Patents

Literature

34results about How to "Improve deformation energy storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

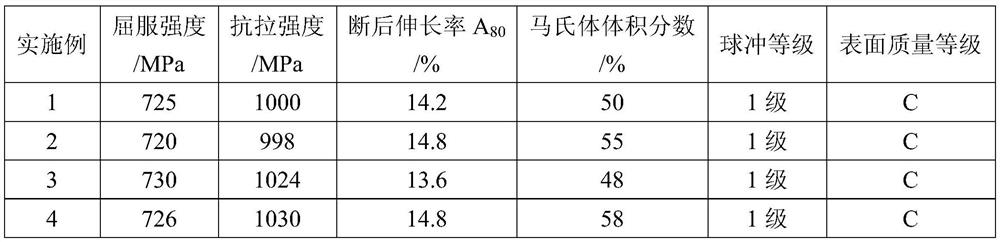

Zinc-plated double-phase steel and production method thereof

The invention belongs to the technical field of cold rolled steel and discloses zinc-plated double-phase steel and a production method of the zinc-plated double-phase steel. The zinc-plated double-phase steel comprises, by weight percentage, 0.085%-0.115% of C, 0.15%-0.24% of Si, 1.45%-1.55% of Mn, not larger than 0.015% of P, not larger than 0.005% of S, 0.025%-0.065% of Alt, 0.14%-0.24% of Cr, 0.24%-0.29% of Mo, not larger than 0.006% of N and the balance Fe and other inevitable impurities. The production method includes the steps of KR desulfuration, converter steelmaking, LF+RH refining treatment, RH calcium treatment, continuous steel casing, billet heating, rough rolling, finish rolling, laminar cooling and winding; unwinding, acid pickling, cold continuous rolling and winding; and unwinding, cleaning, annealing, zinc plating, finishing and winding. Through composition design and process control, the zinc-plated double-phase steel is suitable for annealing production lines having the rapid cooling segment or not.

Owner:SHOUGANG CORPORATION

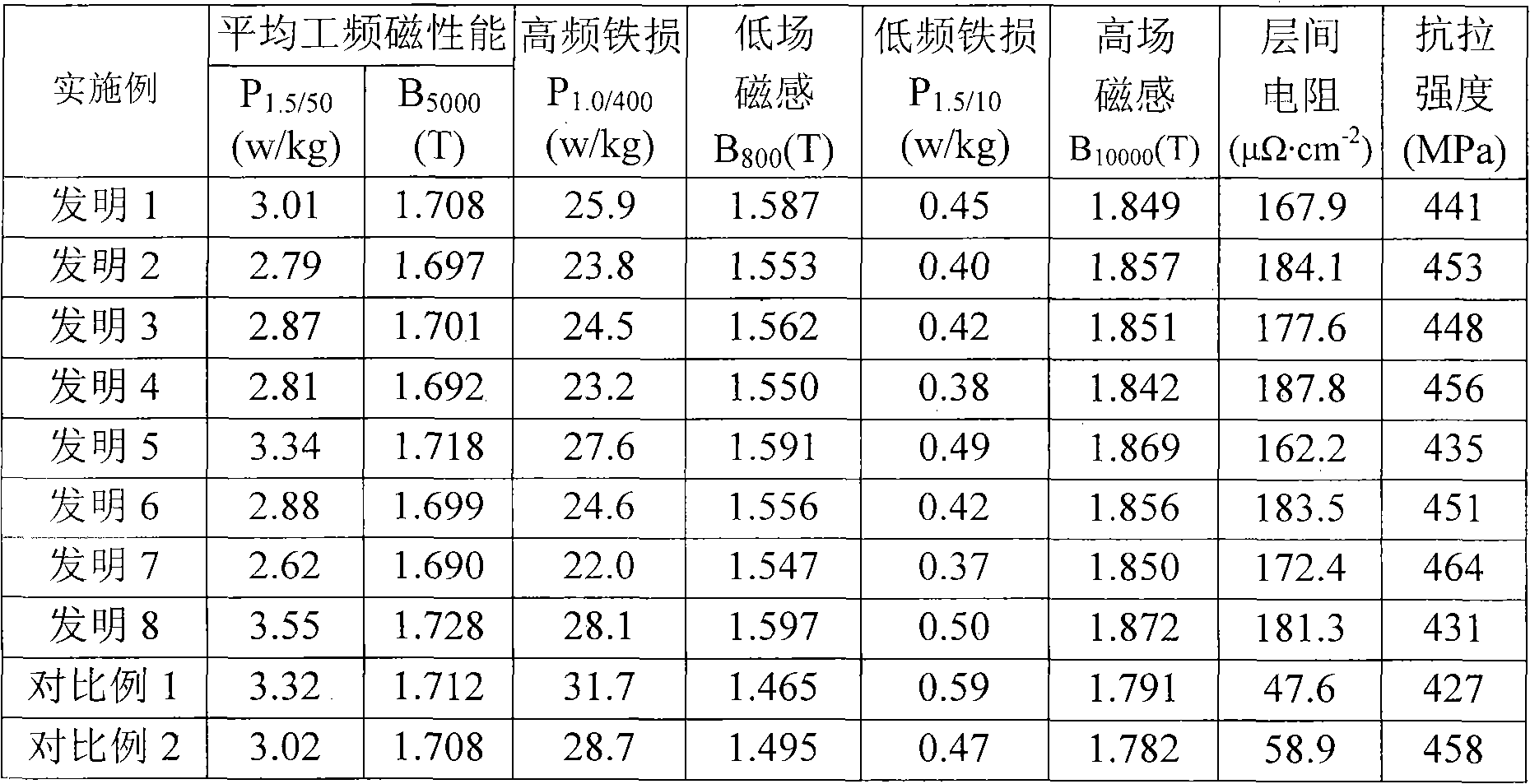

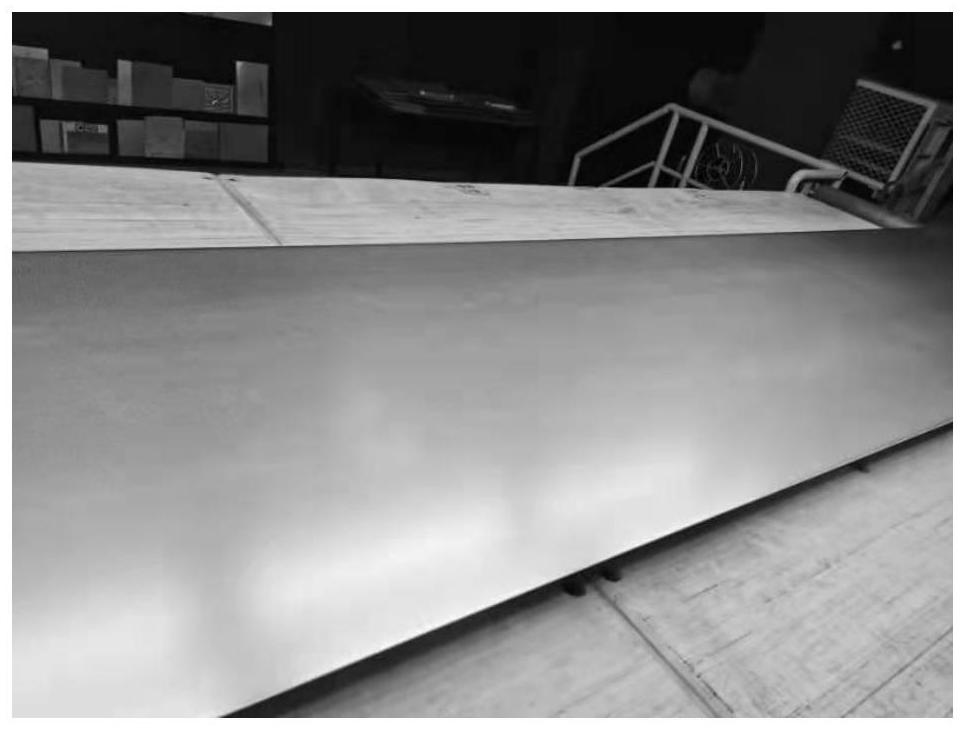

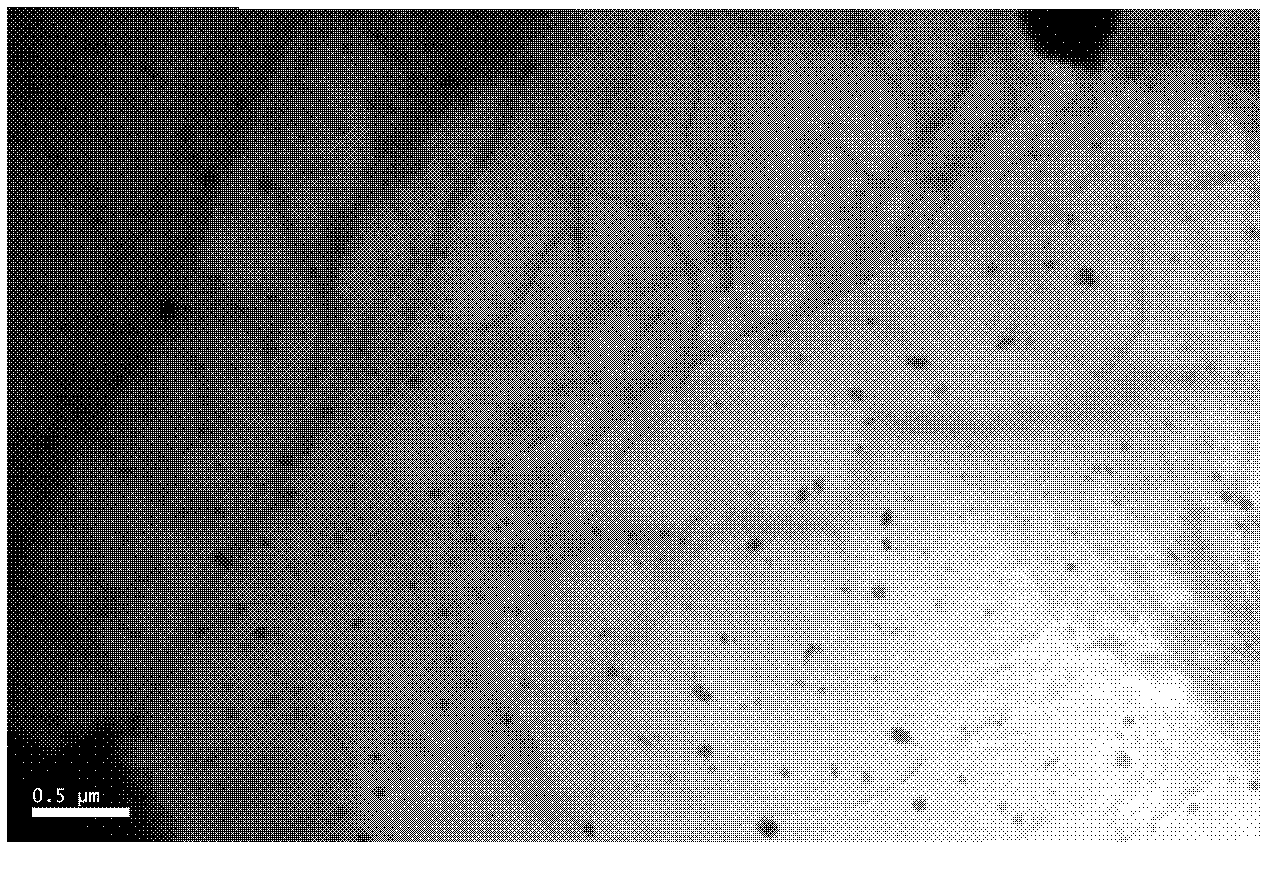

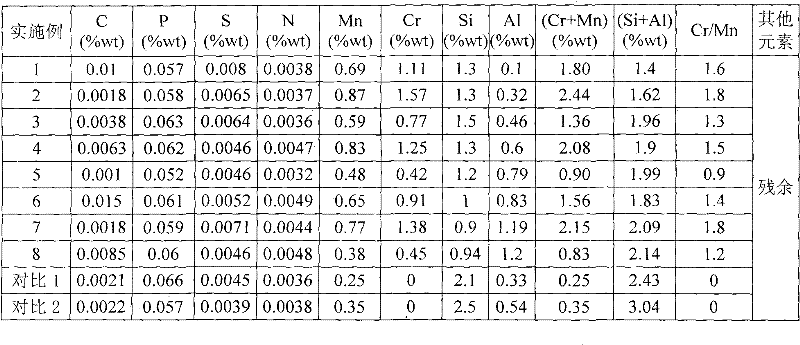

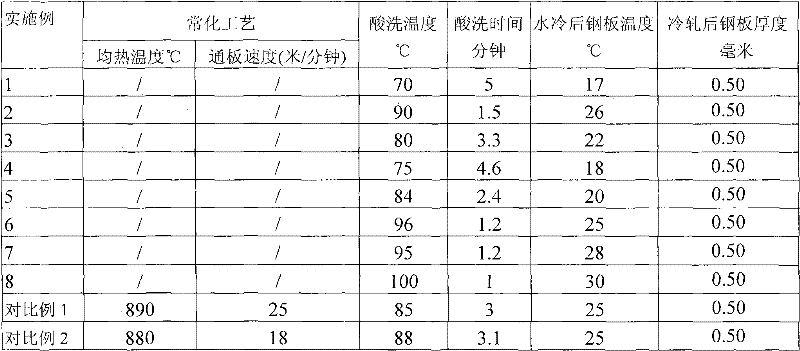

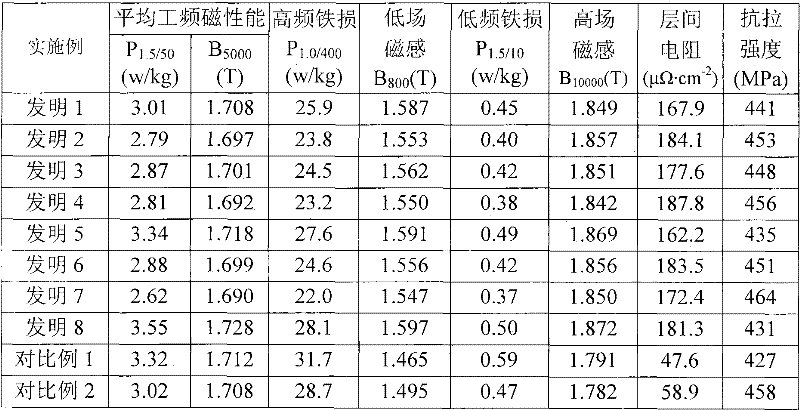

Non-oriented electrical steel for variable frequency motor and production method thereof

InactiveCN101876028AStorage capacity declineRich in componentsManufacturing stator/rotor bodiesElectrical steelFree cooling

