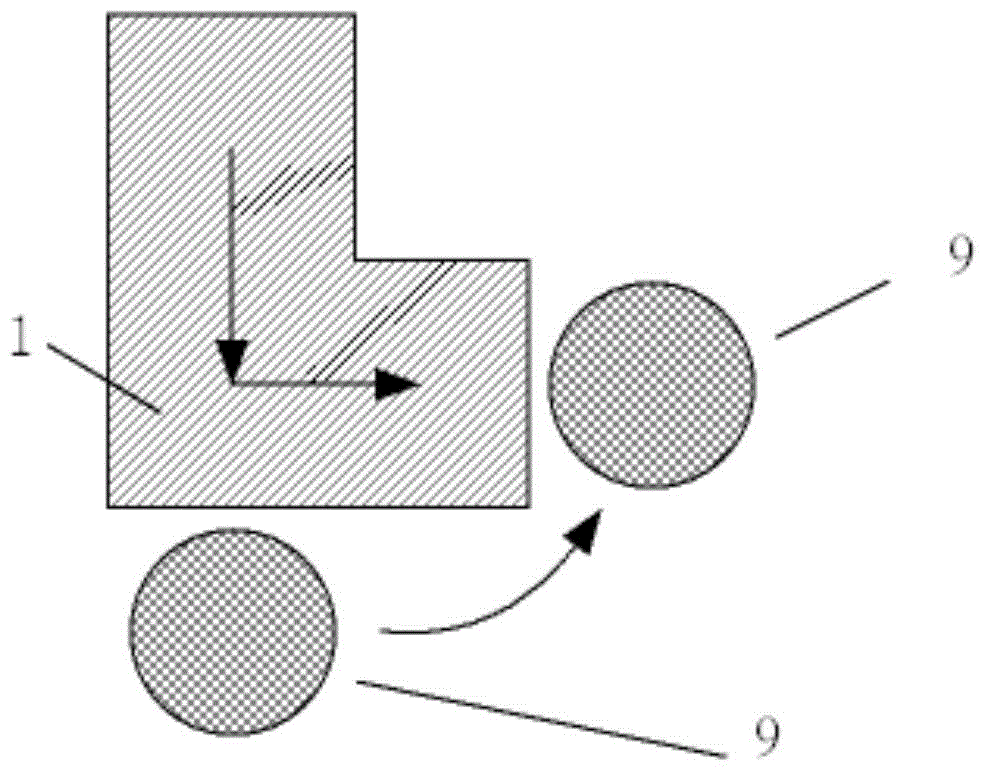

Manufacturing method for improving bearing steel ball surface layer performance

ActiveCN108393418AReduce intensityReduce hardnessBearing componentsWork cooling devicesShear stressSurface layer

The invention relates to the field of hot rolling molding heat treatment, in particular to a manufacturing method for improving bearing steel ball surface layer performance. The manufacturing method for improving the bearing steel ball surface layer performance comprises the following steps that 1, a steel bar is heated to the temperature higher than the austenitizing temperature, and a first inclined roller is used for one-way rotary hot rolling for forming a steel ball; and 2, when the steel ball in the step 1 is subject to hot rolling to 50%-70% deformation, a steel ball bar is transferredto a second inclined roller to be continuously subject to one-way rotary rolling, metal molding deformation of the steel ball bar generates a reverse macroscopic shear stress strip, and the inclined rolling direction of the second inclined roller is opposite to the inclined rolling direction of the first inclined roller, and the roller dip angles are the same. According to the manufacturing method, shortcomings in the existing technology are overcome, the steel ball surface layer (near surface) grain refinement degree is improved for achieving ultrafine grains, and molding damage is reduced.

Owner:DEQING TIANMA BEARING CO LTD

A kind of high-strength and high-plasticity magnesium alloy composite plate and its preparation method

The invention provides a high-intensity and high-plasticity magnesium alloy composite plate and a preparation method thereof. The magnesium alloy plate is prepared from Mg, Al, Zn, Mn, Si, Cu and Fe,and is excellent in mechanical properties such as intensity, plasticity and the like; the room temperature ductility of the plate is not less than 21 percent; the surface vickers microhardness is notless than 126 Hv; and the tensile strength is not less than 270.9 MPa. According to the method provided by the invention, a product with good mechanical properties is finally achieved by steps of stirring and friction processing treatment, surface peening and the like. The raw materials of the composite plate adopt magnesium alloy industry-level rolled plates; the production process is relativelysimple, and the overall performance of the plate is obviously improved.

