Patents

Literature

84 results about "Oxygen potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of TiO2-nanotube-array-supported ruthenium-containing coating catalyst

ActiveCN103014752AGood dispersionImprove catalytic performanceSurface reaction electrolytic coatingElectrodesTio2 nanotubePtru catalyst

The invention provides a preparation method of a TiO2-nanotube-array-supported ruthenium-containing coating catalyst, belonging to the technical field of chlor-alkali industry. An anodic oxidation process is utilized to form an ordered TiO2 nanotube array on a Ti substrate, thereby increasing the specific area of the supporter, reducing the transmission path of charges in the electrode material, enhancing the catalytic property of the anode coating and lowering the chlorine-oxygen potential difference; and a sintering process is utilized to dope titanium tin stibium oxide with similar ionic radius to RuO2 into a RuO2 coating, and the strong interaction between the ruthenium titanium tin stibium solid solution oxide and the substrate is utilized to enhance the stability of the electrode. The method provided by the invention is simple and easy to implement, and has the advantages of high operational safety and low production cost; and the prepared anode coating catalyst has higher electrocatalytic activity for inhibiting oxygen evolution and accelerating chlorine evolution reaction, and can be widely used in the fields of chlor-alkali industry.

Owner:重庆铈坦新材料技术研究院有限公司

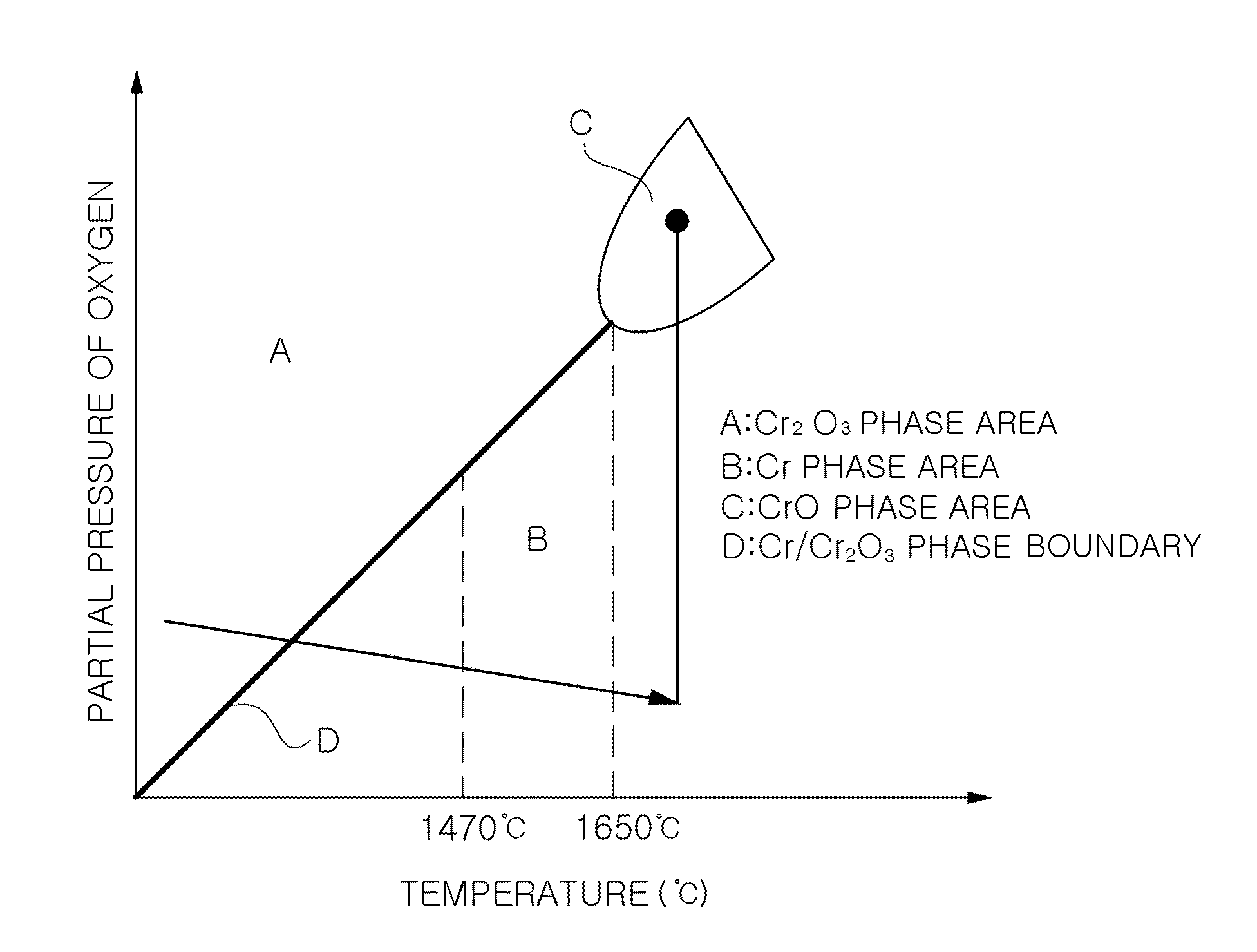

Method of producing large-grained nuclear fuel pellet by controlling chrome cation solubility in uo2 lattice

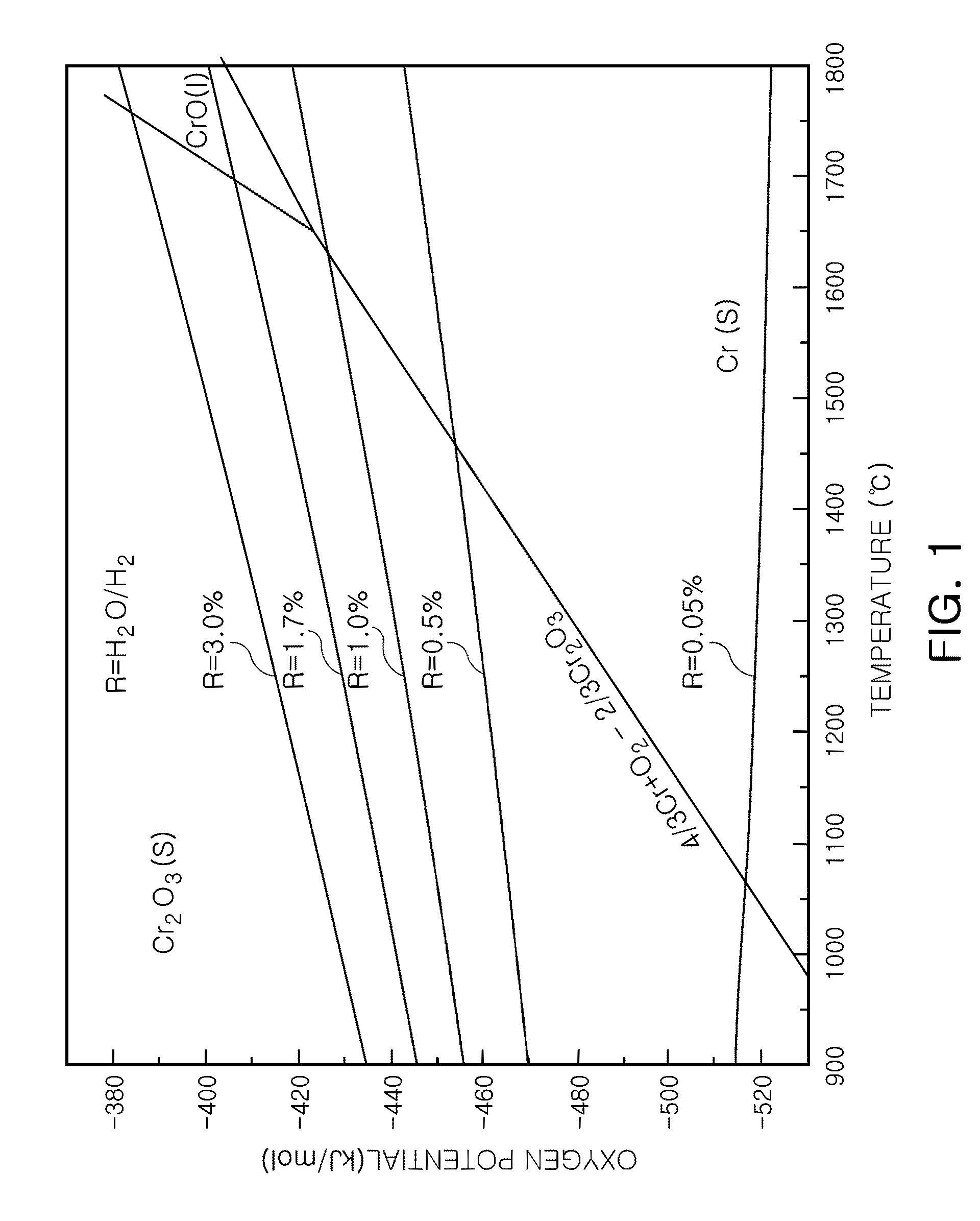

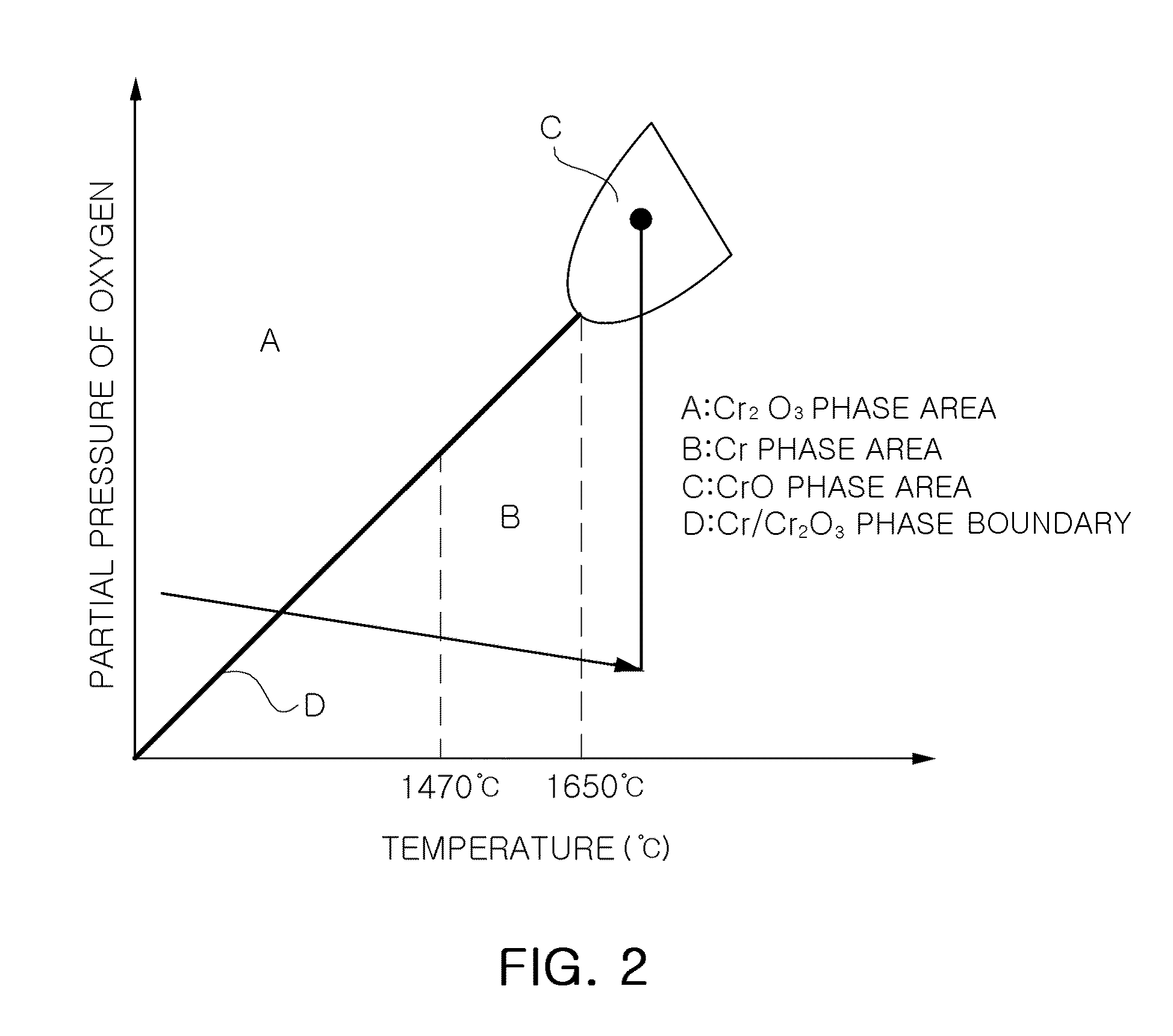

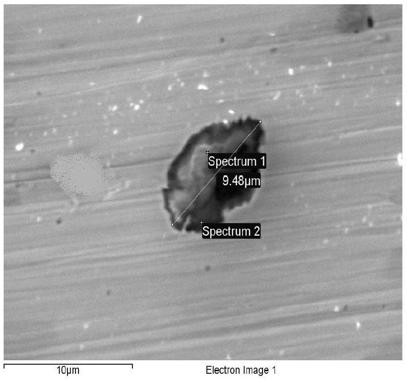

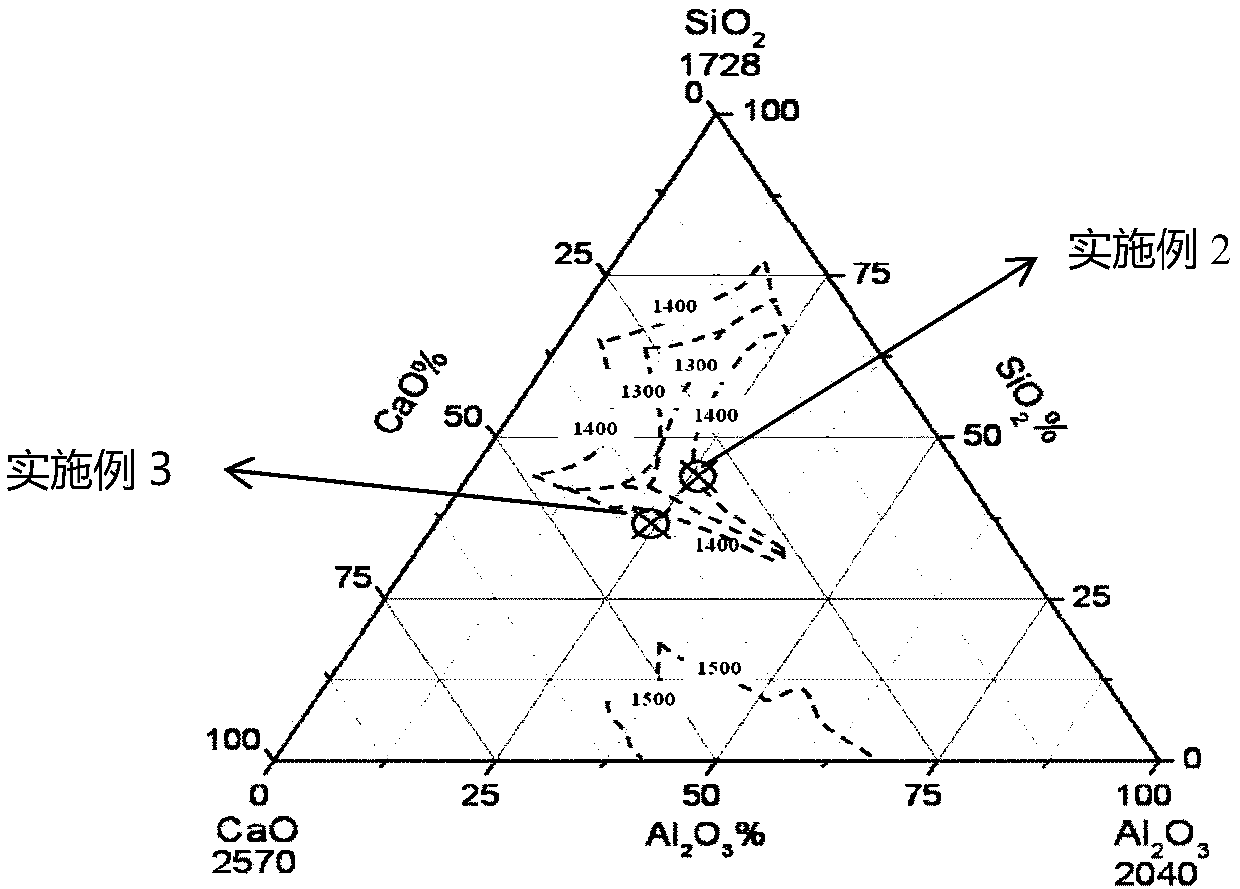

In a method of producing large-grained nuclear fuel pellet, Cr-compound contained in an uranium oxide green pellet is reduced to Cr phase at 1,470° C. or below and maintained to the Cr phase, and the uranium oxide green pellet containing the Cr-compound is then sintered at 1,650° C.-1,800° C. in a gas atmosphere of oxygen potential at which Cr element in the uranium oxide green pellet becomes liquid phase.

