Multiple cooling methods integrated cooling system in strip casting process

A cooling method and cooling system technology, applied in the field of metallurgy, can solve problems such as complex process, reduced performance of finished products, and excessive grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A cooling system integrating multiple cooling modes in the thin strip continuous casting process of the present invention is described in conjunction with embodiments and accompanying drawings.

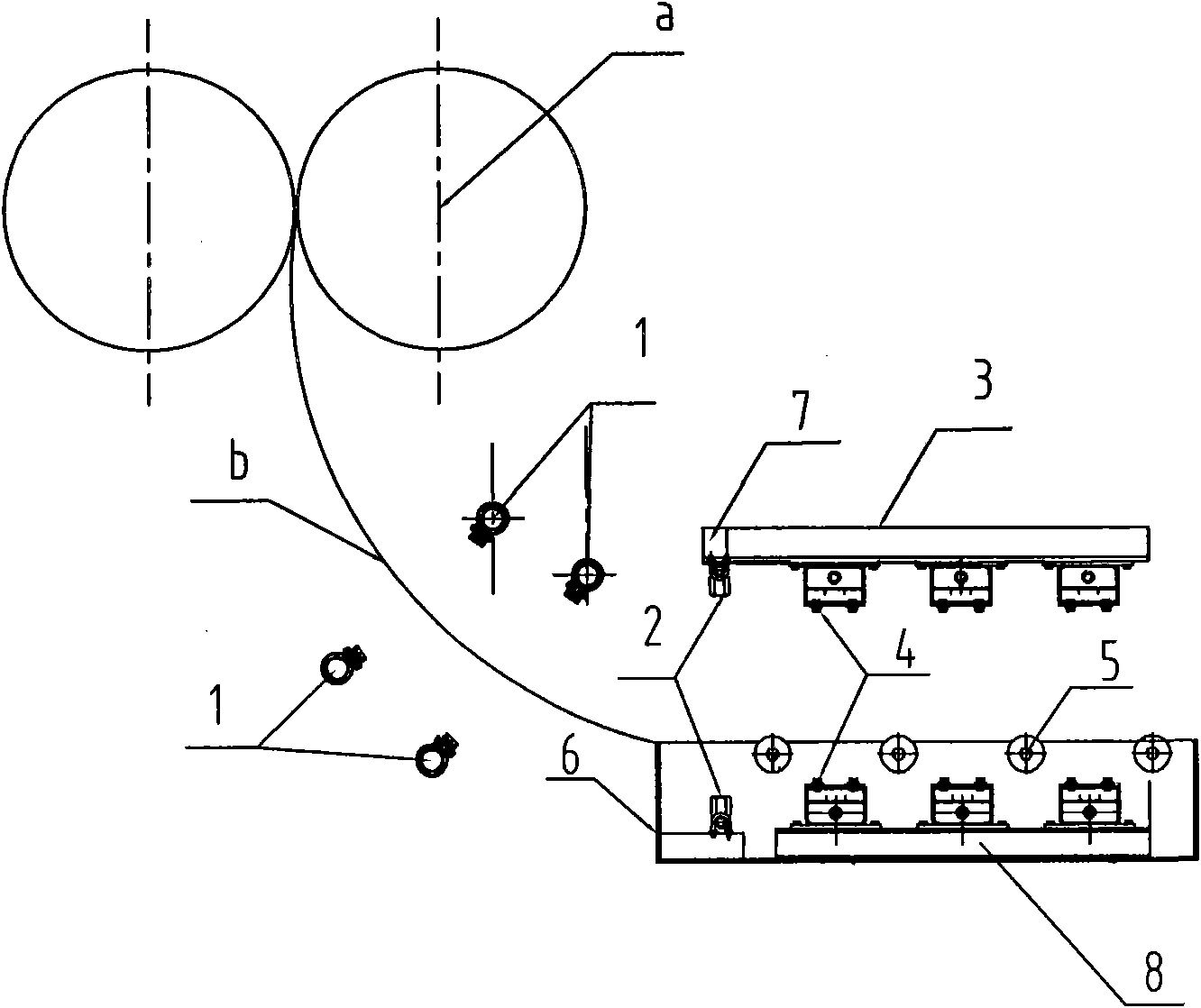

[0025] The system as figure 1 As shown, it includes an air mist cooling device 1, a water spray cooling device 4, a water mist spray gun 2, a water collection tank 6, a roller table 5, a beam 3 and a base 8;