Owner:HEFEI UNIV OF TECH

Martensitic Steel Cryogenic High Pressure Twist Die and Method

ActiveCN111621628BLower recrystallization activation energyReduce the amount of retained austeniteCryogenic treatmentUltimate tensile strength

The invention discloses a martensitic steel copious cooling and high-pressure twisting mold and method, and relates to the technical field of high-strength steel fine grain treatment. A mold with a groove formed in a lower mold is adopted, a USIBOR1500 martensitic high-strength steel plate is contained in liquid nitrogen in the groove of the lower mold, an upper mold descends to be pressed on theplate, the groove of the lower mold is filled with liquid nitrogen, then the upper mold and the lower mold are sealed, copious cooling treatment is carried out on a sample, and the treatment time is 20 min or 30 min; after copious cooling treatment, high-pressure twisting is carried out under the pressure being 4 GPa or 5 GPa, and the twisting angle is 360 degrees; and the USIBOR1500 martensitic high-strength steel plate subjected to copious cooling treatment of different processes and high-pressure twisting is subjected to vacuum electric field assisted recrystallization annealing treatment,the temperature is 750 DEG C, the soaking time is 20 min, and air cooling is carried out after heat preservation is finished. Grains of finally-prepared USIBOR1500 martensitic high-strength steel areeven tiny martensitic grains, and the yield strength, tensile strength and ductility of the steel are all improved to a certain degree by being compared with steel before treatment.

Owner:YANSHAN UNIV

A Forming Process of Large-diameter, Medium-Strength, and Heat-resistant Magnesium Alloy Thick-walled Cylindrical Parts

ActiveCN103909382BImprove deformation abilityImprove grain refinementThick wallPerformance requirement

The invention discloses a large-diameter moderately-strong heat-resisting magnesium alloy thick-wall barrel-shaped piece forming process. The process includes the steps of large-furnace smelting, semi-continuous casting, homogenizing annealing, varying-temperature multi-direction forging, mechanical punching, ring rolling forming and aging treatment. The varying-temperature multi-direction forging is conducted on an oil press, pressing speed is 200-400mm / min, upsetting reduction in pass is 30-40%, drawing down reduction in pass is 5-10%, blank before ring rolling forming is kept at the temperature of 380-400 DEG C for 4-8 hours, and rolling deformation is 60-80%. The thick-wall barrel-shaped piece 700-1100mm in outer diameter, 50-100mm in wall thickness and 300-700mm in height is manufactured. The thick-wall barrel-shaped piece is high in strength and good in heat resistance and meets size and performance requirements of structural parts in the aerospace field.

Owner:CENT SOUTH UNIV

A treatment process of aluminum alloy profiles for photovoltaic module brackets

ActiveCN108179292BHigh strengthHigh tensile strengthHot-dipping/immersion processesUltimate tensile strengthMetal

Owner:NANJING UNIV OF SCI & TECH

Treatment method for improving supporting strength of automobile storage battery

ActiveCN106834645AImprove wear resistanceEasy to support and fixFurnace typesMetallic material coating processesPulp and paper industryEngineering

The invention discloses a treatment method for improving the supporting strength for an automobile storage battery, and belongs to the technical field of automobile machining. Specifically, special modified treatment is carried out on a supporting frame for supporting the automobile storage battery; and the treatment method comprises the steps of (1) cleaning the supporting frame, (2) drying the supporting frame, (3) carrying out variable temperature treatment, and (4) carrying out surface treatment. According to the treatment method for improving the supporting strength for the automobile storage battery, the characteristics of the final treated supporting frame are improved, the strength, the wear resistance, the corrosion resistance and the like are well improved, and therefore the supporting strength and the installation stability for the storage battery are effectively guaranteed, and a good significance is achieved on the improvement of the overall performance of an automobile.

