Patents

Literature

75results about How to "Low iron-loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grain-oriented electrical steel sheet and method of manufacturing the same

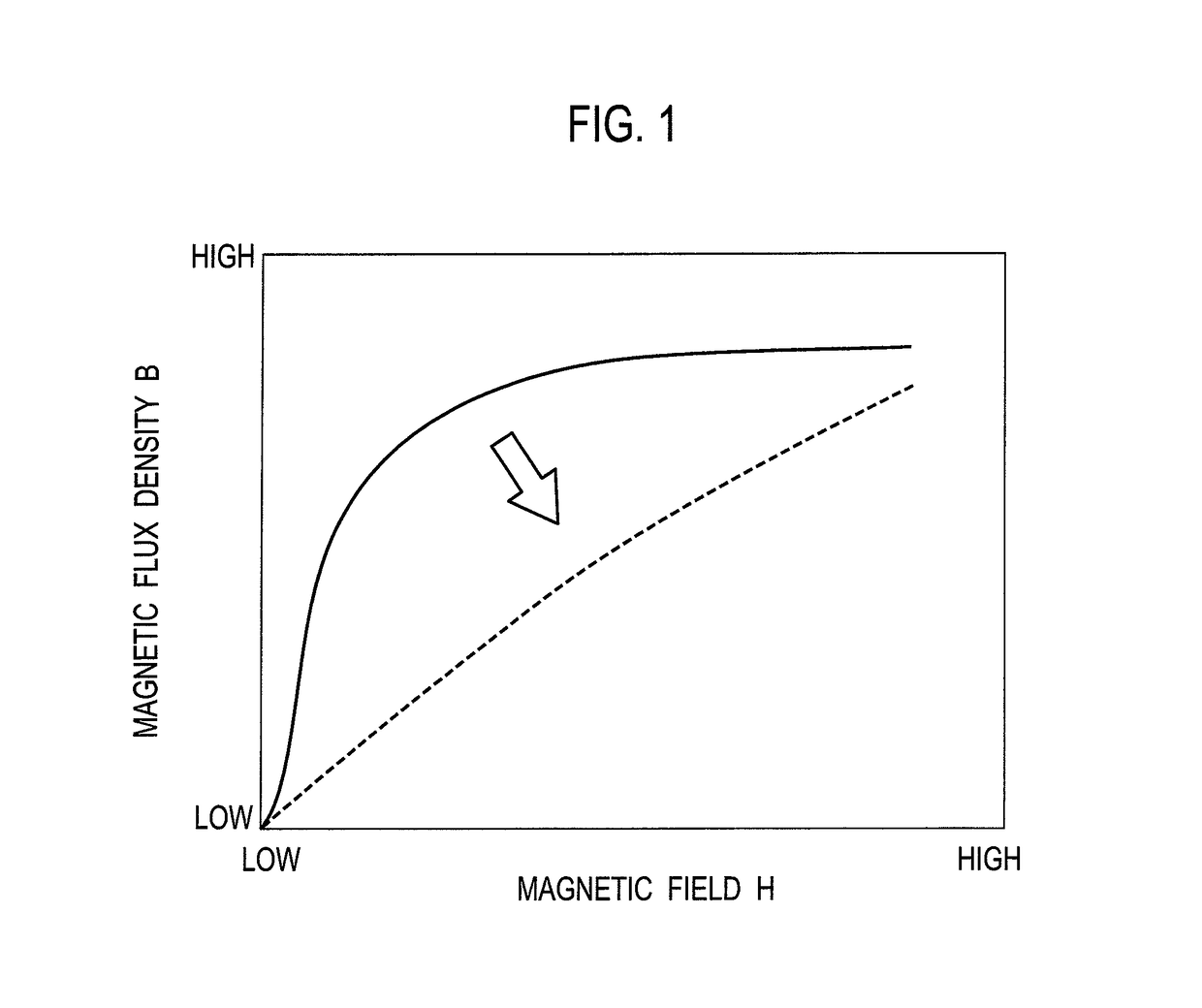

ActiveUS20130139932A1Low iron-lossInorganic material magnetismMagnetic core manufactureElectrical steelSheet steel

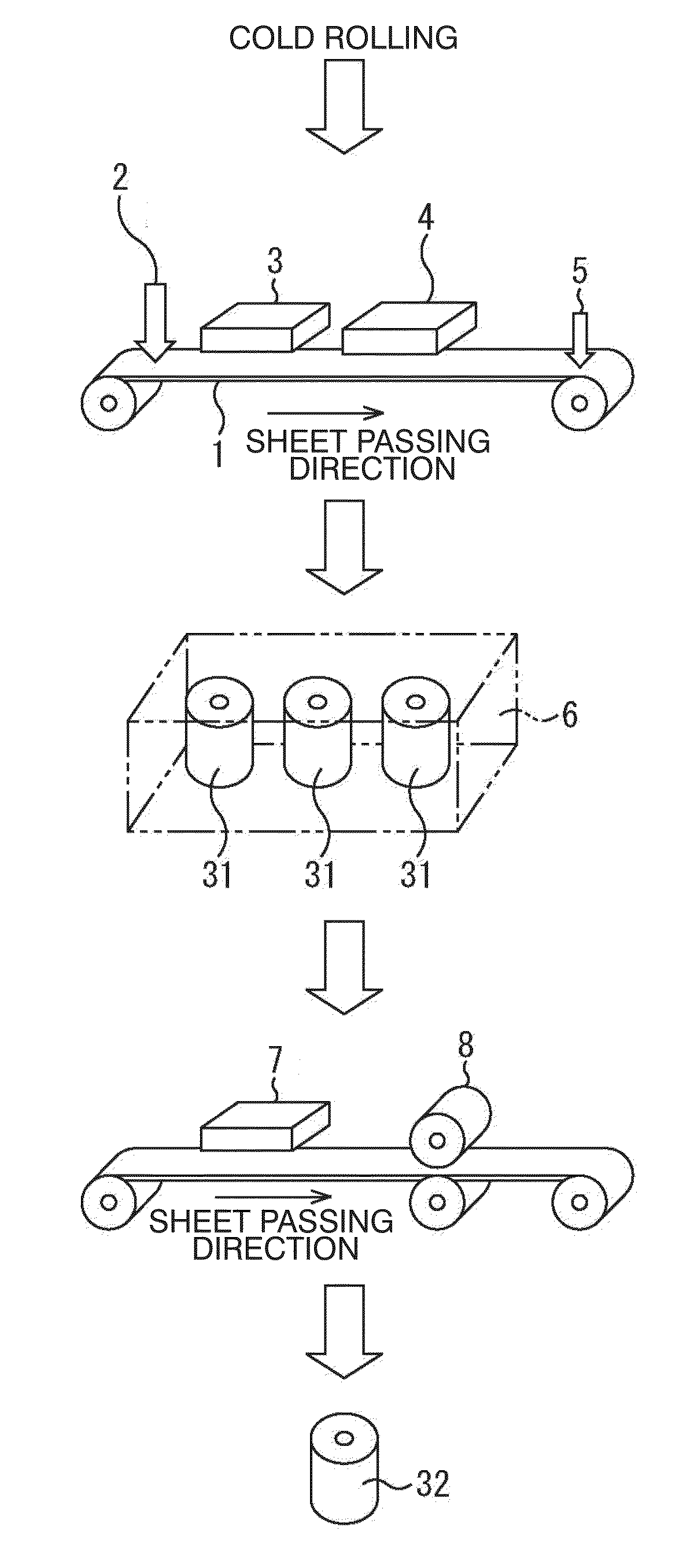

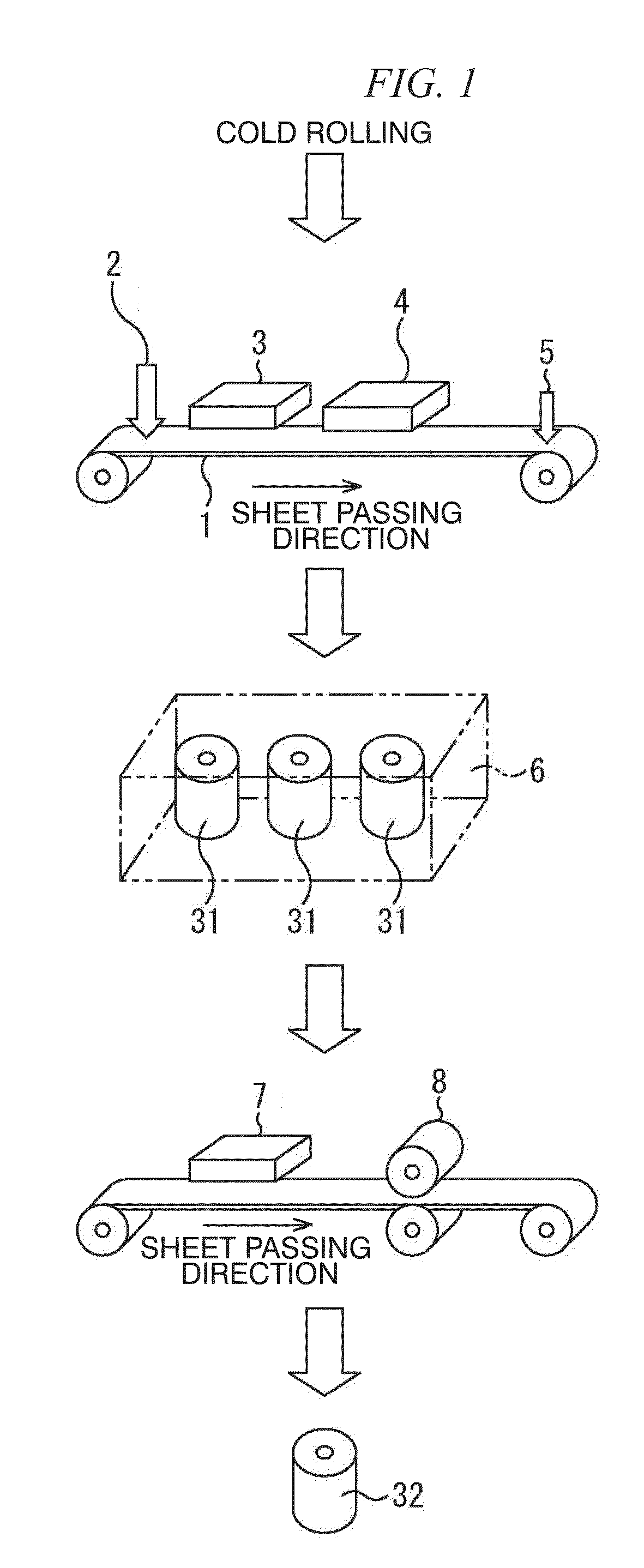

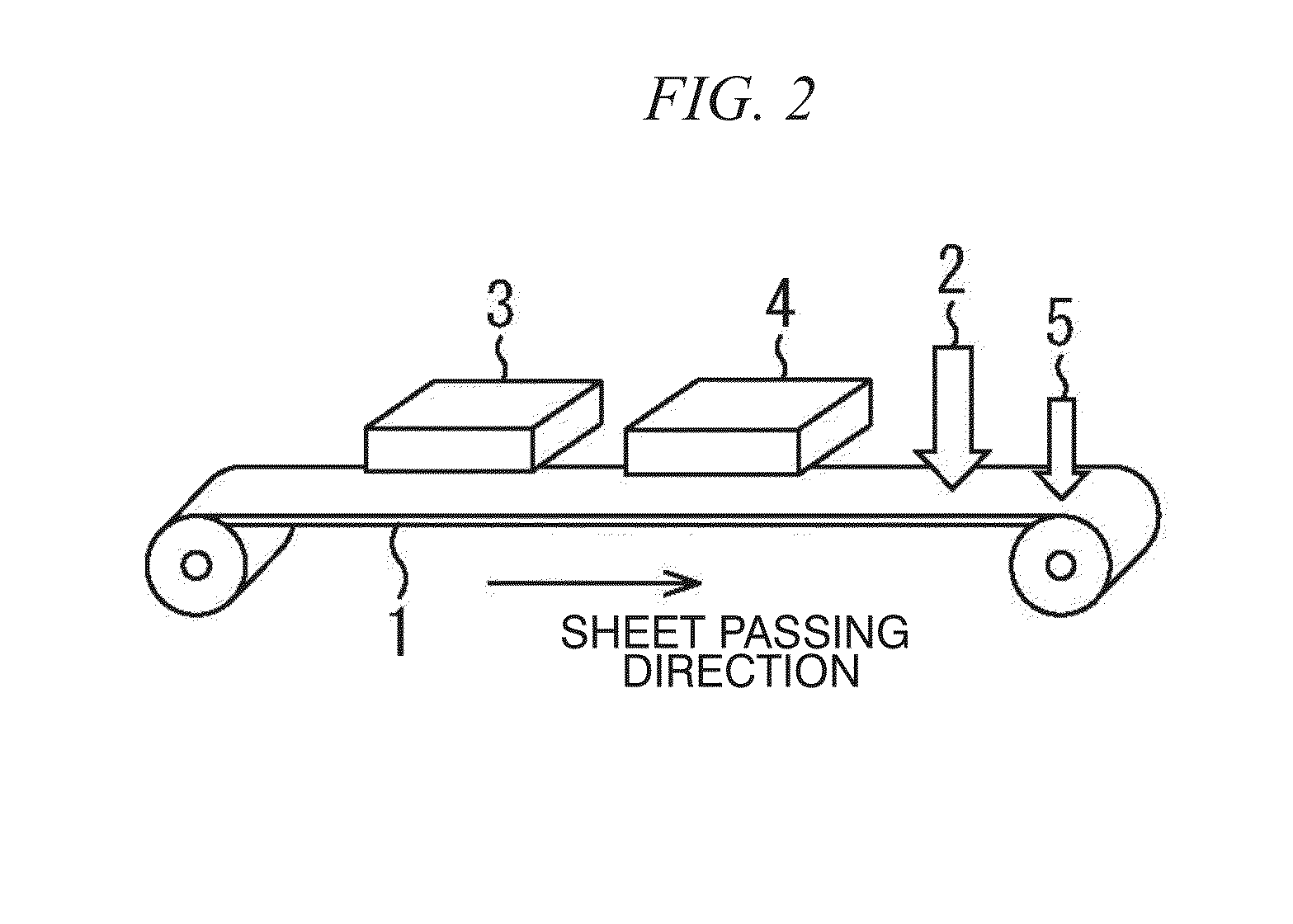

This method of manufacturing a grain-oriented electrical steel sheet includes, between a cold rolling process and a winding process, a groove formation process of irradiating the surface of a silicon steel sheet with a laser beam multiple times at predetermined intervals in a sheet passing direction, over an area from one end edge to the other end edge, in a sheet width direction of the silicon steel sheet, thereby forming a groove along a locus of the laser beam.

Owner:NIPPON STEEL CORP

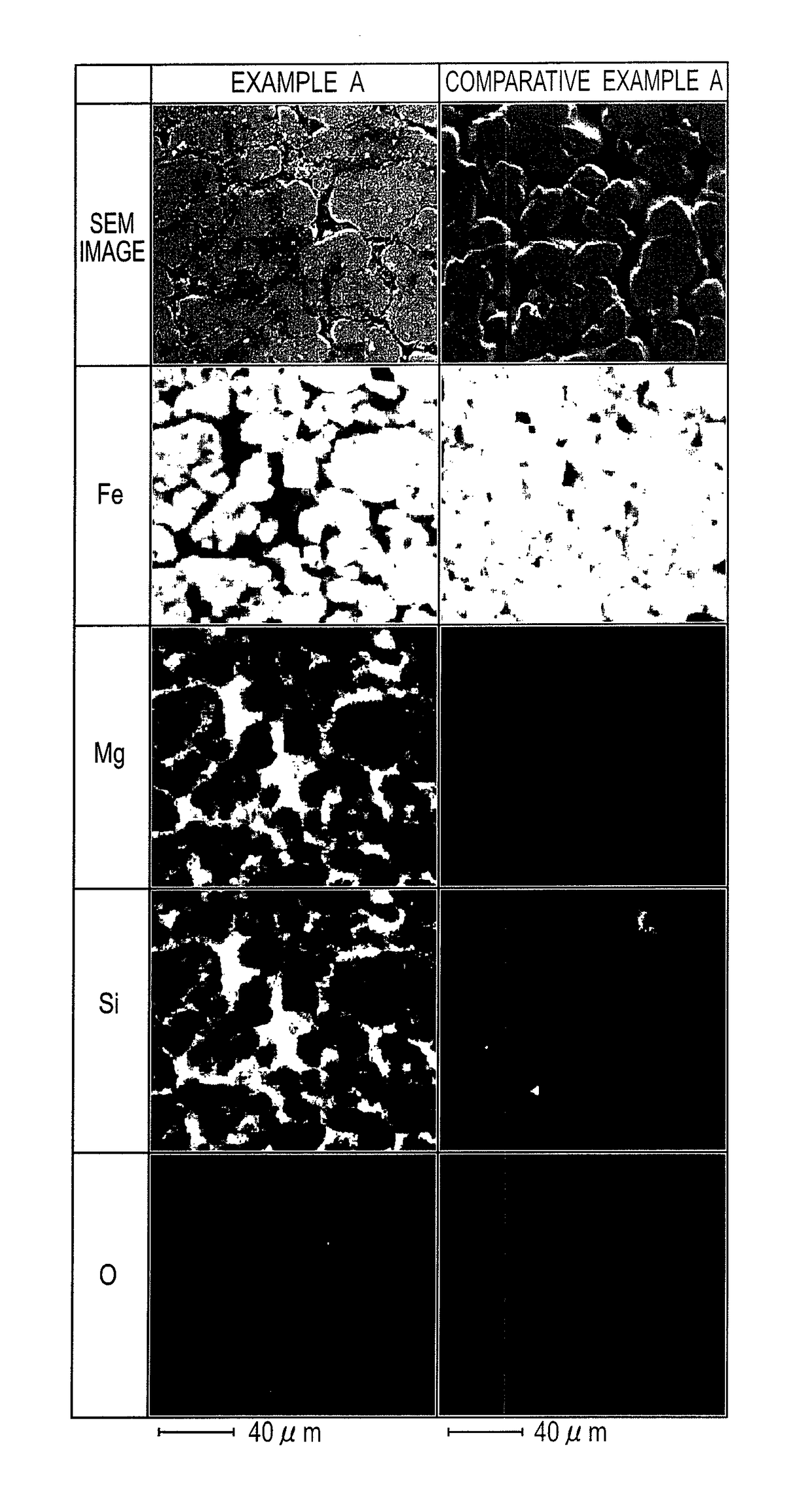

Method for Producing Soft Magnetic Metal Powder Coated With Mg-Containing Oxide Film and Method for Producing Composite Soft Magnetic Material Using Said Powder

InactiveUS20080003126A1High magnetic flux densityLow iron-lossTransportation and packagingMetal-working apparatusMetal powderThermal treatment

