High-carbon martensitic stainless steel and a production method therefor

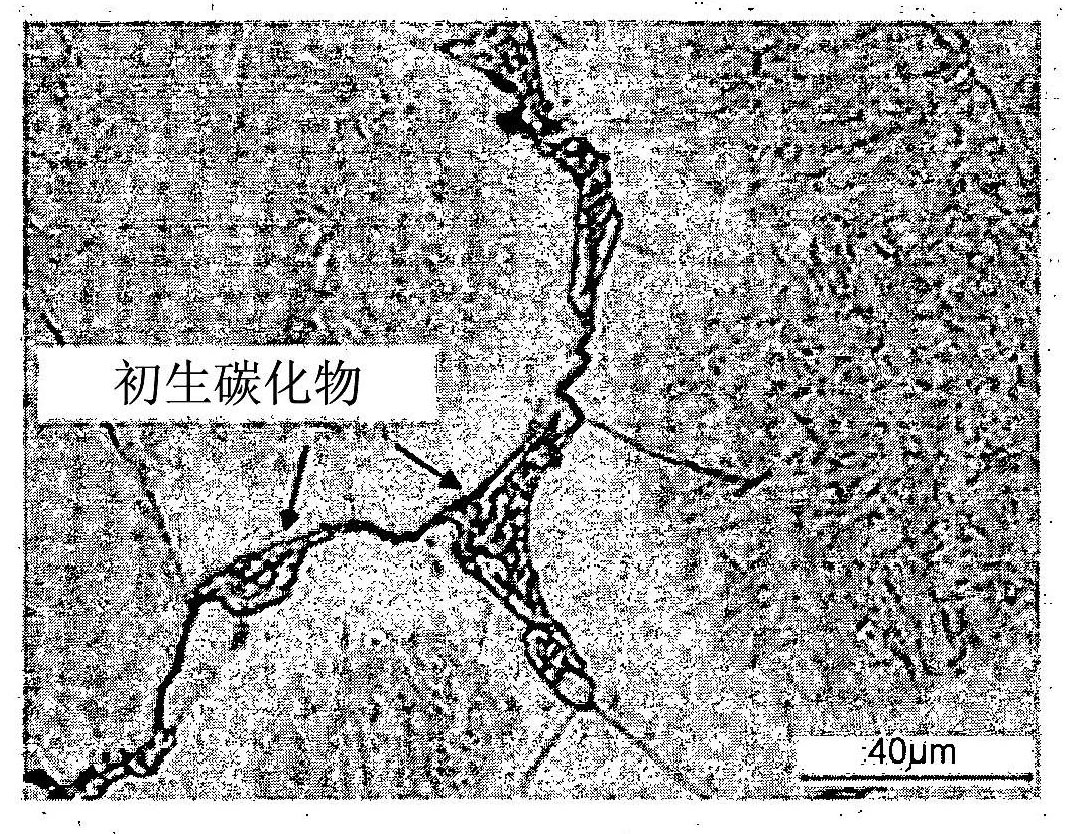

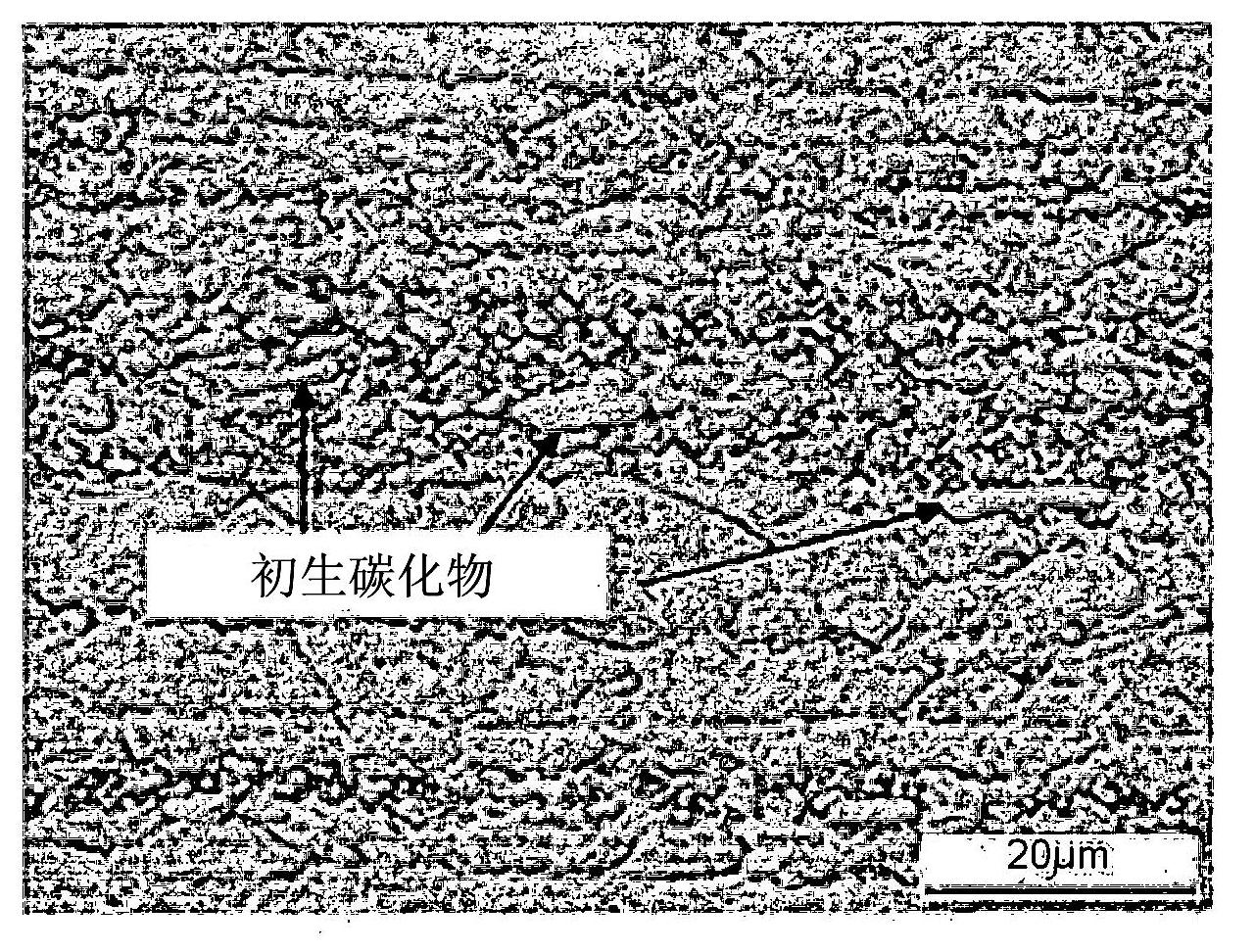

A manufacturing method and technology of stainless steel, applied in the field of high-carbon martensitic stainless steel, can solve the problems of coarse primary carbides and serious segregation, and achieve the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

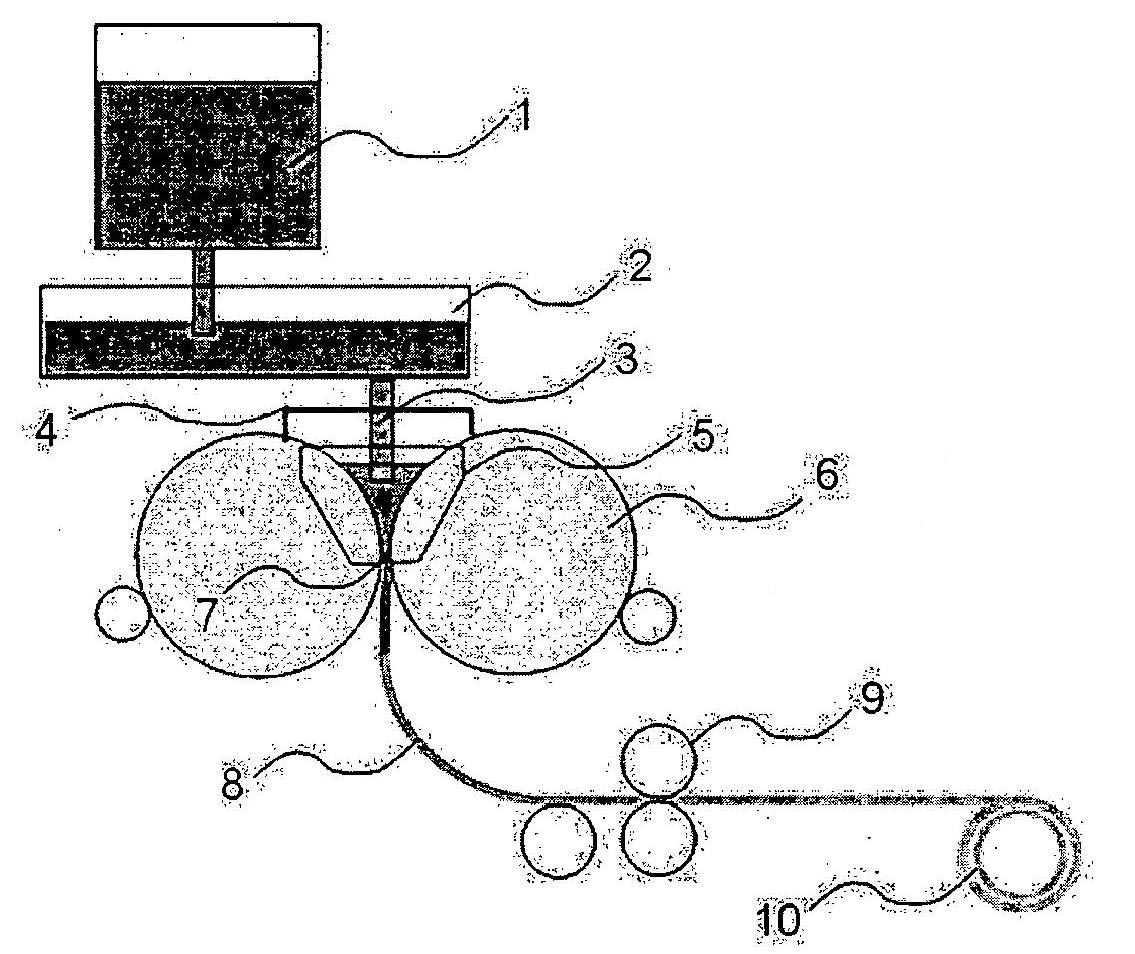

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, embodiments of the present invention and other necessary items will be described in detail with reference to the drawings so that those skilled in the art can easily understand the content of the present invention. However, the present invention can be implemented in various forms without departing from the scope of protection required by the claims, and therefore, the embodiments described below are illustrative regardless of whether they are expressed or not.

[0036] When describing the present invention, when it is considered that a specific description of a related known function or configuration may obscure the gist of the present invention, the detailed description will be omitted. In addition, it should be noted that in the drawings, the same components are denoted by the same reference numerals and signs as much as possible even though they are shown in different drawings. Furthermore, the thickness or size of each layer in the drawings may be exag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com