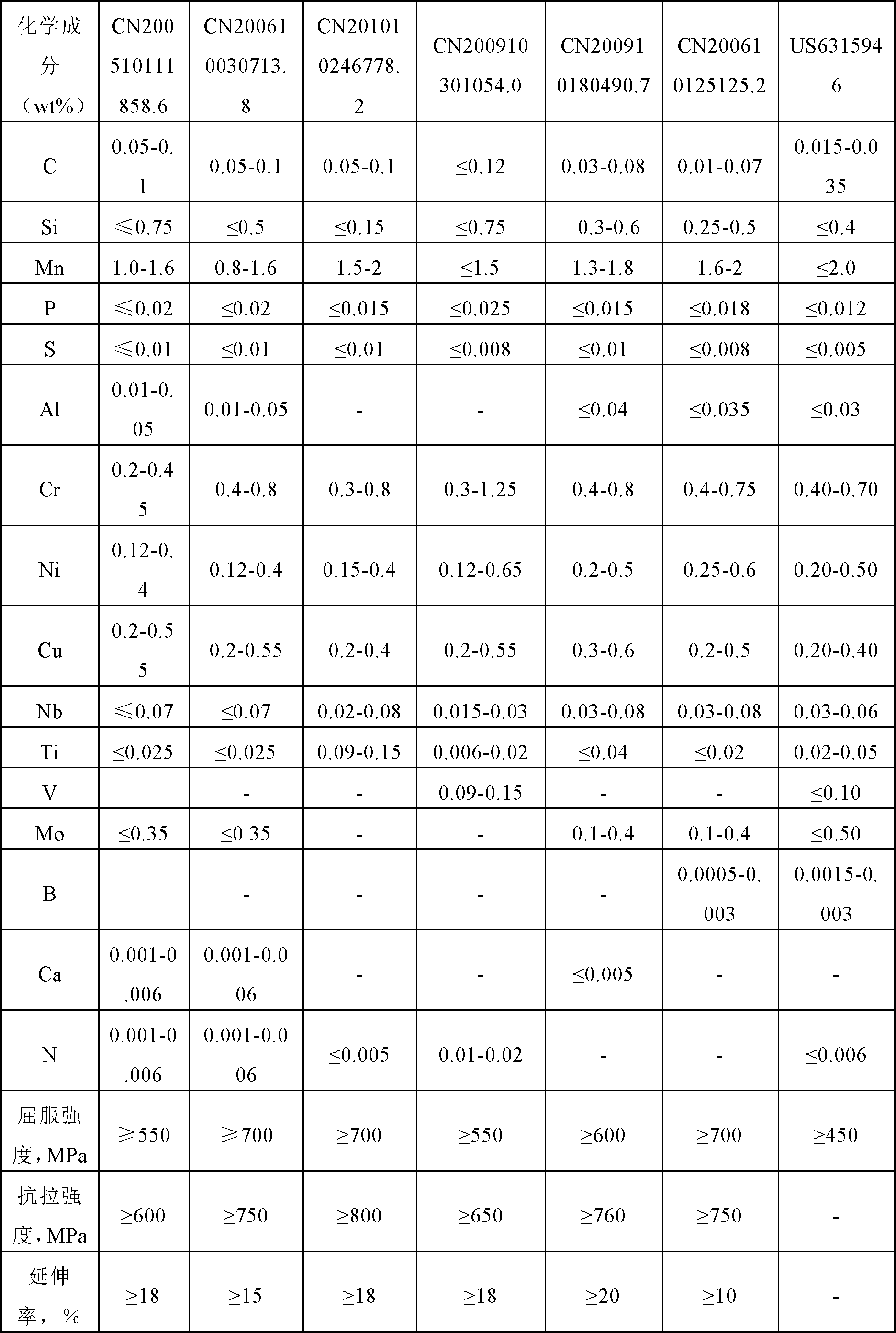

Patents

Literature

546 results about "Strip casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving performance of sintered Nd-Fe-B permanent magnetic material

ActiveCN101615459AEvenly distributed and orderlySolve bad problems such as α-Fe segregationInorganic material magnetismHigh energyPositive pressure

The invention relates to a method for improving performance of sintered Nd-Fe-B permanent magnetic property by a rapid-hardening flake grain boundary diffusion heavy rare earth compound in rare earth material technical field, which comprises the following steps: 1) rapid-hardening technology is adopted to prepare an Nd-Fe-B alloy rapid-hardening flake; 2) a high-energy ball mill is used to prepare the heavy rare earth compound into powder particles with diameter being smaller than 1mu m; 3) the rapid-hardening flake is put into heavy rare earth compound turbid liquid to carry out ultrasonic coating; 4) the coated rapid-hardening flake is put into a sintered furnace filled with Ar2 to carry out positive pressure thermal diffusion; 5) ball milling, powder processing, orientation shaping, isostatic pressing and vacuum sintering are adopted to prepare the strip-casting flake after the heat treatment into a magnet. The chemical formula of the Nd-Fe-B permanent magnetic material is NdxFe(100-x-y-z-xl)ByCozCuxl, and the mass percent is as follows: x is 30-31.5, y is 0.95-1, z is 1-1.2, and xl is 0-0.06. The magnet prepared by the invention improves the intrinsic coercivity on the basis of keeping the current magnetic energy product.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

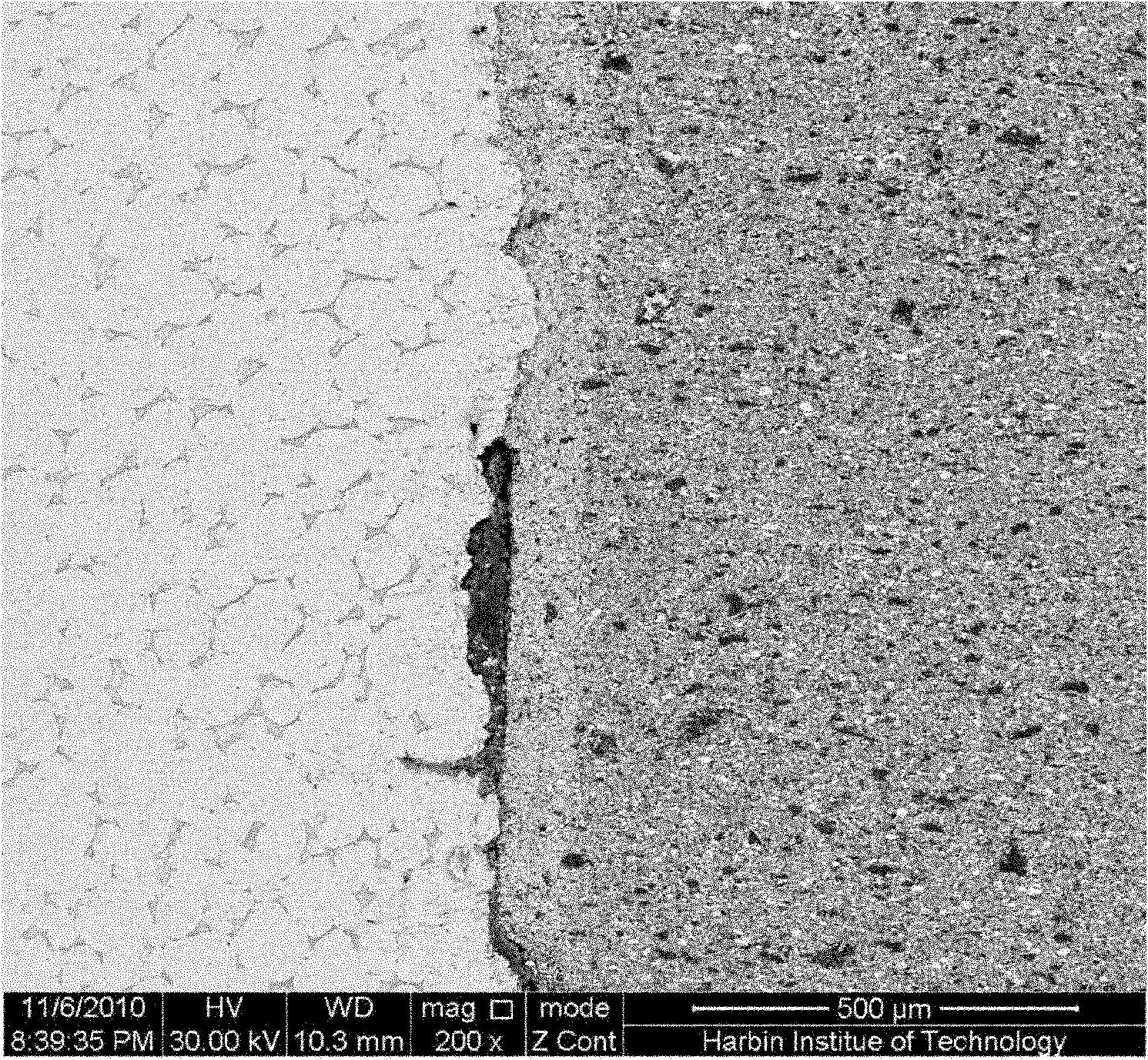

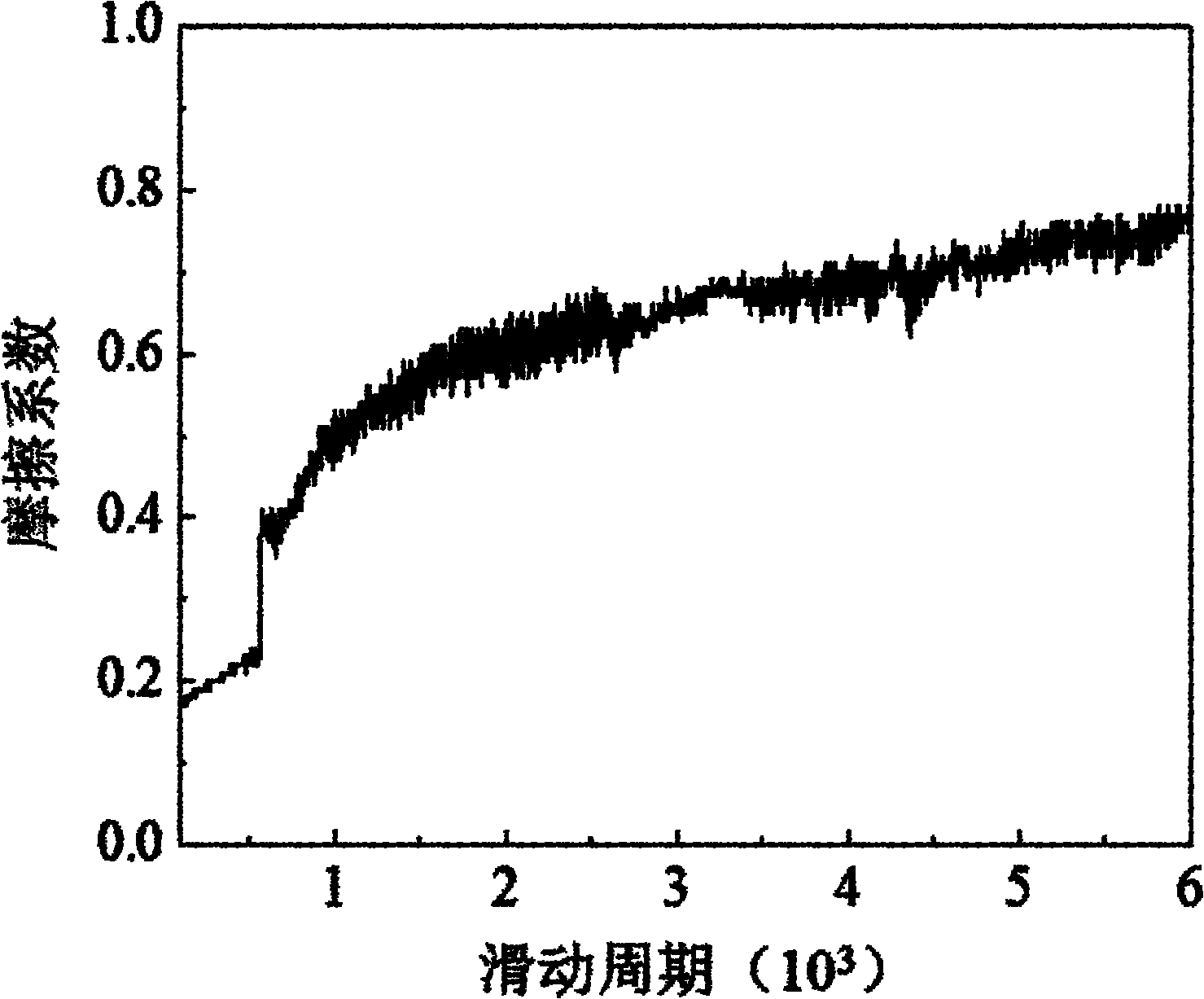

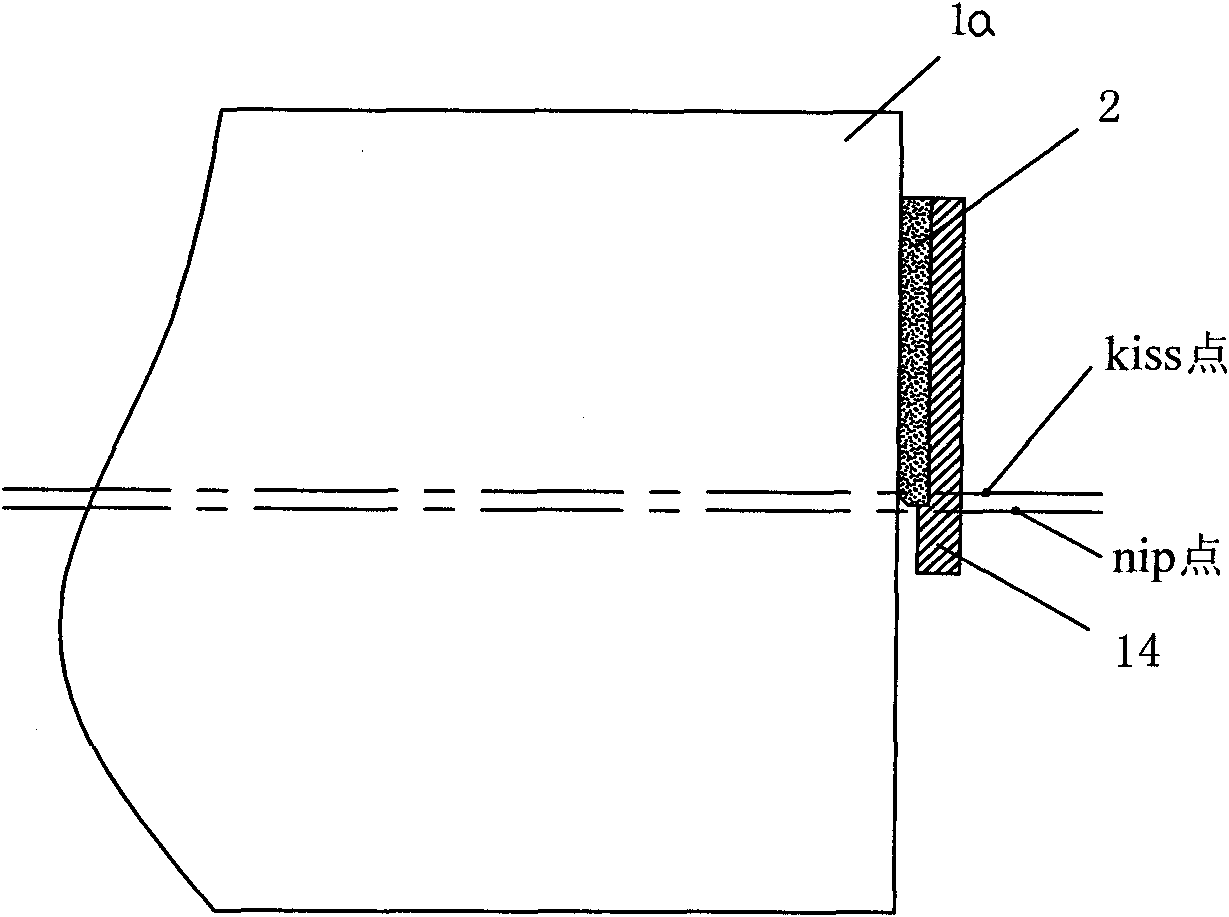

Ceramic composite material for thin-strip casting side sealing plate and preparation method thereof

The invention provides a ceramic composite material for a thin-strip casting side sealing plate and a preparation method thereof, relating to a ceramic composite material and a preparation method thereof and solving the problems that the traditional side sealing plate has high heat conductivity, serious abrasion, poor seal, high preparation cost and large energy consumption, can not be secondarily processed or reused. The ceramic composite material consists of zirconia, boron nitride and additives. The preparation method comprises the following steps: 1, weighing raw materials; 2, ball milling and mixing the raw materials; 3, drying to obtain uniform mixed powder; and 4, carrying out hot pressed sintering, pressureless sintering, air pressure sintering or hot isostatic pressed sintering on the mixed powder, so as to obtain the ceramic composite material for a thin-strip casting side sealing plate. The compactness of the ceramic composite material is 94%-99%, the bending strength of the ceramic composite material, tested by a three-point bending test at room temperature, is 260-420MPa, and the fracture toughness of the ceramic composite material, tested by a unilateral coped beam method, is 3-8 MPa.m<1 / 2>. The ceramic composite material can be widely applied to the field of side sealing plate materials.

Owner:HARBIN INST OF TECH

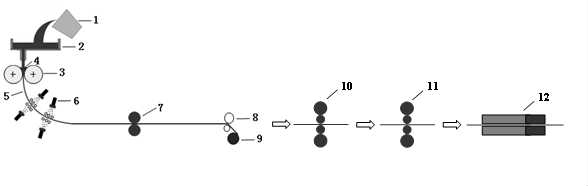

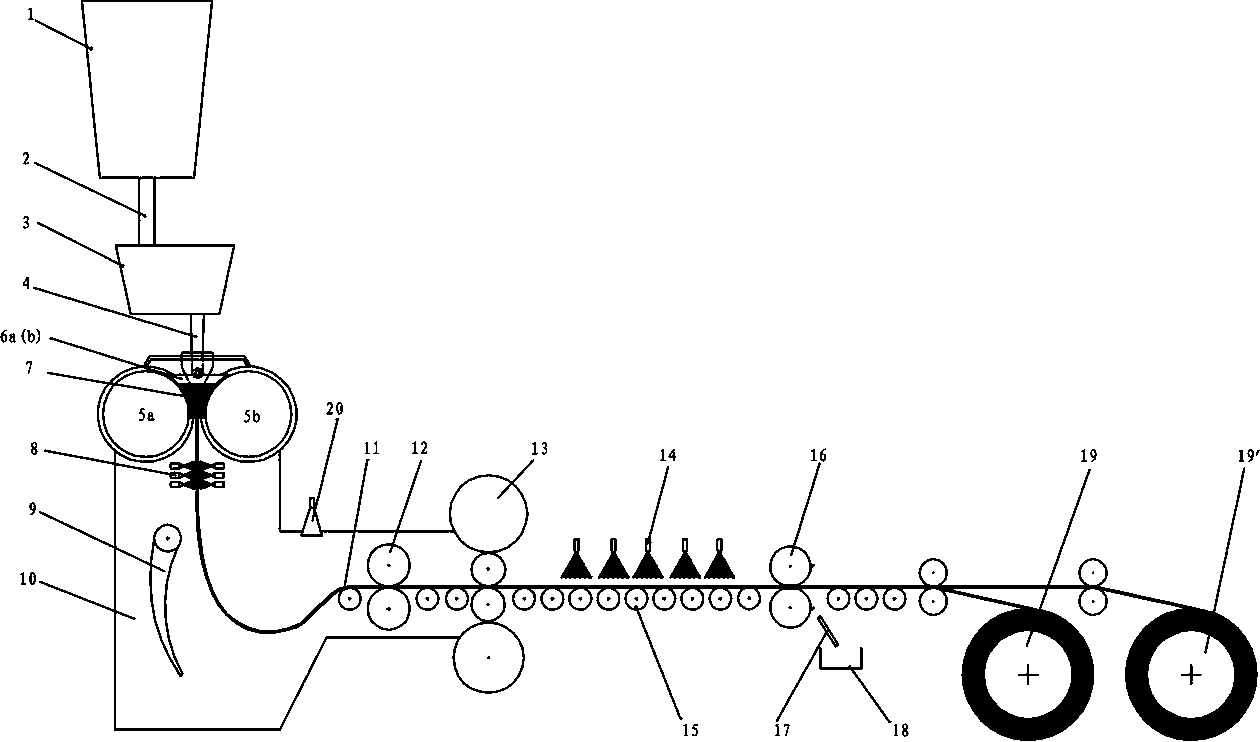

Method for producing high-strength thin strip steel in short process

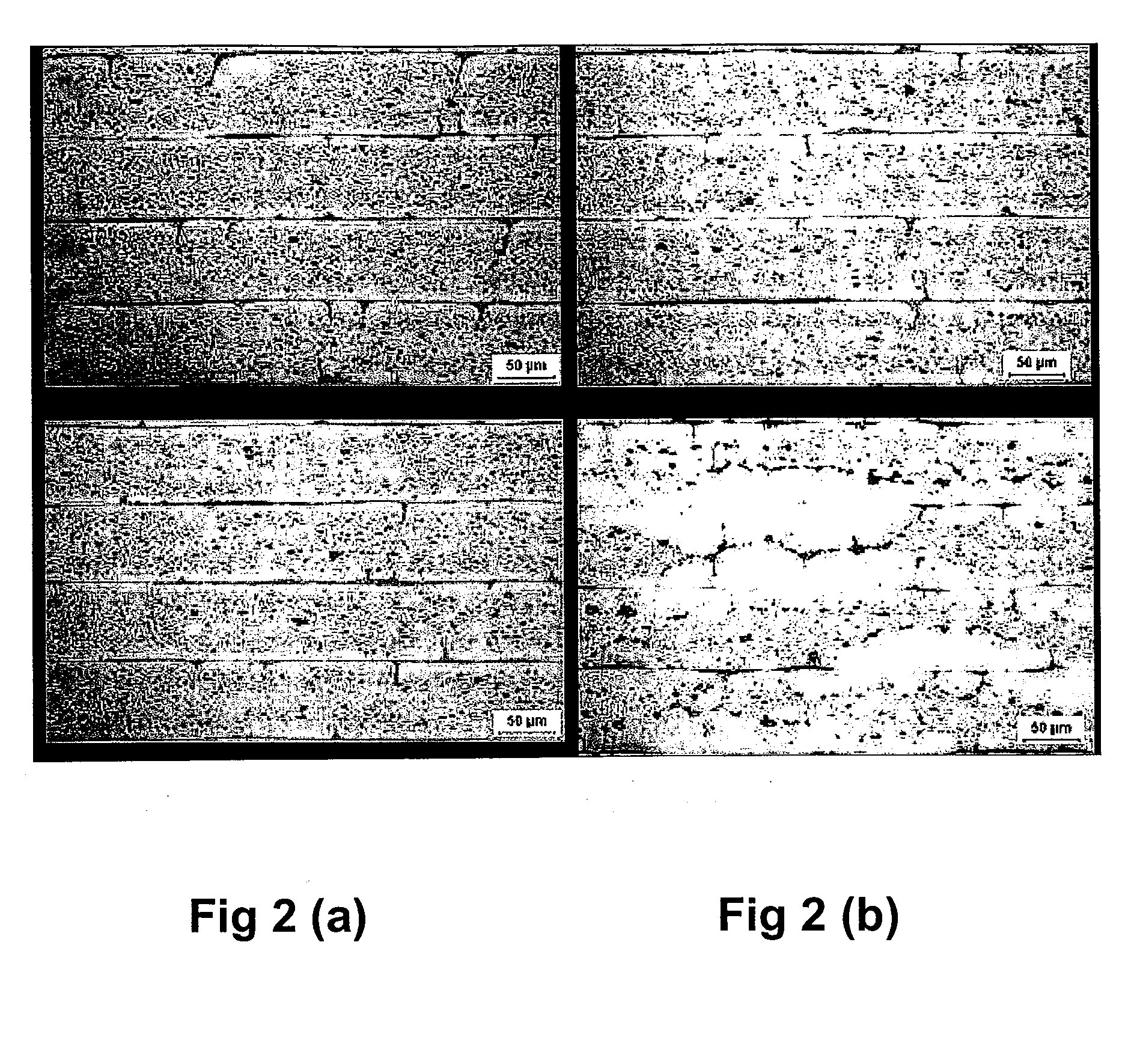

ActiveCN103658178ACost-effectiveShorten the lengthWork treatment devicesMetal rolling arrangementsRare-earth elementMicroscopic scale

