Method for controlling side seal of twin roll thin strip casting and device

A technology of twin-roll thin strip continuous casting and control method, which is applied in the field of continuous casting technology, can solve problems such as tearing of the edge cast strip, deformation and thickening of the edge of the cast strip, failure, etc., to achieve improved stability and control method Reliable, method-proven results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with embodiment:

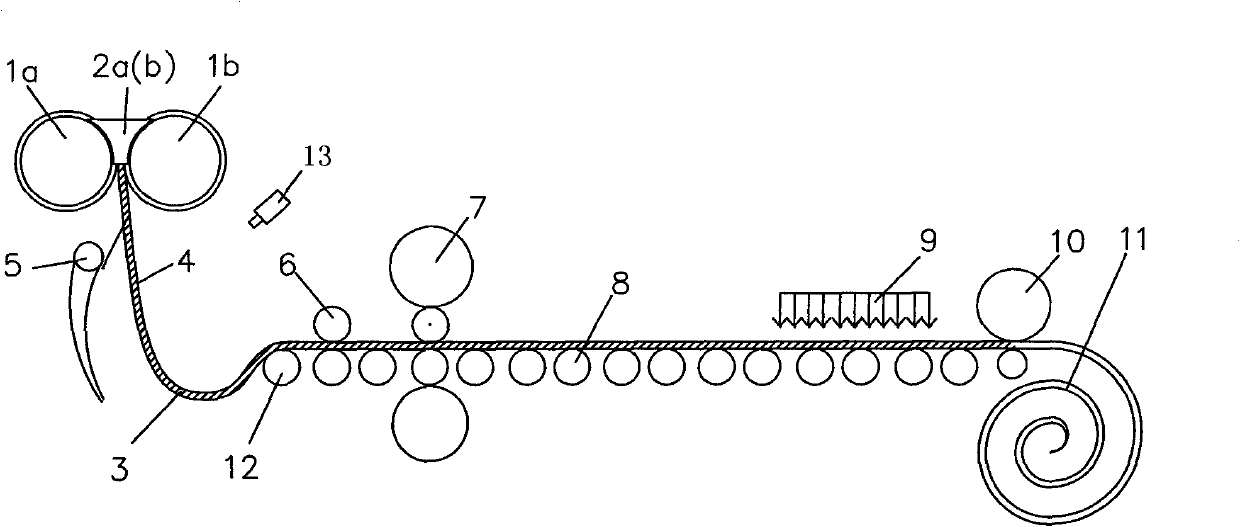

[0046] see Figure 4 , the twin-roll thin strip continuous casting side sealing control device of the present invention, which includes a side sealing plate support system B, and a casting belt edge quality control system A;