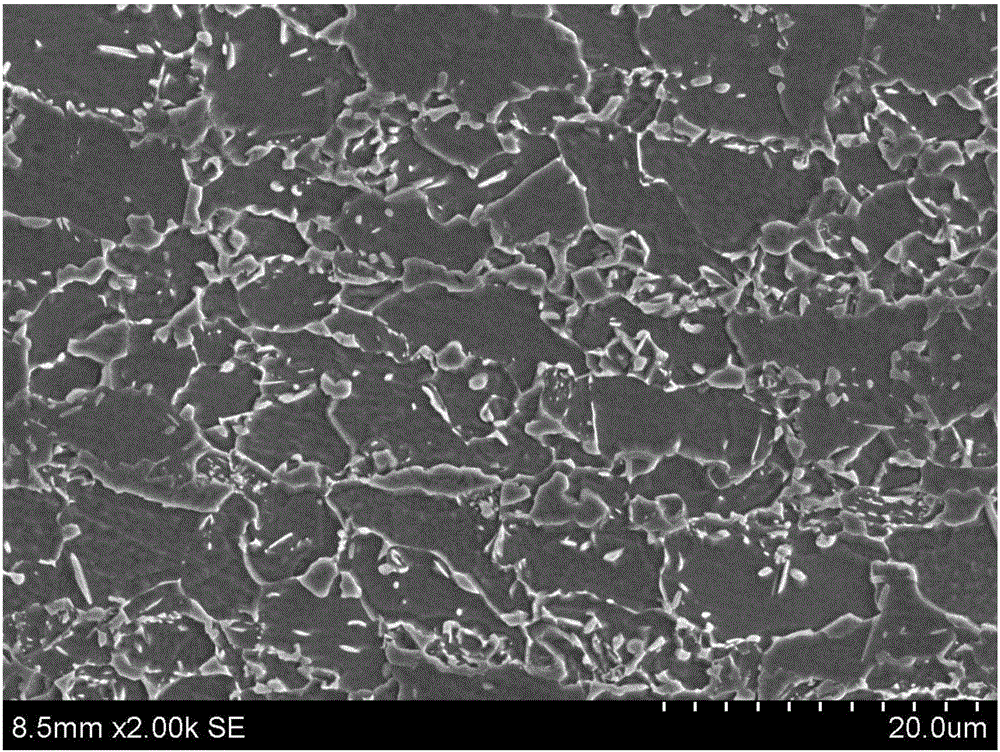

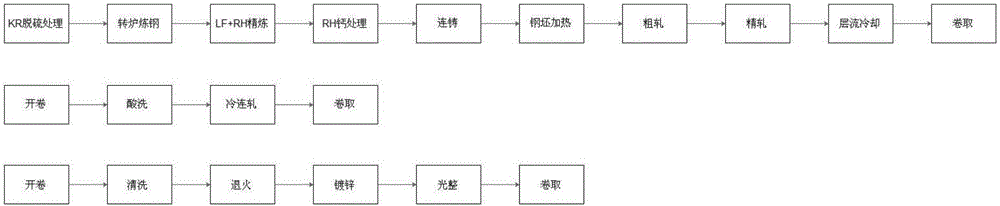

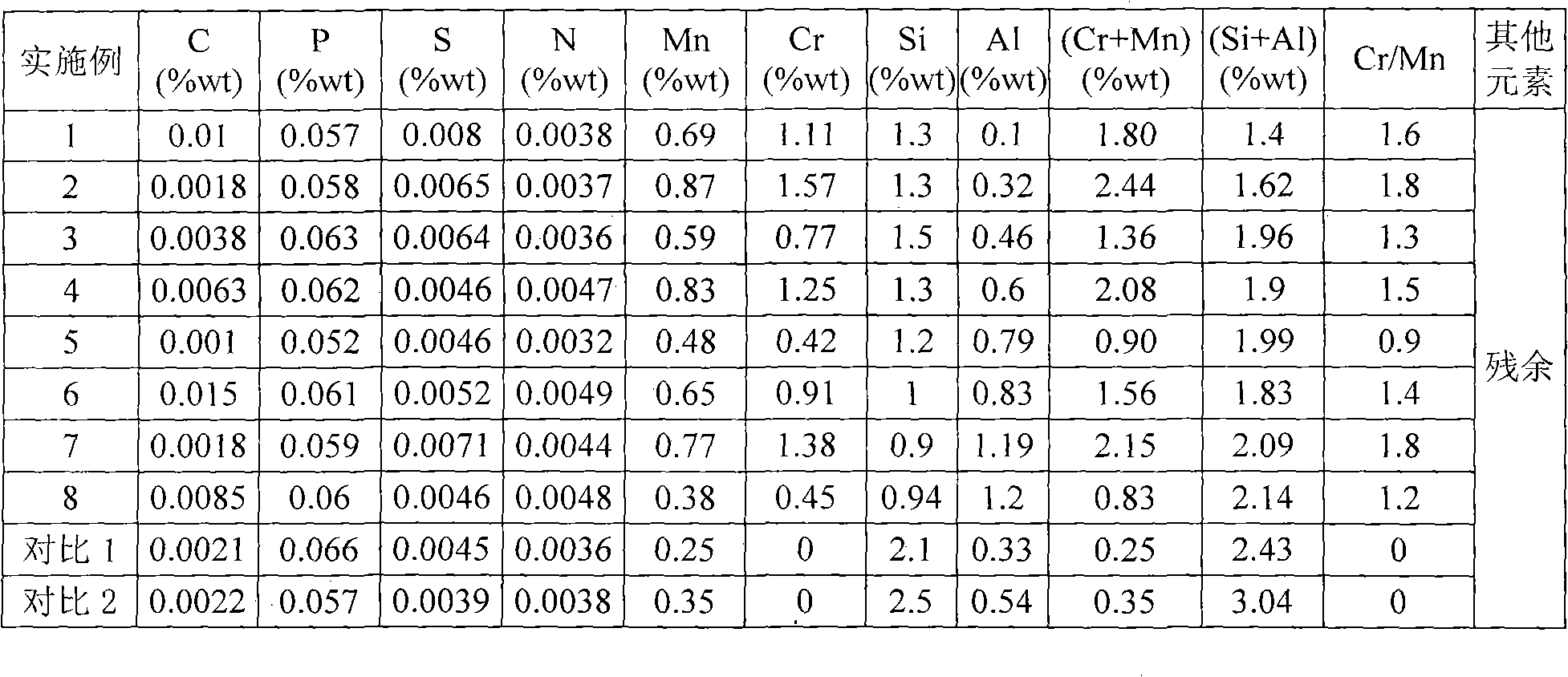

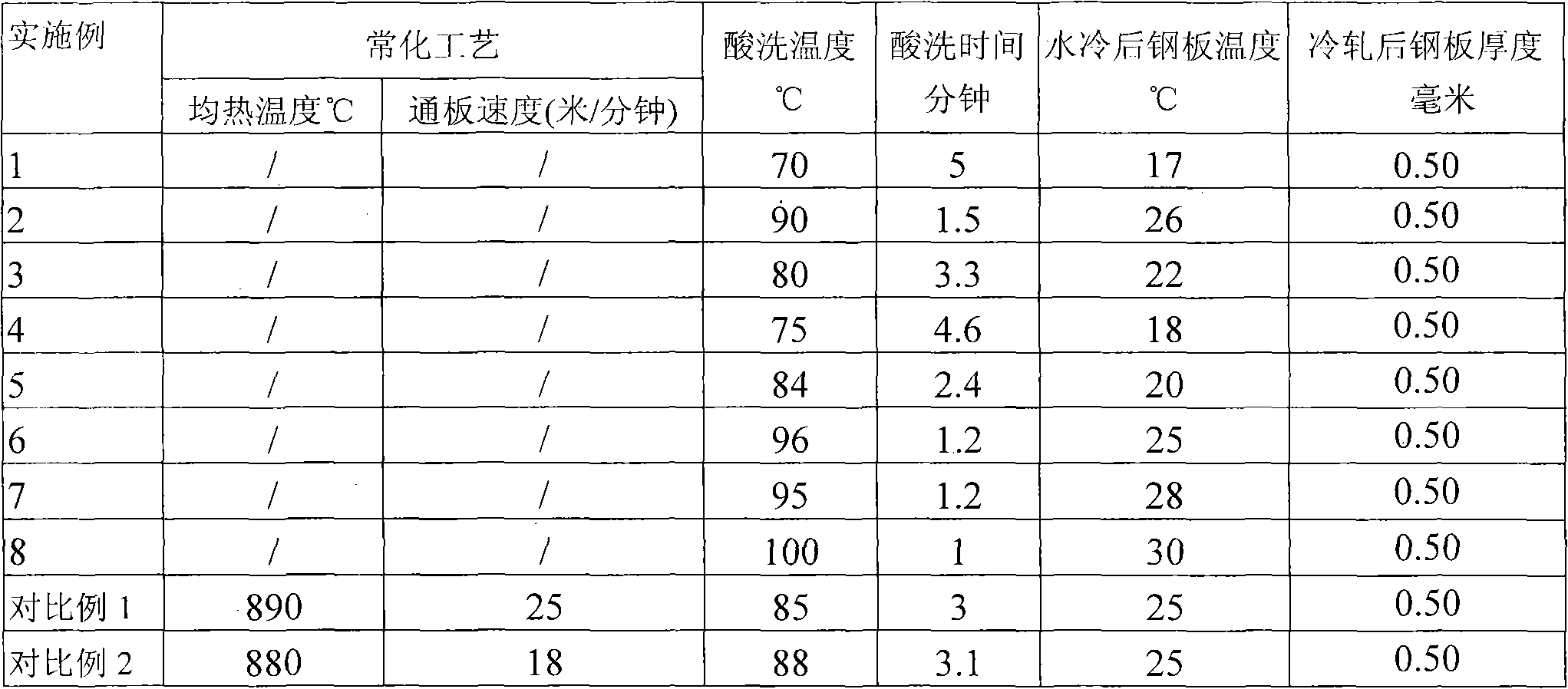

The invention relates to non-oriented electrical steel for a variable frequency motor and a production method thereof, aiming to overcome the defects of traditional non-oriented electrical steel which has high strength and poor toughness and can not meet the requirement of the variable frequency motor and complex process. The non-oriented electrical steel comprises the flowing chemical components in percentage by weight: 0.001-0.015 percent of C, 0.3-0.9 percent of Mn, 0.4-1.6 percent of Cr, 0.1-1.2 percent of Al, 0.9-1.6 percent of Si, no more than 0.08 percent of P, no more than 0.015 percent of S, no more than 0.008 percent of N and the balance of Fe and residue, wherein the sum of the weight percent of Si and Al is 1.4-2.2 percent, the sum of the weight percent of Cr and Mn is 0.7-2.5 percent, and Cr / Mn is 0.9-2.0. The production method comprises the following steps of: smelting by using a clean steel process and continuously casting to form a billet; heating the billet; roughly rolling; finish rolling, and controlling the accumulated percentage of reduction of former four passes to be 80-95 percent; reeling; naturally cooling to the room temperature; washing with acid; cold rolling; decarbonizing; soaking; cooling according to conventional method, coating and finishing. The invention has the advantages of simple process, low iron loss at low frequency and power frequency, lower iron loss at high frequency, higher magnetic induction as well as good corrosion resistance and stamping property.

Owner:WUHAN IRON & STEEL (GROUP) CORP

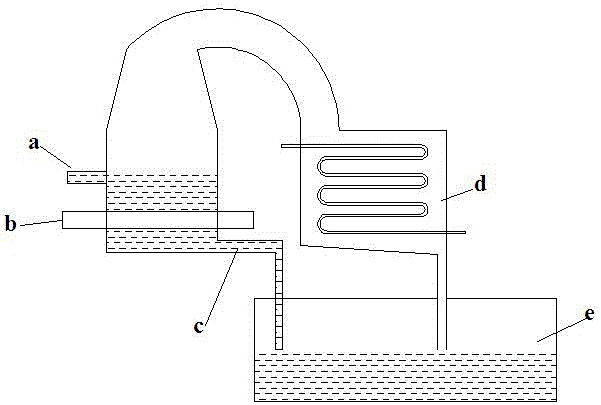

Preparation method and application of 550 MPa-grade ultra-fine grain high-strength weather-resistant steel

InactiveCN107460413AImprove mechanical propertiesGood atmospheric corrosion resistanceWeather resistanceAustenite grain

The invention relates to a preparation method and application of 550 MPa-grade ultra-fine grain high-strength weather-resistant steel and belongs to the technical field of metallurgy. The preparation method comprises the steps that continuous casting blanks directly enter an M rack rough rolling unit under the high pulling speed and are subjected to M-pass continuous heavy reduction (50-60%) rough rolling, and austenite grains are greatly refined; after rough rolling, middle blanks are rapidly heated through an induction heating furnace to the temperature needed for a finish rolling inlet, and meanwhile a reverse temperature field is formed; and then sequentially through a finish rolling set, laminar flow cooling and a reeling machine, finally the organization characteristics that the surface and the core part are coarse, and the portion of the 1 / 4 thickness position is fine are formed. In the production process, finish rolling and rough rolling are both full-headless rolling. An ultra-fine grain high-strength weather-resistant hot-rolling steel belt with the weather resistance being equivalent to corten-A is obtained, and the effects that the thin effect replaces the thick effect and the hot effect replaces the cold effect are achieved; while the weight of a car body is small, the service life of a car plate is prolonged, the production efficiency is improved, and the production cost is reduced; and meanwhile energy consumption is reduced, emission is reduced, and resource-saving and environment-friendly production is achieved.

Owner:UNIV OF SCI & TECH BEIJING +1

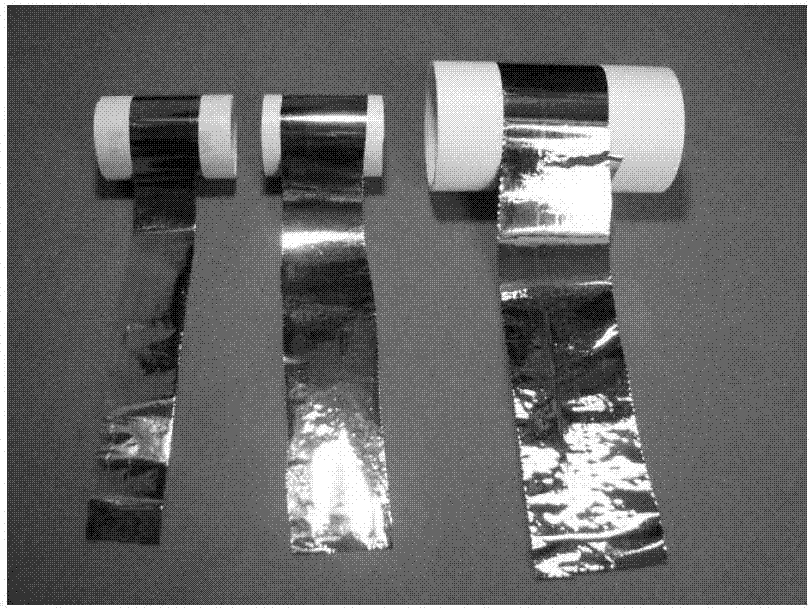

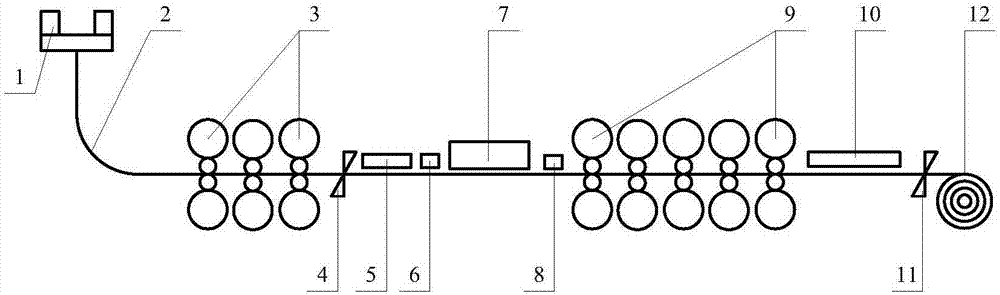

Preparation method of ultrathin Ta-W alloy foil

The invention provides a preparation method of ultrathin Ta-W alloy foil, and belongs to the technical field of Ta-W alloy machining. The preparation method includes the steps that cyclic operation of alloy billet prepared through a powder metallurgy method, cold rolling cogging, and cold rolling and vacuum annealing, 3-5 micrometer foil annealing, and the like. The thickness of the prepared foil can reach 3-5 micrometers. The preparation method is simple in process, the prepared foil is high in precision, and compared with pure Ta foil and other Ta-W alloy foil, the ultrathin Ta-W alloy foil has the advantages of being high in strength, good in surface quality, and the like. The prepared Ta-(5.0-7.5 wt%)W alloy foil with the thickness of 3-5 micrometers is suitable for high-power microwave tubes, traveling wave tubes, and other vacuum devices of electronic components, aerospace, and other industries. The preparation method has great significance on achieving high-power high-performance microwave tube localization, improving microwave tube using performance, prolonging service life, and the like.

Owner:CENT SOUTH UNIV

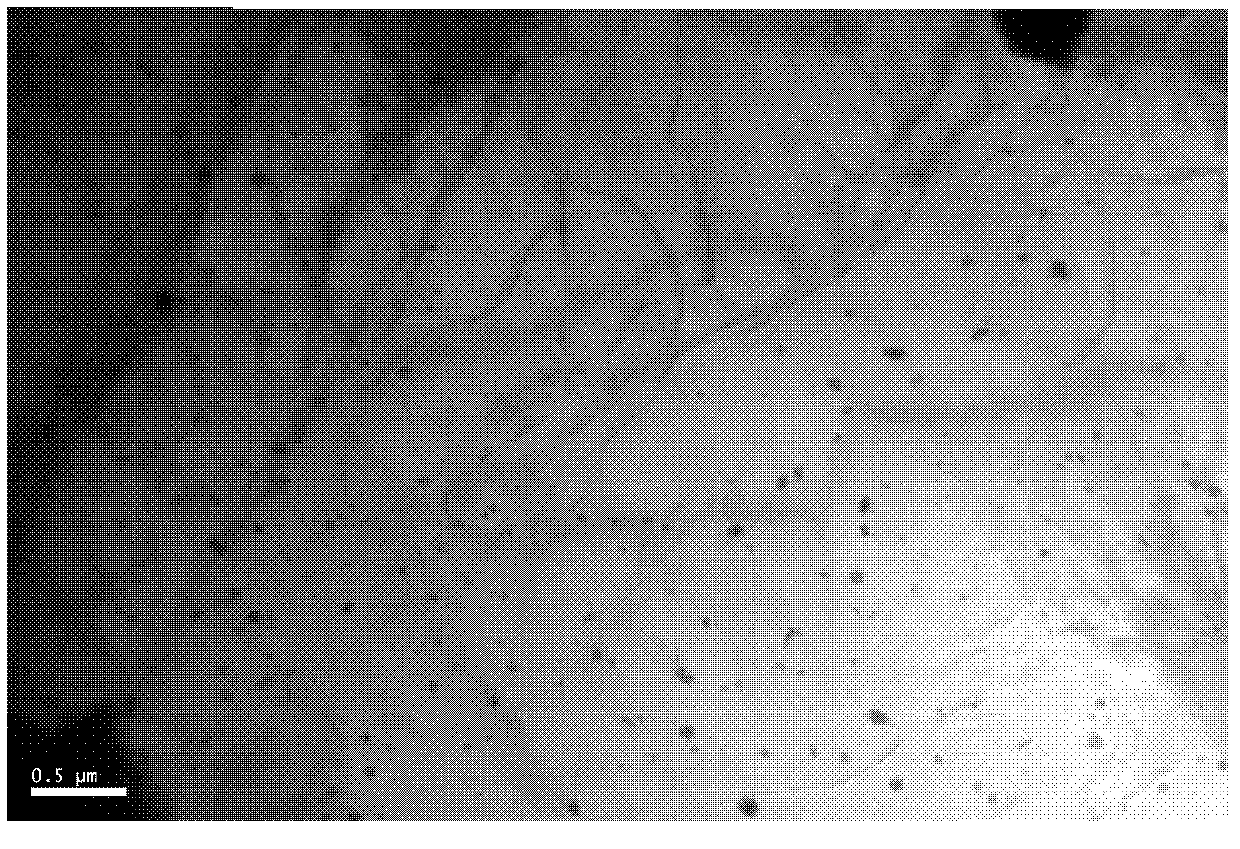

Magnesium alloy reinforced by nano-quasi-crystal particles and preparation method of the alloy

ActiveCN102605227AHigh nucleation energy storageImprove solid solubilitySolution treatmentDistribution characteristic

The invention discloses a magnesium alloy reinforced by nano-quasi-crystal particles and a preparation method of the alloy, and belongs to the technical field of alloy. The alloy comprises the following components in percentage by mass: Er not higher than 10%, Zn not higher than 10%, impurity element with total amount less than 0.05%, and balance of magnesium, wherein the mass ratio of Zn to Er is 4-8. The preparation method comprises the following steps: firstly performing solution treatment to the selected alloy, cleaning the alloy, removing impurities and crushing the alloy; utilizing a multi-cyclic plastic deformation device to process the alloy, at last obtaining an extrusion blank, and extruding the blank with an extruder at 220-350 DEG C to obtain a bar; or utilizing a rolling mill to roll the alloy at a temperature not higher than 300 DEG C, and annealing the rolled alloy. According to the invention, the size of phase I in the alloy is effectively reduced; the distribution characteristics of phase I are reasonably changed; and the size of phase I in the alloy is about 10-100nm.

