A kind of coil type production method of titanium-palladium alloy

A production method, palladium alloy technology, applied in the field of coil production of titanium palladium alloy, can solve the problems of uneven composition of ingots, low production efficiency, small batches, etc., and achieve good appearance quality, high production efficiency and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

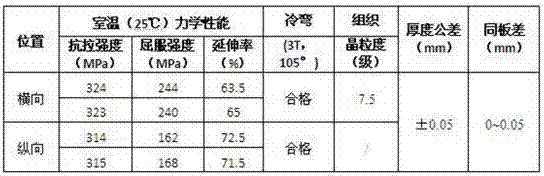

Embodiment 1

[0029] Select grade 0 sponge titanium with a particle size of 3~12.7mm, select and remove the particles with obvious abnormal appearance, use cloth equipment to spread the sponge titanium in layers, sprinkle pure Pd powder (purity greater than 99.95%) evenly on it, and then press and weld the electrodes; The German ALD vacuum consumable electric arc furnace was used for secondary melting to prepare TA8-1 alloy. The Pd content of the slab was 0.06-0.08% and the O content was 0.05-0.06%. The composition was qualified and there was no obvious segregation of Pd element. After forging, shaping and face milling, a qualified TA8-1 slab with a flaw detection level reaching Class A was obtained. The nominal size of the slab was 180×1050×6000mm and the weight was 5.1t.

[0030] After heating with natural gas and holding at 880±20°C, rough rolling and finish rolling are used to prepare 4.5mm thick TA8-1 hot-rolled titanium coils, followed by annealing at 730°C±20°C, shot blasting, descali...

Embodiment 2

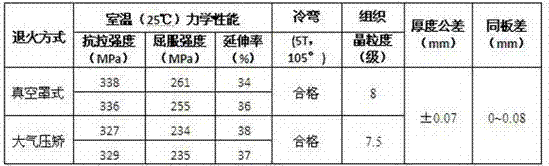

[0036] The same method as in Example 1 was used to prepare TA8 slab, forge and prepare 4.5mm hot-rolled coils, annealed and pickled, and the slab had a Pd content of 0.05-0.08% and an O content of 0.05-0.065%.

[0037] After grinding the surface of the hot-rolled coil, perform multi-pass cold rolling, the rolling deformation rate is about 54%, and the pass deformation rate is ≤12%, to obtain a 2mm thick cold-rolled titanium coil; after rolling, degrease to remove rolling oil, and then Annealing is carried out in a vacuum bell furnace, the annealing temperature is 650°C, and the holding time is about 8h. After annealing, cool to below 200°C, and air-cool after taking out the furnace; after cooling to room temperature, temper rolling with a deformation of ≤1.5% can be carried out to improve the shape of the plate and reduce unevenness; then use a leveler to straighten, and then cut into 2×1000×2000mm finished plates, the unevenness can reach ≤5mm / m.

[0038] Cut a small amount ...

Embodiment 3

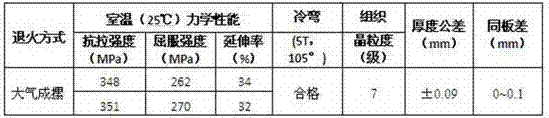

[0045] A method similar to that of Example 1 was used to prepare TA9 ingots, smelt three times, forge and prepare 5mm hot-rolled coils, annealed and pickled, and the Pd content of the slab was 0.15-0.23%, and the O content was 0.05-0.07%.

[0046] After grinding the surface of the hot-rolled coil, perform multi-pass cold rolling, the rolling deformation rate is about 40%, and the pass deformation rate is ≤10%, to obtain a 3mm thick cold-rolled titanium coil; after rolling, degrease to remove rolling oil, and then Cut into 3 × 1000 × 2000mm plates, 25 sheets into a stack, press 50mm steel plates for 650 ° C orthopedic annealing, and then perform sandblasting + pickling treatment, the unevenness of titanium plates can reach ≤ 5mm / m.

[0047] The performance and structure of the 3mm thick TA9 plate in the atmospheric annealed state are shown in Table 3.

[0048] Table 3 Properties and structure of 3mm thick TA9 plate (transverse direction)

[0049]

[0050] The elongation tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com