Owner:KOREA ATOMIC ENERGY RES INST +1

Smelting process for controlling spring steel inclusions

ActiveCN109097518ARelieve pressureFully integratedManufacturing convertersProcess efficiency improvementAlkalinitySmelting process

The invention discloses a smelting process for controlling spring steel inclusions. The smelting process comprises the following steps of (1) KR molten iron desulfurization pretreatment, (2) BOF top-bottom double combined flowing converter smelting, (3) LF furnace refining, (4) RH furnace refining and (5) continuous casting process, wherein the mass fraction of S is controlled to be below 0.005% after molten iron is processed by the step (1); the step (3) is carried out by high-purity silicon carbide for diffusion deoxidation, and the refining slag alkalinity is controlled to be 0.6-0.9; a lowalkalinity slag process is adopted in the step (4), and the final slag alkalinity is 0.5-0.7; and it is ensured that a molten steel contact part is free of aluminum in the step (5), a double electromagnetic stirring process is adopted in a secondary cooling zone and a casting blank solidification end zone, and a central carbon segregation index is controlled to be below 1.15. The smelting processadopts molten iron pretreatment, converter catching carbon, refining low alkali slag, continuous casting protective pouring and special refractory materials. Through the control over the oxygen potential of molten steel, the inclusion form and the central carbon segregation, the spring drawing performance is improved, and the spring fatigue limit is increased.

Owner:NANJING IRON & STEEL CO LTD

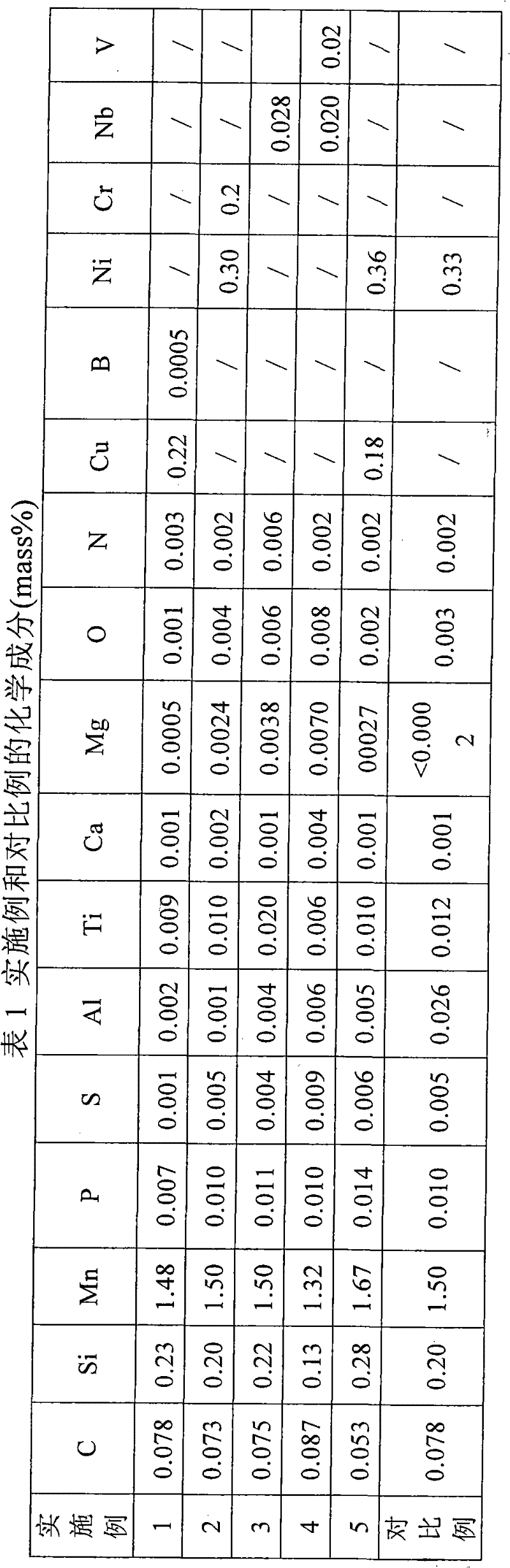

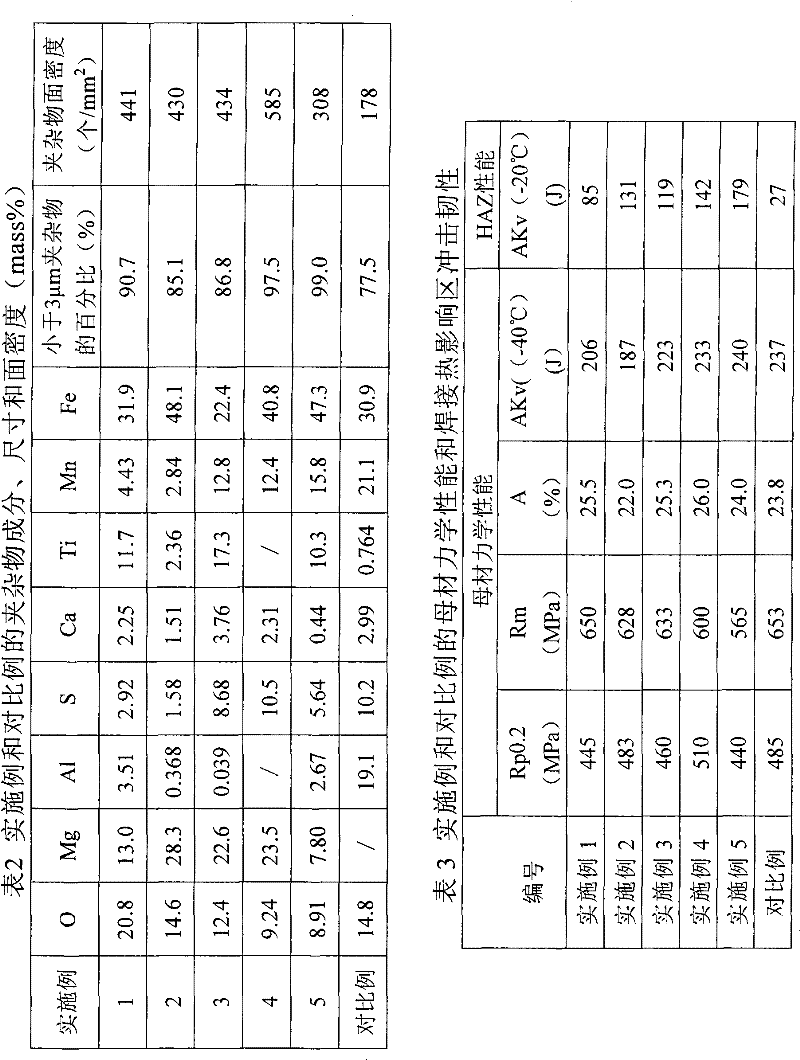

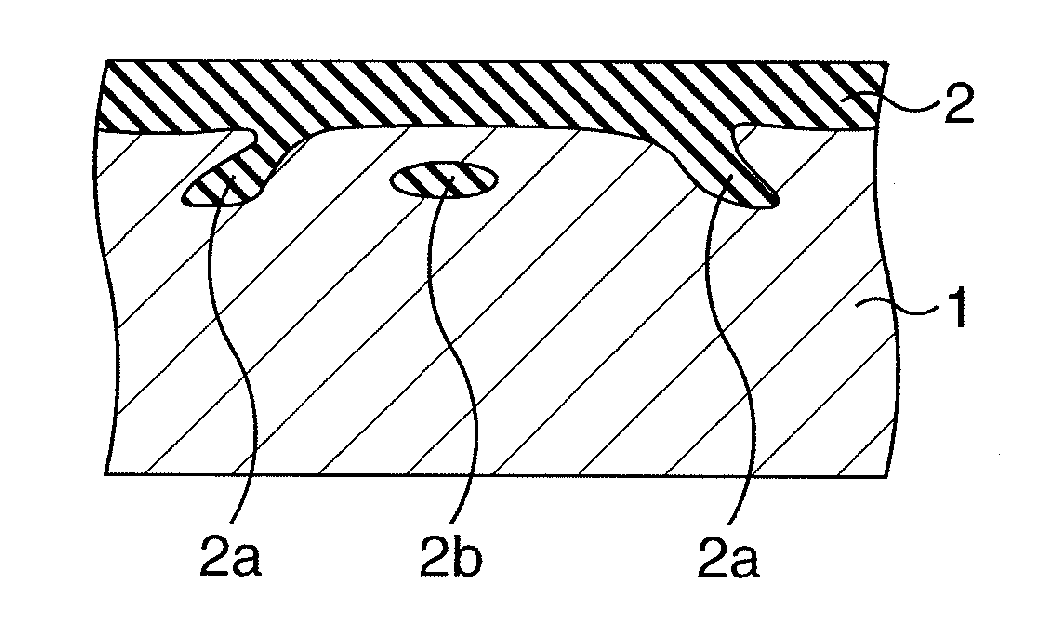

Method for improving high heat input welding performance of thick steel plates

ActiveCN102191429AIncrease the amount of controlPrecise control of initial oxygen positionHeat-affected zoneSheet steel