Owner:北京二七铁丰龙科技有限公司

Preparation method and application of 700 MPa grade ultra-fine grain high-strength weathering steel

InactiveCN107365940AIncrease surface temperatureReduce the temperatureAustenite grainResource saving

The invention relates to a preparation method and application of 700 MPa grade ultra-fine grain high-strength weathering steel. The preparation method includes the steps that a continuous casting blank directly enters an M rack rough rolling unit at a high pulling speed and is subject to M-gate continuous high reduction (50%-60%) rough rolling, austenite grains are greatly refined, after rough rolling is carried out, an intermediate billet is quickly heated by an induction heating furnace to the temperature needed by a finish rolling inlet, and meanwhile a reverse temperature field is formed; and then the blank sequentially passes through a finish rolling unit, a laminar cooling part and a reeling machine, and the microstructure characteristics that the surfaces and core parts are thick and 1 / 4 thickness parts are thin are finally formed. In the production process, finish rolling and rough rolling are both full-endless rolling. By means of the preparation method, an ultra-fine grain high-strength weathering steel strip with the weather fastness equal to that of corten-A can be obtained, the effects of replacing thick parts with thin parts and replacing cold with heat are achieved, and the automotive body weight is small; and meanwhile, the service life of an automotive sheet is prolonged, the production efficiency is improved, the production cost is reduced, energy consumption is reduced, emission is reduced, and resource-saving and environment-friendly production is achieved. The preparation method and application belong to the technical field of metallurgy.

Owner:UNIV OF SCI & TECH BEIJING +1

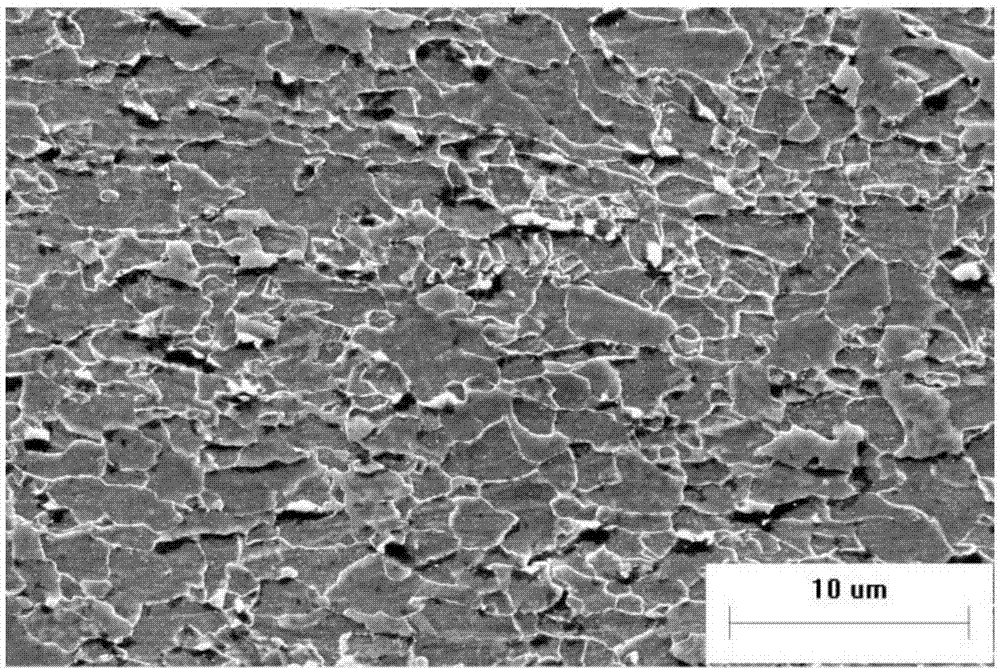

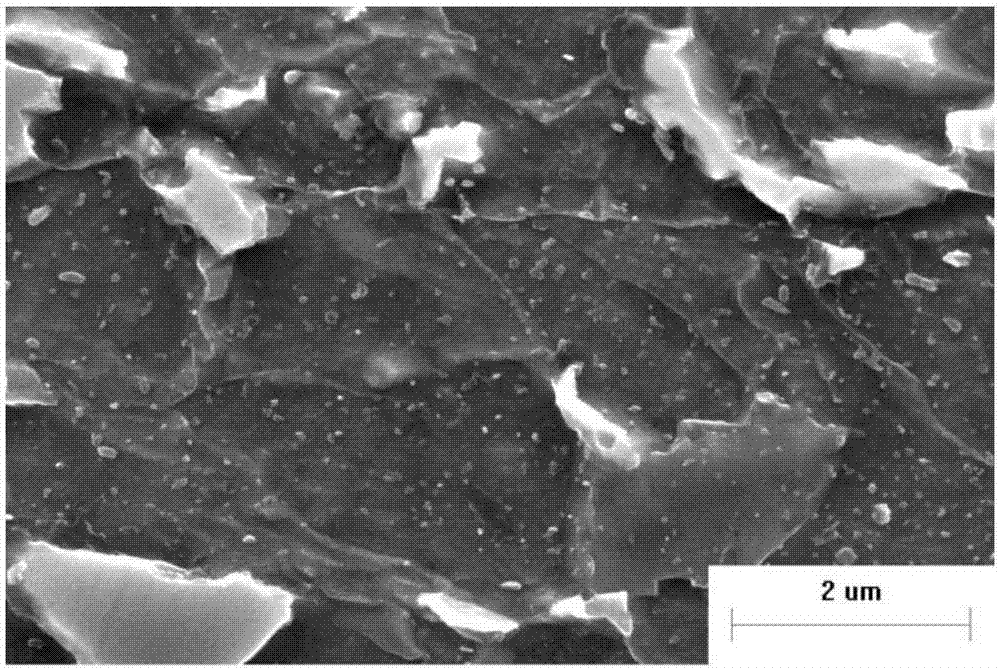

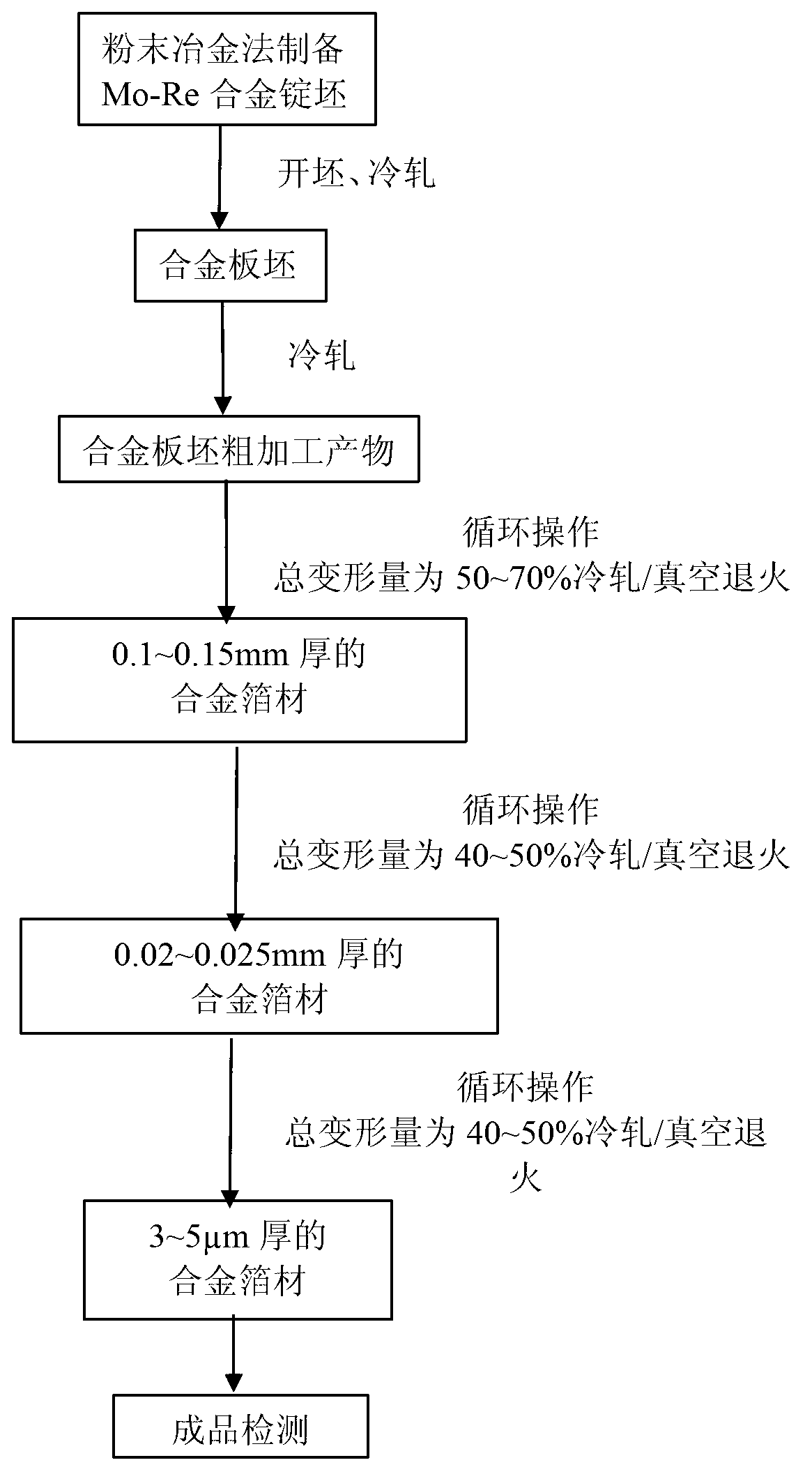

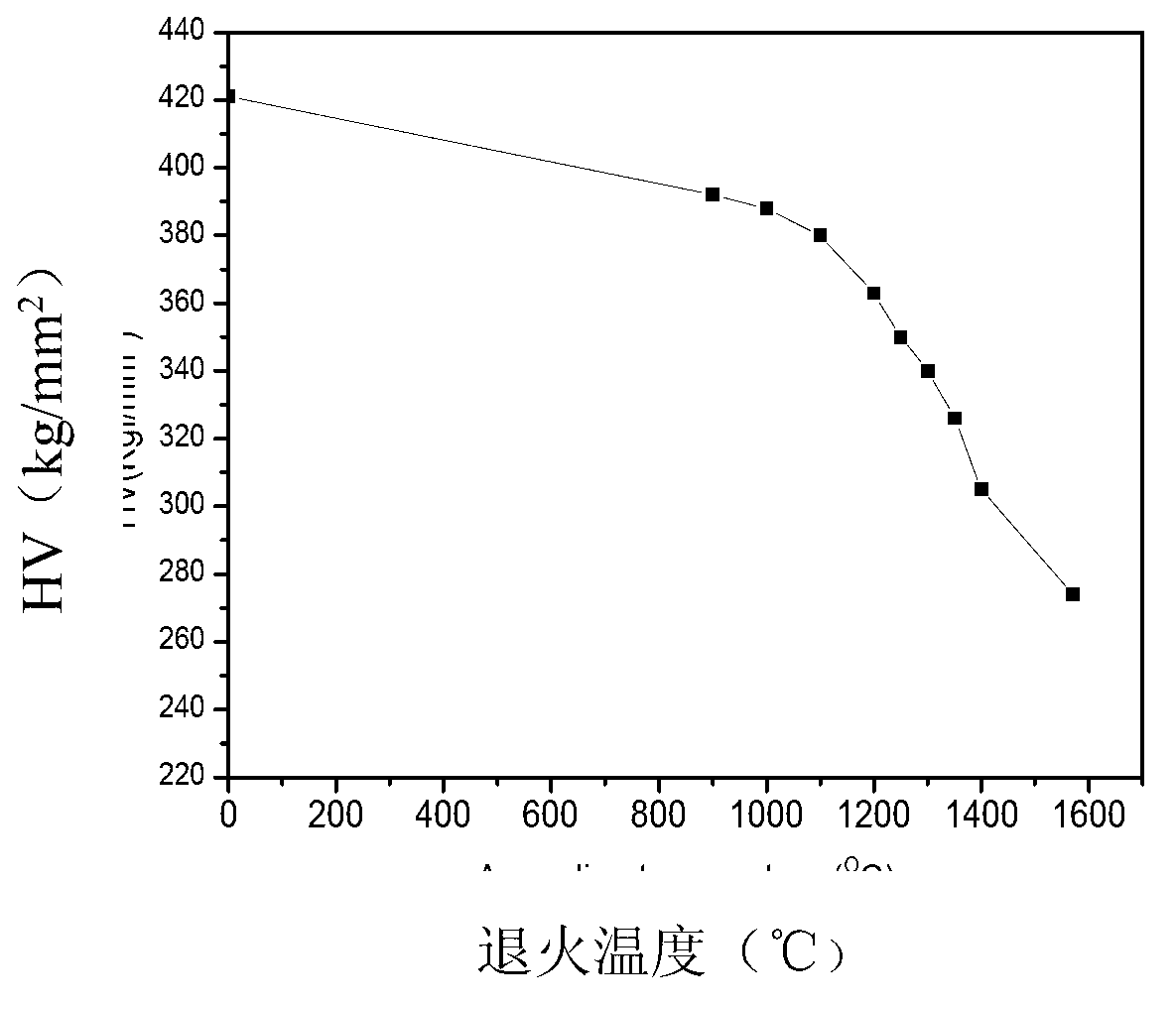

Preparation method of ultrathin Mo-Re alloy foil

InactiveCN103100563ASimple preparation processLow costMetal rolling arrangementsPowder metallurgyMicrometer

The invention provides a preparation method of an ultrathin Mo-Re alloy foil, and belongs to the technical field of Mo-Re alloy machining. The preparation method solves the problems that a Mo-Re alloy foil which is with the thickness smaller than 10 micrometers and good in surface quality is hard to prepare, and can be used for preparing the Mo-Re alloy foil which is with the thickness of 3-5 micrometers and good in surface quality. The preparation method comprises circulating operations of preparing an alloy billet with a powder metallurgy, cold rolling cogging, and cold rolling / vacuum annealing, and the method further comprises a step of annealing of a foil of 3-5 micrometers and other steps. The component range of a prepared alloy foil is, by weight, Re of 43.5-47.5%, and the balance is Mo. The thickness of the prepared alloy foil is 3-5 micrometers. The preparation method is simple in technology, the elastic coefficient of the prepared foil is 340-350 GPa, the tensile strength at 1200 DEG C is 220-260 Mpa, microhardness is 420-450 HV, the surface roughness (Rmax) is 0.02-0.05 micrometer, and the foil is suitable for platinotrons and travelling wave tubes and other vacuum components in aerospace equipment.

Owner:CENT SOUTH UNIV

Cold-rolled steel sheet with 420 MPa grade yield strength and preparation method of steel sheet

ActiveCN106636898AImproved recrystallization kineticsGrain refinementChemical compositionSheet steel

The invention discloses a cold-rolled steel sheet with the 420 MPa grade yield strength and a preparation method of the steel sheet and belongs to the technical field of metallurgy. The steel sheet is prepared from components in percentage by mass as follows: 0.06%-0.09% of C, 0-0.2% of Si, 0.8%-1.0% of Mn, 0-0.02% of Ti, 0.01%-0.025% of Nb and the balance of Fe and inevitable impurity elements. The preparation method comprises steps as follows: (1) according to the ratio of the chemical components of the cold-rolled steel sheet, a steel ingot is obtained through smelting and is forged to form a slab; (2) heat preservation is performed on the slab, hot rolling is performed, and a hot-rolled sheet is prepared and is cooled to the proper temperature at a certain cooling rate for coiling; (3) the coiled hot-rolled sheet is pickled and then cold-rolled, and the cold-rolled sheet is prepared; (4) the cold-rolled sheet is subjected to continuous annealing treatment of low-temperature soaking and step cooling. According to the cold-rolled steel sheet, the microstructure mainly comprises ferrite, pearlite and cementite, the yield strength of the steel sheet ranges from 435 MPa to 450 MPa, the tensile strength ranges from 518 MPa to 548 MPa, and the ductility A80 ranges from 25.0% to 26.3%.

