Cast-rolling method for 6xxx series aluminum alloy plate for automobile

An aluminum alloy plate, casting and rolling technology, applied in the field of aluminum alloy casting and rolling, can solve the problems of few production units, complex procedures, low efficiency, etc., and achieve the effects of improving production efficiency, improving heat exchange rate, and reducing penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

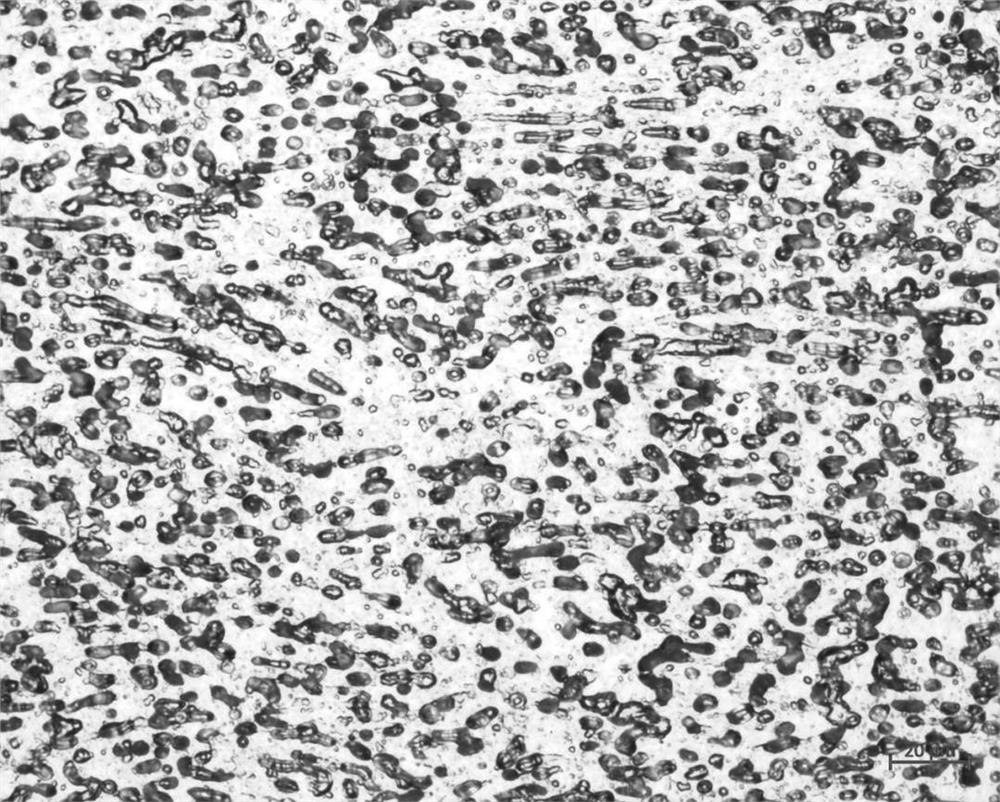

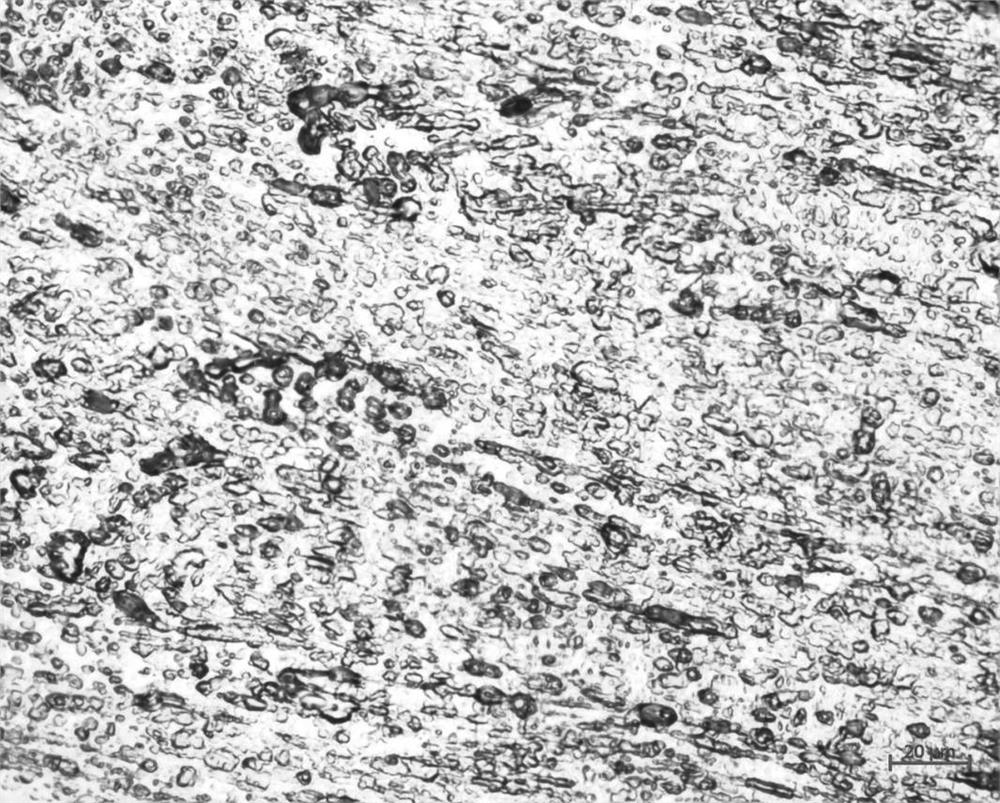

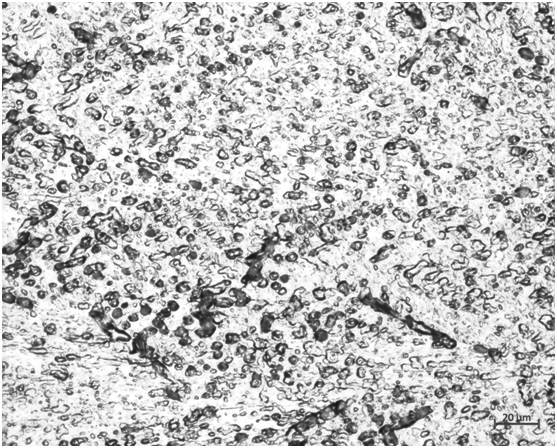

Image

Examples

Embodiment 1

[0053] Step 1, the smelting furnace is loaded with raw materials and melted;

[0054] Pour the raw materials into the molten aluminum and heat to melt. Stir twice during the melting process. Stir the bottom material in the furnace evenly. The stirring time is 4 minutes each time. Add slagging agent during the second stirring. The raw material is pure aluminum ingots. And electrolytic aluminum liquid, without adding other waste materials, aluminum ingots account for 30%;

[0055] Step 2. Adjust alloy content:

[0056] Sampling the melt obtained in step 1, adding different alloys after detecting the alloy composition, and adjusting the mass ratio of alloy content and composition: Fe0.3%, Mg 0.3%, Si 1.0%, Cu≤0.2%, Zn≤0.2% , Mn0.15%, Ti0.1%, Cr0.10%, and the balance is Al. After the charge is completely melted, when the temperature of the melting furnace rises to 710°C, slag removal and stirring are carried out for 8 minutes, and then the first sampling is carried out. When the...

Embodiment 2

[0063] Step 1, the smelting furnace is loaded with raw materials and melted;