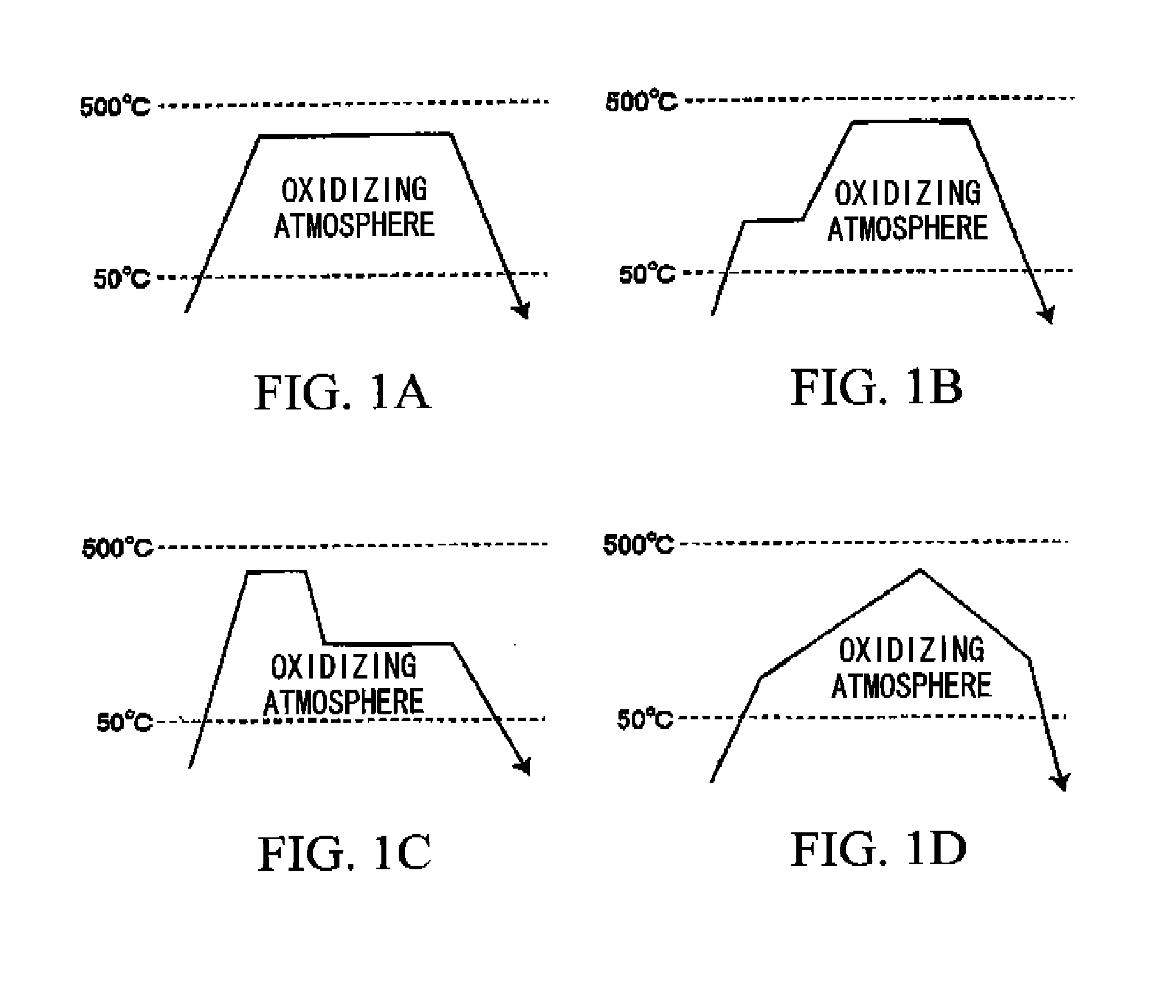

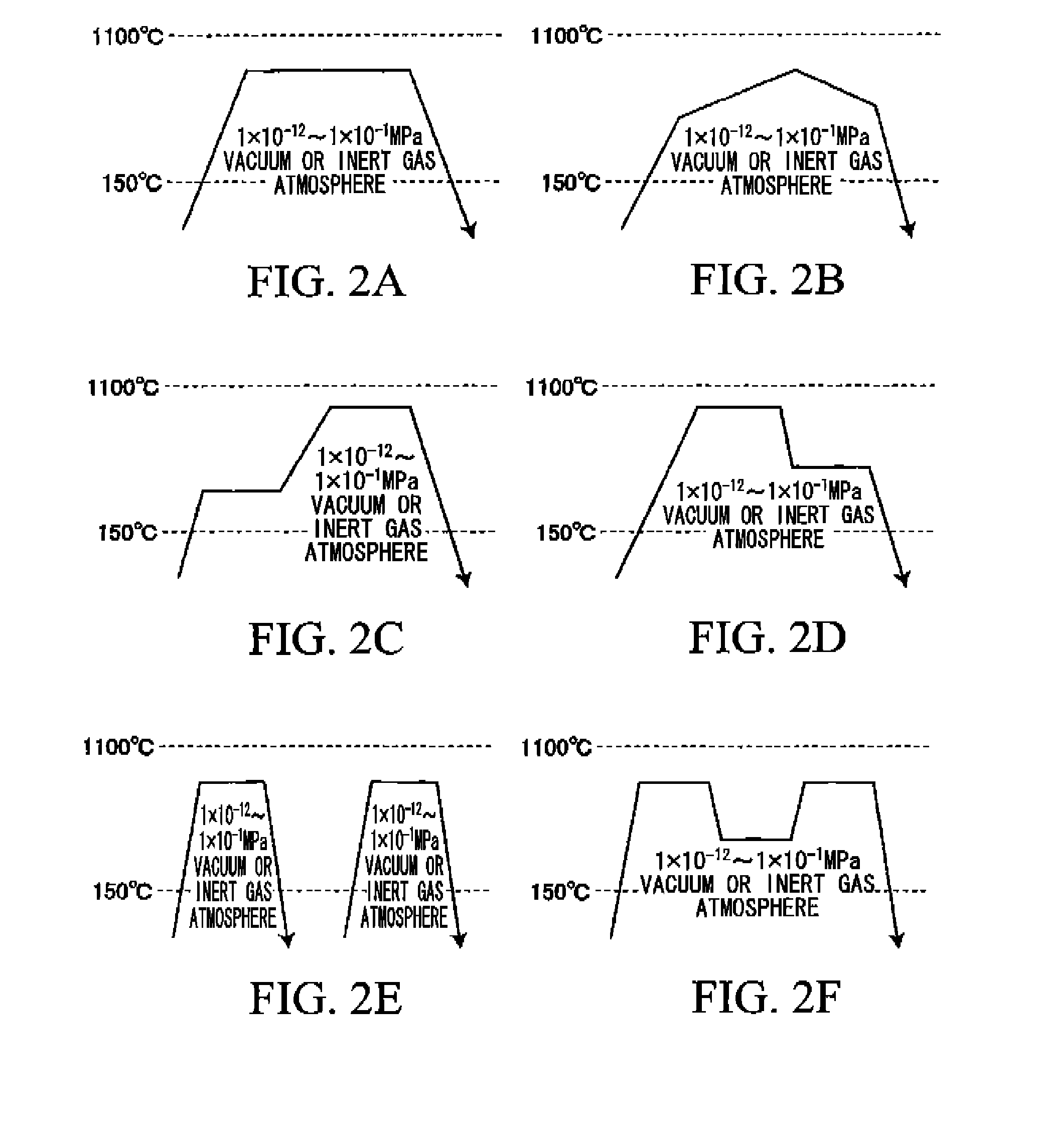

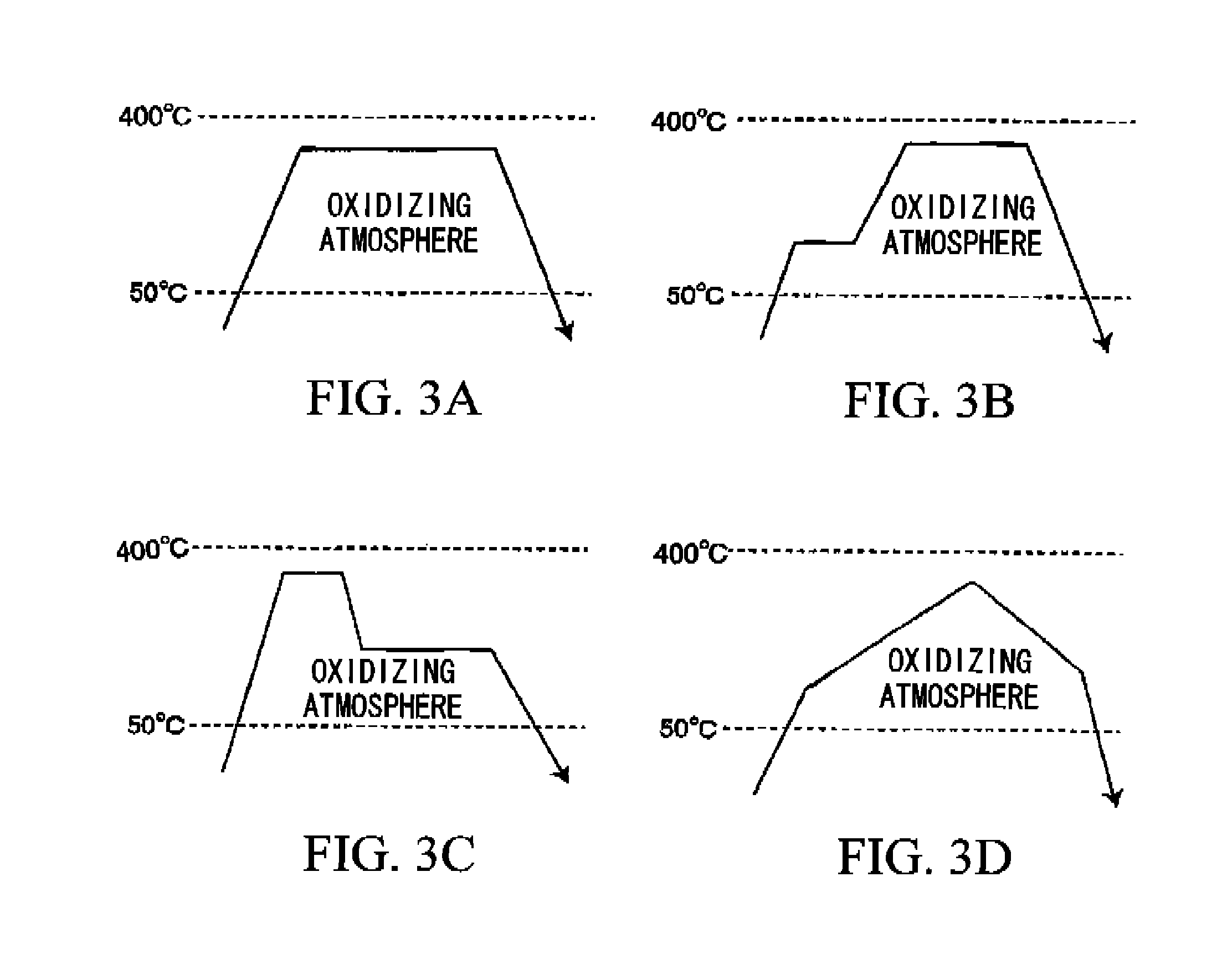

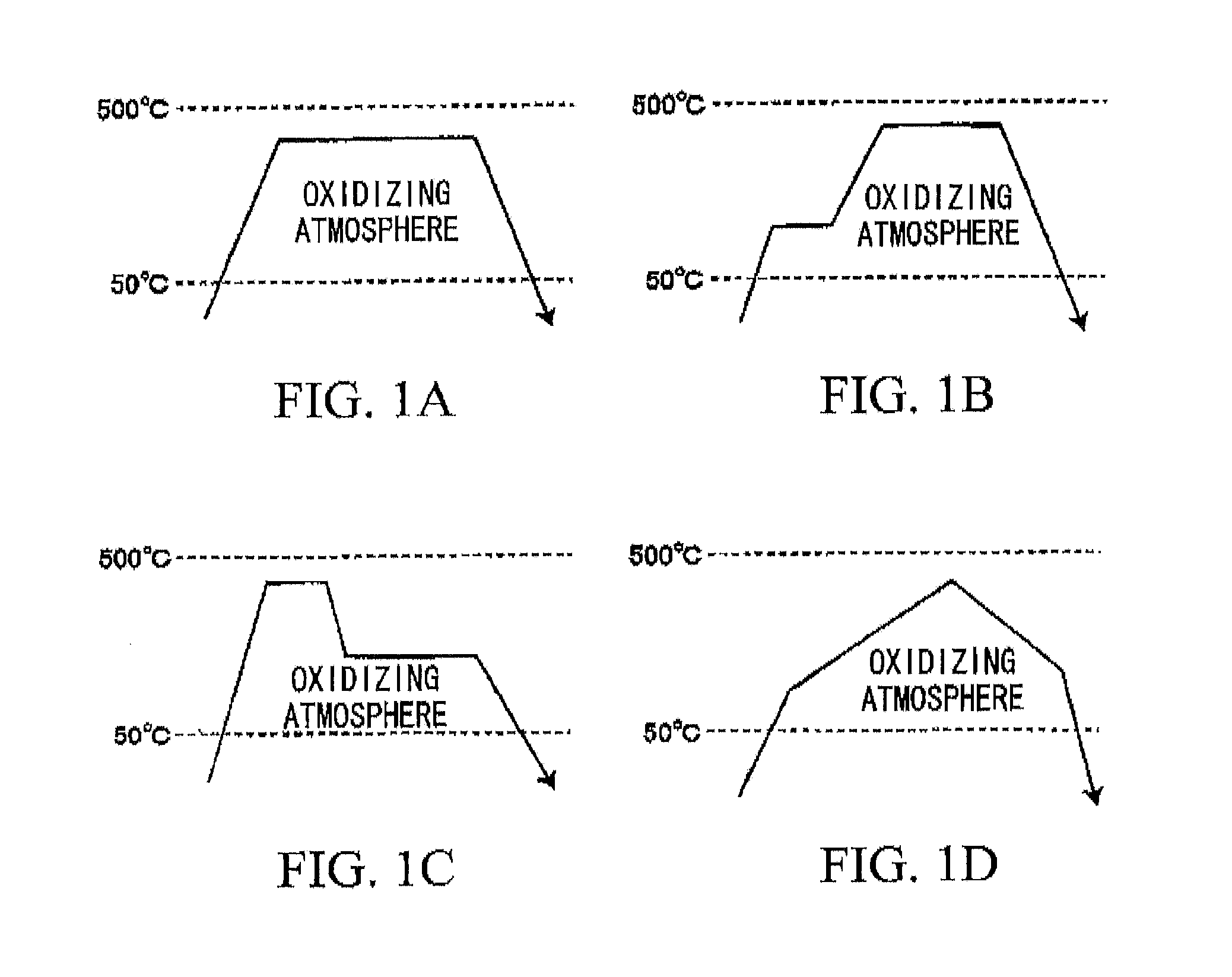

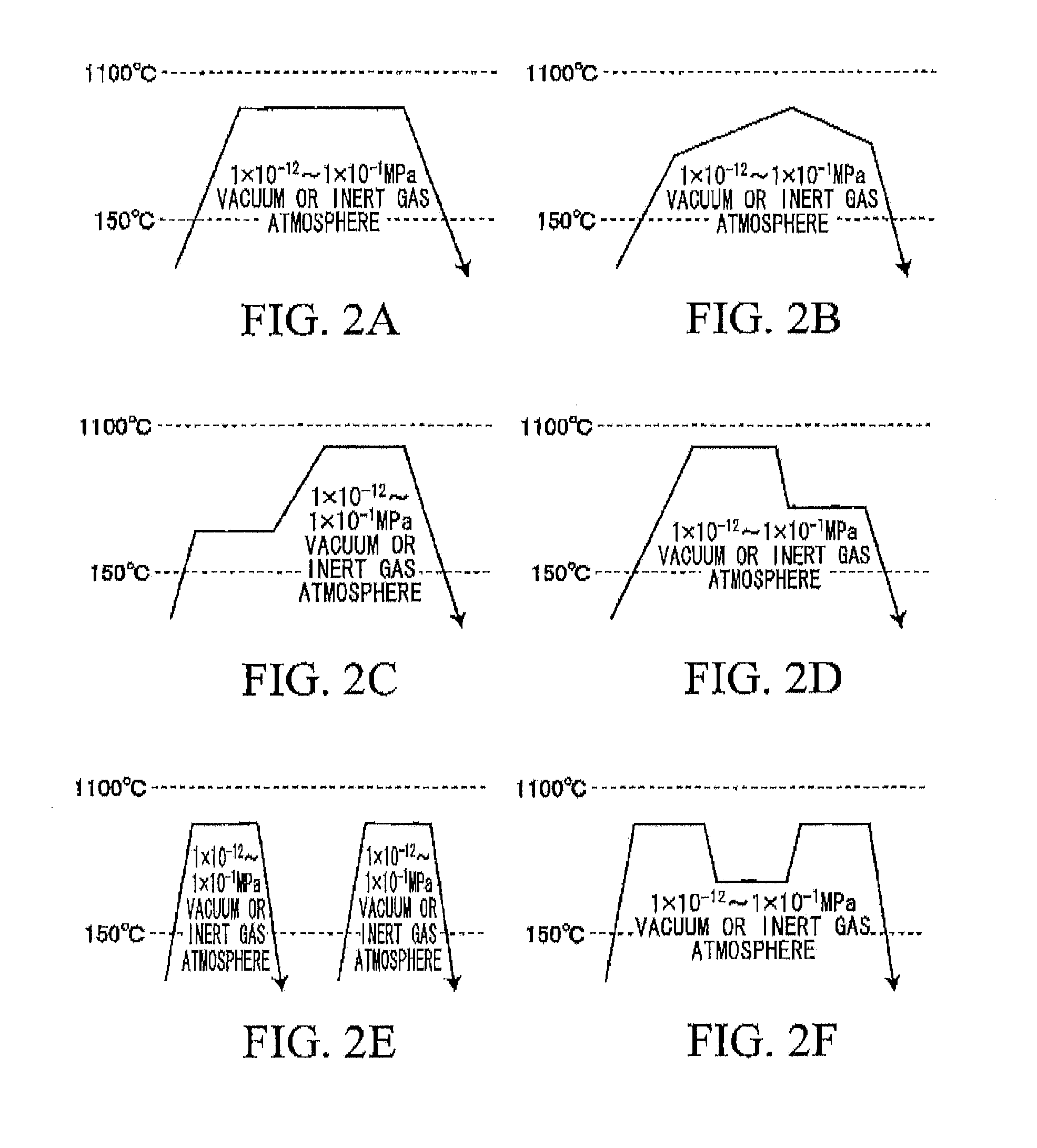

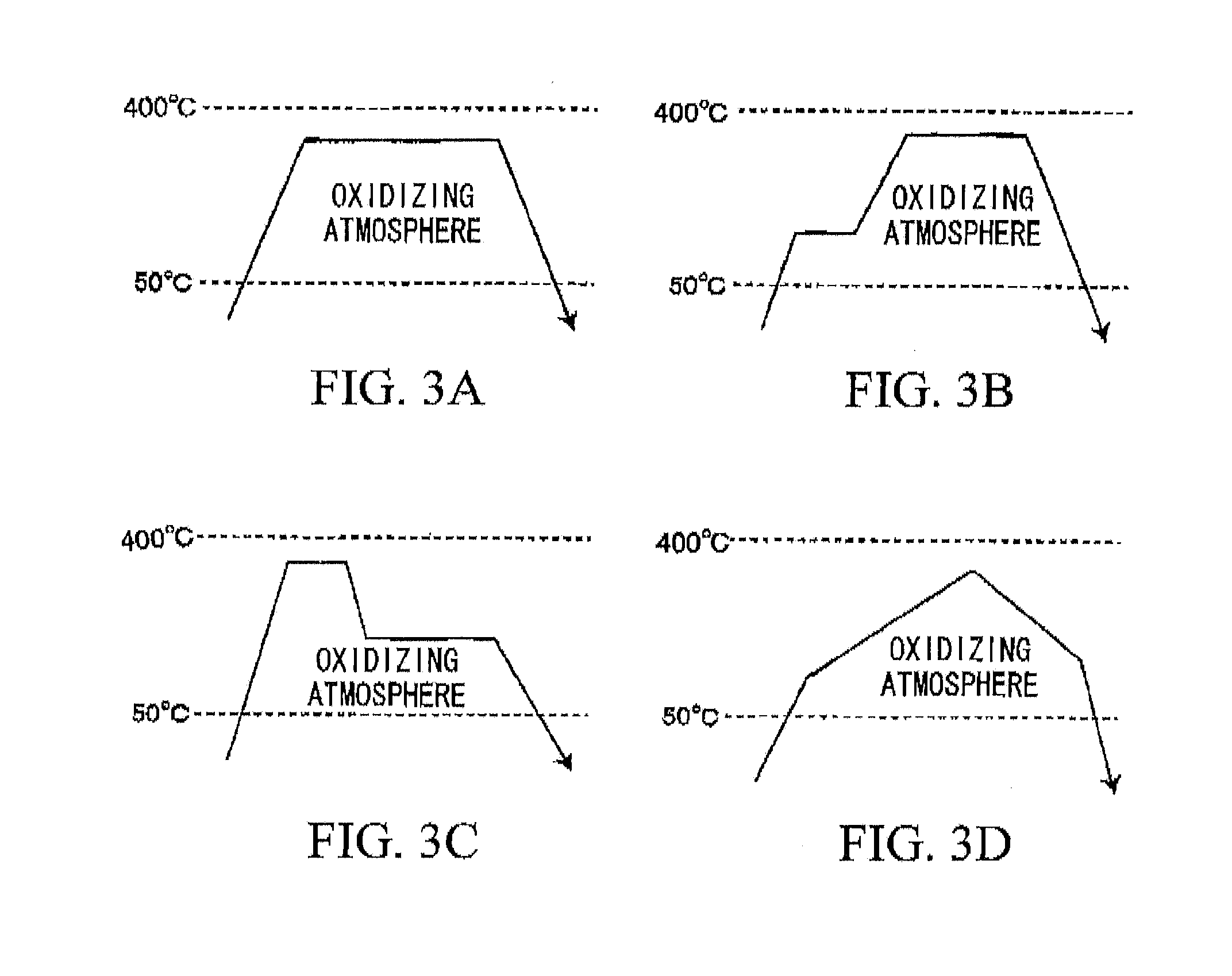

A method for producing a soft magnetic metal powder coated with a Mg-containing oxide film, comprising the steps of adding and mixing a Mg powder with a soft magnetic metal powder which has been subjected to heating treatment in an oxidizing atmosphere at a temperature of 40 to 500° C. to obtain a mixed powder, and heating the mixed powder at a temperature of 150 to 1,100° C. in an inert gas or vacuum atmosphere under a pressure of 1×10−12 to 1×10−1 MPa, while optionally tumbling; and a method for producing a composite soft magnetic material from the soft magnetic metal powder coated with a Mg-containing oxide film.

Owner:DIAMET CORP

Method for producing soft magnetic metal powder coated with mg-containing oxide film and method for producing composite soft magnetic material using said powder

ActiveUS20120070567A1Low resistivityLow production costMagnetic paintsTransportation and packagingMetal powderMaterials science

A method for producing a soft magnetic metal powder coated with a Mg-containing oxide film, comprising the steps of adding and mixing a Mg powder with a soft magnetic metal powder which has been subjected to heating treatment in an oxidizing atmosphere at a temperature of 40 to 500° C. to obtain a mixed powder, and heating the mixed powder at a temperature of 150 to 1,100° C. in an inert gas or vacuum atmosphere under a pressure of 1×10−12 to 1×10−1 MPa, while optionally tumbling; and a method for producing a composite soft magnetic material from the soft magnetic metal powder coated with a Mg-containing oxide film.

Owner:DIAMET CORP

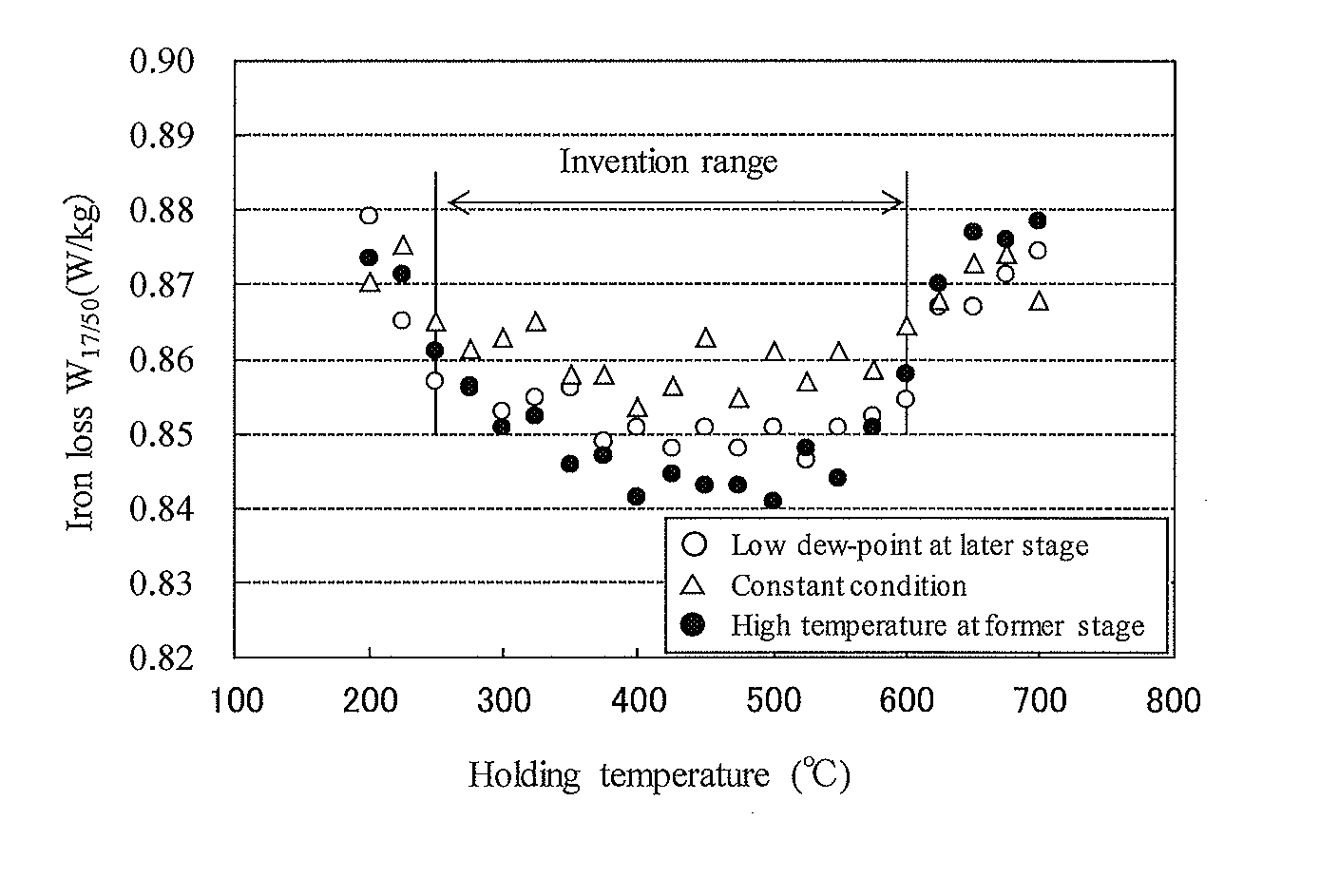

Low-core-loss grain-oriented electromagnetic steel sheet and method for manufacturing same

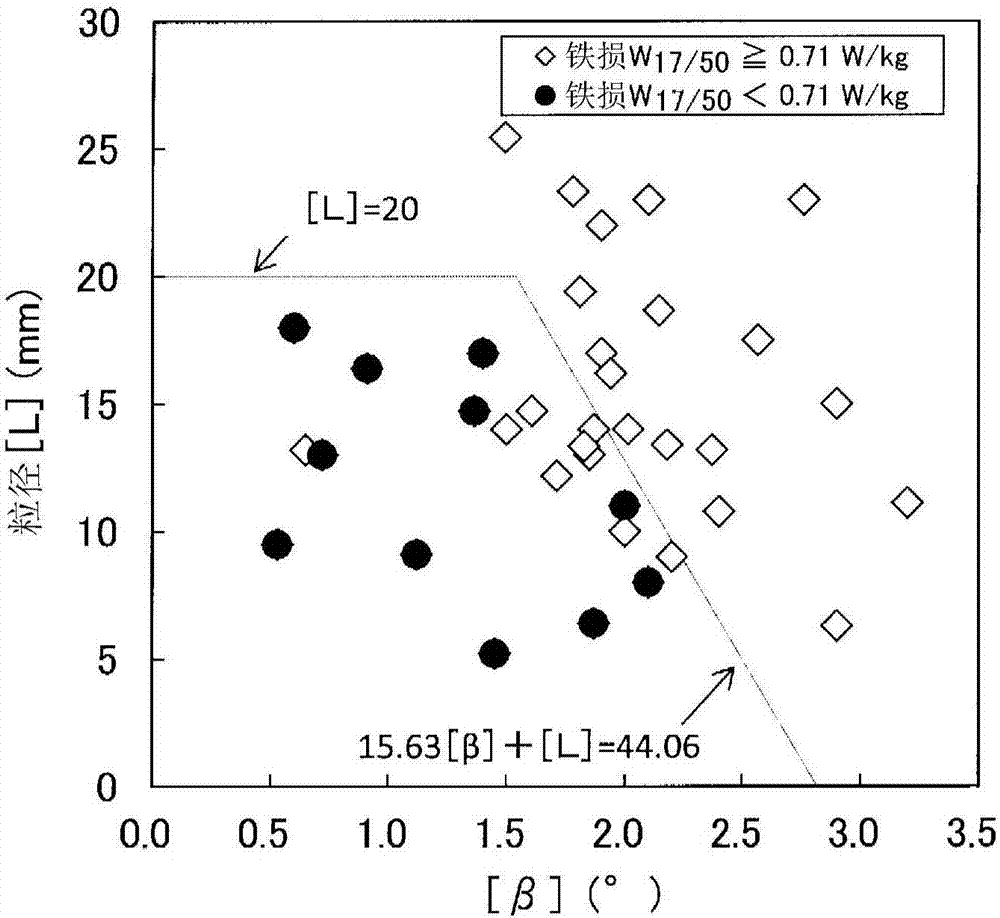

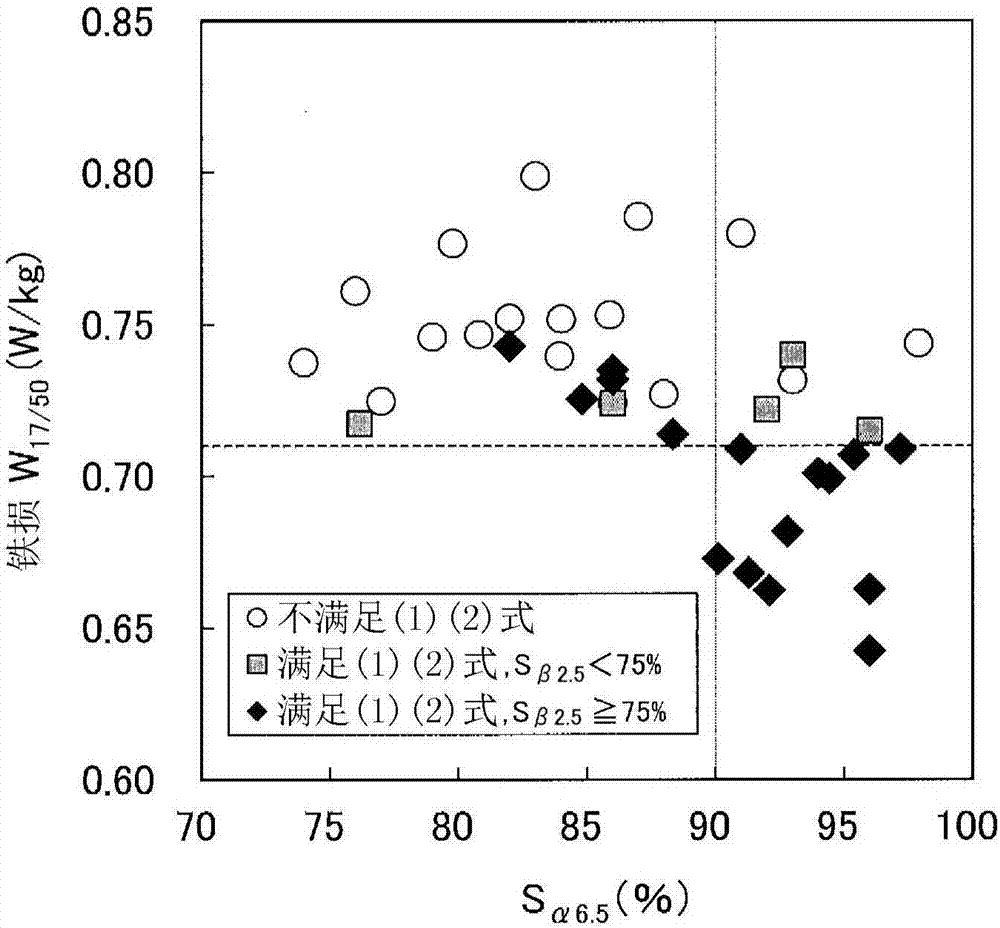

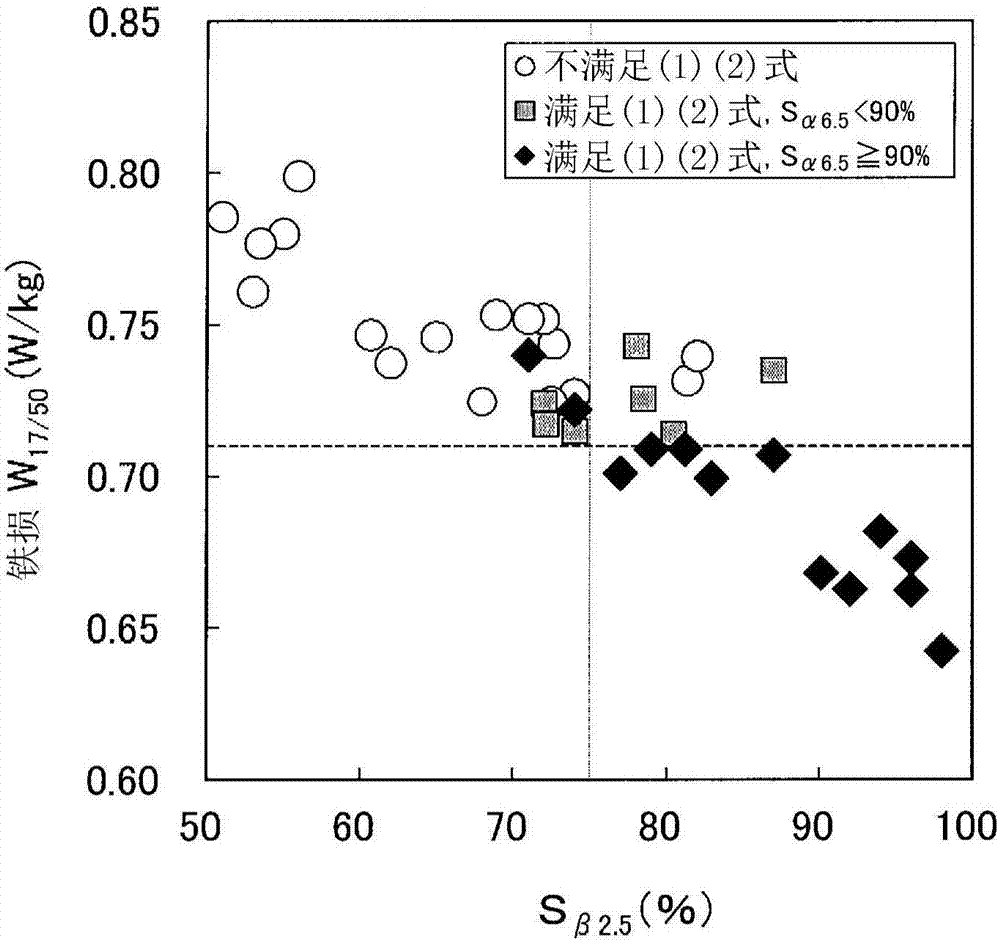

ActiveCN107109552AImproved iron loss characteristicsReduce iron lossInorganic material magnetismFurnace typesMetallurgyOxygen potential

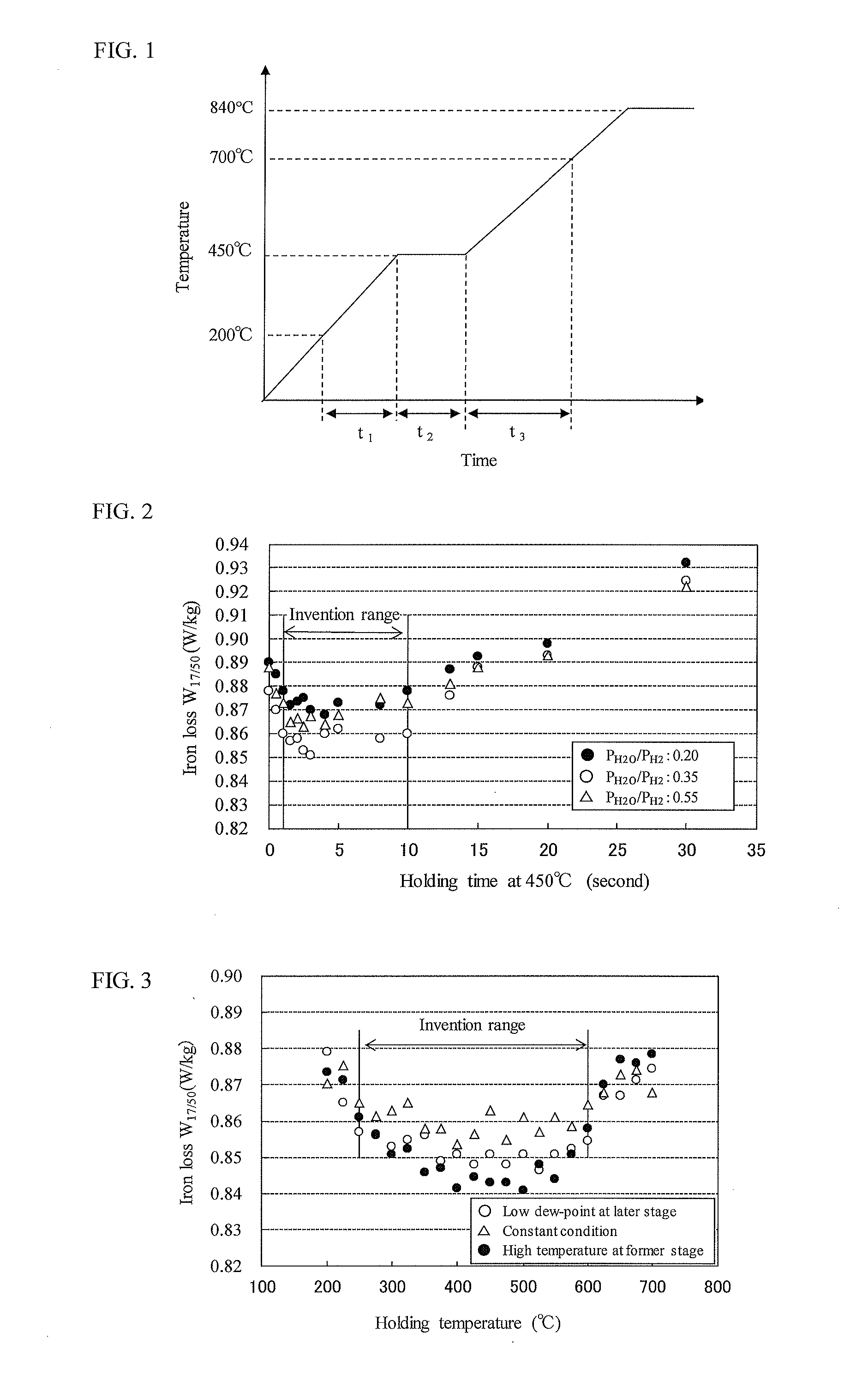

During manufacturing of a grain-oriented electromagnetic steel sheet by subjecting a Si-containing steel slab to hot rolling, cold rolling, primary recrystallization annealing, and finish annealing and forming a tension-imparting coating thereon, a grain-oriented electromagnetic steel sheet having good core loss characteristics is obtained by retention for 1 to 10 seconds at a temperature T from 250 to 600DEG C in the heating process of the primary recrystallization annealing, heating at a rate of 80 DEG C / s in the range of the temperature T to 700 DEG C and 15 DEG C / s in the range of 700 DEG C to a soaking temperature, setting the oxygen potential in the range of 700 DEG C to the soaking temperature to 0.2 to 0.4 and the oxygen potential during soaking to 0.3 to 0.5, and configuring secondary recrystallized grains so that the area ratio for which the deviation angle alpha from the (110)<001> ideal orientation is less than 6.5degrees is at least 90%, the area ratio for which the deviation angle beta is less than 2.5degrees is at least 75%, the average length (L) in a rolling direction is 20 mm or less, and the average value (beta) (degrees) of the deviation angle beta satisfies the expression 15.63* (beta) + [L] <44.06.