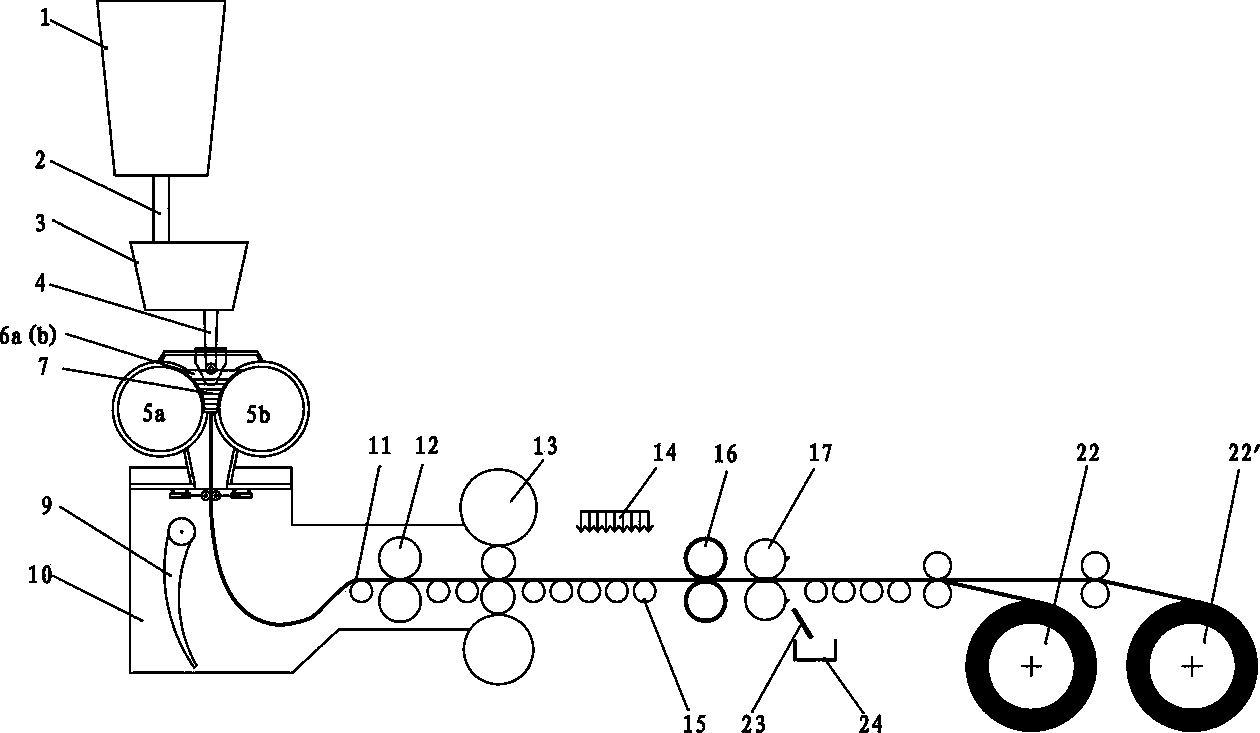

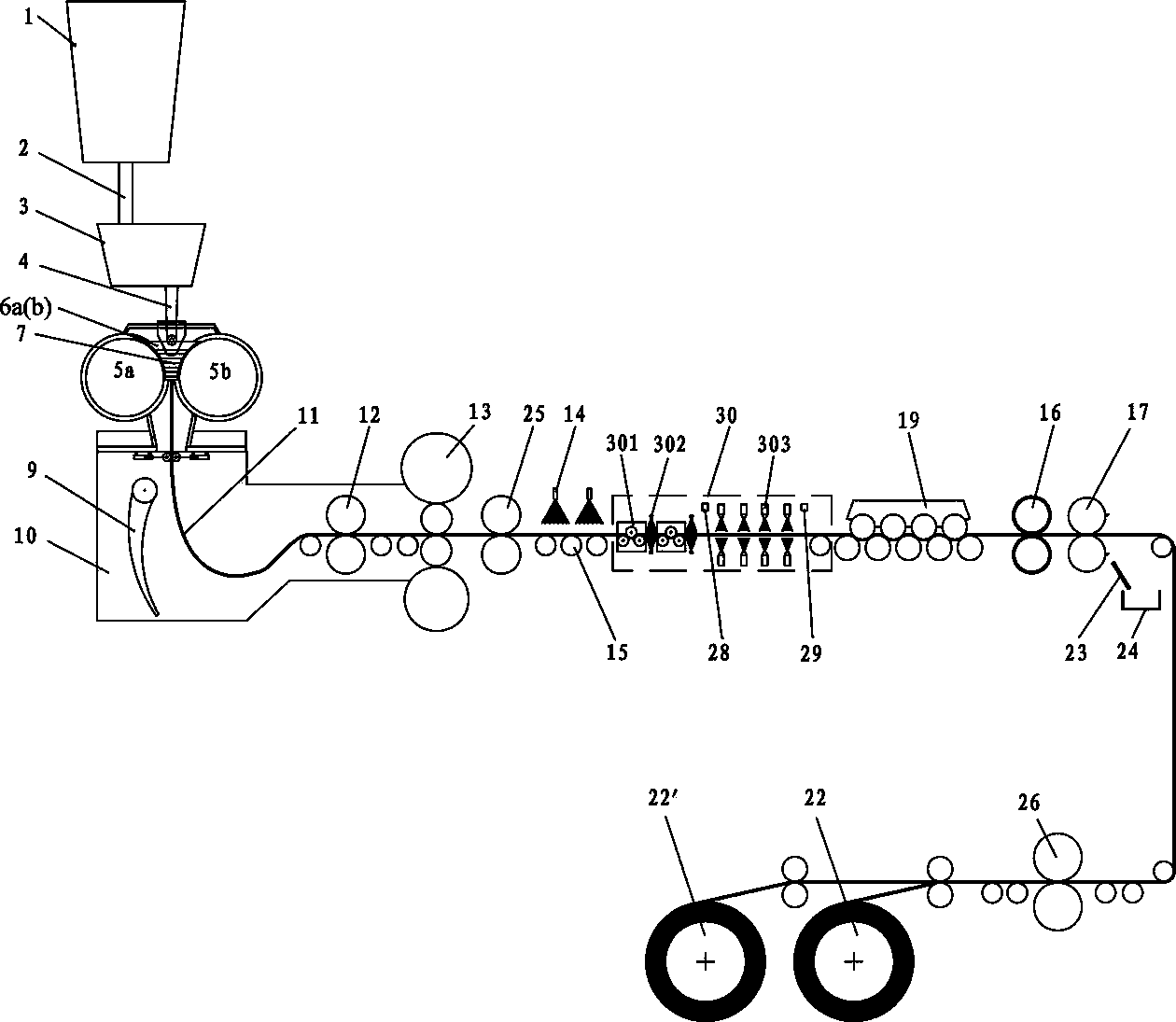

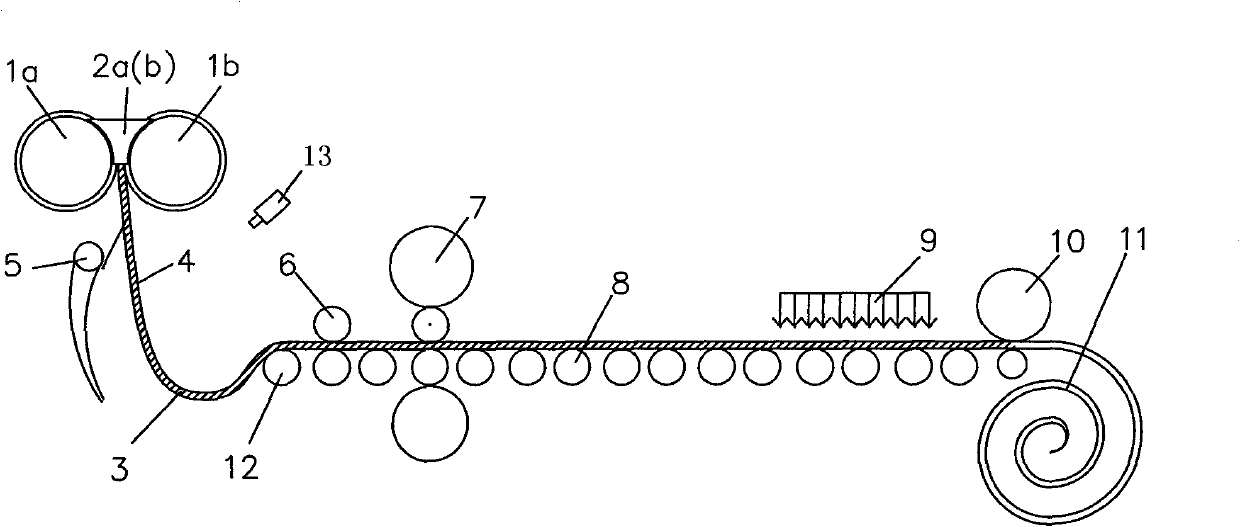

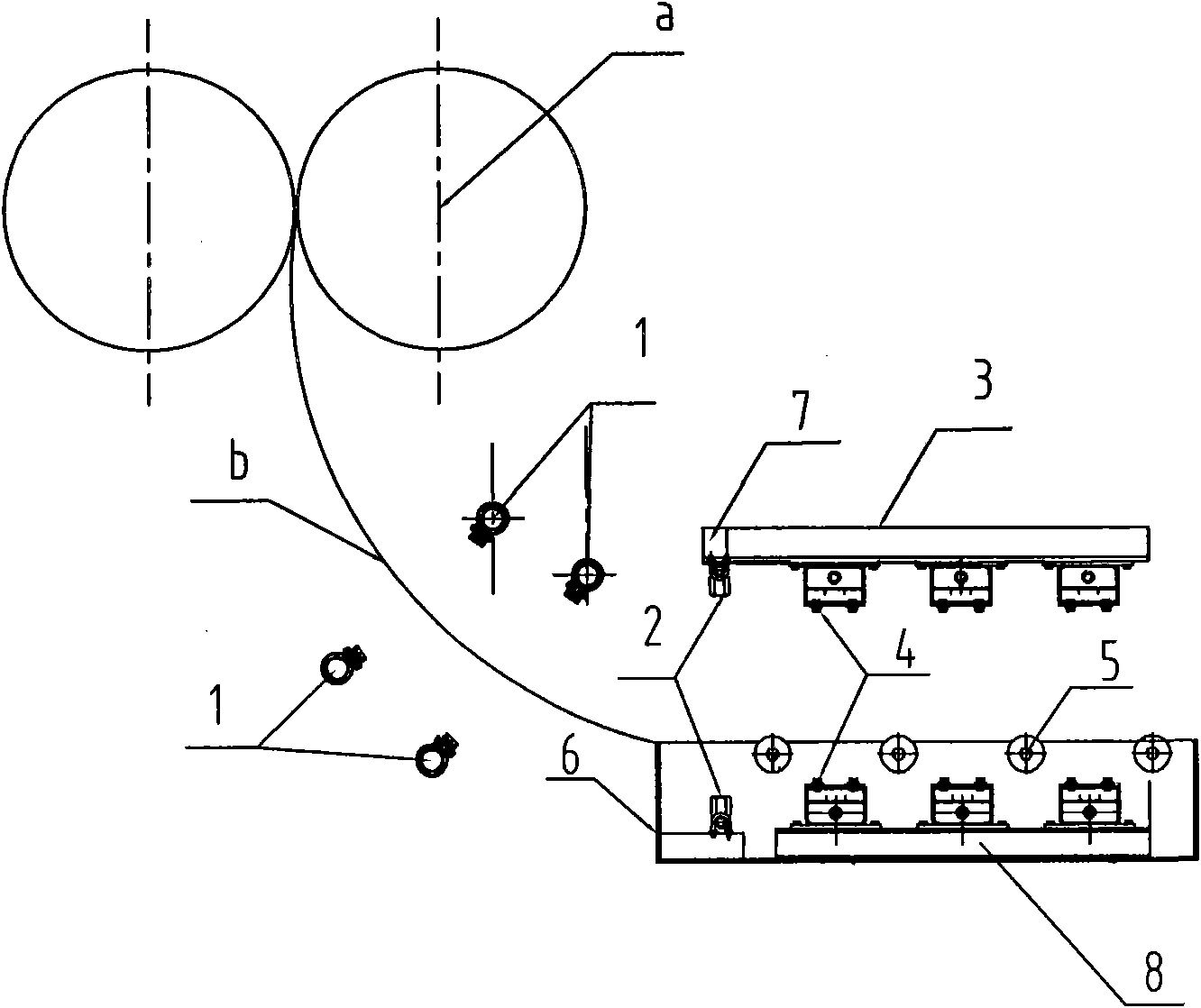

The invention relates to a method for producing high-strength thin strip steel in a short process. Twin roll strip casting is adopted for producing an atmospheric-corrosion-resistant steel casting belt containing a rare earth element Re, hot rolling, cooling and anti-oxidation intensive cooling scale removing are performed on the steel casting belt, and then the steel casting belt is reeled up after being straightened, wherein in the hot rolling process of the strip steel, rolling reduction is not smaller than 20%, and finishing rolling temperature is 850-1000 DEG C; then, a staged cooling mode of atomization cooling plus anti-oxidation intensive cooling ( spraying dry ice) is adopted, and intensive cooling is carried out on the high-temperature strip steel, wherein the cooling rate in the atomization cooling process is 50-100 DEG C / s, and the cooling rate in the anti-oxidation intensive cooling process is 100-200 DEG C / s. In this way, through the combined type staged cooling, the uniform steel of a bainite microscopic structure can be obtained, and the bainite structure can remarkably improve the toughness of the steel. The method is especially applicable to atmospheric-corrosion-resistant high-strength thin strip steel with the surface roughness Ra smaller than 2 microns, the thickness of typical strip steel is 0.8-1.6mm, and the strip steel can be supplied in a hot mode instead of a cool mode.

Owner:BAOSHAN IRON & STEEL CO LTD

Alloy for negative electrode of lithium secondary battery

InactiveUS20070048612A1Large discharge capacityLarge electric chargeTransportation and packagingMetal-working apparatusLithiumMetallic materials

At least two metallic materials containing element such as silicon and tin, which has ability of insertion and desertion of lithium element, and optionally another metallic material containing element such as copper are molten to prepare a melt. The melt is rapidly cooled by strip-cast method at a cooling rate of more than 2×103 ° C. / sec and no more than 104 ° C. / sec to be cast. Further, the cast is milled and classified into alloy powder having an average particle size of 0.1 μm to 50 μm. The alloy powder and conductive agent are laminated with binder onto a collector to obtain a negative electrode for a secondary battery. The negative electrode is employed to obtain a lithium secondary battery having high electric charge and discharge capacity, and good property of charge and discharge cycle.

Owner:SHOWA DENKO KK

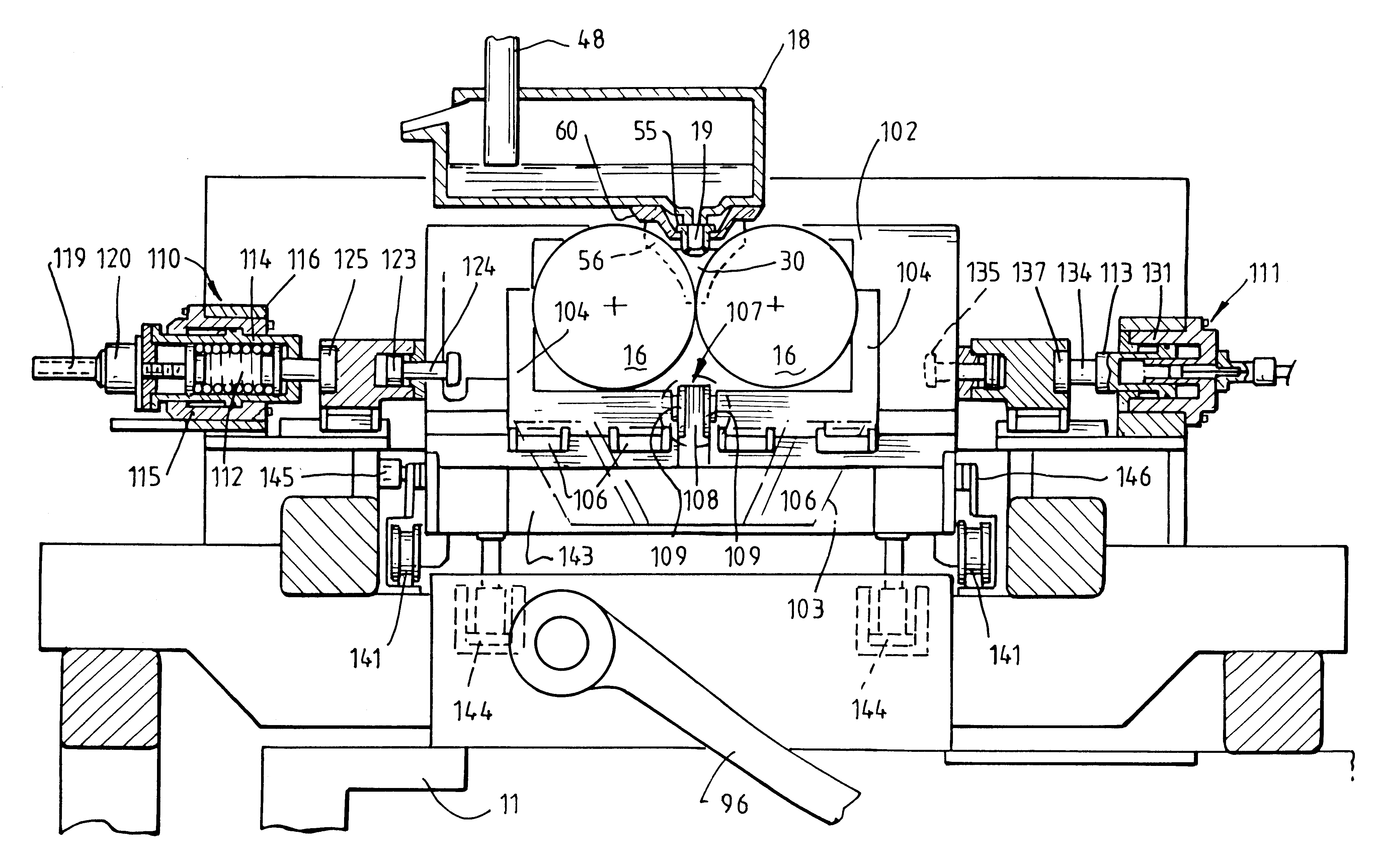

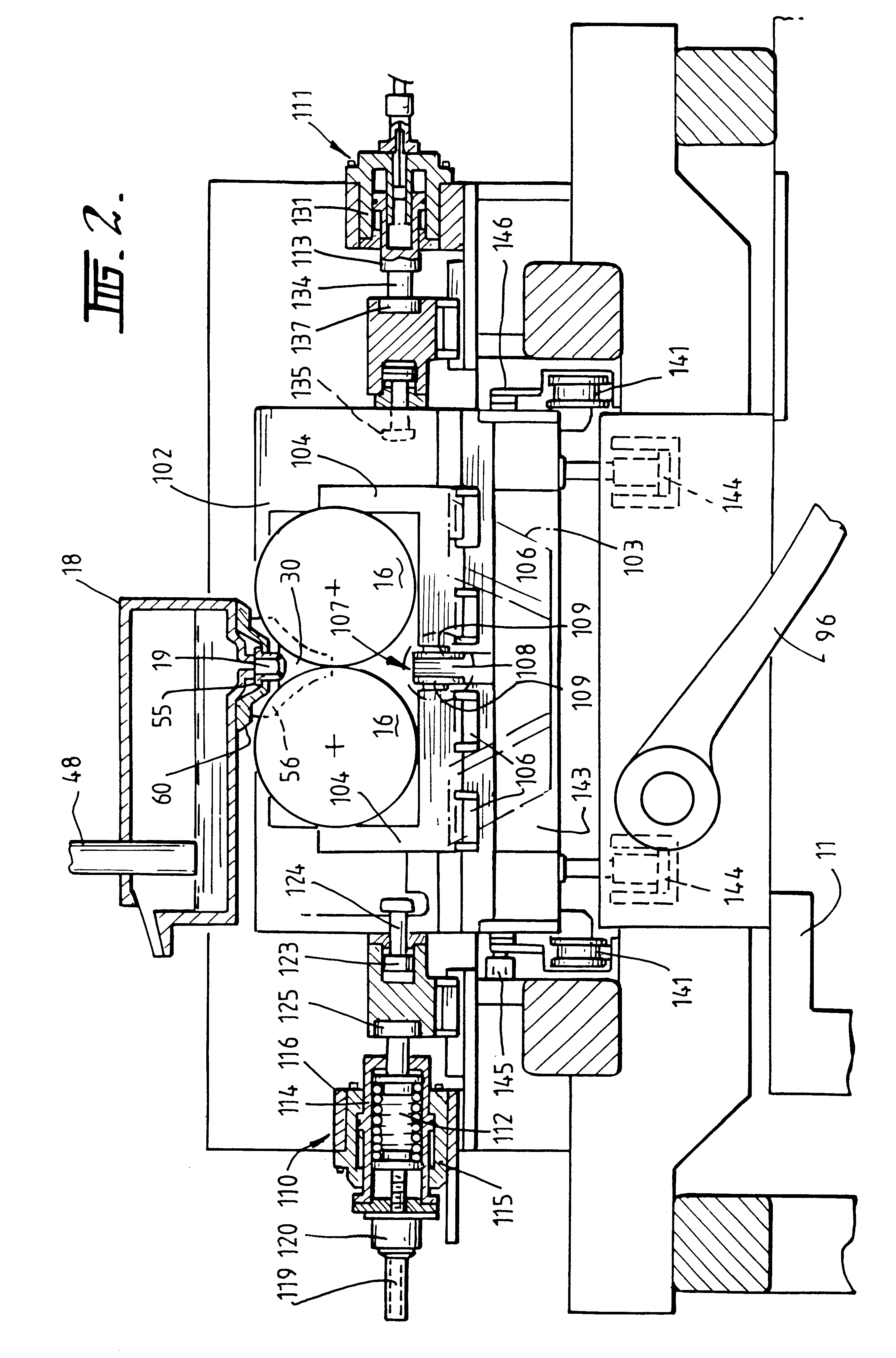

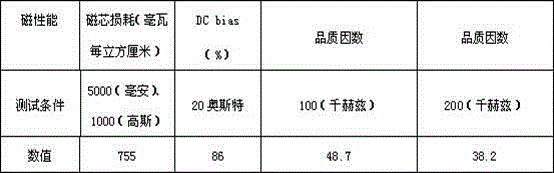

Strip casting apparatus

Twin roll caster for continuously casting metal strip comprises a pair of parallel casting rolls (16) to which molten metal is supplied through a delivery nozzle (19). The rolls are mounted on roll carriers (104) moveable on a frame (102) to allow rolls (16) to move toward and away from one another. Biasing units (110, 111) allow inward biasing forces to be applied to the roll carriers (104) so as to bias one of the rolls (104) toward the other. The biasing units (110) incorporate biasing springs and means to adjust the thrust exerted by the springs.