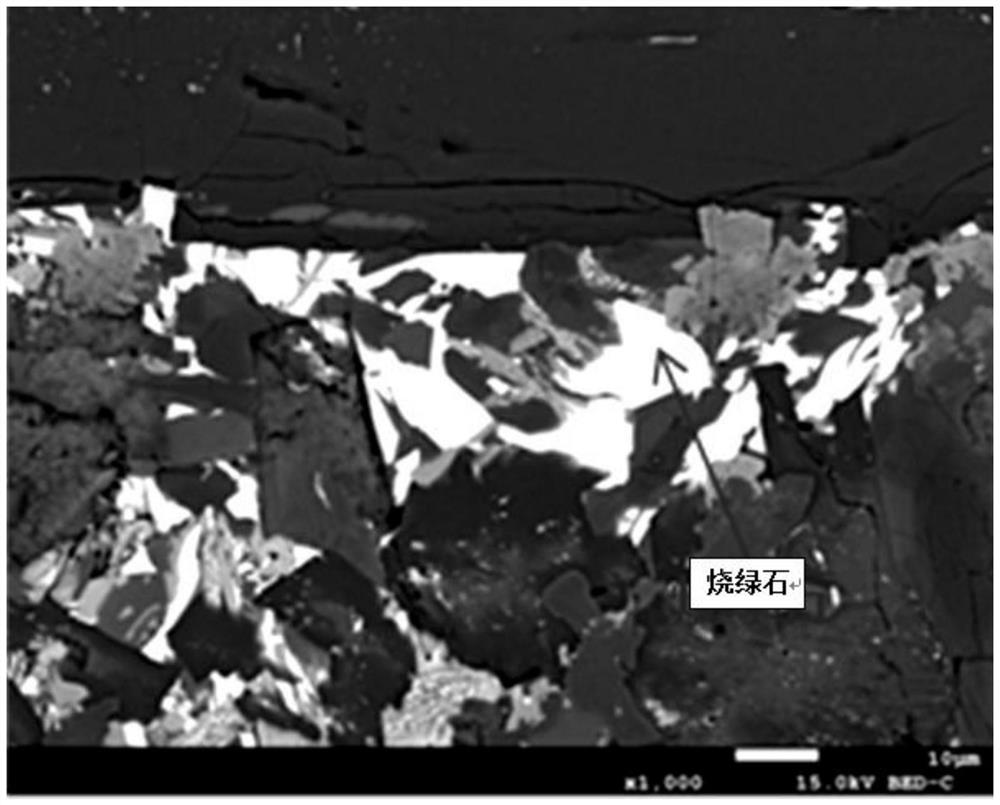

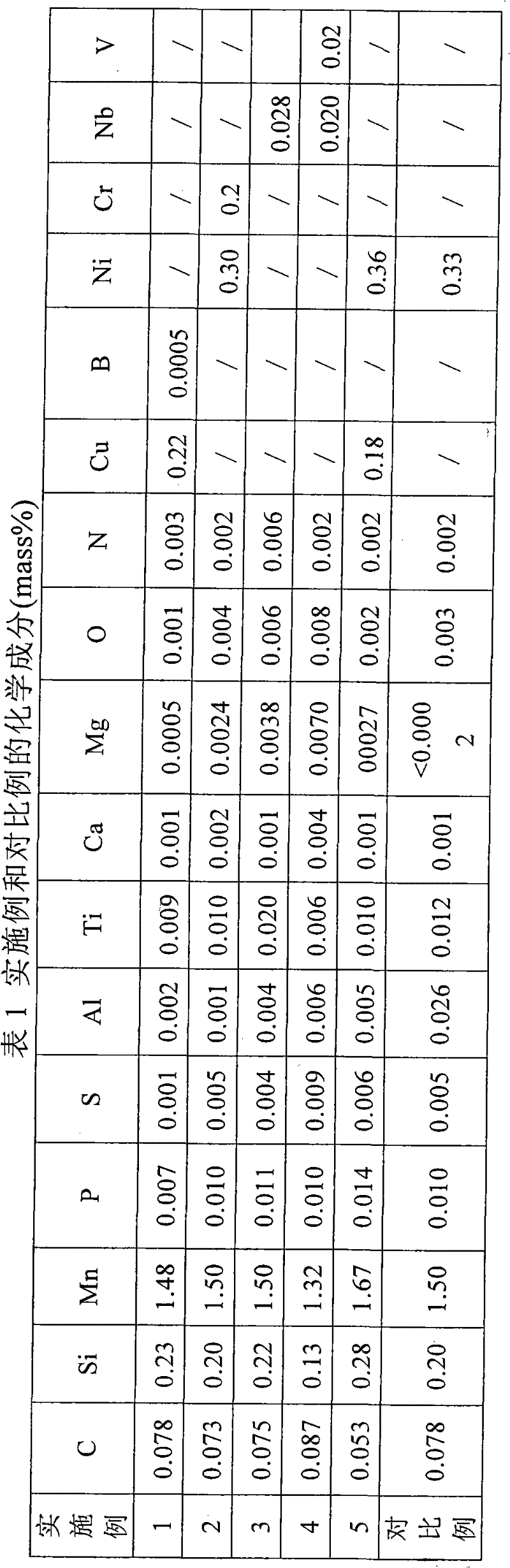

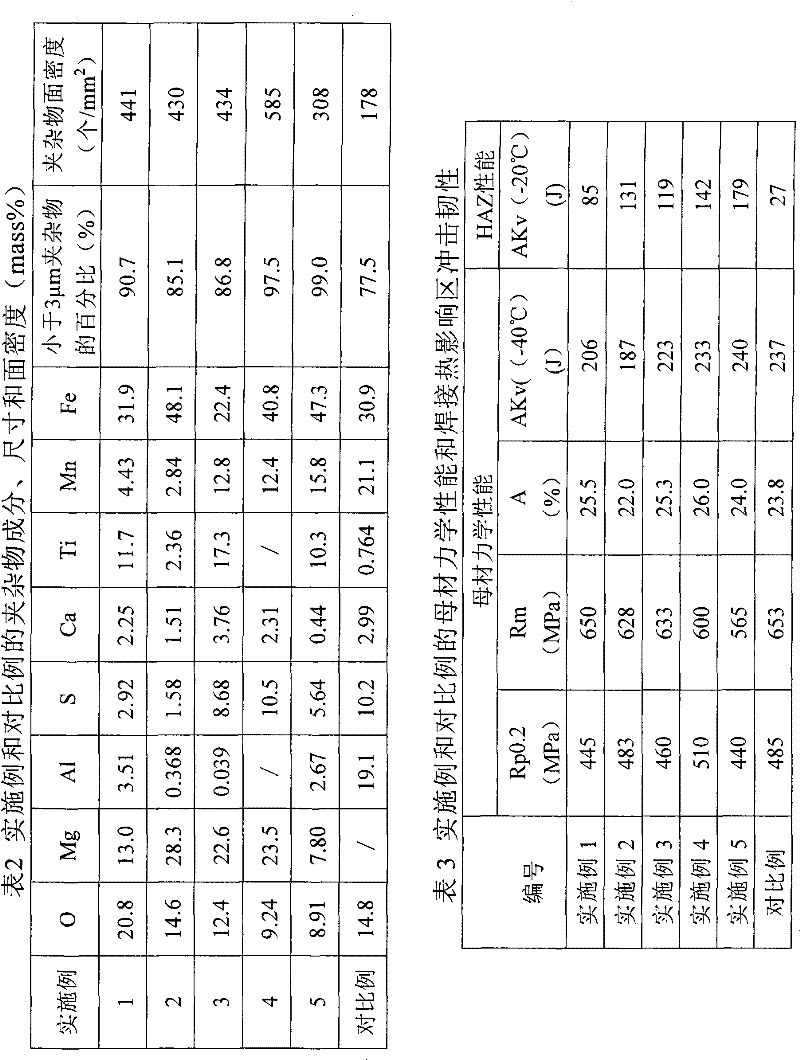

The invention discloses a method for improving the high heat input welding performance of thick steel plates. The method comprises the following steps of: 1) smelting and casting to obtain an ingot, wherein deoxidants are added in the deoxidation process of molten steel, the adding sequence of the deoxidants is Mn and Si, Al, Ti, and Ca, a Mg deoxidant is added in the casting process of the molten steel, and the initial oxygen potential during the deoxidation of Mg is accurately controlled by adding Fe2O3 powder into a casting ingot mould; and 2) rolling and cooling. In the method, microfine dispersive distribution and Mg-containing inclusions, which are formed by adding the deoxidants in the deoxidation process of the molten steel and adding the Fe2O3 powder into the casting ingot mould to accurately control the oxygen potential during the deoxidation of the Mg, can inhibit the growth of austenite grains in a welding heat affected zone, and promotes the growth of ferrite in the grains, so that the high heat input welding performance of the thick steel plates is greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

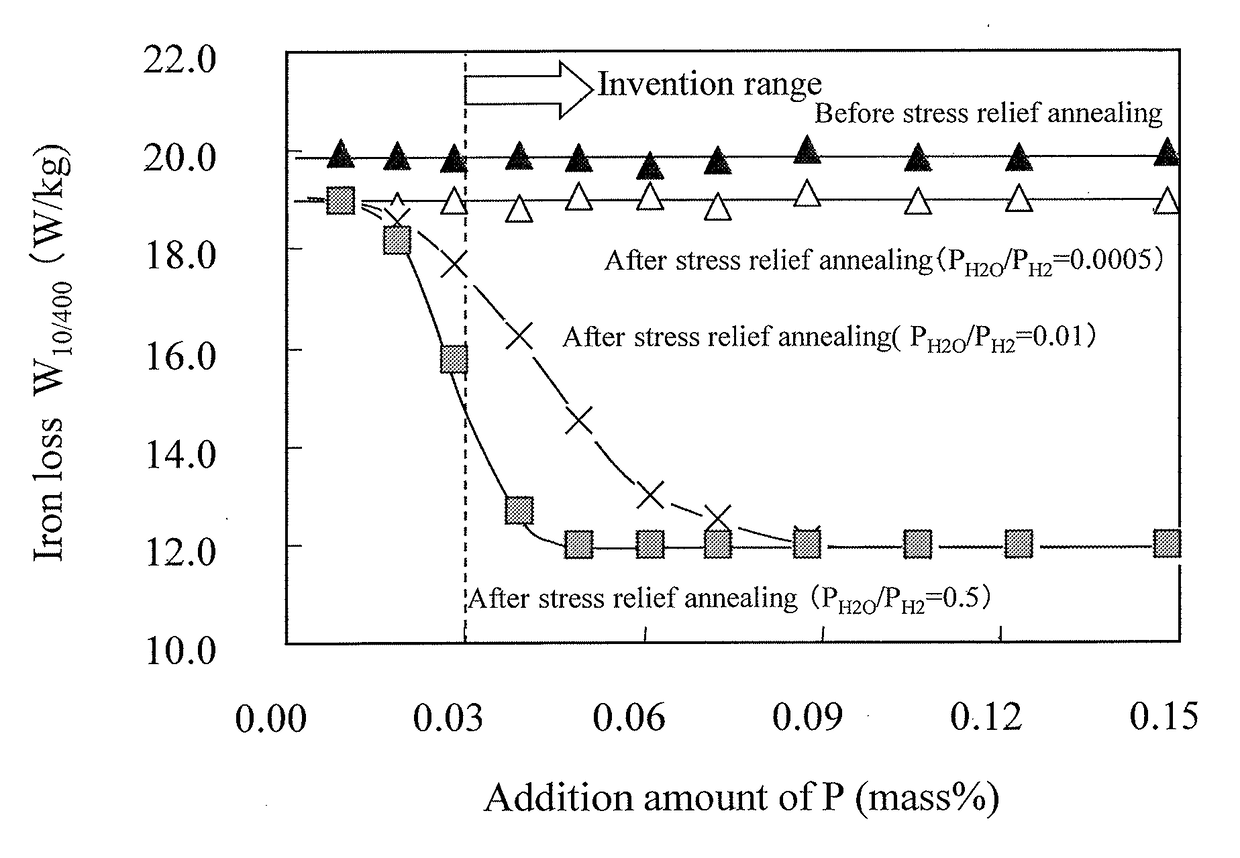

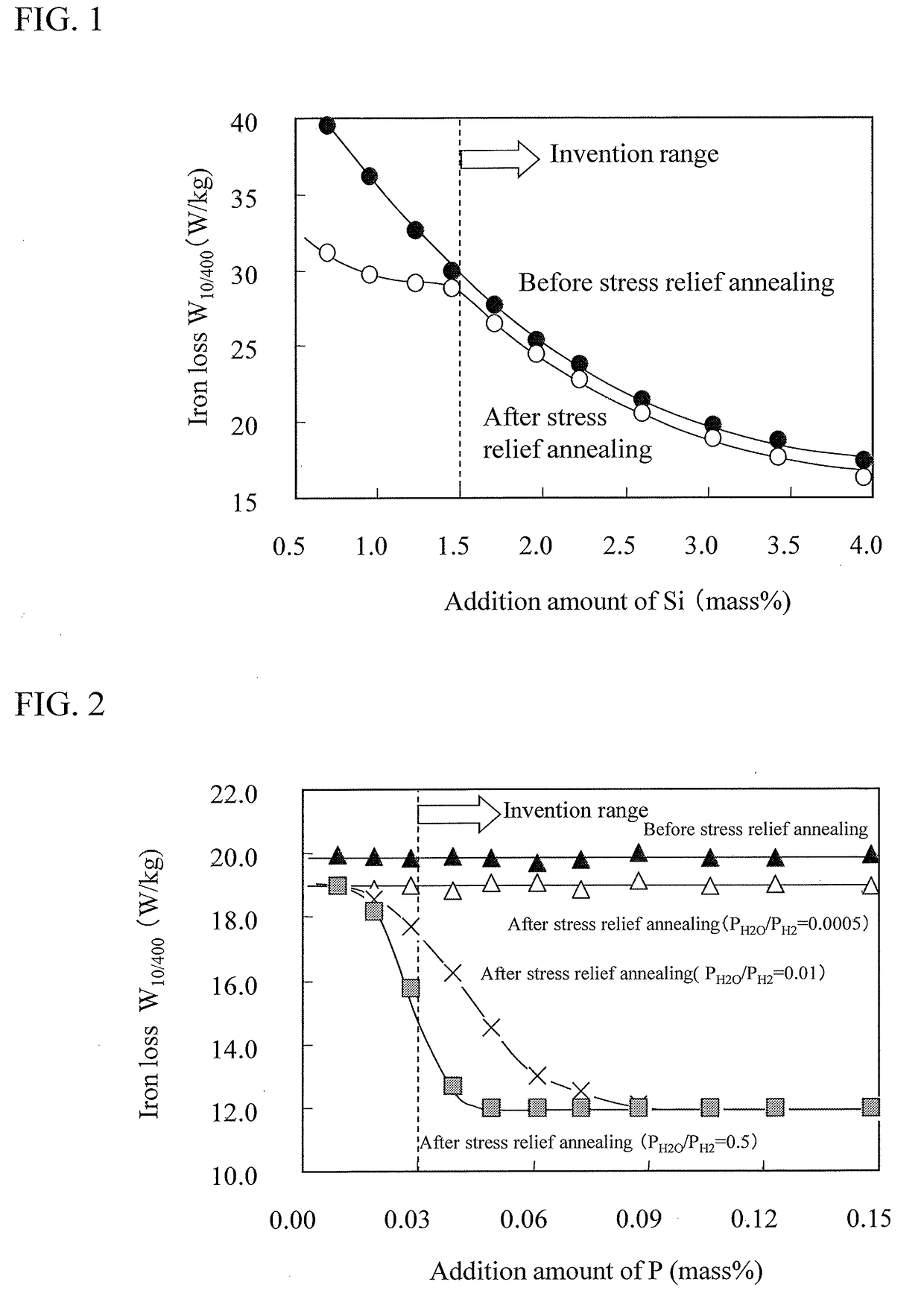

Non-oriented electrical steel sheet, production method therefor, and motor core

ActiveUS20180066333A1High strengthLow iron-lossInorganic material magnetismFurnace typesElectrical steelChemical composition

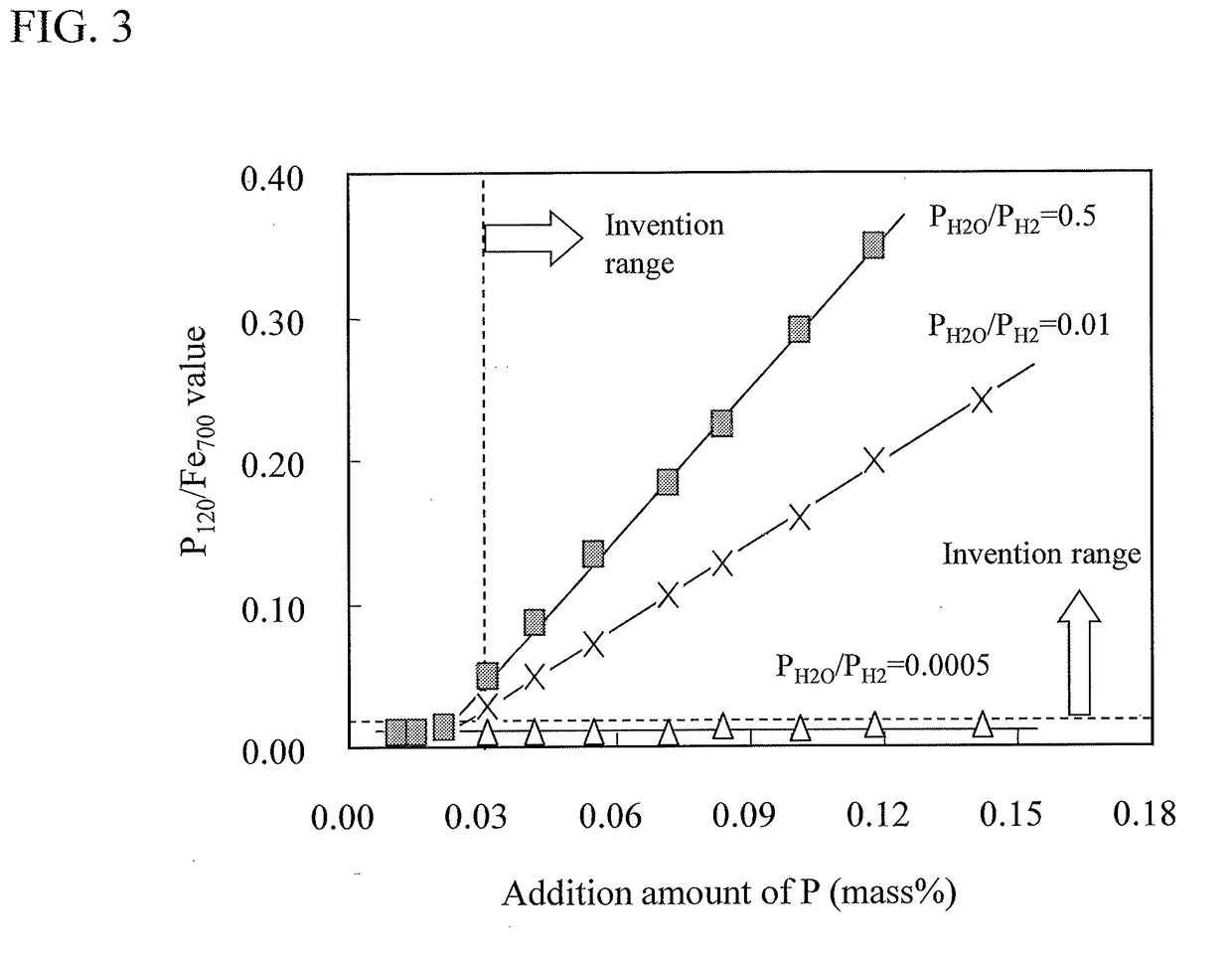

In the production of a non-oriented electrical stress sheet by hot rolling a slab having a chemical composition comprising, by mass %, C: not more than 0.005, Si: 1.5-6.0, Mn: 0.05-2.0 and P: 0.03-0.15, subjecting to a hot band annealing, if necessary, cold rolling, finish annealing, and forming an insulation coating, the cooling from 700° C. to 500° C. in the finish annealing is conducted in an oxidizing atmosphere with an oxygen potential PH2O / PH2of not less than 0.001 for 1-300 seconds, whereby P is segregated into the surface of the steel sheet after the finish annealing to obtain a non-oriented electrical steel sheet enhancing a crystal grain growth properties in the stress relief annealing.