Owner:JFE STEEL CORP

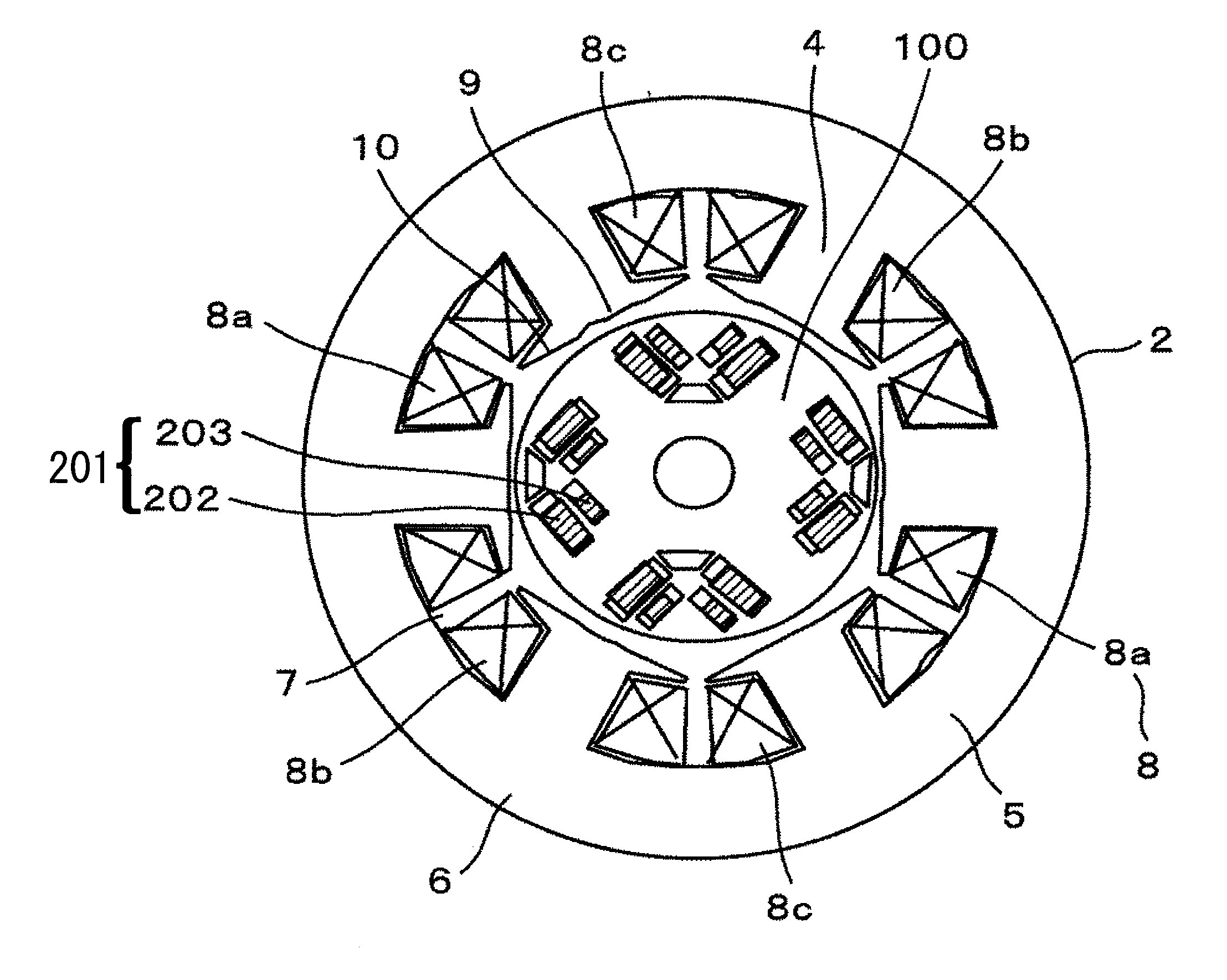

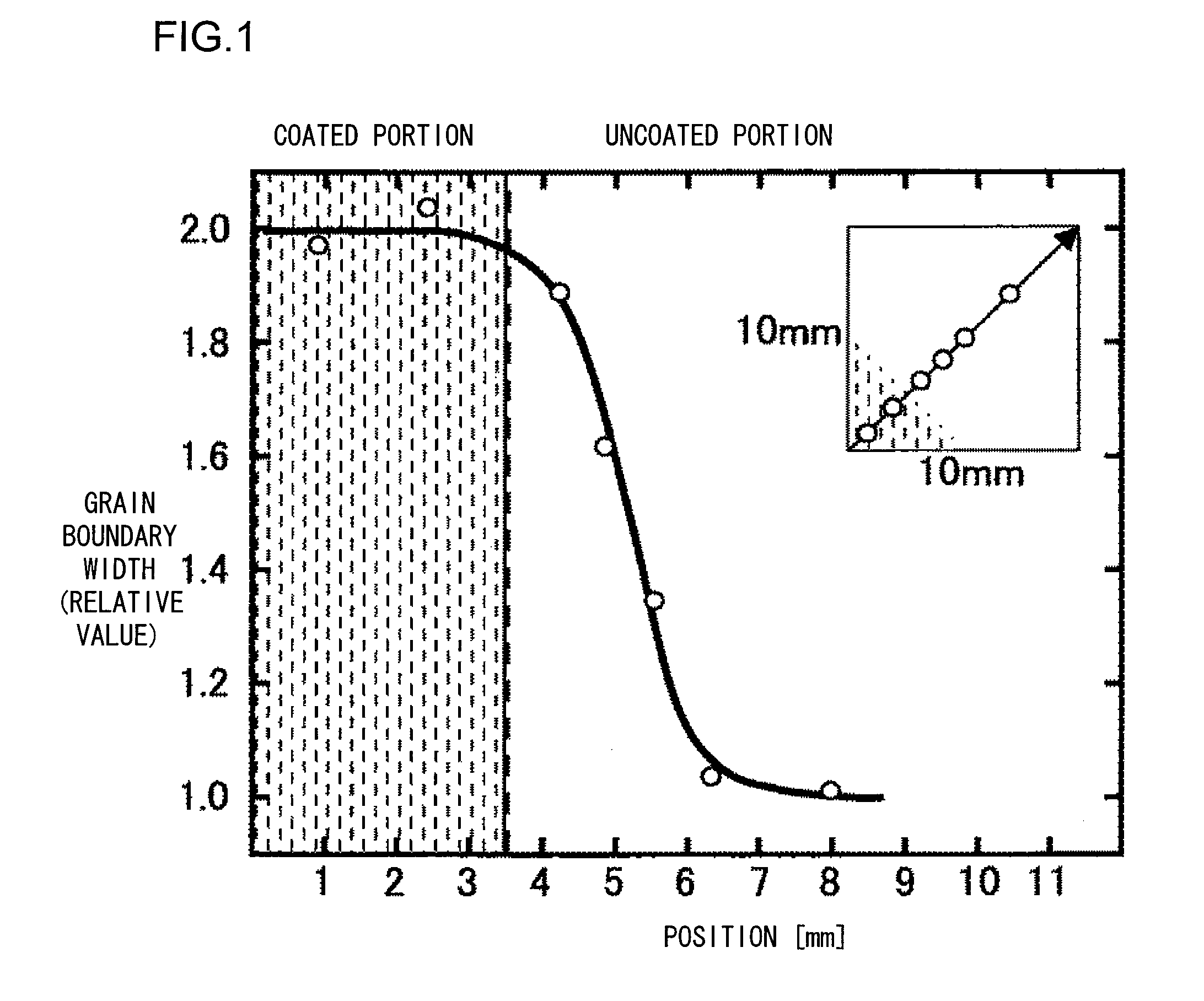

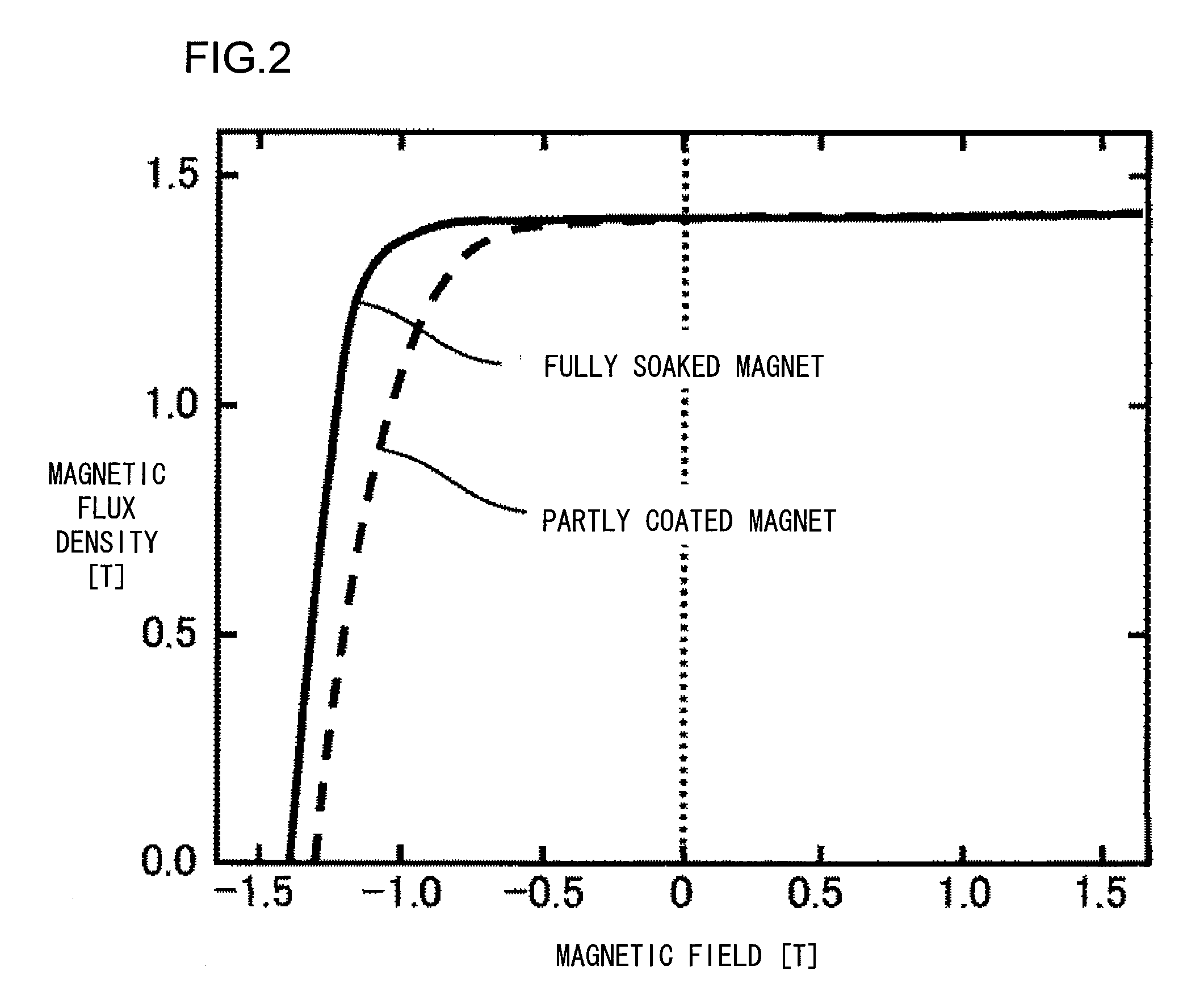

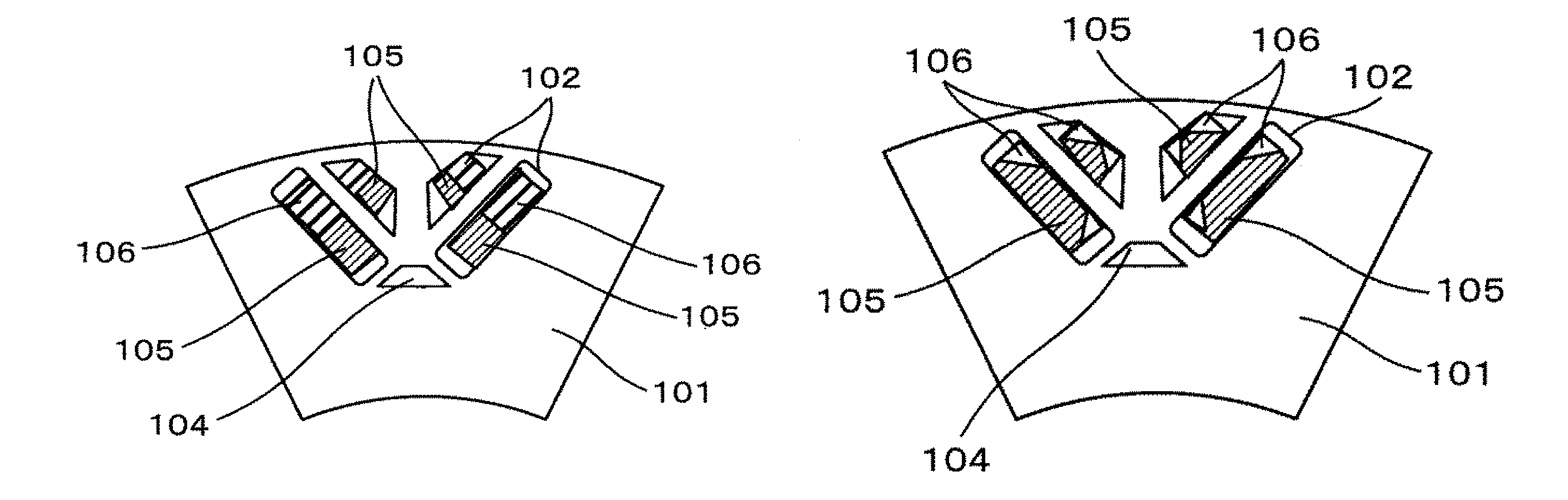

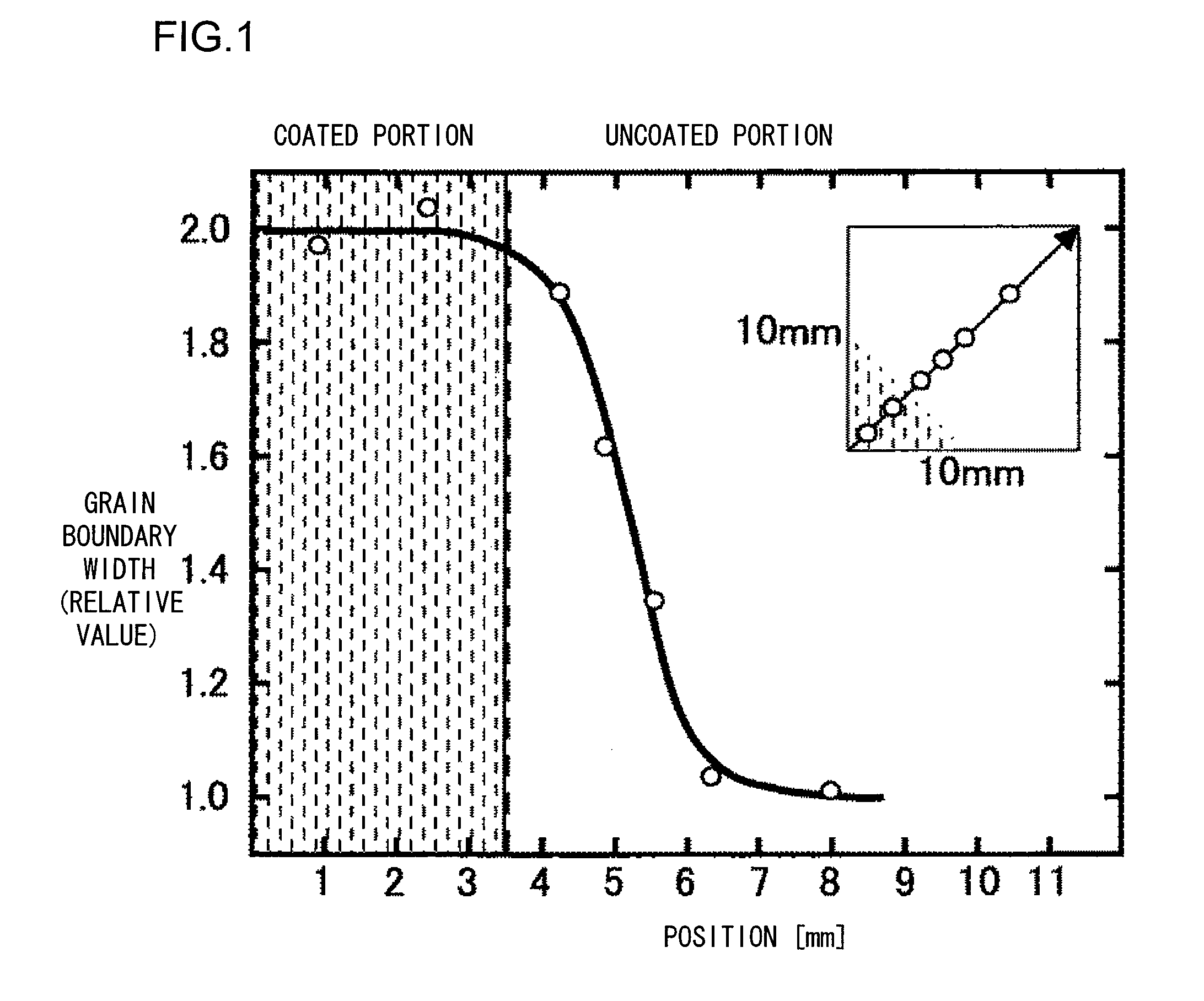

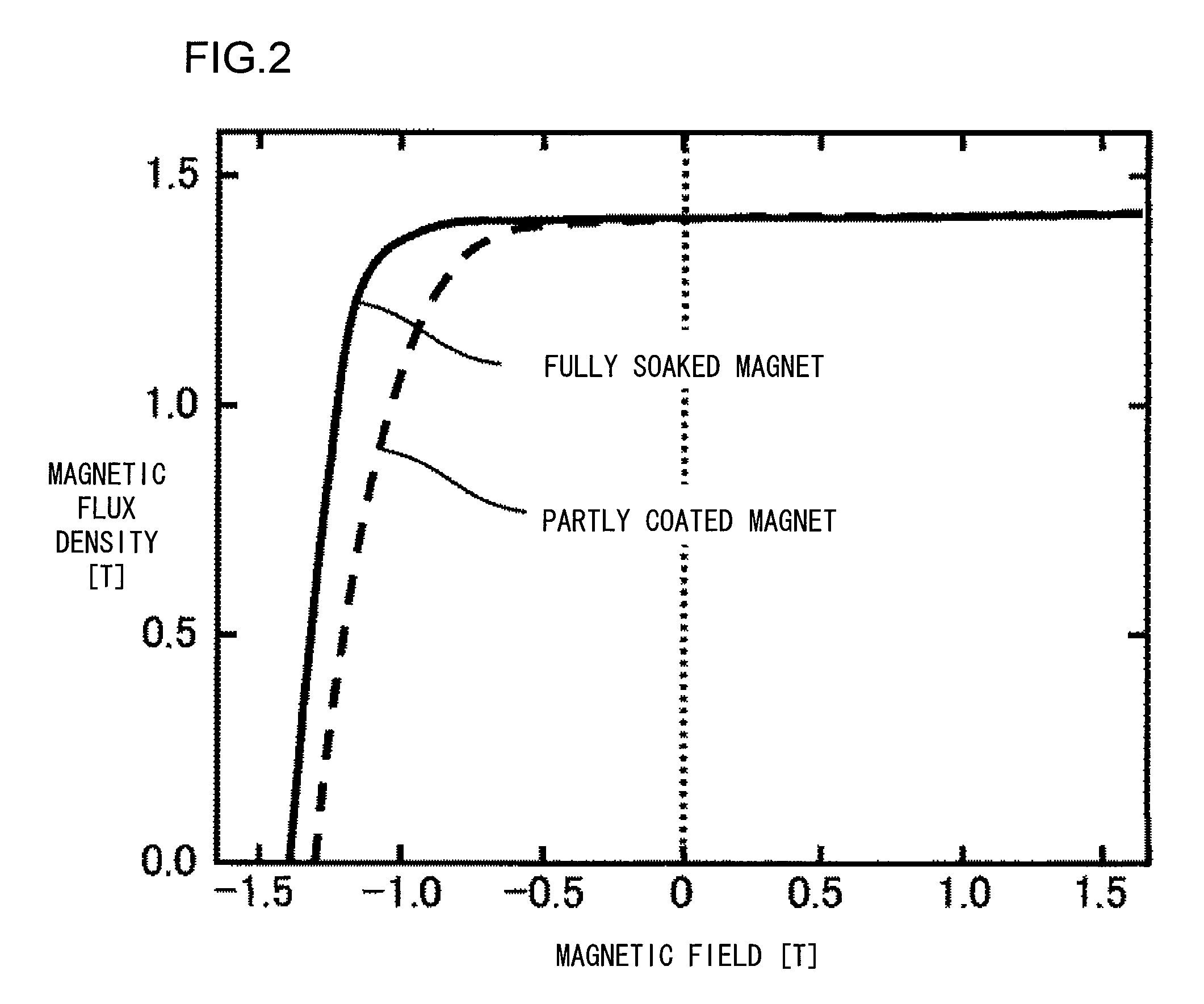

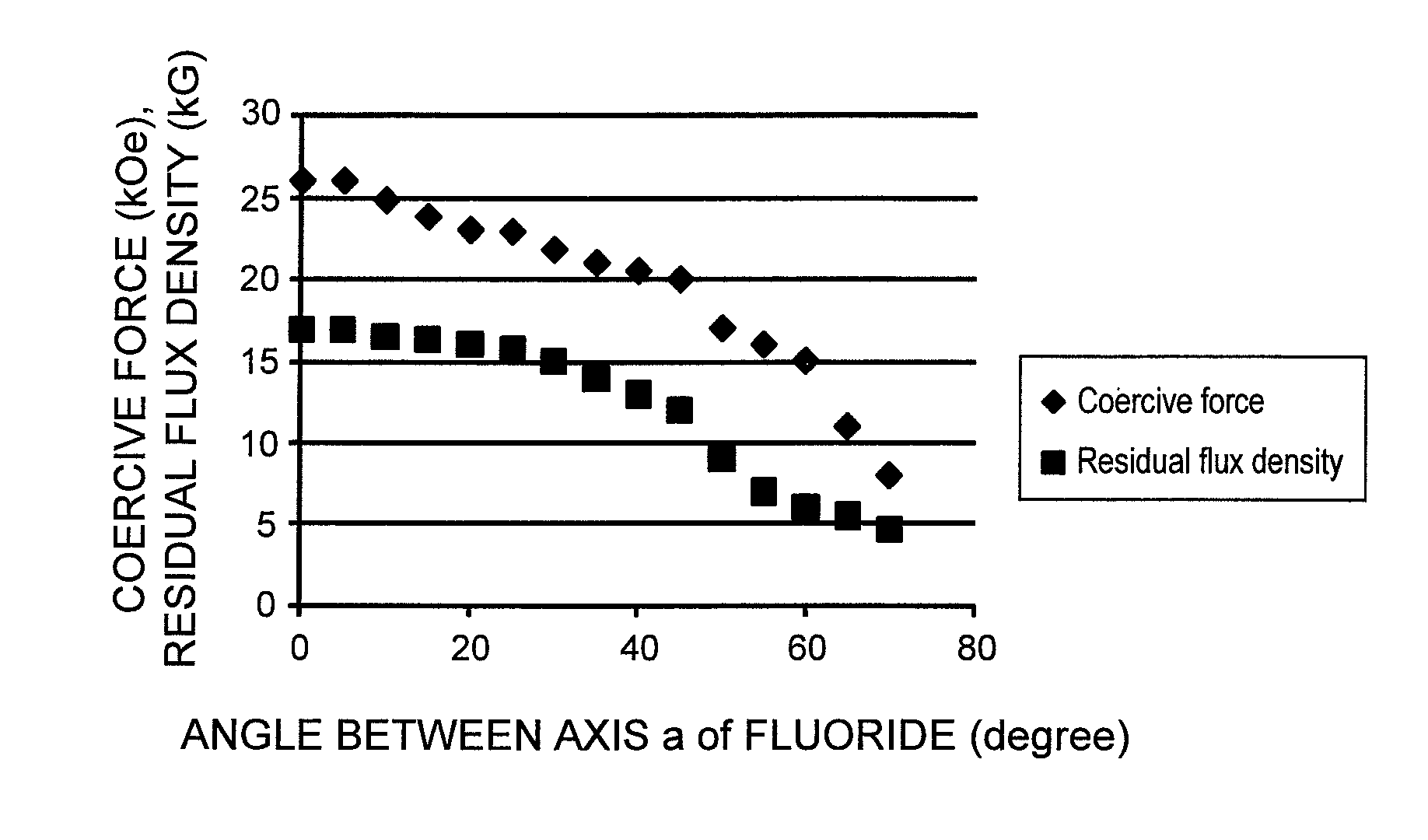

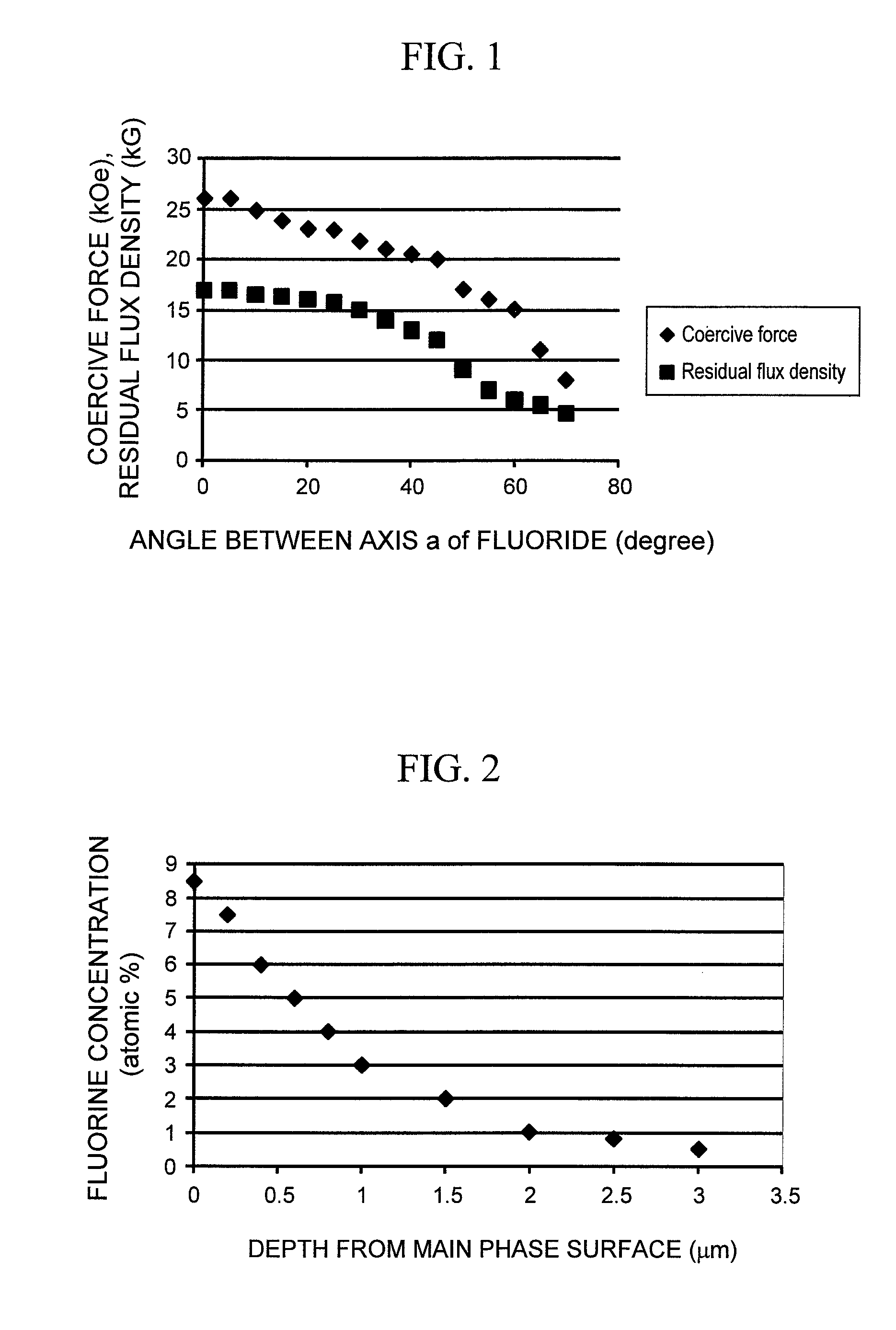

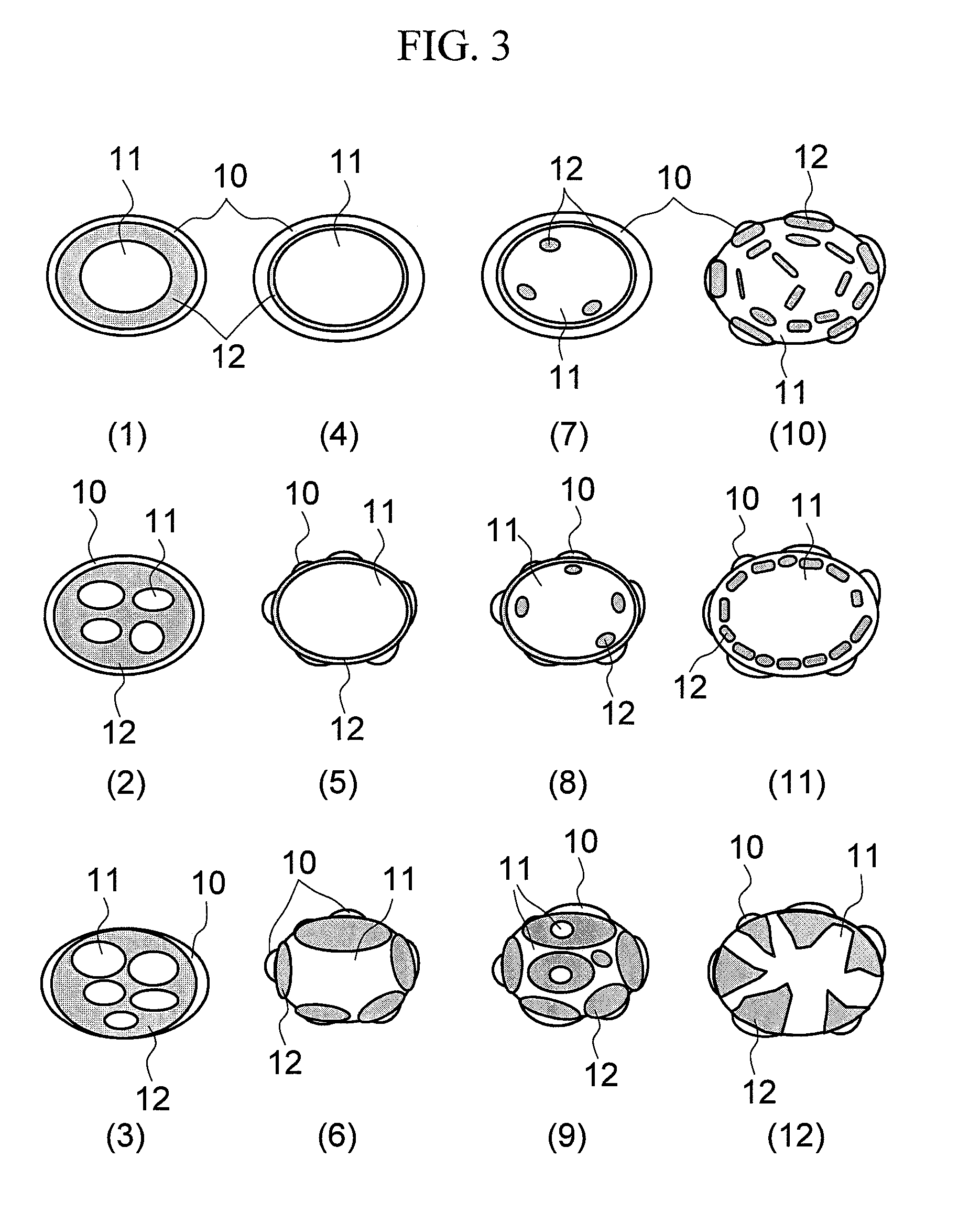

Sintered Magnet and Rotating Machine Equipped with the Same

InactiveUS20100079025A1Reduce the amount requiredImprove uniformityPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementAlkaline earth metal

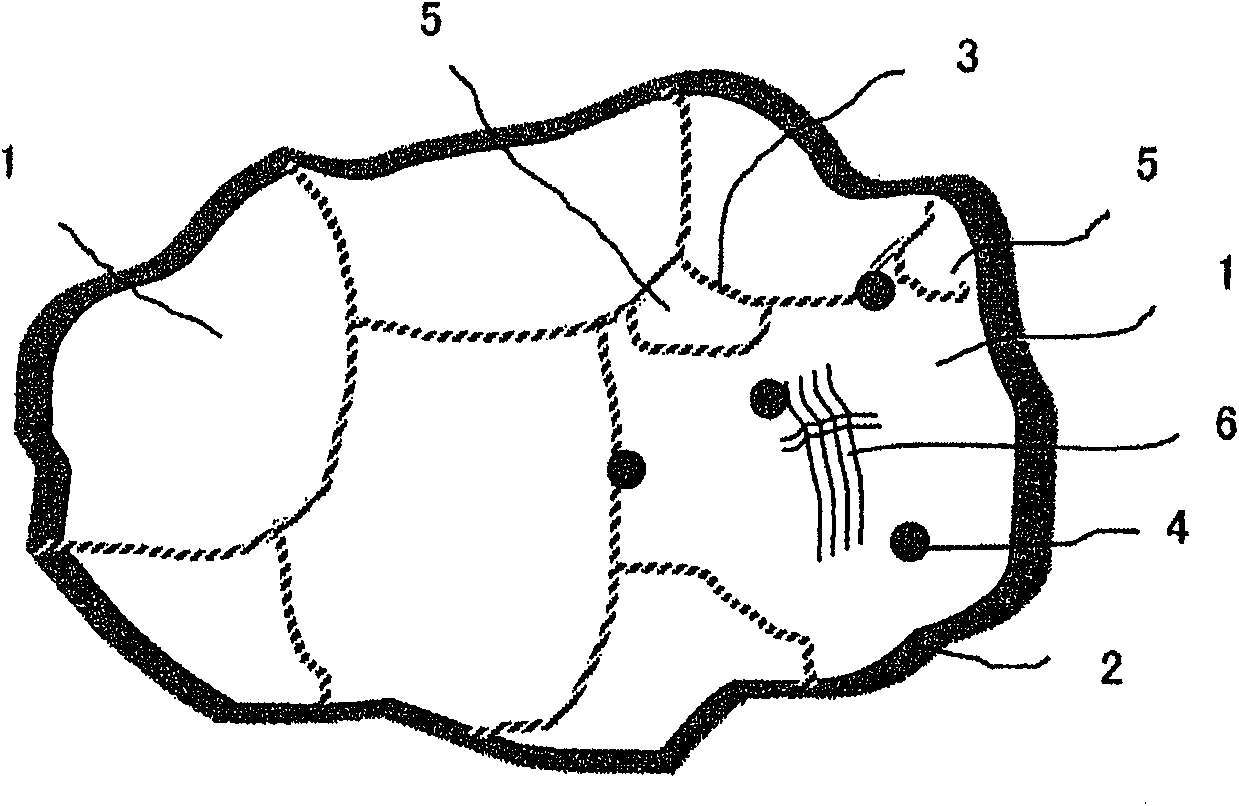

A sintered magnet and a rotating machine equipped therewith are disclosed, which include: crystal grains of a ferromagnetic material consisting mainly of iron, and a fluoride compound or an oxyfluoride compound, containing at least one element selected from the group consisting of an alkali metal element, an alkaline earth metal element, and a rare earth element, the fluoride compound or the oxyfluoride compound being formed inside some of the crystal grains or in a part of a grain boundary part. The oxyfluoride compound or the fluoride compound contains carbon, and a grain boundary width of the ferromagnetic material is smaller than a grain boundary width of the ferromagnetic material in which the fluoride compound or the oxyfluoride compound is formed.

Owner:HITACHI LTD

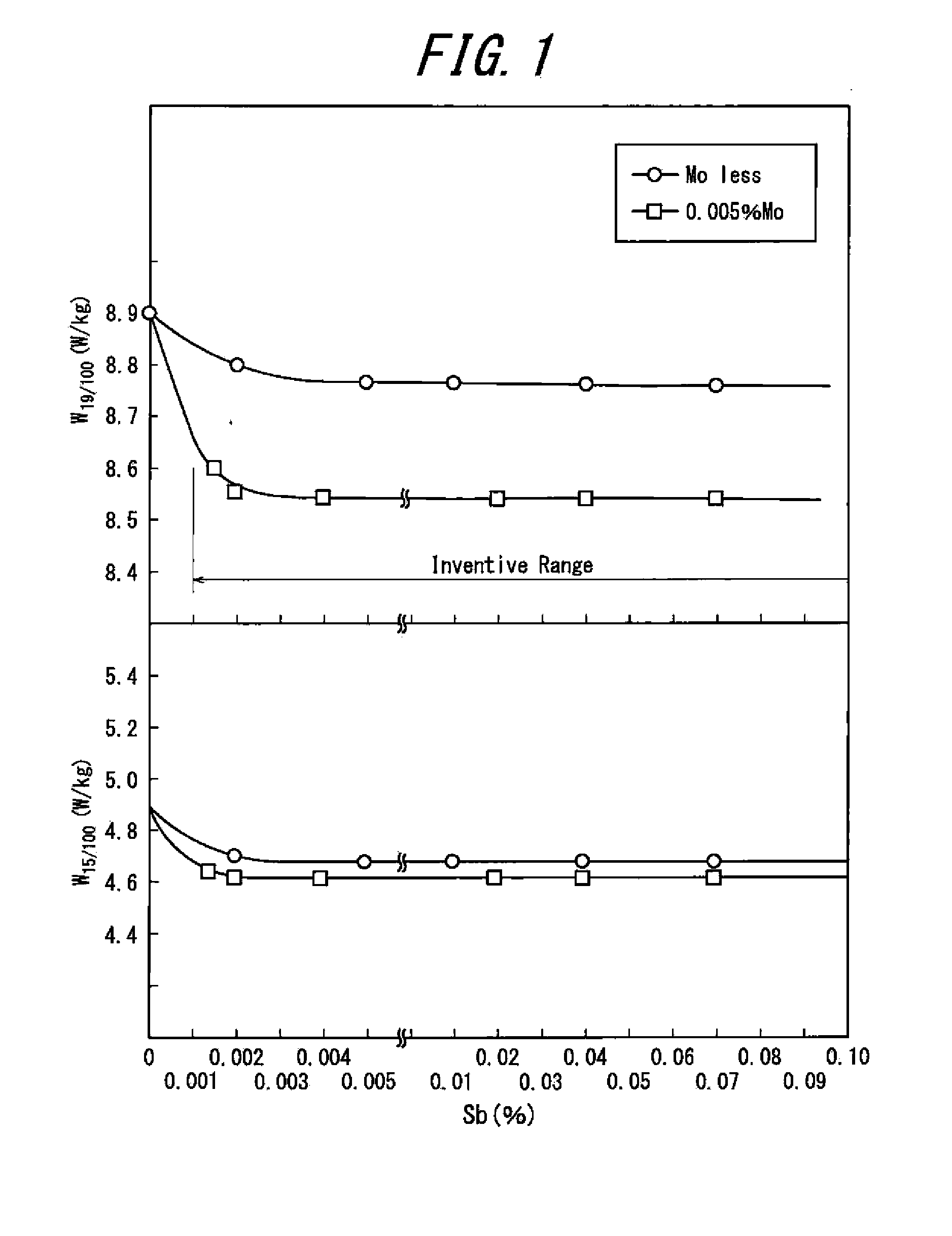

Non-oriented electrical steel sheet

ActiveUS20140345751A1High propertyInhibition formationInorganic material magnetismFurnace typesChemical compositionElectrical steel

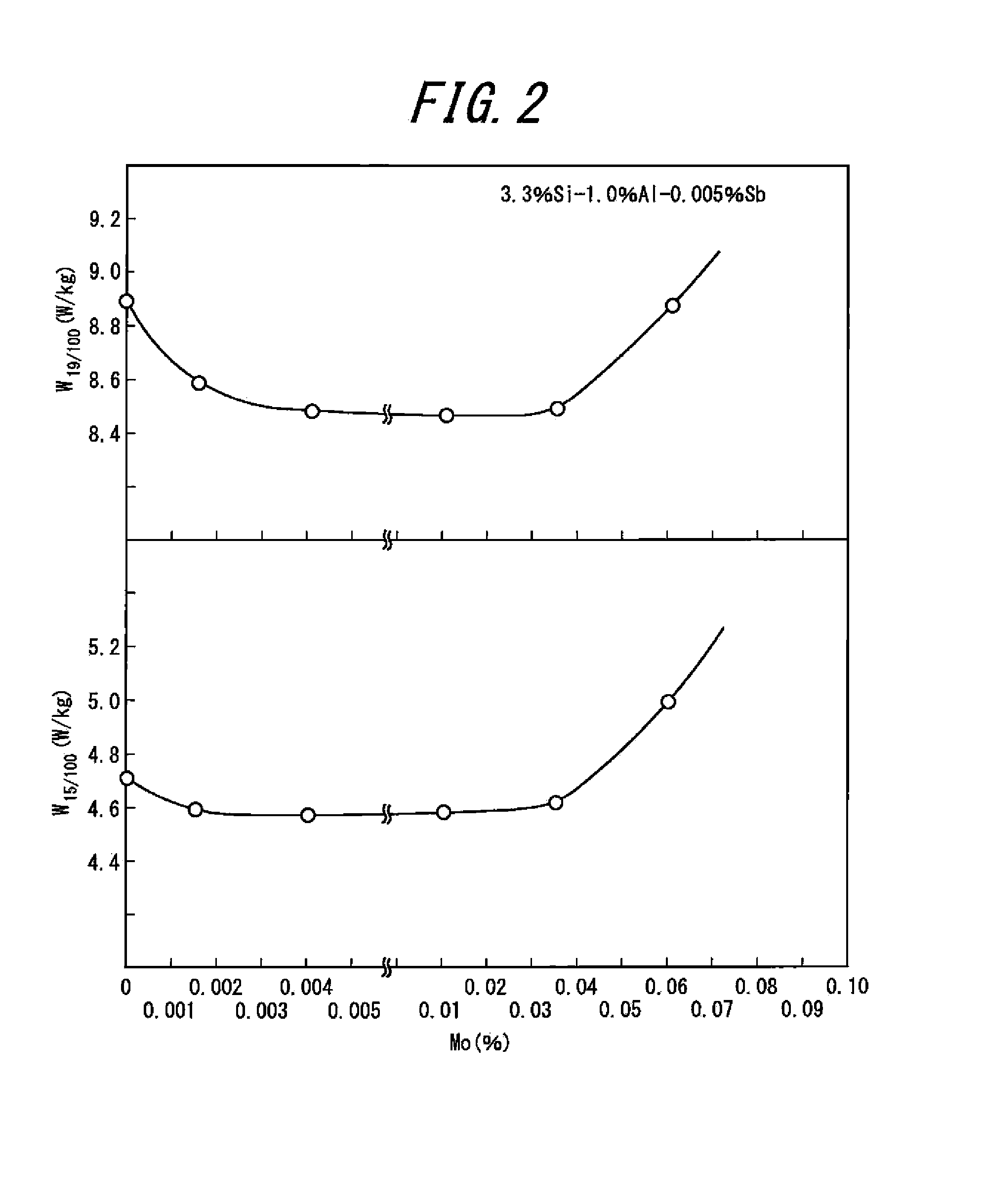

A non-oriented electrical steel sheet has a chemical composition including, in mass %, C: 0.005% or less, Si: 5% or less, Al: 3% or less, Mn: 5% or less, S: 0.005% or less, P: 0.2% or less, N: 0.005% or less, Mo: 0.001 to 0.04%, Ti: 0.0030% or less, Nb: 0.0050% or less, V: 0.0050% or less, Zr: 0.0020% or less, one or both of Sb and Sn: 0.001 to 0.1% in total, and the balance being iron and incidental impurities.