Owner:CASTRIP

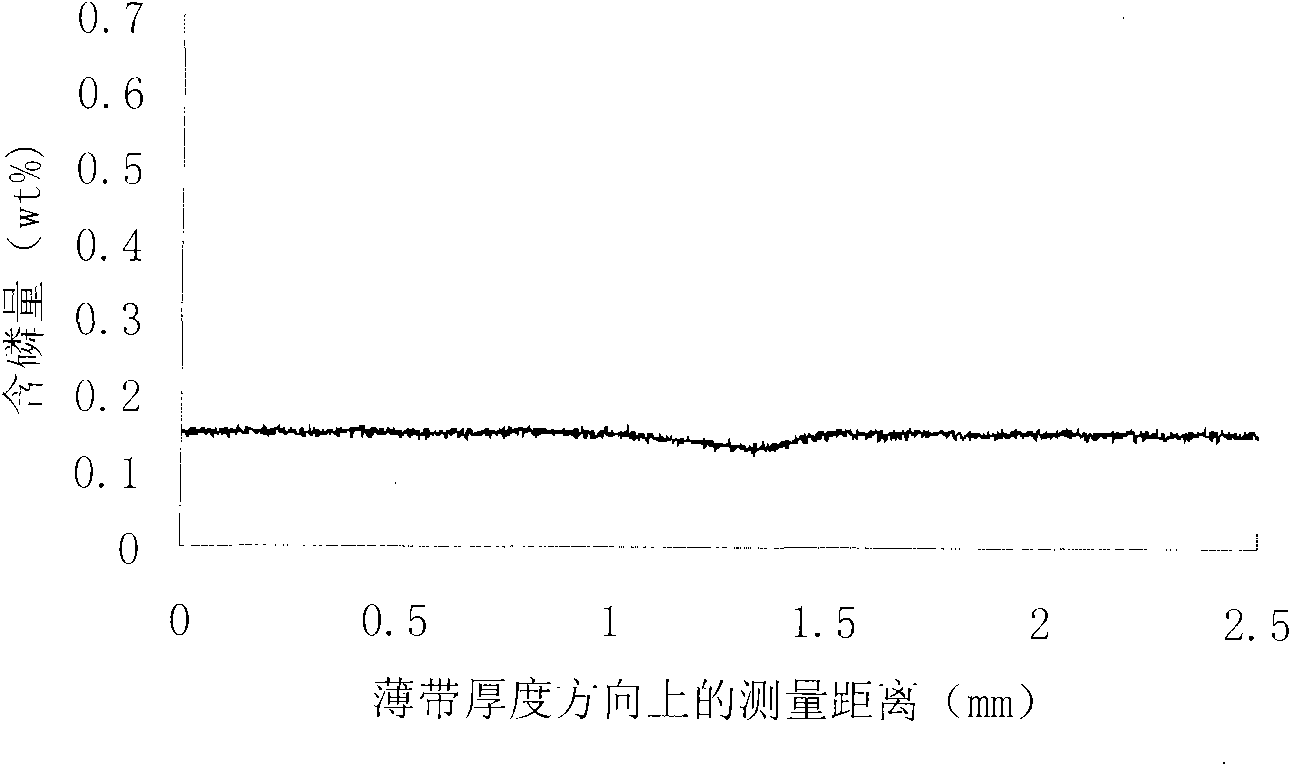

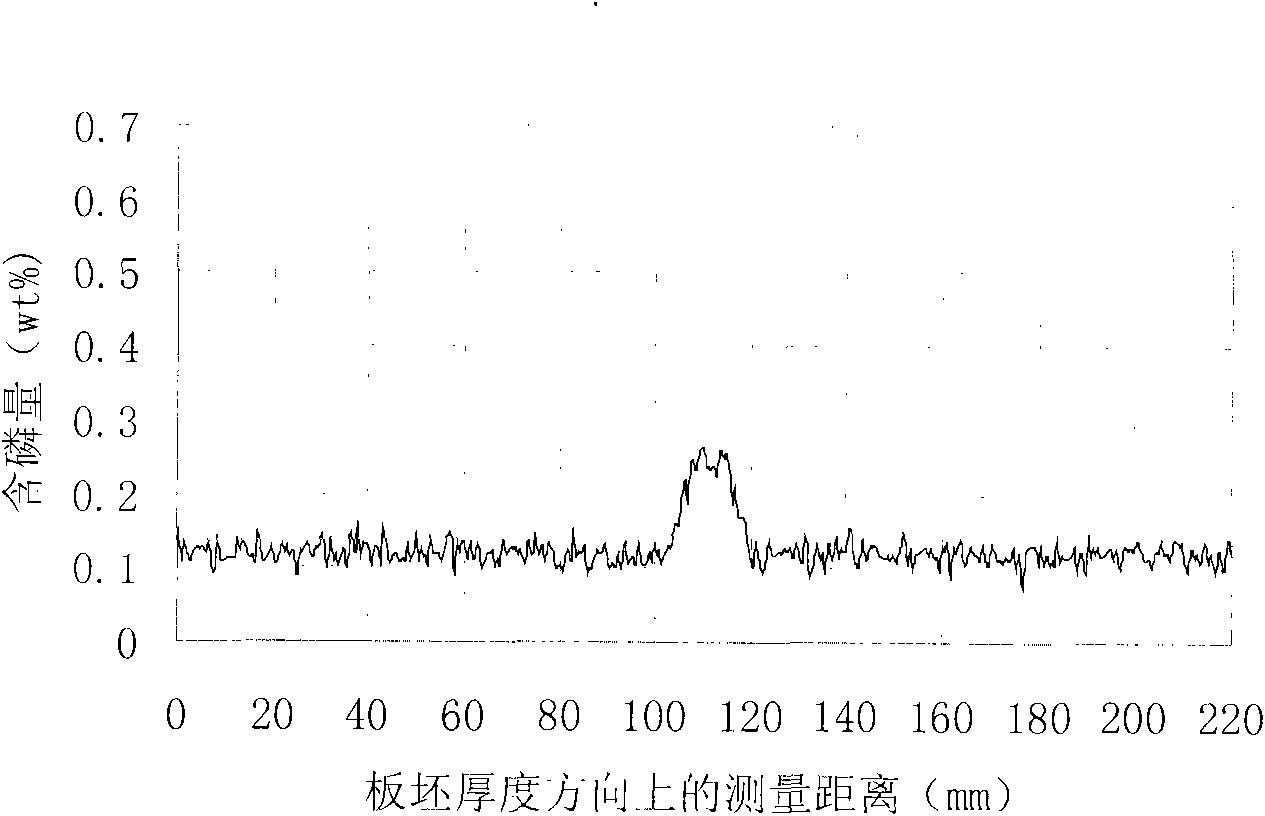

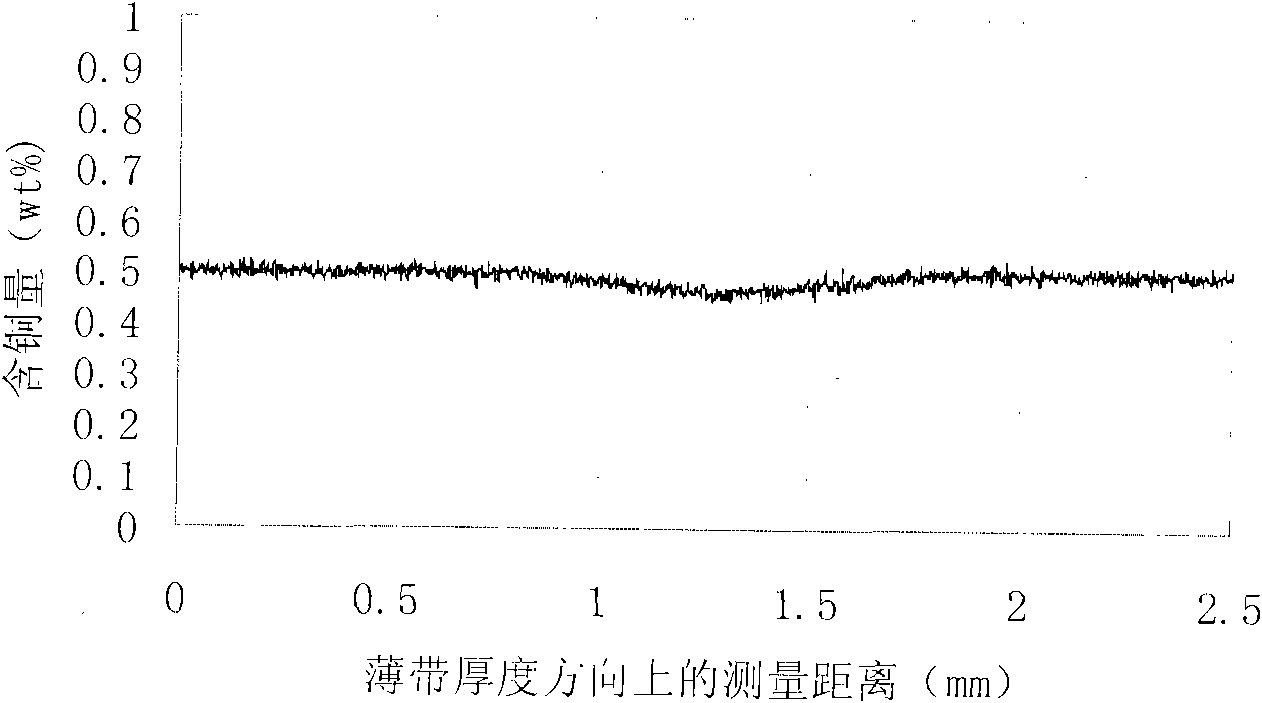

Weather resisting steel produced by strip casting and production method thereof

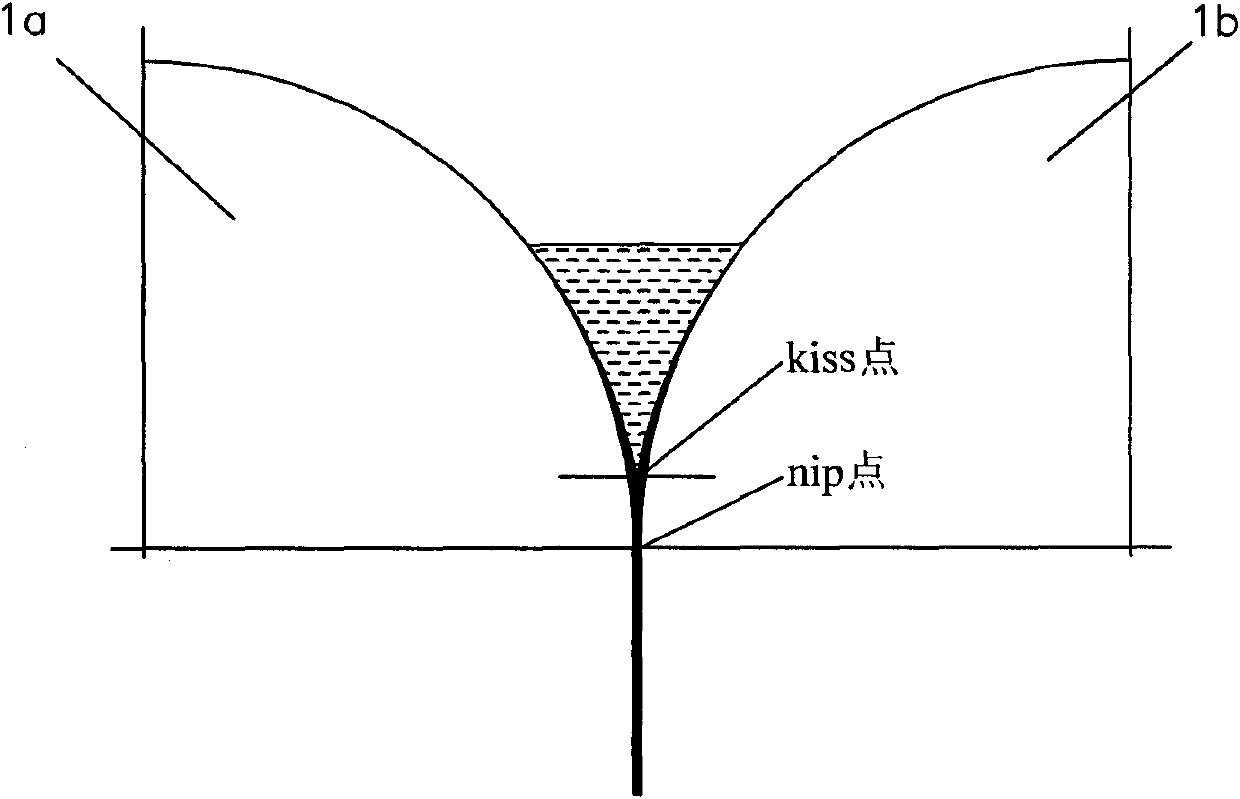

The invention discloses a weather resisting steel produced by strip casting and a production method thereof. The weather resisting steel comprises the following components in mass percentage: 0.06-0.12% of C, 0.20-0.50% of Si, 0.20-0.50% of Mn, 0.15-0.22% of P, less than or equal to 0.008% of S, 0.65-0.80% of Cu, 0.30-0.70% of Cr, 0.12-0.40% of Ni and the balance Fe and inevitable impurities; molten steel smelted according to the above components is poured into a furnace hearth formed by a water-cooled casting roll and a side seal device which rotate oppositely and forms a casting band by being cooled by the water-cooled casting roll; the casting band is sent into an on-line mill via a pinch roll to be rolled into a hot-rolled strip, and the thickness of the casting band is 1-5mm; the cooling speed of the molten steel at least reaches 300 DEG C / s when contacting with the surface of a two-roller caster casting roll; the casting band after leaving the casting roll is hot rolled on line and has the deformation degree of 30-45%.The steel band produced with the strip casting process of the invention has no possibility of macrosegregation of elements such as phosphorus, copper and the like, is convenient and economic to produce, saves energy and lowers consumption.

Owner:BAOSHAN IRON & STEEL CO LTD

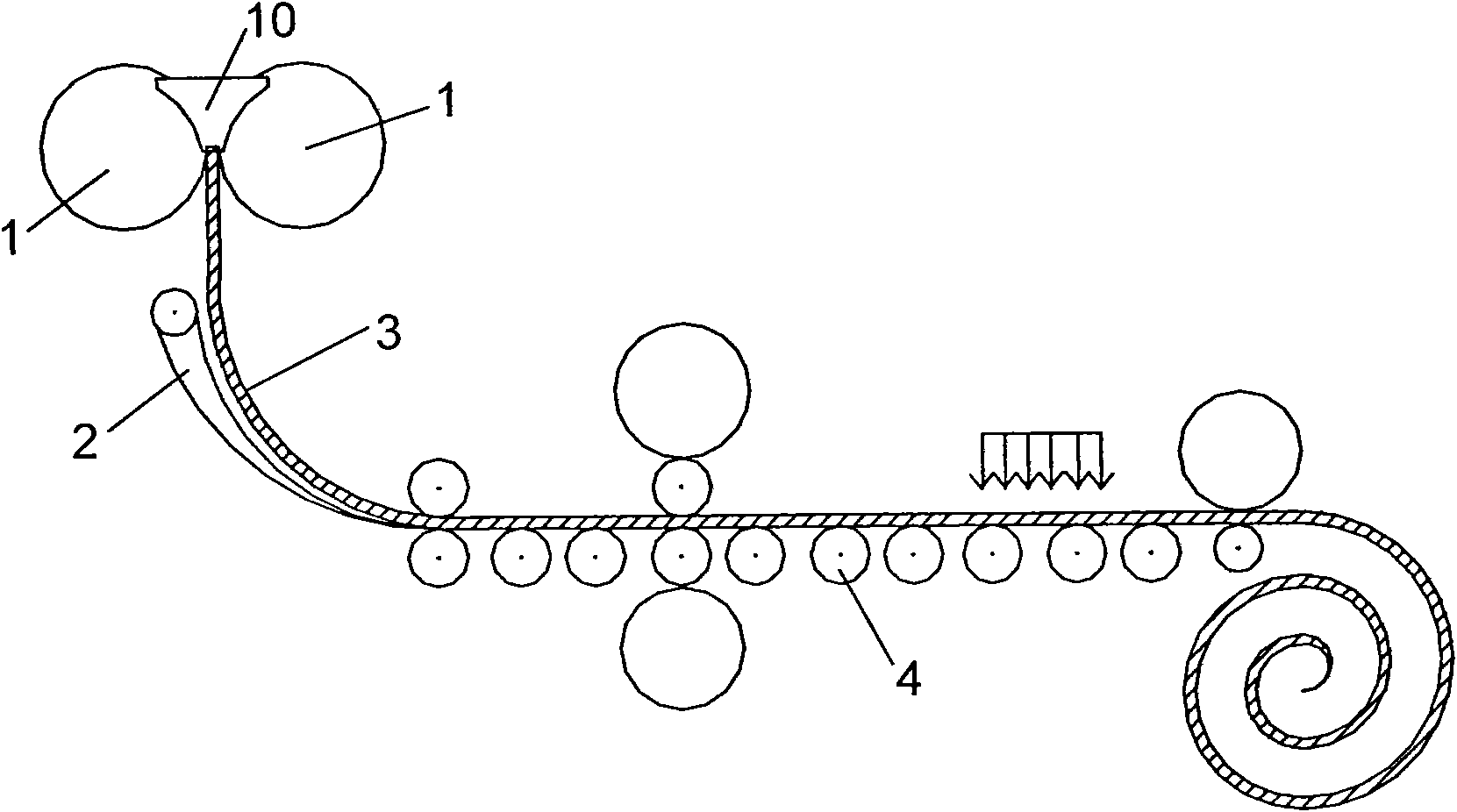

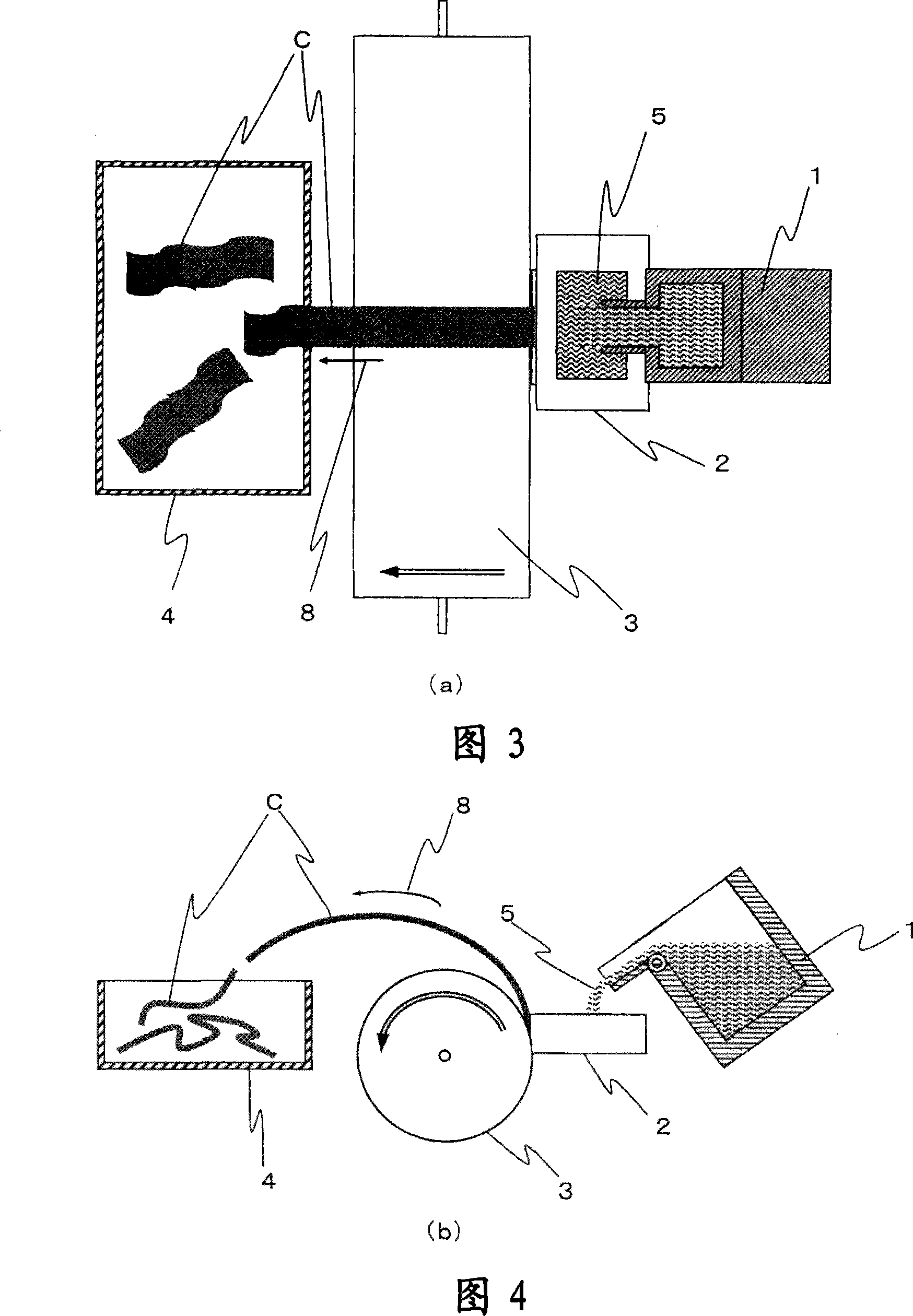

Continuous casting process for producing low carbon steel strips and strips so obtainable with good as cast mechanical properties

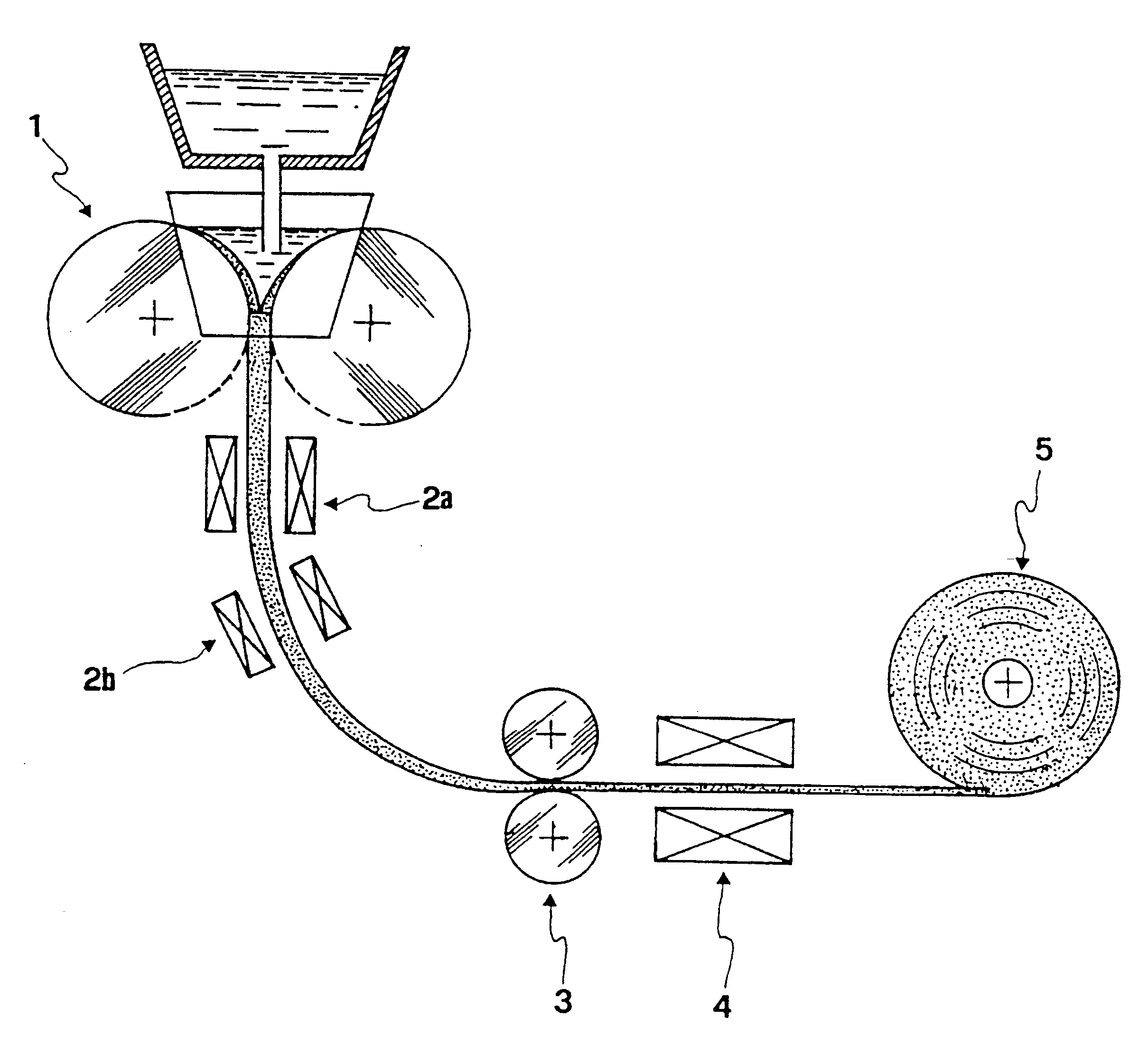

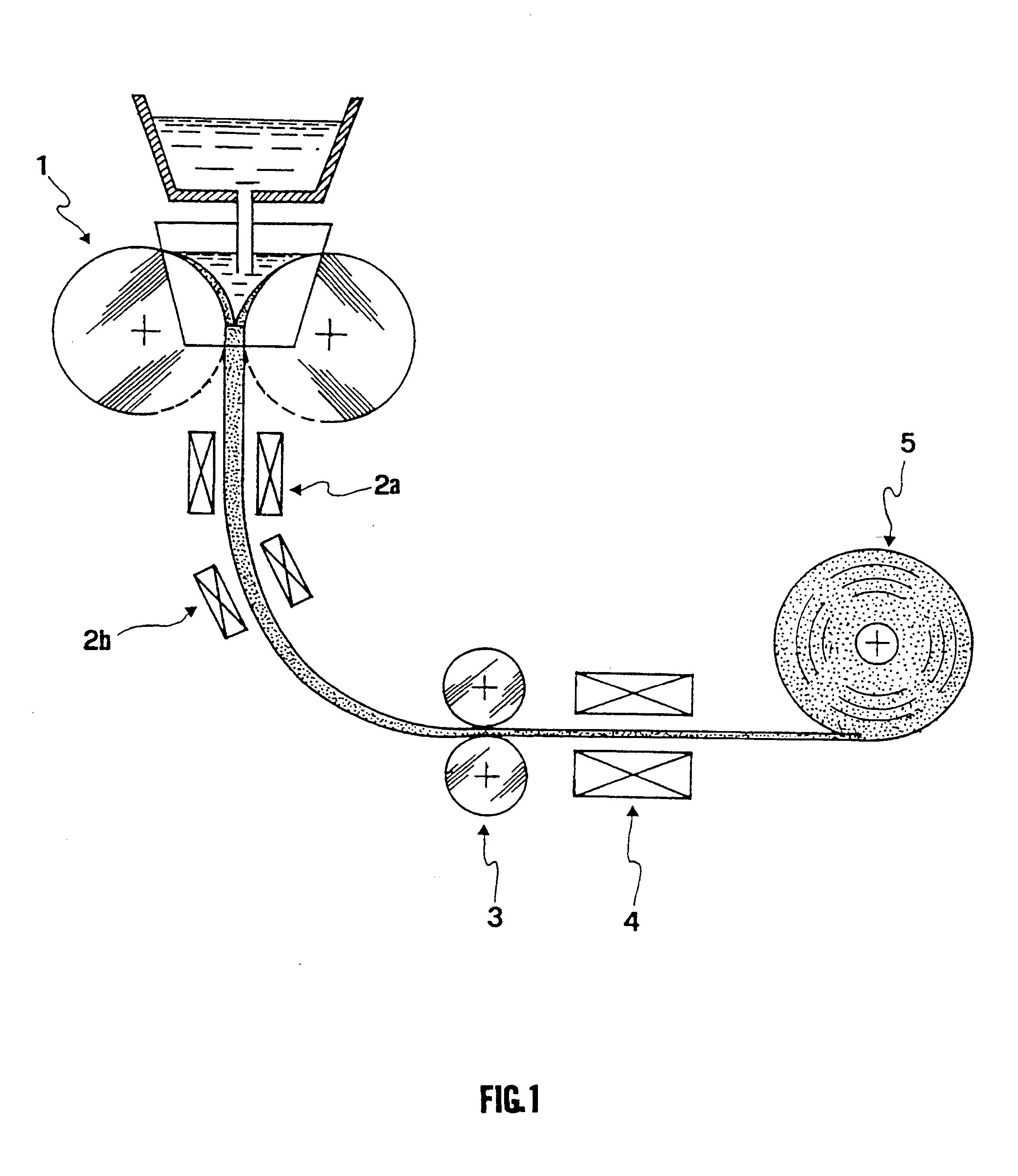

A process for the production of low carbon steel strips having a good combination of strength an formability, as cast, and a good weldability after the pickling by usual processes, comprising the following steps: casting, in a twin rolls continuous casting machine (1) comprising pinch rolls (3), a strip with a thickness comprised between 1 and 8 mm, having the following composition as weight percentage of the total weight: C 0.02-0.10; Mn 0.1-0.6; Si 0.02-0.35; Al 0.01-0.05; S<0.015; P<0.02; Cr 0.05-0.35; Ni 0.05-0.3; N 0.003-0.012; and, optionally, Ti<0.03; V<0.10; Nb<0.035, the remaining part being substantially Fe; cooling the strip in the area comprised between the casting-rolls and the pinch rolls (3); hot deforming the strip cast through said pinch rolls (3) at a temperature comprised between 1000 and 1300° C. until reaching a thickness reduction less than 15%, in order to encourage the closing of the shrinkage porosites; cooling the strip at a speed comprised between 5 and 80° C. / s down to a temperature (Tavv) comprised between 500 and 850° C.; and coiling into a reel (5) the so obtainable strip.

Owner:ACCIAI SPECIALI TERNI SPA +1

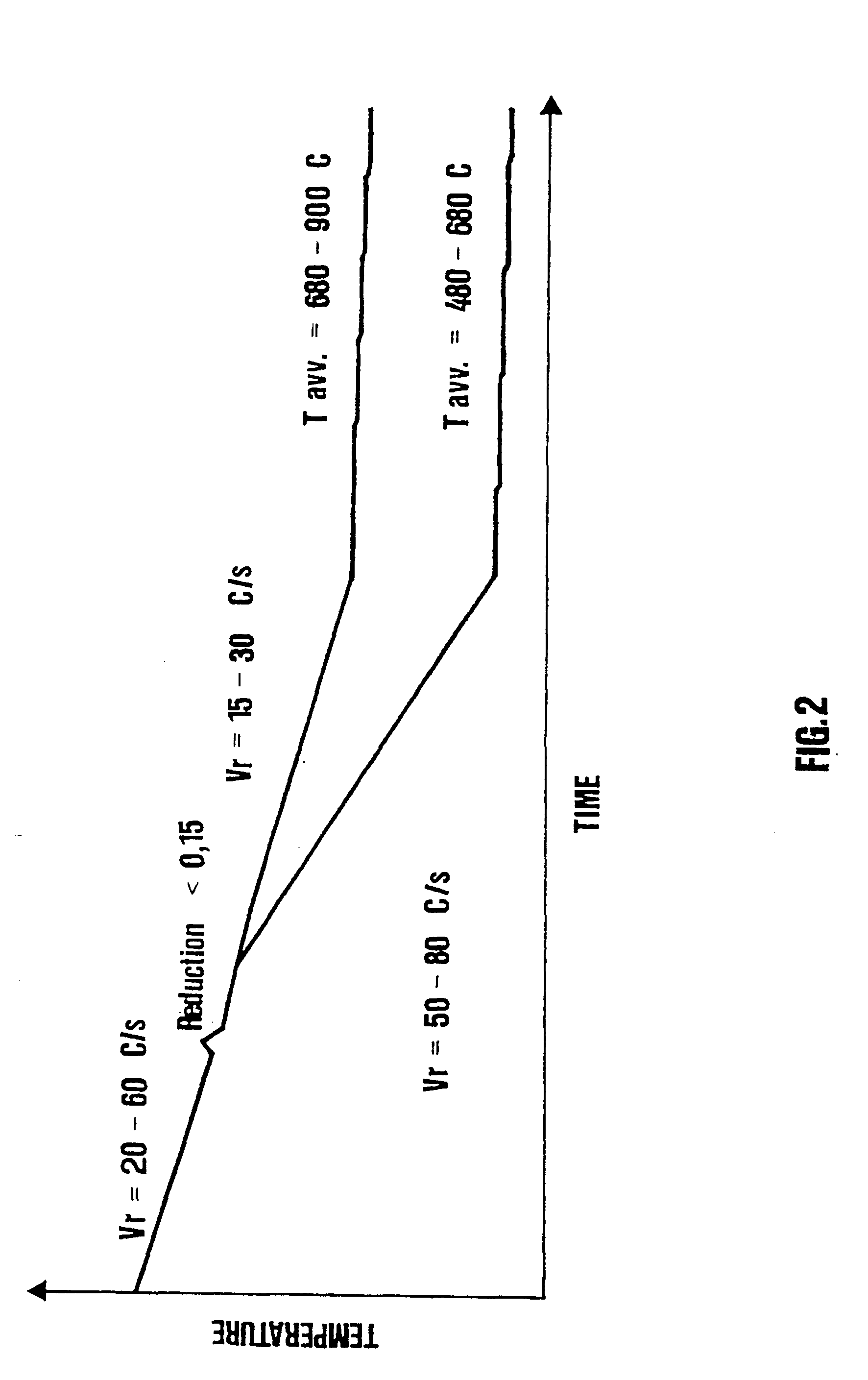

High strength and sagging resistant fin material

The present invention provides a method for producing AlMn strip or sheet for making components by brazing, as well as the products obtained by said method. In particular this method is related to fin materials used in heat exchangers. The fins can be delivered with or without a cladding depending on application.Rolling slabs are produced from a melt which contains 0.3-1.5% Si, ≦0.5% Fe, ≦0.3% Cu, 1.0-2.0% Mn, ≦0.5% Mg, ≦4.0% Zn, ≦0.3% each of elements from group IVb, Vb, or VIb elements, and unavoidable impurity elements, as well as aluminium as the remainder in which the rolling slabs prior to hot rolling are preheated at a preheating temperature of less than 550° C., preferably between 400 and 520° C., more preferably between 450 and 520° C. to control the number and size of dispersoid particles, and the preheated rolling slab is hot rolled into a hot strip. The strip is thereafter cold rolled into a strip with a total reduction of at least 90%, and the cold rolled strip is heat treated to obtain a 0.2% proof stress value that is 50-90% of its proof stress value in the as cold rolled condition to a proof stress value in the range between 100 and 200 MPa. The strip may alternatively be produced by twin-roll strip casting.The composition of the melt tailors the microstructure development during the complete processing to give the desired post braze properties and performance during brazing in combination with adequate delivery properties of the strip. In particular the high post braze strength combined with a good sagging resistance and low susceptibility to liquid core penetration during brazing, as well as a relatively good formability in the delivery condition prior to fin forming.

