A Treatment Method for Significantly Improving the Deformability and Mechanical Properties of High-Strength Aluminum Alloys

A treatment method and aluminum alloy technology, which is applied in the fields of metal material processing and aluminum alloy processing, can solve the problems of poor deformation ability of AZ31 magnesium alloy, long difference in practical application, and small size of rolled blanks, etc. Inhibition of dynamic recovery or recrystallization and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

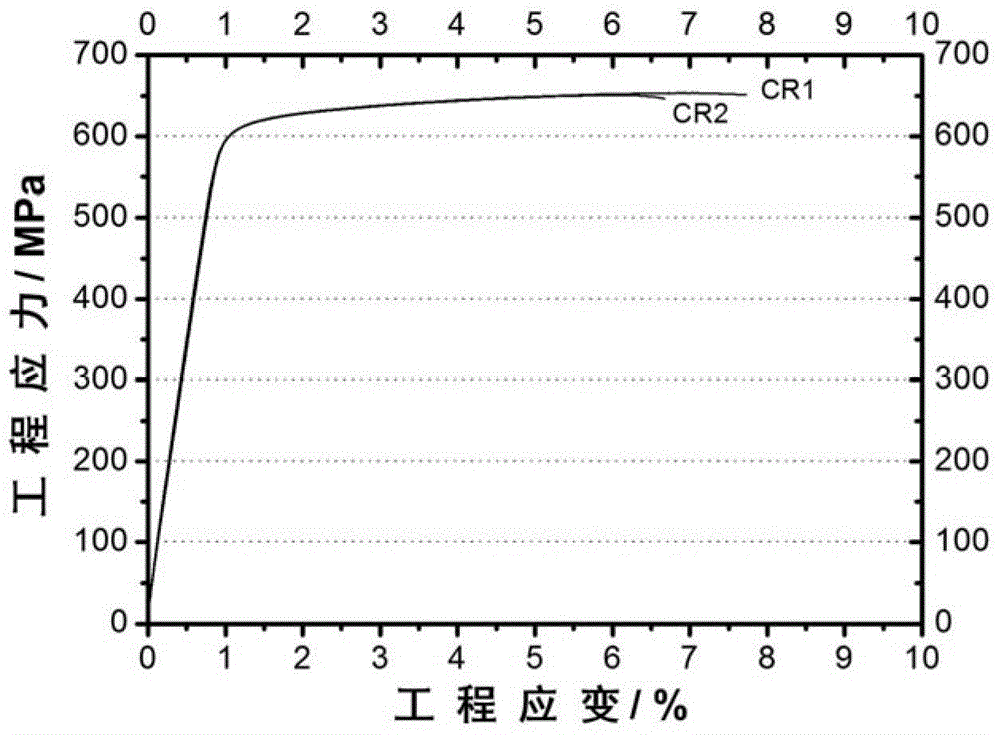

[0033] The industrially produced AA 7050 high-strength aluminum alloy hot-rolled plate is used as the rolling raw material, at 475 o C. After solution treatment for 2 hours, water quenching, the solid solution state AA7050 alloy sheet is milled into pre-rolled sheets with a thickness of 15 mm and 20 mm and smooth upper and lower surfaces. The 15 mm and 20 mm thick AA 7050 alloy sheets were cold-rolled and deformed at room temperature with a deformation of 10% per pass. The interval between each pass is 10-15 minutes or one pass of cold rolling is directly immersed in the next pass of rolling, that is, continuous cold rolling. The results show that the 15 mm thick AA 7050 alloy sheet undergoes serious cracking or cracking after 53% deformation of cold rolling at intervals of 10-15 minutes per pass, and larger cracking occurs after continuous cold rolling of 63%. The 20 mm thick solid solution state AA 7050 alloy plate was rolled at intervals at room temperature with the same p...