Owner:JFE STEEL CORP

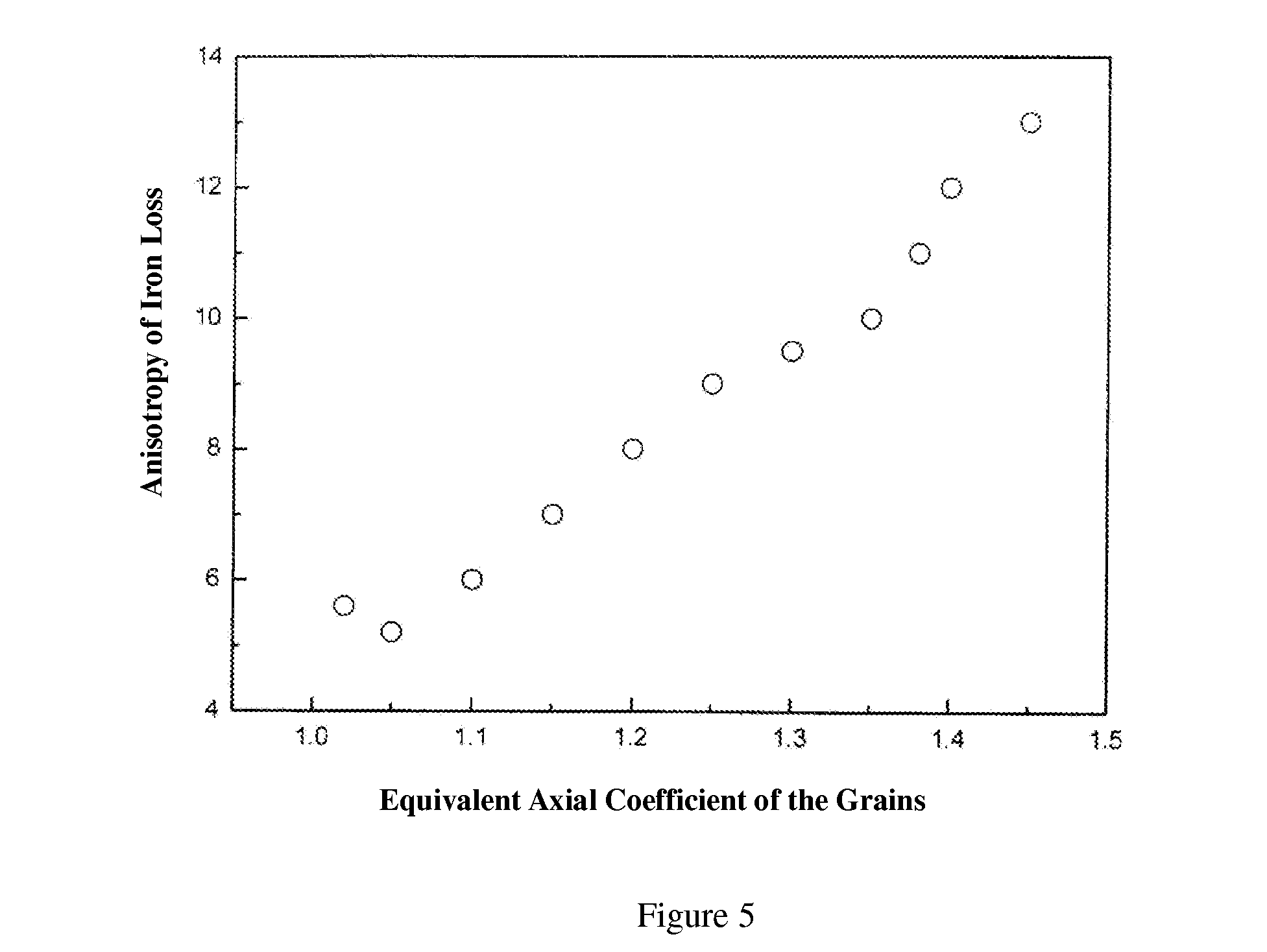

Non-Oriented Silicon Steel and Manufacturing Process Thereof

ActiveUS20150013844A1Improve magnetic propertiesSimple structureInorganic material magnetismFurnace typesSteelmakingMolten steel

The present invention provides a non-oriented silicon steel with excellent magnetic properties and a manufacturing process therefor. During the manufacturing process of the present invention, the temperature T of the molten steel of steel tapped from a converter during steelmaking and the carbon content [C] and the free oxygen content [O] comply with the following formula: 7.27×103≦[O][C]e(−5000 / T)≦2.99×104, and the final annealing step uses tension annealing at a low temperature for a short time. A non-oriented silicon steel with a low iron loss, and excellent anisotropy of iron loss can be obtained by means of the manufacturing process of the present invention.

Owner:BAOSHAN IRON & STEEL CO LTD

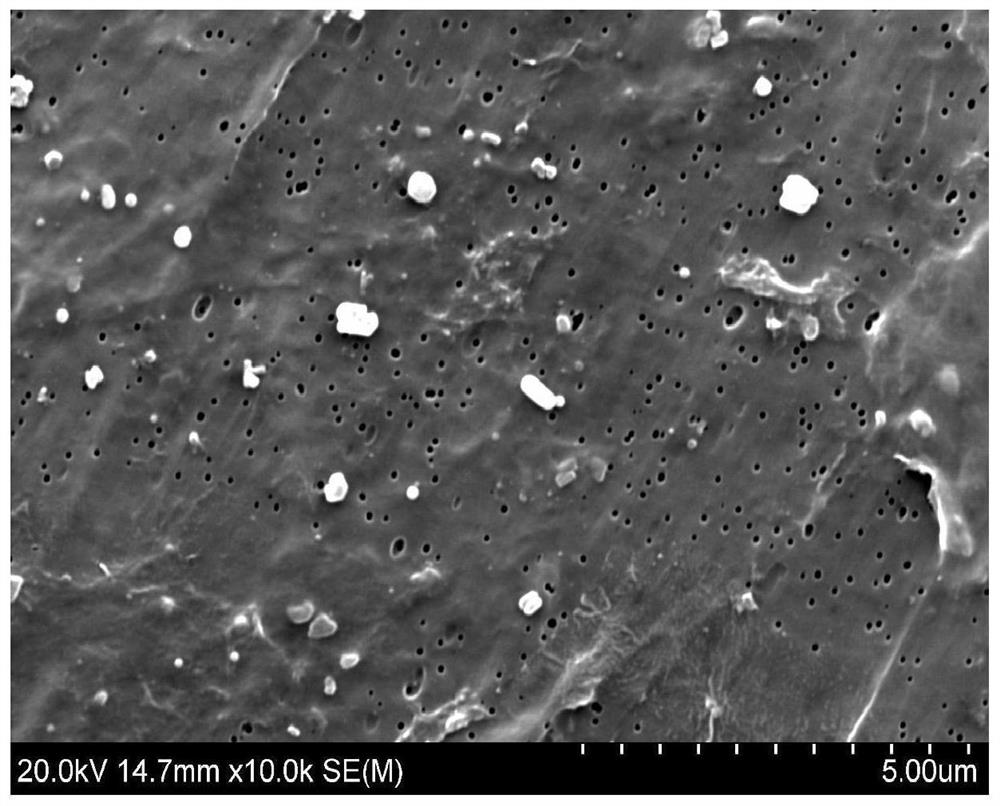

Soft magnetic powder for compact powder body and compact powder body using the same

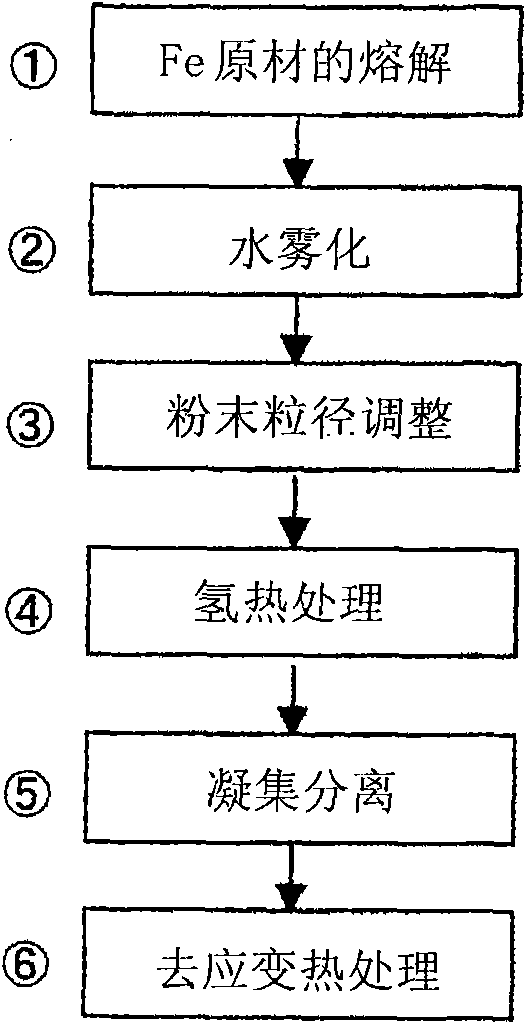

InactiveCN101615465ALow deformation resistanceLow iron lossMetal-working apparatusInorganic material magnetismHydrogenReducing atmosphere

A water atomized Fe powder for a magnetic compact reduced in deformation resistance during molding and annealing temperature for removing strains is provided. A compact having improved magnetic properties is also provided. The water atomized powder containing at least one element selected from Nb, Ta, Ti, Zr and V in an amount of 0.001-0.03 atom % is soft magnetic and has a precipitation in the matrix, which is composed of at least one element selected from Nb, Ta, Ti, Zr and V and oxygen as a main component and has an average size of 0.02-0.5 mum. Disclosed is a method for manufacturing a soft magnetic powder includes adding at least one element selected from Nb, Ta, Ti, Zr and V, and annealing in a hydrogen-containing reduction atmosphere. This method decrease gaseous impurities, particularly oxygen, and defuse it, to improve the magnetic properties of the powder and compact.

Owner:HITACHI LTD

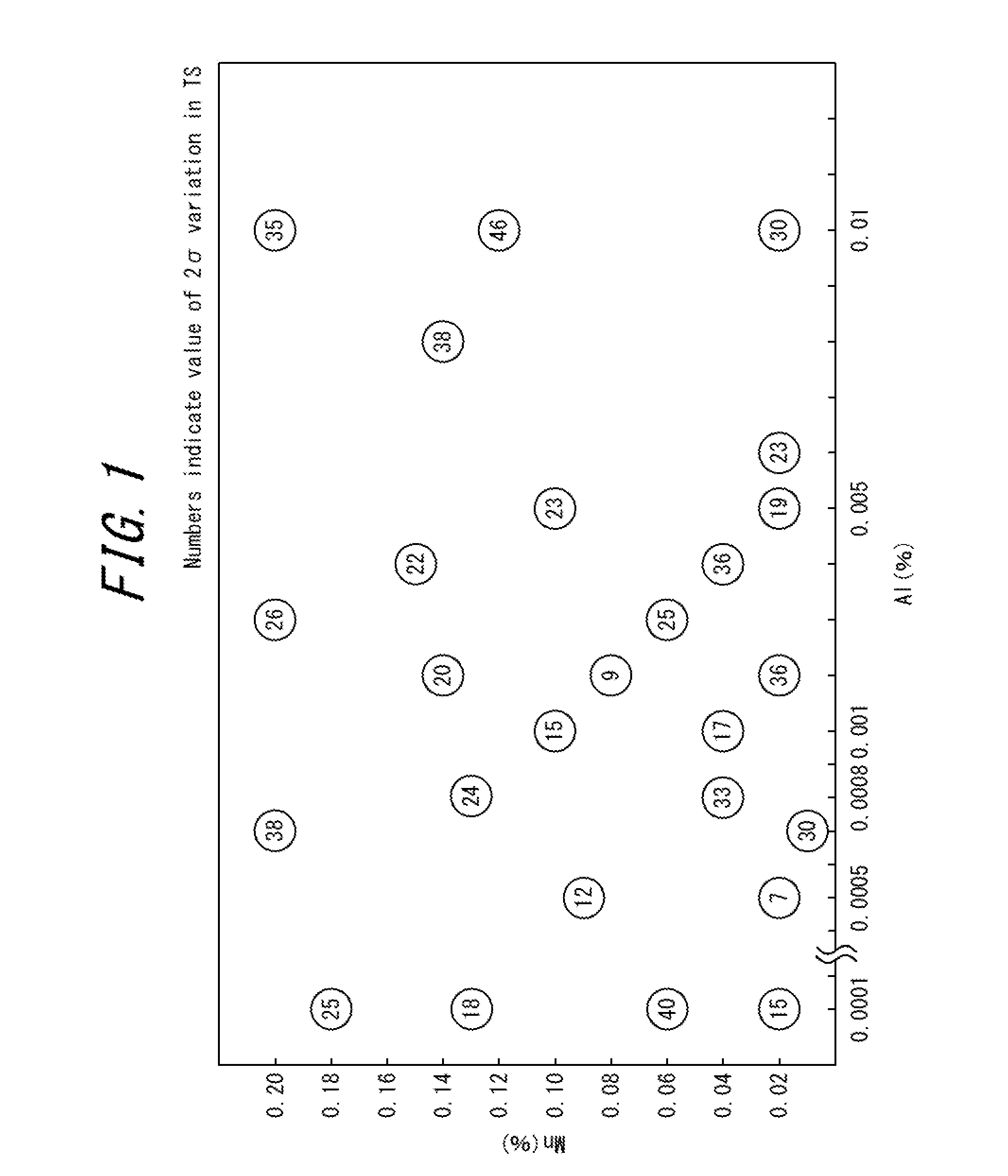

High-strength electrical steel sheet and method of producing the same

ActiveUS20150213928A1Low iron-lossGood workmanshipInorganic material magnetismFurnace typesChemical compositionElectrical steel

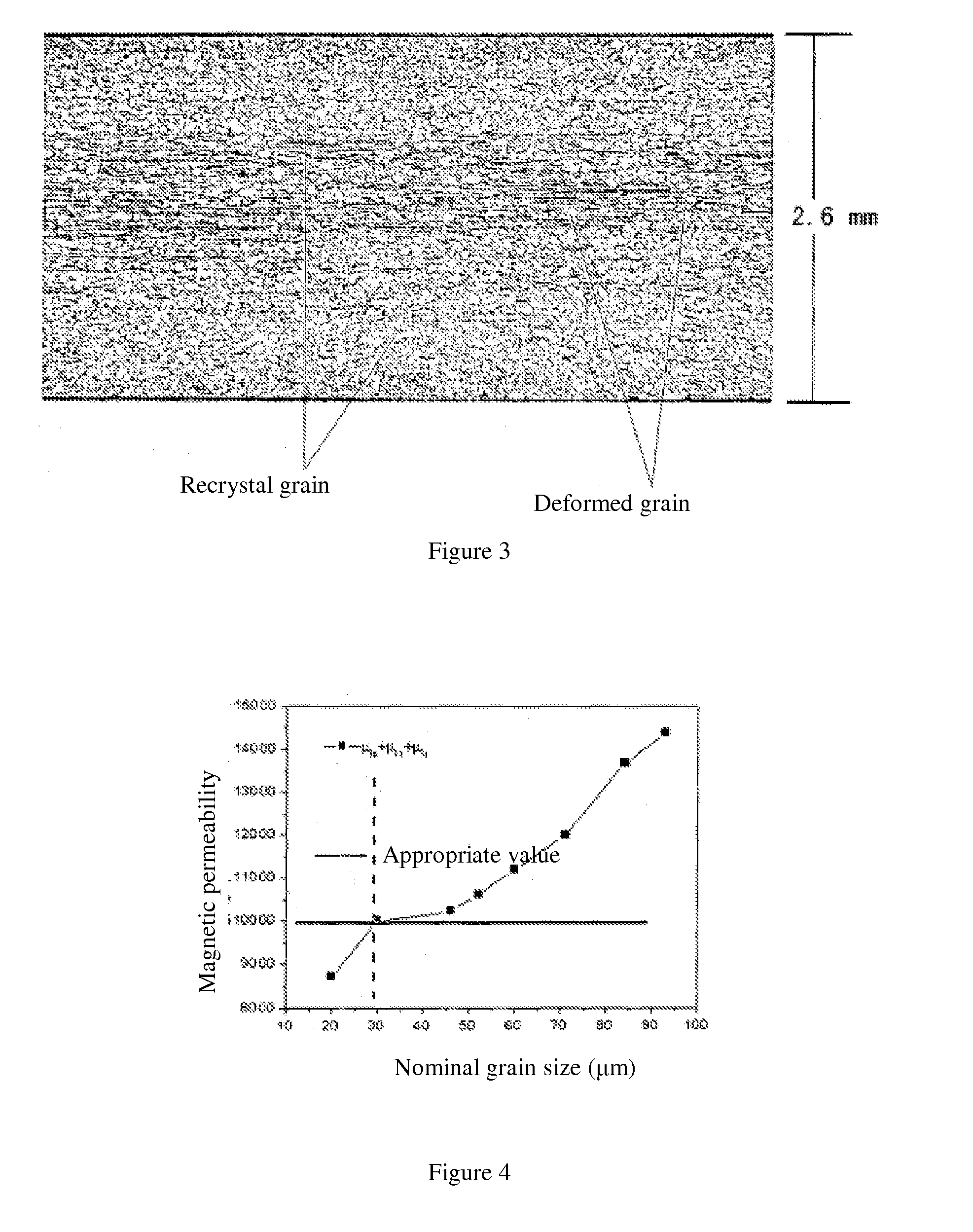

According to the present invention, a high-strength electrical steel sheet that is suitable as rotor material for a high speed motor, steadily has high strength, and also has excellent magnetic properties can be obtained by setting the chemical composition thereof to include, by mass %, C: 0.005% or less, Si: more than 3.5% and 4.5% or less, Mn: 0.01% or more and 0.10% or less, Al: 0.005% or less, Ca: 0.0010% or more and 0.0050% or less, S: 0.0030% or less, and N: 0.0030% or less, Ca / S being 0.80 or more, the balance being Fe and incidental impurities, and by setting the sheet thickness to 0.40 mm or less, the non-recrystallized deformed microstructure to 10% or more and 70% or less, tensile strength (TS) to 600 MPa or more, and iron loss W10 / 400 to 30 W / kg or less.

Owner:JFE STEEL CORP

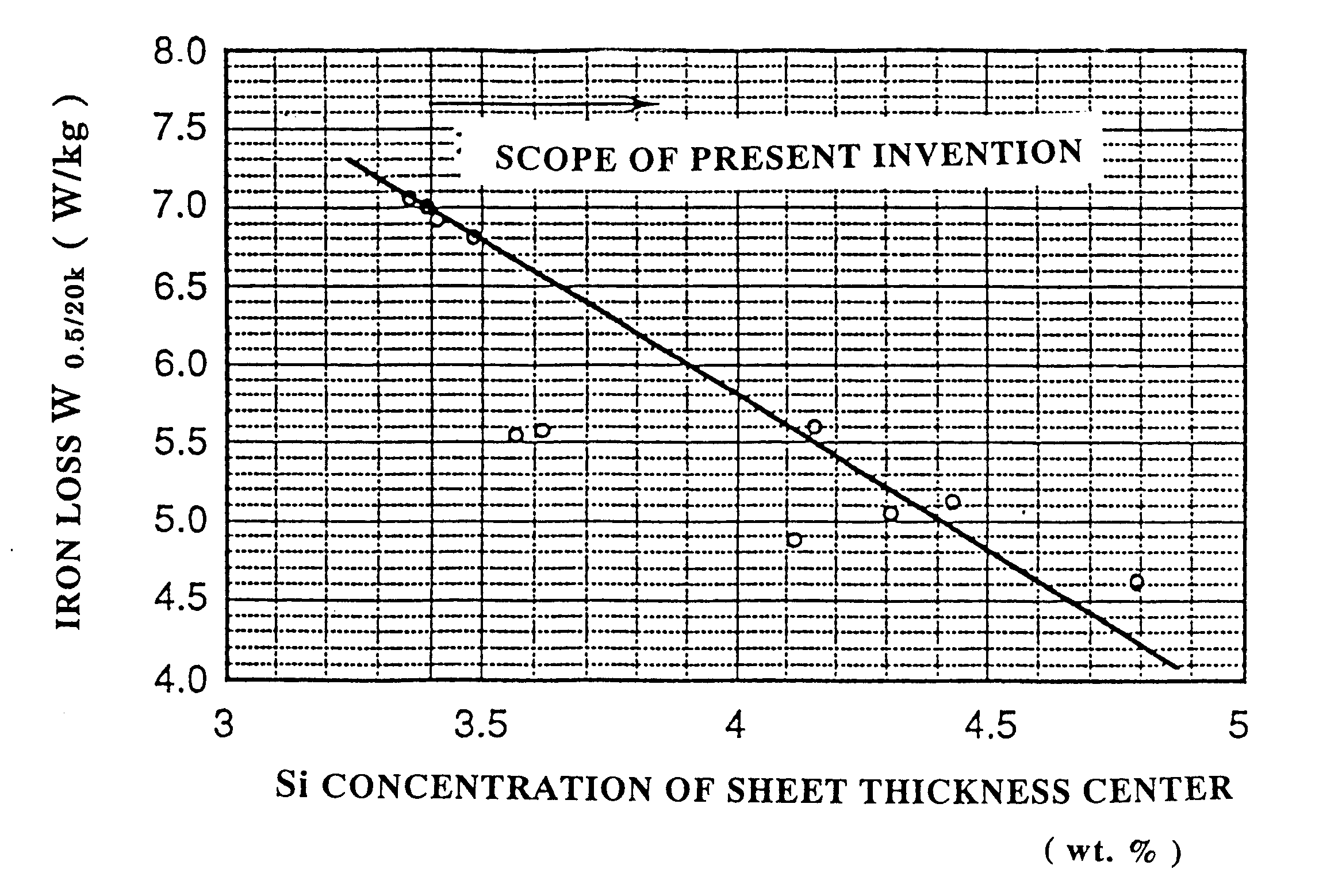

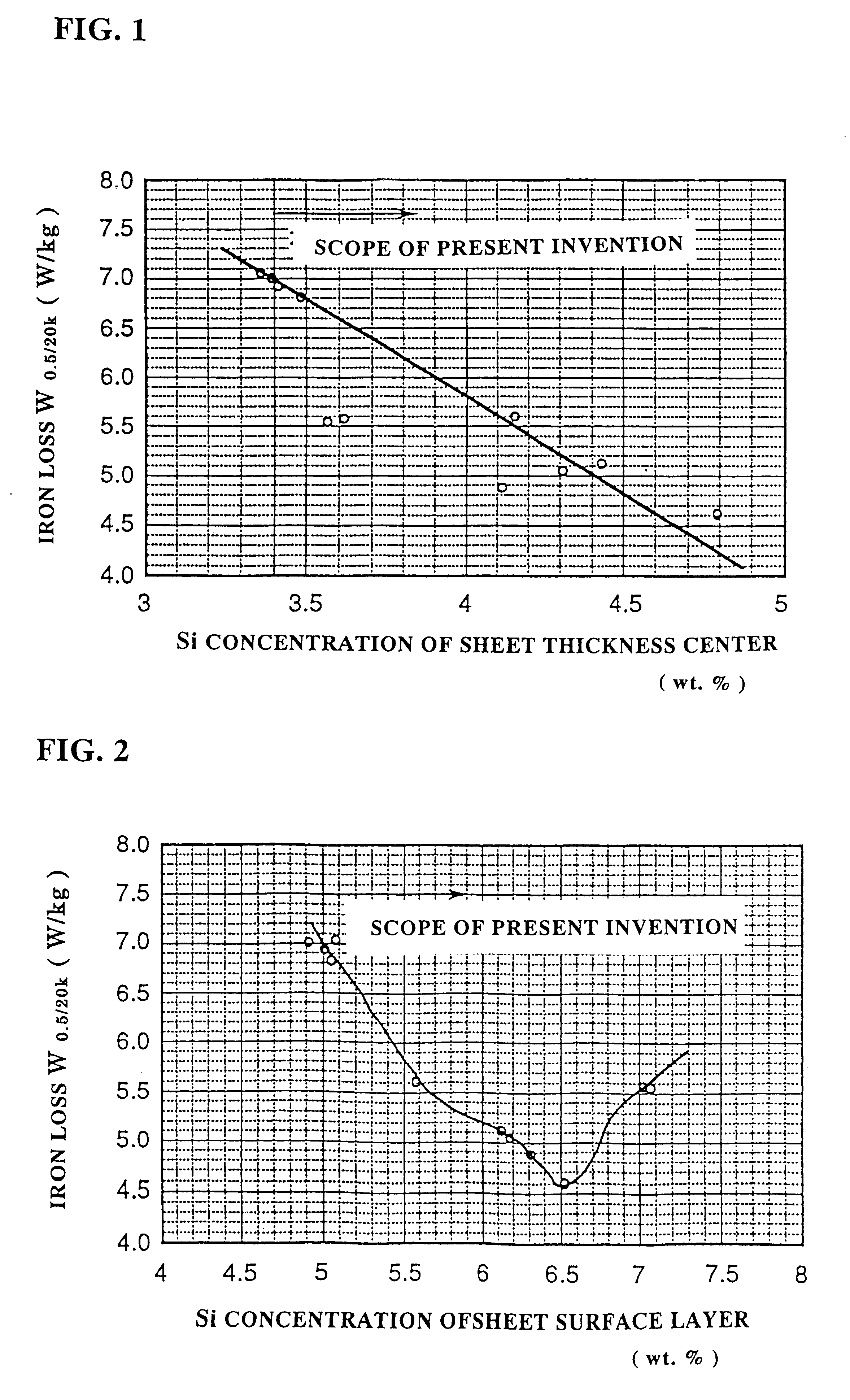

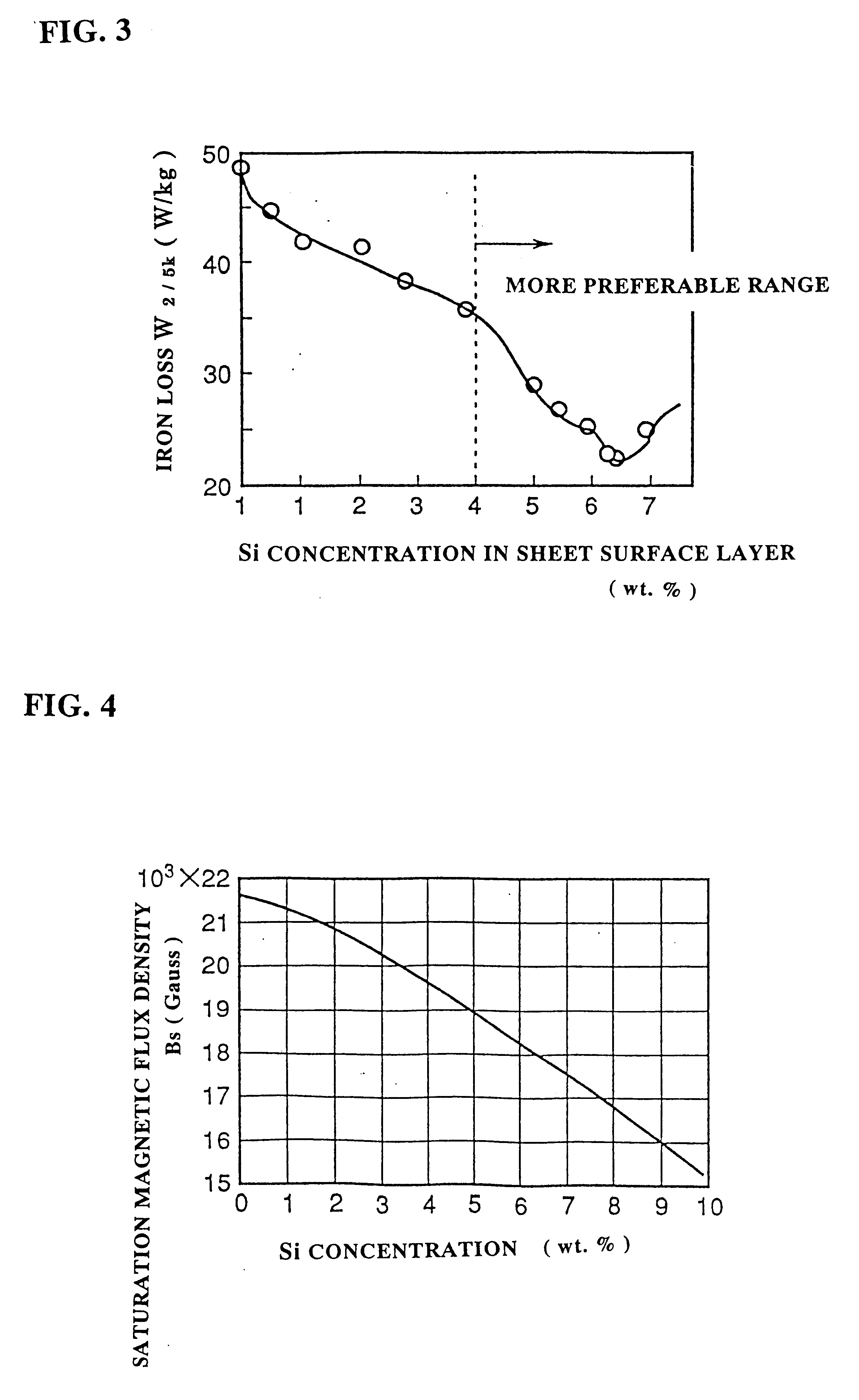

Silicon steel sheet and method for producing the same

InactiveUS6527876B2Low iron-lossHigh frequencyInorganic material magnetismSolid state diffusion coatingSheet steelSurface layer

A silicon steel sheet having low iron loss of high frequency has a surface layer of the steel sheet which has Si concentration higher than Si concentration of a center portion of the steel sheet. Si concentration of sheet thickness center is 3.4 wt. % or more and Si concentration of the surface layer of the steel sheet is 5 wt. % or more. Si concentration in a surface layer portion is 5 to 8 wt. %. The production method comprises siliconizing treatment and diffusing treatment. Velocity of siliconizing and diffusing are controlled, and Si concentration distribution in the sheet thickness direction of the steel sheet is controlled.

Owner:JFE STEEL CORP +1

Sintered magnet and rotating machine equipped with the same

InactiveUS7880357B2Reduce the amount requiredImprove uniformityMagnetic circuit rotating partsMagnetic circuit stationary partsRare-earth elementAlkaline earth metal

Owner:HITACHI LTD

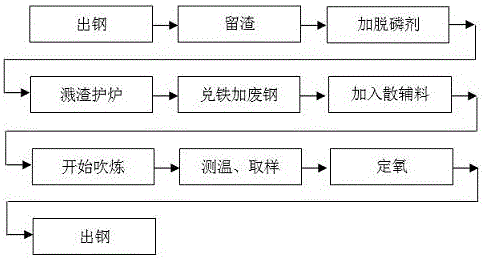

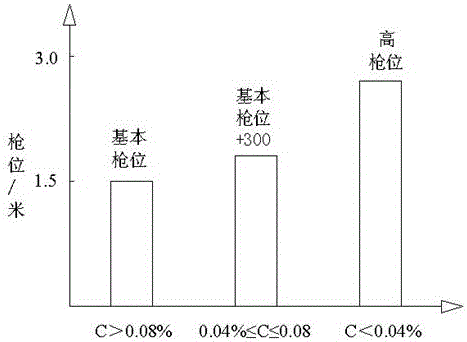

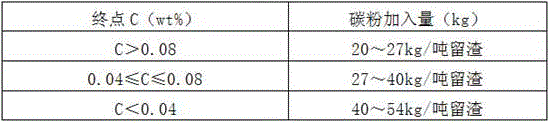

Dephosphorization method for oxygen top-blown converter slag remainder

InactiveCN106119459AReduce phosphorus contentReduce carryoverManufacturing convertersProcess efficiency improvementSmelting processHeat losses

The invention discloses a dephosphorization method for oxygen top-blown converter slag remainder. The dephosphorization method includes the steps that before slag-splashing for protection of a converter, a dephosphorization agent is added to the slag remainder in the converter after tapping, then inert gases are top-blown by an oxygen gun for the operation of slag-splashing for protection of the converter, and dephoshprized slag remainder serve as initial slag of the next melt of smelting. According to the method, the oxygen top-blown converter slag remainder operation is combined with the slag remainder dephosphorization process, the phosphorus content in the slag remainder can be lowered effectively, and the drag-in amount of phosphorus in the next melt of converter smelting process is lowered, so that the lime addition amount in the next melt of converter smelting process can be reduced, and the converter smelting cost is lowered. By the adoption of the dephosphorization method, part of the phosphorus element in the slag remainder in the converter can be removed, the slag amount is small in the smelting process, the heat loss is low, the iron loss is small, the converter slag dephosphorization effect is good, and the smelting cost is lowered remarkably.