Owner:JFE STEEL CORP

Composition for reducing the oxygen potential of slag

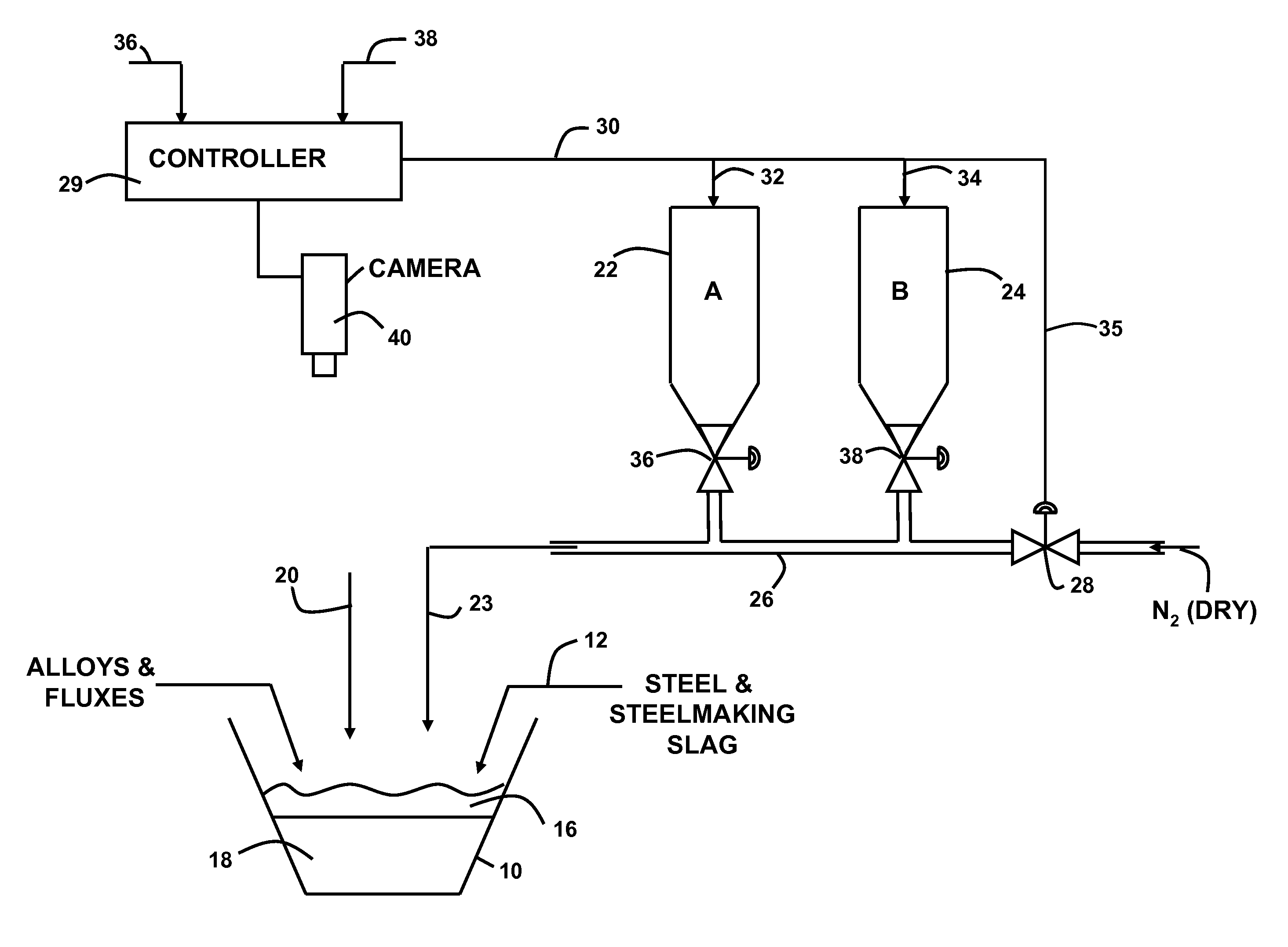

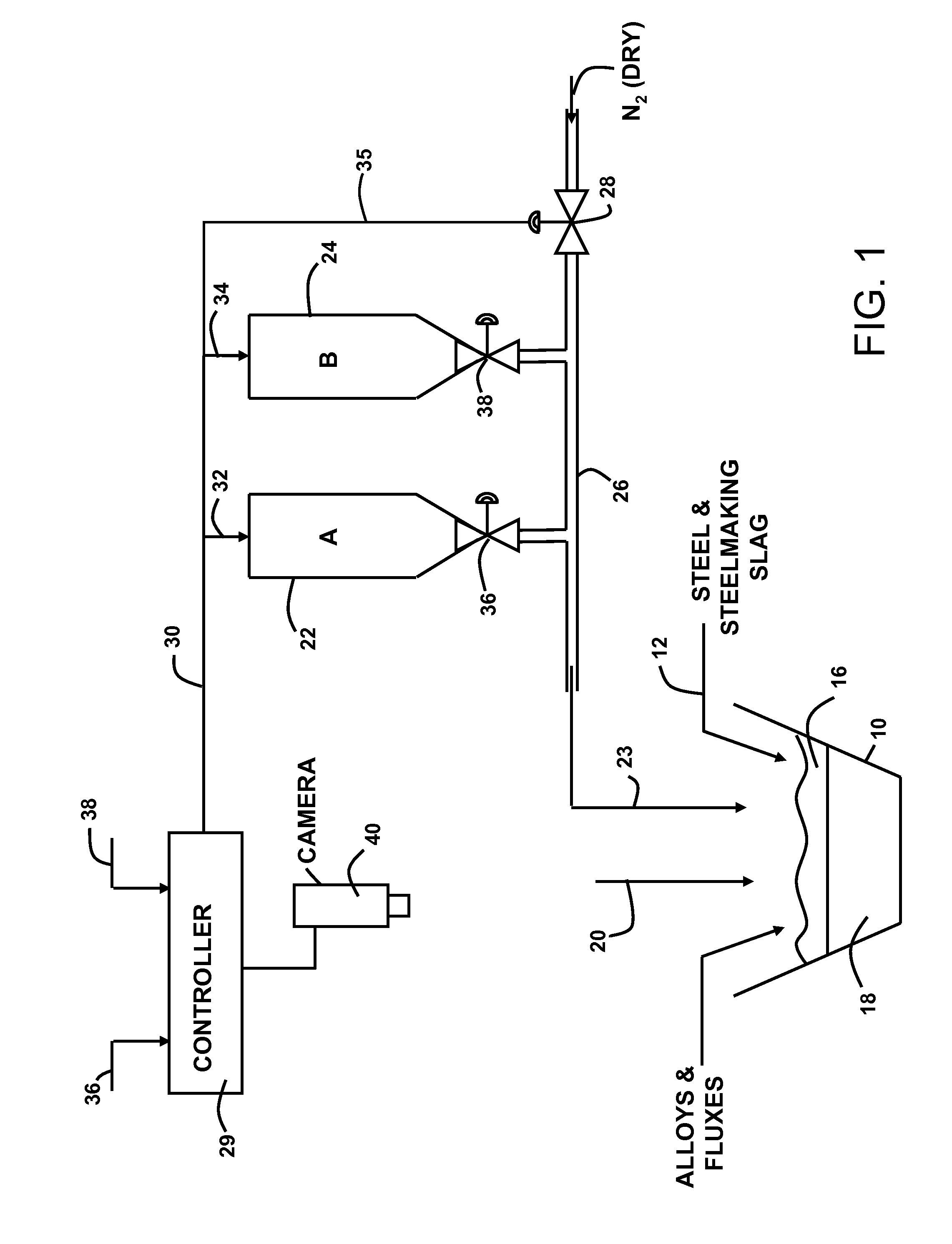

InactiveUS20130019715A1Easy to producePromote productionBlast furnace componentsBlast furnace detailsSteelmakingSilicon oxide

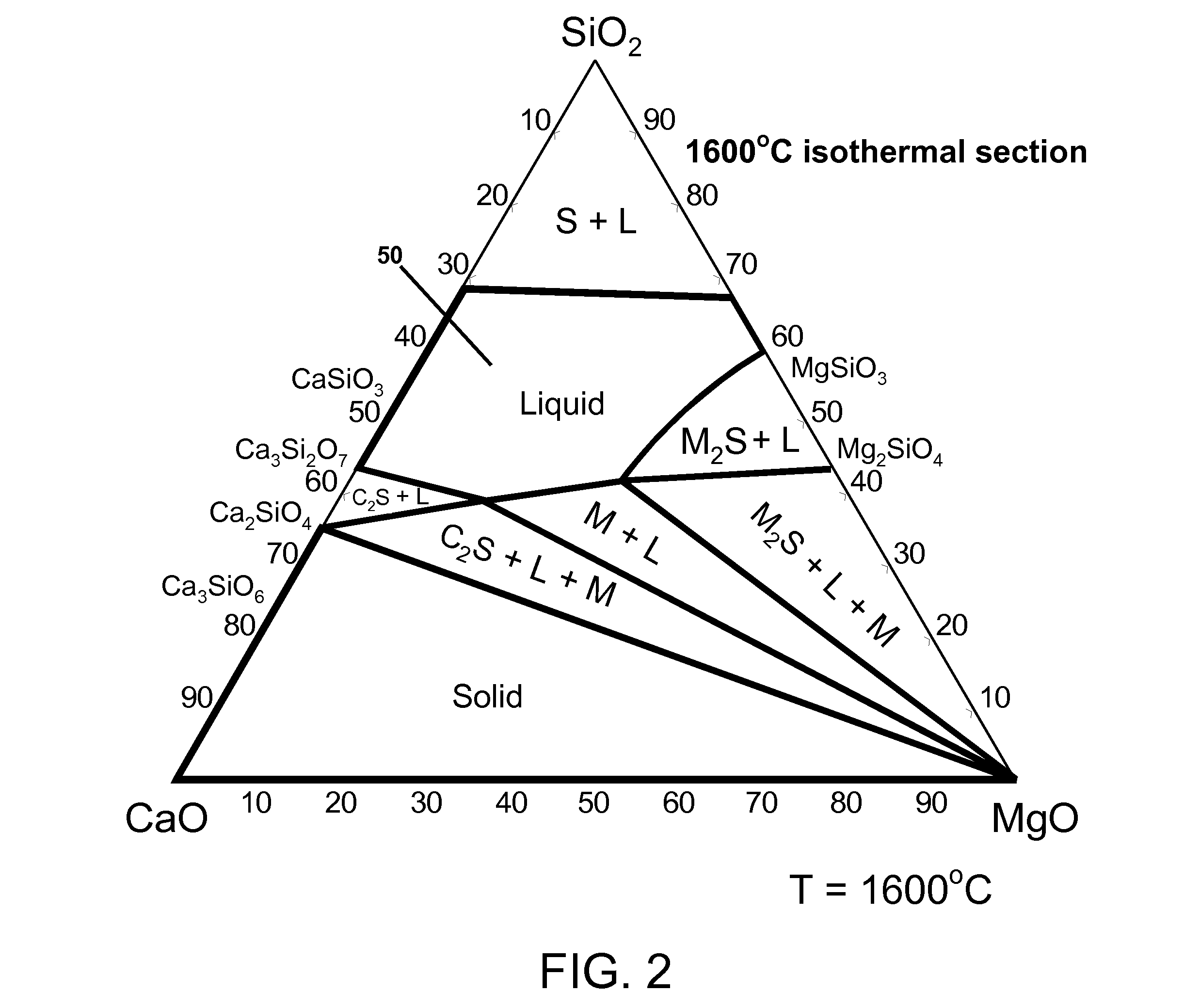

A slag composition containing steelmaking slag and from about 0.3 to about 10 weight percent of reducing agent. The steelmaking slag contains from about 20 to about 55 weight percent of calcium oxide, from about 8 to about 50 weight percent of ferrous oxide, from about 4 to about 20 weight percent of magnesium oxide, from about 8 to about 30 weight percent of silicon oxide, from 0.5 to about 10 weight per cent aluminum oxide, and from about 0.5 to about 10 weight percent of manganese oxide. The reducing agent contains from about 15 to about 70 weight percent of calcium carbide and from about 10 to about 50 weight percent silicon carbide, wherein the ratio of calcium carbide to silicon carbide is between 0.7 and 7.