Owner:NORTHEASTERN UNIV LIAONING

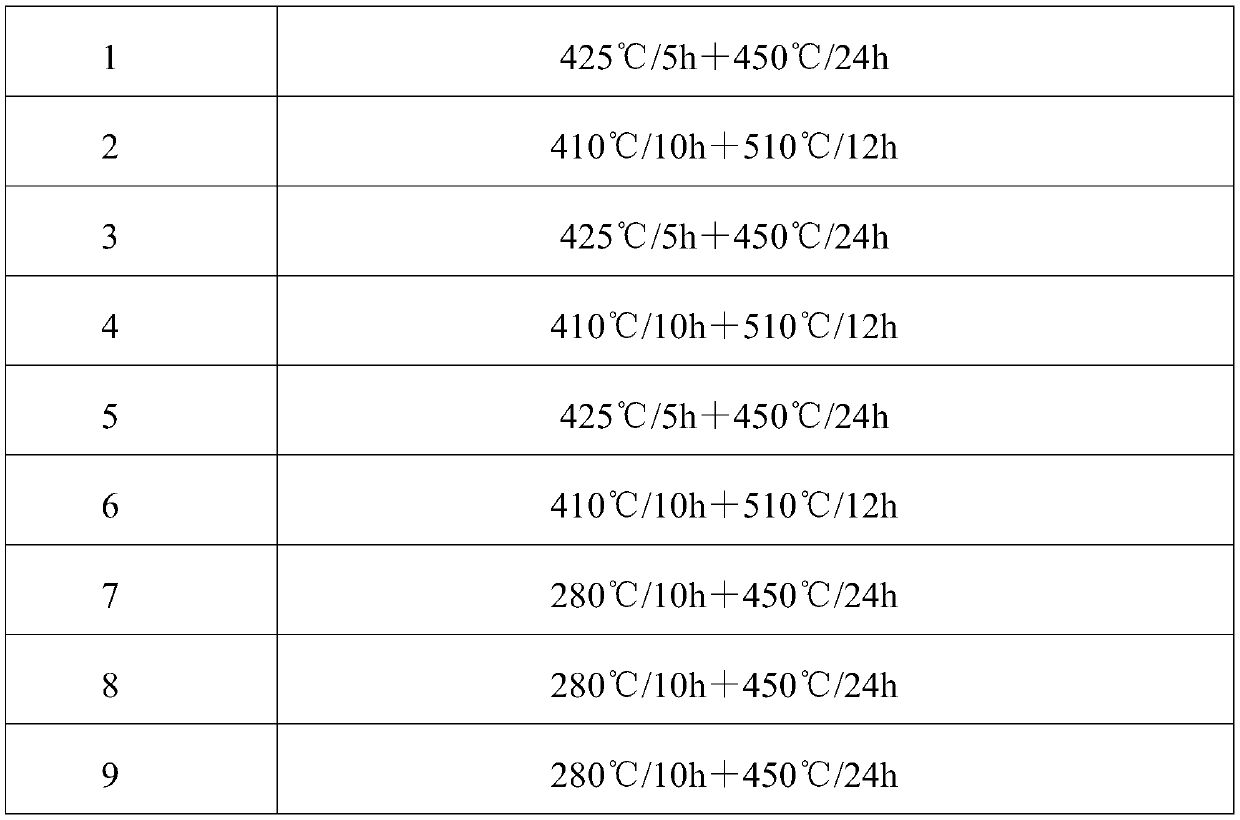

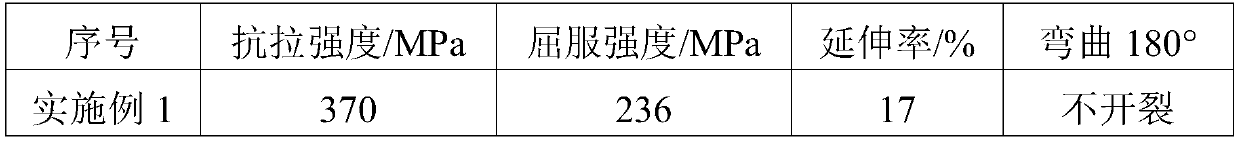

Stable manufacturing method of aluminium-alloy medium-thickness plate

The invention discloses a stable manufacturing method of an aluminium-alloy medium-thickness plate and belongs to the technical field of aluminium alloy. The stable manufacturing method comprises thefollowing steps: (S1) preparation of aluminium-alloy molten liquid; (S2) preparation of an aluminium-alloy cast ingot; (S3) destressing treatment; (S4) sawing of the aluminium-alloy ingot; (S5) solution treatment; (S6) multidirectional forging; (S7) prestretching; (S8) ageing treatment to obtain the finished product. The stable manufacturing method disclosed by the invention has the beneficial effects that by adoption of a reasonable machining process, the comprehensive properties of ductility, strength of extension, yield strength and the like of the aluminium-alloy medium-thickness plate areimproved.

Owner:湖南恒佳新材料科技有限公司

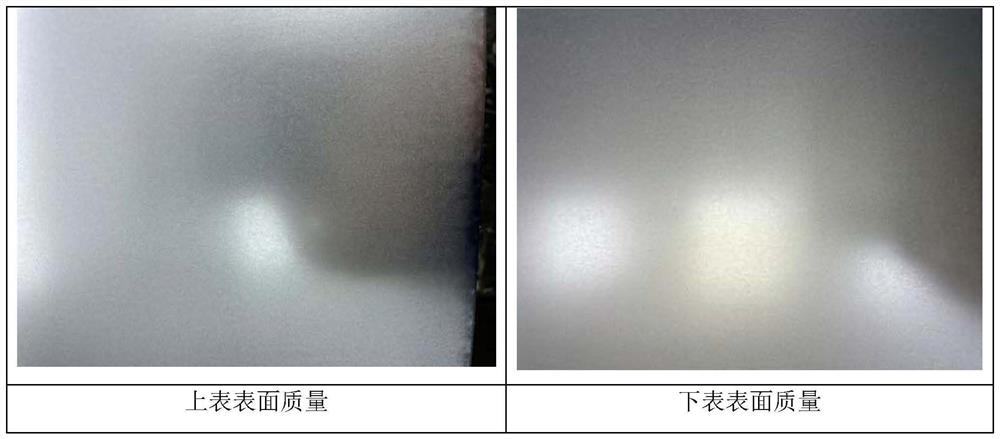

450MPa-grade hot-dip galvanized dual-phase steel with high work hardening rate and surface quality and production method of 450MPa-grade hot-dip galvanized dual-phase steel

PendingCN114107806AExcellent surface coating qualityImprove strong plasticityHot-dipping/immersion processesManganeseSlow cooling

The invention discloses 450MPa-grade hot-dip galvanized dual-phase steel and a production method thereof, and belongs to the field of galvanized automobile steel manufacturing, the 450MPa-grade hot-dip galvanized dual-phase steel adopts a low-carbon-low-manganese component design of trace Si, low Mo and high Cr, processes of coiling at a low temperature of 520-560 DEG C, slow cooling at a temperature of 640-660 DEG C and rapid cooling at a temperature of more than or equal to 10 DEG C are carried out, and the 450MPa-grade hot-dip galvanized dual-phase steel is prepared by matching a dew point in a furnace at a temperature of less than or equal to-40 DEG C and an oxygen content of less than or equal to 5ppm. And obtaining the 450MPa-grade hot-dip galvanized dual-phase steel under the atmosphere that the dew point of a furnace nose is not more than-20 DEG C. According to the produced hot-dip galvanized dual-phase steel with the tensile strength of 450 MPa, the uniform elongation is 18%-23%, the work hardening rate n value is not lower than 0.19, the after-fracture elongation A80 reaches up to 28%-33%, and the hot-dip galvanized dual-phase steel is suitable for being used as a high-drawing and high-flanging complex forming automobile part.

Owner:MAANSHAN IRON & STEEL CO LTD

Deep hypothermia forming method of electrolysis pure copper

The invention discloses a deep hypothermia forming method of electrolysis pure copper. The deep hypothermia forming method comprises the following steps: at first, carrying out 2-4-pass equal-diameterangle extrusion on electrolysis pure copper on an all-purpose testing machine equipped with an environment box, then, soaking the extruded sample in liquid nitrogen for 20-30 minutes and taking the sample out, and sequentially carrying out multi-pass cold rolling deformation on the sample on a rolling mill and annealing treatment to obtain the copper sample, and the grain size of the copper sample is 500nm-20 microns. With adoption of the deep hypothermia forming method, uniform equiaxial recrystallized small crystalline grains can be obtained within short time to greatly improve the strengthof pure copper.