Owner:TANGSHAN IRON & STEEL GROUP

Method for manufacturing of insulated soft magnetic metal powder formed body

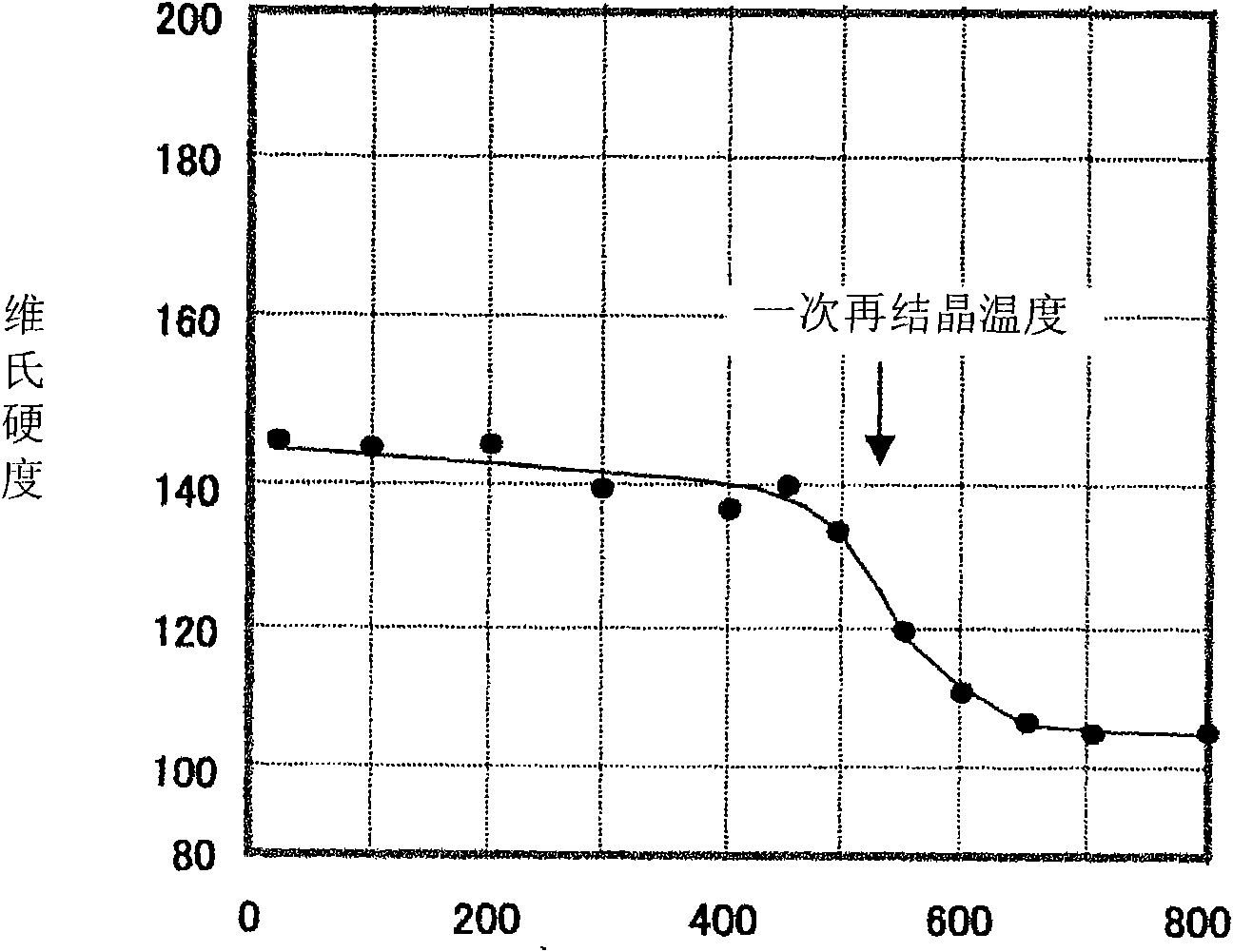

ActiveUS20090116990A1Low iron-lossHigh mechanical strengthTransportation and packagingMetal-working apparatusCurie temperatureMetal powder

A method for manufacturing bodies formed from insulated soft magnetic metal powder by forming an insulating film of an inorganic substance on the surface of particles of a soft magnetic metal powder, compacting and molding the powder, then carrying out a heat treatment to provide a body formed from insulated soft magnetic metal powder the method comprising: compacting and molding the powder; then magnetically annealing the powder at a high temperature above the Curie temperature for the soft magnetic metal powder and below the threshold temperature at which the insulating film is destroyed in a non-oxidizing atmosphere, such as a vacuum, inert gas, or the like; and then carrying out a further heat treatment at a temperature of from 400° C. to 700° C. in an oxidizing atmosphere, such as air, or the like.

Owner:MITSUBISHI STEEL MFG CO LTD

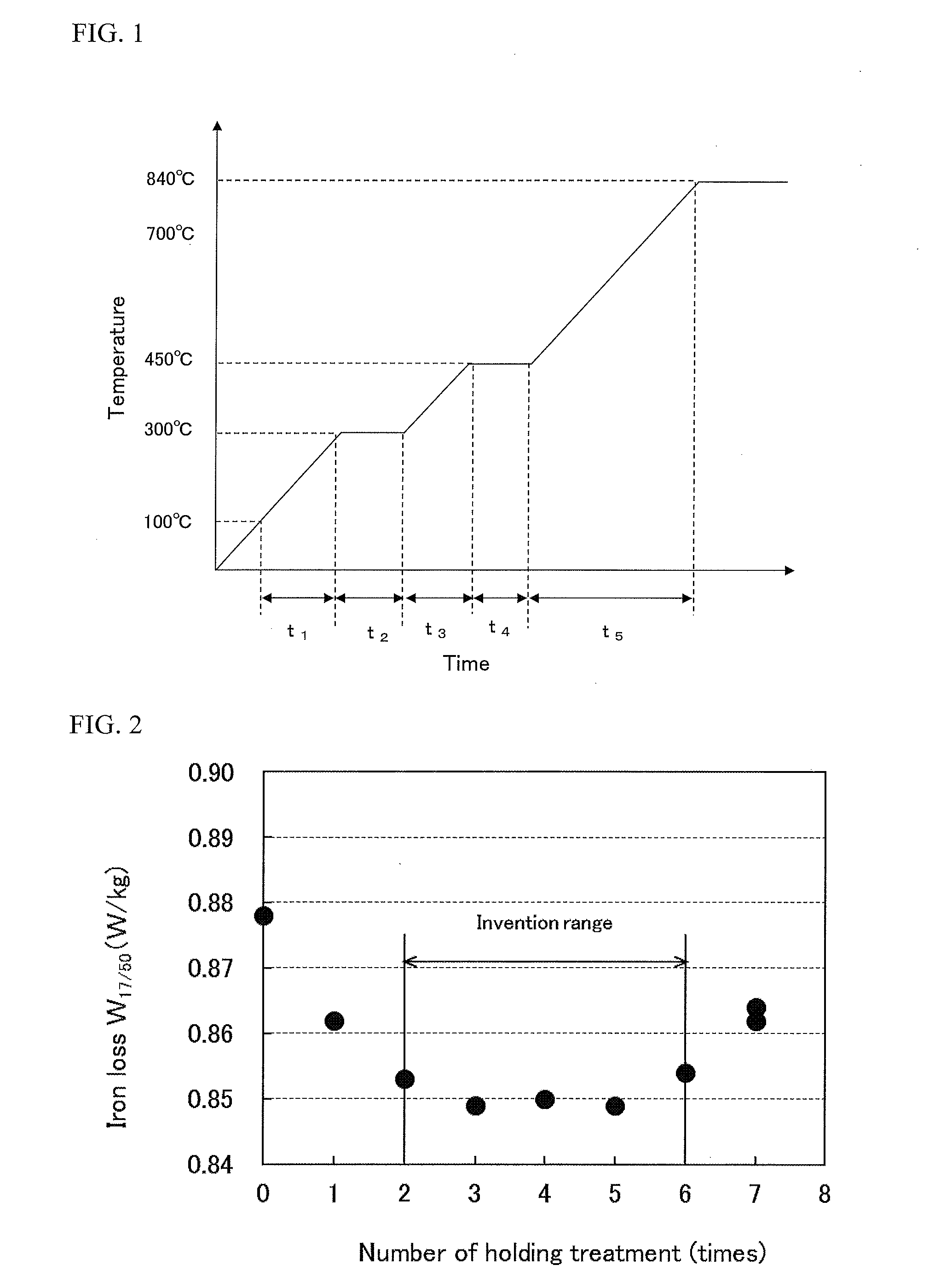

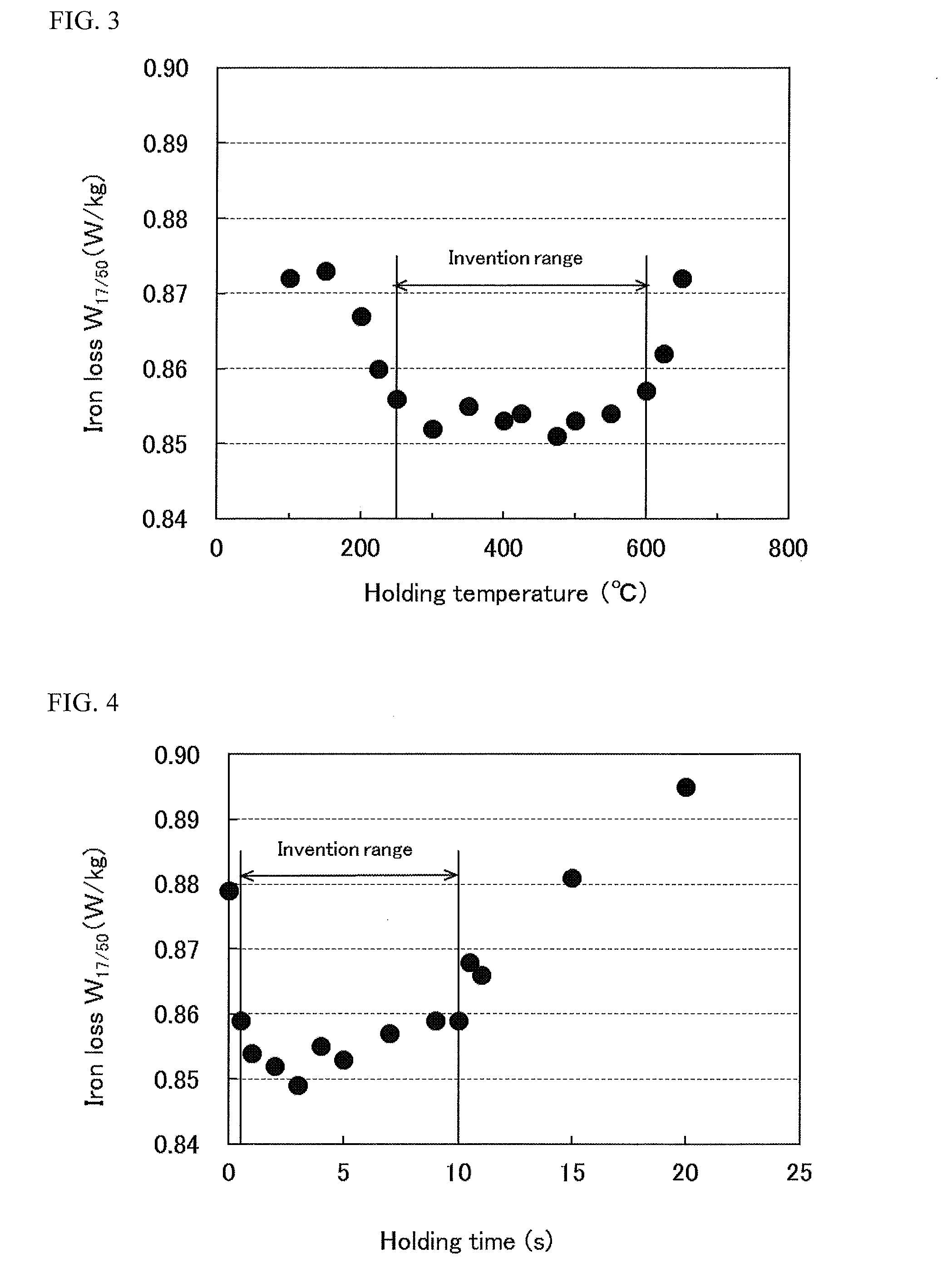

Method for producing grain-oriented electrical steel sheet

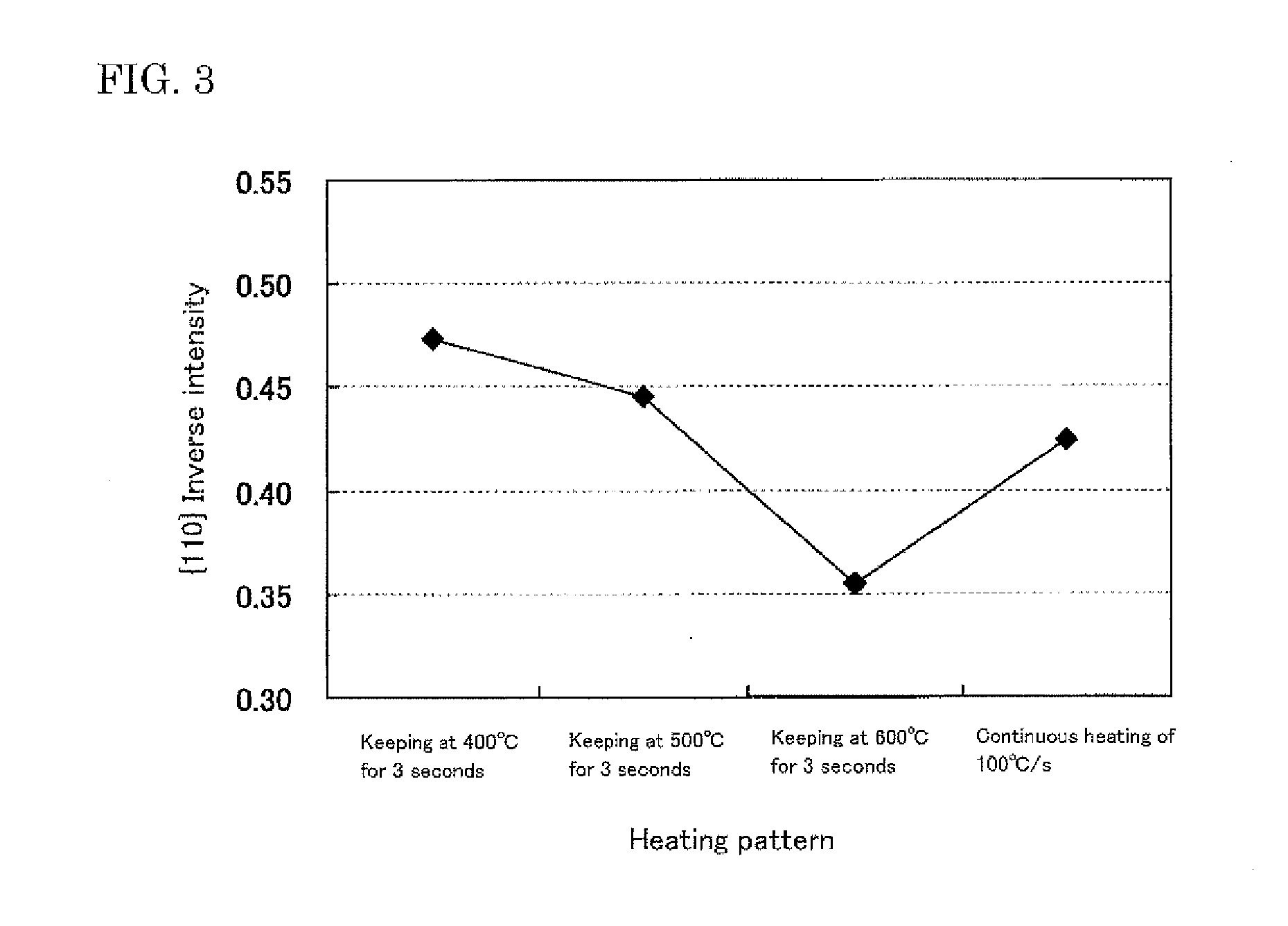

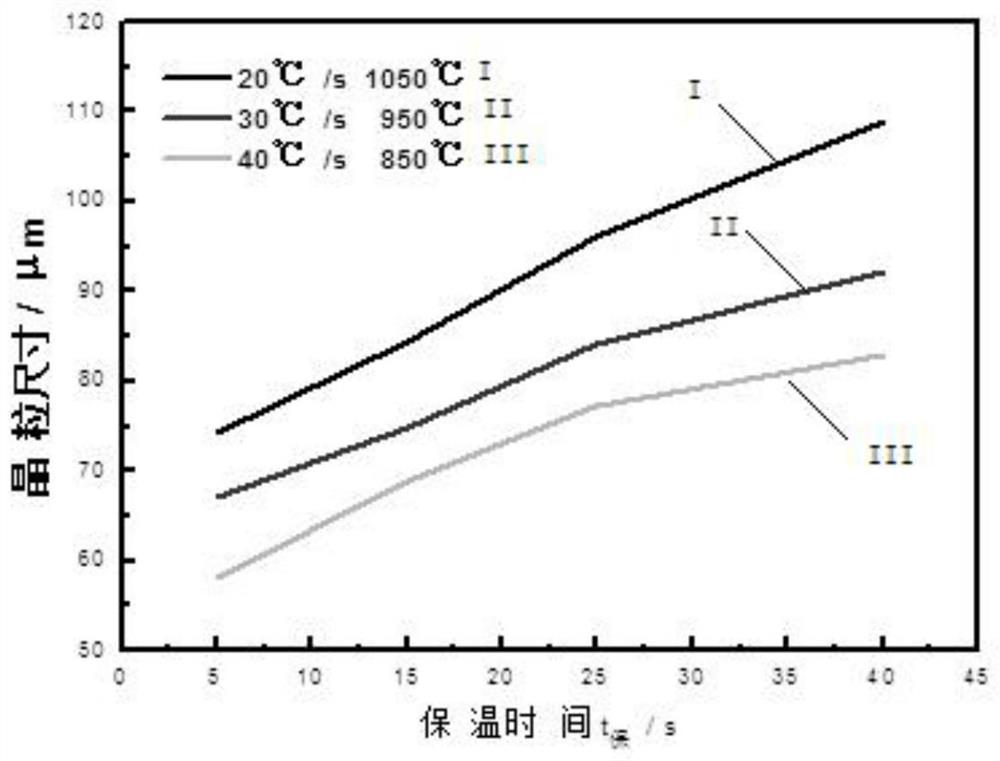

ActiveUS20160020006A1Easy to adjustHeating fastInorganic material magnetismSolid state diffusion coatingElectrical steelDecarburization

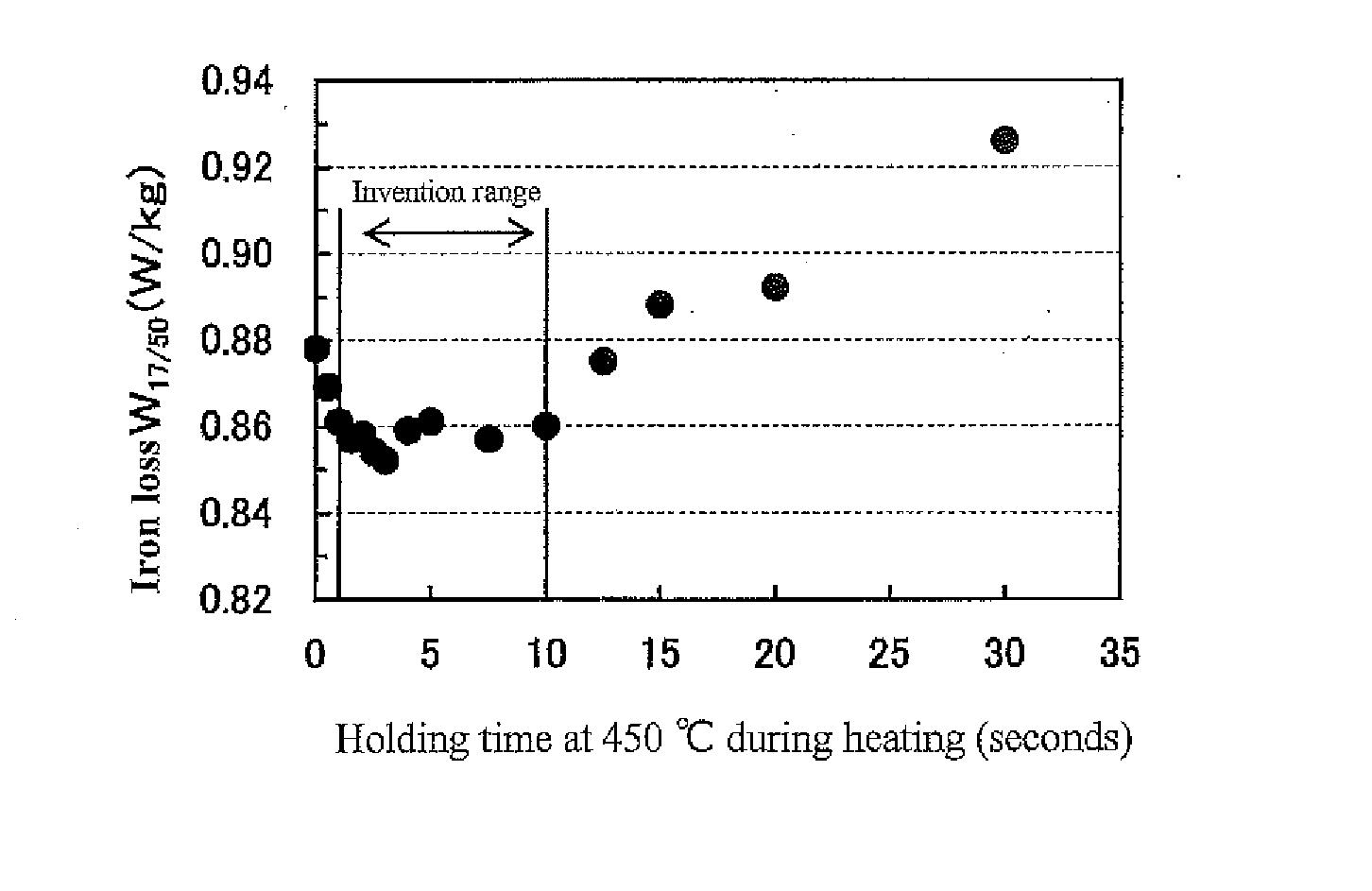

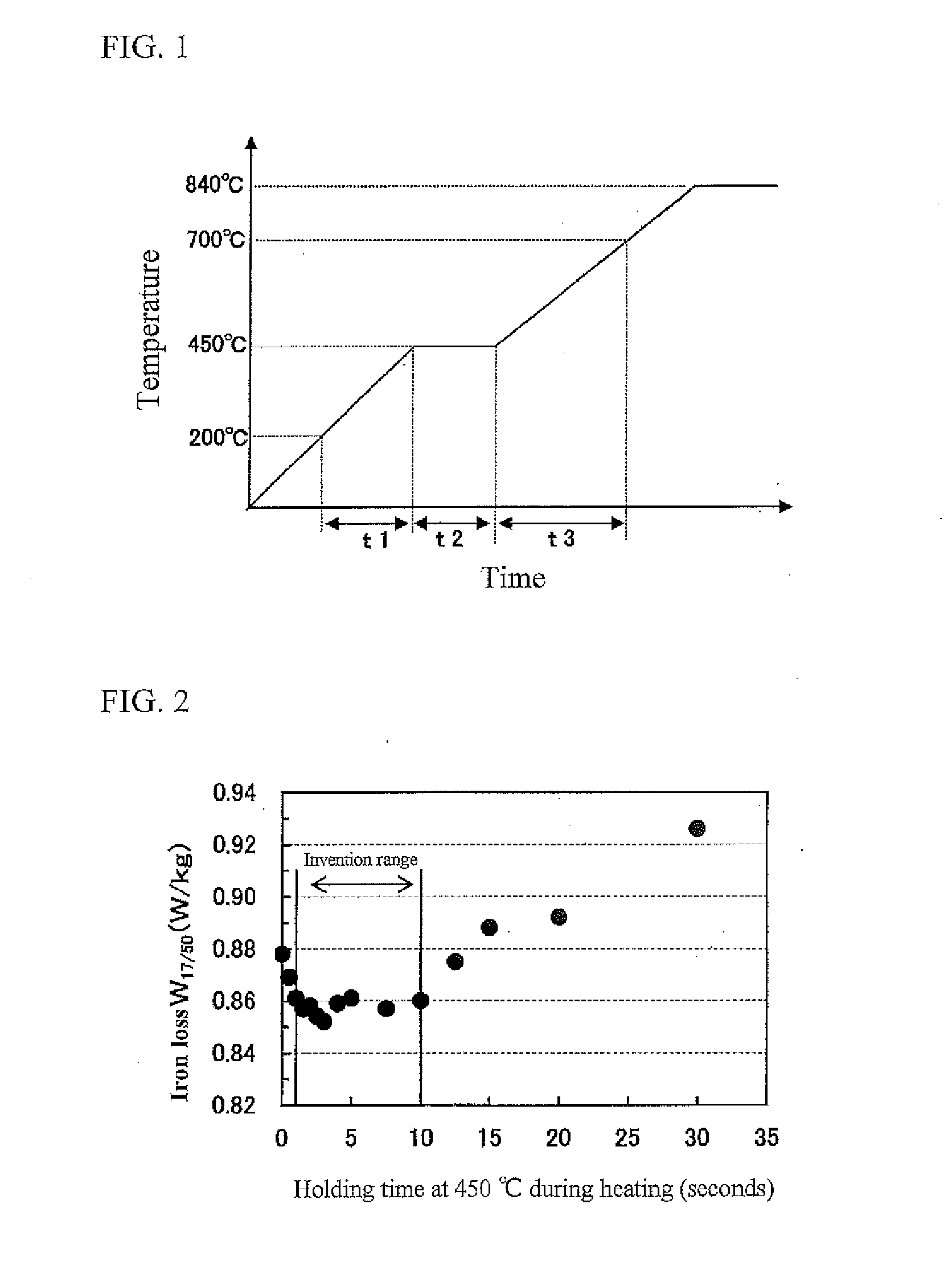

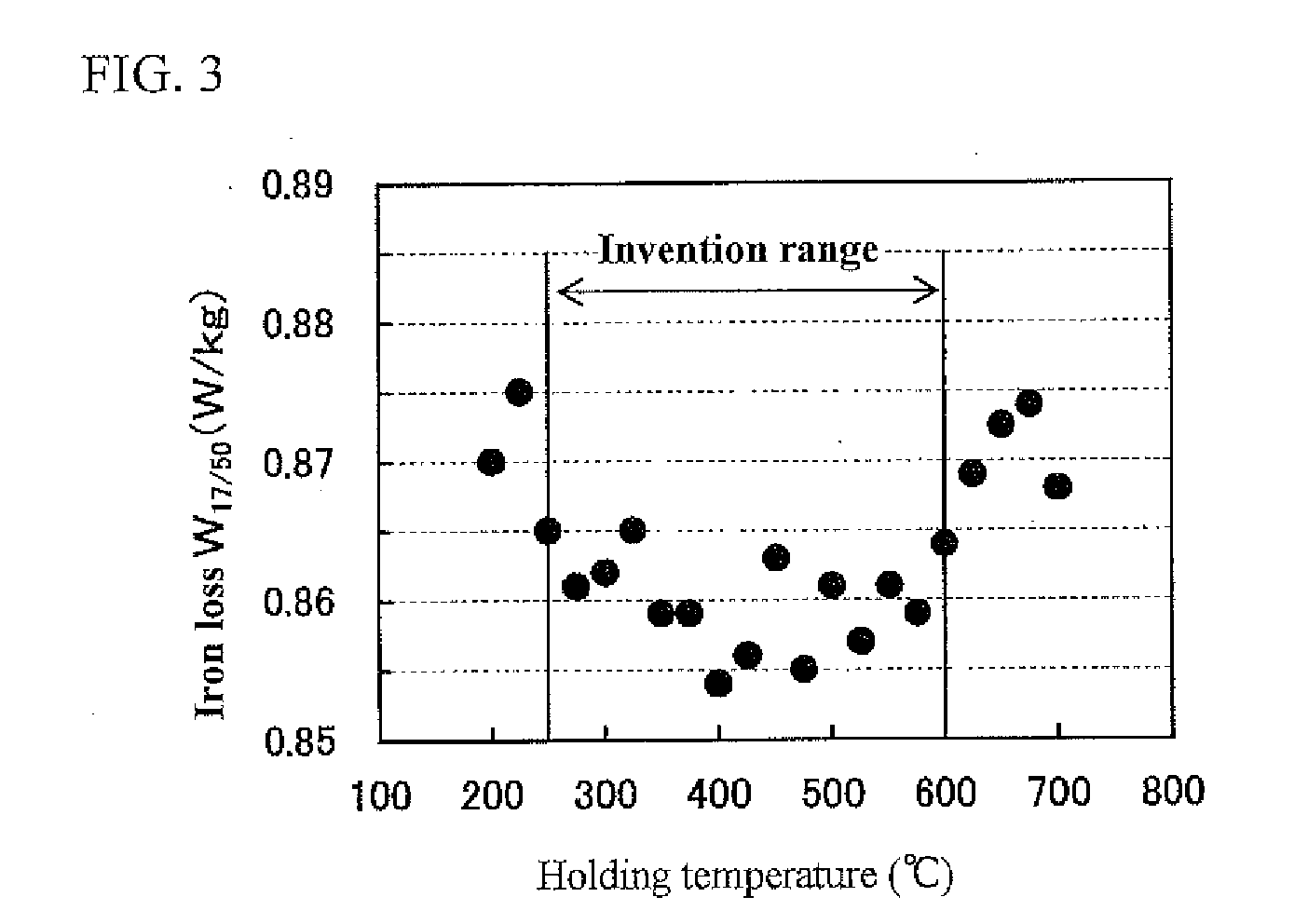

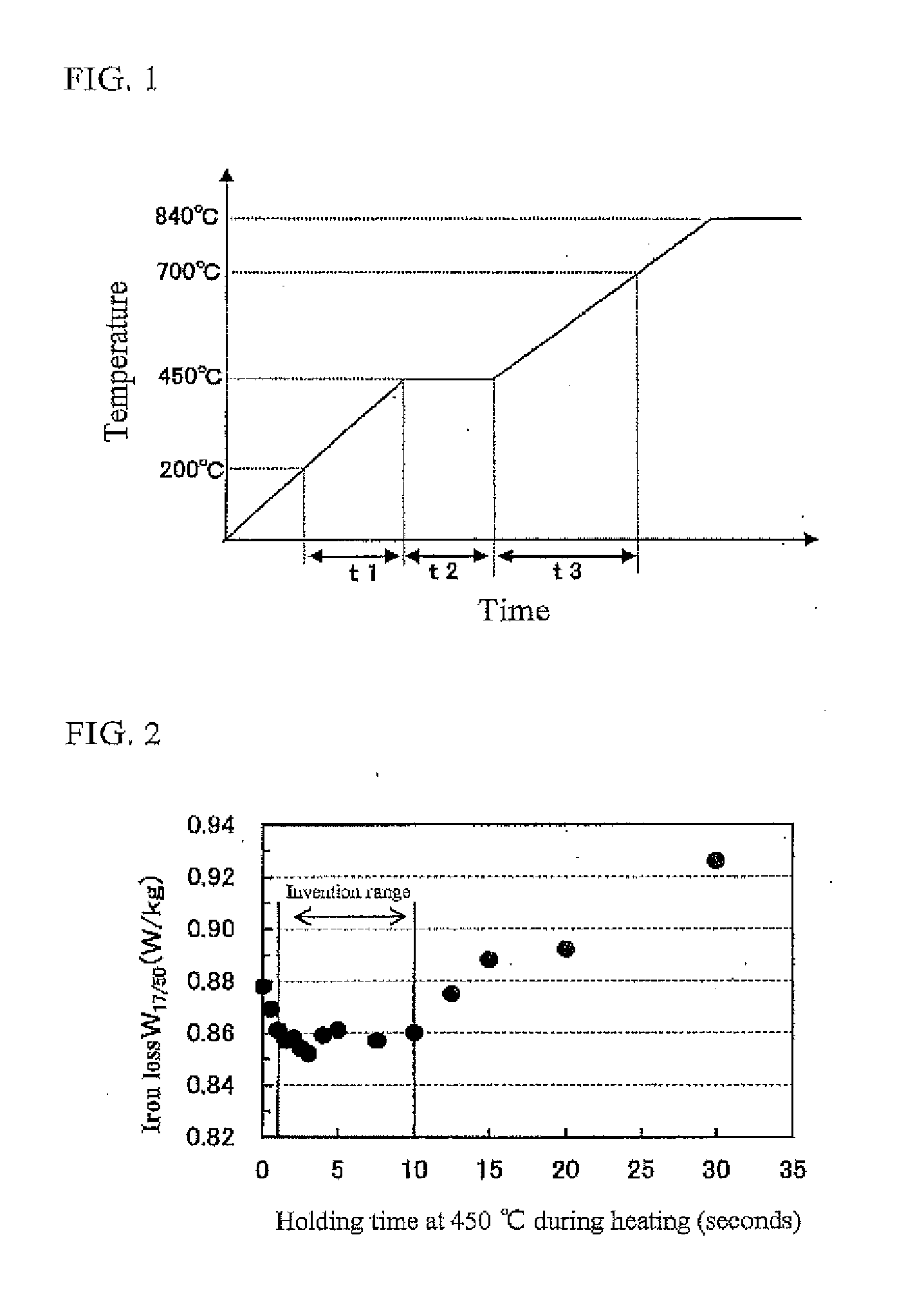

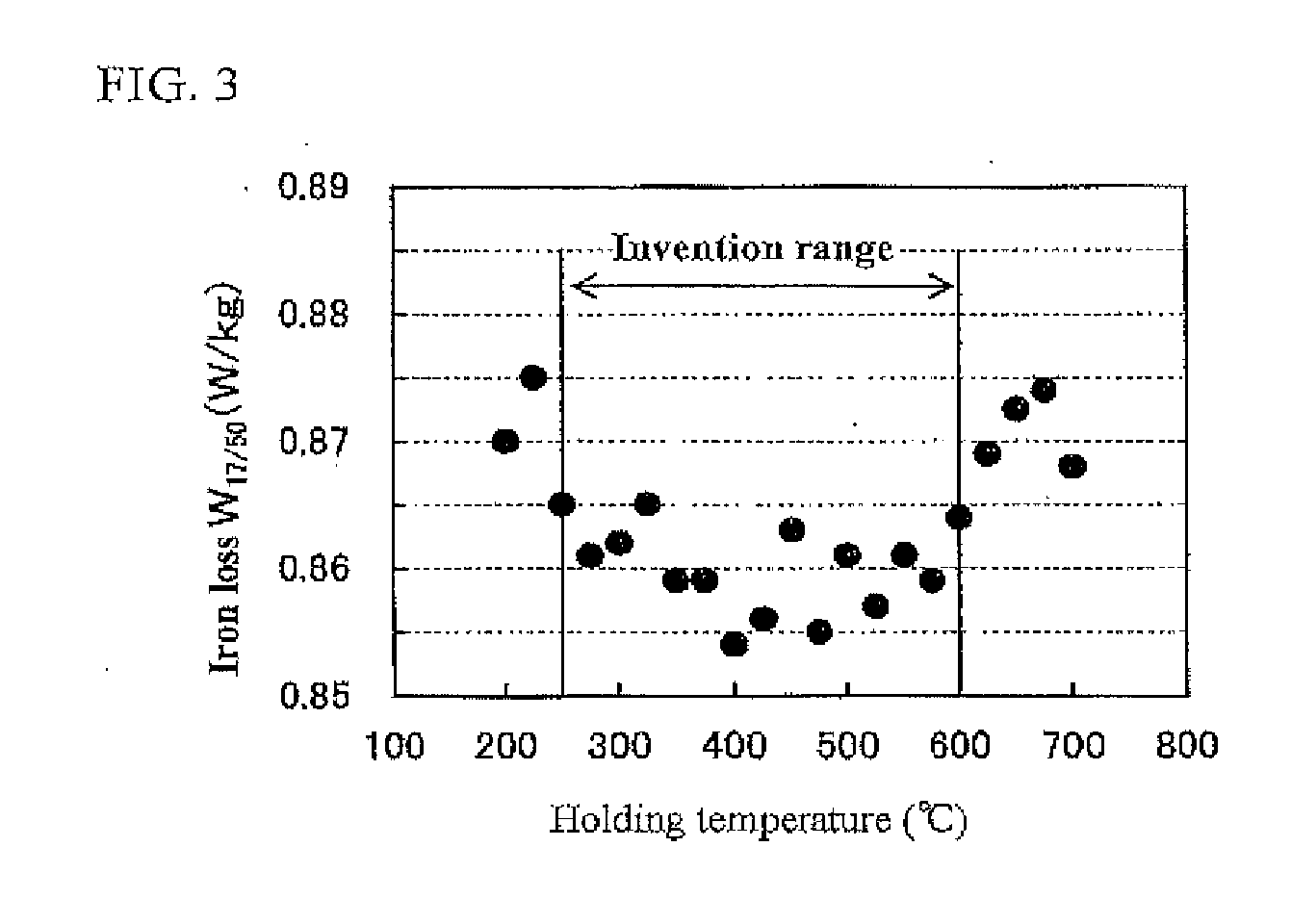

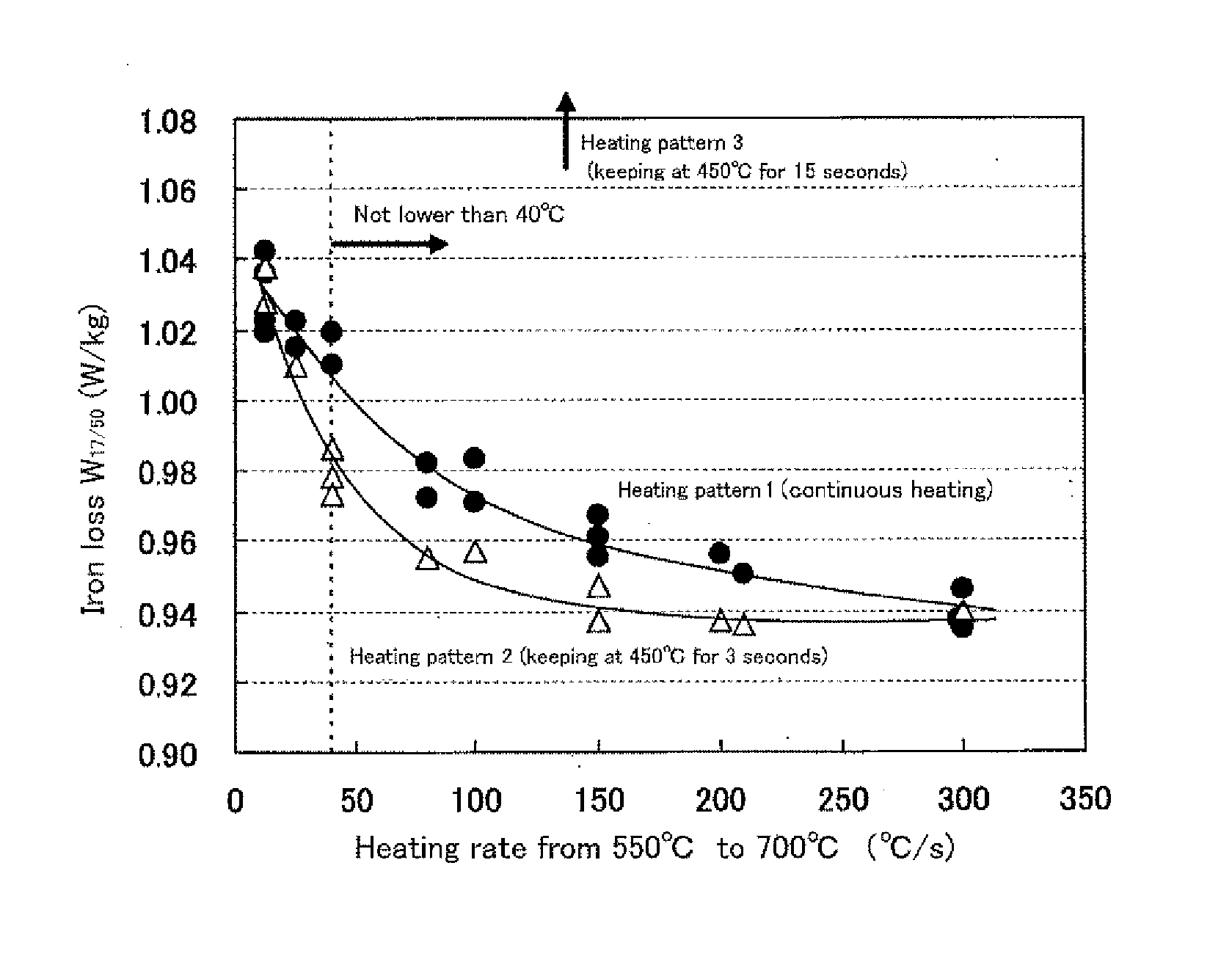

In a method for producing a grain-oriented electrical steel sheet by comprising a series of steps of hot rolling a raw steel material comprising C: 0.002-0.10 mass %, Si: 2.0-8.0 mass %, and Mn: 0.005-1.0 mass %, subjecting the steel sheet to a hot band annealing as required, cold rolling to obtain a cold rolled sheet having a final sheet thickness, subjecting the steel sheet to primary recrystallization annealing combined with decarburization annealing, applying an annealing separator to the steel sheet surface and then subjecting to final annealing, rapid heating is performed at a rate of not less than 50° C. / s in a region of 200-700° C. in the heating process of the primary recrystallization annealing, and the steel sheet is held at any temperature of 250-600° C. in the above region for 1-10 seconds, while a soaking process of the primary recrystallization annealing is controlled to a temperature range of 750-900° C., a time of 90-180 seconds and PH2O / PH2 in an atmosphere of 0.25-0.40, whereby a grain-oriented electrical steel sheet being low in the iron loss and small in the deviation of the iron loss value is obtained.