Owner:NUFLUX

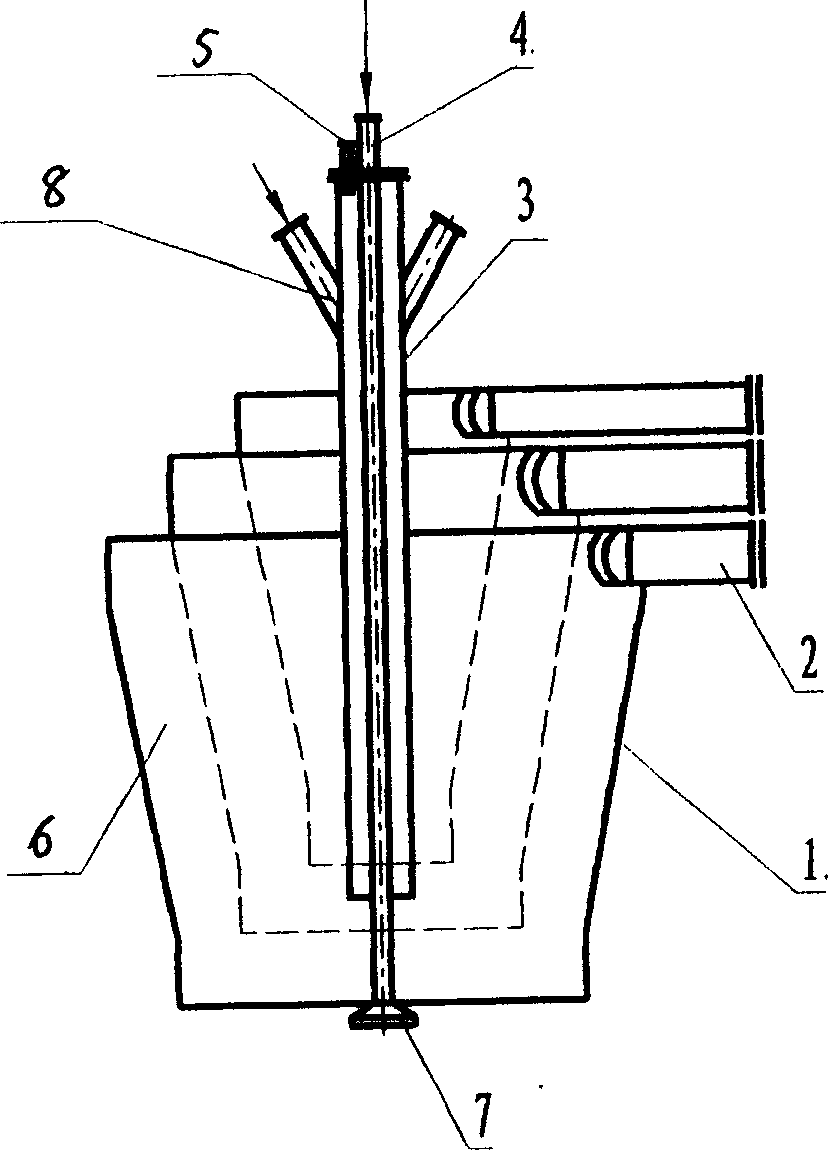

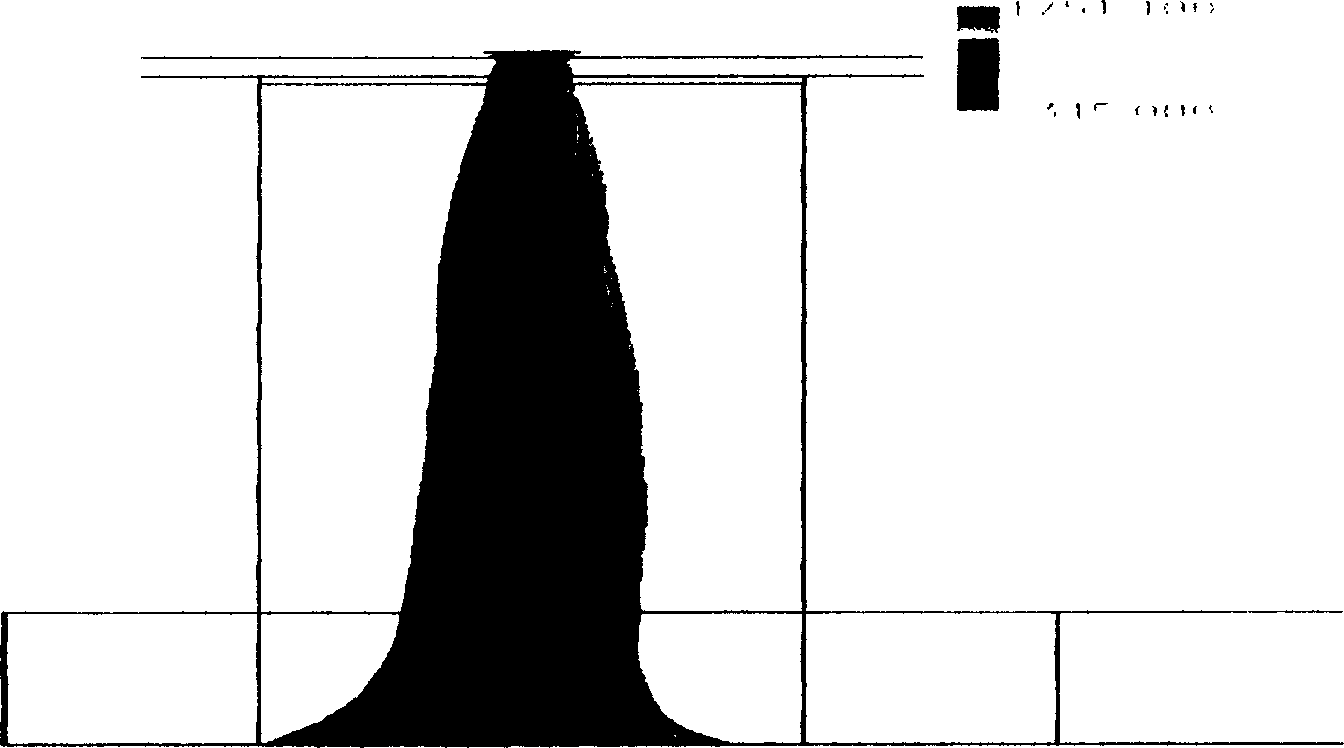

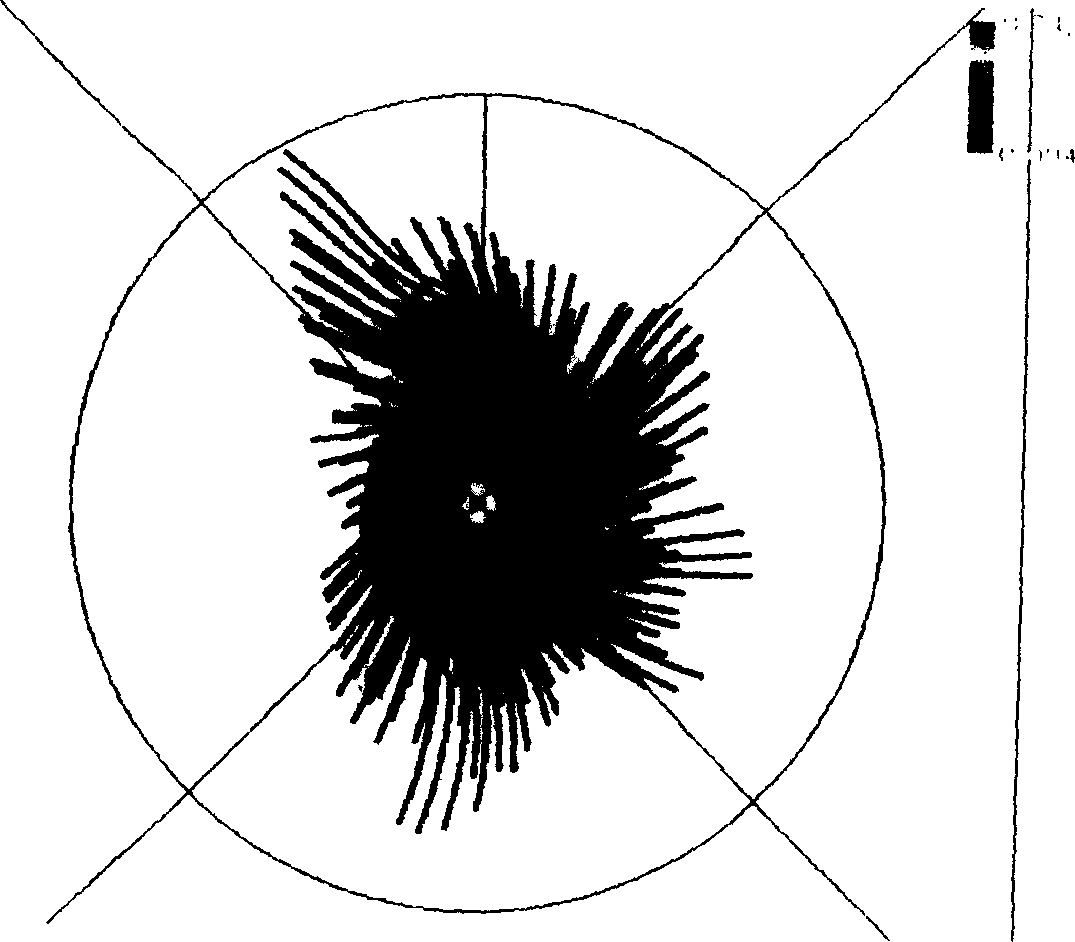

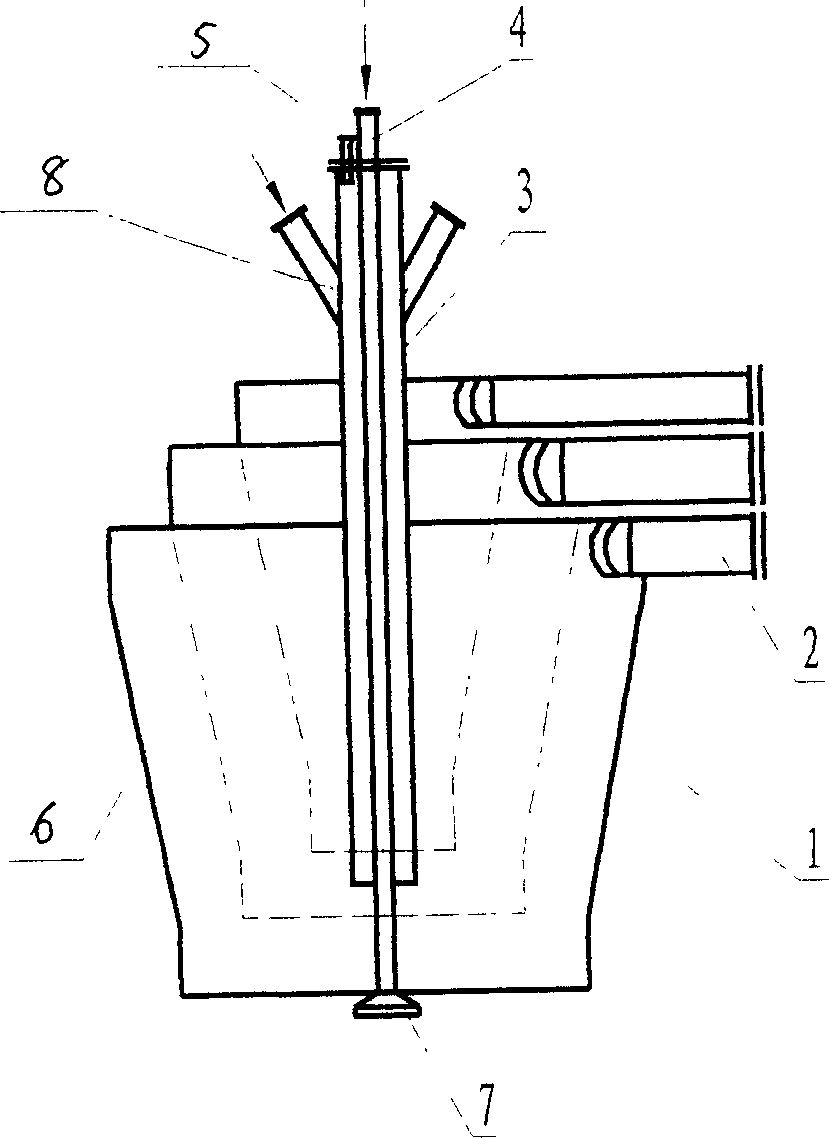

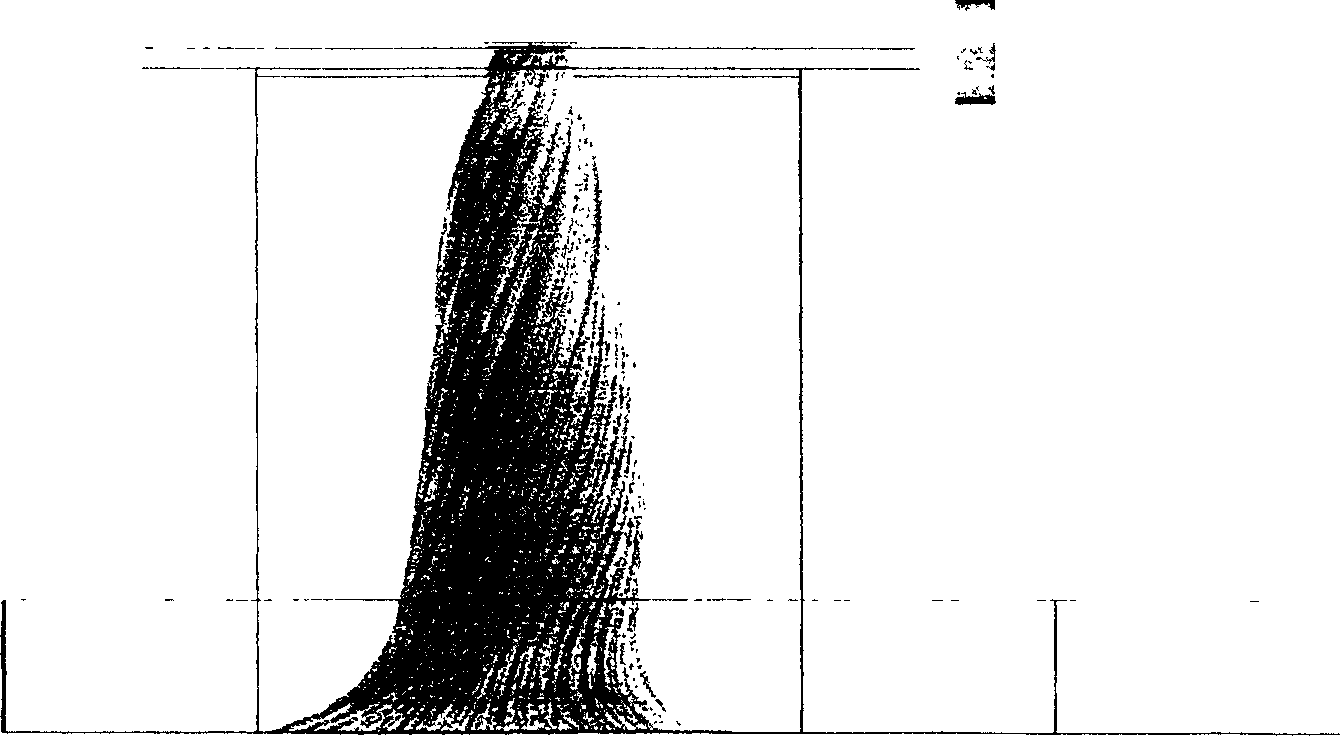

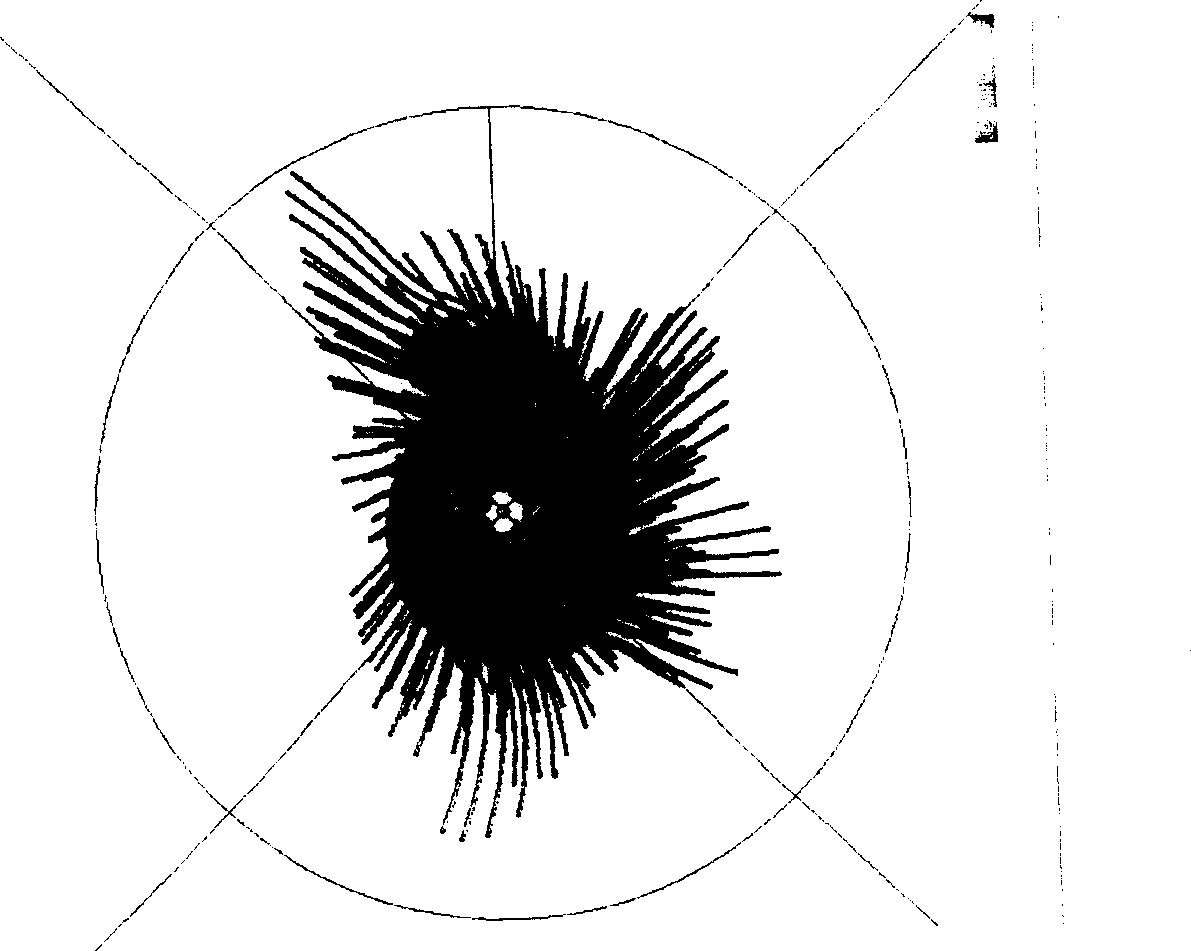

Central vortex column flash smelting process

InactiveCN1528926AReduce washoutReduce corrosionRotary drum furnacesCrucible furnacesSmelting processNuclear engineering

The invention discloses a kind of centre swirl flash quick smelting process. The process sprays the dried powder materials and oxygen into the reactor form the muzzle at the centre of the top, and forms the swirl pole high temperature reaction area along the shaft line of the reactor. There has a ring untouchable transition circle between the high temperature reaction area and the reactor wall in lengthwise. There has a ring untouchable transition circle that has particle grad, oxygen potential grad and temperature grad which weakened towards the reactor wall direction between the high temperature reaction area and the reactor wall. Because of the untouchable circle, it reduces the impact of high temperature, particles, and air, so it can protect the reactor wall.