Owner:界首万昌新材料技术有限公司

Fine-grained magnesium alloy strip continuous extrusion production system and production method

ActiveCN102688907BShort processIncrease productivityExtrusion control devicesLine heatingManufacturing line

Owner:DALIAN JIAOTONG UNIVERSITY

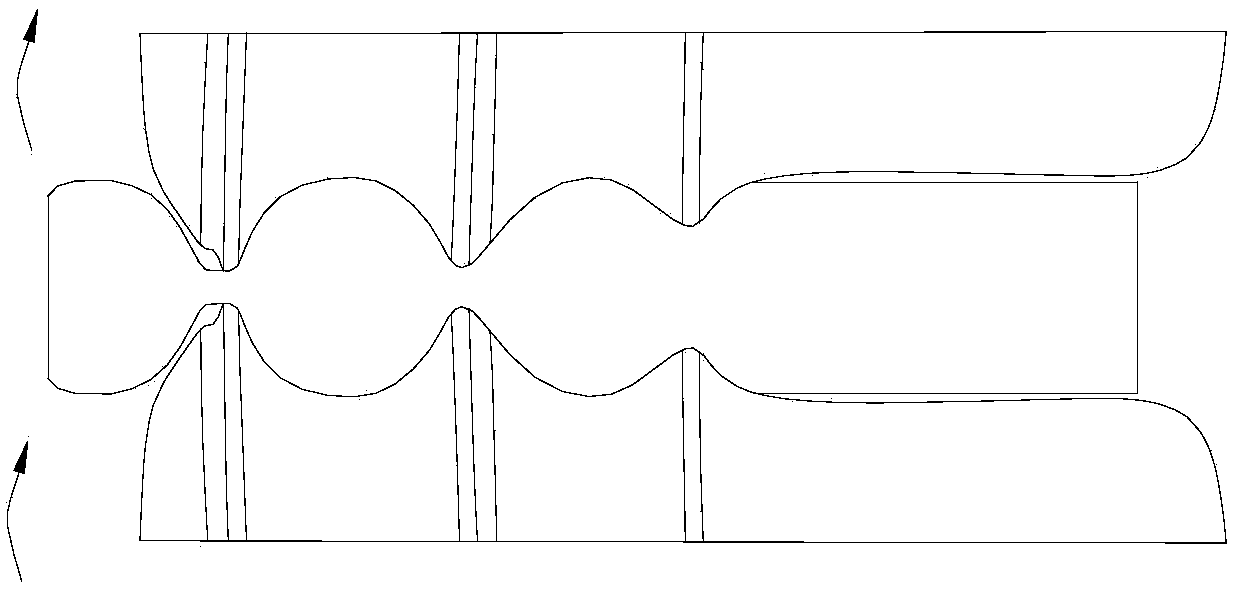

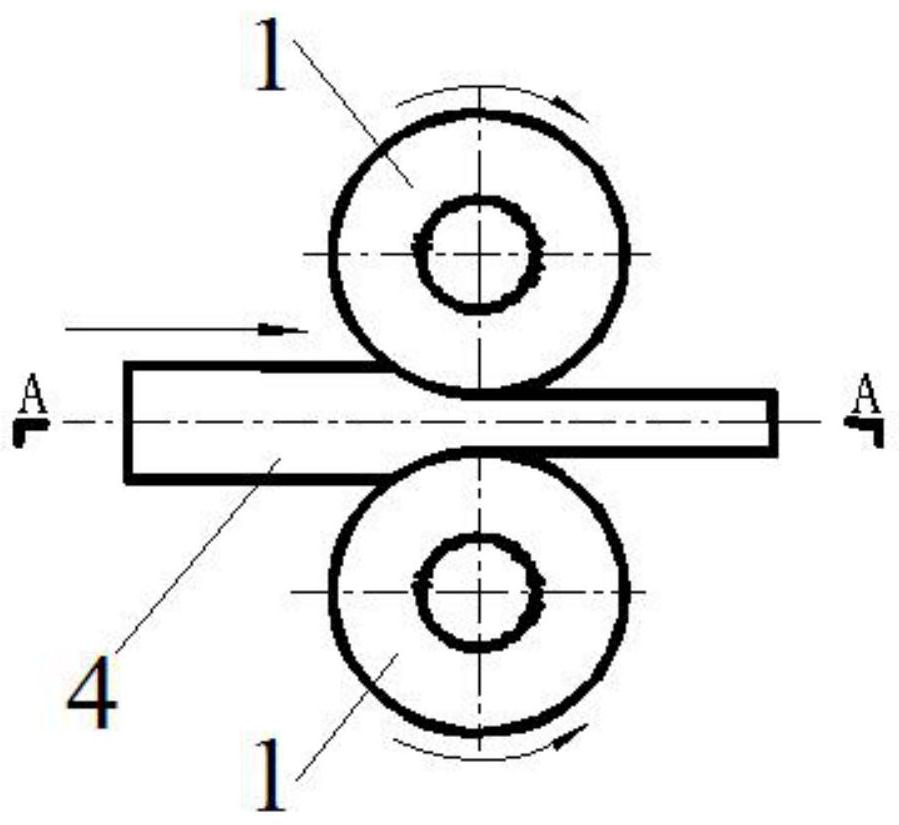

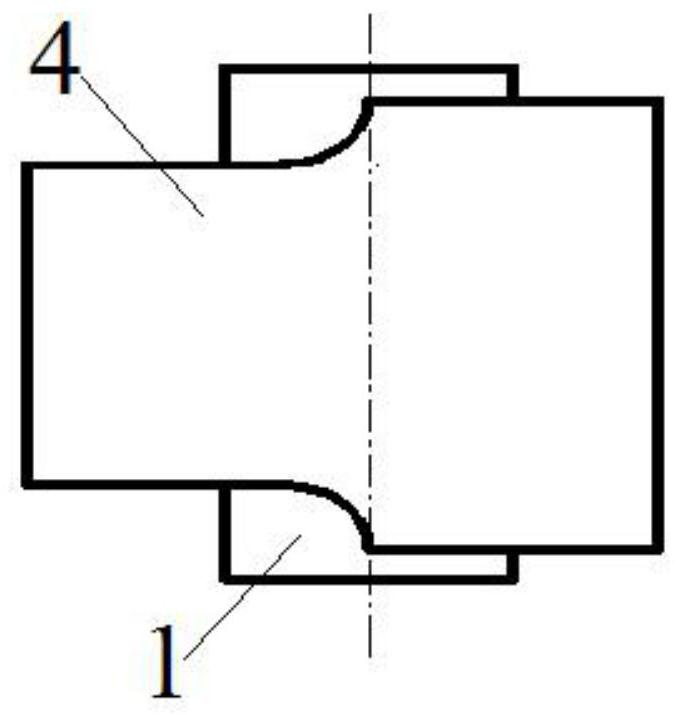

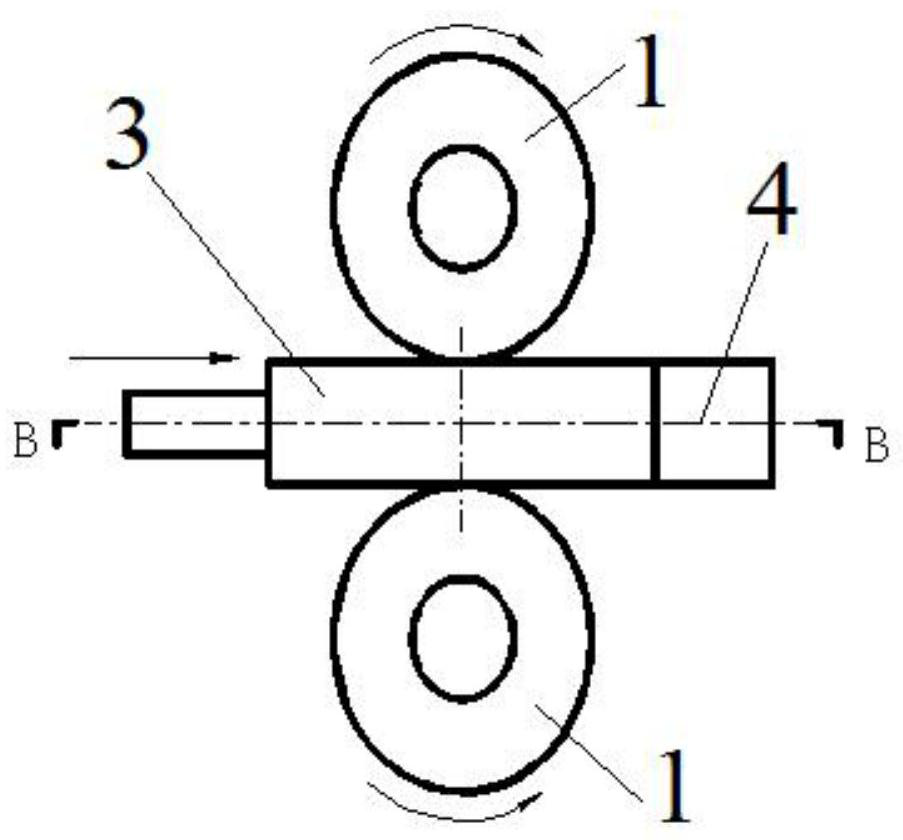

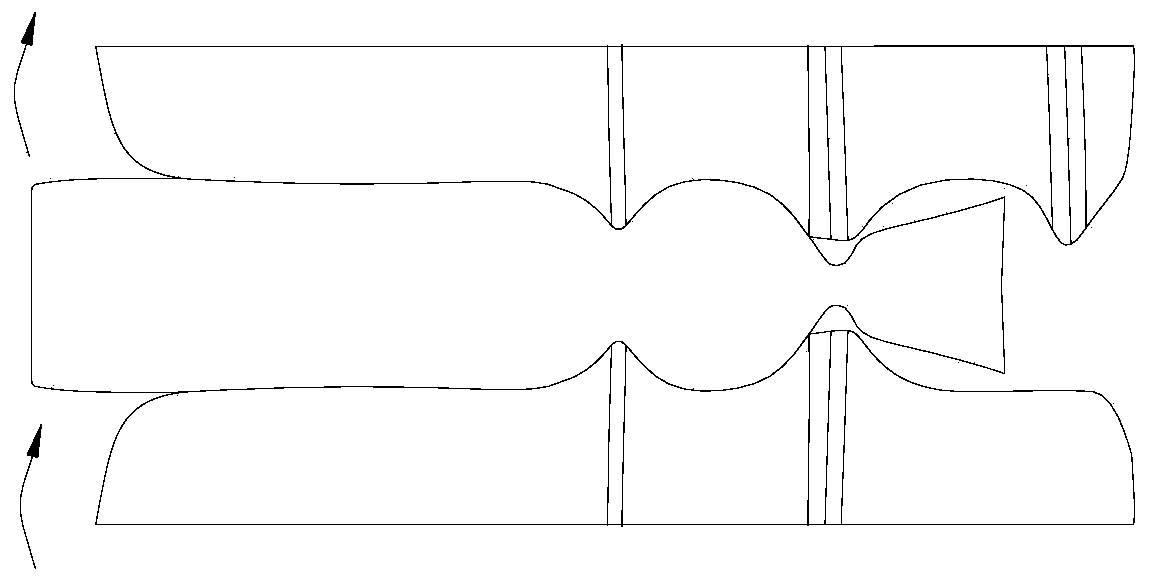

Multidirectional rolling strong deformation process

ActiveCN112427455AImprove performanceImprove grain refinementRollsMetal rolling arrangementsSpinningPhysics

The invention discloses a multidirectional rolling strong deformation process. The multidirectional rolling strong deformation process is used for carrying out multipass circulating multidirectional rolling on a plate, and specifically comprises the following steps that a feeding mechanism feeds the plate between a first pair of rollers along the feeding direction, so that the thickness of the plate is reduced, and the width size of the plate is increased; the plate continues feeding between a second pair of rollers in the feeding direction, a pair of side spinning wheels are oppositely arranged on the two sides of the second pair of rollers, the width and thickness of the plate are recovered to the initial size, and first-pass multi-direction rolling is completed; and then the first procedure of the first pass is repeated, finally, a fourth pair of rollers with the surfaces alternately provided with protrusions and grooves are used for rolling, and the rollers can enable the local area of the plate to be subjected to repeated thinning and thickening cyclic deformation in a rolling process. According to the multidirectional rolling strong deformation process, overall multi-directional cyclic deformation rolling and local cyclic deformation rolling are conducted on the plate, an excellent structure which is higher in grain refinement degree and uniform in distribution can be obtained, and the comprehensive performance of the plate is remarkably improved.