Owner:JFE STEEL CORP

Method for producing grain-oriented electrical steel sheet

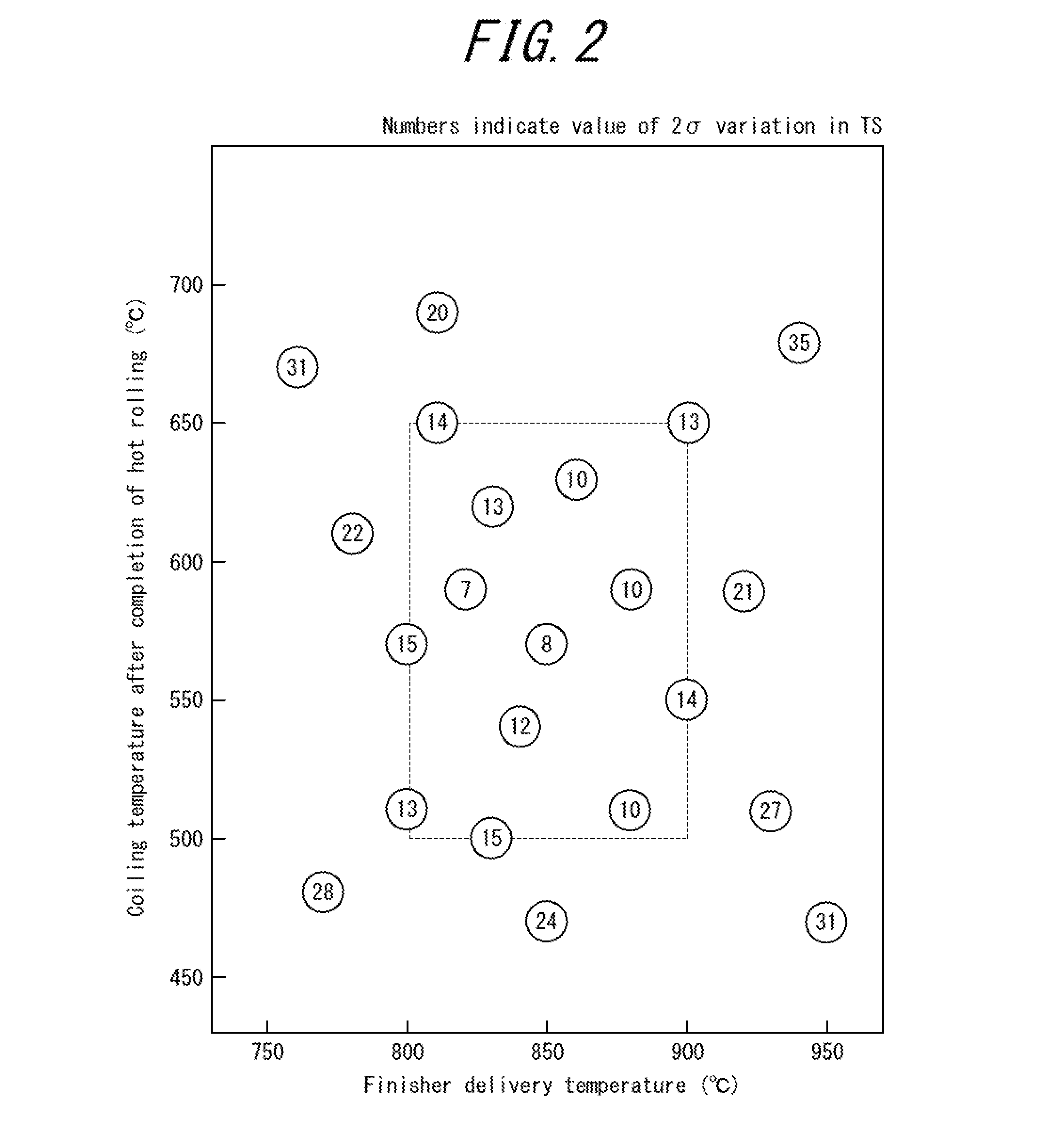

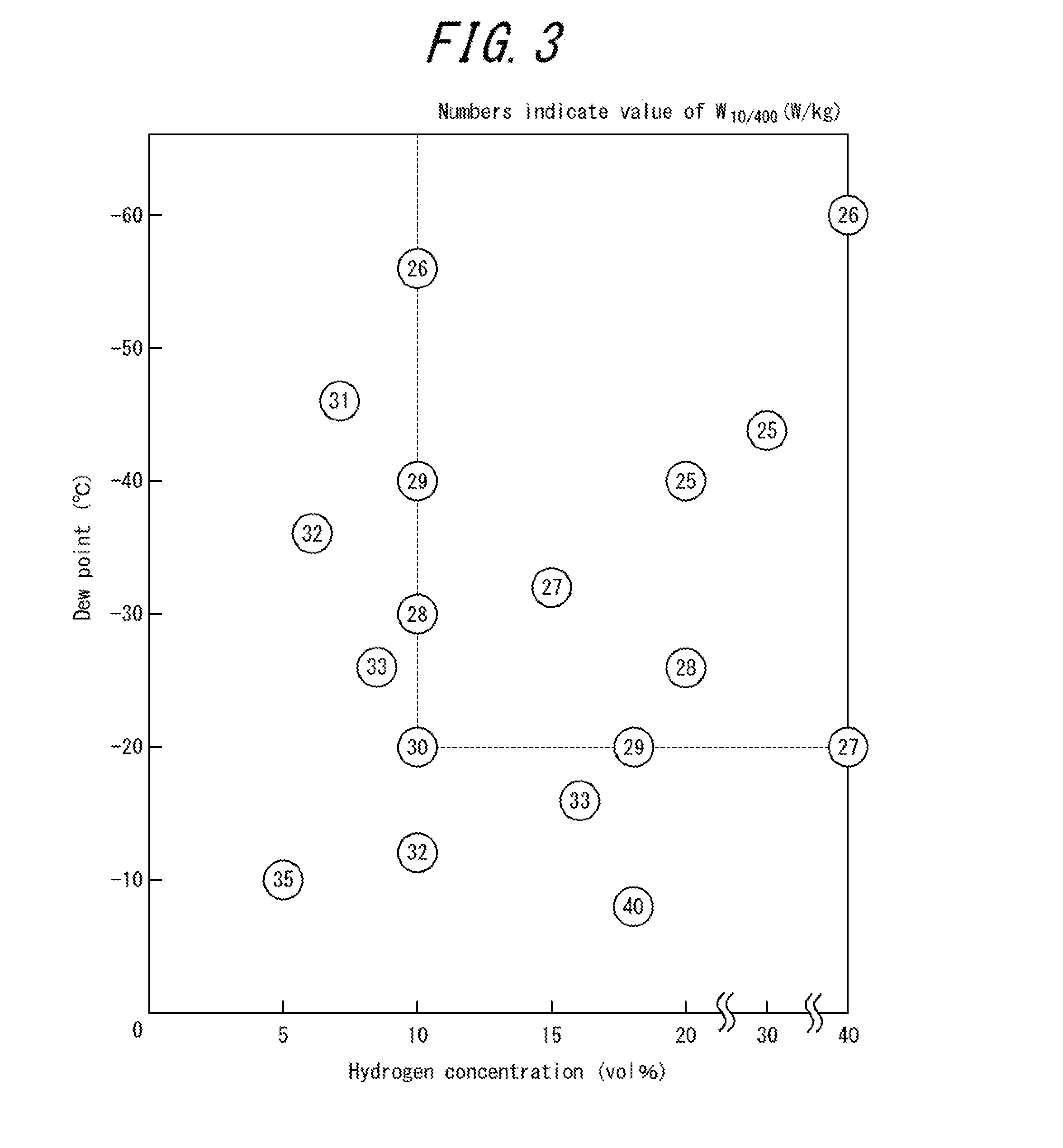

ActiveUS20150187473A1Avoid large deviationLow iron-lossInorganic material magnetismFurnace typesElectrical steelSheet steel

A method for producing a grain-oriented electrical steel sheet includes hot rolling a raw steel material containing C: 0.002˜0.10 mass %, Si: 2.0˜8.0 mass % and Mn: 0.005˜1.0 mass % to obtain a hot rolled sheet, subjecting the sheet after or without hot band annealing to one or two or more stage cold rollings including an intermediate annealing to obtain a cold rolled sheet having a final sheet thickness, subjecting the rolled sheet to decarburization annealing and primary recrystallization annealing, applying an annealing separator to the sheet surface and subjecting to a final annealing, when rapid heating is performed at a rate of at least 50° C. / s in a range of 200˜700° C. of the decarburization annealing, the rolled sheet is subjected to holding at any temperature of 250˜600° C. for 1˜10 seconds to produce a grain-oriented electrical steel sheet being low in the iron loss and small in the deviation of the iron loss value.

Owner:JFE STEEL CORP

Method for producing grain-oriented electrical steel sheet

ActiveUS20160319390A1Low iron-lossSmall in deviation of iron loss valueInorganic material magnetismFurnace typesSheet steelElectrical steel

Owner:JFE STEEL CORP

Method of producing grain-oriented electrical steel sheet

ActiveUS20150170813A1Heating fastFast heatingInorganic material magnetismFurnace typesElectrical steelChemical composition

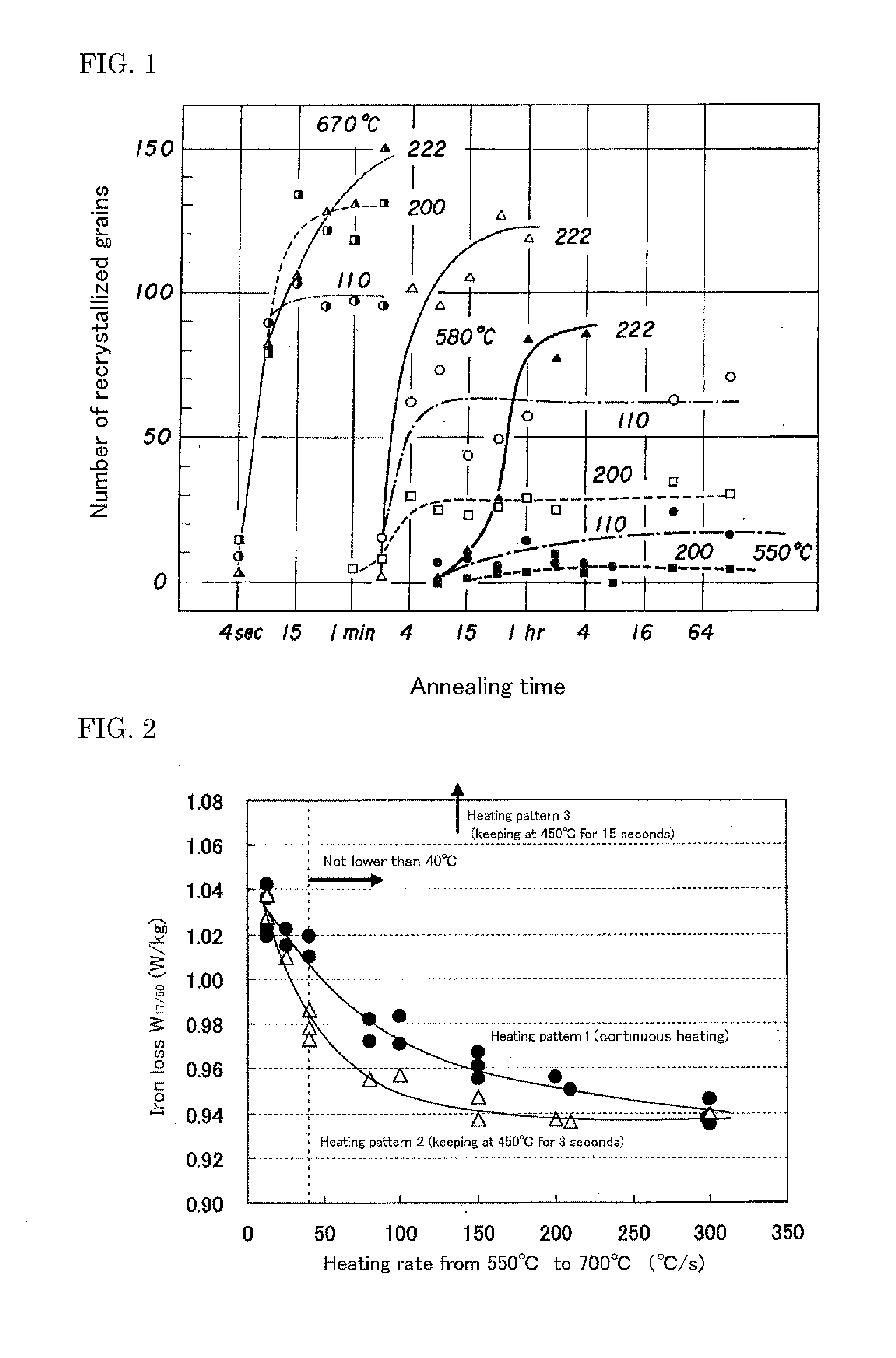

In a method of producing a grain-oriented electrical steel sheet by hot rolling a steel slab having a chemical composition including C: 0.001˜0.10 mass %, Si: 1.0˜5.0 mass %, Mn: 0.01˜0.5 mass %, S and / or Se: 0.01˜0.05 mass %, sol. Al: 0.003˜0.050 mass % and N: 0.0010˜0.020 mass %, subjecting to single cold rolling or two or more cold rollings including an intermediate annealing therebetween to a final thickness, performing primary recrystallization annealing, and thereafter applying an annealing separator to perform final annealing, a temperature range of 550° C. to 700° C. in a heating process of the primary recrystallization annealing is rapidly heated at an average heating rate of 40˜200° C. / s, while any temperature zone of from 250° C. to 550° C. is kept at a heating rate of not more than 10° C. / s for 1˜10 seconds, whereby the refining of secondary recrystallized grains is attained and grain-oriented electrical steel sheets are stably obtained with a low iron loss.

Owner:JFE STEEL CORP

Non-oriented electrical steel sheet having excellent magnetic properties

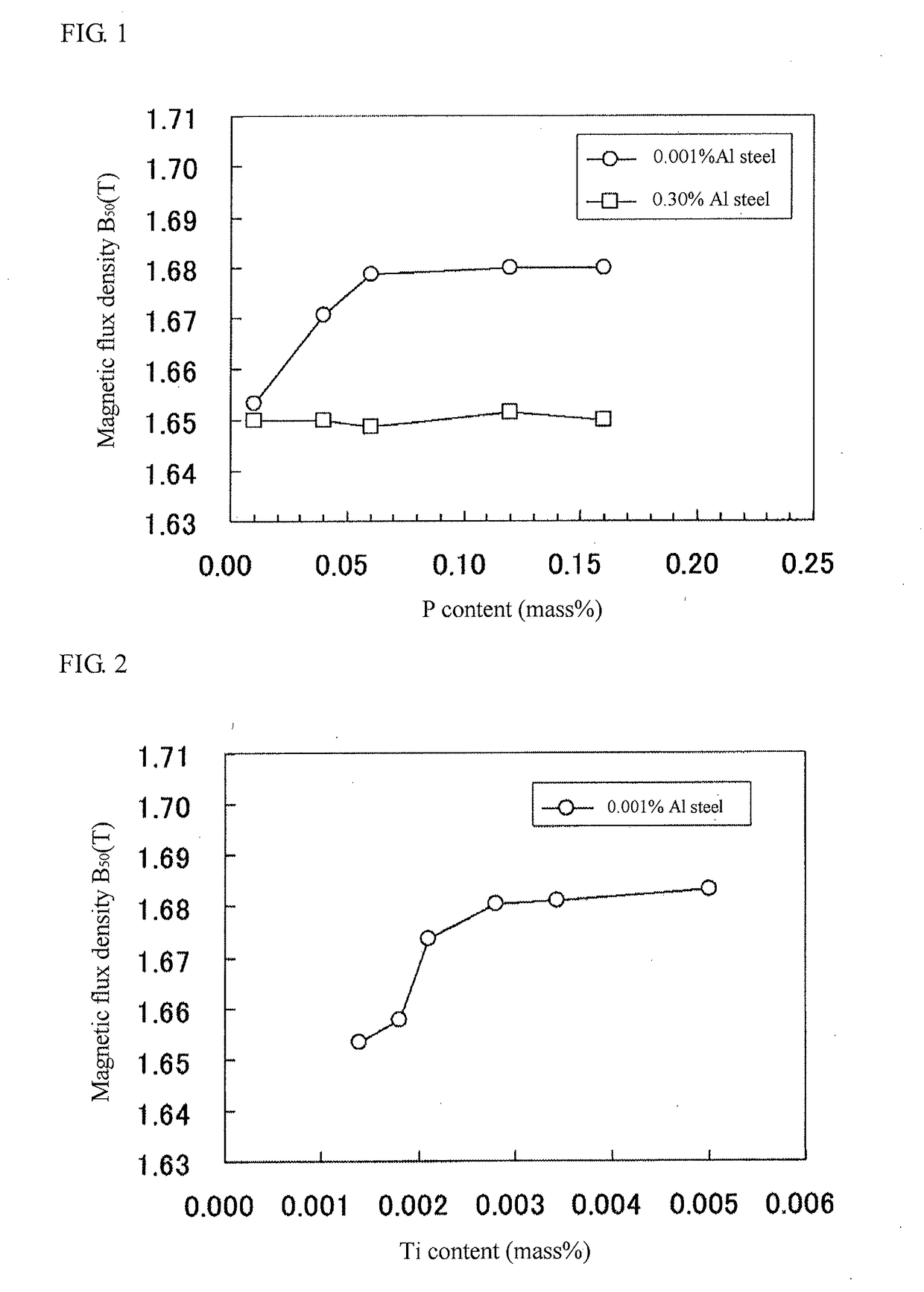

InactiveUS20170229222A1Low costSolve the low generation efficiencyPropulsion using engine-driven generatorsInorganic material magnetismElectrical steelMagnetic flux

A non-oriented electrical steel sheet having a high magnetic flux density and a low iron loss includes C: not more than 0.01 mass %, Si: 1.3-5.0 mass %, Mn: 0.001-3 mass %, sol. Al: not more than 0.004 mass %, P: 0.03-0.20 mass %, S: not more than 0.005 mass %, N: not more than 0.005 mass %, Ti: more than 0.0020 mass % but not more than 0.1 mass %, and further contains one or more selected from Sn: 0.001-0.1 mass %, Sb: 0.001-0.1 mass %, Ca: 0.001-0.02 mass % and Mg: 0.001-0.02 mass % as required.

Owner:JFE STEEL CORP

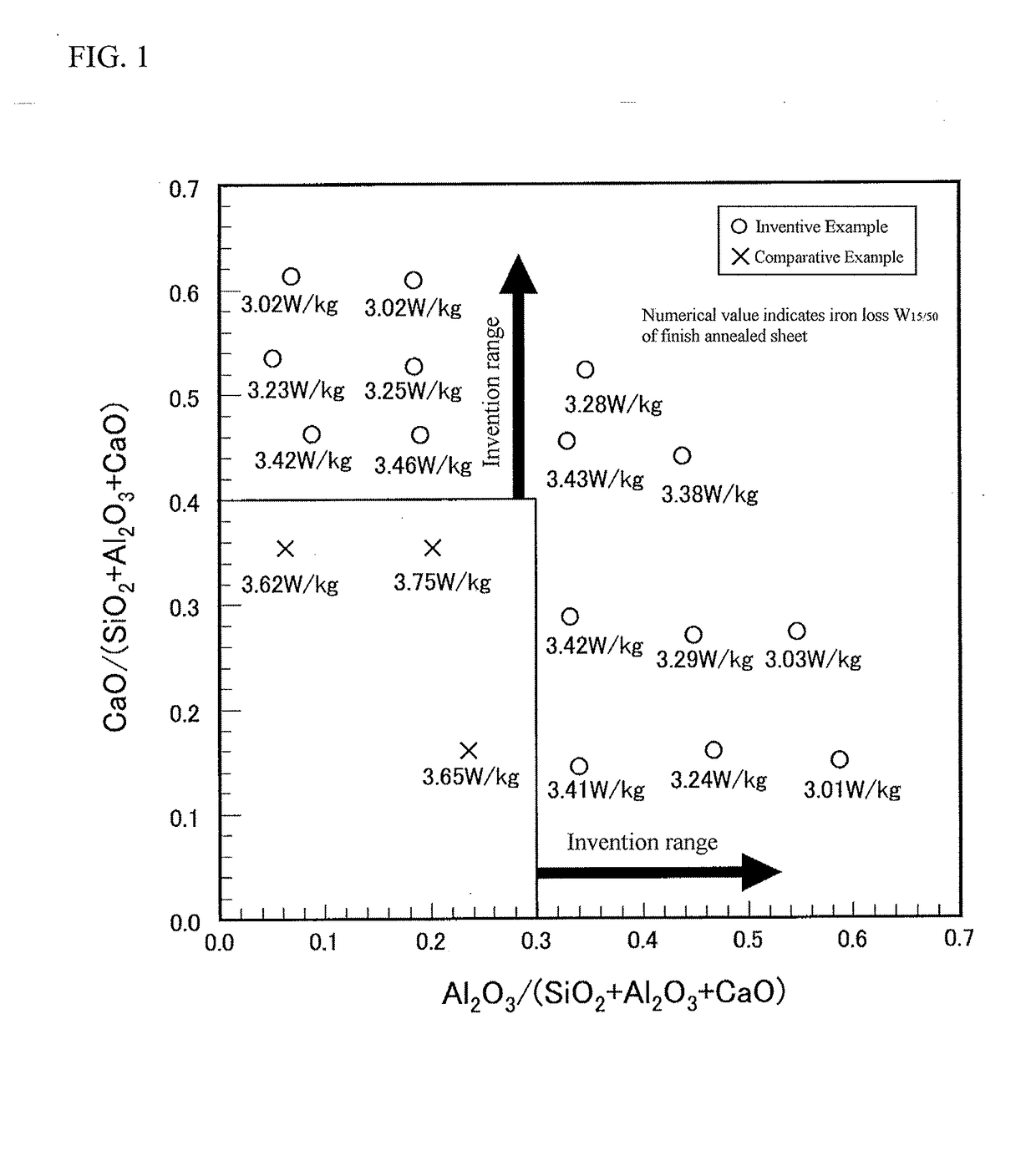

Non-oriented electrical steel sheet and hot rolled steel sheet thereof

ActiveUS20160203895A1Low iron-lossHigh magnetic flux densityInorganic material magnetismMetal rolling arrangementsChemical compositionSheet steel

A non-oriented electrical steel sheet having a high magnetic flux density and a low iron loss at not only a commercial frequency but also a high frequency zone, which has a chemical composition including C: not more than 0.0050 mass %, Si: more than 1.5 mass % but not more than 5.0 mass %, Mn: not more than 0.10 mass %, sol. Al: not more than 0.0050 mass, P: more than 0.040 mass % but not more than 0.2 mass %, S: not more than 0.0050 mass %, N: not more than 0.0040 mass % and Ca: 0.001-0.01 mass % and the remainder being Fe and inevitable impurities and a compositional ratio of CaO in oxide-based inclusions existing in a steel sheet of not less than 0.4 and / or a compositional ratio of Al2O3 of not less than 0.3, and a hot rolled steel sheet used as a raw steel material thereof.

Owner:JFE STEEL CORP

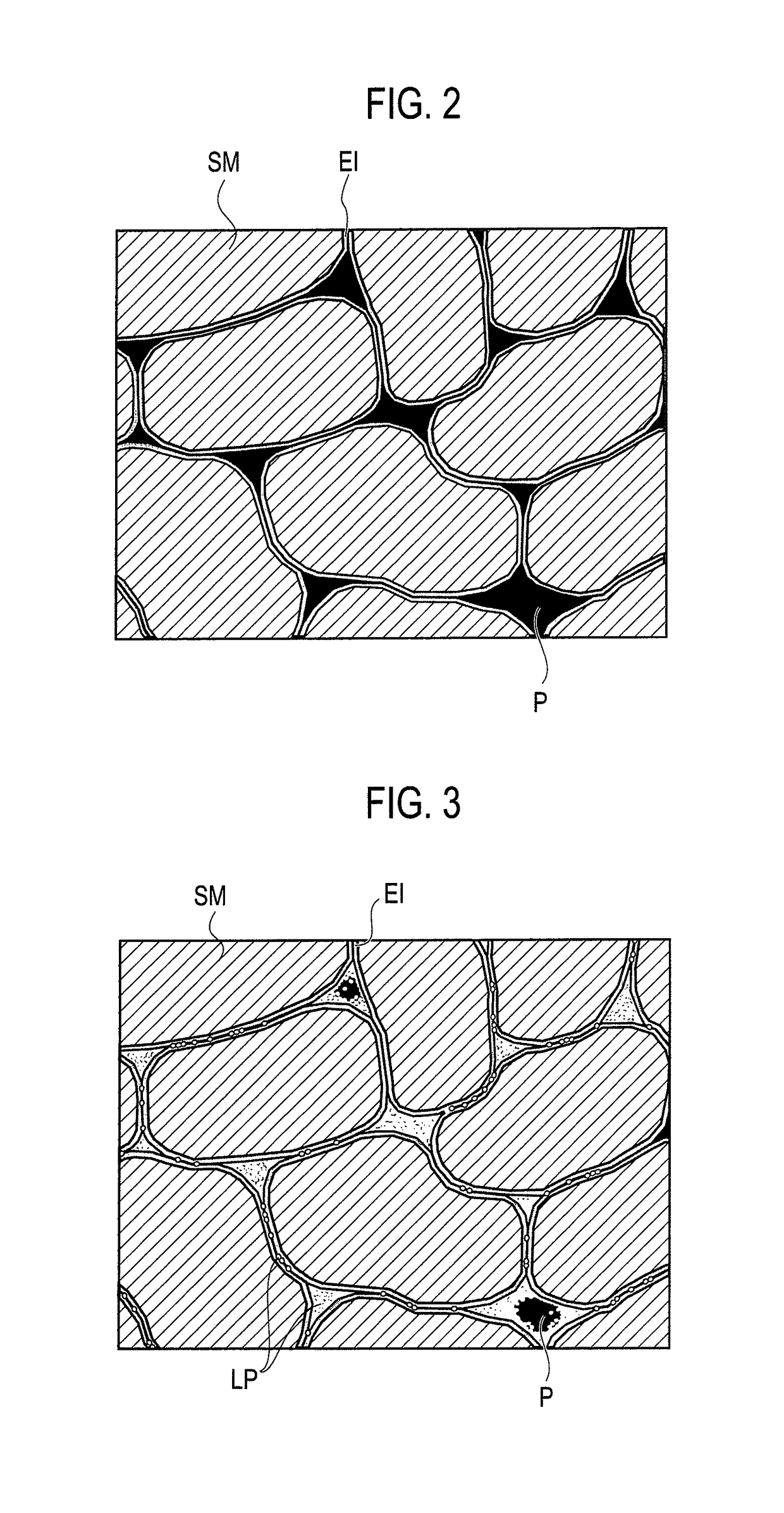

Powder magnetic core and method for producing the same

ActiveUS9646756B2Low iron-lossExcellent constancy of magnetic permeability characteristicTransportation and packagingMetal-working apparatusRelative permeabilityMaterials science

The present invention provides a powder magnetic core which has a low iron loss and an excellent constancy of magnetic permeability and is suitably used as a core for a reactor mounted on a vehicle. The powder magnetic core is a compact of a mixed powder containing an iron-based soft magnetic powder having an electrical insulating coating formed on its surface and a powder of a low magnetic permeability material having a heat-resistant temperature of 700° C. or higher than 700° C. and a relative magnetic permeability of not more than 1.0000004. The density of the compact is 6.7 Mg / m3 or more, and the low magnetic permeability material exists in the gap among the soft magnetic powder particles in the green compact.