Owner:CHINA NERIN ENG

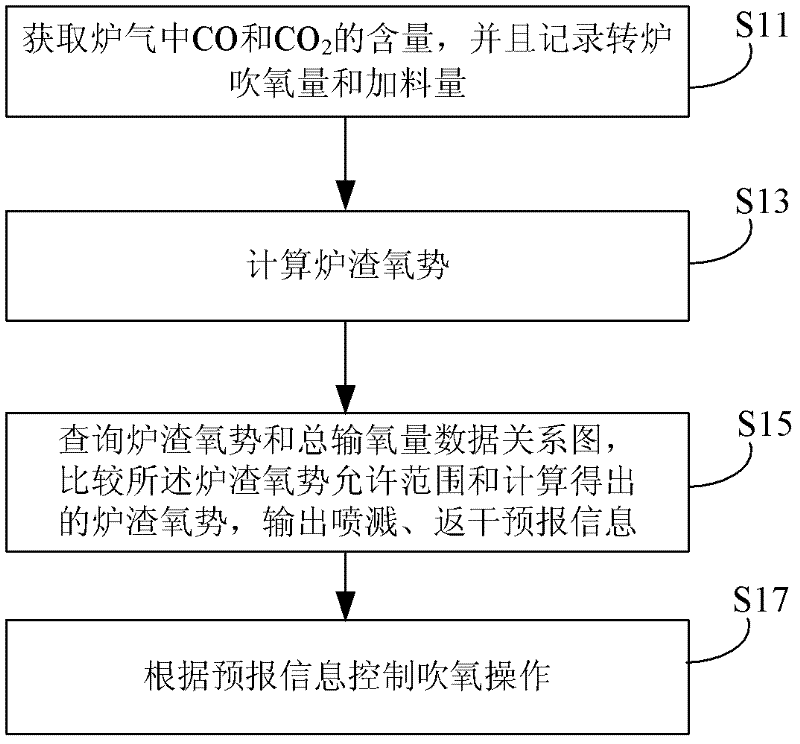

Method, device and system for controlling furnace conditions of convertor steelmaking

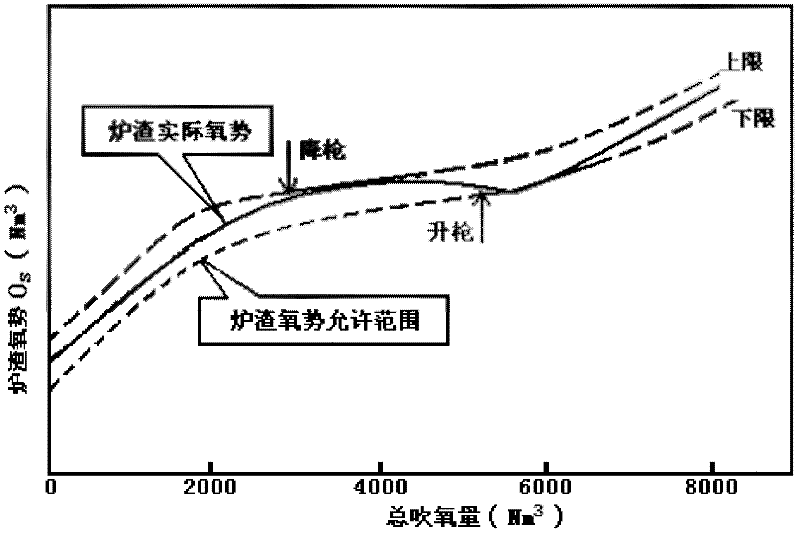

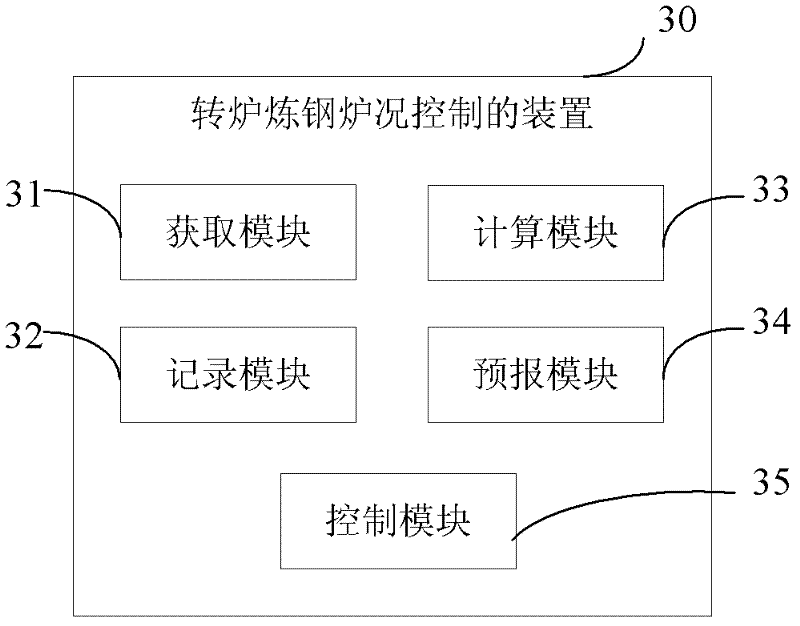

ActiveCN102363825AOvercome the disadvantage of poor stability of artificial experience controlEasy to controlManufacturing convertersSteelmakingSmelting process

The invention provides a method, a device and a system for controlling furnace conditions of convertor steelmaking. By the method, the device and the system, the problem that a control effect is influenced by the descending of a convertor smoke hood and accumulated slag at a furnace mouth and the problem of poor control accuracy in the prior art are solved. The method comprises the following steps of: acquiring the content of CO and CO2 in furnace gas ingredients, and recording the oxygen blowing amount of a convertor and charging quantity; calculating slag oxygen potential according to the content of the CO and the CO2, the oxygen blowing amount of the convertor and charging information; inquiring the permission range of the slag oxygen potential from a data relational graph of the slag oxygen potential and the total oxygen blowing amount according to the oxygen blowing amount of the convertor, comparing the permission range of the slag oxygen potential with the calculated slag oxygen potential, and outputting spattering forecast information or drying return forecast information according to a comparison result; and controlling the oxygen blowing operation according to the forecast information. Due to the adoption of the technical scheme, the defect of poor stability of control by artificial experience is overcome; and compared with the conventional sonar slag-reducing method, the method has the advantages that: the control effect is not influenced by the descending of the convertor smoke hood and the accumulated slag at the furnace mouth; the control is more accurate; and the stability of the smelting process is improved.

Owner:田陆

Method for improving performance of furnace slag obtained by smelting vanadic titanomagnetite in blast furnace

InactiveCN102206719AImprove performanceIncrease oxygen potentialBlast furnace detailsOxygen potentialTitanomagnetite

The invention provides a method for improving performance of furnace slag obtained by smelting vanadic titanomagnetite in a blast furnace. The method comprises the following steps: adding vanadic titanomagnetite in the blast furnace for smelting, obtaining molten iron and slag, wherein, when vanadic titanomagnetite is added in the blast furnace for smelting, poor manganese ore is added in vanadic titanomagnetite, the MnO content in the furnace slag is 0.8 to 1.2% by an addition of the poor manganese ore. According to the invention, a certain proportion of poor manganese ore is added into the smelting raw materials in the blast furnace, the characteristic that MnO containing in poor manganese ore is hard to reduce is used, oxygen potential of high-temperature region at bottom of the blast furnace is increased, generation of substance of Ti (CN) and the like with high-melting point in slag can be effectively controlled for improving the performance of high Titanium slag. Simultaneously, low MnO and TFe contained in the manganese ore can not be effectively used, so an effective utilization of the poor manganese ore is realized by the method.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

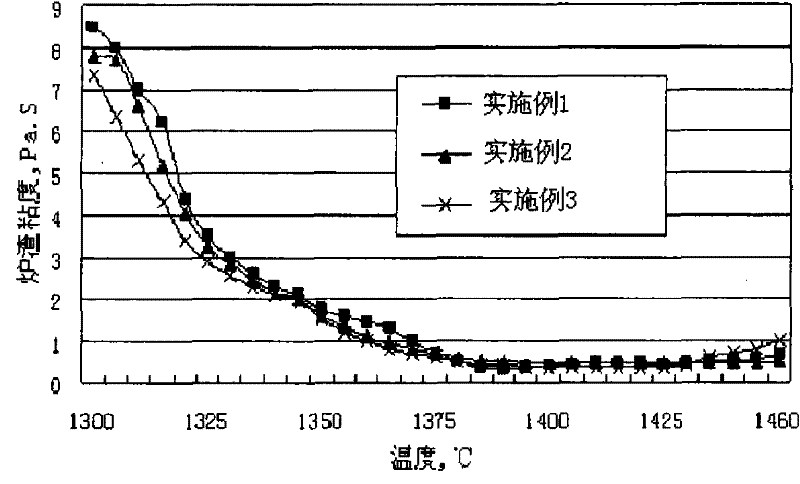

Preparation method of high titanium slag TiO2 photocatalysed superfine fiber

InactiveCN101811037ALower melting temperatureEasy to shapePhysical/chemical process catalystsCatalytic decompositionVolumetric Mass Density

The invention relates to a preparation method of a high titanium slag TiO2 photocatalysed superfine fiber. SiO2 and other components with lower density and lower melting point are added to lower the melting temperature of titanium slag, a scorification process similar to a melt phase-separation method is adopted to make impurities float on the top of the molten slag and cooled and solidified firstly by the principle of glass phase separation, technologies of regulating titanium slag components, controlling oxygen potentials and the like are combined to remove impurities and enrich the content of the titanium, the obtained molten high titanium slag is directly formed into fiber via oxygen blowing by a high-speed centrifugal special device, and then retraining heating is carried out to convert crystal forms to manufacture discarded metallurgical titanium slag into the TiO2 superfine fiber with photocatalysis. The diameter of the high titanium slag TiO2 photocatalysed superfine fiber prepared by the method is 3-6 microns, the length is 0.9-3.0 millimeters, which is conductive to the molding of catalytic materials and greatly increases the contact area, the crystal form of TiO2 is anatase, and the high titanium slag TiO2 photocatalysed superfine fiber can be used as the catalytic decomposition material and the filter material of industrial toxic waste gas, organic sewage and waste water.