Owner:GRAENGES SWEDEN AB

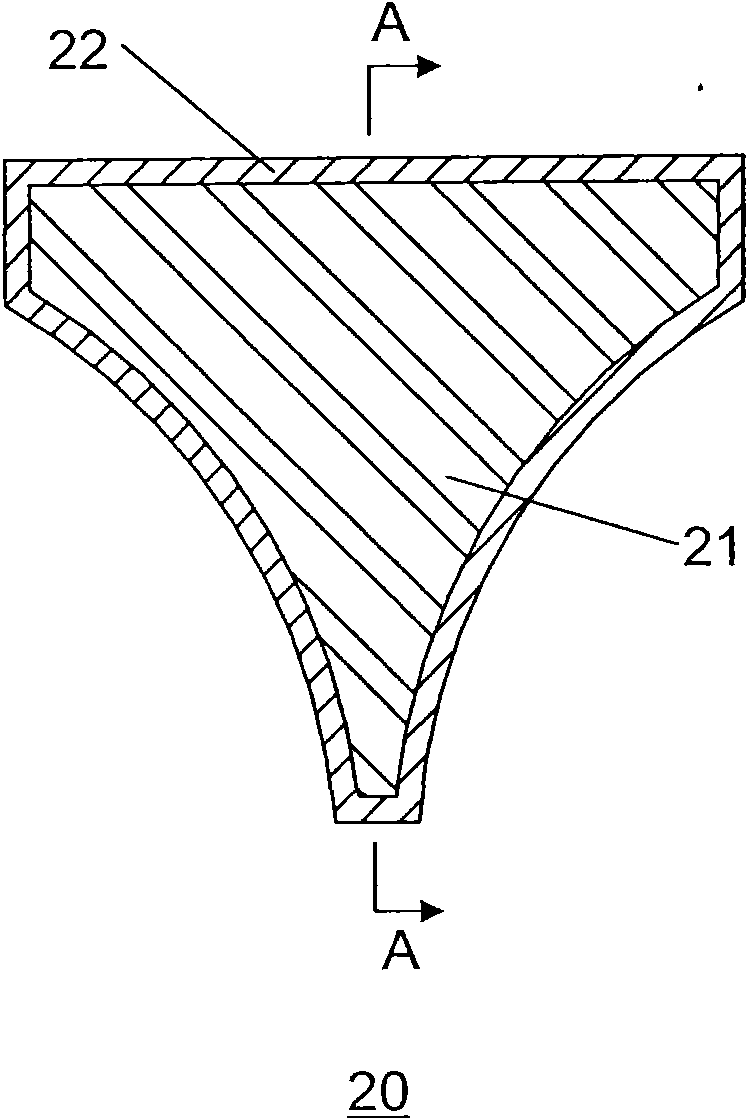

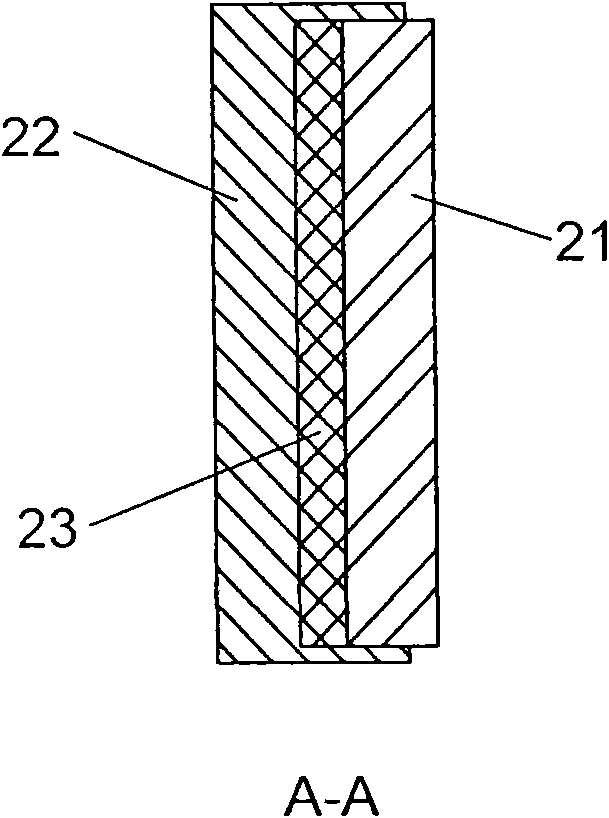

Twin-roll thin-strip casting side sealing plate and manufacturing method thereof

ActiveCN101648260ANot easy to loseQuality assuranceLaminationLamination apparatusThermal insulationThermal expansion

The invention discloses a twin-roll thin-strip casting side sealing plate. The side sealing plate comprises a panel containing boron nitride materials and a base plate with aluminum-silicon thermal insulation materials, wherein the panel and the base plate are fixed through adhesion. The invention also discloses a method for manufacturing the side sealing plate. As the thermal conductivity of thebase plate of the side sealing plate is much less than that of the panel, the heat of the base plate is not easy to dissipate, and heat-insulation effect is improved so as to ensure the quality of theside parts of strip steel. Moreover, equal thermal expansion coefficients of the base plate and the panel can avoid twist deformation or cracking after the side sealing plate is heated. Modified silicone resin binder resistant to high temperature not only enhances bonding strength, but also plays a role in thermal insulation.

Owner:BAOSHAN IRON & STEEL CO LTD

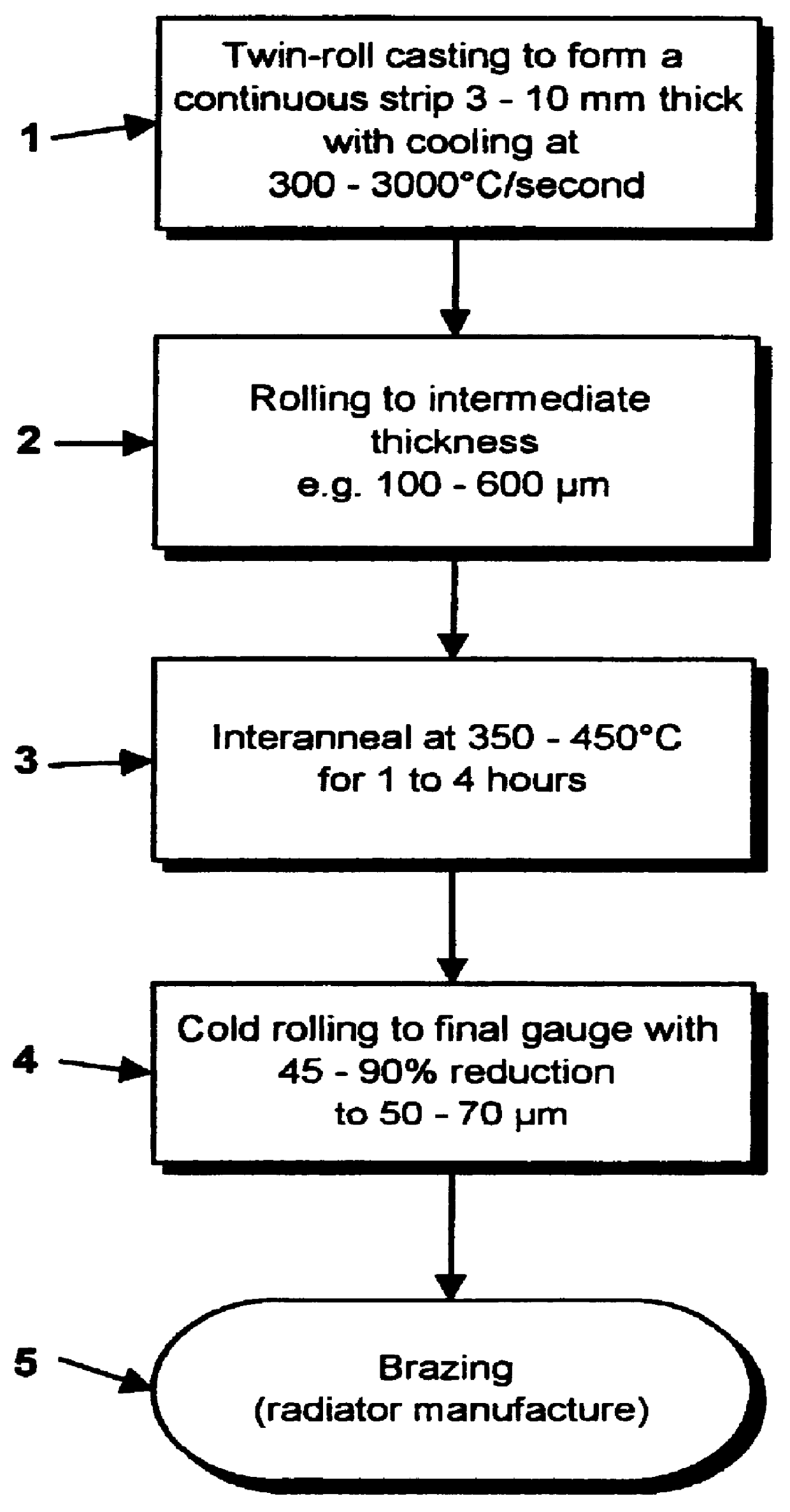

Process of producing aluminum fin alloy

InactiveUS6165291ALower (more negative) corrosion potentialImprove thermal conductivityWelding/cutting media/materialsHeat exchange apparatusMetallurgyHeat sink

An aluminum alloy fin stock of lower (more negative) corrosion potential and higher thermal conductivity is produced by a process, which comprises continuously strip casting the alloy to form a strip, cold rolling the strip to an intermediate gauge sheet, annealing the sheet and cold rolling the sheet to final gauge. Lower corrosion potential and higher thermal conductivity are imparted by carrying out the continuous strip casting while cooling the alloy at a rate of at least 300 DEG C. / second, e.g. by conducting the casting step in a twin-roll caster.

Owner:NOVELIS INC

Rare earth aluminum alloy for heat exchanger and preparation method thereof

InactiveCN102286679AHigh tensile strengthHeat exchange apparatusRare-earth elementMetallic materials

The invention discloses a rare earth aluminum alloy used for heat exchangers in the technical field of metal materials and a preparation method thereof. The composition ratio of the alloy is: Si: 0.06-0.5%, Mn: 1.1-1.9%, Cu: 0.3 ~1.0%, Mg: 0~0.7%, Fe: 0.1~0.6%, Zr: 0~0.2%, Ti: 0~0.2%, Ce or rare earth mainly composed of Ce element: 0.06~0.5%, impurity element content Less than 0.05%, the rest is Al. The invention realizes microalloying and microstructure control by adding rare earth elements to low-silicon and high-manganese aluminum alloys, and adopts casting, hot-rolling and cold-rolling processes to prepare corresponding plates and strips.

Owner:SHANGHAI JIAO TONG UNIV +1

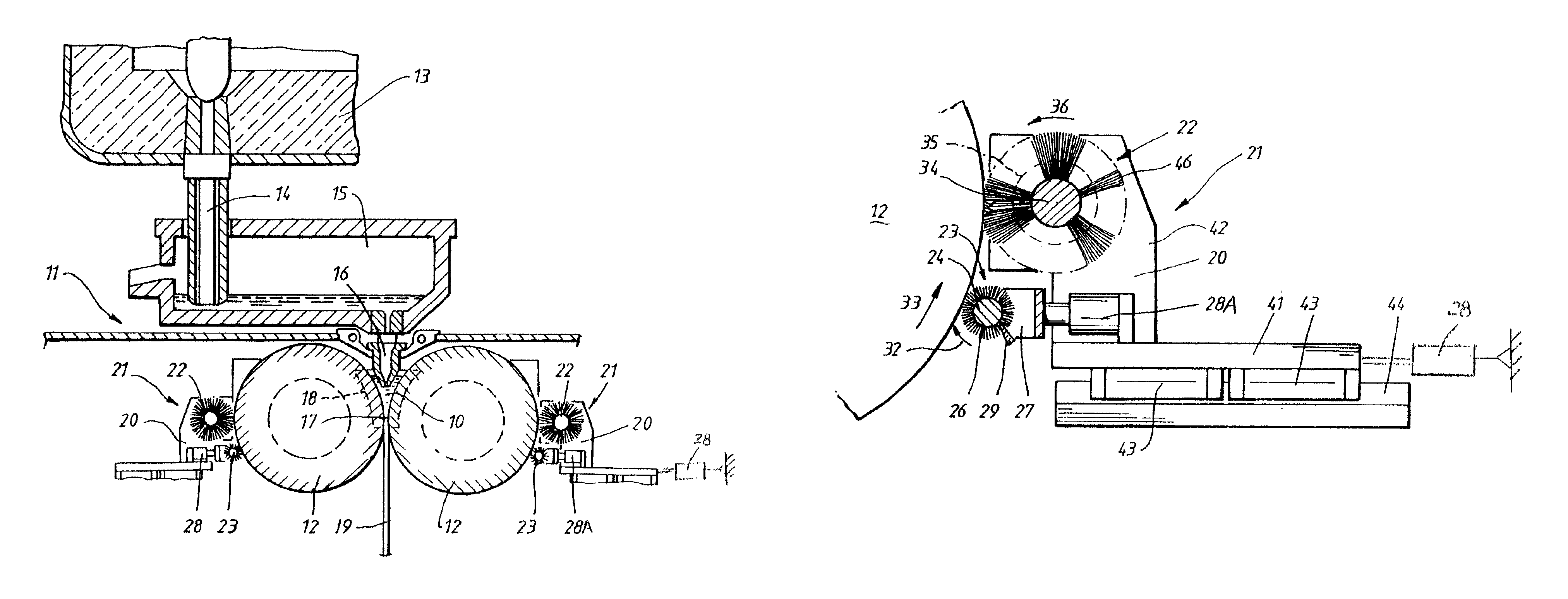

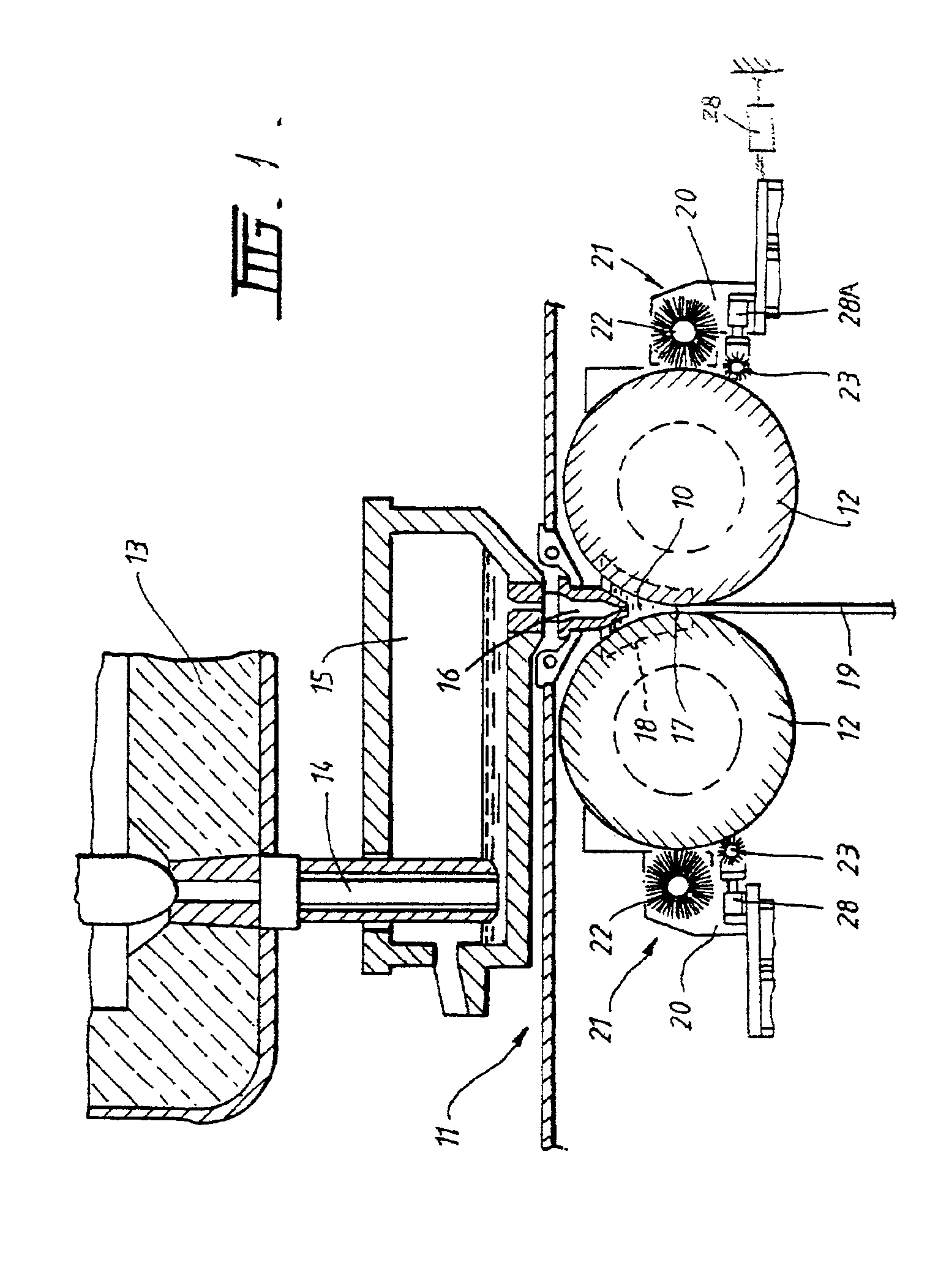

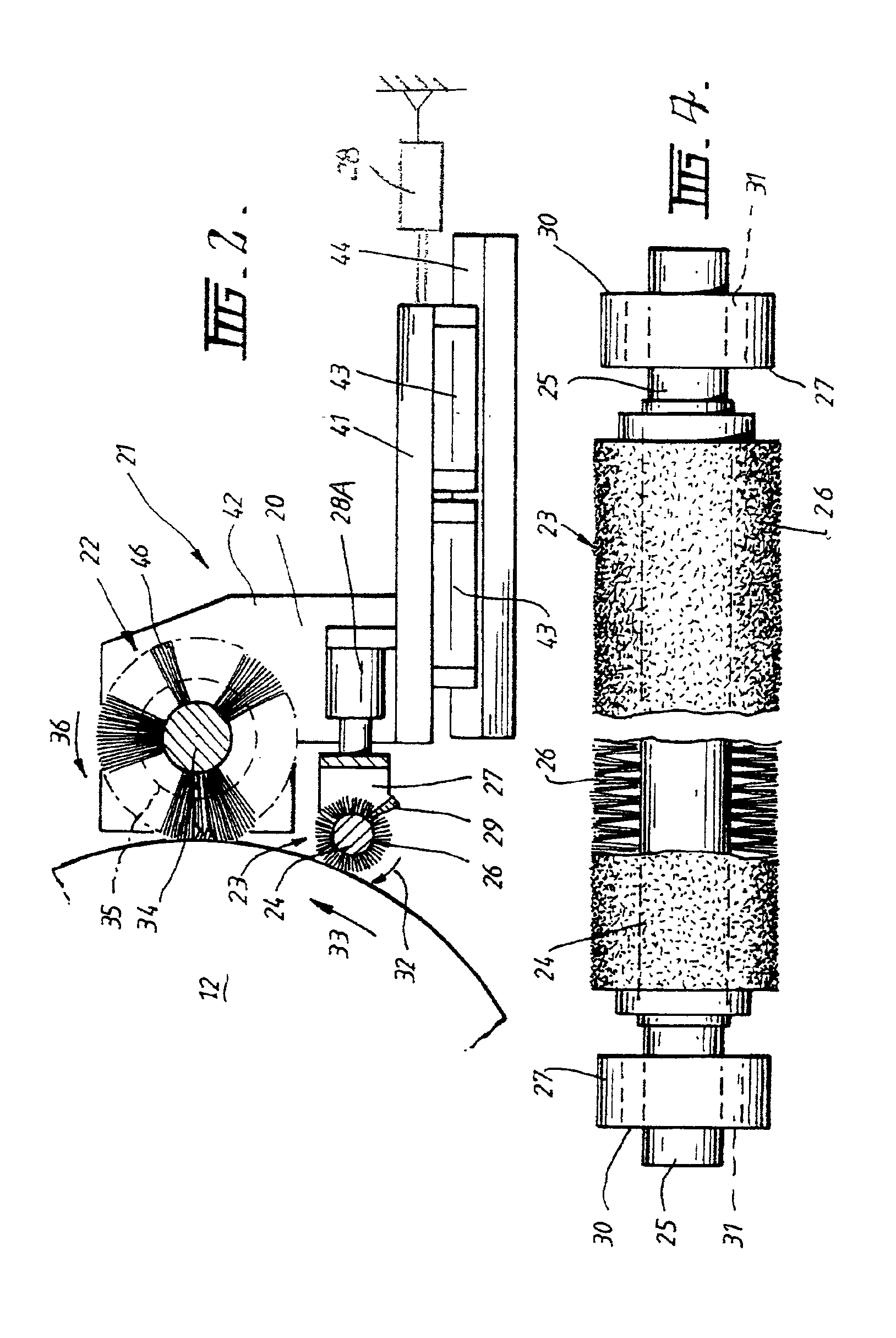

Strip casting apparatus

An apparatus for casting metal strip in which molten metal is applied to a casting roll the surface of which is cleaned by a cleaning brush device comprising a main brush extending across the roll surface by sweeper brush actuator 28A and a sweeper brush extending across the roll and capable of tangentially engaging the peripheral longitudinal roll surface in advance of the main brushing device. Both brushes are mounted on mounting frames moveable to bring the main and sweeper brushes into contact with the casting roll. The sweeper brush is independently moveable on the frame by operation of an sweeper brush actuator to move the sweeper brush into engagement with the surface of the casting roll near the start and end of the casting run and the main brush actuator to move the main brush into engagement with the peripheral longitudinal surface of the casting roll during normal casting operation.