Owner:RESONAC CORPORATION

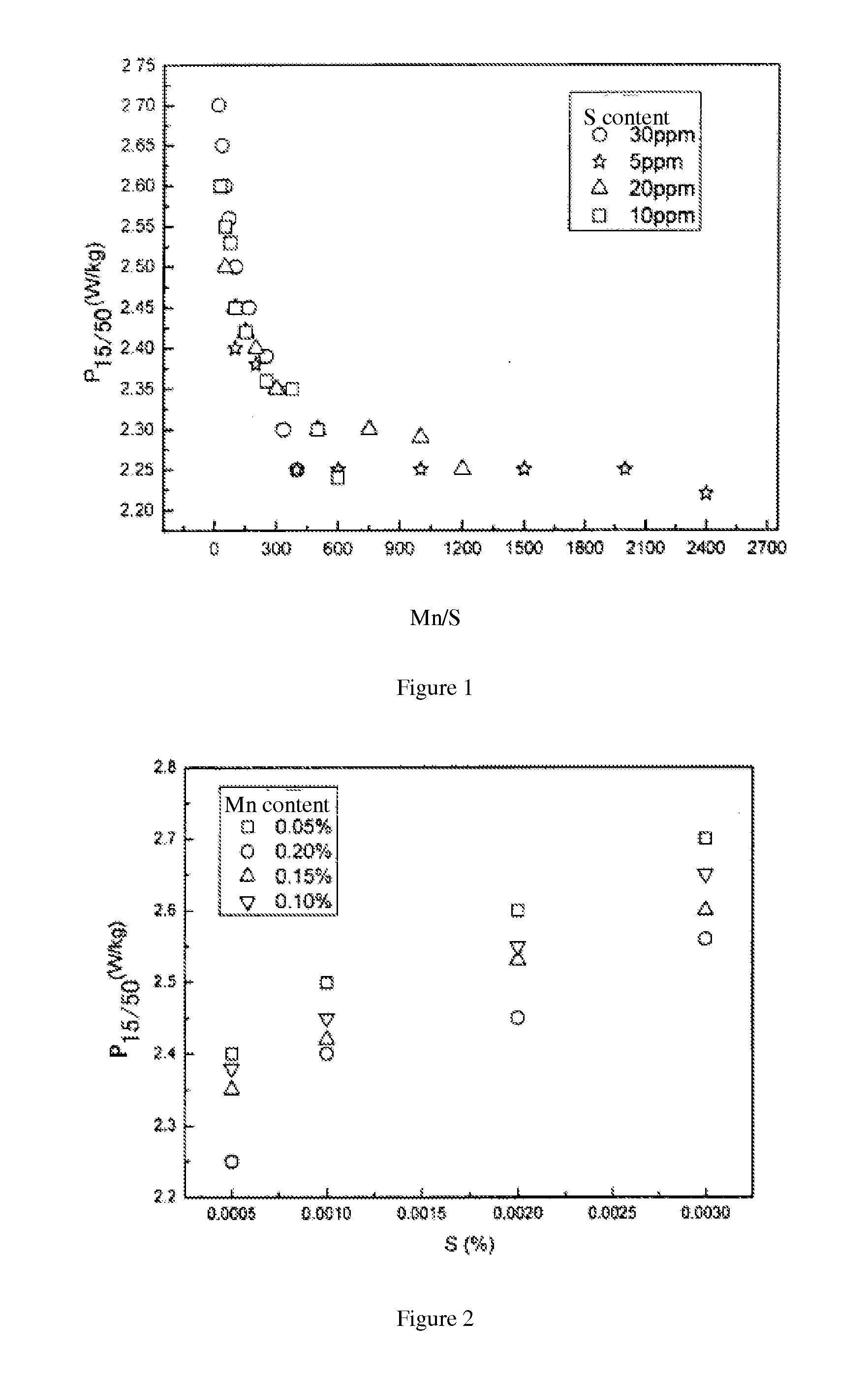

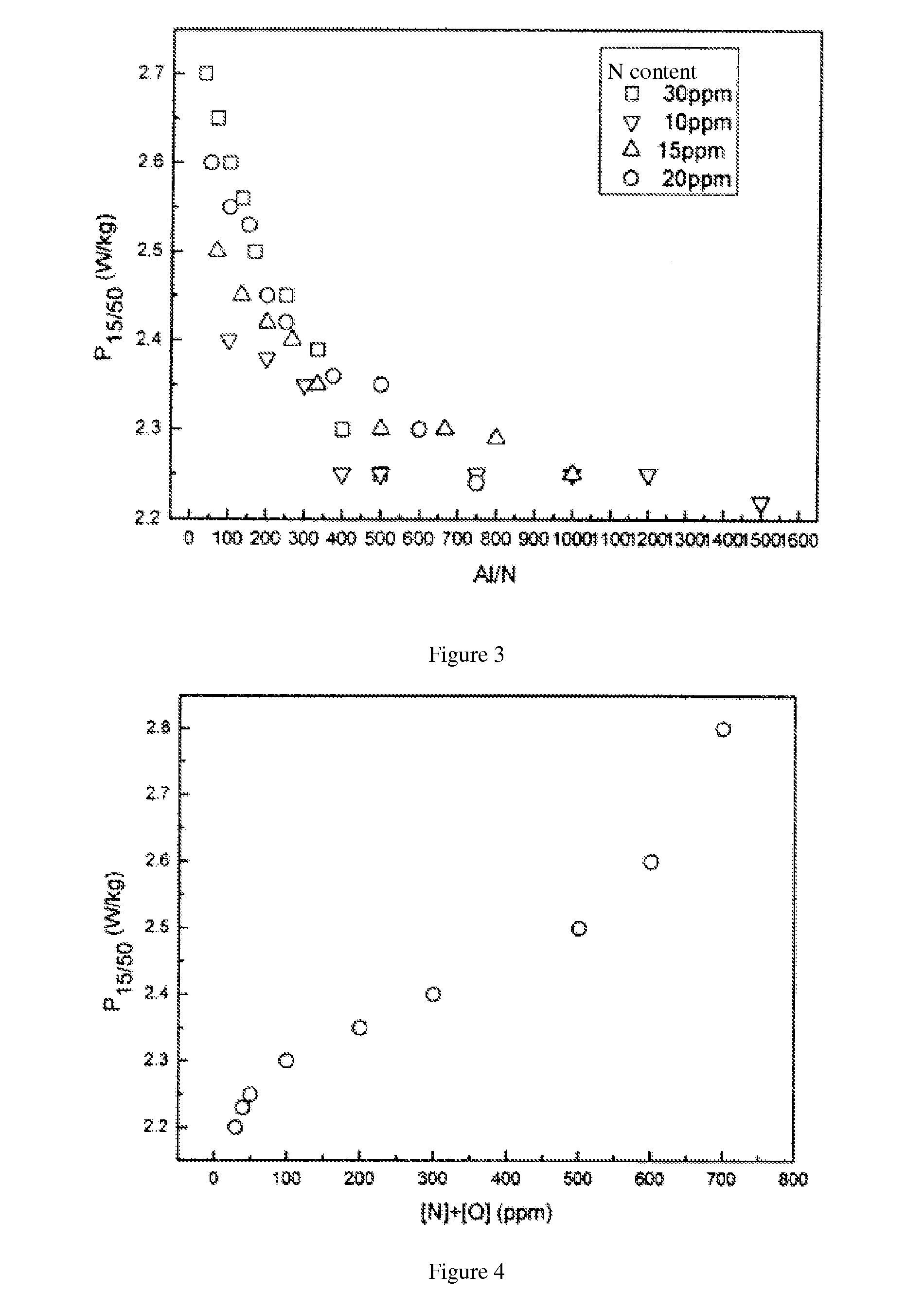

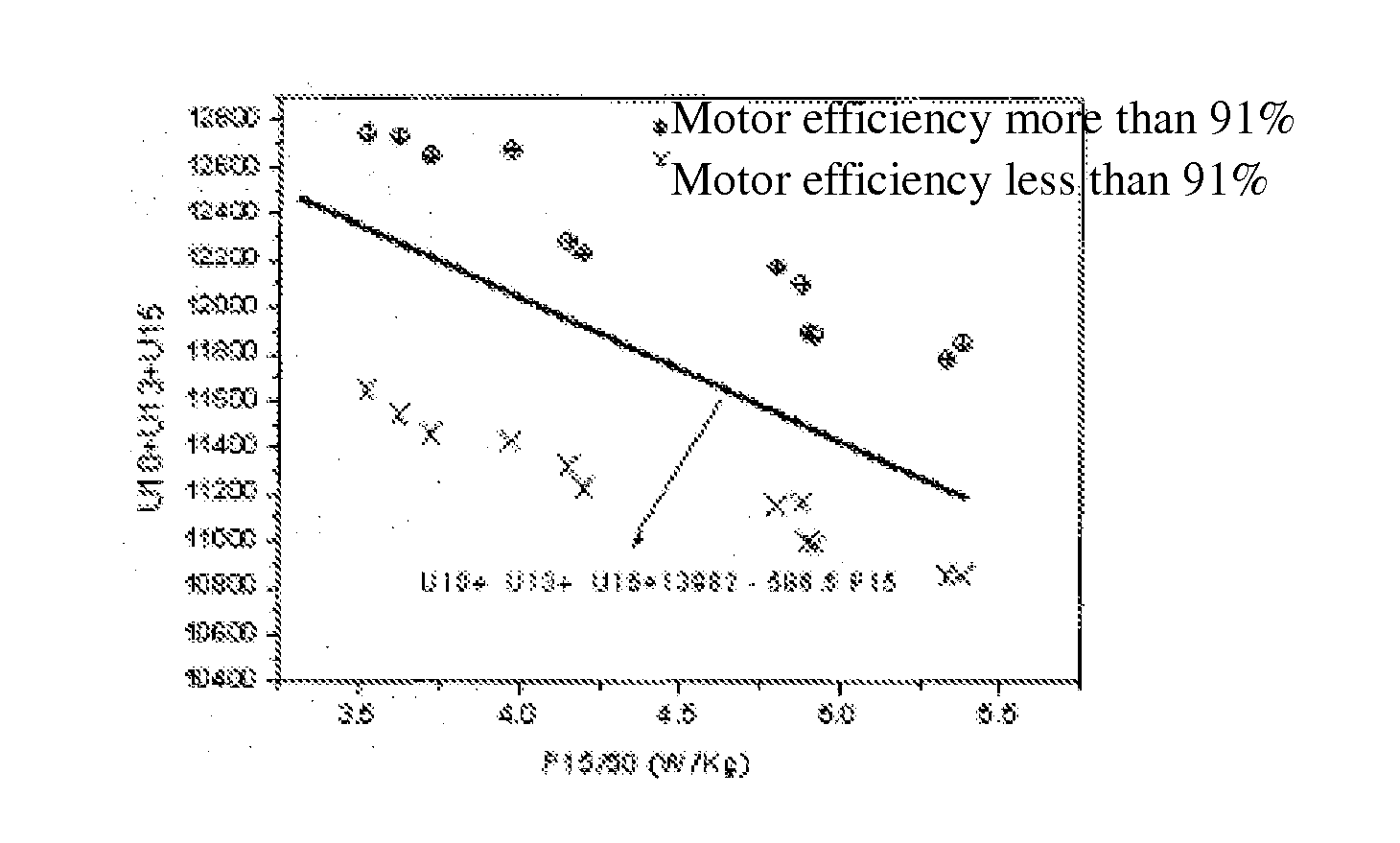

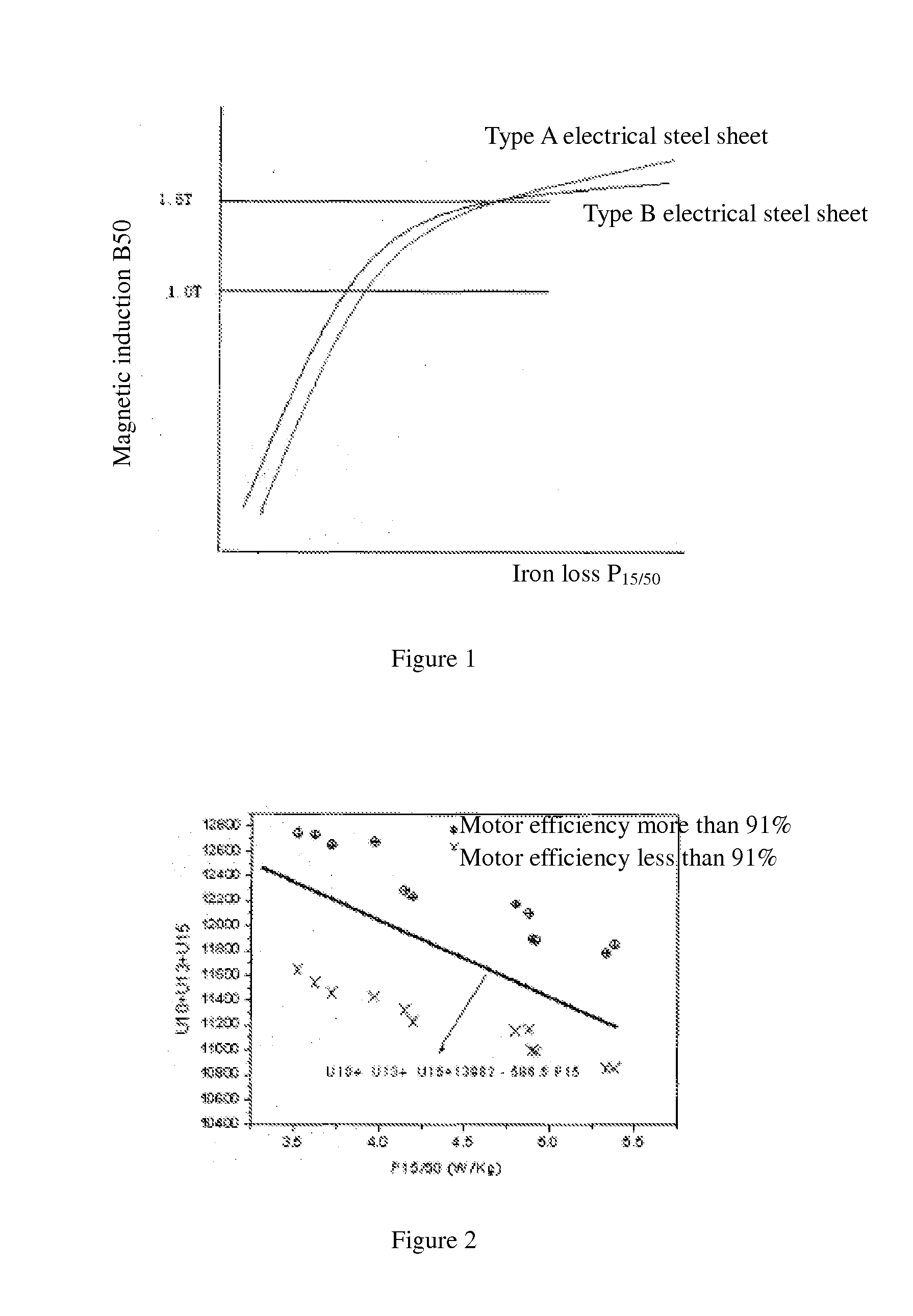

Non-Oriented Electrical Steel Plate and Manufacturing Process Therefor

ActiveUS20140377124A1Low production costHigh cost performanceWork treatment devicesInorganic material magnetismElectrical steelUltimate tensile strength

Disclosed are a non-oriented electrical steel plate with low iron loss and high magnetic conductivity and a manufacturing process therefor. The casting blank of the steel plate comprises the following components: Si: 0.1-2.0 wt %, Al: 0.1-1.0 wt %, Mn: 0.10-1.0 wt %, C: ≦0.005 wt %, P: ≦0.2 wt %, S: ≦0.005 wt %, N: ≦0.005 wt %, the balance being Fe and unavoidable impurities. The magnetic conductivity of the steel plate meets the following relationship formula: μ10+μ13+μ15≧13982−586.5P15 / 50; μ10+μ13+μ15≧10000, wherein P15 / 50 is the iron loss at a magnetic induction intensity of 1.5 T at 50 Hz; μ10, μ13, and μ15 are relative magnetic conductivities at induction intensities of 1.0 T, 1.3 T, and 1.5 T at 50 Hz, respectively. The steel plate can be used for manufacturing highly effective and ultra-highly effective electric motors.

Owner:BAOSHAN IRON & STEEL CO LTD

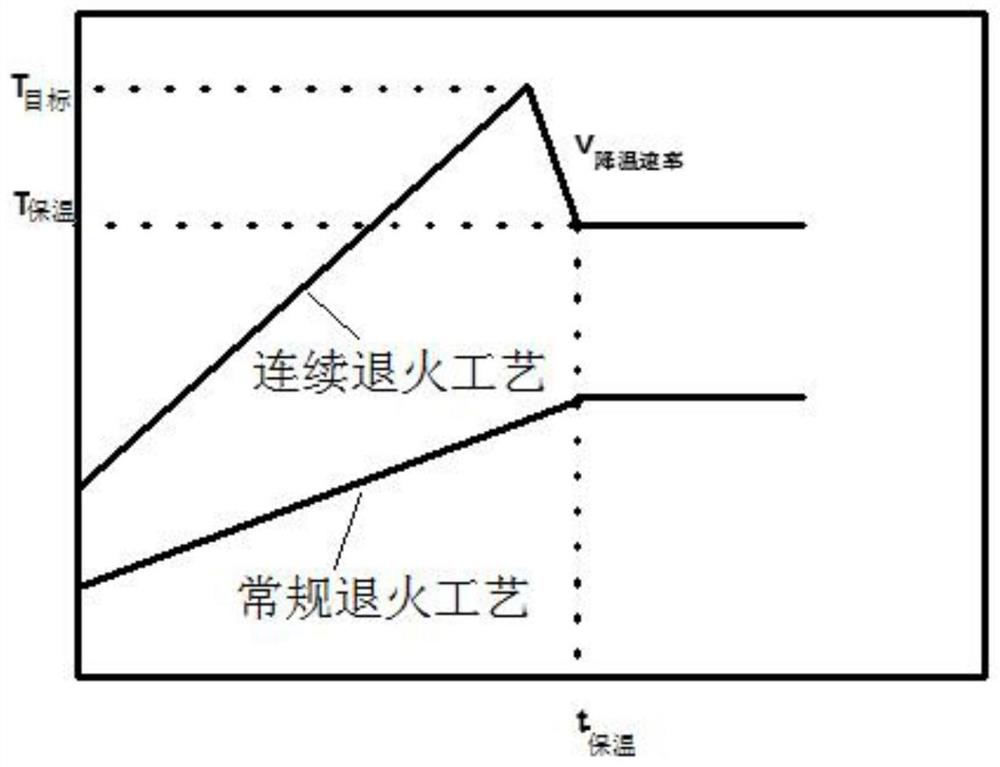

Non-oriented electrical steel plate with extremely-low iron loss and continuous annealing process of non-oriented electrical steel plate

The invention discloses a non-oriented electrical steel plate with the extremely-low iron loss. The non-oriented electrical steel plate is prepared from the chemical elements including, by mass, morethan 0 and less than or equal to 0.005% of C, 1.0%-3.45% of Si, 0.1%-1.2% of Mn, 0.001%-2.0% of Al, 0-0.2% of Cu, 0-0.0015% of Ti, one or both of Sb and Sn with the total content ranging from 0.005% to 0.2%, one or more of Ca, Mg and RE with the total content ranging from 0.0005% to 0.01% and the balance Fe and other inevitable impurities. Besides, the invention discloses a continuous annealing process of the non-oriented electrical steel plate with the extremely-low iron loss. In addition, the invention discloses a manufacturing method of the non-oriented electrical steel plate with the extremely-low iron loss. The method includes the following steps that smelting is performed; casting is performed; hot rolling is performed; normalizing is performed; cold rolling is performed; the continuous annealing process is carried out; and the plate is coated with an insulating coating, so that the non-oriented electrical steel plate with the extremely-low iron loss is obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

Magnetic material and motor using the same

InactiveUS8821649B2Improve coercive forceHigh magnetic flux densityInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementResidual flux

Characteristics of a magnetic material are improved without using a heavy rare earth element as a scarce resource. By incorporating fluorine into a magnetic powder and controlling the crystal orientation in crystal grains, a magnetic material securing magnetic characteristics such as coercive force and residual flux density can be fabricated. As a result, the resource problem with heavy rare earth elements can be solved, and the magnetic material can be applied to magnetic circuits that require a high energy product, including various rotating machines and voice coil motors of hard discs.

Owner:HITACHI LTD

Casting composite slag remover

The invention discloses a casting slag remover. A casting composite slag remover consists of pre-treated expanded perlite and a composite additive, wherein the composite additive comprises the following components of, in parts by weight, 2-40 parts of quartz sand powder, 0.1-10 parts of iron ore tailing powder, 5-40 parts of magnesia powder and 35-60 parts of sodium bentonite powder, and the weight ratio of the pre-treated expanded perlite to the composite additive is 80-95: 5-20. The casting composite slag remover can be used for correspondingly selecting and adjusting the use ratio accordingto different situations such as casting alloy types, casting processes, casting sizes and the like. The casting composite slag remover has the characteristics of strong adhesion to molten slag, highslag collecting layer strength, difficult crushing during slagging off, high slag removal efficiency and the like. The casting composite slag remover can also be used as a nonferrous alloy casting slag remover.

Owner:建平天正矿业有限公司

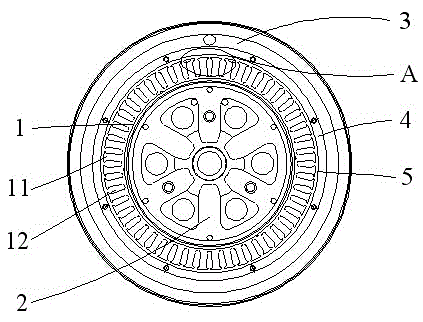

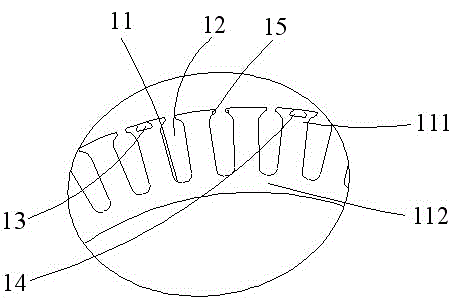

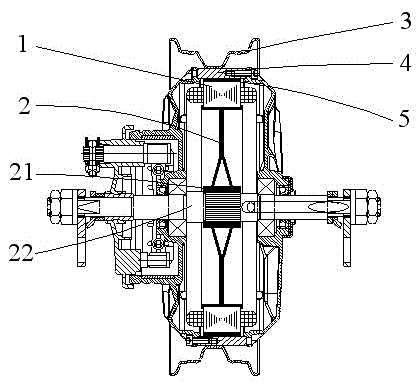

Permanent-magnet brushless direct-current hub motor having high efficiency and low material loss for electric vehicle

ActiveCN105099111AImprove conversion efficiencyIncrease profitSynchronous machine detailsElectric machinesEngineeringElectric vehicle

A permanent-magnet brushless direct-current hub motor having high efficiency and low material loss for an electric vehicle comprises a stator assembly and a rotor assembly, wherein the stator assembly comprises a fixed support and a stacked stator steel sheet, the stacked stator steel sheet is formed by laminating a plurality of silicon steel sheets and comprises tooth parts and a tooth groove part, the tooth part comprise tooth ribs and a tooth yoke, the tooth groove part is composed of a semi-closing inner cavity formed between every two tooth parts, a single silicon steel sheet is provided with an automatic-buckling groove, the tooth groove part is of a semi-closing pear-shaped groove structure, a first Hall groove, a second Hall groove and a third Hall groove are arranged on the stacked stator steel sheet, and the stator assembly comprises a rim arranged at the periphery, a magnetic conduction ring and a plurality of magnetic steel sheets. By the permanent-magnet brushless direct-current hub motor, the pole groove ratio is optimized, the performance is improved, the usage of magnetic steel and an enameled wire is reduced, cost is saved, the installation positions of the Hall grooves and the winding mode are optimized, the production efficiency is improved, and the installation accuracy is enhanced.

Owner:TAIZHOU JINYU ELECTROMECHANICAL

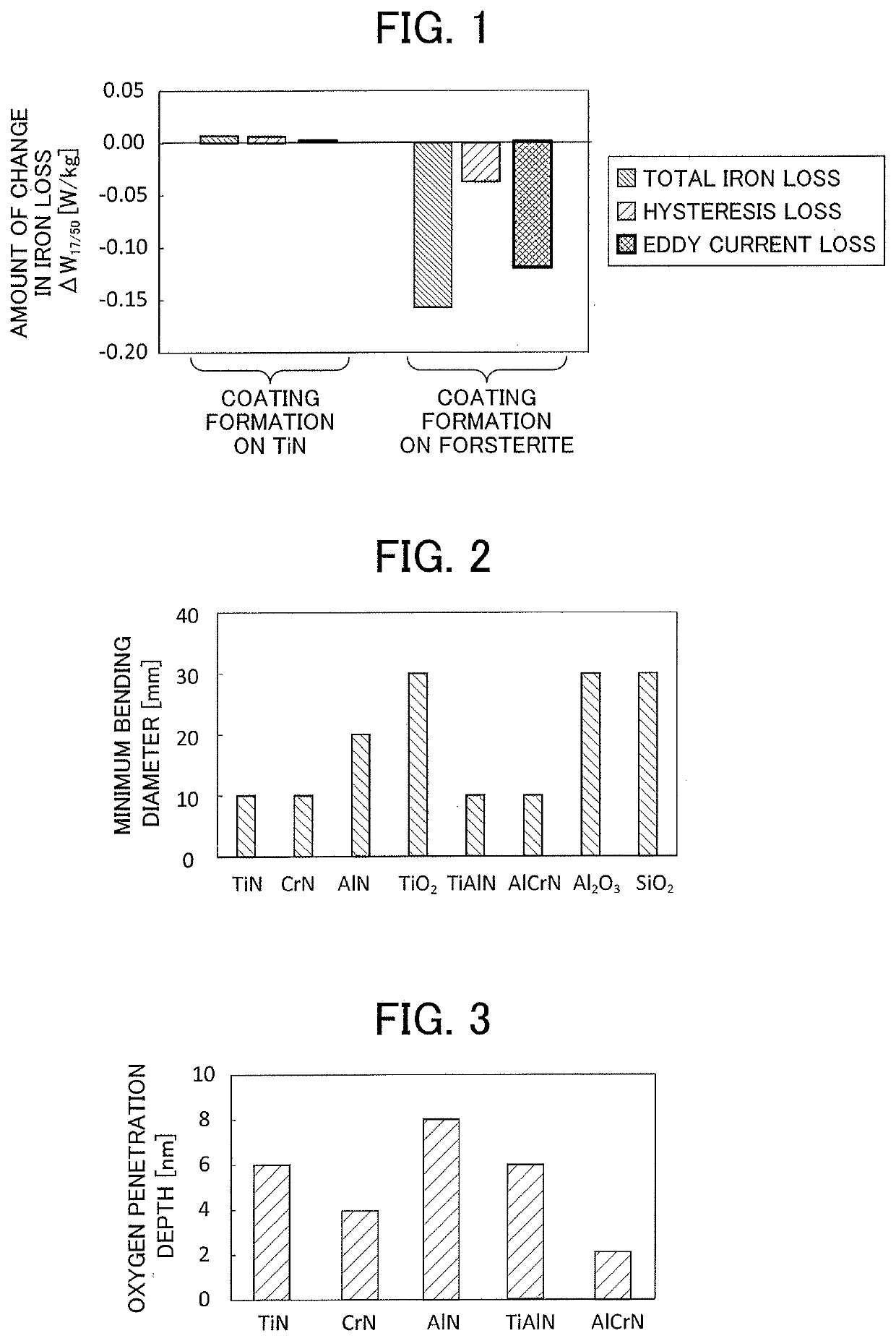

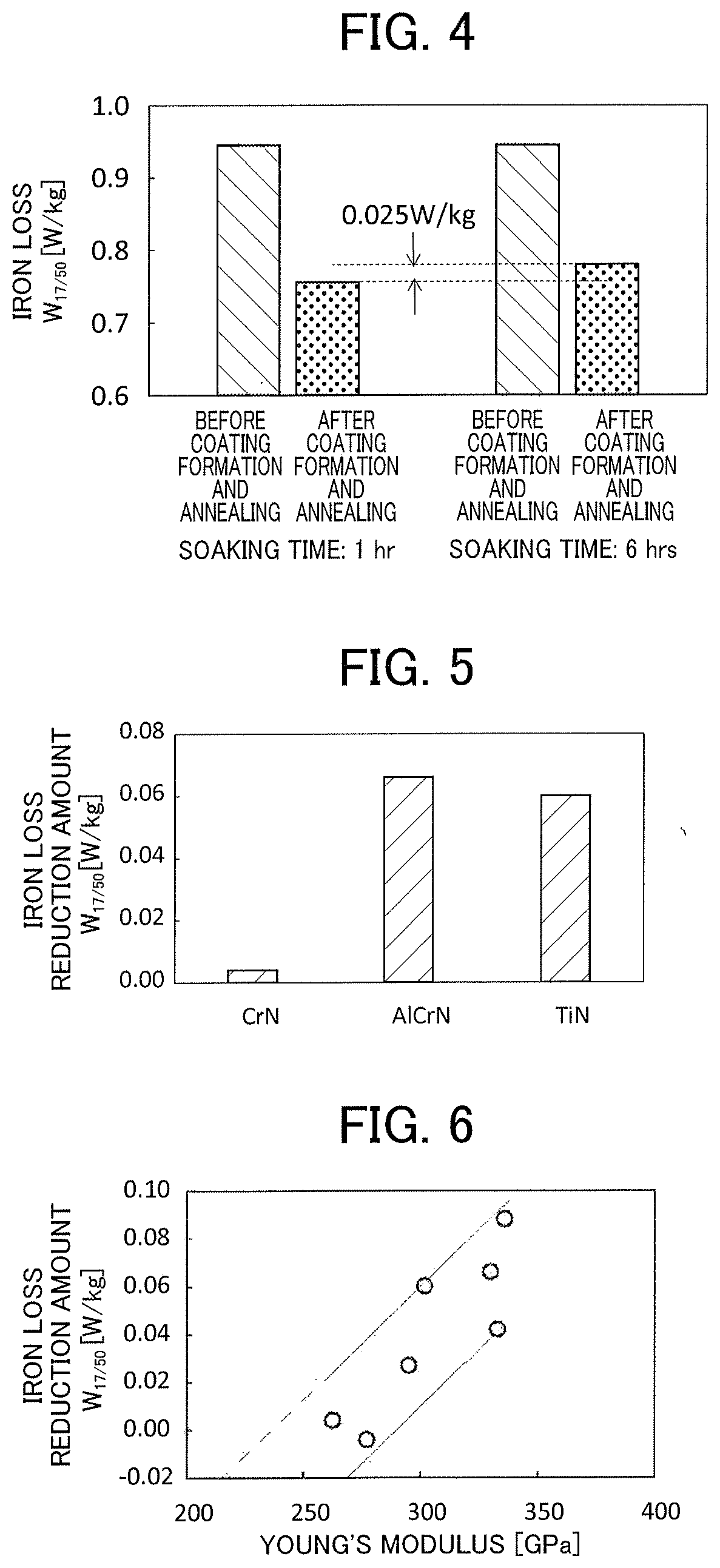

Grain-oriented electromagnetic steel sheet and method for producing grain-oriented electromagnetic steel sheet

ActiveUS20200056256A1High tensionImprove workabilityVacuum evaporation coatingSputtering coatingCeramic coatingYoung's modulus

Provided are: a grain-oriented electromagnetic steel sheet exhibiting excellent coating film adhesion and excellent magnetic characteristics; and a method for producing this grain-oriented electromagnetic steel sheet. This grain-oriented electromagnetic steel sheet is provided with a ceramic coating film arranged on a steel sheet, and an oxide insulating tension coating film arranged on the ceramic coating film. The ceramic coating film contains a nitride and an oxide; the nitride contains at least one element selected from the group consisting of Cr, Ti, Zr, Mo, Nb, Si, Al, Ta, Hf, W and Y; and the oxide has a corundum crystal structure. The Young's modulus of the ceramic coating film as determined by a nanoindentation method is 230 GPa or more; the average film thickness of the ceramic coating film is from 0.01 μm to 0.30 μm (inclusive); and the tension of the oxide insulating tension coating film is 10 MPa or more.