Owner:YANSHAN UNIV

A manufacturing method for improving the surface performance of bearing steel balls

ActiveCN108393418BReduce intensityReduce hardnessBearing componentsWork cooling devicesShear stressSteel ball

The invention relates to the field of hot rolling molding heat treatment, in particular to a manufacturing method for improving bearing steel ball surface layer performance. The manufacturing method for improving the bearing steel ball surface layer performance comprises the following steps that 1, a steel bar is heated to the temperature higher than the austenitizing temperature, and a first inclined roller is used for one-way rotary hot rolling for forming a steel ball; and 2, when the steel ball in the step 1 is subject to hot rolling to 50%-70% deformation, a steel ball bar is transferredto a second inclined roller to be continuously subject to one-way rotary rolling, metal molding deformation of the steel ball bar generates a reverse macroscopic shear stress strip, and the inclined rolling direction of the second inclined roller is opposite to the inclined rolling direction of the first inclined roller, and the roller dip angles are the same. According to the manufacturing method, shortcomings in the existing technology are overcome, the steel ball surface layer (near surface) grain refinement degree is improved for achieving ultrafine grains, and molding damage is reduced.

Owner:DEQING TIANMA BEARING CO LTD

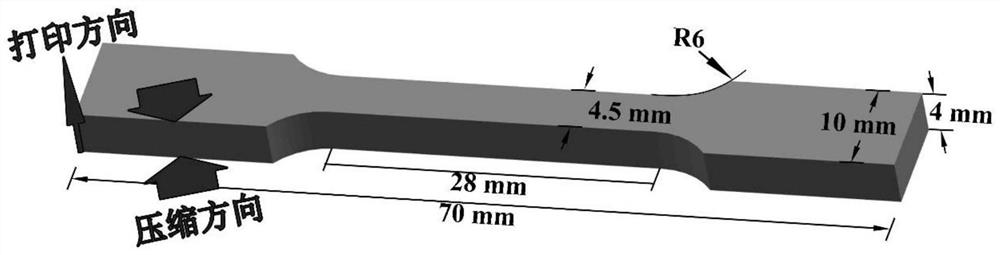

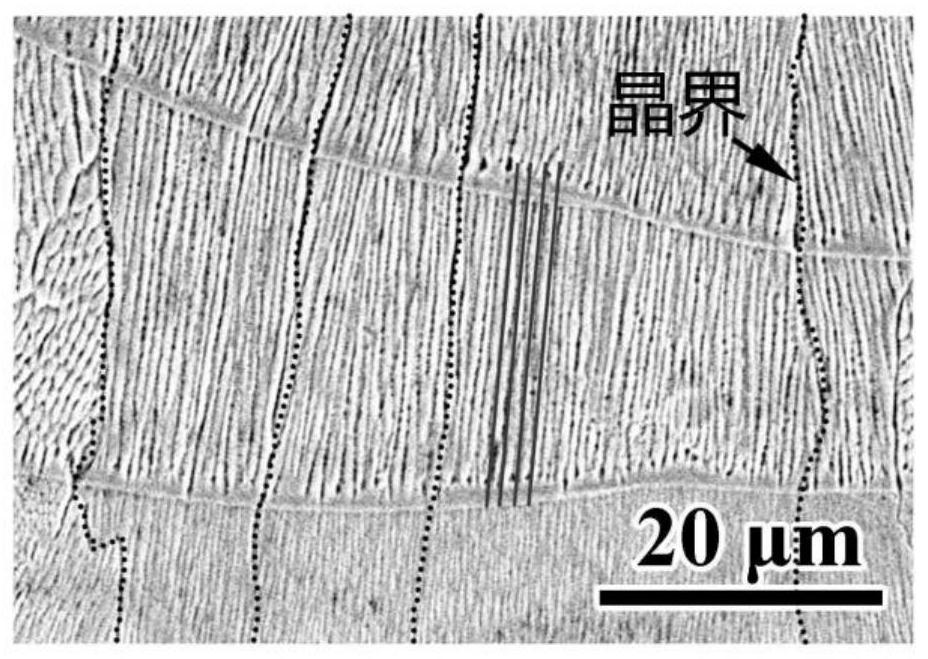

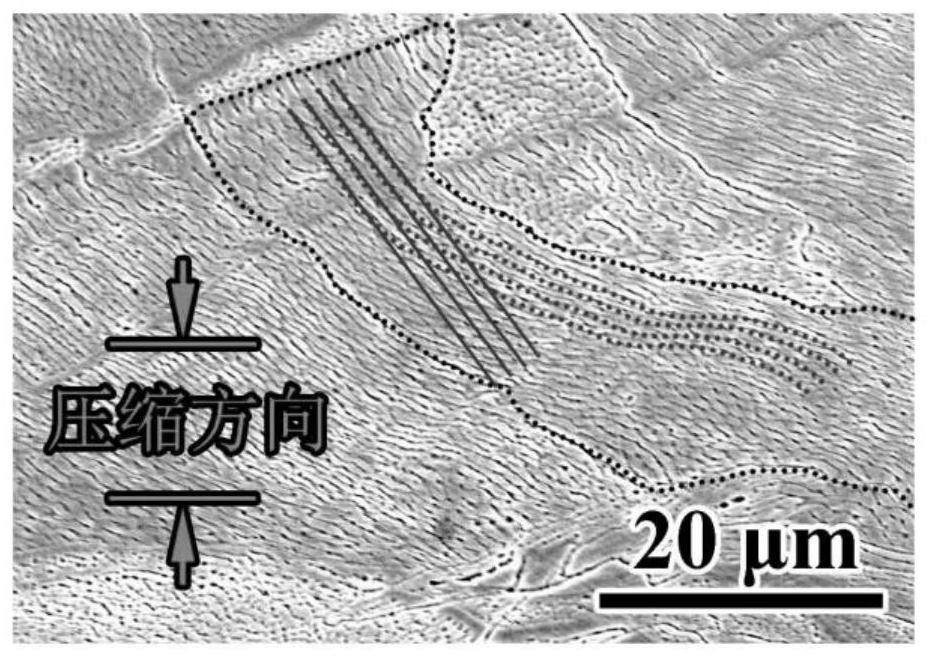

Preparation method of high-performance fine-grain FeCoCrNi alloy

ActiveCN113523281AImprove deformation energy storageGrain refinementAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHigh entropy alloys

The invention discloses a preparation method of a high-performance fine-grain FeCoCrNi alloy. The preparation method comprises the following steps: step 1, a high-entropy alloy is printed by adopting a selective laser melting method to prepare a printed FeCoCrNi alloy; according to the selective laser melting printing method, gas atomization spherical powder with the equal molar ratio of FeCoCrNi is adopted as a raw material; 2, the printed FeCoCrNi