Embodiment 2

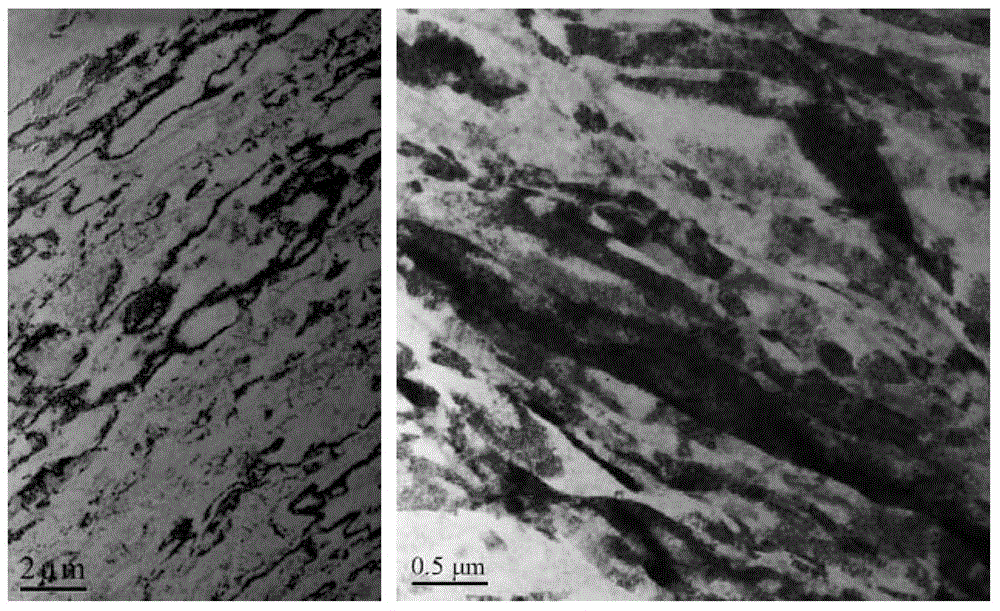

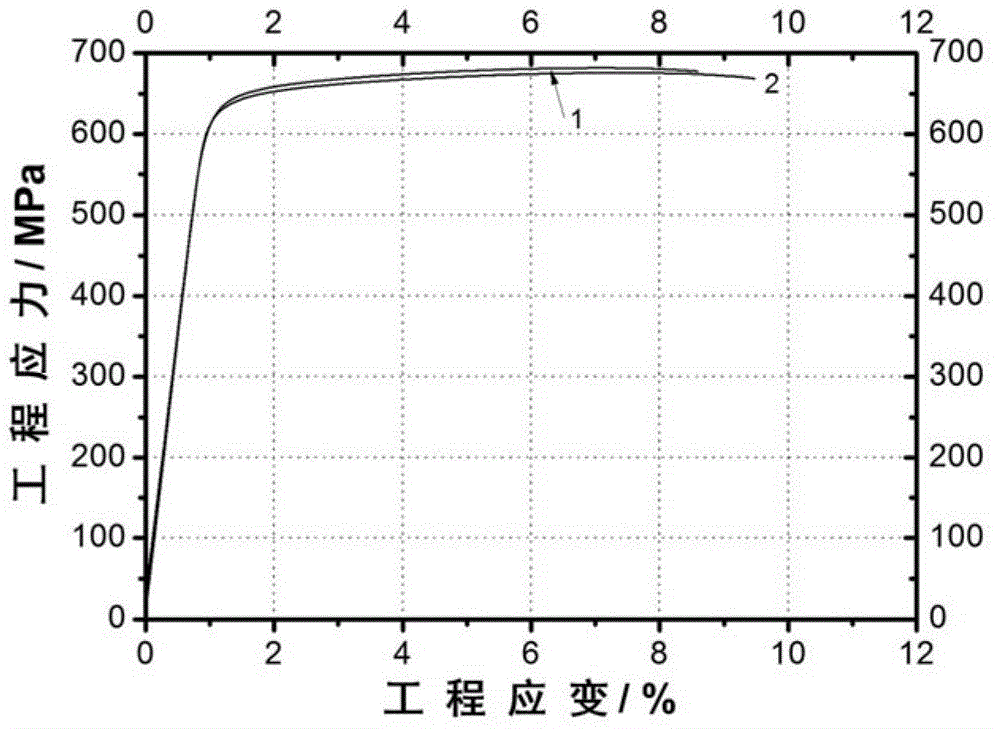

[0035] The industrially produced AA 7050 high-strength aluminum alloy hot-rolled plate is used as the rolling raw material, at 475 o After C solution treatment for 2 hours, water quenching, the solution quenched state AA 7050 alloy plate is then heated at 350 o C heat preservation treatment for 1 hour, out of the furnace and water quenching. The state alloy plate was milled into a pre-rolled plate with a thickness of 20 mm and smooth upper and lower surfaces. The milled 20 mm thick AA 7050 high-strength aluminum alloy plate was immersed in liquid nitrogen to cool for more than 2 hours, and then the 20 mm thick plate was rolled in multiple passes with a pass reduction of 10%, and the total deformation was 66% . Before rolling each pass, the alloy plate is immersed in liquid nitrogen for cooling for 15-20 minutes. It was found that after 350 o After C-1 h treatment, the 20 mm thick AA 7050 high-strength aluminum alloy plate did not appear cracking or edge cracking after roll...

Embodiment 3

[0037] The industrially produced AA 7050 high-strength aluminum alloy hot-rolled plate is used as the rolling raw material, at 475 o After C solution treatment for 2 hours, water quenching, the solution quenched state AA 7050 alloy plate was then heated at 200 o C heat preservation treatment for 10 hours, and water quenching after taking out of the furnace. The state alloy plate was milled into a pre-rolled plate with a thickness of 15 mm and smooth upper and lower surfaces. The milled 15 mm thick AA 7050 high-strength aluminum alloy plate was immersed in liquid nitrogen to cool for more than 2 hours, and then the 15 mm thick plate was rolled in multiple passes with a pass reduction of 10%, and the total deformation was 74% . The alloy plates were immersed in liquid nitrogen for 20 minutes before each rolling pass. At the same time, the same reduction is used for multi-pass room temperature interval rolling, and the deformation is 70%. It was found that after 200 o After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com