Owner:NUCOR CORP

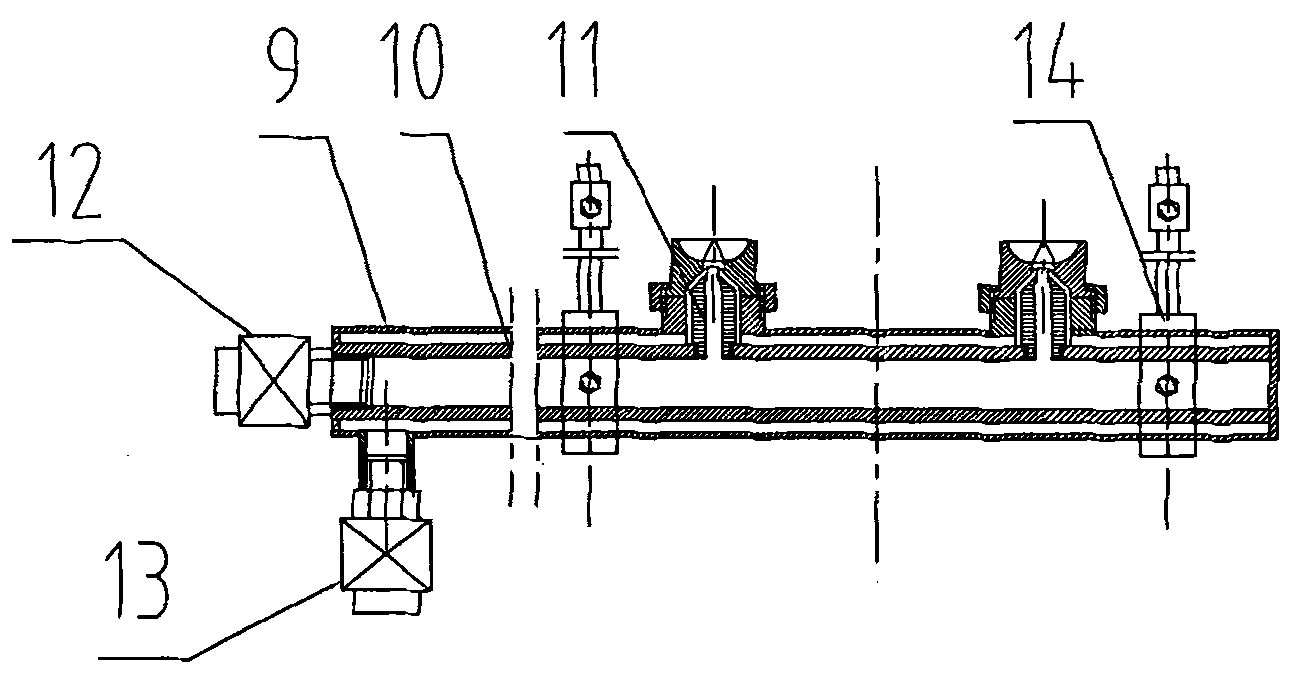

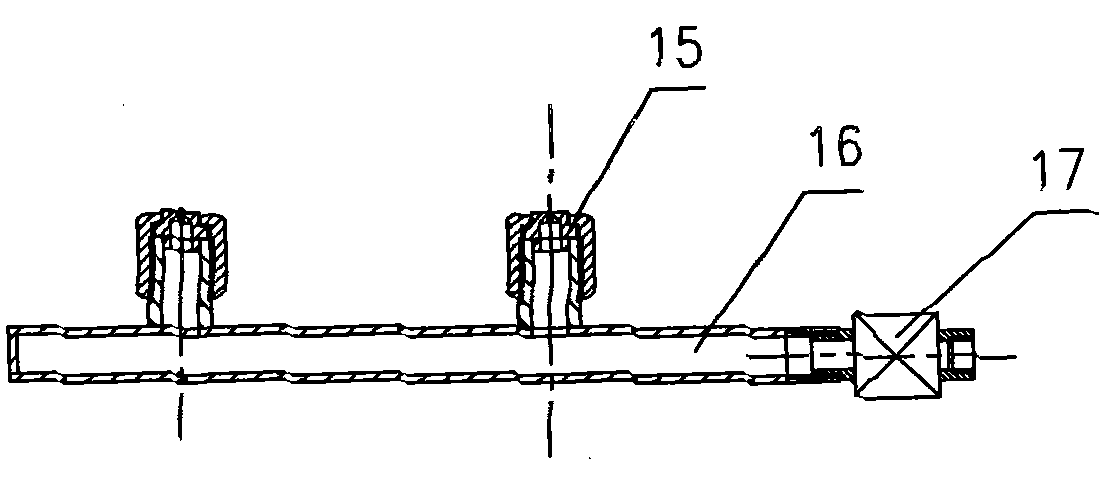

Method for controlling side seal of twin roll thin strip casting and device

Owner:BAOSHAN IRON & STEEL CO LTD +1

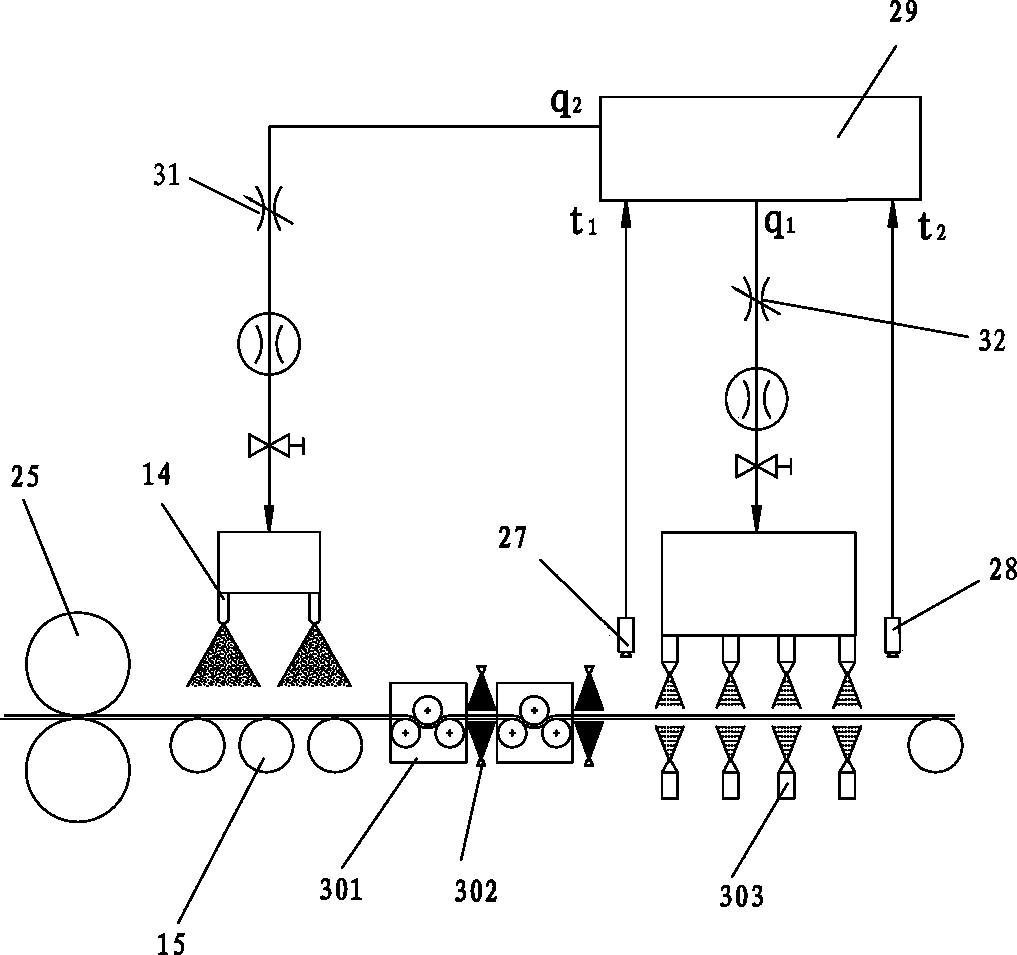

Multiple cooling methods integrated cooling system in strip casting process

The invention provides a multiple cooling methods integrated cooling system in the strip casting process, belonging to the technical field of metallurgy. The system comprises air mist cooling devices, water spray cooling devices, water mist spray guns, a water collection tank, a roller table, a beam, a chassis and a casting rolling mill rack, wherein each air mist cooling device comprises first air inlet pipes, first water inlet pipes, air mist nozzles, an air flow regulating valve, a first water flow regulating valve and an air mist cooling spray gun installing support; each water mist spray gun comprises nozzles, a second water inlet pipe and a second water flow regulating valve; and each water spray cooling device comprises a case, a third water inlet pipe, shunt pipes, a deflector, water nozzles and third water flow regulating valves. The system comprises the following advantages: multiple cooling methods such as air spraying, mist spraying, water spraying and the like are integrated on the cooling system and large-scale cooling rate is realized by selecting the types and flow of cooling media and the opening quantity of different nozzles according to the requirement of online different cooling processes for casting and rolling the strips made of different materials to obtain the required structures.

Owner:NORTHEASTERN UNIV LIAONING

A manufacturing method of non-oriented silicon steel sheet based on twin-roll strip continuous casting technology

The invention relates to the technical field of metallurgical technology, in particular to a method for manufacturing a non-oriented silicon steel plate based on a twin-roll thin strip continuous casting technology. The method comprises the steps of: smelting molten steel with the silicon content of 2.9-3.5wt% at a temperature of 1610-1720 DEG C; pouring the molten steel in a tundish, wherein themolten steel flows into a cavity formed by two crystallizing rolls which rotate at a linear velocity of 20-60m / min and a side-closing plate through the tundish, and is in contact with the crystallizing rolls to generate a solidified shell, and a cast band is led out of the crystallizing rolls; obtaining a cast band coil after the cast band is subjected to the online side-shearing treatment and coiling; warm-rolling the cast band coil after the cast band coil is cooled down to 200-600 DEG C in air, wherein the amount of deformation in warm-rolling is 5-30 percent; and cold-rolling, annealing and coating the warm-rolled cast band coil to prepare a non-oriented silicon steel plate. The method provided by the invention has the advantages that the process is simple and compact, energy is saved, consumption is reduced, microscopic structures of the cast band can be effectively controlled, the drawability, the plate shape and the surface quality of the cast band can be improved, and the magnetic induction intensity of the non-oriented silicon steel plate can be effectively increased.

Owner:NORTHEASTERN UNIV

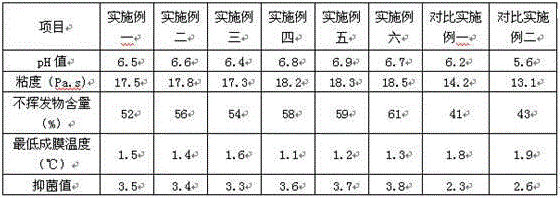

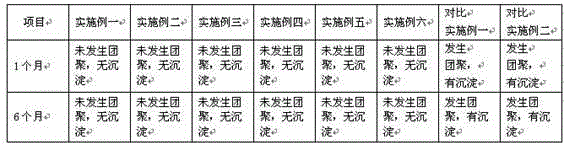

Tourmaline-containing sheath-core composite fibers

ActiveCN104451940AHas antibacterial and antibacterial effectImprove itchingPhysical treatmentConjugated cellulose/protein artificial filamentsGlycerolSlurry

The invention relates to fibers, in particular to tourmaline-containing sheath-core composite fibers. The tourmaline-containing sheath-core composite fibers are prepared through the following steps: (1) tourmaline processing; (2) core layer material processing, that is, bast fibers and palm fibers after degumming processing are combed and cut into short bast fibers and short palm fibers, the short bast fibers and the short palm fibers are then soaked in a mixed manner in a lignocellulose aerogel solution for 15 to 20 minutes according to a formula, the short bast fibers and the short palm fibers after the mixed soaking are then taken out for draining, the short bast fibers and the short palm fibers after the draining are sent to an opener for opening and mixing, the short bast fibers and the short palm fibers after the opening and mixing pass through airflows and are arranged through a roller groove to form meshed semi-products with S-shaped section structures, and the meshed semi-products go through spunlace to form non-woven needled bast-palm fiber aerogel core layer materials; (3) sheath layer material processing, that is, a first pulp is prepared from processed tourmalines and ethylene glycol, phthalic acid and glycerol are used for esterification reaction, the first pulp, magnesium oxide and calcium hydroxide are added after the reaction for condensation polymerization, and polyester chip sheath layer materials are obtained through strip casting and sized dicing; (4) composite melt spinning for obtaining of the tourmaline-containing sheath-core composite fibers. The tourmaline-containing sheath-core composite fibers provided by the invention achieve the antibacterial and healthcare effects, high degree of comfort, as well as environment friendliness.