[0064] The raw materials are poured into molten aluminum and then heated and melted. Stir three times during the process of melting the material. Stir the bottom material in the furnace evenly. The stirring time is 6 minutes each time. Add slagging agent during the second stirring. The raw material is pure aluminum ingot And electrolytic aluminum liquid, without adding other waste materials, aluminum ingots account for 45%;

[0065] Step 2. Adjust alloy content:

[0066] Sampling the melt obtained in step 1, adding different alloys after detecting the alloy composition, adjusting the mass ratio of the alloy content to: Fe0.5%, Mg0.8%, Si1.5%, Cu0.2%, Zn0. 2%, Mn0.2%, Ti0.15%, Cr0.10%, and the balance is Al. After the charge is completely melted, when the temperature of the smelting furnace rises to 720°C, carry out slag removal and stirring for 10 minutes, and then take the first sampling , when t...

Embodiment 3

[0073] Step 1, the smelting furnace is loaded with raw materials and melted;

[0074] The raw materials are poured into molten aluminum and then heated and melted. Stir 2-3 times during the process of melting the material. Stir the bottom material in the furnace evenly. The stirring time is 5 minutes each time. Add slagging agent during the second stirring. The raw material is pure Aluminum ingots and electrolytic aluminum liquid, without adding other waste materials, aluminum ingots account for 40%;

[0075] Step 2. Adjust alloy content:

[0076] Sampling the melt obtained in step 1, adding different alloys after detecting the alloy composition, adjusting the mass ratio of the alloy content to: Fe 0.2%, Mg0.35%, Si 1.2%, Mn0.1%, Ti0.08% , Cr0.05%, and the balance is Al. After the charge is completely melted, when the temperature of the smelting furnace rises to 710-720°C, carry out slag removal and stirring for 8-10min, then take the first sampling, and add compounding at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com