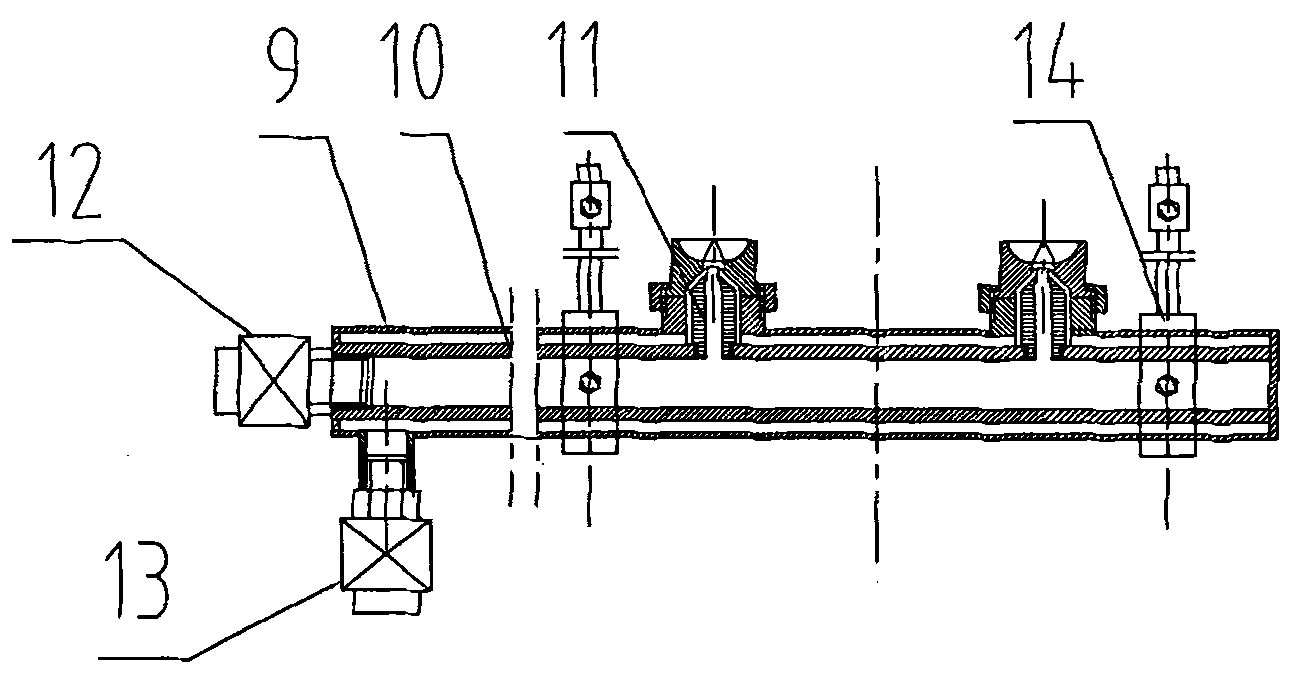

[0026] Air mist cooling device 1 such as figure 2 As shown, it includes a first water inlet pipe 9, a first air inlet pipe 10, an aerosol nozzle 11, a gas flow regulating valve 12, a first water flow regulating valve 13 and a mounting bracket 14;

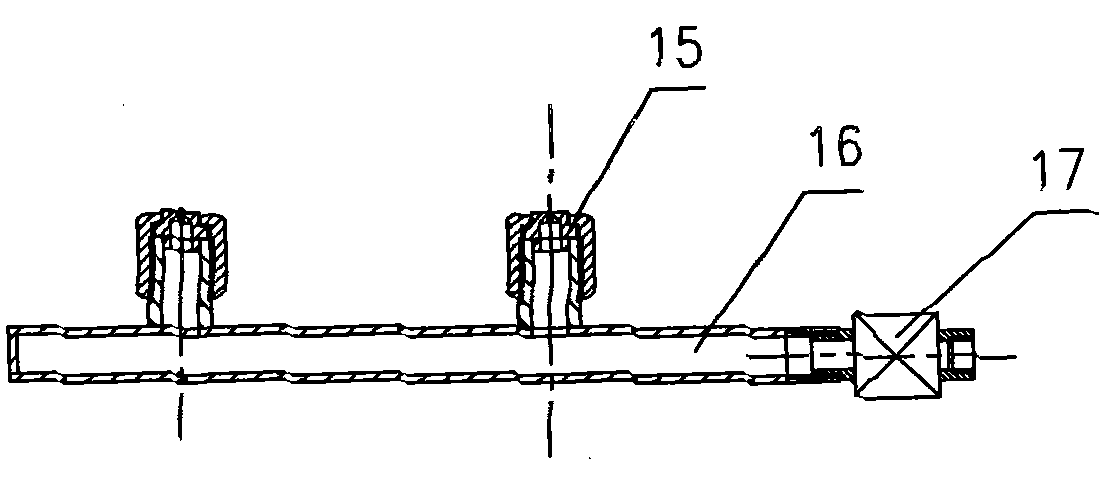

[0027] Water mist spray gun 2 such as image 3 As shown, it includes a nozzle 15, a second water inlet pipe 16 and a second water flow regulating valve 17;

[0028] As shown in Figure 4 (a), Figure 4 (b) and Figure 4 (c), the water spray cooling device 4 includes a housing 22, a third water inlet pipe 18, a shunt pipe 19, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com