Owner:FUZHOU UNIV

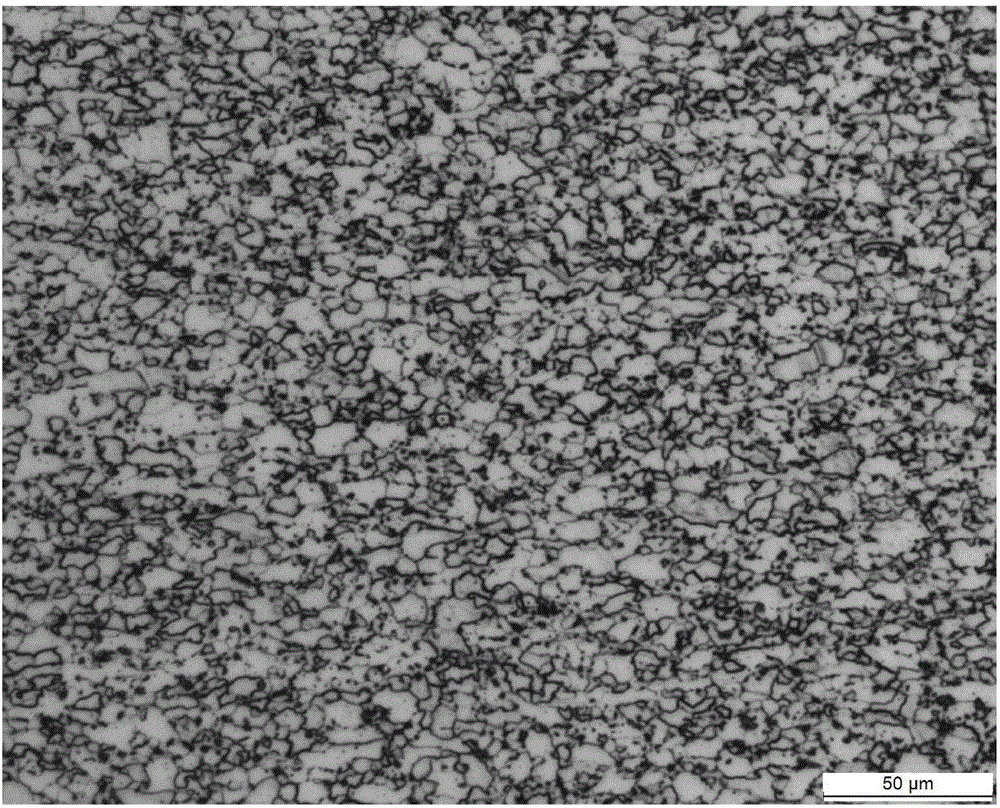

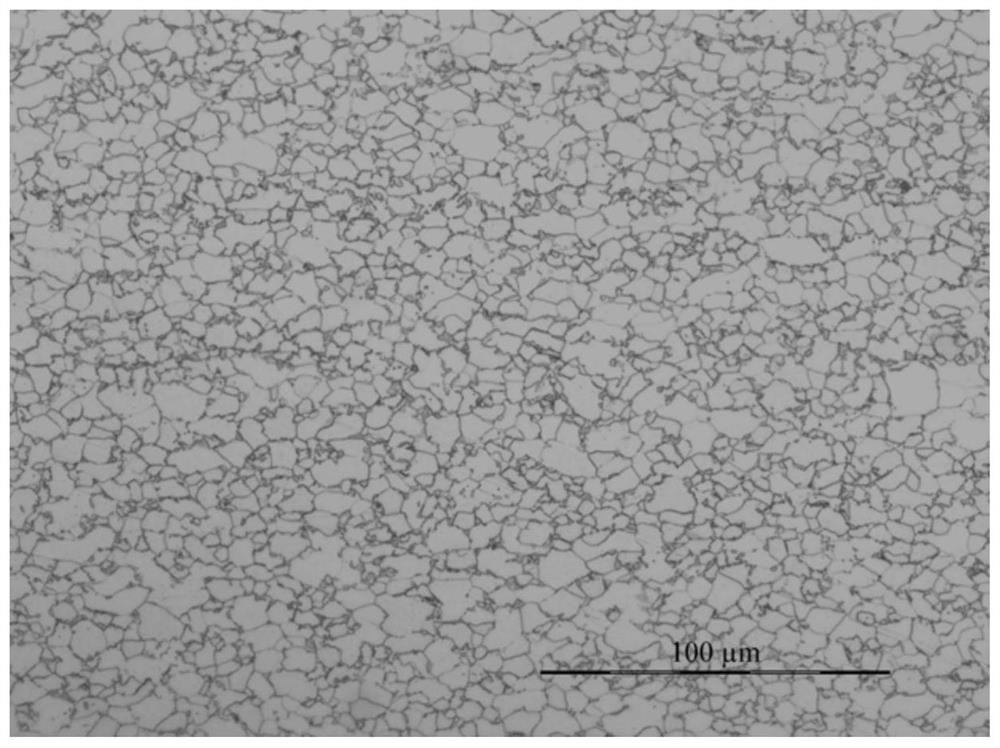

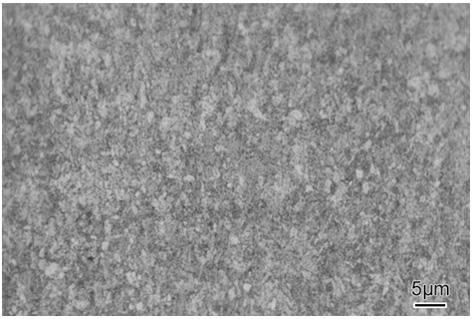

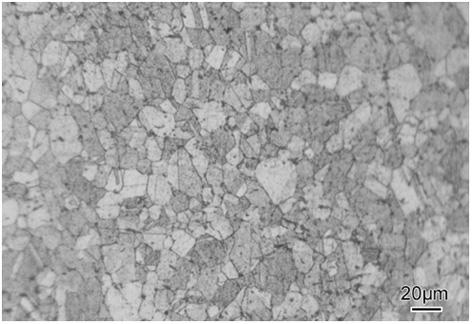

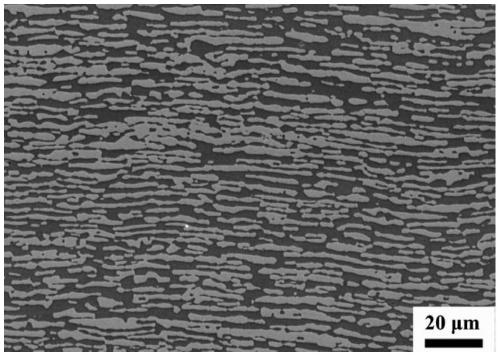

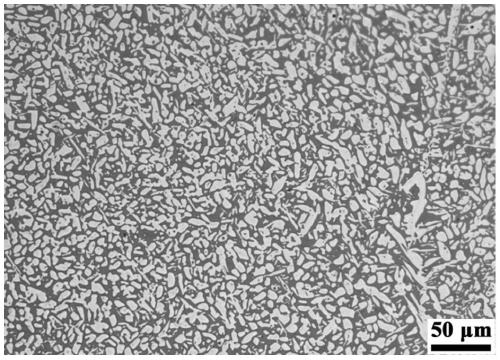

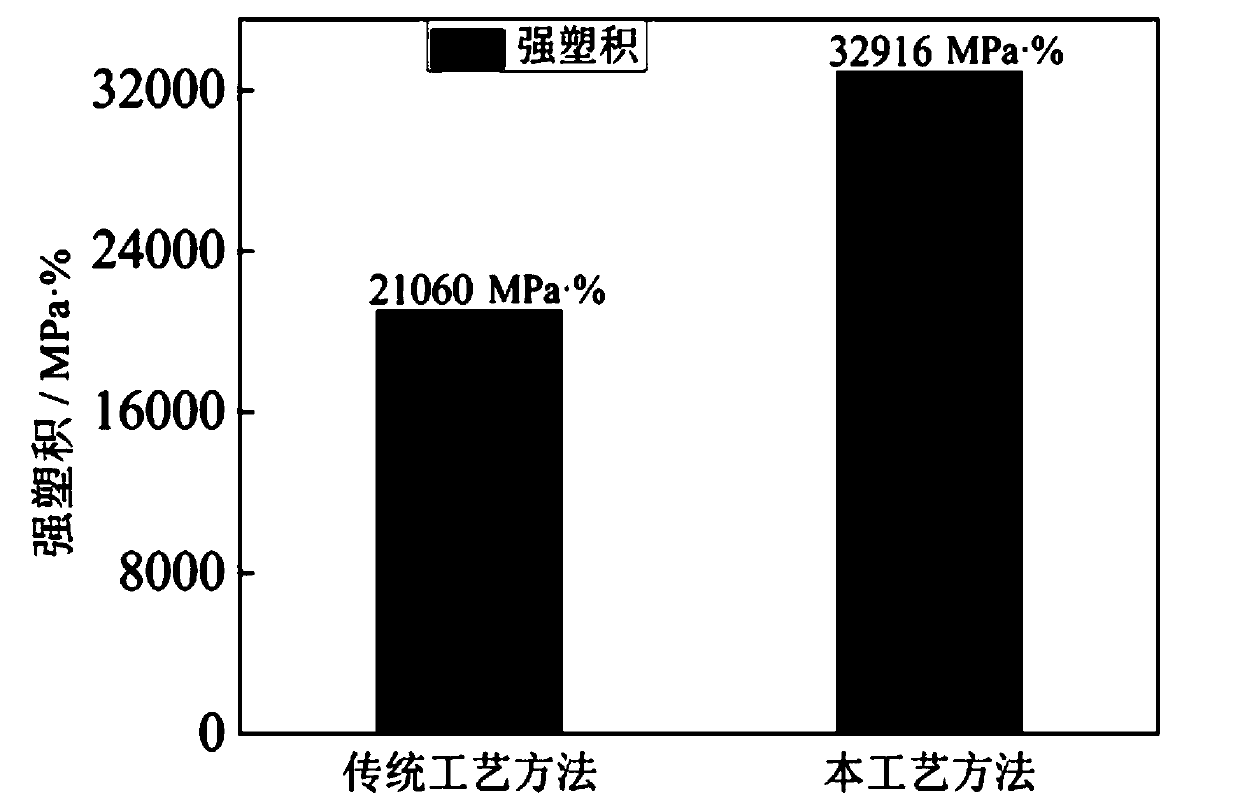

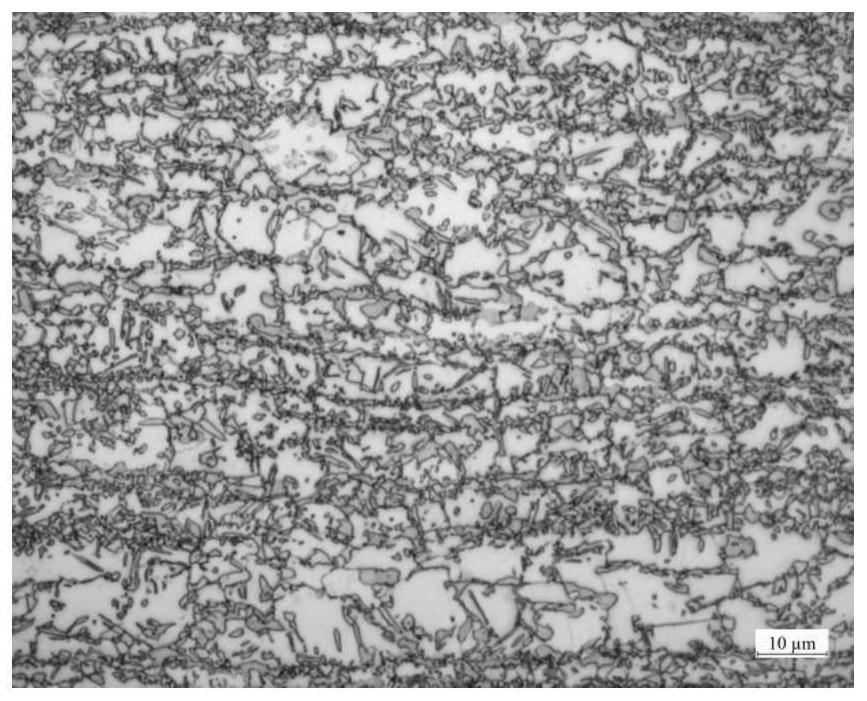

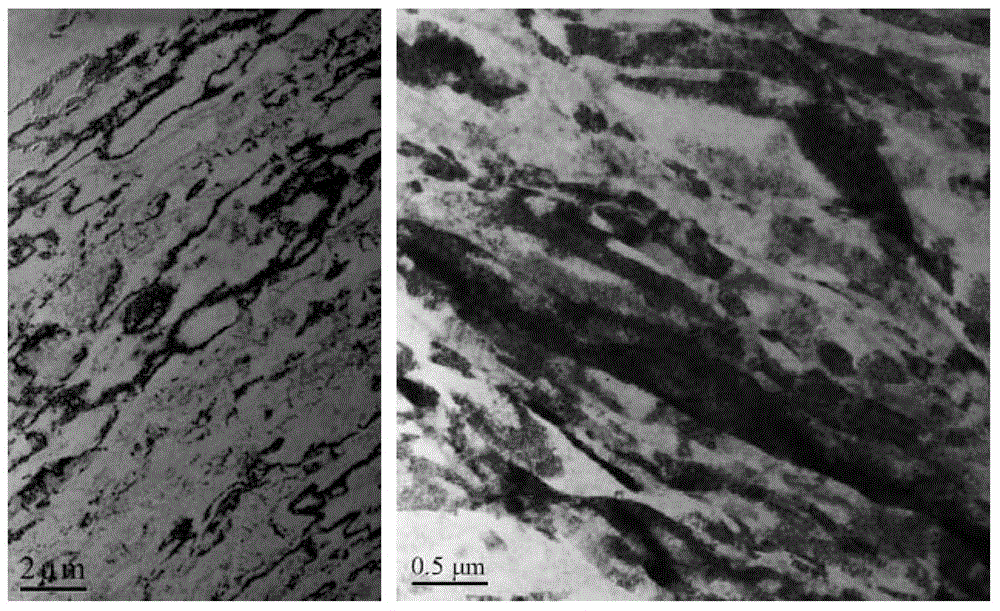

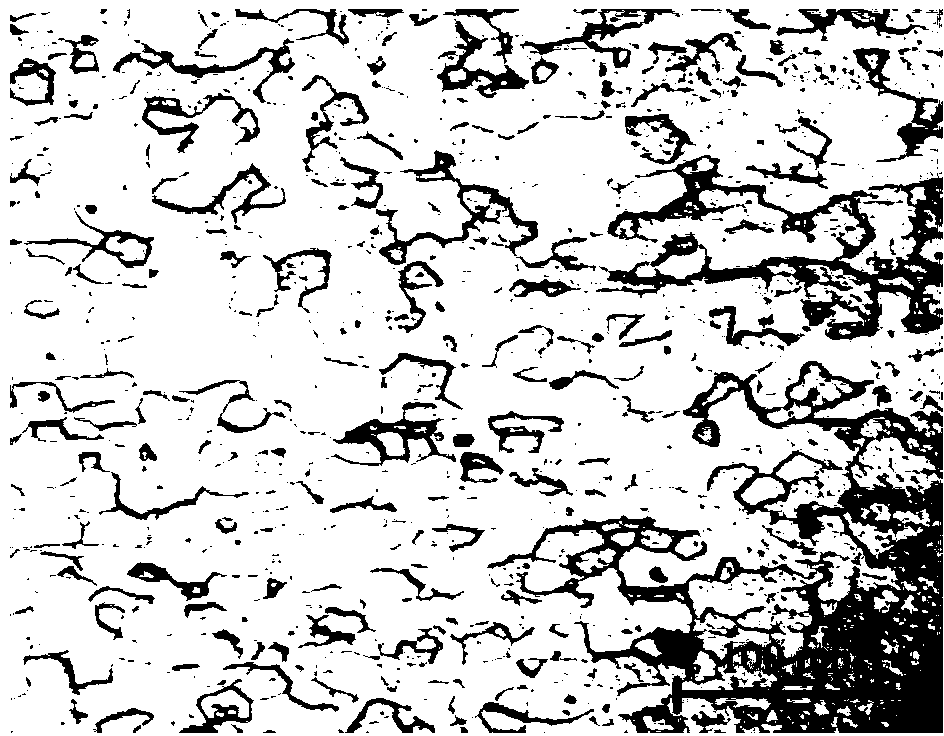

Heat treatment process of a high-strength plastic ferritic-austenitic duplex stainless steel

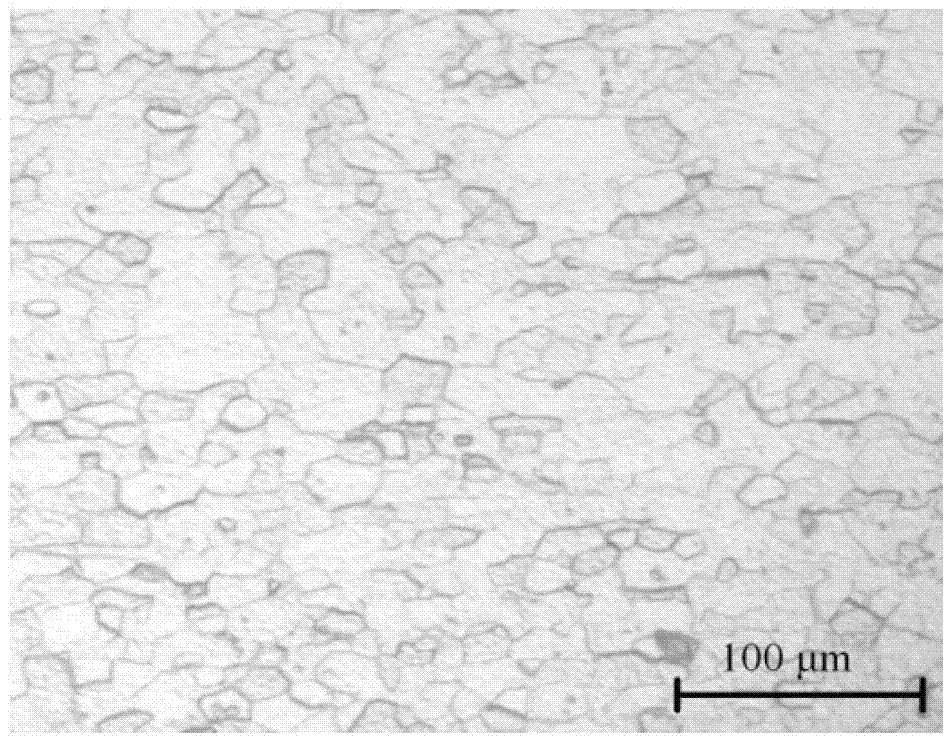

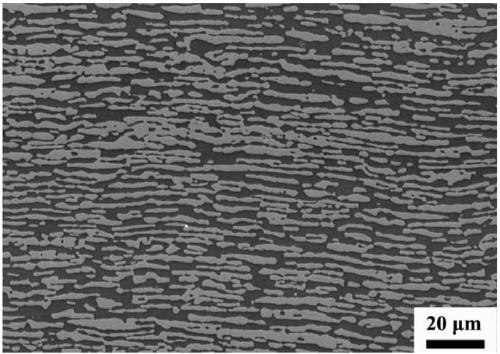

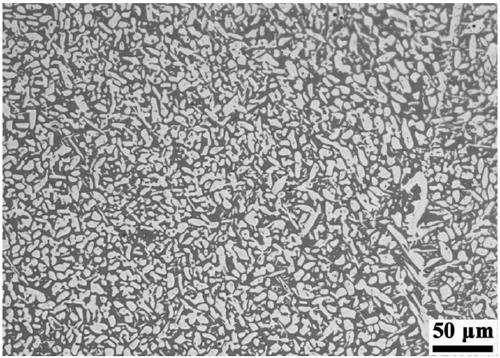

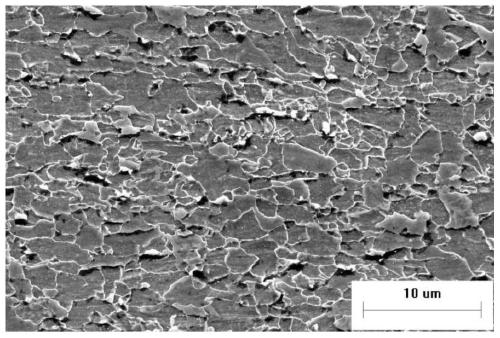

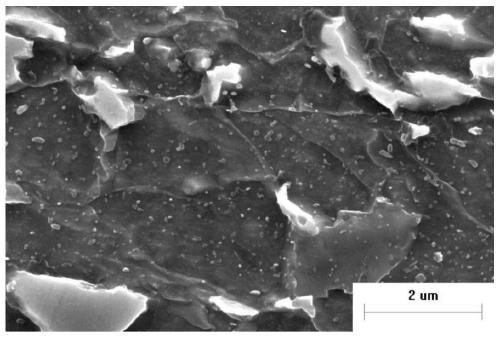

ActiveCN109487060BReduce grain boundary areaEvenly distributedFurnace typesHeat treatment furnacesSolution treatmentFerritic matrix

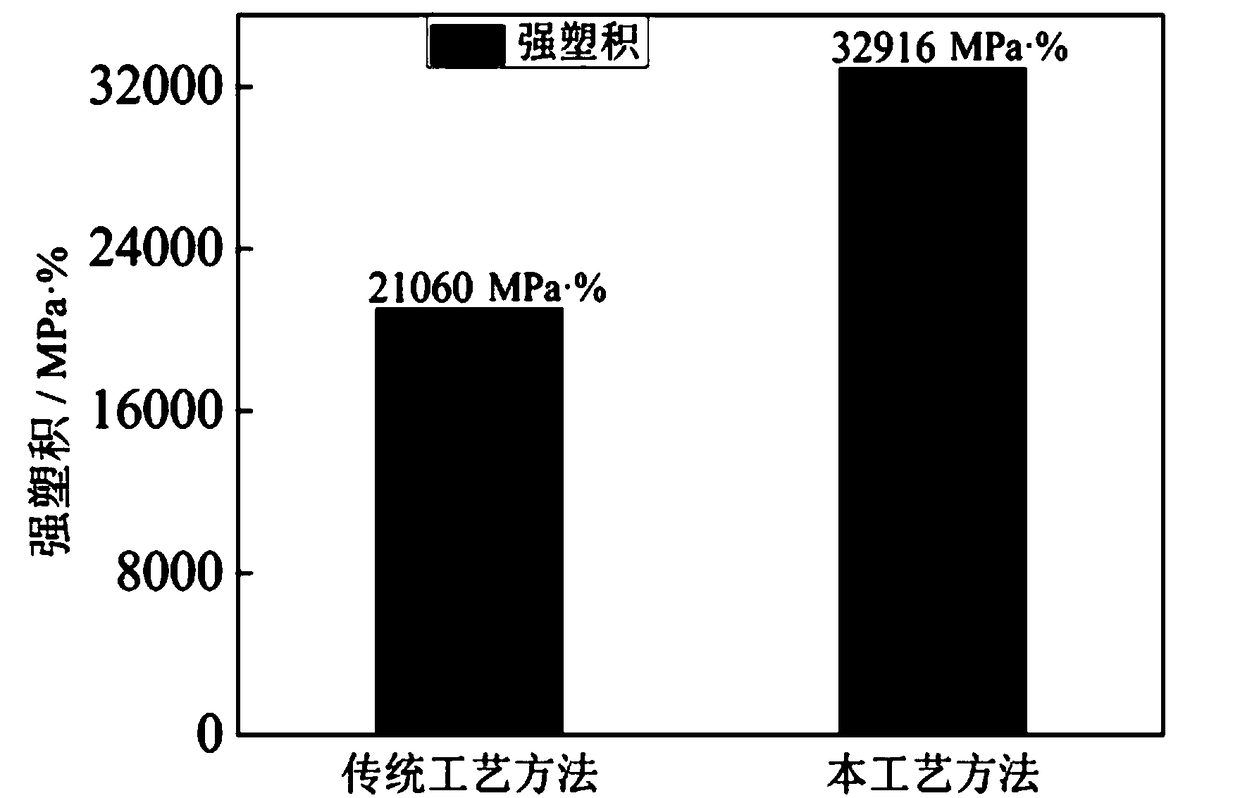

A heat treatment process for high-strength plastic ferrite-austenitic duplex stainless steel, which belongs to the field of material heat treatment technology. The steps are as follows: (1) one-level solid solution treatment; (2) pre-deformation treatment; (3) two-level solid solution treatment. After using the process of the present invention to process ferrite-austenite duplex stainless steel, the traditional duplex structure of duplex stainless steel in which two phases are alternately distributed in layers can be eliminated, and an equiaxed austenite particle phase + ferrite can be obtained. The dual-phase structure of the body matrix phase can increase the strong plastic volume of the material by more than 50%.

Owner:NORTHEASTERN UNIV LIAONING

High-strength Al-Mg-Zr welding wire for ships and preparation method of high-strength Al-Mg-Zr alloy welding wire

InactiveCN111334693AImprove mechanical propertiesHigh tensile strengthWelding/cutting media/materialsSoldering mediaMechanical propertyZr alloy

The invention discloses a high-strength Al-Mg-Zr welding wire for ships. Alloy plate material of the alloy welding wire comprises, by weight: 5.5-6.5% of Mg, 0.7-1.1% of Mn, 0.02-0.15% of Zr, 0-0.3% of Er, 0-0.4% of Si, 0-0.4% of Fe, less than or equal to 0.1% of other single impurity element, and the balance Al. The invention also discloses a preparation method of the alloy welding wire. According to the high-strength Al-Mg-Zr alloy welding wire for the ships and the preparation method of the alloy welding wire, the micro Er element is selected as an effective component of the alloy, so thatthe mechanical property of the whole aluminum alloy welding wire is effectively improved, meanwhile, the deformation energy storage of the surface layer of the aluminum alloy is higher, and thus the tensile strength of a welding wire joint, the bending degree of the welding joint and the elongation rate after the joint is broken are effectively improved; and in addition, the process is simple andeasy to operate, and through adopting the method, the homogenization annealing treatment is thorough in the process of manufacturing the welding wire, so that the mechanical property and corrosion resistance of the manufactured product are effectively improved.