alloy is compressed in the printing direction, and the compressed FeCoCrNi alloy is obtained; and 3, the compressed FeCoCrNi alloy is subjected to annealing for 1.8 h to 2.2 h, and after cooling, the high-performance fine-grain FeCoCrNi alloy is obtained. According to the method, crystal grains can be greatly refined only through one-time compression and annealing circulation, the production cost is greatly reduced, and the machining efficiency is greatly improved. By applying the method, the strength and plasticity of the material can be remarkably improved, and the application range is greatly widened.

Owner:TIANJIN UNIV

A kind of preparation method of sheet metal parts with different thickness of foamed metal

InactiveCN104858232BImprove grain refinementHigh tensile strengthShaping toolsSuperstructure subunitsHot stampingFoaming agent

Owner:刘志民

A large-scale fine-grained tungsten rod and its two-roll rolling preparation method

ActiveCN110000387BAvoid harmEliminates doping preparation processFurnace typesHeat treatment furnacesCompression moldingMetallurgy

The invention discloses a preparation method of a large-scale fine-grained tungsten rod and a large-scale fine-grained tungsten rod prepared by using the same. The preparation method of the large-scale fine-grained tungsten rod includes the steps of: powder preparation step: selecting tungsten powder, and Sieve to obtain tungsten powder; press forming step: press and form the tungsten powder to obtain a tungsten compact; sintering step: sinter the tungsten compact to obtain a tungsten sintered compact; two-roll rolling step: The tungsten sintered billet is continuously rolled by two rolls to obtain a tungsten rod; the swaging and shaping step: the tungsten rod is cleaned and polished, and then swaged into a circle to obtain a pure tungsten rod; annealing step: the pure tungsten rod is obtained Tungsten rods are annealed to obtain fine-grained tungsten rods. The preparation method of the large-scale fine-grained tungsten rod of the present invention has the advantages of high production efficiency, large amount of deformation, high degree of grain refinement, few human factors, stable product quality and small fluctuations, and the like.