Owner:HEYE HEALTH TECH CO LTD

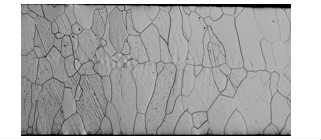

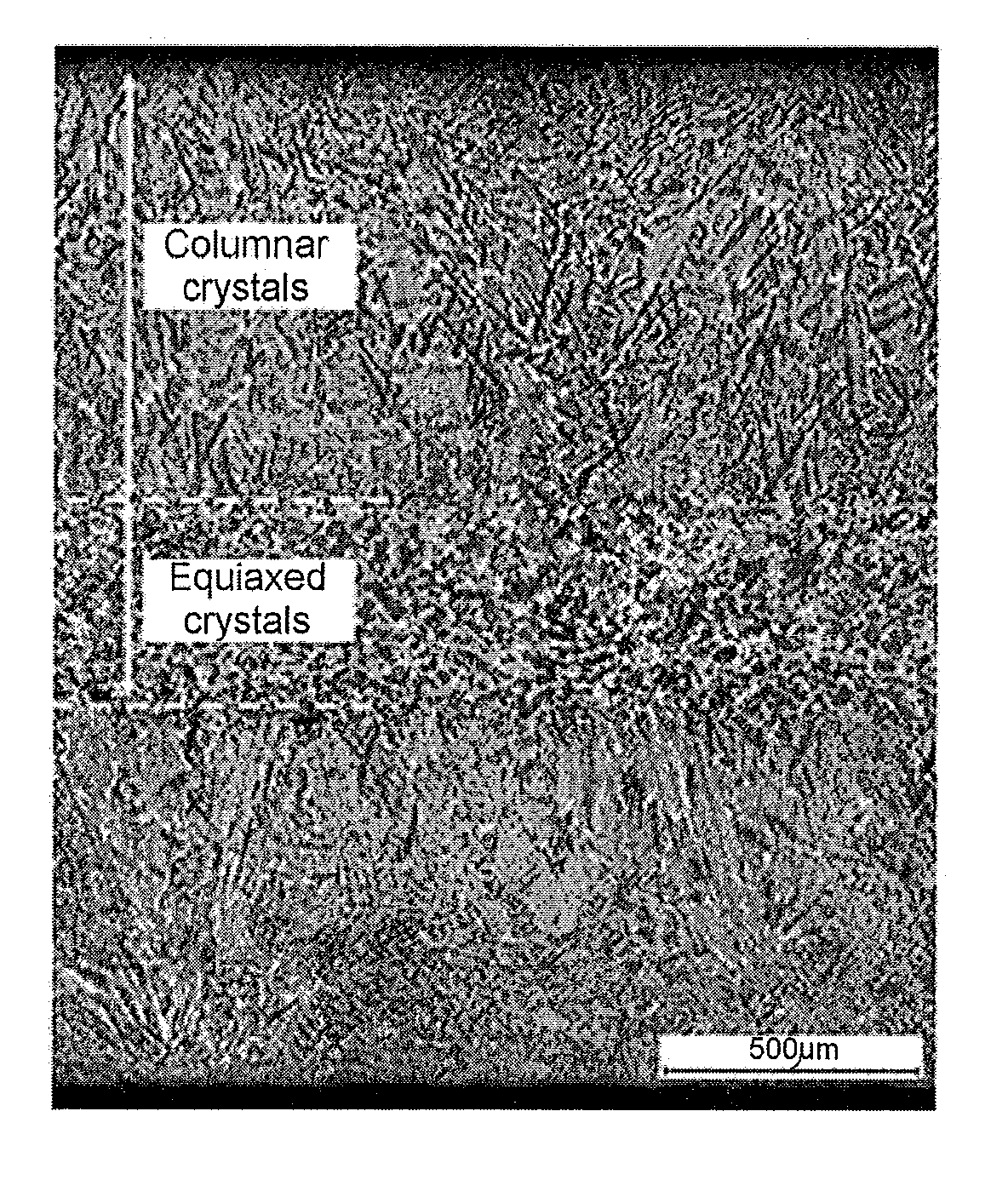

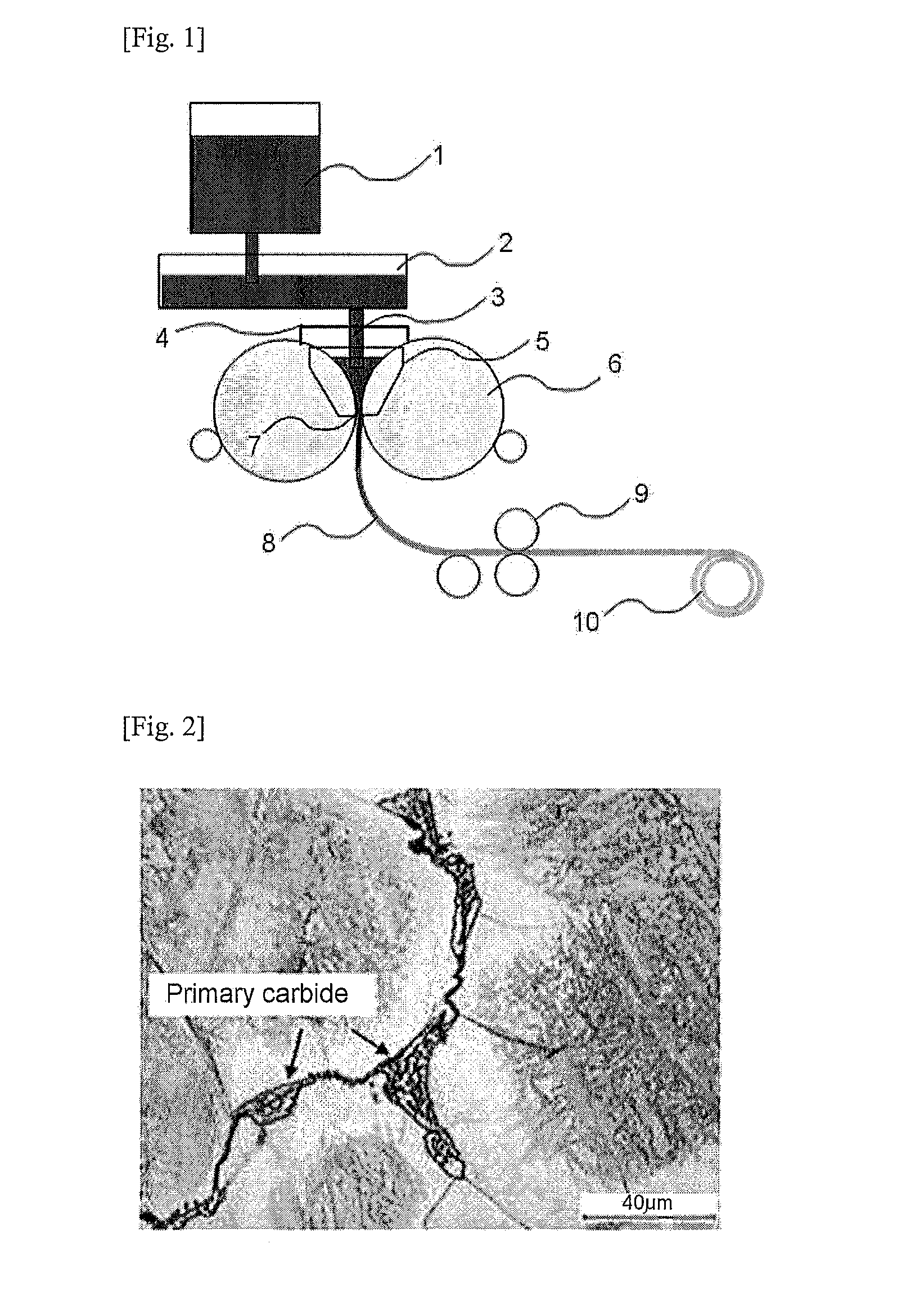

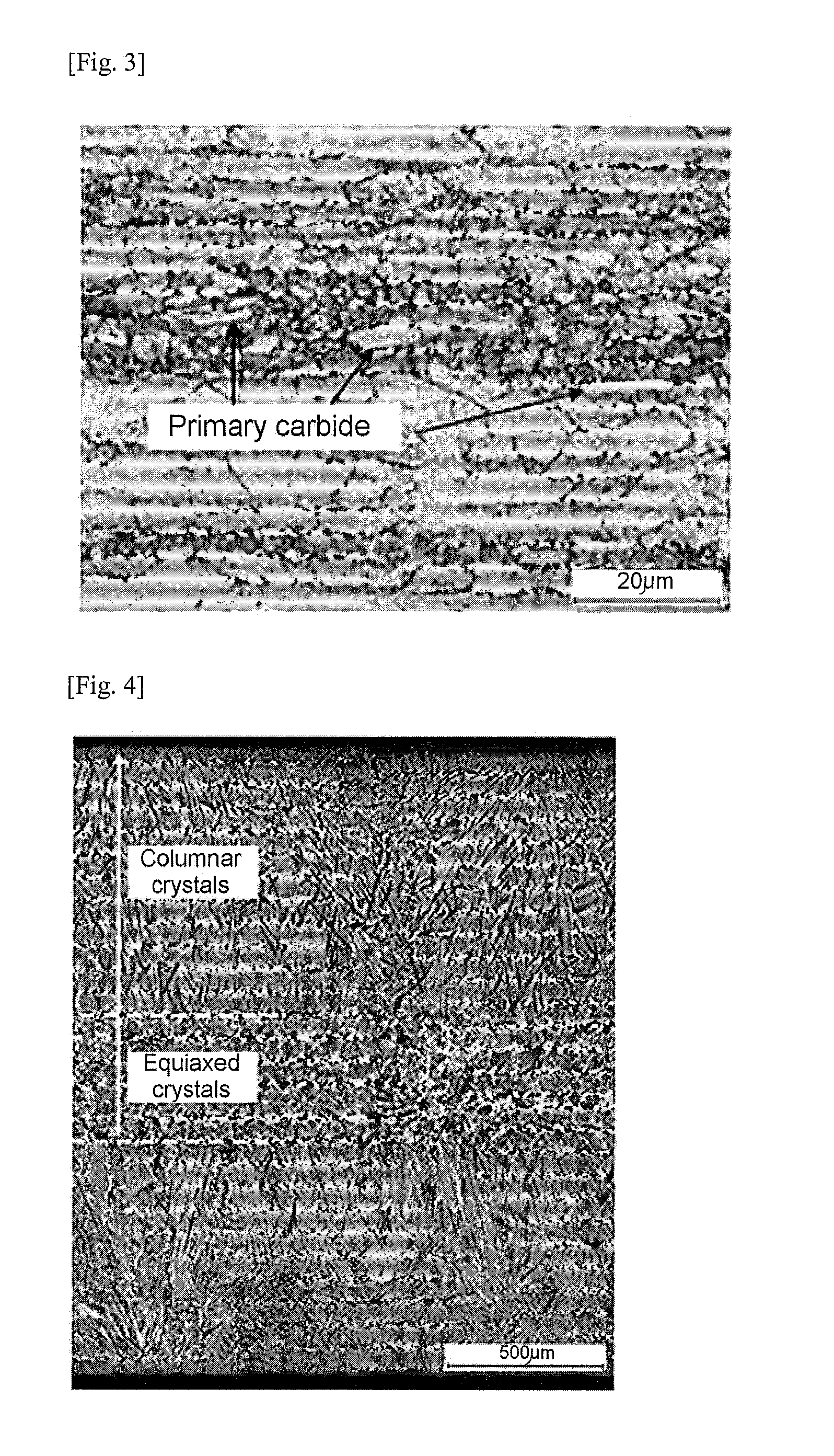

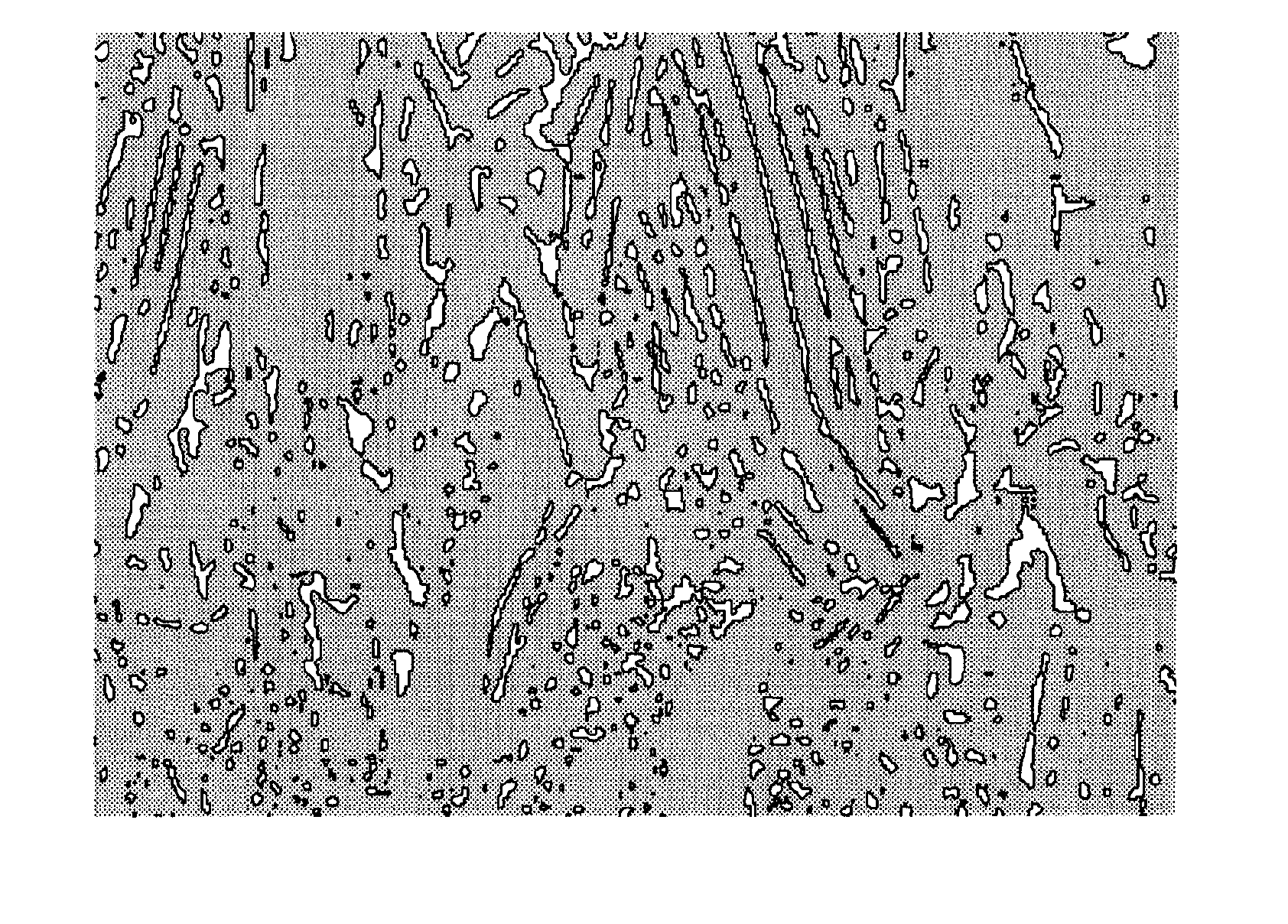

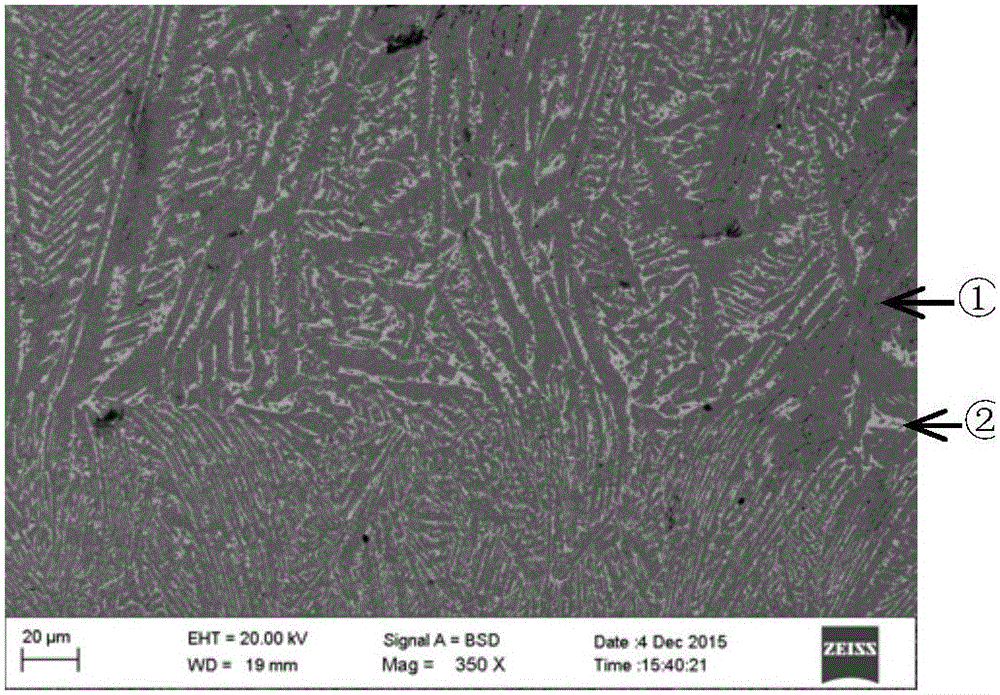

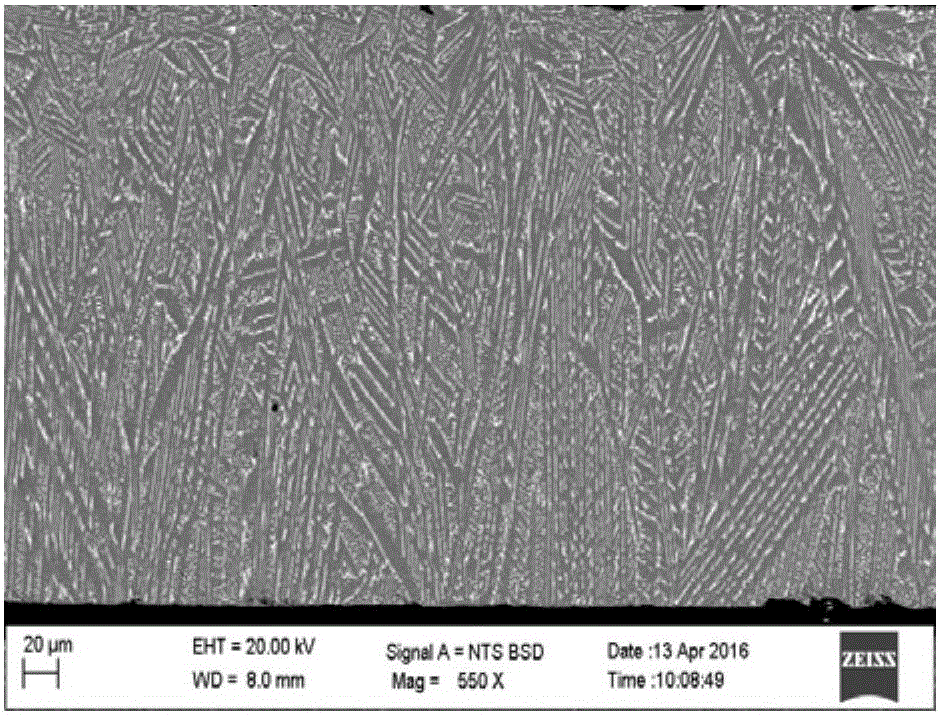

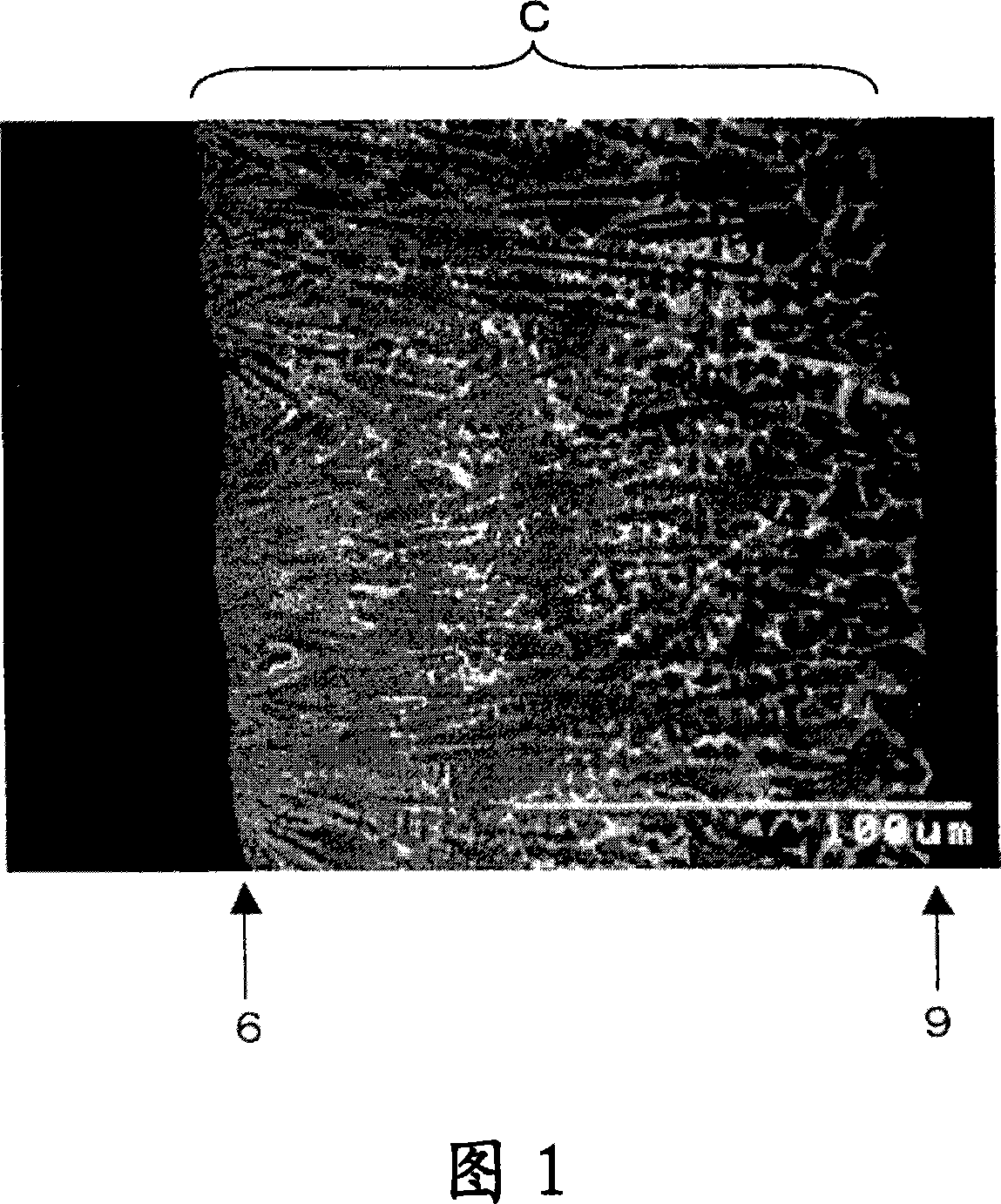

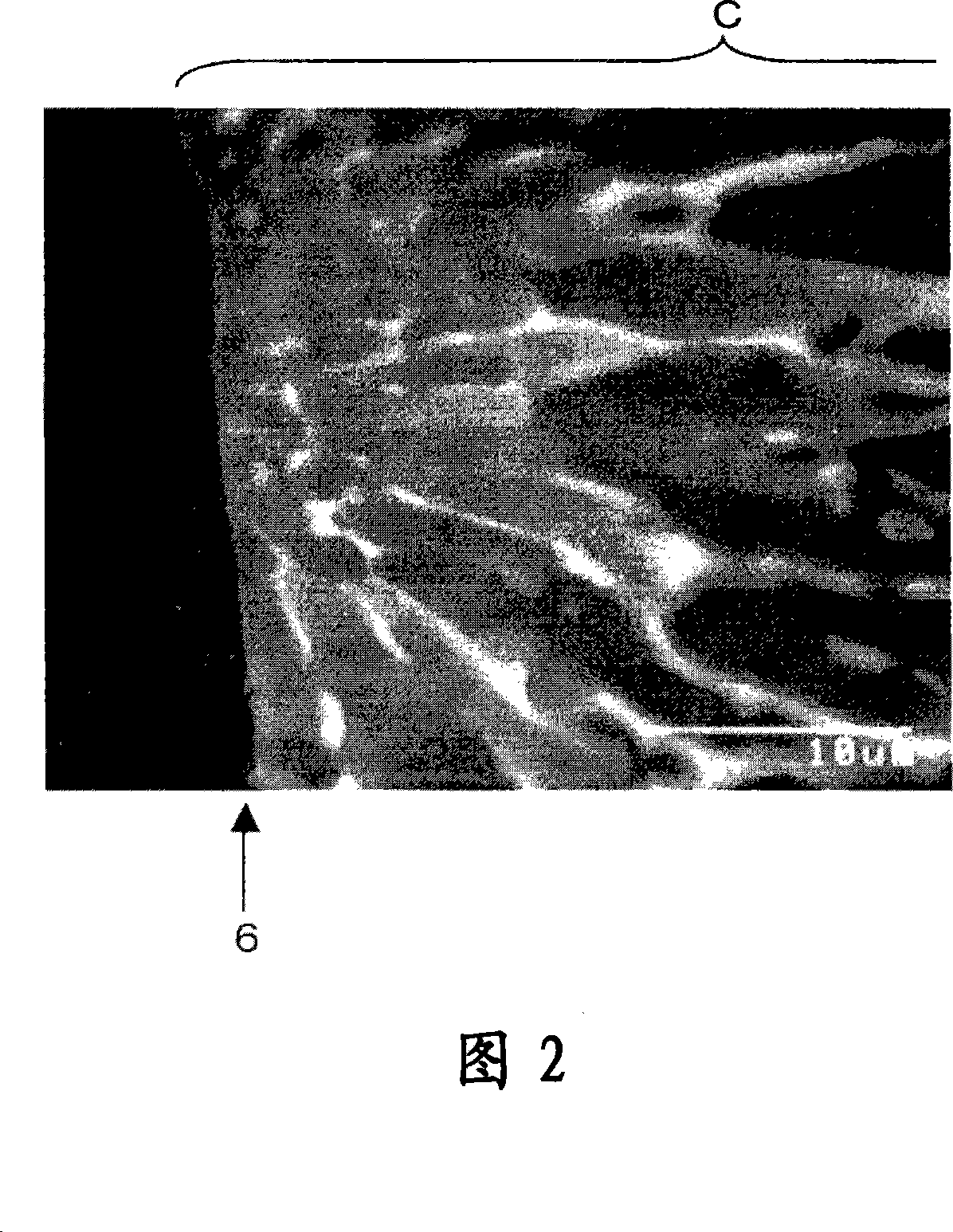

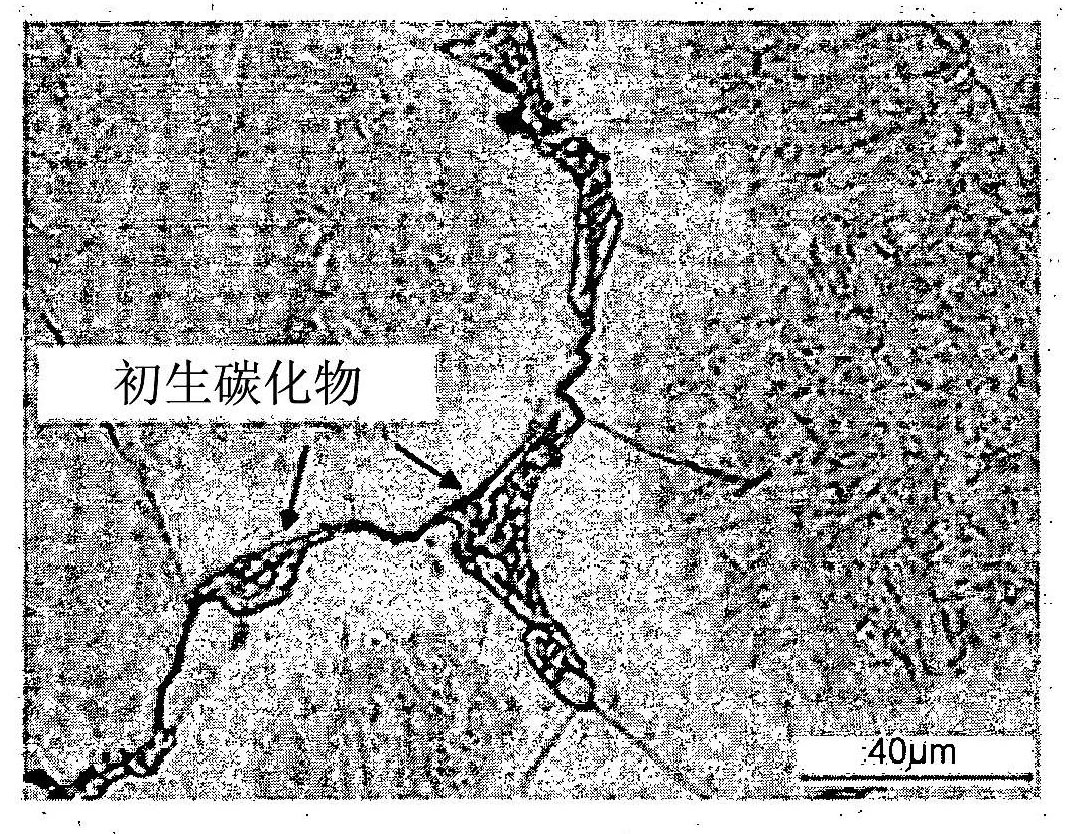

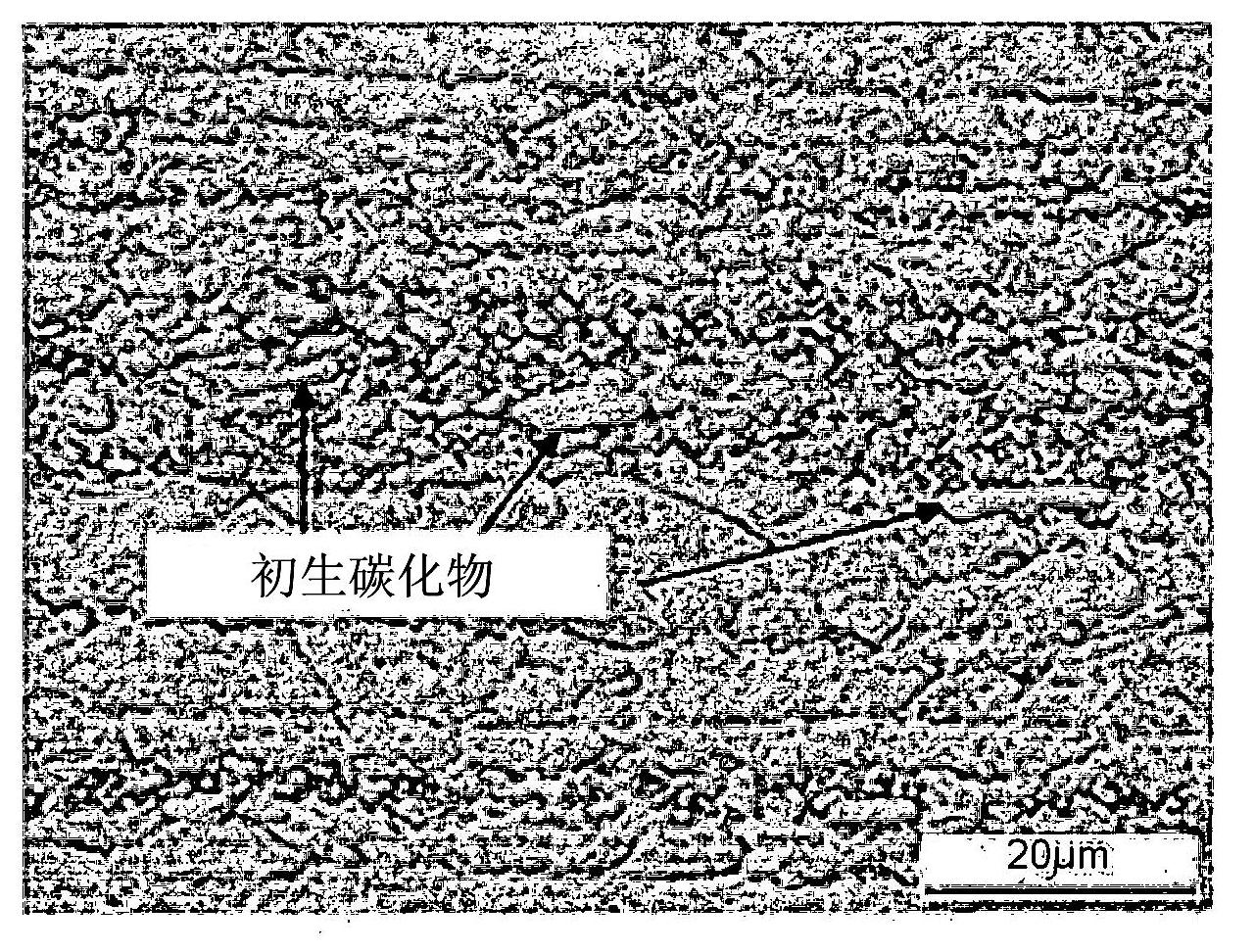

High-Carbon Martensitic Stainless Steel and Production Method Therefor

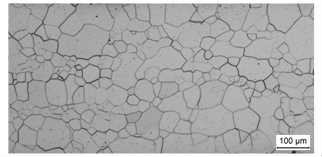

The present invention relates to a production method for high-carbon martensitic stainless steel as used in razorblades, knives and the like, which contains, as percentages by weight, 0.40 to 0.80% carbon and 11 to 16% chromium as main components. Provided is a production method for high-carbon martensitic stainless steel in a strip-casting device, wherein a stainless-steel thin sheet is cast by supplying a stainless molten steel containing, as percentages by weight, 0.40 to 0.80% carbon and from 11 to 16% chromium to a molten steel pool from a tundish via a nozzle, and the cast stainless-steel thin sheet is made into a hot-rolled annealed strip using in-line rollers to a rolling reduction of 5 to 40% immediately just after the casting so that the size of primary carbides within the microstructure of the hot-rolled annealed strip is 10 μm or less, and also provided is martensitic stainless steel produced by means of the production method. By reducing the size of the primary carbides formed in the cast structure and the hot-rolled sheet to 10 μm or less, the present invention produces high-carbon martensitic stainless steel having outstanding blade-end quality for use in cutting implements.

Owner:POHANG IRON & STEEL CO LTD

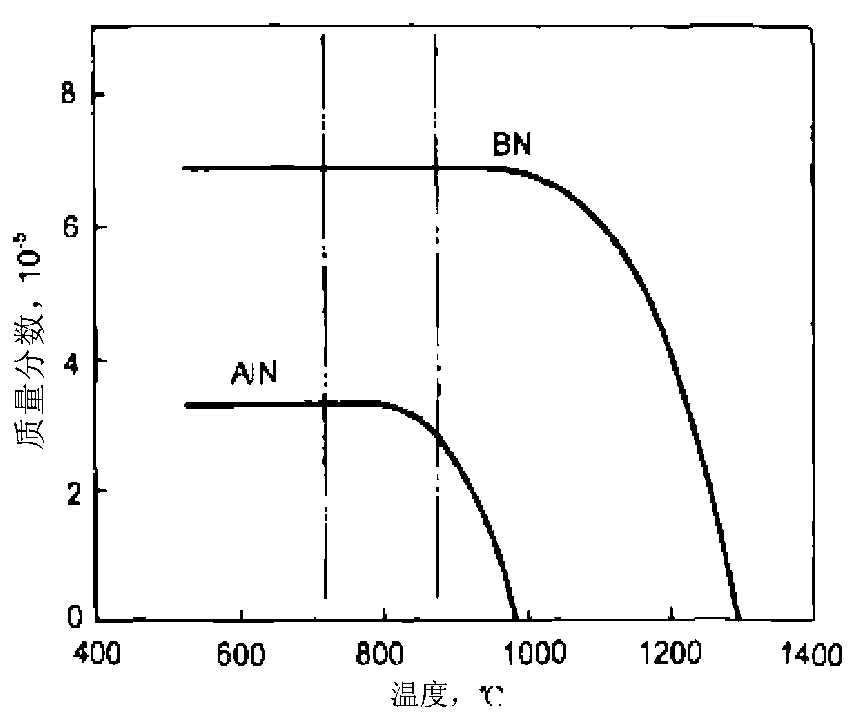

Steel made of boron containing microalloy and resisting atmosphere corrosion and manufacturing method of steel

ActiveCN102796969ACost-effectiveLow yield ratioWork treatment devicesMetal rolling arrangementsBoron nitrideCorrosion

The invention relates to steel made of boron containing microalloy and resisting atmosphere corrosion, and a manufacturing method of the steel. Steel containing boron and resisting atmosphere corrosion is produced through twin-roll thin strip continuous casting, a crystal roll produced through strip casting is sprayed with dry ice, cast strips are uniformly cooled in an strengthened manner, and are cooled below 1,280 DEG C quickly, the cooling rate is 200 to 300 DEG C / s, the strip steel subjected to boronizing is cooled in such a cooling way to promote the separation-out of thick and large BN (Boron Nitride), prevent the occurrence of low-melting-point B2O3 and the separation-out of fine ALN and achieve the purposes of uniforming austenite crystals and reducing the tensile ratio; and then, austenite is subjected to on-line recrystallization rolling, atomoization cooling and coiling. Through the invention, the steel with lower tensile ratio can be manufactured, the problems of steel produced through strip casting that the structure is non-uniform, the tensile ratio is higher, the moulding is difficult, and the requirement of cold rolled material cannot be met are effectively solved, the use requirement of cold rolled base materials is met, and the steel can be directly used in a way of replacing the cold rolling by the hot rolling.

Owner:BAOSHAN IRON & STEEL CO LTD

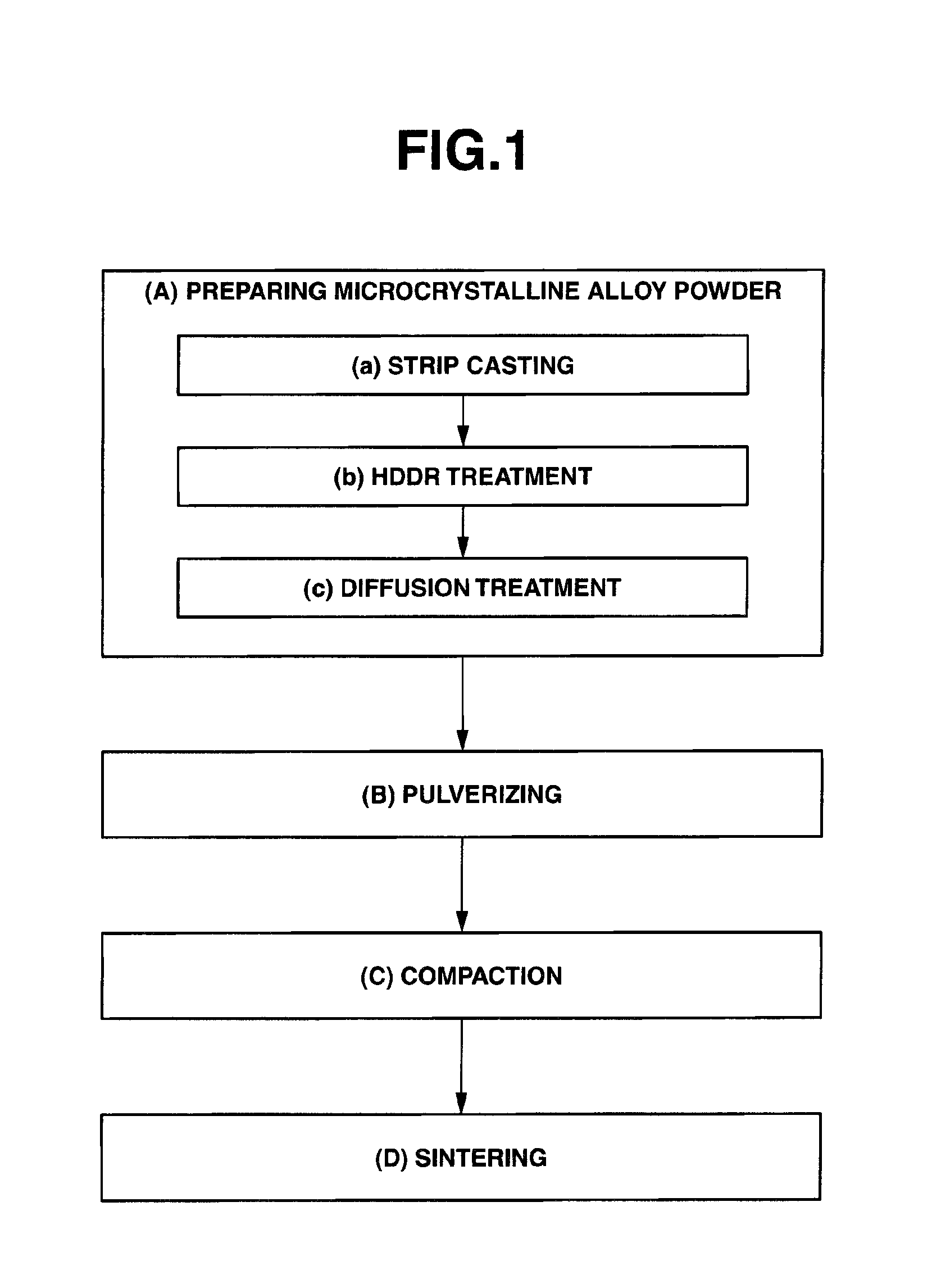

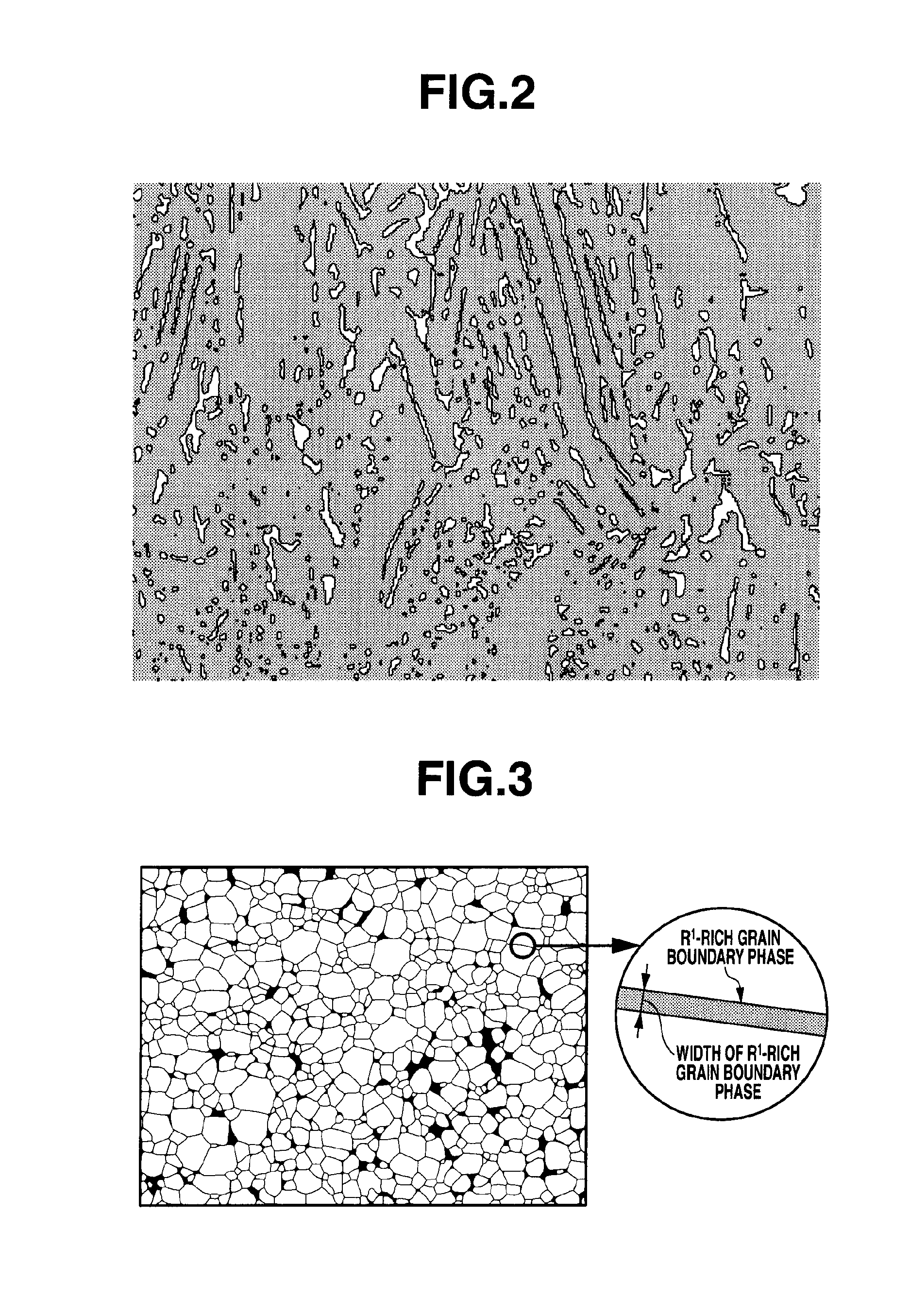

Rare earth sintered magnet and making method

ActiveUS20140105779A1Improve performanceInorganic material magnetismInductances/transformers/magnets manufactureSintered magnetsRare earth

A strip cast alloy containing Nd in excess of the stoichiometry of Nd2Fe14B is subjected to HDDR treatment and diffusion treatment, yielding microcrystalline alloy powder in which major phase crystal grains with a size of 0.1-1 μm are surrounded by Nd-rich grain boundary phase with a width of 2-10 nm. The powder is finely pulverized, compacted, and sintered, yielding a sintered magnet having a high coercivity.