Owner:JFE STEEL CORP

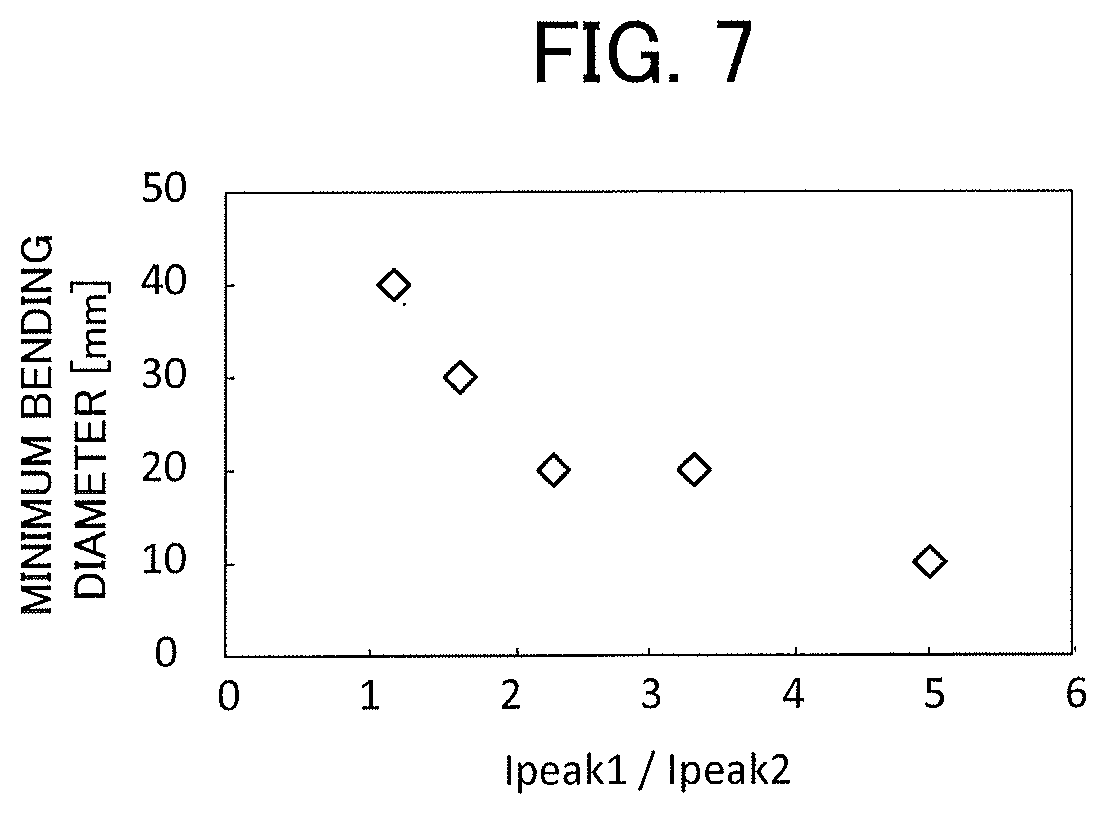

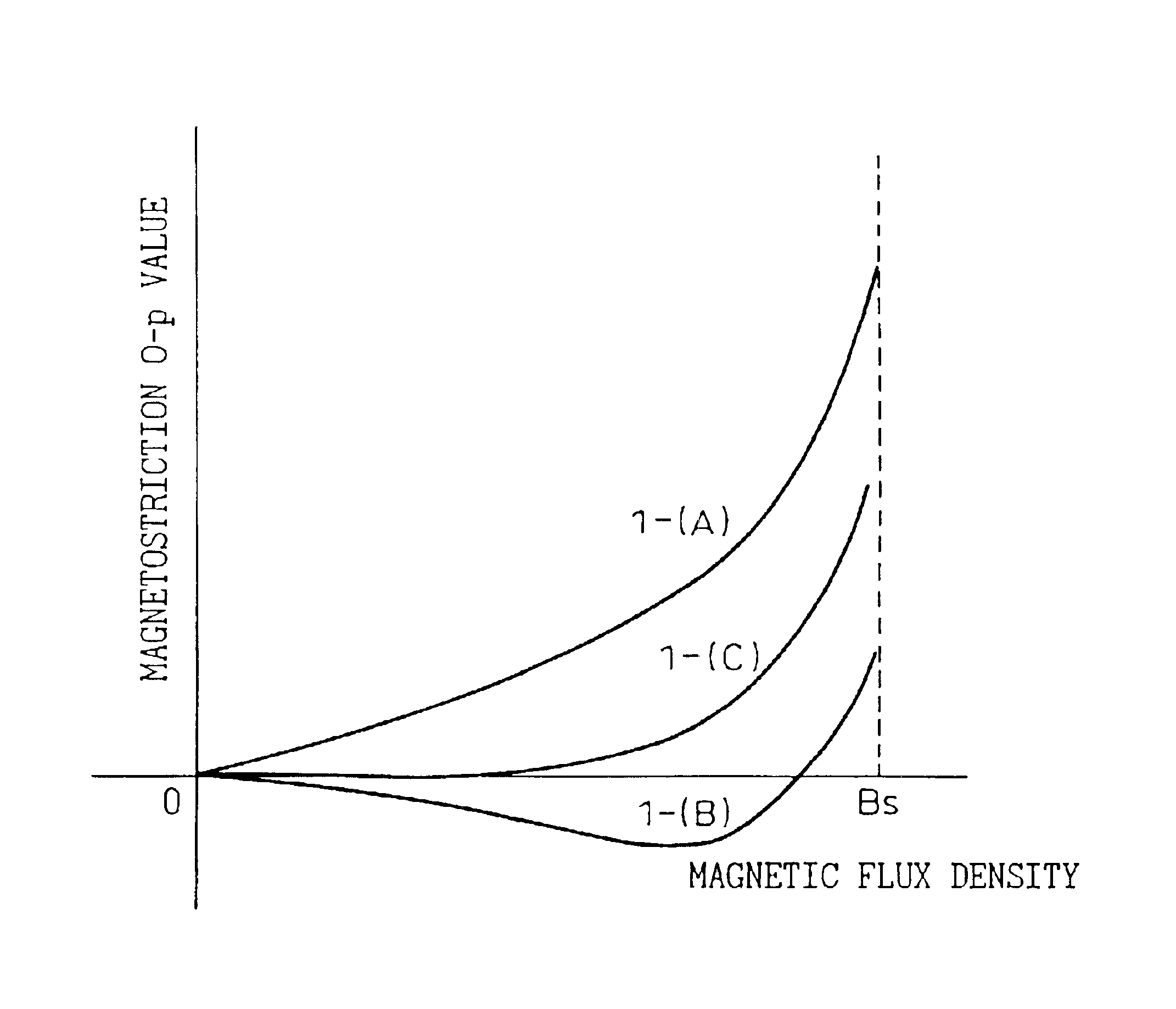

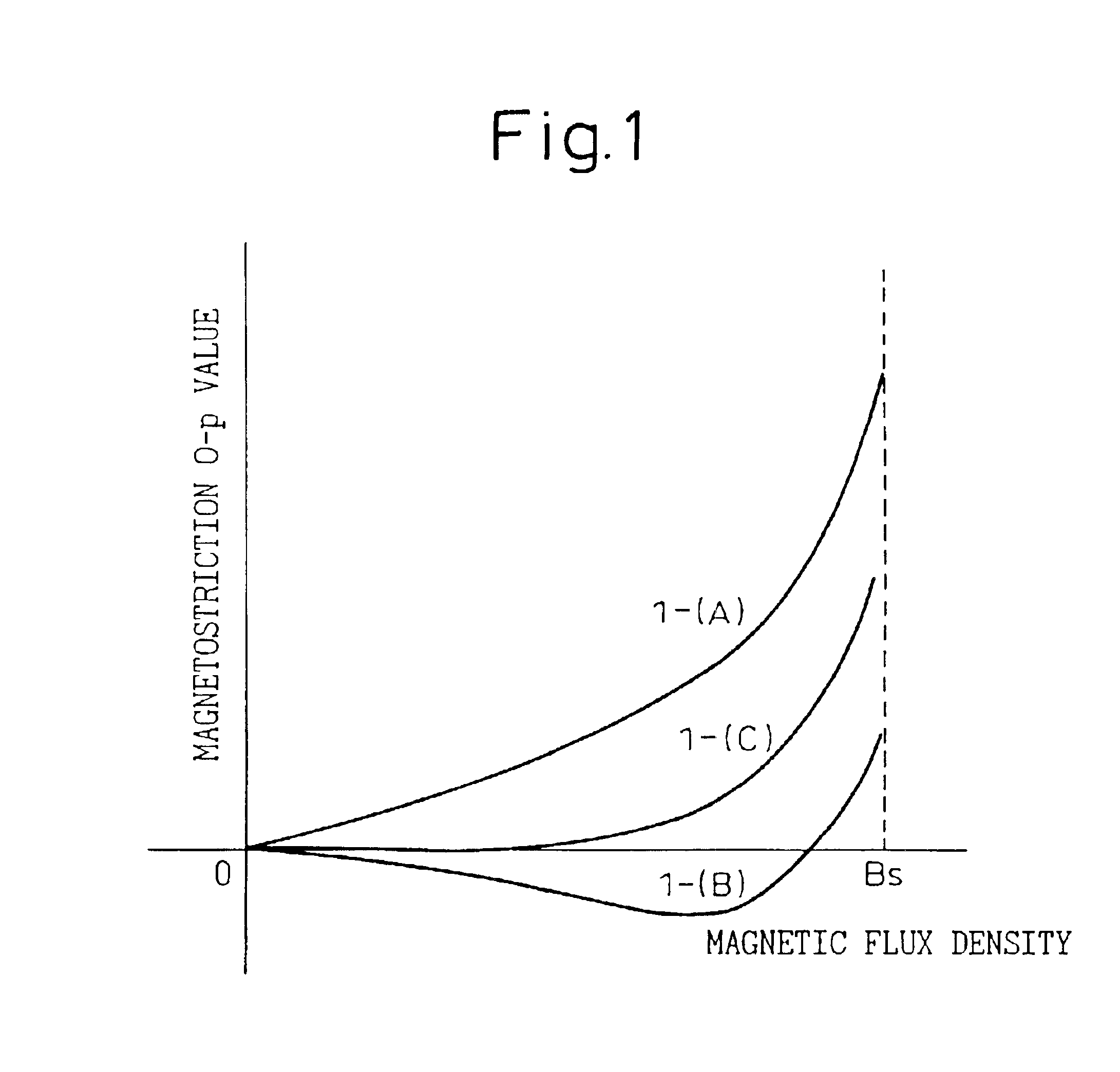

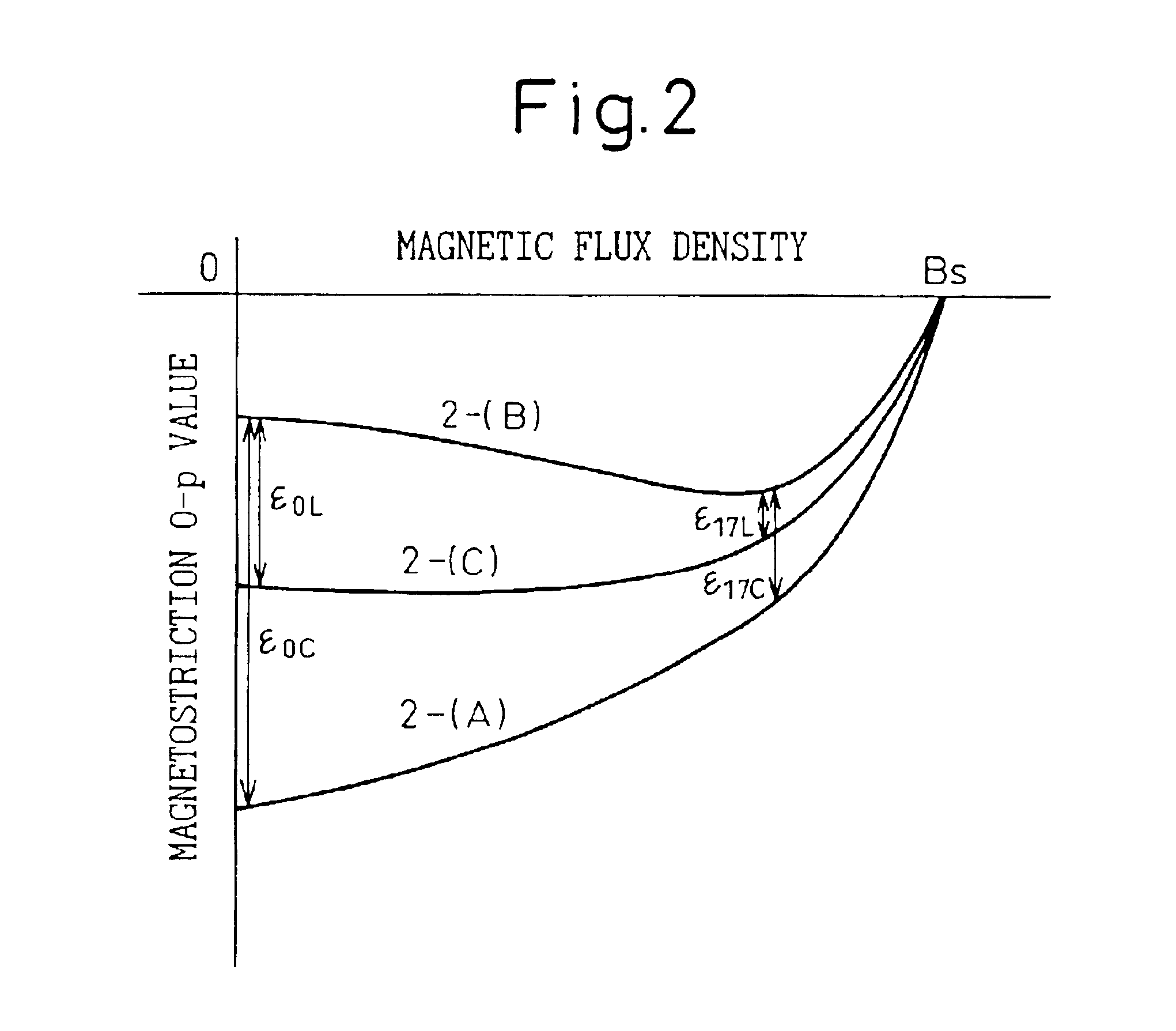

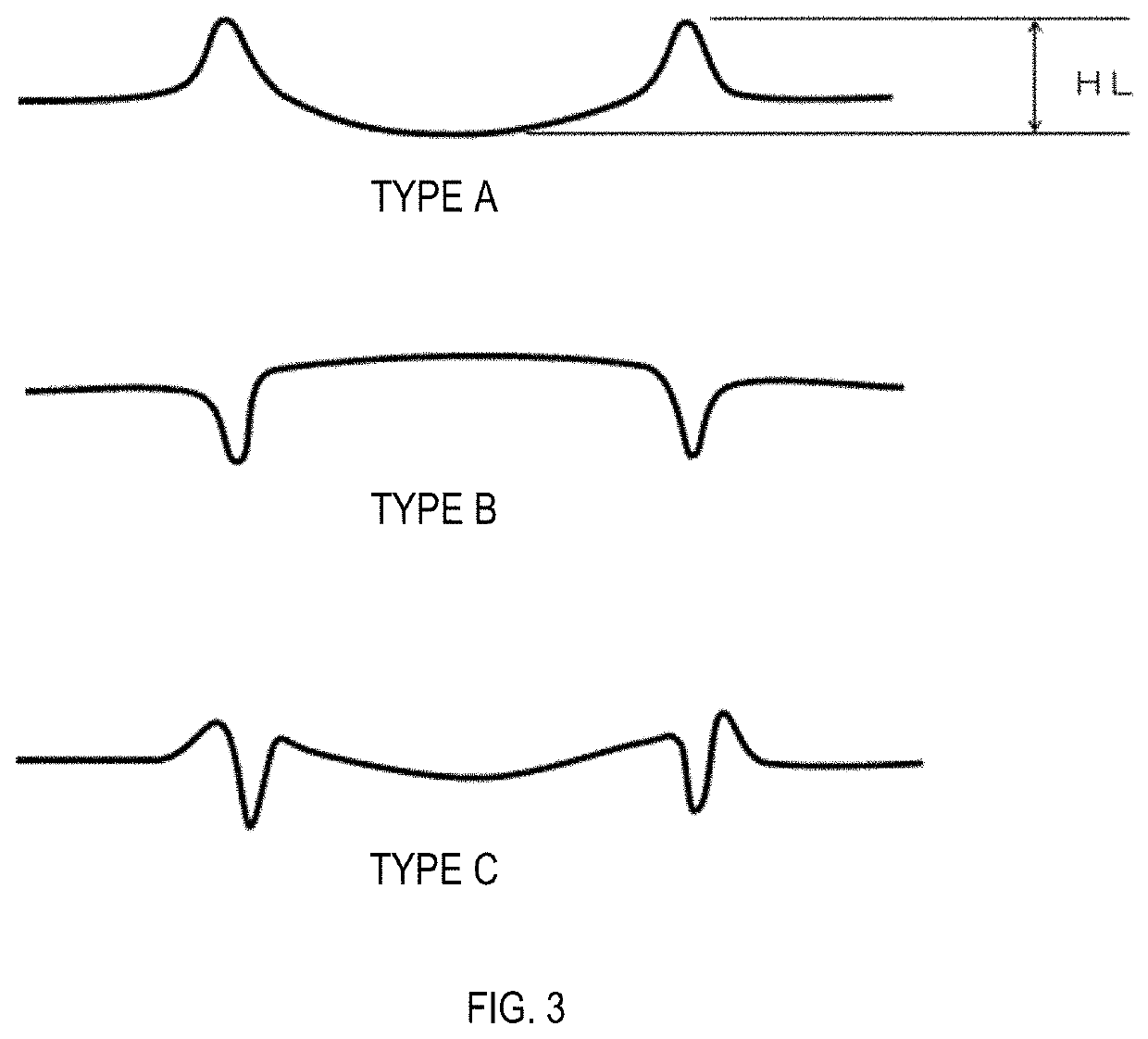

Low iron loss and low noise grain-oriented electrical steel sheet and a method for producing the same

InactiveUS6918966B2Reduce noiseLow iron lossInorganic material magnetismWelding/soldering/cutting articlesLow noiseElectrical steel

The object of the present invention is to provide a low iron loss and low noise grain-oriented electrical steel sheet for securing both low core loss and low noise of a transformer at the same time.The present invention relates to a grain-oriented electrical steel sheet containing Si: 1.0-4.0 wt % produced by controlling, with regard to εO, which is defined as a 0-p value when a grain-oriented electrical steel sheet is magnetized up to a saturated magnetic flux density, and ε17, which is defined as the value obtained by subtracting a 0-p value at the magnetization magnetic flux density of 1.7 T from a 0-p value at a saturated magnetic flux density, εOC and ε17L, which are absolute values deviated by forming a tension film and a forsterite film, and εOL and ε17L, which are absolute values deviated by irradiating laser after the film formation, in adequate ranges respectively, and further controlling λ17, which is a 0-p value at the magnetization magnetic flux density of 1.7 T, in the most appropriate range, when measuring a 0-p value of magnetostriction vibration in the rolling direction.

Owner:NIPPON STEEL CORP

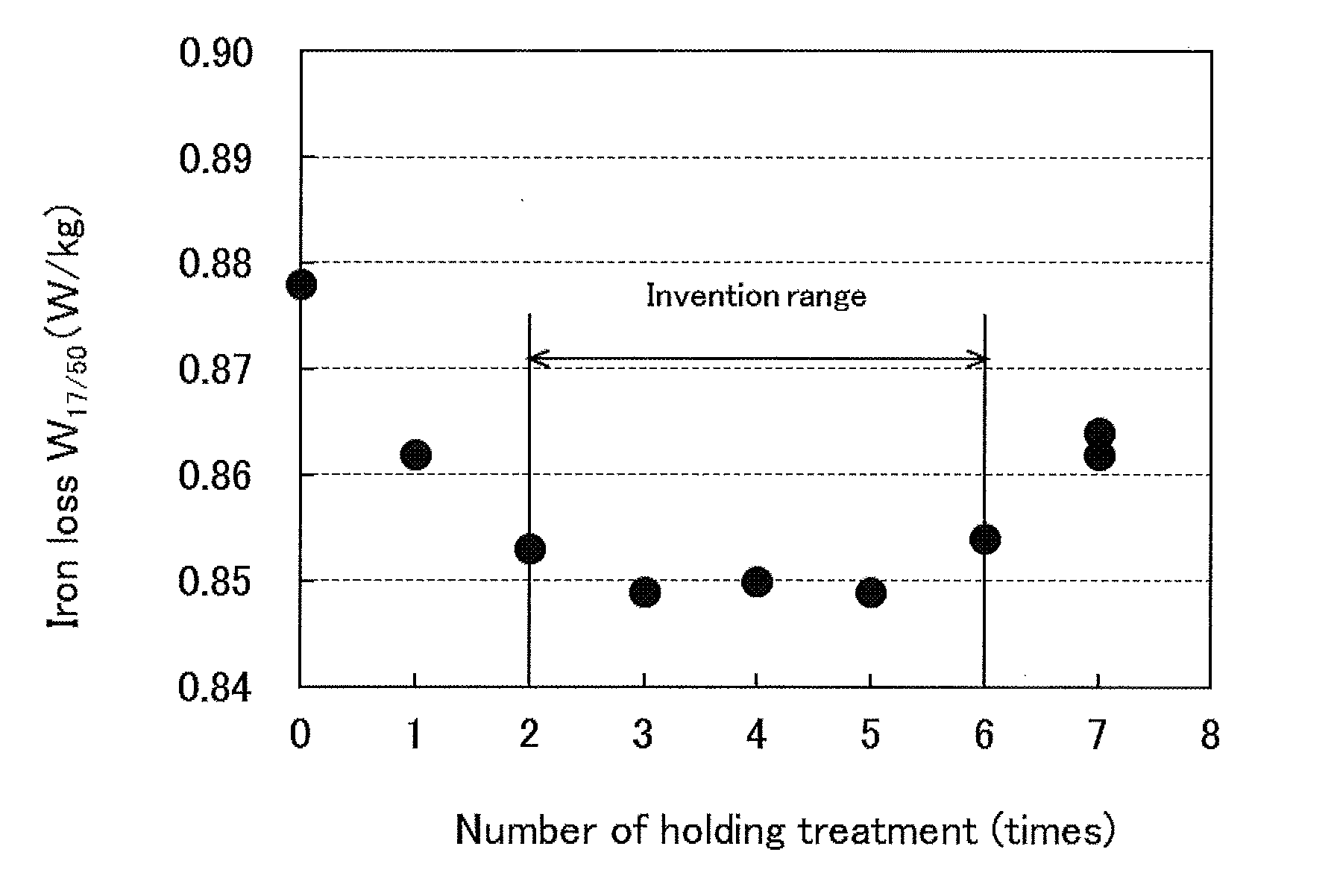

Method for producing grain-oriented electrical steel sheet (as amended)

ActiveUS20160012949A1Low iron-lossHeating fastInorganic material magnetismFurnace typesElectrical steelDecarburization

In a method for producing a grain-oriented electrical steel sheet by hot rolling a raw steel material containing C: 0.002˜0.10 mass %, Si: 2.0˜8.0 mass % and Mn: 0.005˜1.0 mass % to obtain a hot rolled sheet, subjecting the hot rolled sheet to a hot band annealing as required and further to one cold rolling or two or more cold rollings including an intermediate annealing therebetween to obtain a cold rolled sheet having a final sheet thickness, subjecting the cold rolled sheet to a primary recrystallization annealing combined with decarburization annealing, applying an annealing separator to the steel sheet surface and then subjecting to a final annealing, when rapid heating is performed at a rate of not less than 50° C. / s in a range of 100˜700° C. in the heating process of the primary recrystallization annealing, the steel sheet is subjected to a holding treatment at any temperature of 250˜600° C. for 0.5˜10 seconds 2 to 6 times to thereby obtain a grain-oriented electrical steel sheet being low in the iron loss and small in the deviation of the iron loss value.

Owner:JFE STEEL CORP

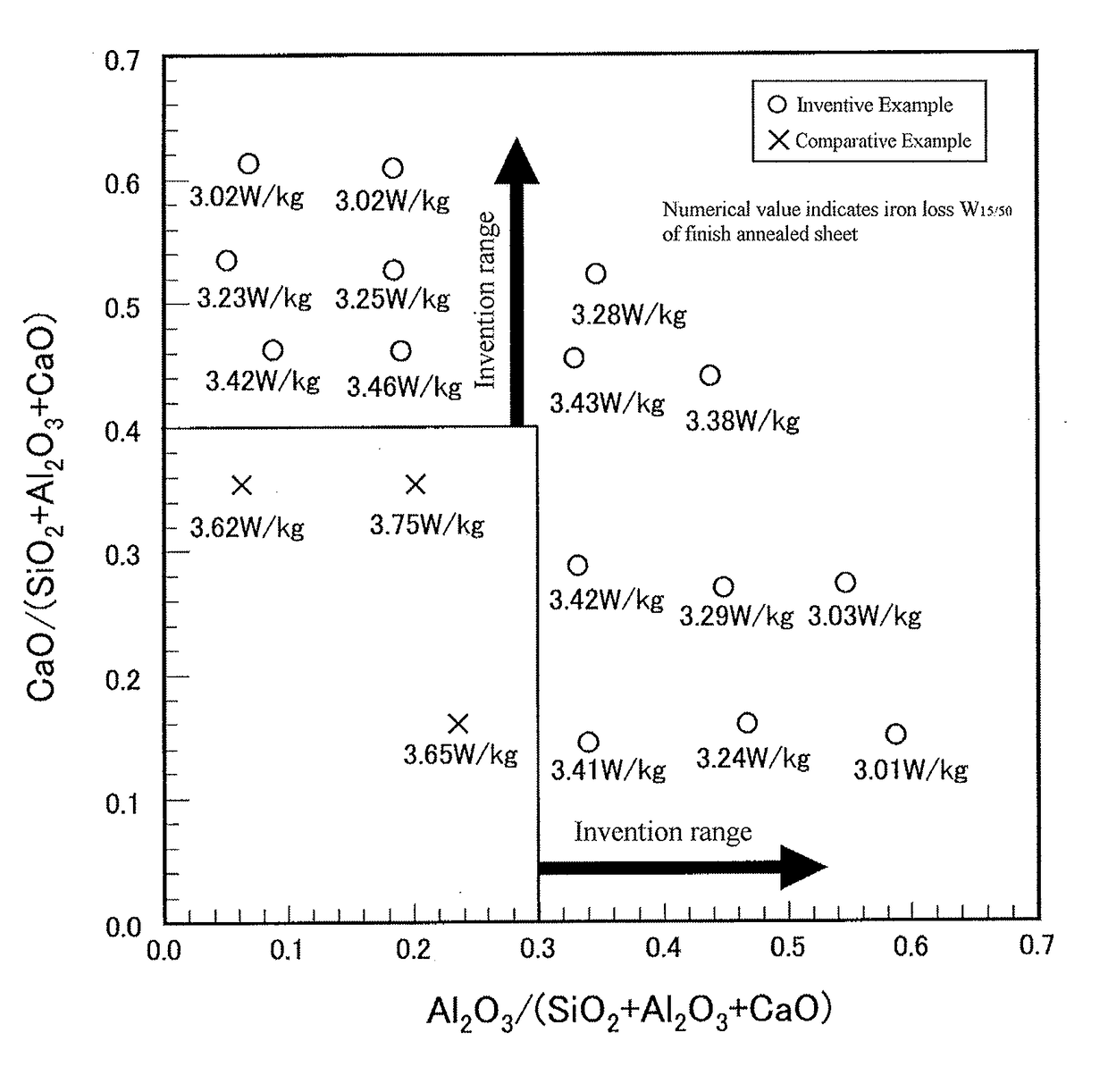

Non-oriented electrical steel sheet and method for producing the same

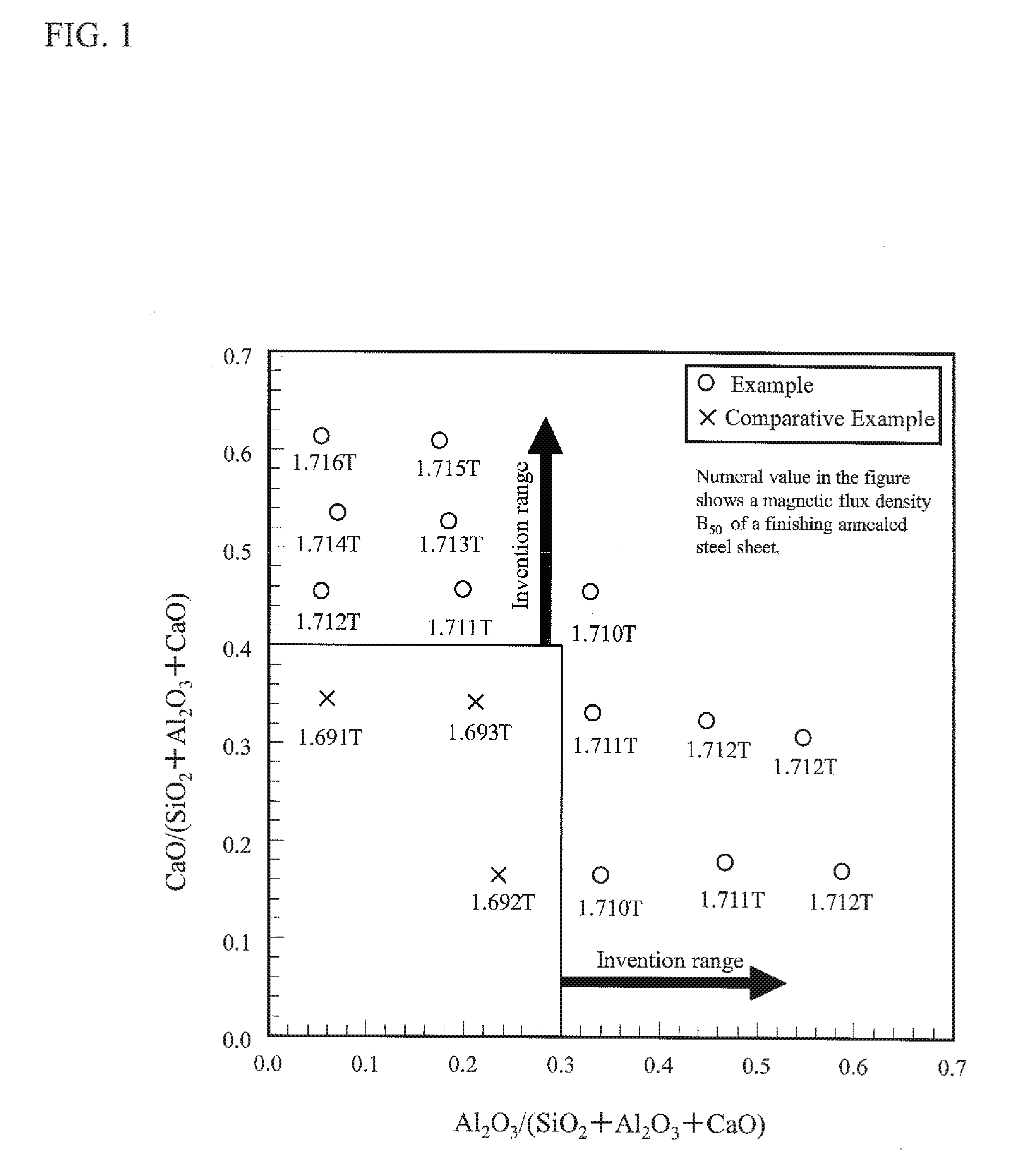

ActiveUS20180002789A1Increase production capacityHigh magneticInorganic material magnetismProcess efficiency improvementElectrical steelHot rolled

When a non-oriented electrical steel sheet is produced by hot rolling a slab containing, by mass %, C: not more than 0.0050%, Si: 1.5-5.0%, Mn: 0.20-3.0%, sol. Al: not more than 0.0050%, P: not more than 0.2%, S: not more than 0.0050% and N: not more than 0.0040% to form a hot rolled sheet, cold rolling the hot rolled sheet without conducting a hot band annealing and then subjecting to a finish annealing, a compositional ratio of CaO in oxide-based inclusions existing in the slab defined by CaO / (SiO2+Al2O3+CaO) is set to not less than 0.4 and / or a compositional ratio of Al2O3 defined by Al2O3 / (SiO2+Al2O3+CaO) is set to not less than 0.3, and a coiling temperature in the hot rolling is set to not lower than 650° C.

Owner:JFE STEEL CORP

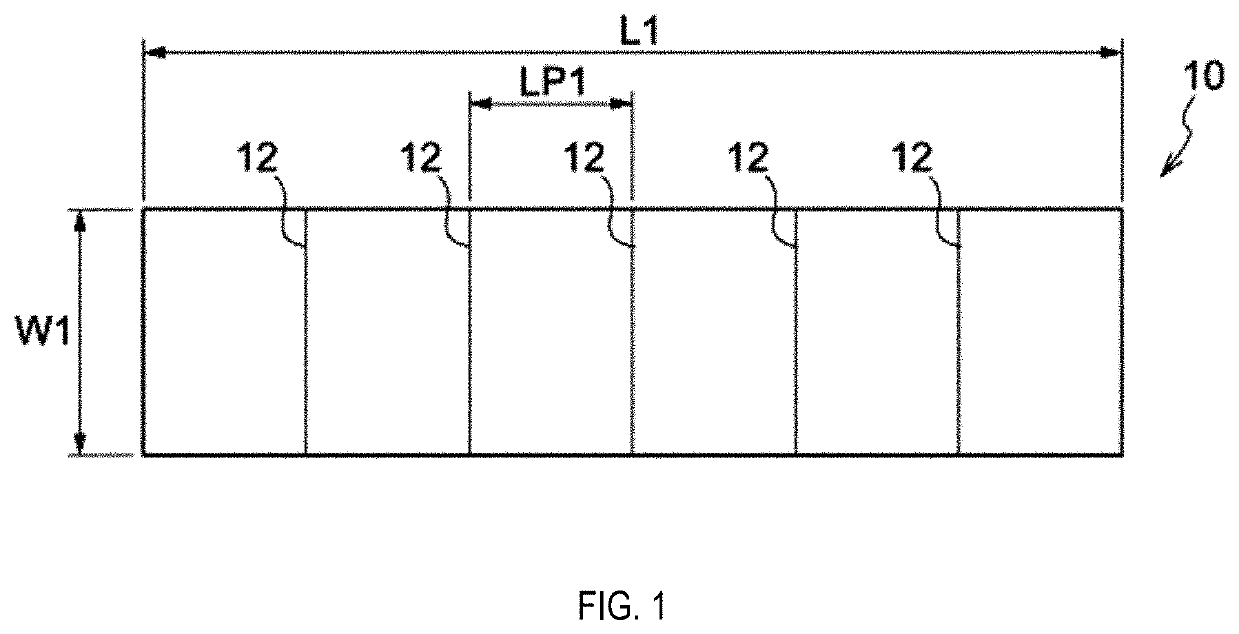

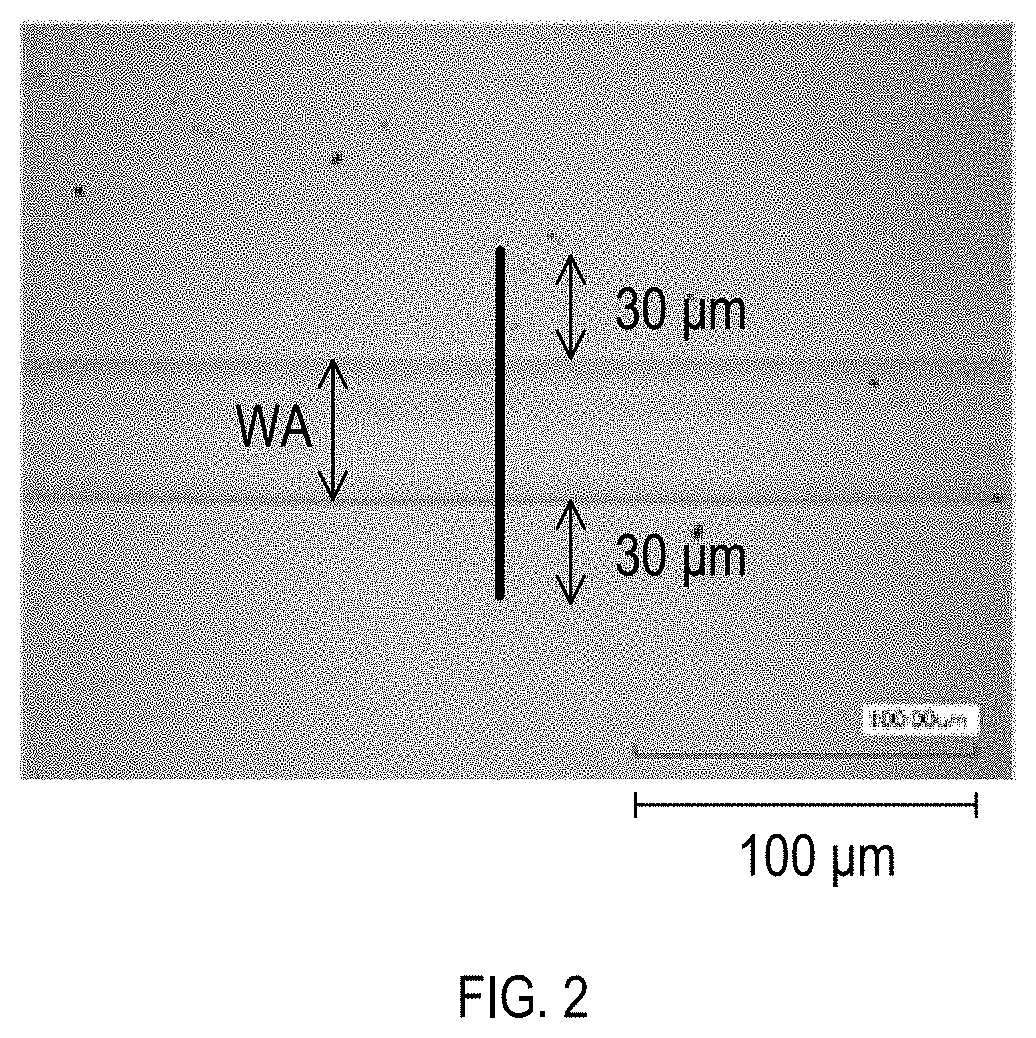

Fe-BASED AMORPHOUS ALLOY RIBBON, PRODUCTION METHOD THEREOF, IRON CORE, AND TRANSFORMER

PendingUS20220364212A1Low iron-lossLess deformationFurnace typesTransformers/inductances magnetic coresPhoto irradiationTransformer

An Fe-based amorphous alloy ribbon reduced in iron loss, less deformed, and highly productive in a condition of a magnetic flux density of 1.45 T is provided. One aspect of the present disclosure provides an Fe-based amorphous alloy ribbon having first and second surfaces, and is provided with continuous linear laser irradiation marks on at least the first surface. Each linear laser irradiation mark is formed along a direction orthogonal to a casting direction of the Fe-based amorphous alloy ribbon, and has unevenness on its surface. When the unevenness is evaluated in the casting direction, a height difference HL×width WA calculated from the height difference HL between a highest point and a lowest point in a thickness direction of the Fe-based amorphous alloy ribbon and the width WA which is a length of the linear irradiation mark on the first surface is 6.0 to 180 μm2.

Owner:PROTERIAL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com