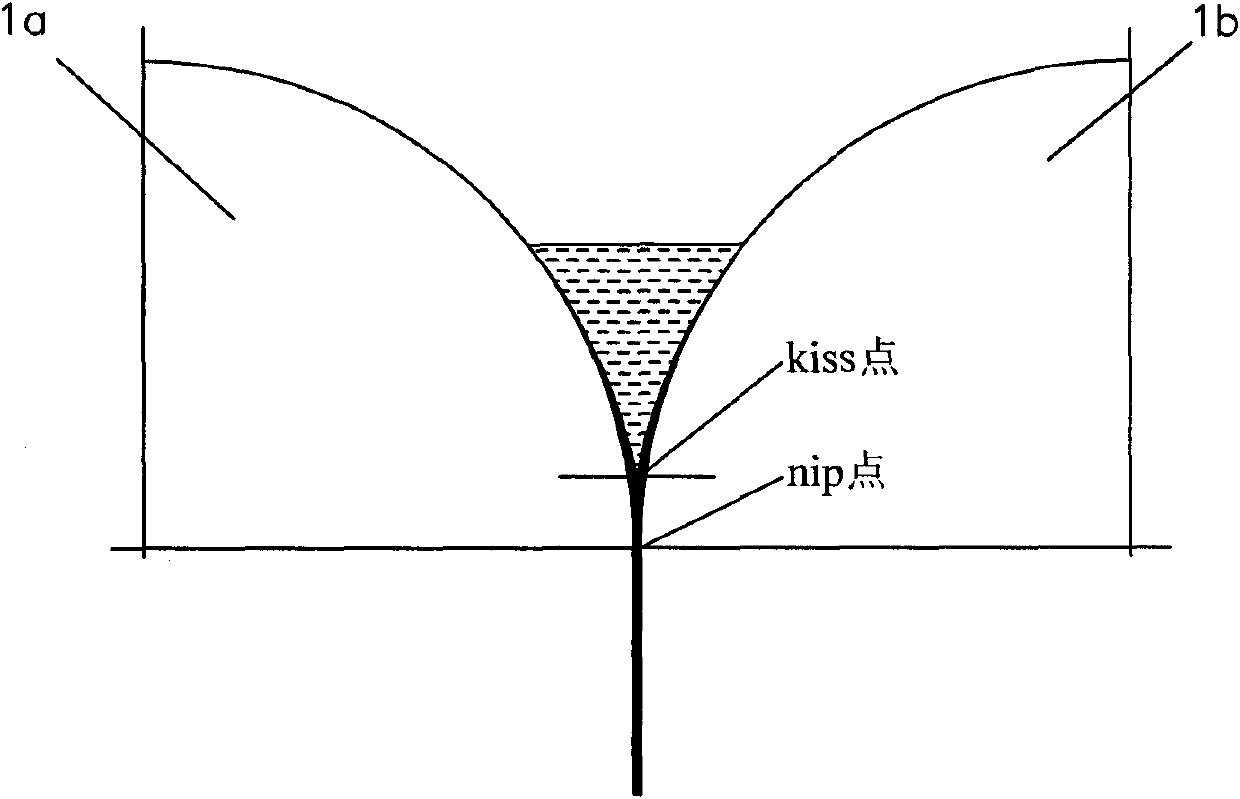

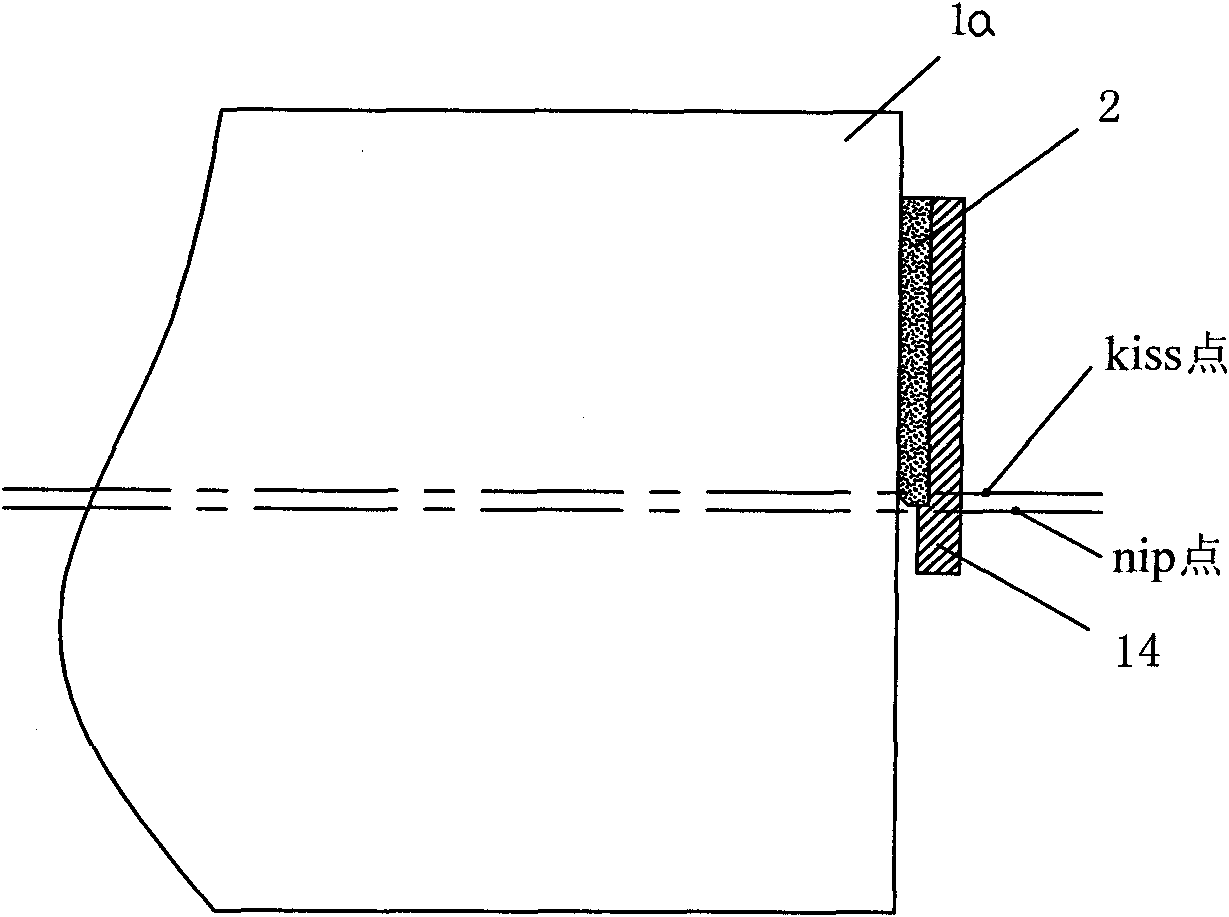

[0047] Wherein, the side sealing plate support system B includes, the supporting plate 14, which is a box structure with one side opening, and the side sealing plate 2b (2a) is placed on the opening side of the supporting plate; the first hydraulic cylinder 15, the front end of the piston rod is vertical Connect the support plate 14 to control the horizontal displacement of the support plate 14. A displacement sensor 16 is arranged at the rear of the first hydraulic cylinder; the front end of the piston rod of the second hydraulic cylinder 18 is connected to the top clamping plate through a connecting block, and the piston rod and the support plate 14 are arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com