Owner:BEIJING ALUMIP DEVING +2

Rolling fatigue resistant bearing steel ball and preparation method thereof

InactiveCN106636942ADeformation temperature refinementReduce interlamellar spacingRolling resistanceHardness

The invention discloses a rolling fatigue resistant bearing steel ball. The rolling fatigue resistant bearing steel ball comprises the following components of, by weight, 1%-1.1% of C, 1.4%-1.5% of Cr, 0.2%-0.4% of Si, 0.3%-0.5% of Mn, 0.02%-0. 04% of Ni, 0.1%-0.15% of Mo, 0.03%-0.04% of Nb, 0-0.02% of S, 0-0.02% of P, Al, and the balance Fe, wherein the expression of 'Al=C-16.5 Nb' is met. The invention further discloses a preparation method of the rolling fatigue resistant bearing steel ball. The rolling fatigue resistant bearing steel ball has good hardness, abrasion resistance and rolling fatigue resistance.

Owner:芜湖市永帆精密模具科技有限公司

Heat treatment technology of high-strength and high-plasticity ferrite-austenite duplex stainless steel

ActiveCN109487060AReduce grain boundary areaEvenly distributedFurnace typesHeat treatment furnacesSolution treatmentFerritic matrix

The invention belongs to the technical field of material heat treatment, and discloses a heat treatment technology of high-strength and high-plasticity ferrite-austenite duplex stainless steel. The heat treatment technology comprises the following steps of (1) first-stage solution treatment, (2) predeformation treatment and (3) second-stage solution treatment. After the technology is adopted for treating the ferrite-austenite duplex stainless steel, a traditional dual phase structure of the duplex stainless steel can be eliminated, wherein two phases of the dual phase structure are alternatelydistributed in a layer shape; and a dual phase structure of an equiaxial austenite particle phase and a ferrite matrix phase can be obtained, and the product of strength and elongation of a materialcan be improved by 50% or above.

Owner:NORTHEASTERN UNIV

A kind of preparation method and application of 700mpa grade ultra-fine grain high-strength weathering steel

Owner:UNIV OF SCI & TECH BEIJING +1

Preparation method and application of DP980 chilled steel strip

PendingCN113957221AGuaranteed solid solutionEliminate casting defectsHot-dipping/immersion processesContinuous annealingMolten steel

The invention relates to the technical field of steel rolling, in particular to a preparation method and application of a DP980 chilled steel strip. The preparation method comprises the following steps: (1) smelting molten steel; (2) carrying out hot rolling on a continuous casting blank to obtain a hot-rolled plate; coiling the hot-rolled plate; and (3) carrying out acid rolling on the hot-rolled plate to obtain a chilled steel strip. The DP980 chilled steel strip can be used for producing continuous annealing products and / or galvanized products. The DP980 chilled steel strip can be used for producing continuous annealing products as well as galvanized products, and dual-phase steel which is produced at low cost and has excellent performance can be obtained on the premise that the surface quality of the products is not reduced.

Owner:SD STEEL RIZHAO CO LTD

Wear-resisting bearing steel ball and preparing method thereof

InactiveCN106834956ALower deformation temperaturePrevent from growing thickerHardnessResidual stress

The invention discloses a wear-resisting bearing steel ball. The wear-resisting bearing steel ball comprises, by weight, 0.8%-0.9% of C, 1.5%-1.65% of Cr, 0.1%-0.3% of Si, 0.4%-0.6% of Mn, 0.01%-0.03% of Ni, 0.2%-0.4% of Mo, 0.3%-0.4% of Al, 0.1%-0.2% of V, smaller than or equal to 0.01% of S, smaller than or equal to 0.01% of P and the balance Fe, wherein the expression that C-0.8Al-1.3V is smaller than 0.51% is met. The invention further discloses a preparing method of the above wear-resisting bearing steel ball. Due to the fact that all the elements are matched with a proper proportion and the proper preparing method is matched, small spherical carbide can be promoted to be evenly distributed in the steel ball, the spheroidizing annealing time is shortened, the large amount of carbide is promoted to be subjected to solid solution, wear resistance, hardness, strength and toughness of the wear-resisting bearing steel ball are greatly improved, and residual stress is eliminated.

Owner:芜湖市永帆精密模具科技有限公司

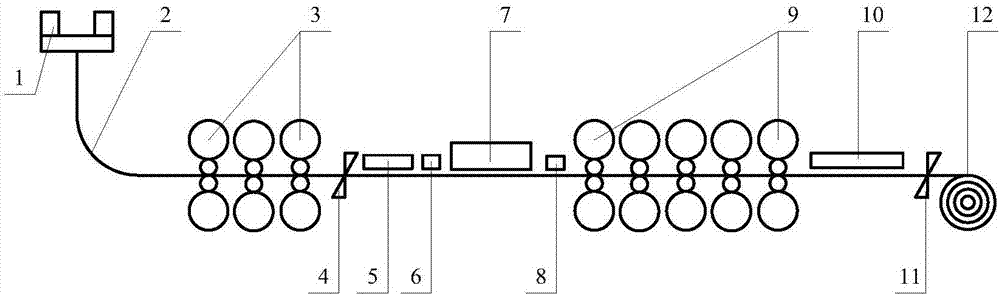

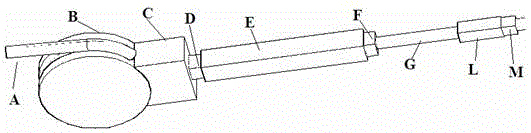

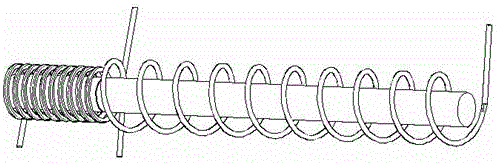

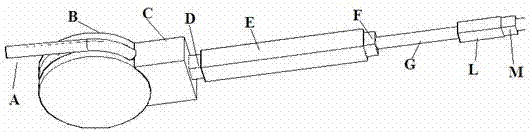

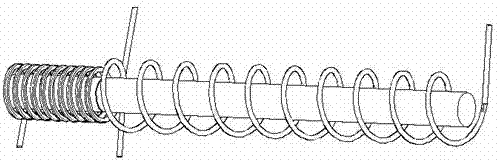

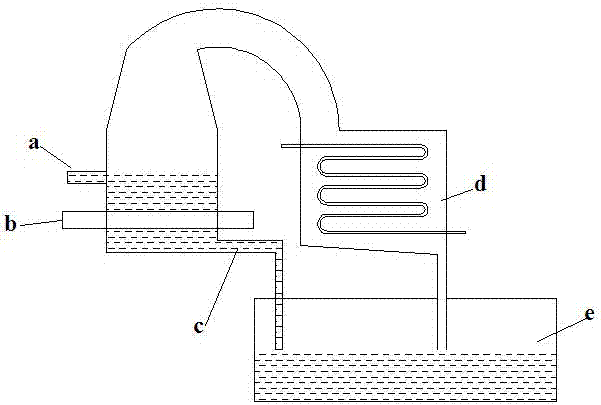

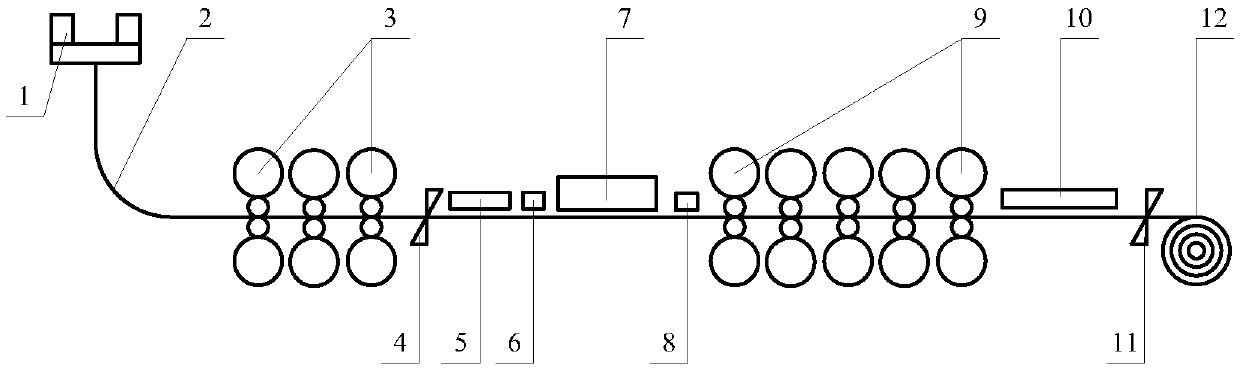

On-line solid-state phase change treatment device for alloy rod billet and treatment method thereof

The invention relates to an on-line solid-state phase change treatment device for alloy rod billets and a treatment method thereof. The device comprises a continuous extruder, a coil induction fast heating device, a first cooling device, a heating insulating device and a second cooling device which are arranged sequentially from front to back, wherein the coil induction fast heating device comprises a heating induction coil and an insulating induction coil, and the heating induction coil is positioned in front of the insulating induction coil. The on-line solid-state phase change treatment device for alloy rod billets and the treatment method thereof disclosed by the invention organically combine continuous extrusion, on-line solid solution and on-line aging, realize integration and serialization of on-line solid-state phase change heat treatment of alloy rod billets, and have the advantages of high production efficiency and stable product performance.

Owner:CHINA RAILWAY CONSTR ELECTRIFICATION BUREAU GRP KANG YUAN NEW MATERIALS CO LTD

Reinforced plastic dual-phase steel for 800MPa-grade hot galvanizing and preparation method of reinforced plastic dual-phase steel

PendingCN114045437AImprove stabilityLow costHot-dipping/immersion processesHeat treatment process controlUltimate tensile strengthDual-phase steel

The invention belongs to the technical field of cold-rolled strip production, and particularly relates to reinforced plastic dual-phase steel for 800MPa-grade hot galvanizing and a preparation method of the reinforced plastic dual-phase steel. The technical problem to be solved by the invention is to provide the reinforced plastic dual-phase steel for 800MPa-grade hot galvanizing and the preparation method of the reinforced plastic dual-phase steel. Through reasonable design of chemical components of the dual-phase steel and adjustment of preparation process parameters, the yield strength of the obtained 800MPa-grade reinforced plastic dual-phase steel for hot galvanizing ranges from 455 MPa to 525 MPa, the tensile strength ranges from 810 MPa to 880 MPa, and the elongation A80 ranges from 23.0% to 29.0%; the microstructure of the steel plate is composed of 40%-50% of ferrite, about 25%-30% of martensite, 5%-25% of bainite and 5%-10% of retained austenite.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

An online solid-state phase transformation treatment device and treatment method for alloy rod billet

The invention relates to an on-line solid-state phase change treatment device for alloy rod billets and a treatment method thereof. The device comprises a continuous extruder, a coil induction fast heating device, a first cooling device, a heating insulating device and a second cooling device which are arranged sequentially from front to back, wherein the coil induction fast heating device comprises a heating induction coil and an insulating induction coil, and the heating induction coil is positioned in front of the insulating induction coil. The on-line solid-state phase change treatment device for alloy rod billets and the treatment method thereof disclosed by the invention organically combine continuous extrusion, on-line solid solution and on-line aging, realize integration and serialization of on-line solid-state phase change heat treatment of alloy rod billets, and have the advantages of high production efficiency and stable product performance.

Owner:CHINA RAILWAY CONSTR ELECTRIFICATION BUREAU GRP KANG YUAN NEW MATERIALS CO LTD

450mpa-grade hot-dip galvanized dual-phase steel and its production method

ActiveCN113584395BImprove uniformityClear opening and closing methodHot-dipping/immersion processesChemical compositionDual-phase steel

The invention discloses a 450MPa grade hot-dip galvanized dual-phase steel and a production method thereof, belonging to the technical field of cold-rolled strip production. The chemical composition of the dual-phase steel by mass percentage is: C 0.03%-0.10%, Si 0.20-0.60%, Mn 1.20%-2.00%, P≤0.020%, S≤0.010%, Als 0.015%-0.070%, N ≤0.0060%, the remaining elements are Fe and inevitable impurities; its microstructure is: 90-96% ferrite and 4-10% martensite by volume percentage. The preparation method includes the steps of smelting, hot rolling, pickling and hot-dip galvanizing. The production method of the dual-phase steel of the present invention adopts the sparse cooling method, which is beneficial to the stable control of the microstructure and properties; the opening and closing methods of the descaling and the cooling water between the racks are defined, which is beneficial to obtain a good surface quality. Combined with the smelting and hot-dip galvanizing process, the good mechanical properties and surface quality of the 450MPa hot-dip galvanized dual-phase steel sheet have been obtained, which has good market competitiveness.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Preparation method of magnesium alloy reinforced by nano-quasi-crystal particles

ActiveCN102605227BSmall sizeReasonably change the distribution characteristicsSolution treatmentDistribution characteristic

Owner:北京二七铁丰龙科技有限公司

Non-oriented electrical steel for variable frequency motor and production method thereof

InactiveCN101876028BStorage capacity declineRich in componentsManufacturing stator/rotor bodiesElectrical steelFree cooling

The invention relates to non-oriented electrical steel for a variable frequency motor and a production method thereof, aiming to overcome the defects of traditional non-oriented electrical steel which has high strength and poor toughness and can not meet the requirement of the variable frequency motor and complex process. The non-oriented electrical steel comprises the flowing chemical componentsin percentage by weight: 0.001-0.015 percent of C, 0.3-0.9 percent of Mn, 0.4-1.6 percent of Cr, 0.1-1.2 percent of Al, 0.9-1.6 percent of Si, no more than 0.08 percent of P, no more than 0.015 percent of S, no more than 0.008 percent of N and the balance of Fe and residue, wherein the sum of the weight percent of Si and Al is 1.4-2.2 percent, the sum of the weight percent of Cr and Mn is 0.7-2.5percent, and Cr / Mn is 0.9-2.0. The production method comprises the following steps of: smelting by using a clean steel process and continuously casting to form a billet; heating the billet; roughly rolling; finish rolling, and controlling the accumulated percentage of reduction of former four passes to be 80-95 percent; reeling; naturally cooling to the room temperature; washing with acid; cold rolling; decarbonizing; soaking; cooling according to conventional method, coating and finishing. The invention has the advantages of simple process, low iron loss at low frequency and power frequency,lower iron loss at high frequency, higher magnetic induction as well as good corrosion resistance and stamping property.

Owner:武钢集团有限公司

Hot rolling production method for 400 series stainless steel coils

InactiveCN102125931BShorten the production cycleImprove performanceTemperature control deviceMetal rolling arrangementsFree coolingNational standard

The invention discloses a hot rolling production method for 400 series stainless steel coils, which comprises the following steps of: 1) hot rolling: rolling at low temperature of between 780 and 880DEG C; 2) coiling: coiling at high temperature of between 730 and 850DEG C; 3) heating: charging at a temperature higher than 300DEG C, and raising the temperature to 750-850DEG C at a high speed of 85DEG C / h; 4) keeping the temperature: starting to keep the temperature when the external temperature of the coils reaches the keeping temperature of between 750 and 850DEG C, and stopping heating whenthe temperature of the bottom centers of the coils reaches the keeping temperature for more than 2 hours; and 5) cooling: cooling with a heating hood, cooling by using a cooling hood, and naturally cooling respectively. By the method, the production efficiency of the finished hot-rolled coils is farther higher than that of the conventional hot rolling production process, and the batching annealing production efficiency is improved by over 50 percent; in addition, the hot rolled coils have good performance, and the performance of strip steel meets various standards such as national standard, Japanese standard and American standard, so the hot rolled coils and the strip steel have good application and promotion prospect.