Owner:安泰天龙钨钼科技有限公司 +1

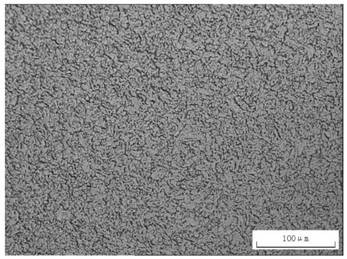

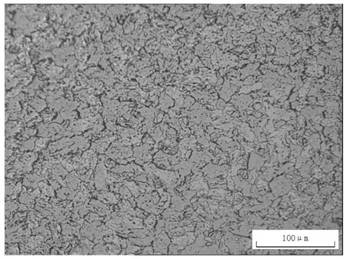

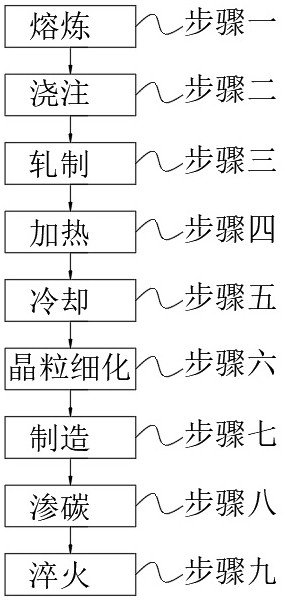

Cyclic torsion machining process capable of improving mechanical performance of metal material

InactiveCN113462867AImprove mechanical propertiesImprove grain refinementSolid state diffusion coatingProcess efficiency improvementMetallic materialsCarburizing

The invention discloses a cyclic torsion machining process capable of improving the mechanical performance of a metal material. The cyclic torsion machining process capable of improving the mechanical performance of the metal material comprises the following steps: step 1, smelting; step 2, pouring; step 3, rolling; step 4, heating; step 5, cooling; step 6, grain refinement; step 7, manufacturing; step 8, carburizing; and step 9, quenching. According to the cyclic torsion machining process capable of improving the mechanical performance of the metal material, in the process of preparing the metal material, rolling and heat-preservation pressurizing treatment are carried out on a blank, so that increasing for the grain refinement degree of the metal material is benefited, and then improvement for cyclic torsion performance in the mechanical performance of the metal material is benefited; and meanwhile, in the subsequent process for preparing the metal material, carburizing treatment is carried out on the metal material, so that increasing for the strength of the metal material is benefited, the phenomenon that the metal material is fractured after the metal material is cyclically twisted is avoided, and then the application range of the metal material is widened.

Owner:YANGTZE NORMAL UNIVERSITY

Molten soup forging method and die thereof

ActiveCN103084560BAvoid damageMeet the mechanical performance requirementsMechanical propertyRefined grains

The invention relates to a molten soup forging method and a molten soup forging die. The molten soup forging method and the molten soup forging die comprise an upper die, a lower die and side dies, to-be-produced wheel-shaped die cavity is formed among the upper die, the lower die and the side dies, wherein the molten soup forging method and the molten soup forging die are characterized in that a lower die assembly formed by coaxially enclosing the plurality of side dies and the lower die is coaxially embedded in a pressure bearing die sleeve, and a hydraulic pressure lifting mechanism which is vertically upward and used for lifting products is coaxially arranged at the lower end of the lower die. The molten soup forging method and the molten soup forging die have the advantages of improving product quality, reducing molten soup dosage, improving inner structure refined grain of metals, improving product mechanical property, tensile property and other overall properties, shortening product production time, reducing equipment maintenance cost, increasing output, improving production efficiency and prolonging die service life.

Owner:TIANJIN NANUO MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com