Owner:鹤壁洁联新材料科技有限公司

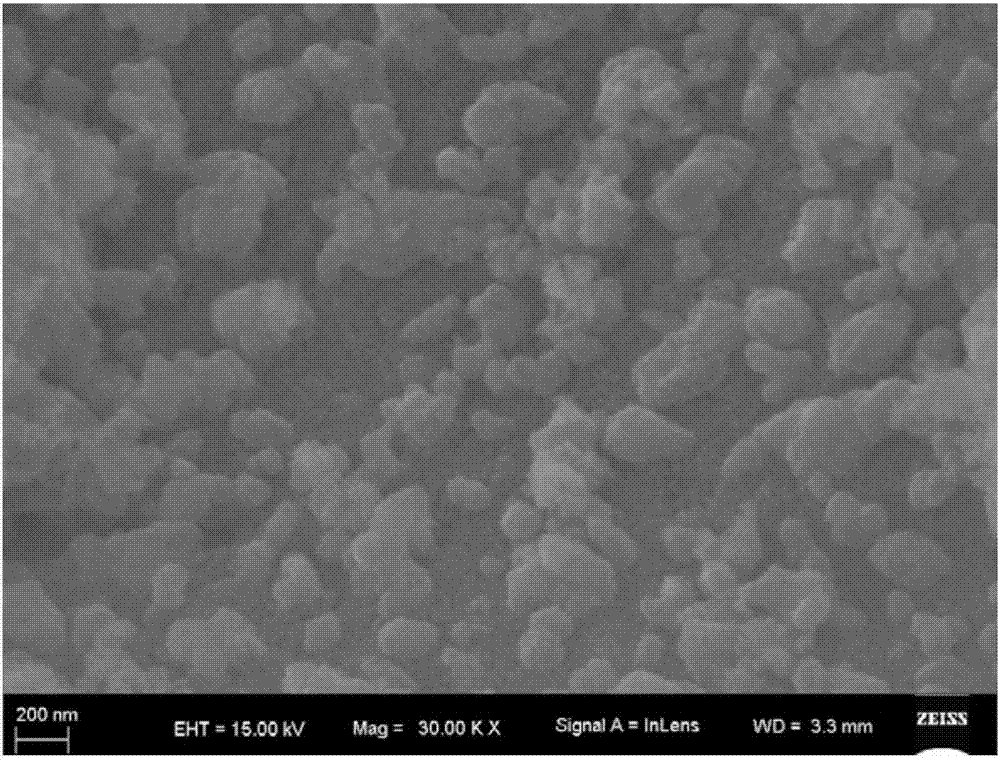

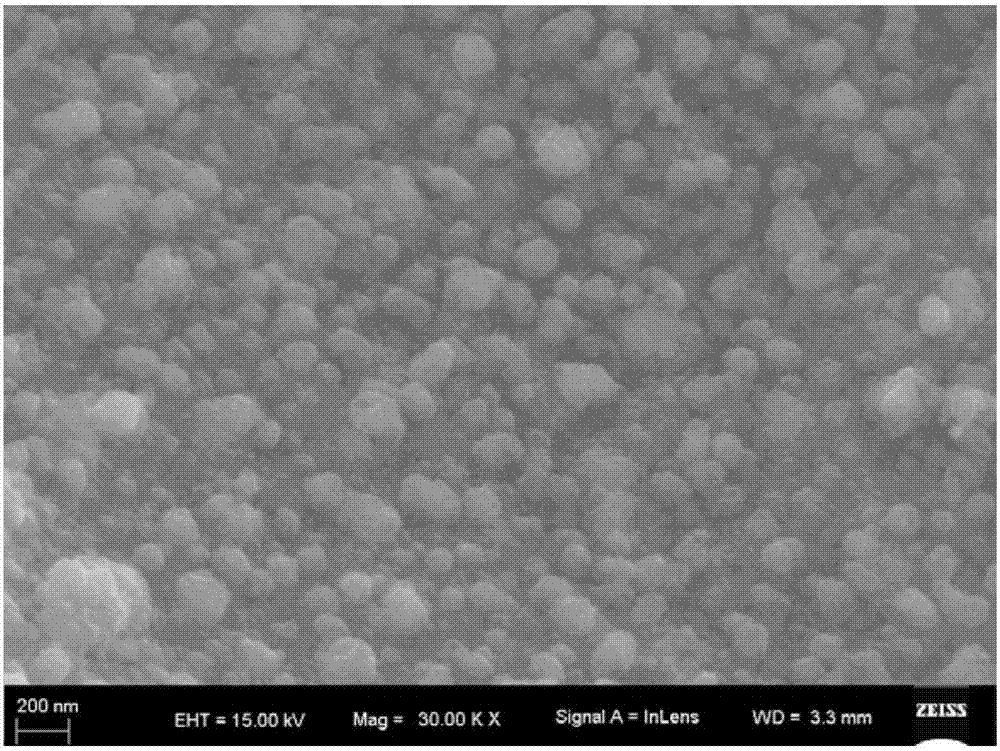

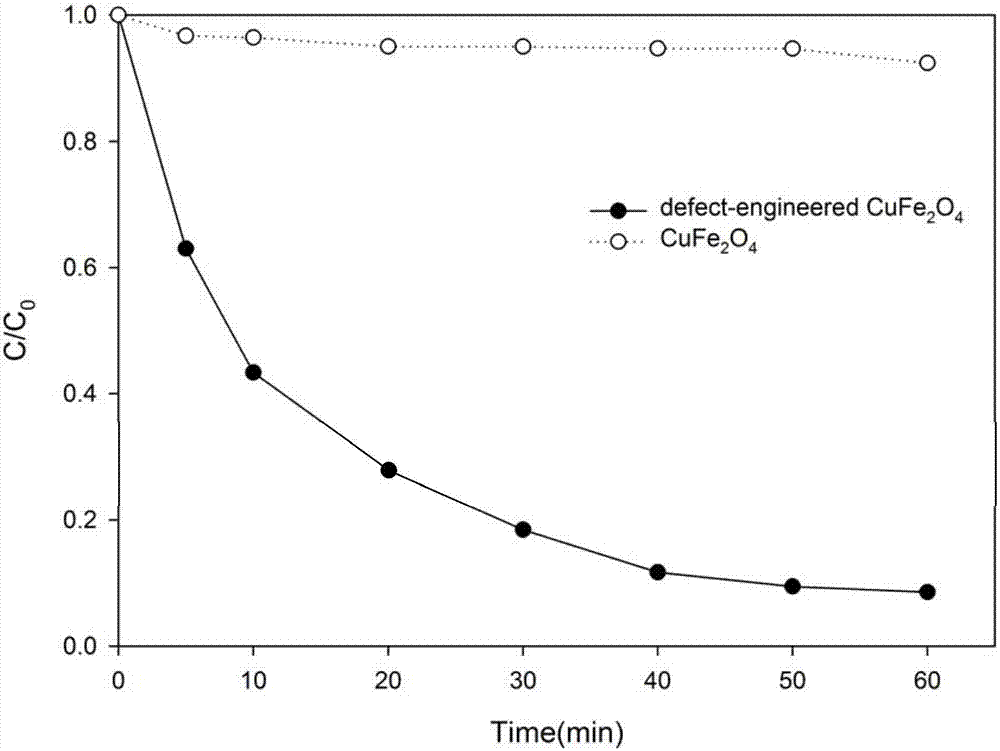

Preparation method and application of oxygen-potential-deficiency magnetic copper ferrite catalyst

ActiveCN106861695AContinuous degradationEfficient CatalysisWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsNitratePersulfate

The invention discloses a preparation method and application of an oxygen-potential-deficiency magnetic copper ferrite catalyst. The preparation method comprises the following steps: (1) dissolving copper nitrate and iron nitrate into de-ionized water at the mol ratio of 1 to 2 and adding a certain amount of sodium citrate; (2) magnetically stirring the material obtained by the step (1) in an oil bath; (3) taking out the material obtained by the step (2) and drying to form sol; (4) calcining the sol obtained by the step (3) in a muffle furnace to obtain a first component; (5) reducing the first component in a hydrogen atmosphere to obtain the oxygen-potential-deficiency magnetic copper ferrite catalyst. The oxygen-potential-deficiency magnetic copper ferrite catalyst prepared by the preparation method can be used for effectively catalyzing persulfate and the catalyst is magnetic and can be used again after being magnetically separated.

Owner:HUAQIAO UNIVERSITY

Central vortex column flash smelting process

InactiveCN1246486CReduce washoutReduce corrosionRotary drum furnacesCrucible furnacesSmelting processNuclear engineering

The invention discloses a kind of centre swirl flash quick smelting process. The process sprays the dried powder materials and oxygen into the reactor form the muzzle at the centre of the top, and forms the swirl pole high temperature reaction area along the shaft line of the reactor. There has a ring untouchable transition circle between the high temperature reaction area and the reactor wall in lengthwise. There has a ring untouchable transition circle that has particle grad, oxygen potential grad and temperature grad which weakened towards the reactor wall direction between the high temperature reaction area and the reactor wall. Because of the untouchable circle, it reduces the impact of high temperature, particles, and air, so it can protect the reactor wall.

Owner:CHINA NERIN ENG CO LTD

Low-nitrogen boron-containing steel smelting method for improving boron element yield

ActiveCN108588541AShorten the smelting processStabilized boron contentManufacturing convertersLow nitrogenSlag

The invention discloses a low-nitrogen boron-containing steel smelting method for improving the boron element yield. Converter end point boiling tapping is conducted, the frequency that molten steel absorbs nitrogen from air is reduced, a slag modifier and lime are added after converter tapping is finished for adjusting slag oxygen potentials and components, and in the tapping process, a steel ladle is subjected to bottom blowing and stirring in the whole process; after tapping is finished, molten steel is conveyed to be subjected to RH treatment, after the steel ladle is conveyed in place, vacuum pumping is conducted, C in the molten steel is utilized for deoxygenation, and after the oxygen content is reduced to be 0.02% or below, aluminum is added for deoxygenation and alloying, the 1.0-3.5 kg / t of slag modifier is added in the slag face of the steel ladle, and after all the alloy and the slag modifier are added, clean circulation is conducted for 5 min or longer time, T.O in the molten steel is smaller than or equal to 0.002%, the steel slag T.Fe+MnO is smaller than or equal to 2.0%; then, a boron-iron alloy is added, clean circulation is conducted for 8 min or longer time, andvacuum breaking and tapping are conducted. During RH tapping, the boron yield reaches 89% or above, the content and the yield of the boron element in the molten steel are stably controlled, BN precipitation in the later continuous casting process can be reduced, and important significance is achieved for stabilizing the mass and performance of the boron containing steel.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

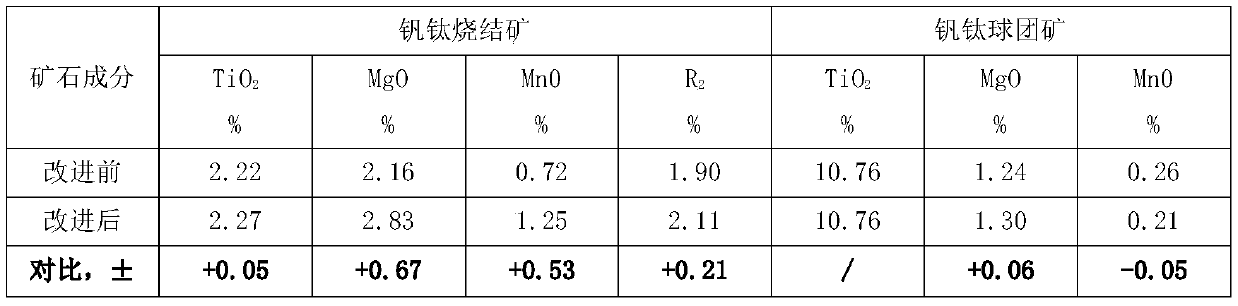

Method for improving performance of high titanium slag

InactiveCN111304390ASolve thickeningImprove liquidityBlast furnace detailsOxygen potentialOxygen content

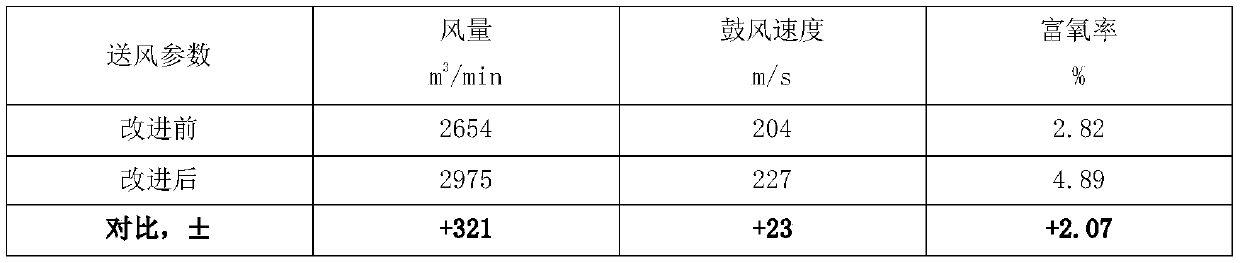

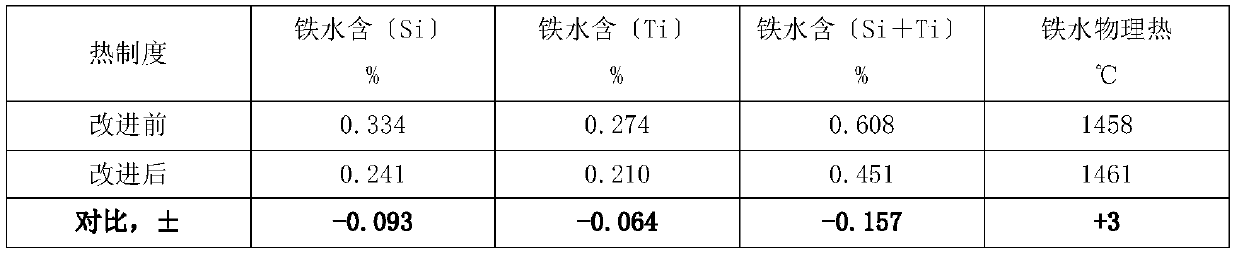

The invention discloses a method for improving the performance of high titanium slag. According to the titanium slag thickening mechanism, the blast furnace air volume and the oxygen content are greatly increased in a targeted mode, the oxygen potential of a blast furnace hearth is increased, and generation of high-melting-point TiC and TiN by reduction is restrained and reduced; on the basis thatMgO and MnO have good fluidity and high oxidability, the content of MgO and MnO in the slag is increased, the content of R2 and R4 in the slag is increased, and the purpose of improving the mobilityand the desulfuration capacity of the slag while promoting the oxidization of the high-melting-point TiC and TiN generated by reduction is achieved; and a narrow smelting temperature interval is controlled, the tapping frequency is increased, slag iron is discharged fully in time, the staying time of the high titanium slag in a furnace is shortened so as to restrain formation of foaming slag, andtherefore the performance of the high titanium slag is successfully improved.