Owner:BAOSHAN IRON & STEEL CO LTD

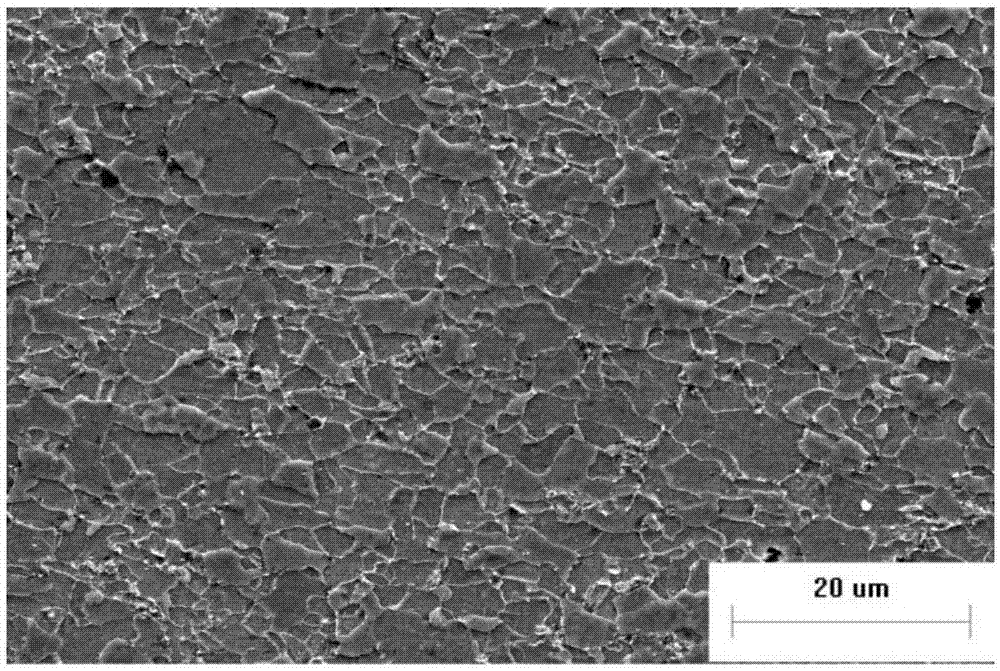

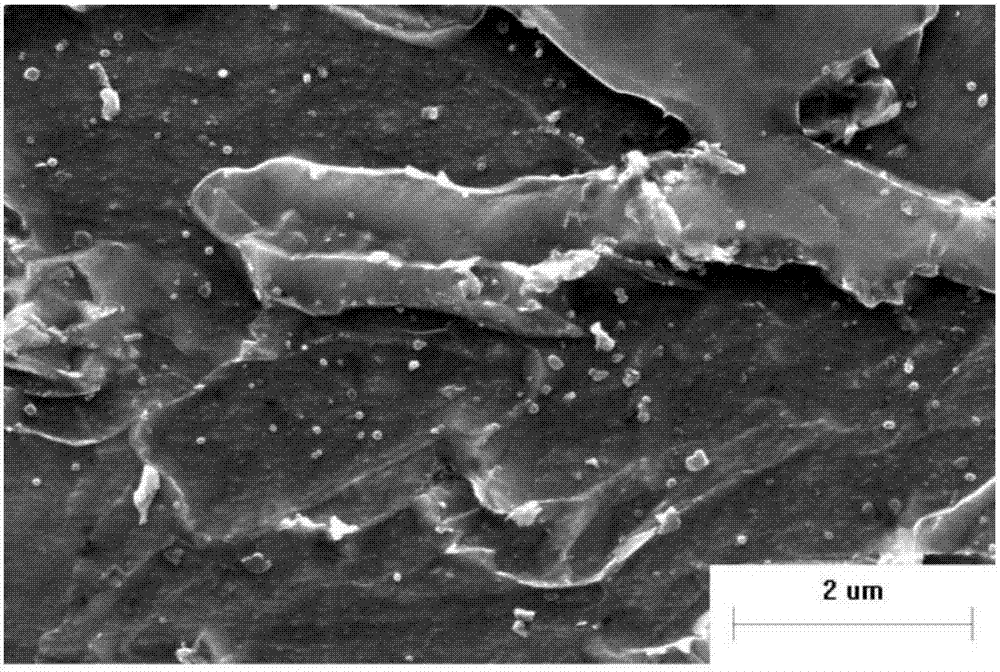

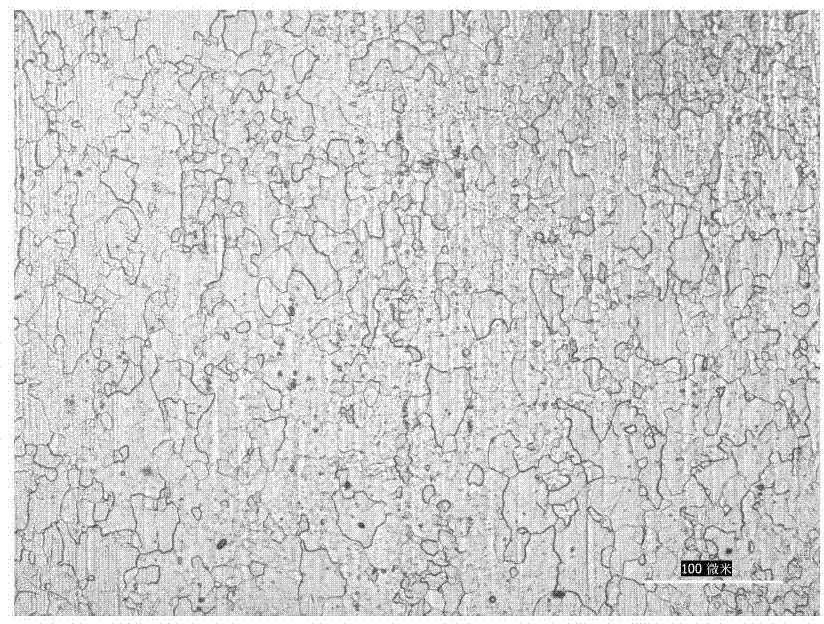

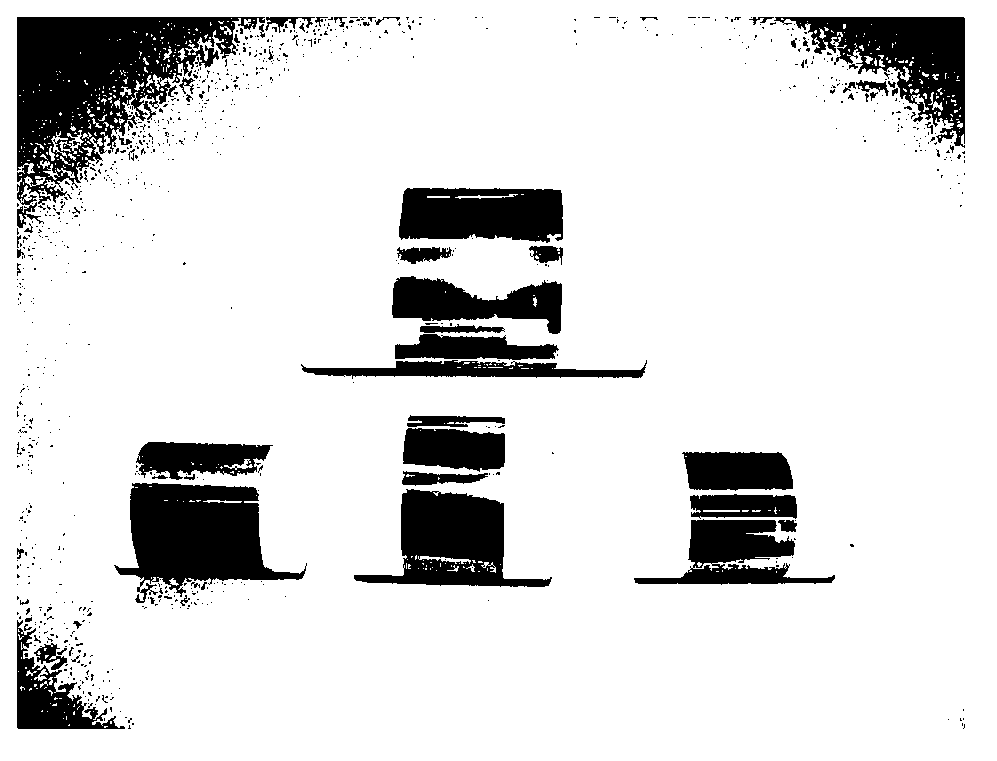

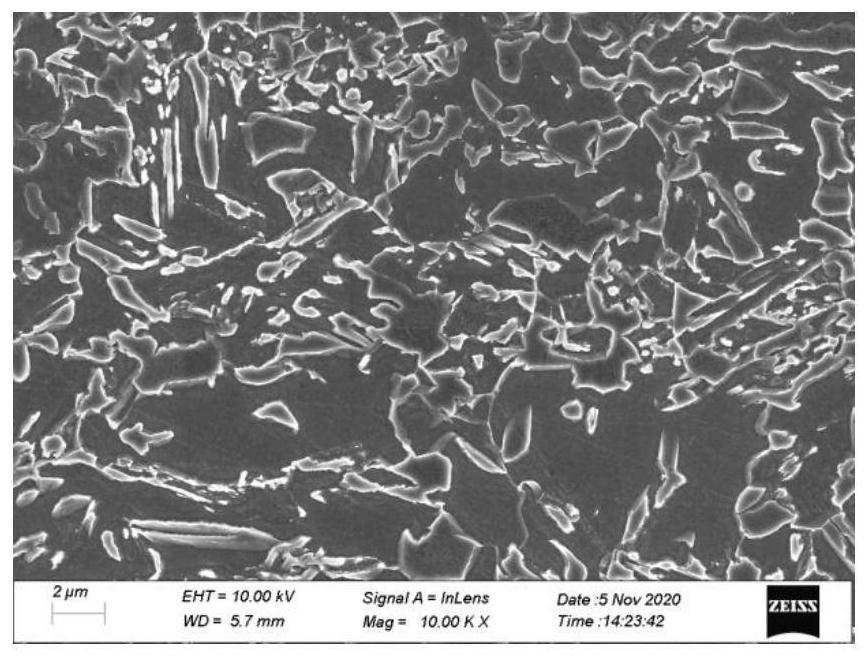

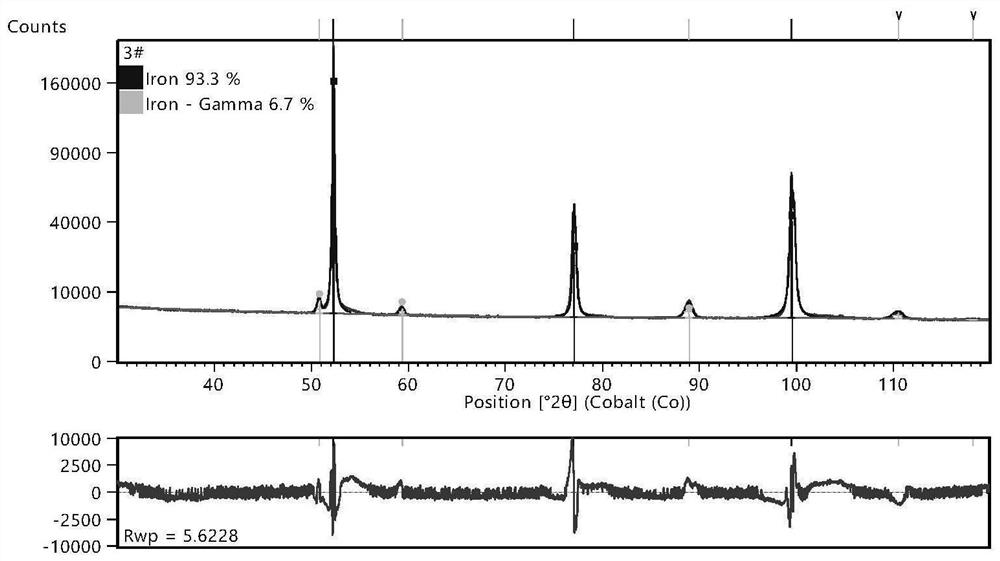

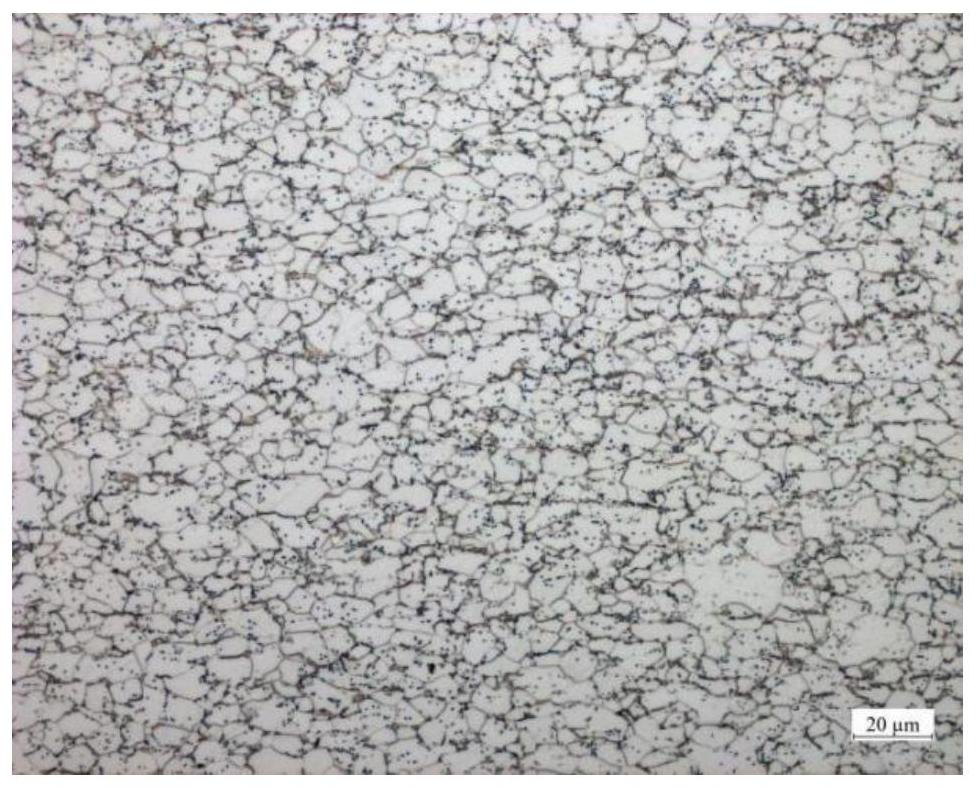

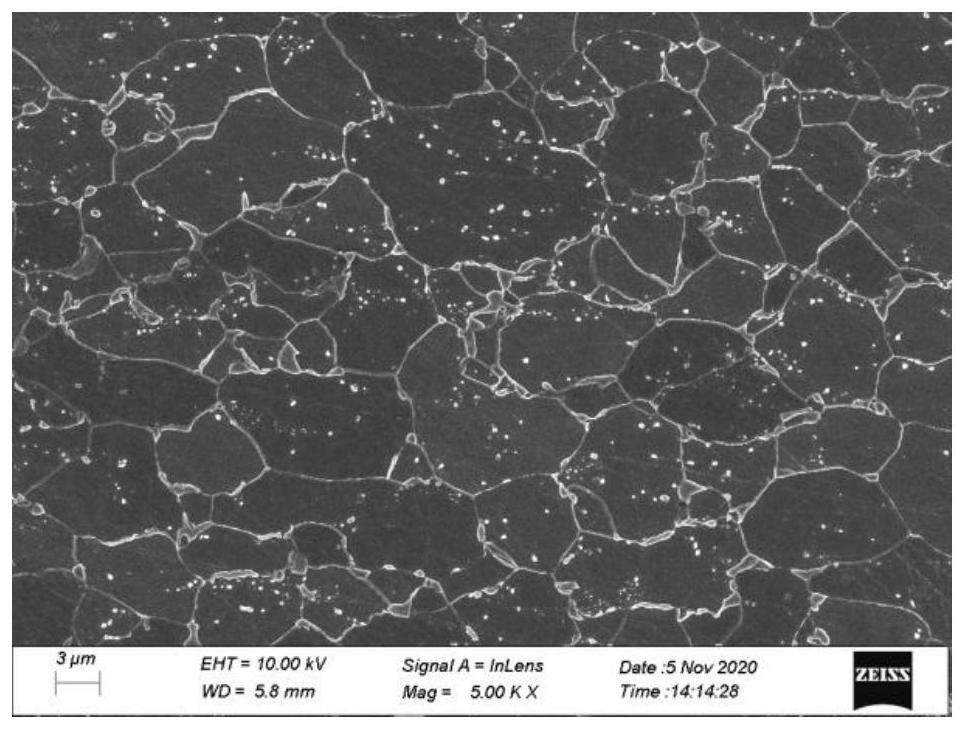

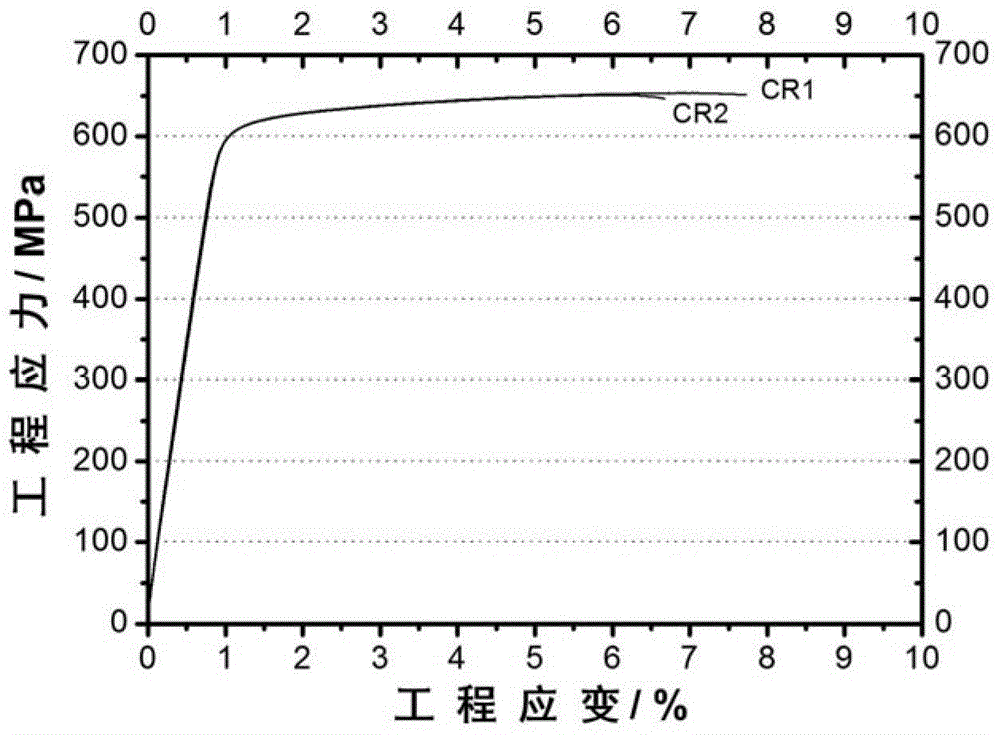

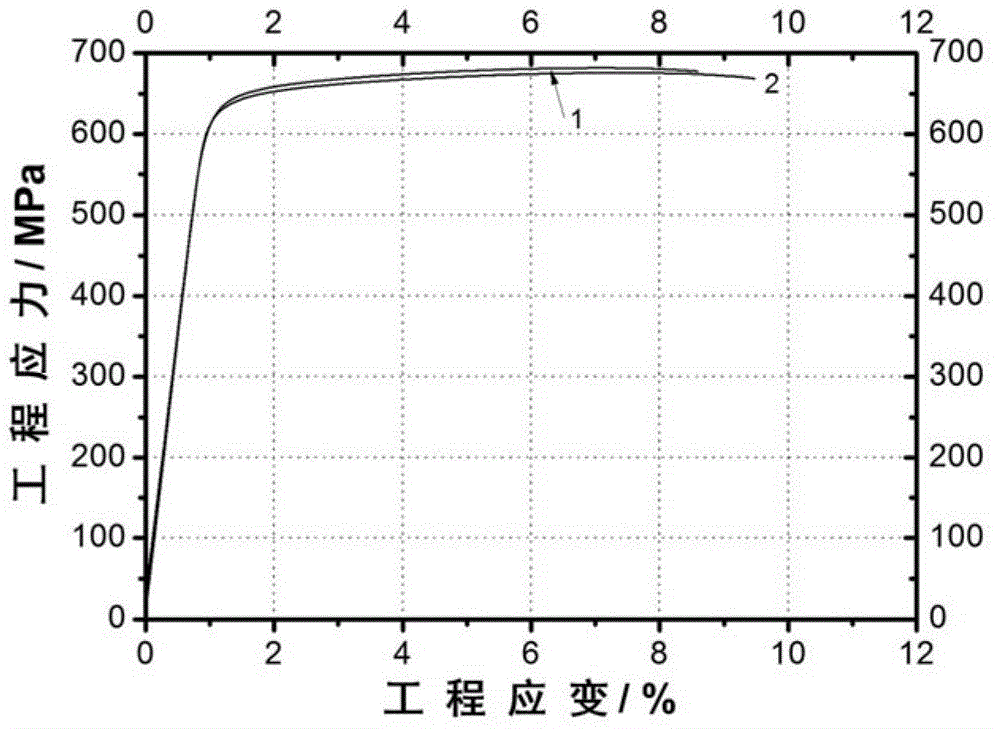

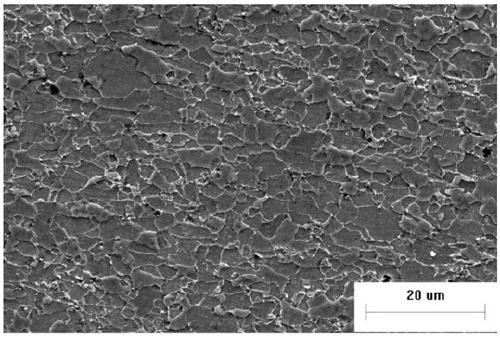

Preparation method of high-performance fine-grain FeCoCrNi alloy

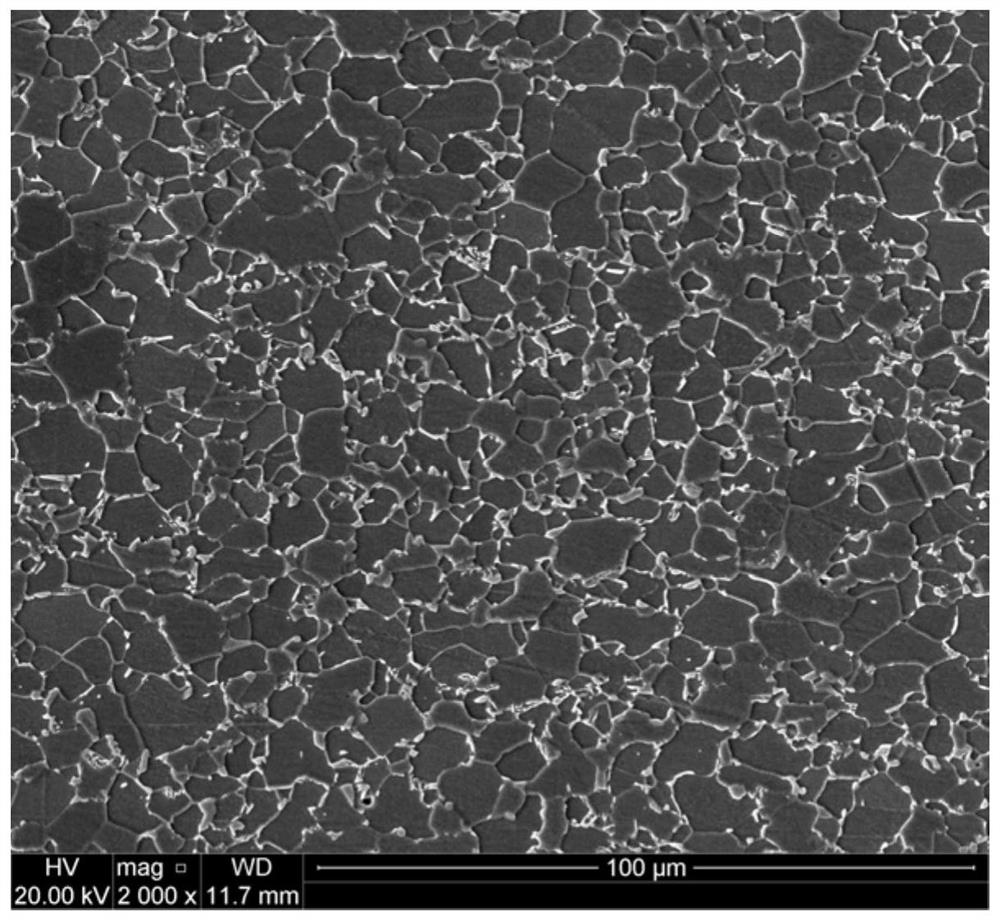

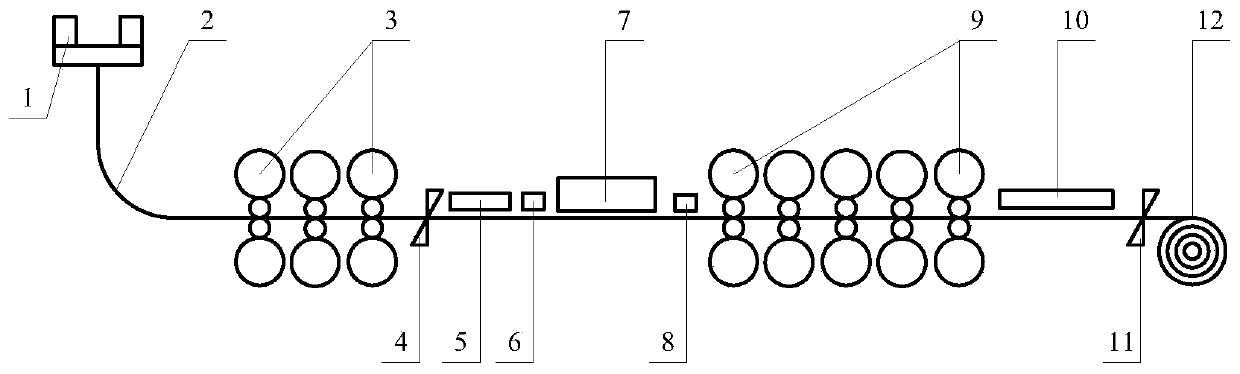

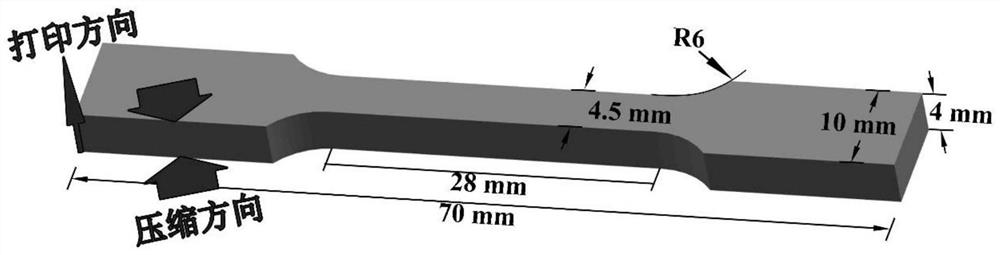

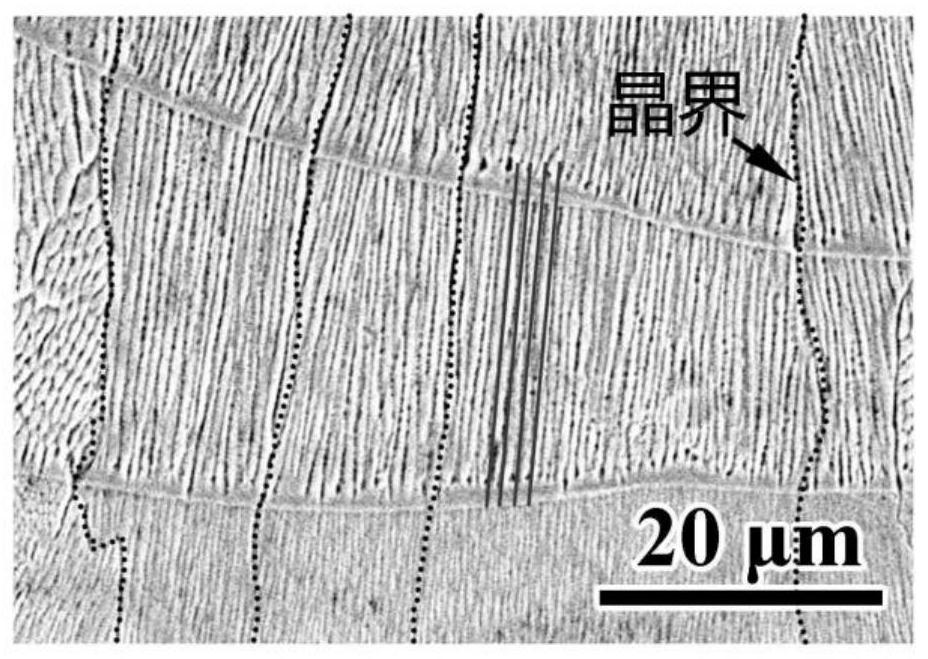

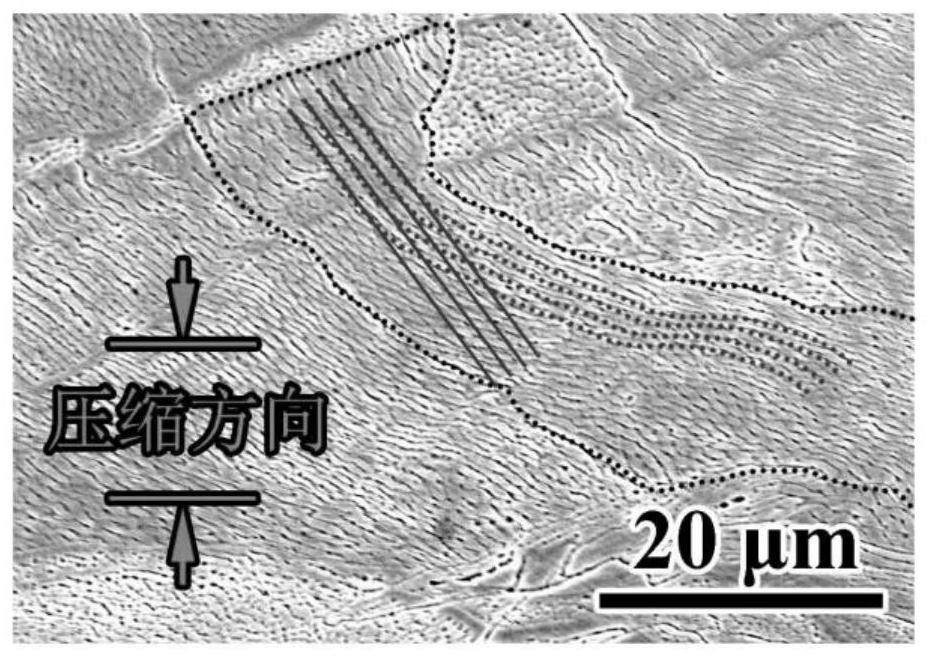

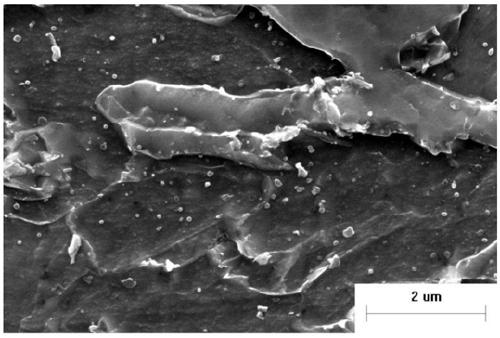

ActiveCN113523281AImprove deformation energy storageGrain refinementAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingHigh entropy alloys

The invention discloses a preparation method of a high-performance fine-grain FeCoCrNi alloy. The preparation method comprises the following steps: step 1, a high-entropy alloy is printed by adopting a selective laser melting method to prepare a printed FeCoCrNi alloy; according to the selective laser melting printing method, gas atomization spherical powder with the equal molar ratio of FeCoCrNi is adopted as a raw material; 2, the printed FeCoCrNi alloy is compressed in the printing direction, and the compressed FeCoCrNi alloy is obtained; and 3, the compressed FeCoCrNi alloy is subjected to annealing for 1.8 h to 2.2 h, and after cooling, the high-performance fine-grain FeCoCrNi alloy is obtained. According to the method, crystal grains can be greatly refined only through one-time compression and annealing circulation, the production cost is greatly reduced, and the machining efficiency is greatly improved. By applying the method, the strength and plasticity of the material can be remarkably improved, and the application range is greatly widened.

Owner:TIANJIN UNIV

A kind of cold-rolled steel plate with a yield strength of 420mpa and its preparation method

ActiveCN106636898BImproved recrystallization kineticsGrain refinementChemical compositionSheet steel

A cold-rolled steel plate with a yield strength of 420MPa and a preparation method thereof, belonging to the field of metallurgical technology; the steel plate composition and its mass percentage are: C 0.06~0.09%, Si 0~0.2%, Mn 0.8~1.0%, Ti 0~0.02 %, Nb 0.01~0.025%, the rest is Fe and unavoidable impurity elements; preparation method: 1) According to the chemical composition ratio of the cold-rolled steel plate, melt it into a steel ingot and forge it into a slab; 2) Insulate the slab and heat it After rolling to obtain the hot-rolled plate, it is coiled when cooled to