Owner:SHIN ETSU CHEM IND CO LTD

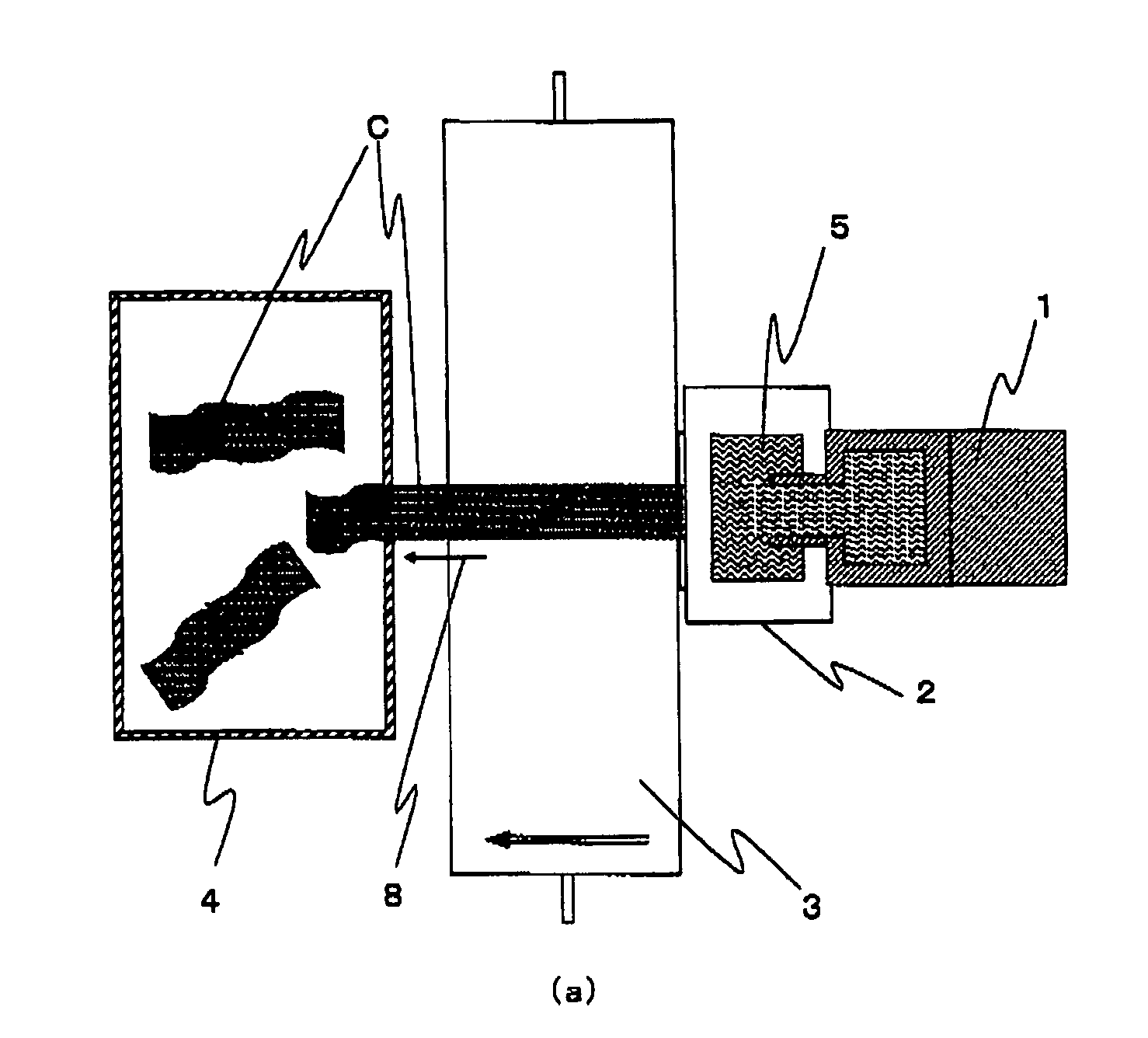

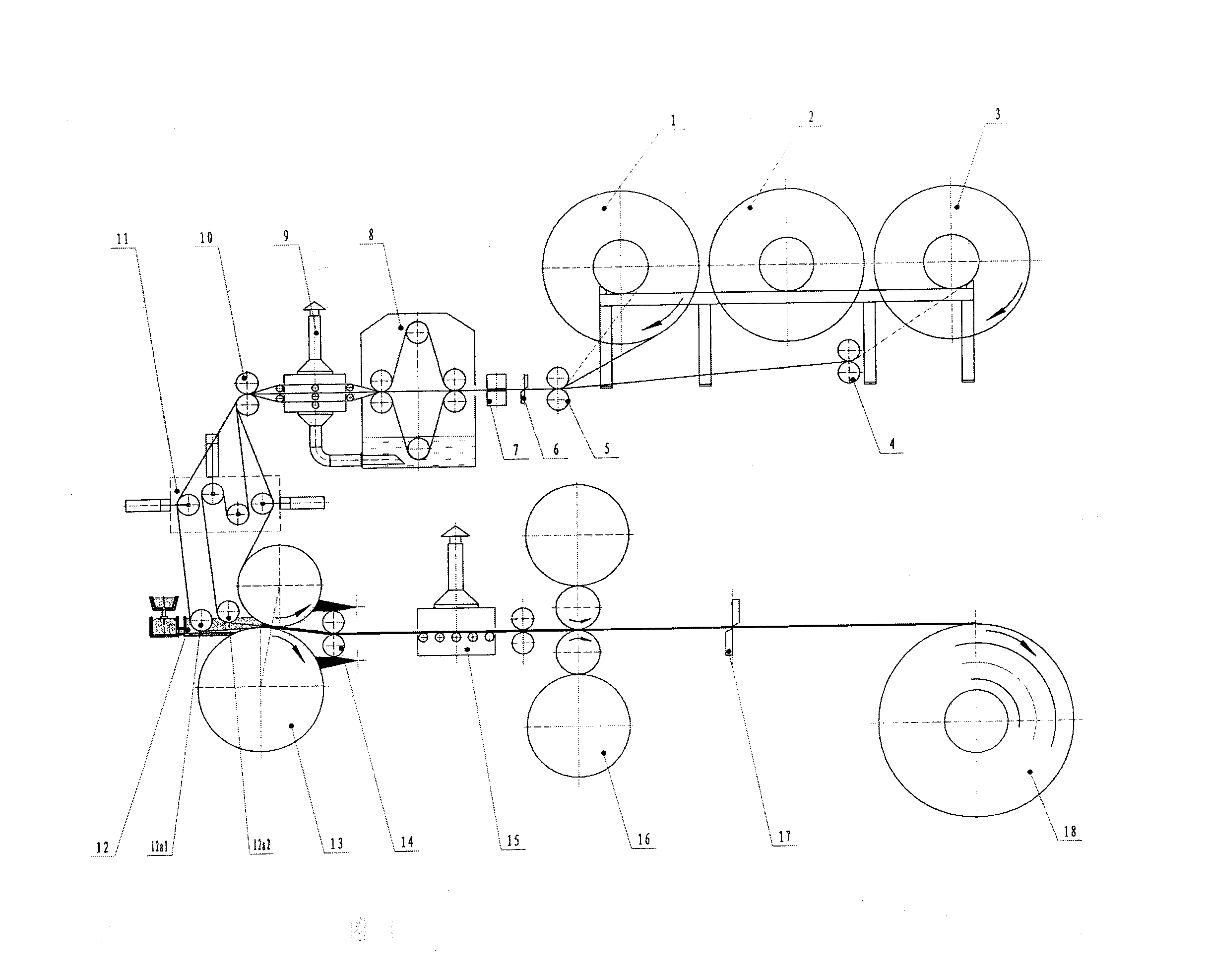

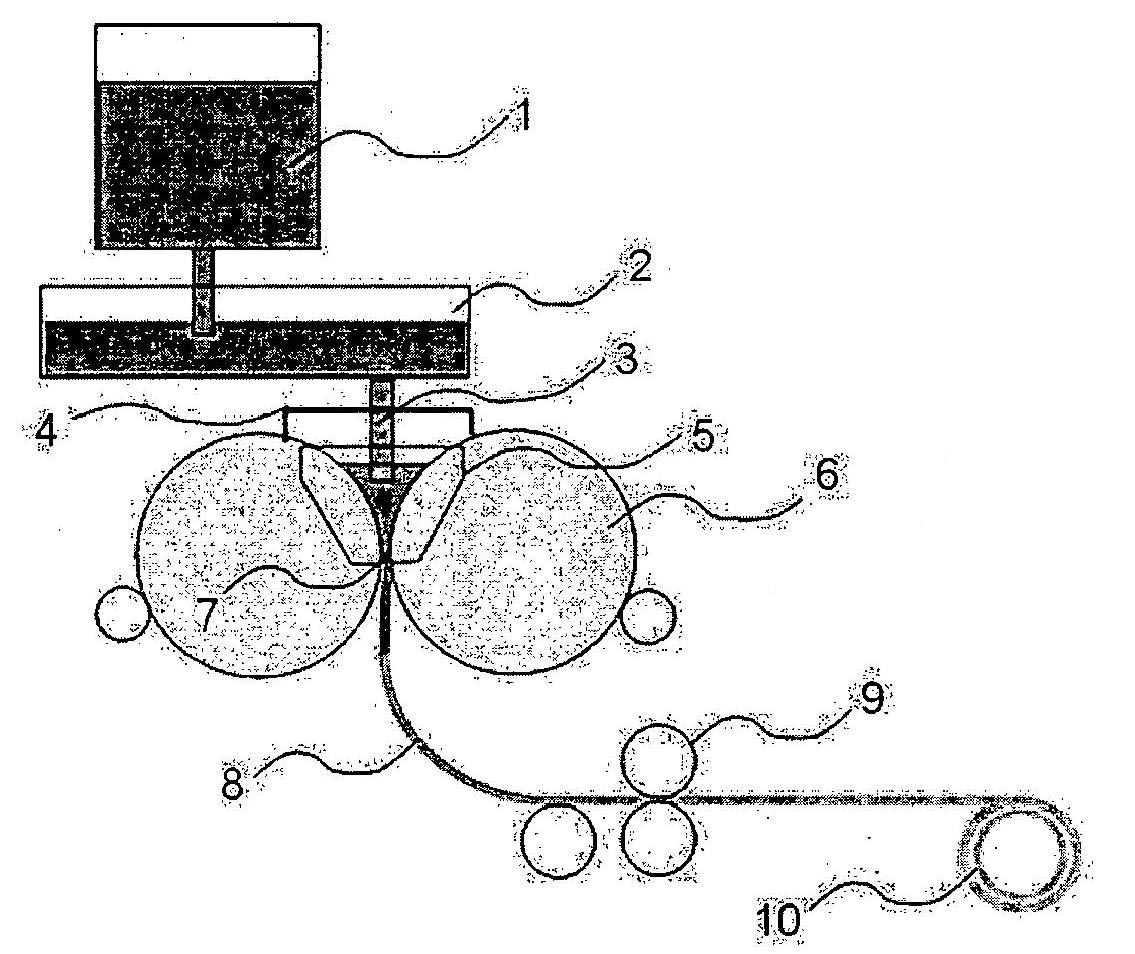

Solid-liquid phase metal cast rolling compounding method and device

ActiveCN103252369AIncrease productionHigh dimensional accuracyAuxillary arrangementsMetal rolling arrangementsProduction lineMetal strips

The invention provides a solid-liquid phase metal cast rolling compounding method and device capable of producing a novel metal composite strip through one time continuously by using multi-layer and various metal plates through liquid metal. On the basis of a plate strip cast rolling process, an open feeding nozzle is adopted, a pre-processed multi-layer metal strip penetrates through a cast rolling machine roll gap after soaking in metal melt in the feeding nozzle, the metal strip and the metal melt cooled to be in a semi-solid state and a solid state in a cast rolling area are rolled together, the metal melt is cured and attached to the metal strip, metallurgical bonding of two or more than two types of metal is formed, and the metal composite strip with the preset thickness is produced. The solid-liquid phase metal cast rolling compounding method and device has the advantages of being less in investment, low in production cost and energy consumption, good in product performance and wide in product range. The device comprises an uncoiling unit, a first dragging machine, a second dragging machine, an end shear, a splicer, a washing machine, a drying machine, a third dragging machine, a strip length and tension adjusting device, a cast rolling machine, (a heat preservation heating device, a hot continuous rolling machine), a shearing machine and a coiling machine production line.

Owner:秋海滨

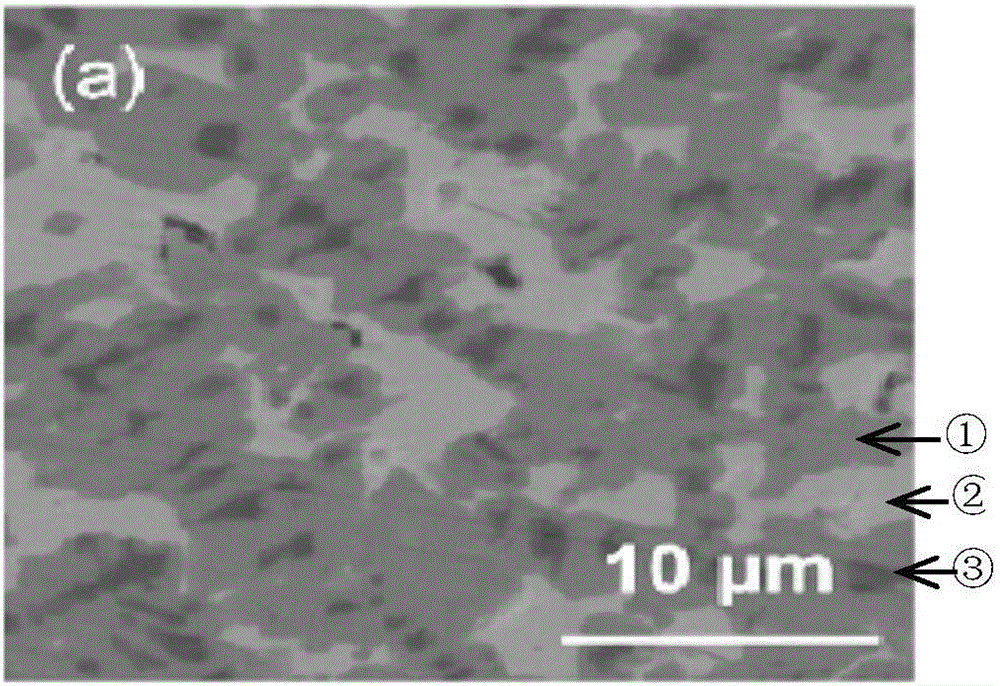

Low-cost rare earth iron-boron permanent magnet and preparation method therefor

ActiveCN106128670AHigh crystallinityFill the gap in magnetic performanceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementHydrogen

The invention belongs to the technical field of a rare earth permanent magnet material, and relates to a high-Ce-content and low-cost rare earth iron-boron permanent magnet and a preparation method therefor. The chemical formula of the permanent magnet is as follows based on mass percentage: (Ce<1-x>RE<x>)(Fe, TM)<100-a-b>B, wherein x is greater than or equal to 0 and less than or equal to 0.20; a is greater than or equal to 28 and less than or equal to 40; b is greater than or equal to 1.21 and less than or equal to 1.50; RE is selected from one or several kinds of rare earth elements of Pr, Nd, Ho, Gd, Y, La or Er; and TM is selected from one or several kinds of Ga, Co, Al, Si, Cu, Nb, Zr, Ti, Mn, Ni, Ag or Su. The preparation method for the rare earth permanent magnet material comprises the steps of preparing raw materials, preparing a strip-casting flake, and carrying out hydrogen crushing, orientation shaping and pressing, sintering and thermal treatment. According to the low-cost rare earth iron-boron permanent magnet, the efficient utilization of the low-cost Ce element can be realized; particularly, the content of Ce accounts for 80-100% of the total rare earth content; a sintered magnet with relatively high coercivity and comprehensive magnetic performance still can be obtained; and in addition, the maximum magnetic energy product (BH)max of the permanent magnet is greater than or equal to 10MGOe, so that the low-cost rare earth iron-boron permanent magnet has the remarkable cost and price advantages.

Owner:CENT IRON & STEEL RES INST

Alloy for negative electrode of lithium secondary battery

InactiveCN101233632ALittle change in volumeHigh charge and discharge capacityActive material electrodesLi-accumulatorsMetallic materialsAlloy

At least two metallic materials containing element such as silicon and tin, which has ability of insertion and desertion of lithium element, and optionally another metallic material containing element such as copper are molten to prepare a melt. The melt is rapidly cooled by strip-cast method at a cooling rate of more than 2x103 ° C. / sec and no more than 104 ° C. / sec to be cast. Further, the cast is milled and classified into alloy powder having an average particle size of 0.1 mum to 50 mum. The alloy powder and conductive agent are laminated with binder onto a collector to obtain a negative electrode for a secondary battery. The negative electrode is employed to obtain a lithium secondary battery having high electric charge and discharge capacity, and good property of charge and discharge cycle.

Owner:SHOWA DENKO KK

High-carbon martensitic stainless steel and a production method therefor

InactiveCN102665964ASimple preparation processReduce manufacturing costsHigh carbonMartensitic stainless steel

The present invention relates to a production method for high-carbon martensitic stainless steel as used in razor blades, knives and the like, which contains from 0.40 to 0.80 wt.% of carbon and from 11 to 16 wt.% of chromium as the main components. Provided is a production method for high-carbon martensitic stainless steel in a strip-casting device, wherein steel for stainless steel containing, as percentages by weight, from 0.40 to 0.80% of carbon and from 11 to 16% of chromium is supplied from a tundish, via a nozzle to a molten steel pool in such a way that a stainless-steel thin sheet is cast, and the cast stainless-steel thin sheet is made into hot-rolled annealed strips using in-line rollers to a rolling reduction of from 5 to 40% immediately after casting such that the primary carbides within the hot-rolled annealed strip microstructure are no more than 10 [mu]m,; and also provided is martensitic stainless steel produced by means of the production method. By reducing the size of the primary carbides formed in the cast structure and the hot-rolled sheet to no more than 10 [mu]m, the present invention produces high-carbon martensitic stainless steel having outstanding blade-end quality for use in cutting implements.

Owner:POHANG IRON & STEEL CO LTD

Preparation method of cast-infiltration high-carbon high-chromium manganese-containing wear-resistant composite material

ActiveCN105108055AGood metallurgical bondHigh surface hardnessFoundry mouldsFoundry coresHigh carbonWear resistant

Disclosed is a preparation method of a cast-infiltration high-carbon high-chromium manganese-containing wear-resistant composite material. The preparation method includes the steps of firstly, weighing raw materials of chromium, carbon, manganese, nitrogen and nickel according to the mass percent of (57-66) to (5.5-6.5) to (5-15) to (0-0.15) to (2-5); secondly, adding polyvinyl butyral and absolute ethyl alcohol sequentially into alloy powder to mix to form a coating, and then igniting to achieve curing; thirdly, applying the coating to corresponding parts of a cast cavity, pouring molten steel, at the temperature of 1550-1600 DEG C, into the cast cavity, and cooling the molten steel naturally and then stripping castings; fourthly, subjecting the castings to water toughening at the temperature of 900-1000 DEG C to obtain products. By means of manganese adding and follow-up heat treatment processes, a cast-infiltration layer and a matrix are good in metallurgical bonding, the austenitic matrix with an alloy layer containing great quantity of carbide and nitride is produced, and surface hardness of the products is improved.

Owner:HENAN UNIV OF SCI & TECH

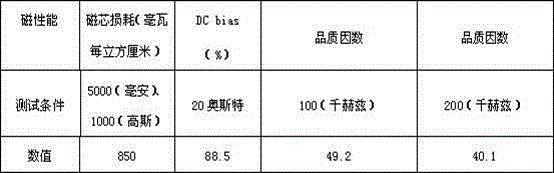

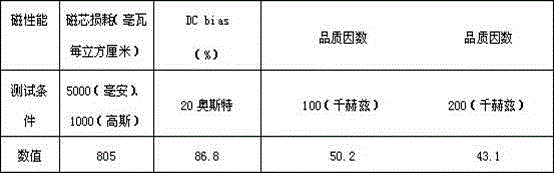

Method for preparing iron silicon soft magnetic alloy powder core

InactiveCN102974821AImprove magnetic propertiesMeet performance requirementsInorganic material magnetismEpoxySilicon alloy

The invention discloses a method for preparing an iron silicon soft magnetic alloy powder core. The method for preparing the iron silicon soft magnetic alloy powder core comprises the steps of 1, melting an iron silicon alloy by adopting a rapid solidification strip casting furnace, and preparing the alloy into powder by using a ring hammer mill after rapid quenching; 2, mixing the powder with atomized iron silicon alloy powder, and sieving the resultant powder; 3, performing surface treatment on the powder in a protective atmosphere furnace; 4, adding phosphoric acid, deionizer water, isopropanol and normal silicate ester, mixing, stirring and drying in a frying way; 5, pressing the powder into the powder core by using a hydraulic press; 6, performing protective atmosphere heat treatment on the powder core; and 7, performing protective treatment on the surface of the powder core through the reinforcement of epoxy resin and the spray painting. The iron silicon soft magnetic alloy powder core prepared by the method is high in cost performance and has the advantages of direct current overlapping characteristic, high-frequency low-loss and good characteristic; and in addition, the better magnetic performance still can be kept under a high temperature.

