Weather resisting steel produced by strip casting and production method thereof

A technology for atmospheric corrosion-resistant steel and a production method, which is applied to the production of atmospheric corrosion-resistant steel by thin strip continuous casting and its production field, can solve the problems of slow solidification and cooling speed, anisotropy of cast slabs, sacrificing weather resistance and the like, and achieves the production method. Simple and economical, low cost of production, effect of avoiding carbides and inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

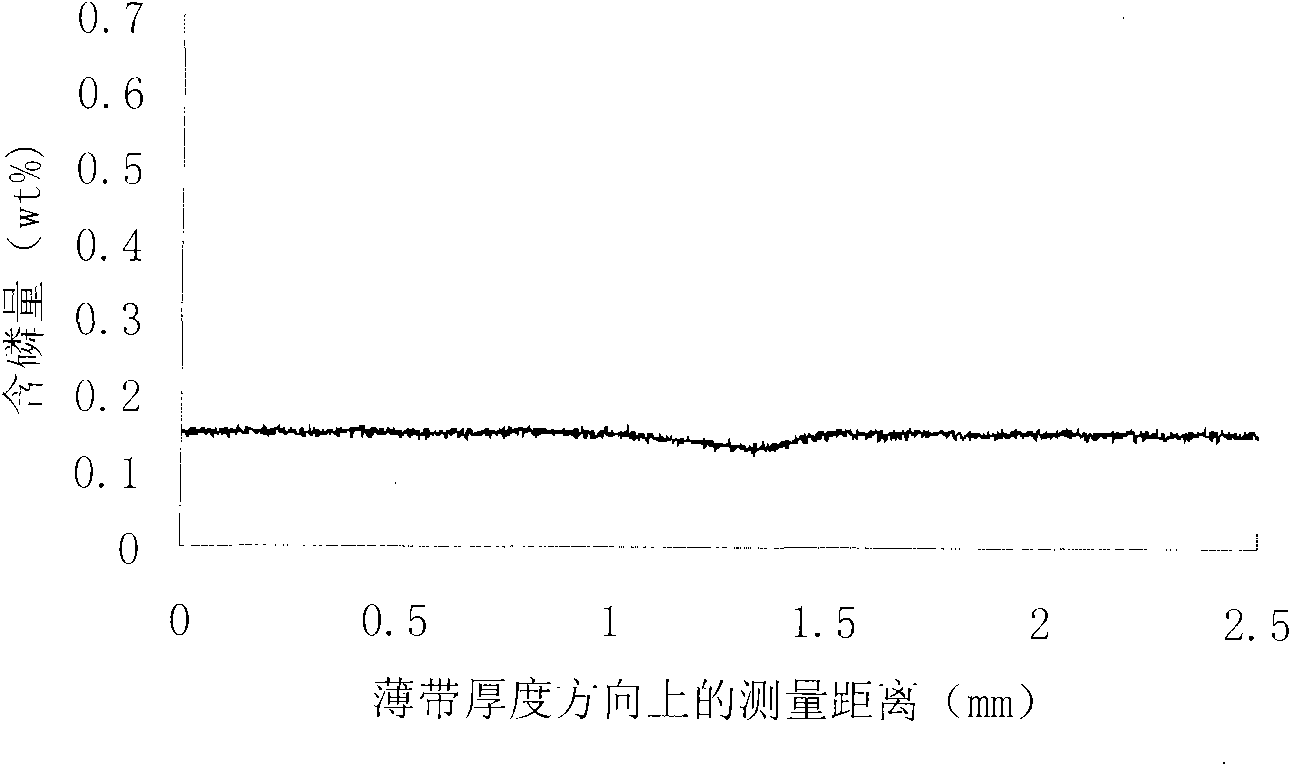

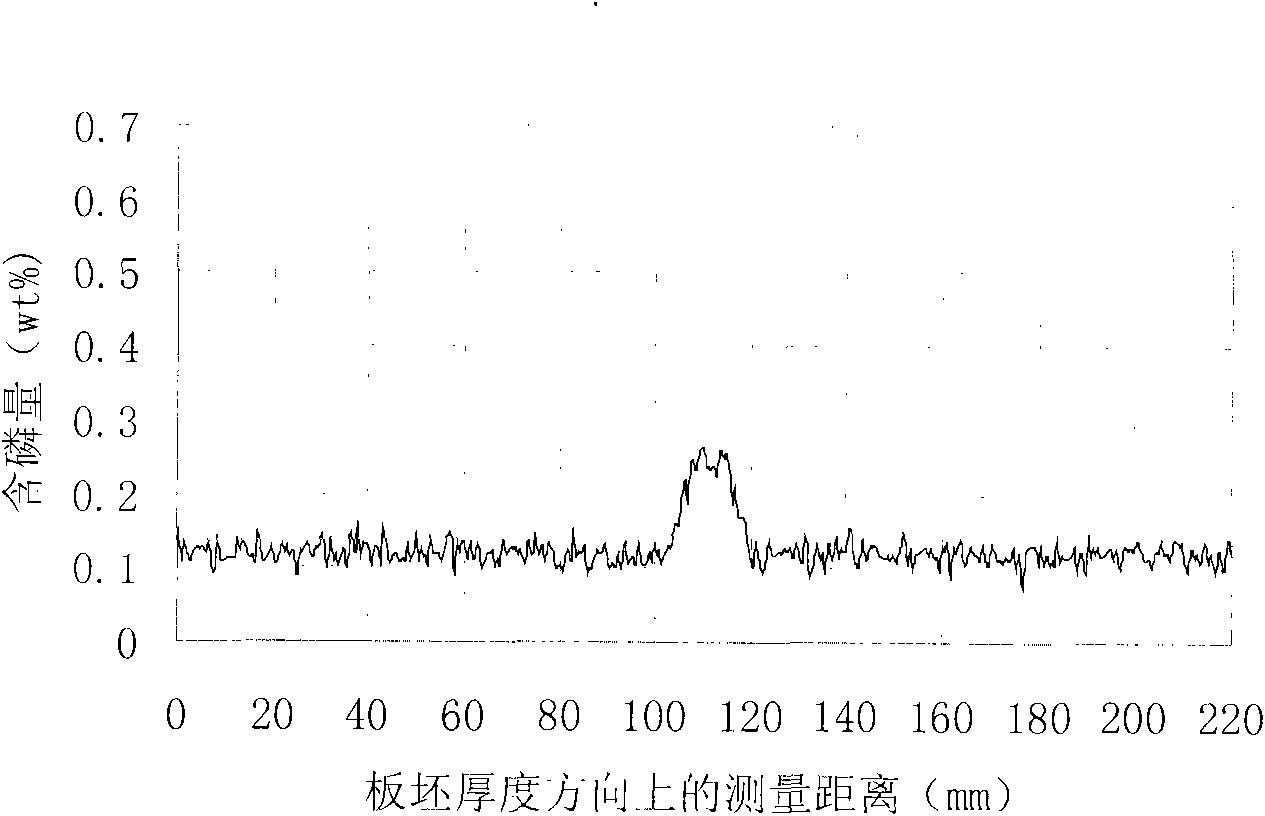

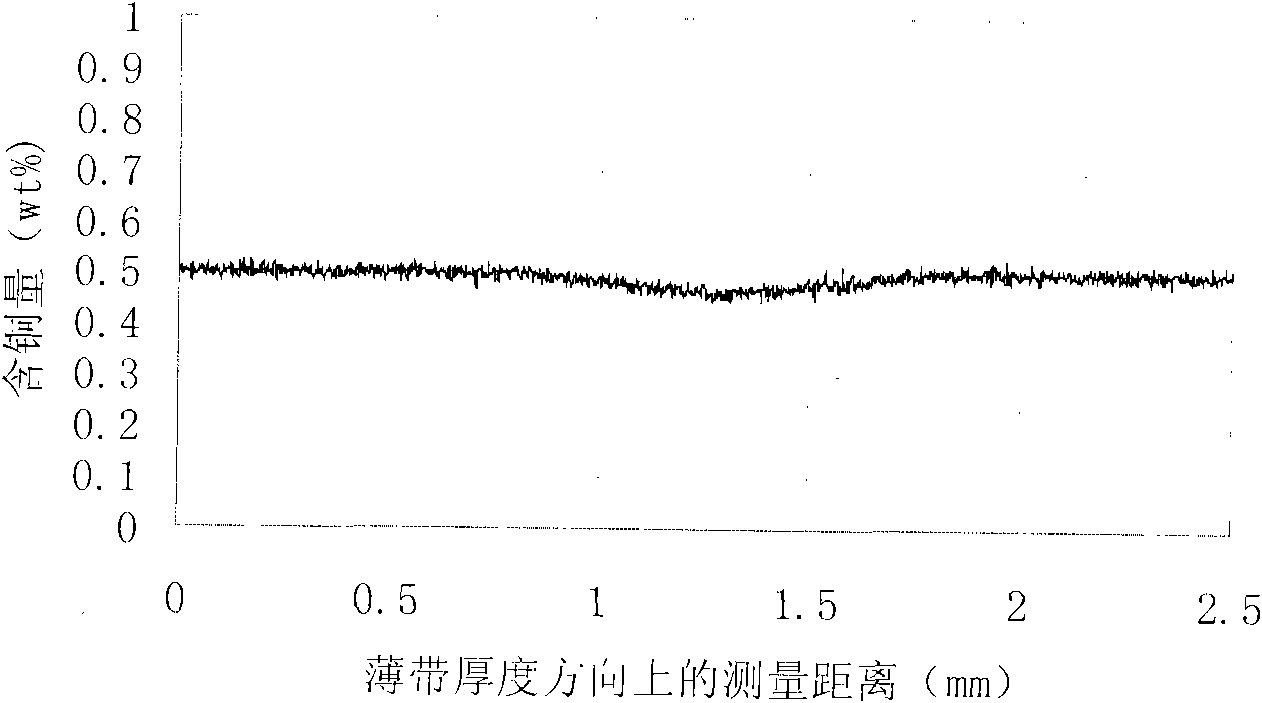

[0047] Table 2 is an example of the present invention. The molten steel smelted in accordance with the above chemical composition is continuously cast to form a 4mm cast strip, which is formed into a 2.5mm thick thin strip by on-line hot rolling at a reduction rate of 37.5%. During the thin strip casting process, the cooling rate of the molten steel contacting the surface of the crystal roll of the twin roll caster is 300°C / s.

[0048] Table 2 Unit: mass percentage

[0049]

Embodiment 2

[0051] A cast strip with a thickness of 2 mm is formed, and a thin strip with a thickness of 1.4 mm is formed by on-line hot rolling at a reduction ratio of 30%. During the thin strip casting process, the cooling rate of the molten steel contacting the surface of the crystal roll of the twin roll caster is 500°C / s.

Embodiment 3

[0053] A cast strip with a thickness of 2.7mm is formed, and a thin strip with a thickness of 1.5mm is formed by on-line hot rolling at a reduction ratio of 45%. During the thin strip casting process, the cooling rate of the molten steel contacting the surface of the crystal roll of the twin roll caster is 1000°C / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com