an appropriate temperature at a certain cooling rate; 3) The coiled hot-rolled plate is pickled and then cold-rolled to obtain a cold-rolled plate; 4) The cold-rolled plate is obtained The plate adopts continuous annealing treatment of low-temperature soaking and segmented cooling. The yield strength 420MPa grade cold-rolled steel plate of the present invention has a microstructure that mainly includes ferrite, pearlite and cementite. The yield strength is 435-450MPa, the tensile strength is 518-548MPa, and the elongation A80 is 25.0-26.3%.

Owner:NORTHEASTERN UNIV LIAONING

A Treatment Method for Significantly Improving the Deformability and Mechanical Properties of High-Strength Aluminum Alloys

ActiveCN103343306BLarge rolling deformationImprove the effect of processing strengtheningUltimate tensile strengthMechanical property

Owner:UNIV OF SCI & TECH BEIJING +1

Preparation method of ultrathin Ta-W alloy foil

Owner:CENT SOUTH UNIV

Preparation method and application of a 550mpa grade ultra-fine grain high-strength weathering steel

InactiveCN107460413BImprove mechanical propertiesGood atmospheric corrosion resistanceAustenite grainWeather resistance

The invention relates to a preparation method and application of 550 MPa-grade ultra-fine grain high-strength weather-resistant steel and belongs to the technical field of metallurgy. The preparation method comprises the steps that continuous casting blanks directly enter an M rack rough rolling unit under the high pulling speed and are subjected to M-pass continuous heavy reduction (50-60%) rough rolling, and austenite grains are greatly refined; after rough rolling, middle blanks are rapidly heated through an induction heating furnace to the temperature needed for a finish rolling inlet, and meanwhile a reverse temperature field is formed; and then sequentially through a finish rolling set, laminar flow cooling and a reeling machine, finally the organization characteristics that the surface and the core part are coarse, and the portion of the 1 / 4 thickness position is fine are formed. In the production process, finish rolling and rough rolling are both full-headless rolling. An ultra-fine grain high-strength weather-resistant hot-rolling steel belt with the weather resistance being equivalent to corten-A is obtained, and the effects that the thin effect replaces the thick effect and the hot effect replaces the cold effect are achieved; while the weight of a car body is small, the service life of a car plate is prolonged, the production efficiency is improved, and the production cost is reduced; and meanwhile energy consumption is reduced, emission is reduced, and resource-saving and environment-friendly production is achieved.

Owner:UNIV OF SCI & TECH BEIJING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com