Owner:GUANGDONG IRON & STEEL INST

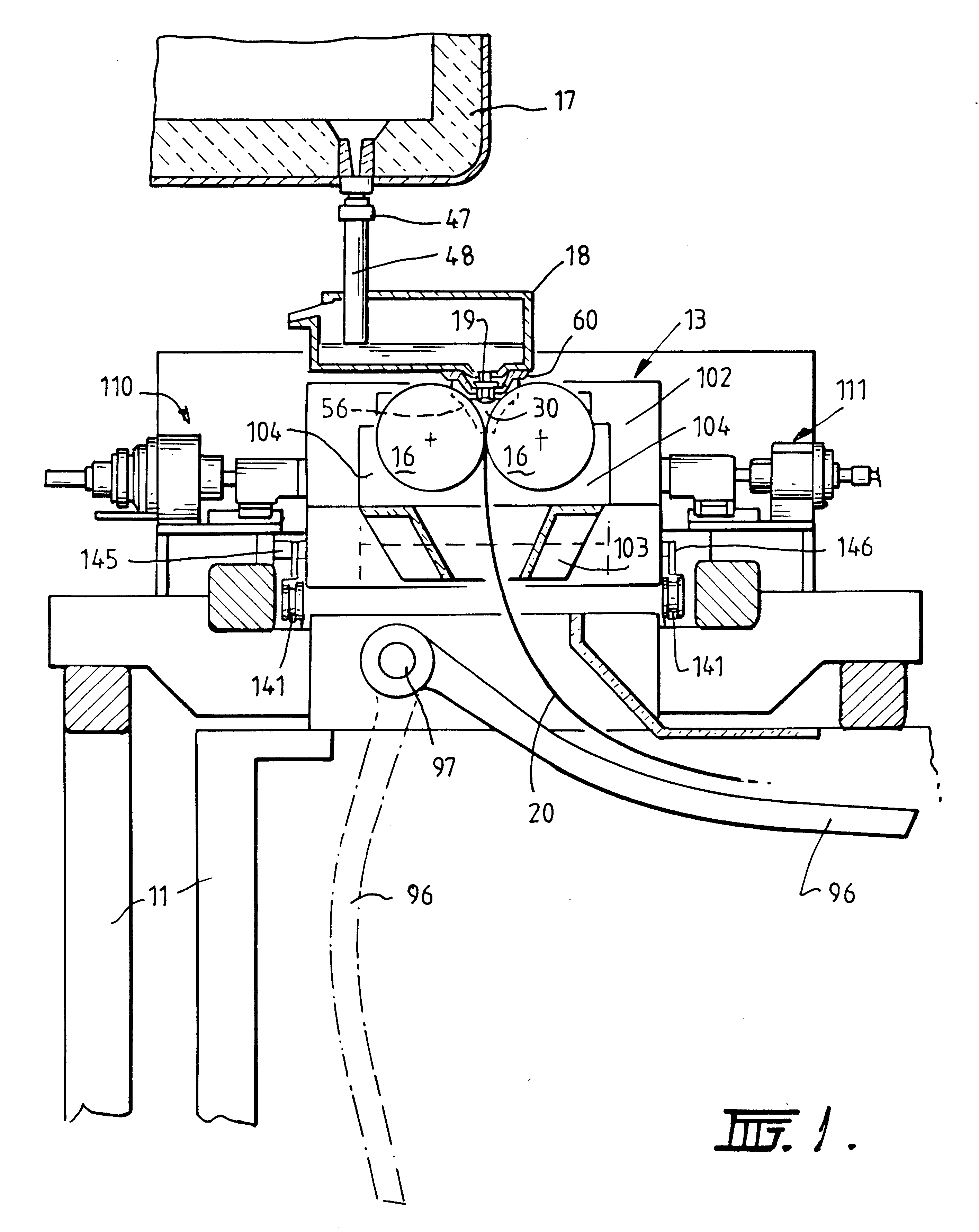

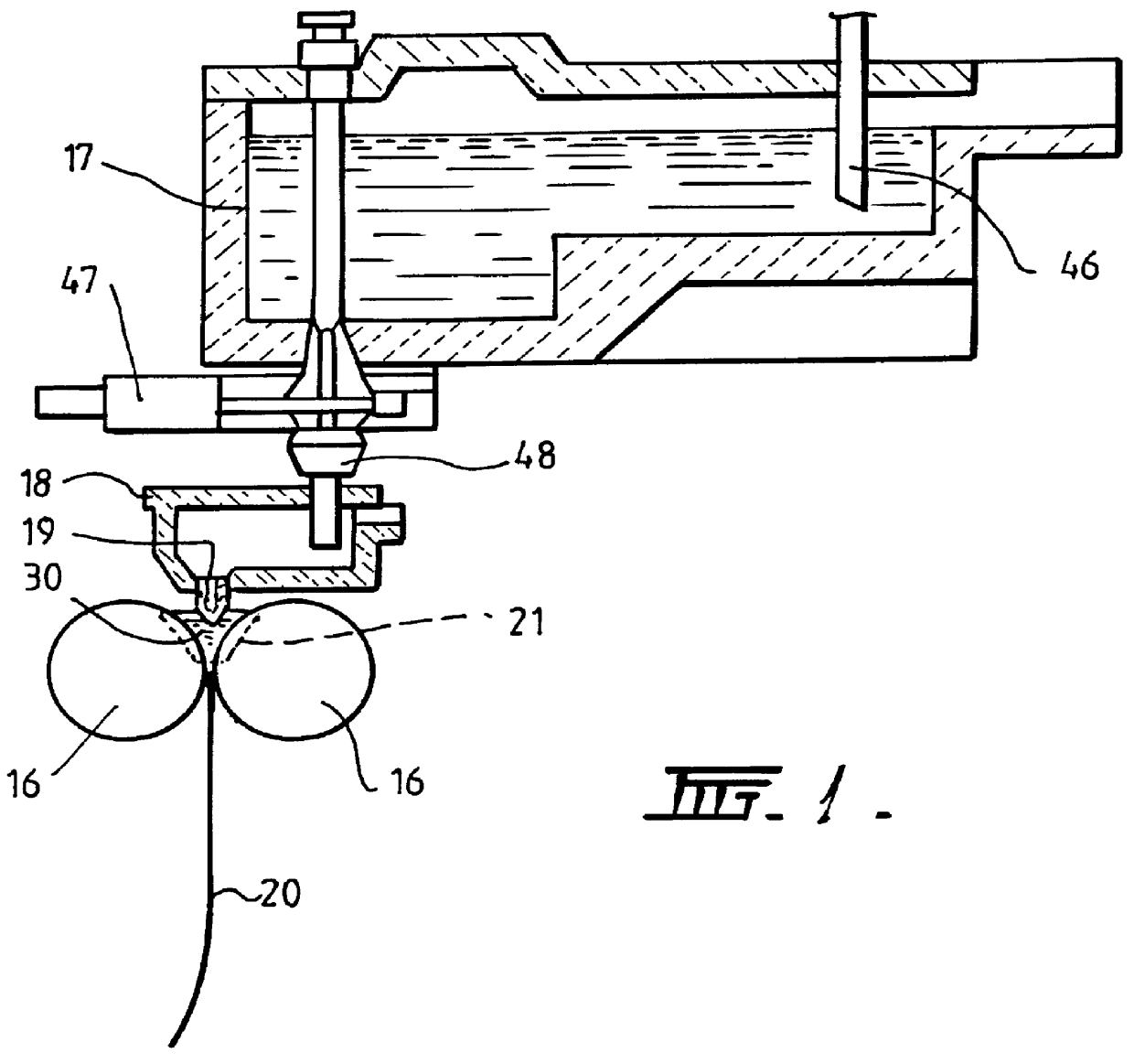

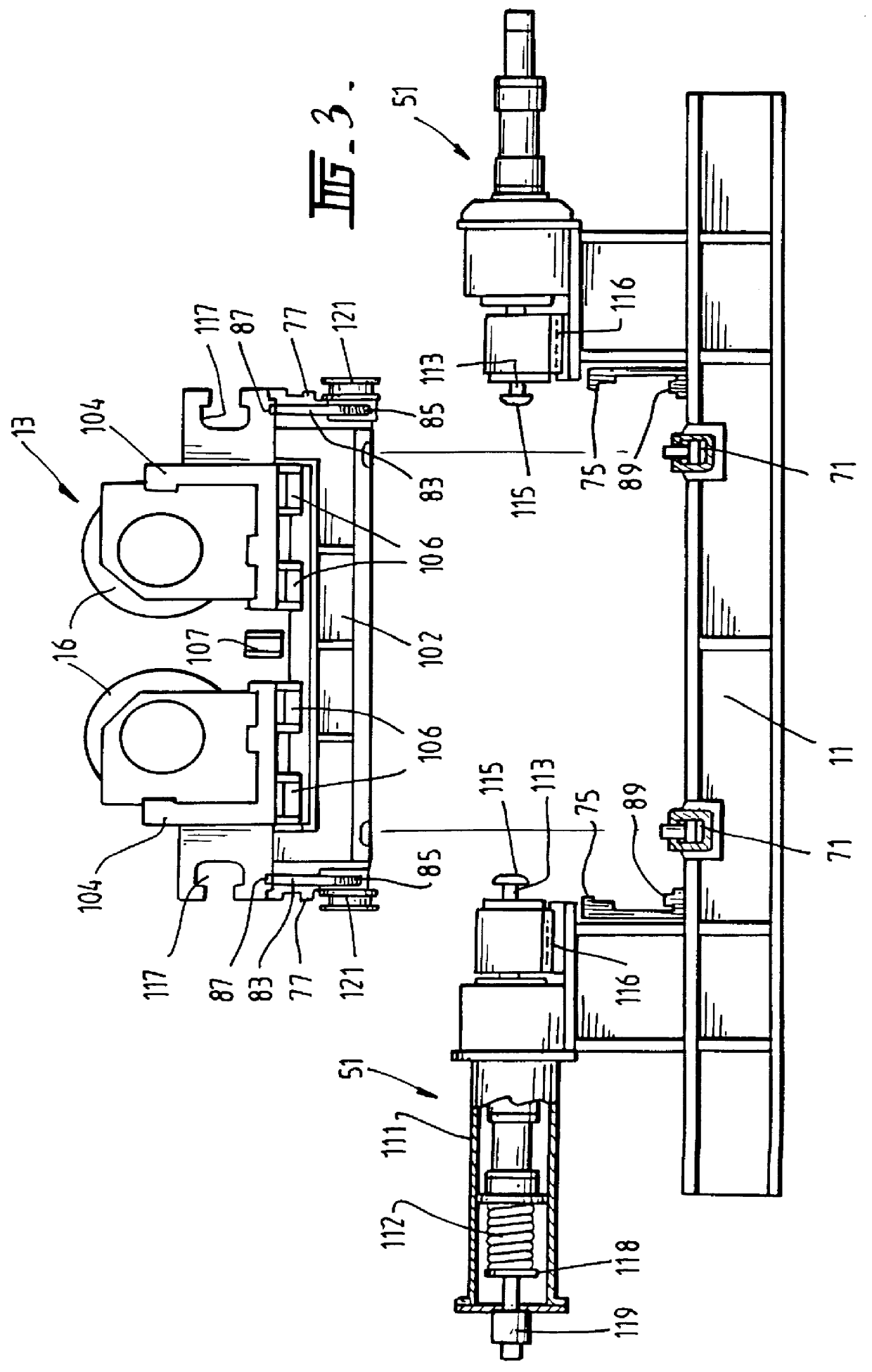

Strip casting apparatus

InactiveUS6164366APrecise positioningOut of operationMetal rolling stand detailsMetal rolling arrangementsStrip castingMolten metal

Apparatus for continuously casting metal strip comprises a pair of parallel casting rolls (16). In use of the apparatus molten metal is delivered between the casting rolls which are rotated to deliver cast strip product downwardly from the rolls. Casting rolls (16) are mounted on a roll module (13) installed in and removable from the caster as a unit. Module (13) is movable horizontally from a stand-by position to an intermediate position beneath a casting position of the rolls and can be hoisted from the intermediate position by operation of hoists (71) to lift the rolls (16) into their casting position.

Owner:CASTRIP

Method for restoring roll body of steel casting roll of twin-roll strip casting

The invention discloses a method for restoring a roll body of a steel casting roll of twin-toll strip casting. The method comprises the following steps of: (1) clearing and turning the incomplete surface of the roll body of a casting roll to remove crackles and pits from the surface of the roll body of the casting roll; (2) preheating the treated casting roll in a furnace at the temperature of between 450 and 550 DEG C; (3) slowly rotating the preheated casting roll on a submerged arc welding machine at the rotating linear speed of between 15 and 40 m / h, and overlaying at least three layers of welding wires on the surface of the casting roll; (4) performing annealing thermal treatment on the casting roll after overlaying, cooling the casting roll to the temperature of 180 DEG C along with the furnace, wherein the annealing temperature is between 450 and 550 DEG C and the heat preservation time is 10 hours; and (5) cutting the roll body of the cast roll after the annealing thermal treatment to meet the requirements of a new roll on size and accuracy. The method of the invention has the characteristics of simplicity, convenient operation, prolonged service life of the casting roll, and reduction in production cost.

Owner:张子益 +1

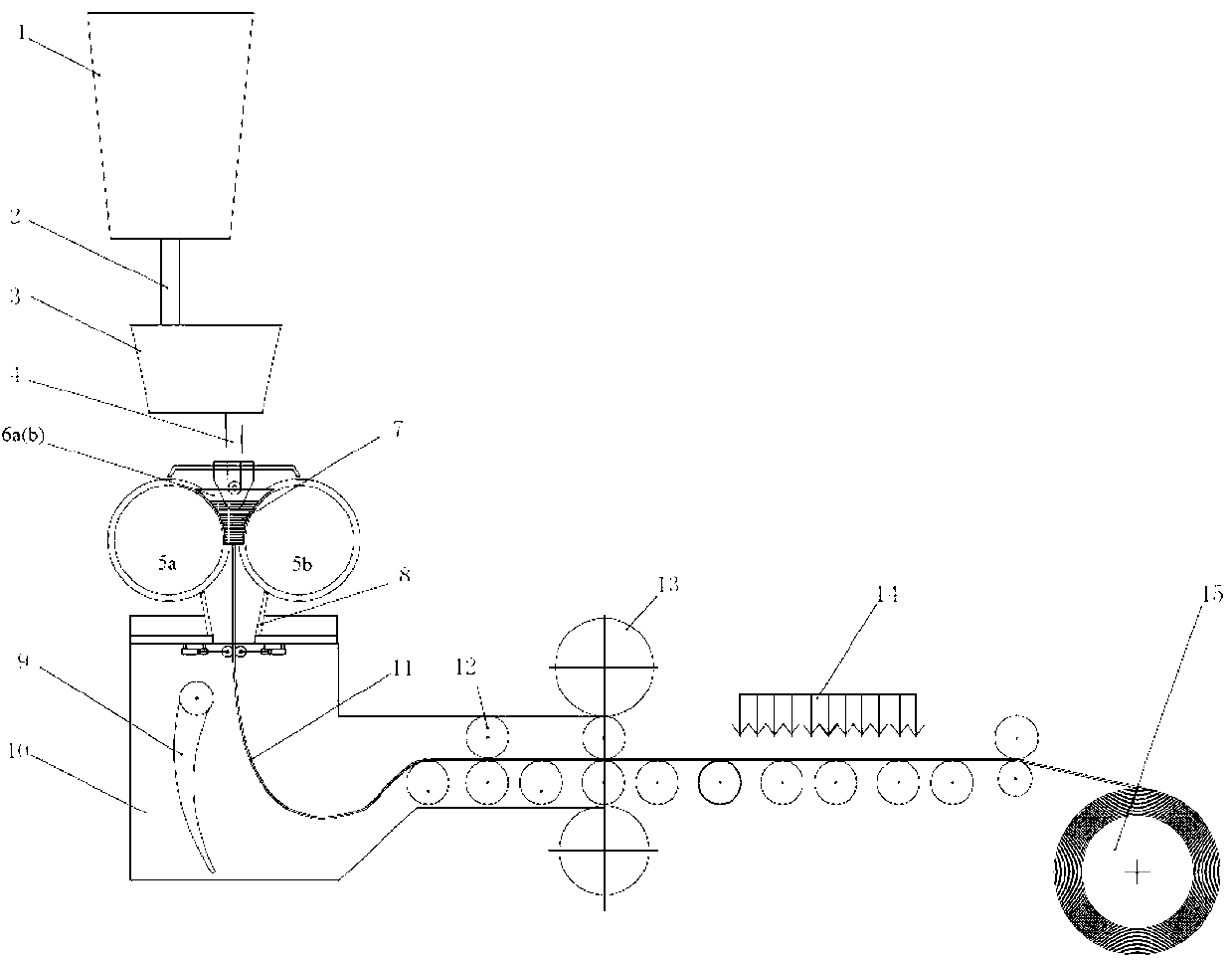

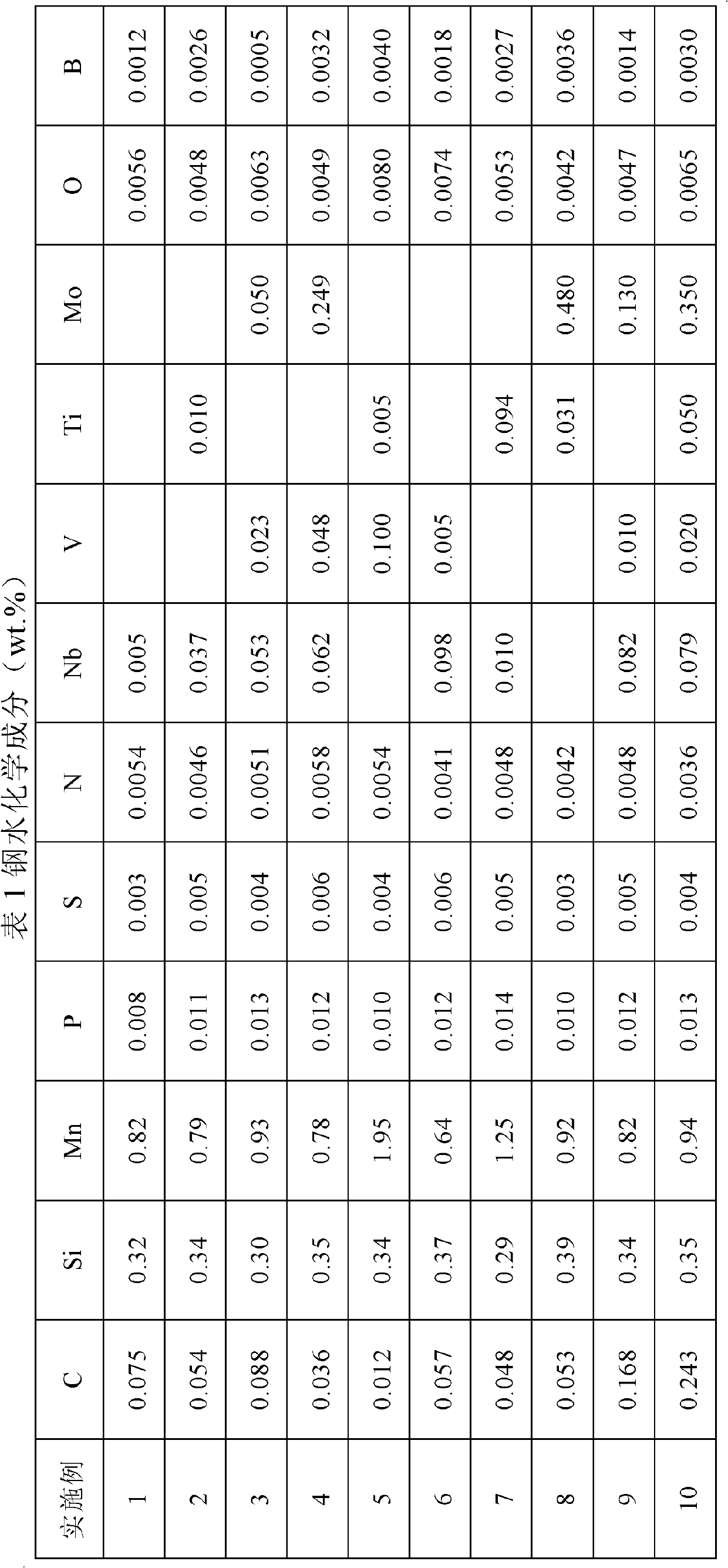

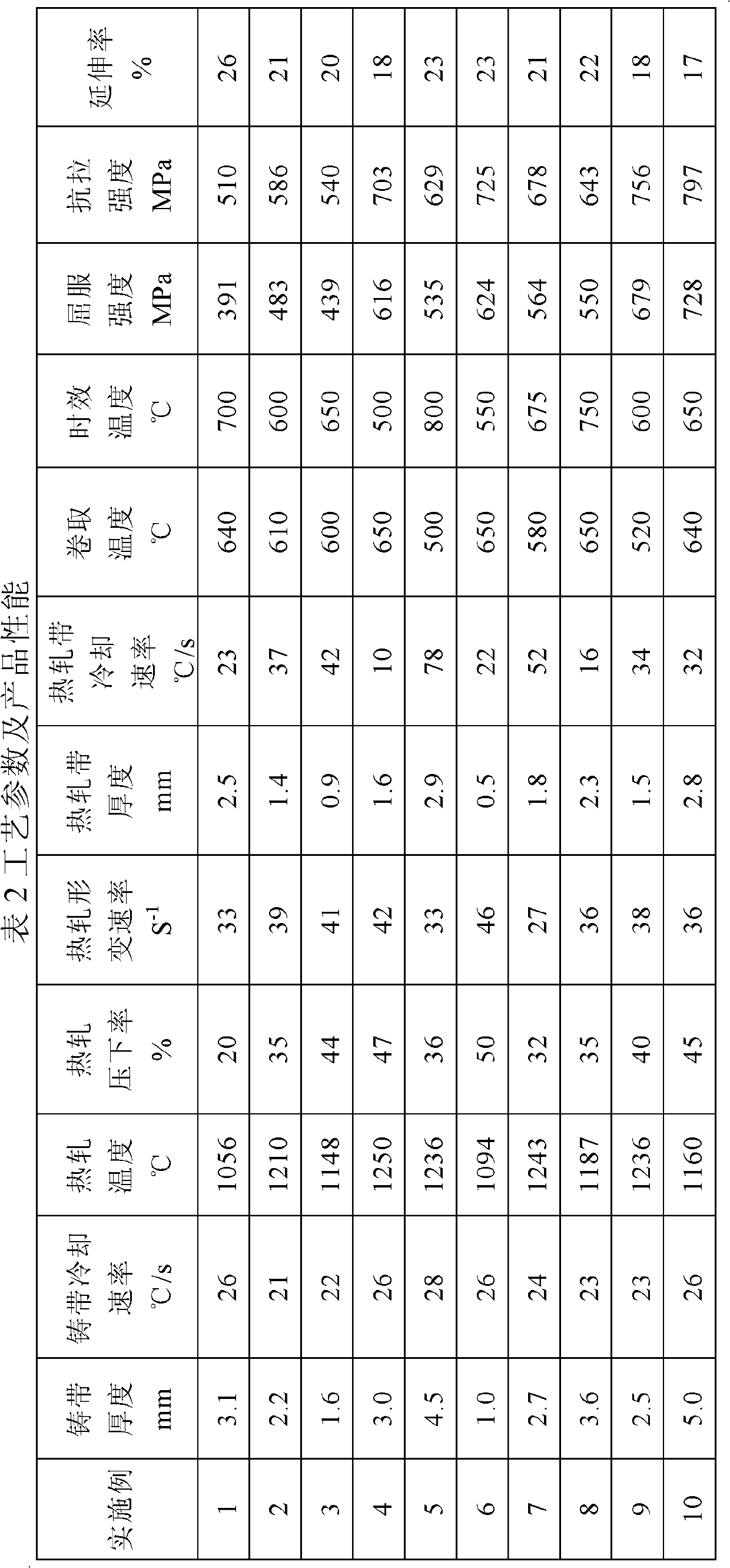

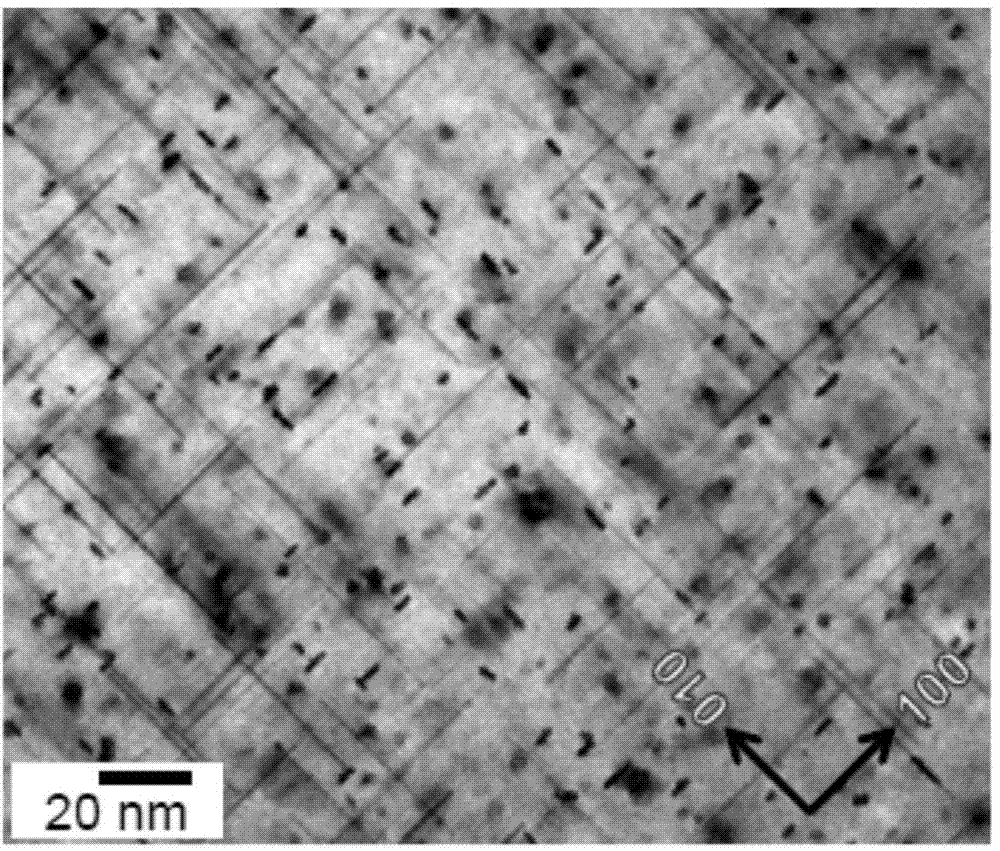

Manufacturing method of age-hardened thin-strip casting low-carbon microalloyed steel strip

The invention discloses a manufacturing method of age-hardened thin-strip casting low-carbon microalloyed steel strip. The method comprises the following steps of: 1) smelting, and continuously casting a thin strip, wherein the weight percents of the components are as follows: 0.01-0.25% of C, not more than 0.4% of Si, 0.6-2.0% of Mn, not more than 0.015% of P, not more than 0.01% of S, not more than 0.006% of N, not more than 0.008% of O, 0.0005-0.004% of B, 0.005-0.1% of Nb, 0.005-0.1% of V, 0.005-0.1% of Ti, and 0.05-0.5% of Mo, and the balance of Fe and unavoidable impurities, and the casting thickness in the dual-roller continuous casting machine is 1-5mm; 2) cooling the cast strip, wherein the cooling rate is more than 20DEG C / s; 3) hot-rolling at 1050-1250 DEG C, wherein the reduction rate is 20-50%, and the deformation rate is more than 20s-1; 4) cooling, wherein the cooling rate is 10-80DEG C / s; 5) reeling at 550-700 DEG C; 6) performing age-hardening treatment, wherein the age-hardening temperature is 500-800 DEG C, and the heating time is 0.1-30 minutes. The austenite online recrystallization of the cast strip after hot-rolling is realized, the obtained steel strip is provided with uniformly distributed bainite and acicular ferrite, the structure comprises nanoscale precipitation such niobium carbonitride, and a product has high strength and extensibility.

Owner:BAOSHAN IRON & STEEL CO LTD

Non-oriented silicon steel thin strip and preparation method thereof

ActiveCN101967602ALow iron lossImprove surface qualityProcess efficiency improvementChemical compositionEnergy consumption

The invention belongs to the field of metallurgical technology and material science and particularly relates to a non-oriented silicon steel thin strip and a preparation method thereof. The non-oriented silicon steel thin strip of the invention comprises the following chemical components in percentage by weight: 3.0 to 3.6 percent of Si, 0.6 to 1.0 percent of Al, 0.1 to 0.6 percent of Mn, less than or equal to 0.005 percent of N, less than or equal to 0.004 percent of S, less than or equal to 0.02 percent of P, less than or equal to 0.003 percent of O, less than or equal to 0.005 percent of C and the balance of Fe. The preparation method comprises: smelting non-oriented silicon steel in a vacuum smelting furnace; performing double roll thin strip casting and rolling; normalizing the cast strip at 1,100 to 1,150 DEG C for 3 to 5 minutes; preheating at 150 to 300 DEG C and performing cold rolling; and recrystallizing and annealing. The preparation method is simple in process, low in energy consumption, high in yield; and the magnetic performance of the product prepared by the method is high.

Owner:NORTHEASTERN UNIV

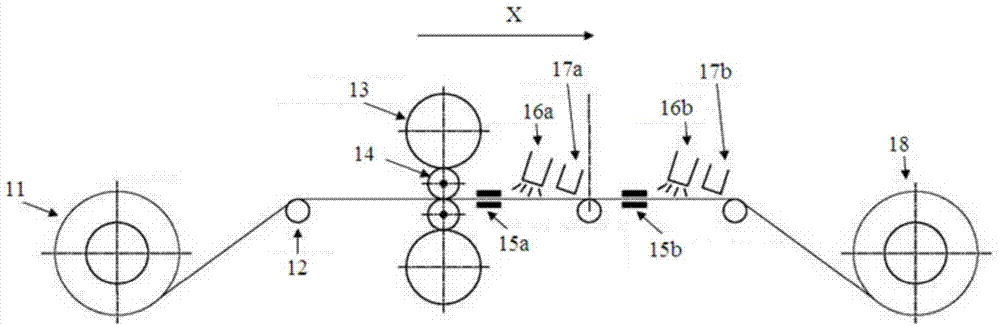

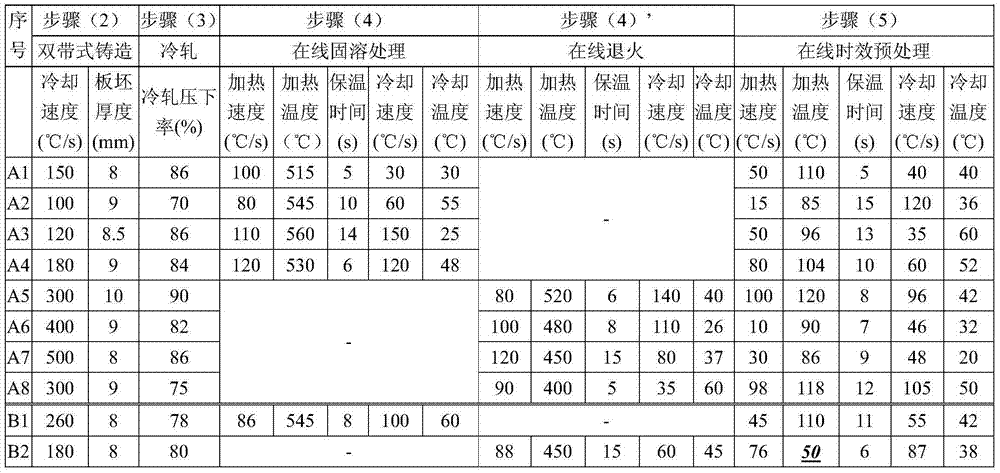

High-strength aluminum-alloy material, aluminum-alloy plate and manufacturing method thereof

The invention discloses a high-strength aluminum-alloy material. The high-strength aluminum-alloy material contains the chemical elements in percentage by mass: not lower than 1.5% and not higher than 3.0% of Mg, not lower than 0.05% and not higher than 0.2% of Si, not lower than 0.1% and not higher than 0.2% of Mn, not lower than 0.2% and not higher than 0.4% of Fe, higher than 0 and not higher than 0.03% of Cu, higher than 0 and not higher than 0.05% of Ti, either not lower than 0.05% and not higher than 0.15% of Ca or not lower than 0.05% and not higher than 0.15% of Sr and the balance of Al and other unavoidable impurities. The invention further discloses an aluminum-alloy plate manufactured from the aluminum-alloy material. The invention further discloses a manufacturing method of the aluminum-alloy plate, wherein the method comprises the steps of carrying out double-strip casting, carrying out cold rolling, carrying out online solid solution treatment and carrying out online aging pretreatment. The high-strength aluminum-alloy material and the aluminum-alloy plate, disclosed by the invention, have relatively high strength and good natural aging stability. After painting and baking, the yield strength of the high-strength aluminum-alloy material and the aluminum-alloy plate is higher than 300Mpa.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com