Owner:WUKUN STEEL

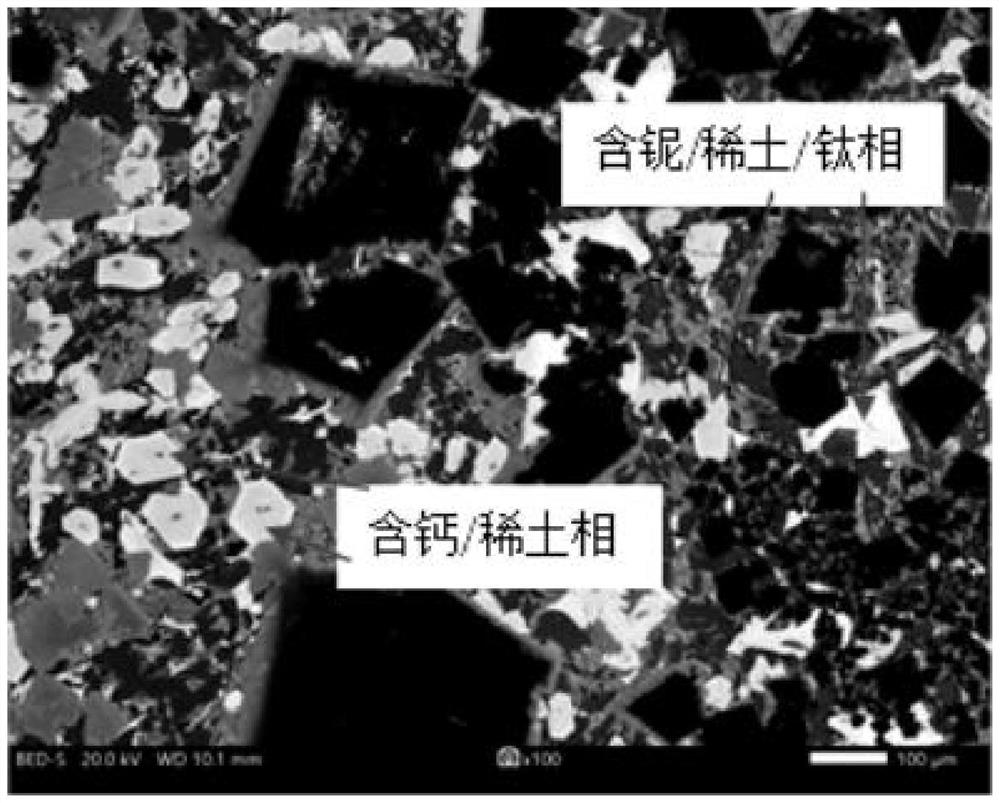

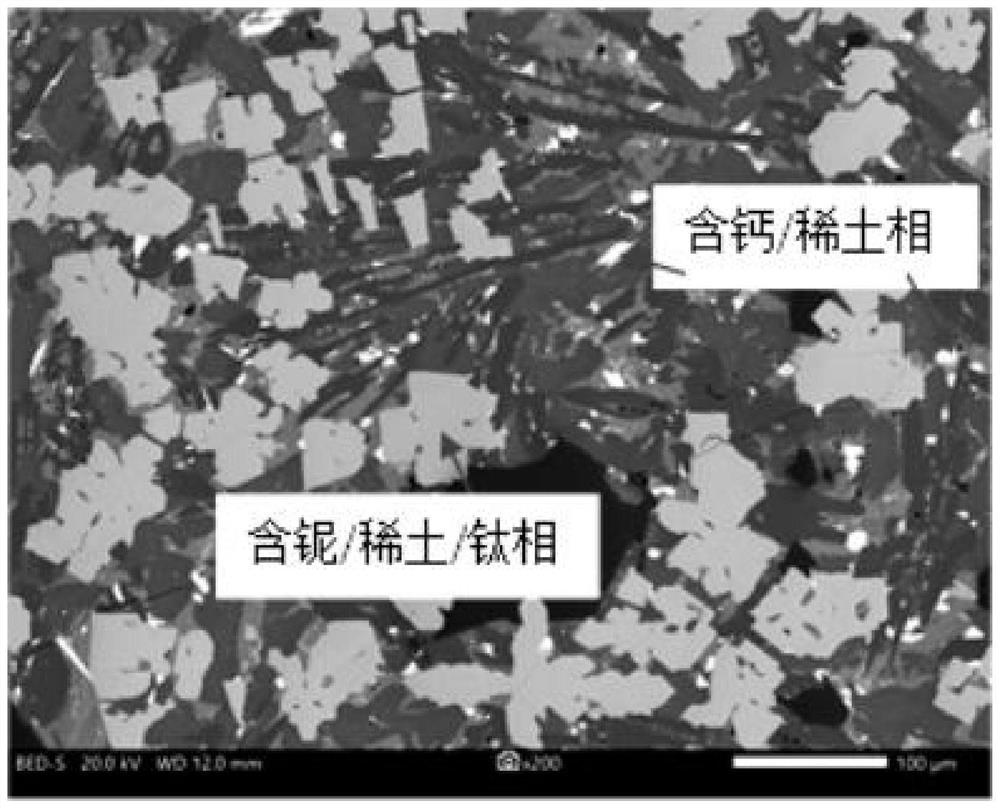

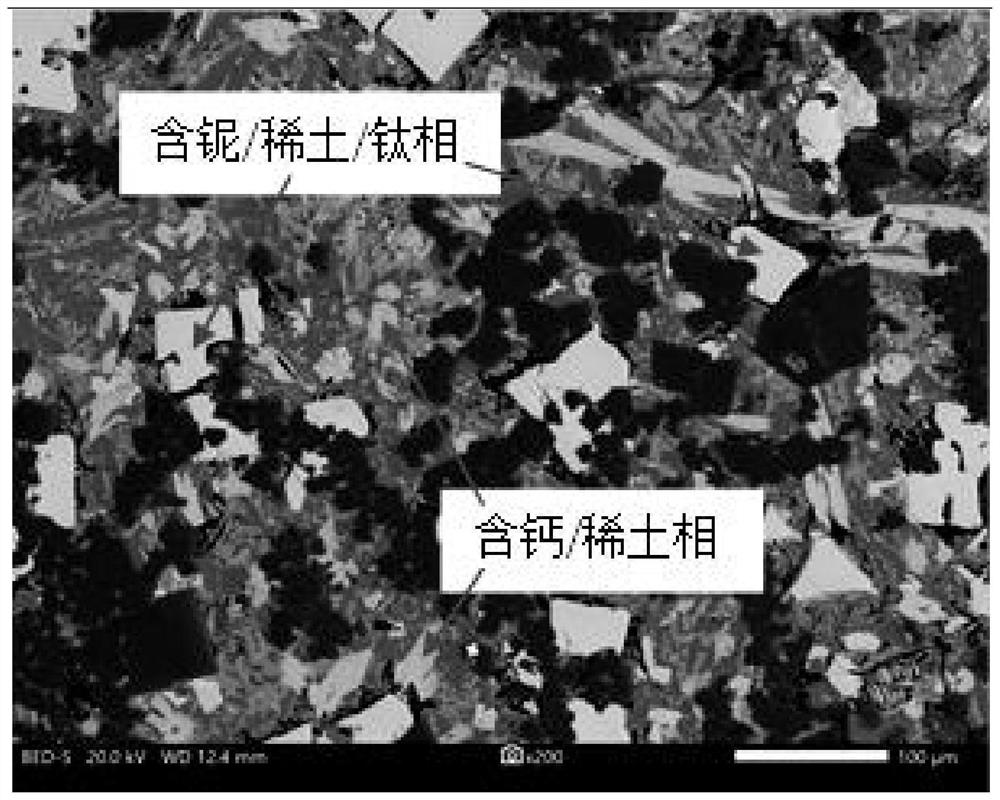

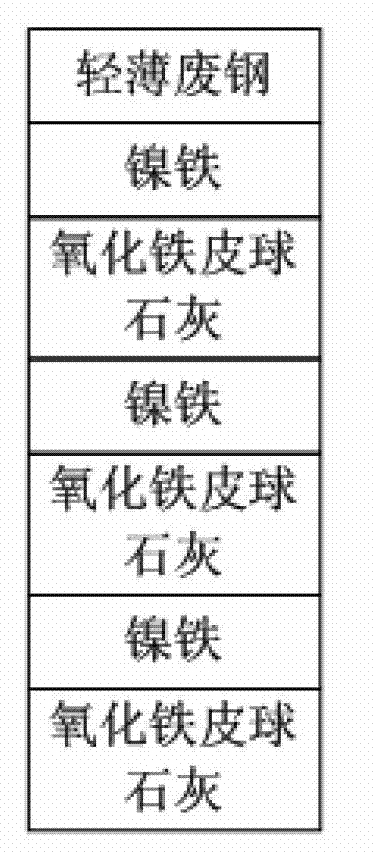

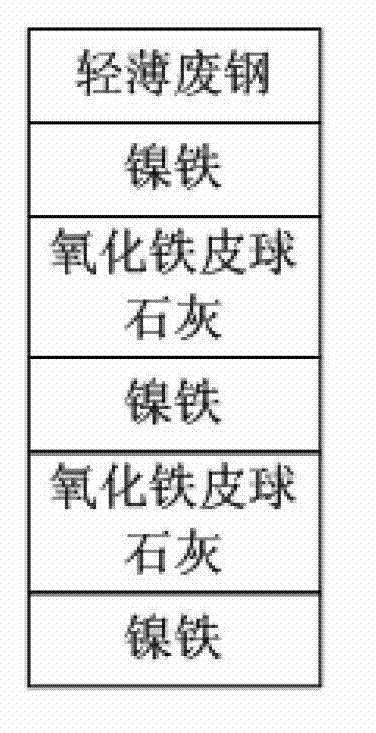

Method for comprehensively recovering niobium, rare earth and titanium from polymetallic ore containing iron, niobium and rare earth

The invention discloses a method for comprehensively recovering niobium, rare earth and titanium from polymetallic ore containing iron, niobium and rare earth. The method comprises the following stepsof mixing the polymetallic ore containing iron, niobium and rare earth, a slag former and a reducing agent in a mass ratio of 100: (0-50): (2-25); putting the obtained ingredients into a smelting furnace to be smelted, and producing furnace slag and smoke through smelting; adjusting the oxygen potential in the furnace and the CaO / SiO2 mass ratio to a proper range and the CaO / SiO2 mass ratio of furnace slag to 0.8-2.3 by controlling the composition of ingredients and the oxygen potential in the furnace and monitoring the components of smelting products and the recovery rate of iron; discharging the produced furnace slag into a slag ladle, cooling and crystallizing to obtain furnace slag containing multiphase minerals; and finely grinding the furnace slag after crushing, and obtaining high-grade concentrates containing niobium, rare earth and titanium and high-grade rare earth concentrates by adopting a beneficiation process. The method is simple in process, convenient to operate and high in practicability, and various valuable metal elements and various high-grade concentrates can be comprehensively obtained.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

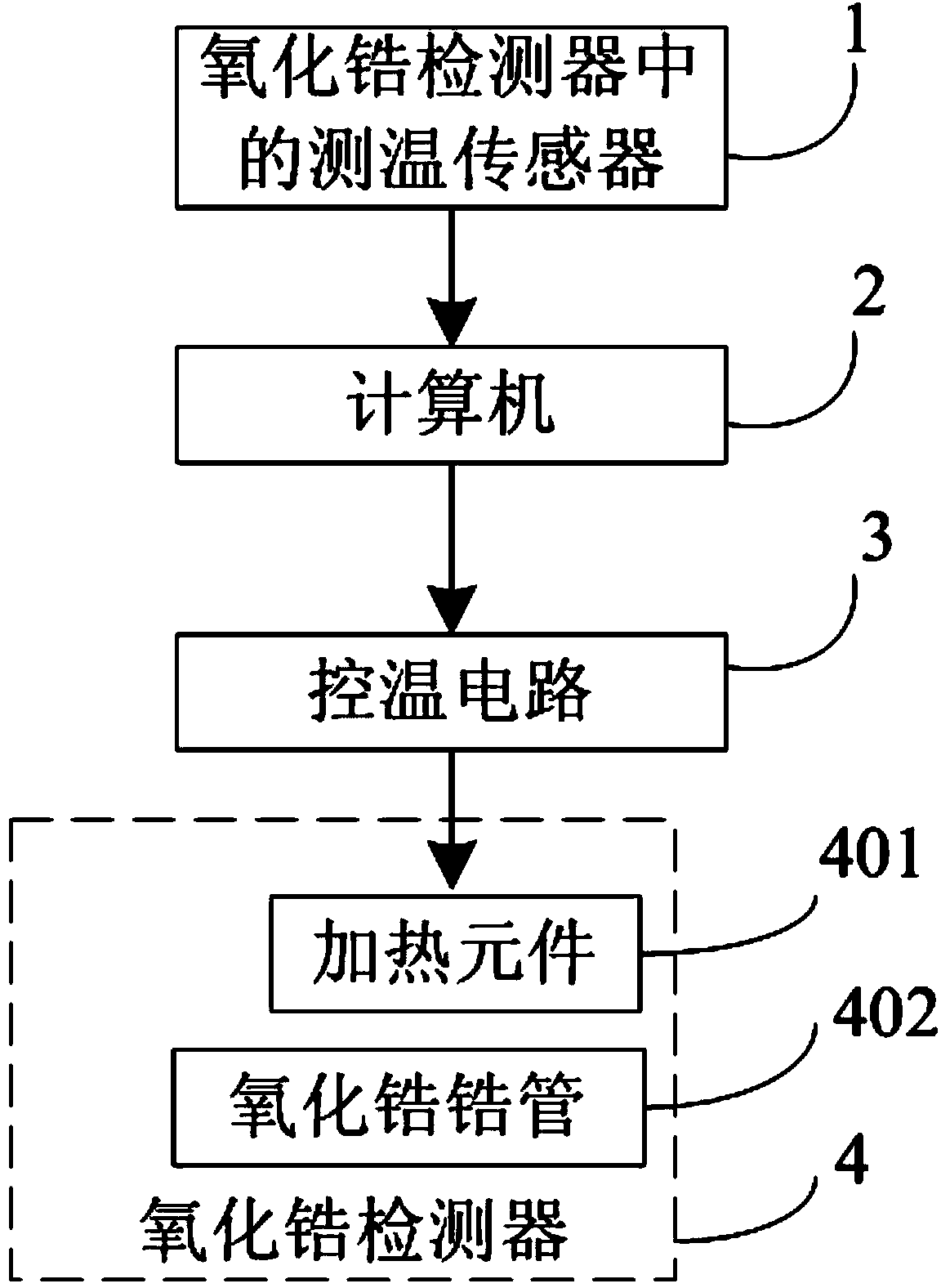

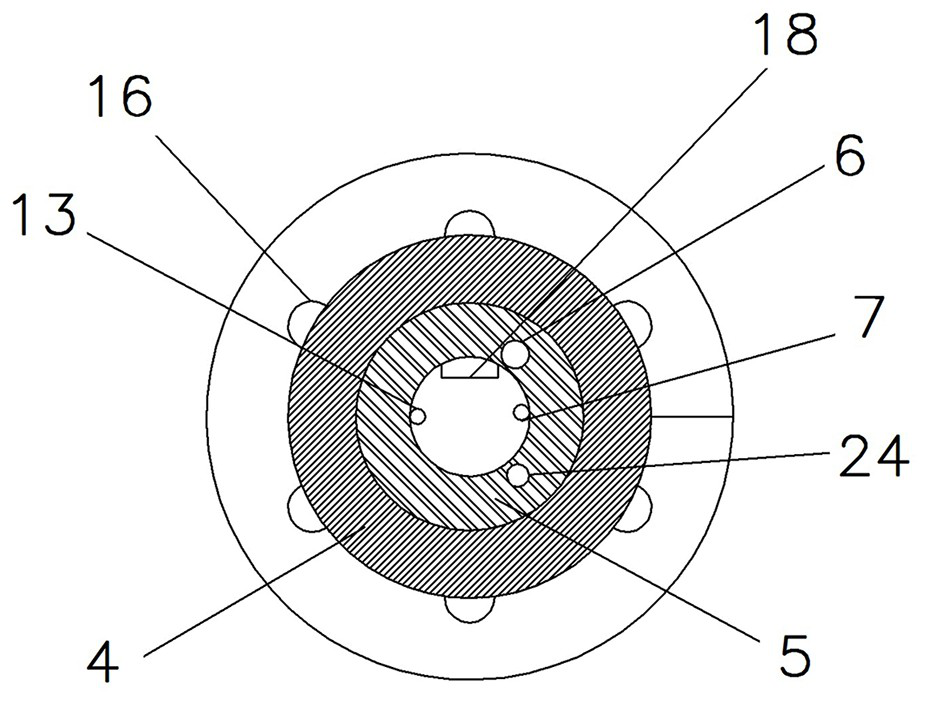

Oxygen content measurement device and oxygen content measurement method for zirconium oxide

InactiveCN103808784AHigh measurement accuracyExtended service lifeMaterial analysis by electric/magnetic meansWorking temperatureOperating temperature range

The invention discloses an oxygen content measurement device and an oxygen content measurement method for zirconium oxide. The oxygen content measurement device for zirconium oxide comprises a temperature measurement sensor, a computer, a temperature control circuit and an zirconium oxide detector which are connected with one another in sequence, wherein the temperature measurement sensor is arranged in the zirconium oxide detector. According to the oxygen content measurement method for the zirconium oxide, the zirconium oxide detector works within a stable working temperature range by a fuzzy control method and then outputs oxygen potential and a temperature value of gas to be detected; the oxygen concentration of the gas to be detected by the zirconium oxide detector is calculated through a transformation formula of a nernst formula. The oxygen content measurement device and the oxygen content measurement method have the beneficial effects that the fuzzy control method replaces the conventional PID (proportion, integration and differentiation) temperature control method, so that the problem that the oxygen concentration of the detected gas, which is measured by an instrument, is inaccurate due to the influence on a control result of a PID temperature control algorithm, caused by the change of an environment factor of an object characteristic of an electric heating furnace of the conventional oxygen concentration instrument for the zirconium oxide, is solved; the measurement precision of the zirconium oxide instrument is improved, and the service life of the zirconium oxide instrument is prolonged.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for keeping surface color of heated bearing part uniform

ActiveCN106065429AEasy to cleanImprove purityFurnace typesHeat treatment process controlProduction lineMetallurgy

The invention discloses a method for keeping the surface color of a heated bearing part uniform, which is based on a quenching salt bath and quenching heating furnace integrated roller hearth furnace salt quenching production line with a nitrogen-based protective atmosphere. Through increasing the cleaning degree of a workpiece, improving the purity degree of quenching salt bath, strengthening the control on the nitrogen-based protective atmosphere in the furnace and selecting a reasonable oxygen potential control parameter of an oxygen probe, the atmosphere in the furnace is controlled within a relatively reasonable level, so that the workpiece is neither decarburized nor oxidized, and the color of the workpiece is kept uniform. By applying the method, a shot blasting or sand blasting process of the workpiece can be reduced, the goods delivery speed of the heated bearing part can be increased, and the demands of users can be met. The invention provides a novel workpiece surface quality control method by which the color of a non-contact surface in a thermal treatment process of a bearing part is uniform and is changed from the original blue graniphyric into uniform dark blue.

Owner:LUOYANG LYC BEARING +1

Low-cost efficient dephosphorization smelting process for electric arc furnace

InactiveCN102965467AOvercoming the problem of low dephosphorization efficiencyFlexible structureProcess efficiency improvementElectric furnacePhosphorus lowAlkalinity

A low-cost efficient dephosphorization smelting process for electric arc furnace belongs to the field of electric arc furnace smelting. According to the invention, reasonable blending process is carried out in a charging stage of the electric arc furnace; accessories in a traditional electric arc furnace smelting process is moved to a charging stage; through reasonable distribution of the cold raw materials and accessories in the electric arc furnace, problems of contradiction of theoretical demands of the dephosphorization oxygen potential, alkalinity and temperature during melting process of the cold raw materials and accessories is solved; and smelting dephosphorization process of the electric arc furnace runs through the whole process from starting to the end of the melting, so as to achieve the goal of efficient dephosphorization. The invention has the following advantages: the difficulty in dephosphorization of electric arc furnace traditional smelting process is solved; dephosphorization is basically realized when the melting down of the cold materials; and the process realizes dephosphorization rate of 75%-90%, rephosphorization rate after deslagging less than 5%, and end point phosphorus lower than 0.01%.

Owner:德龙钢铁有限公司

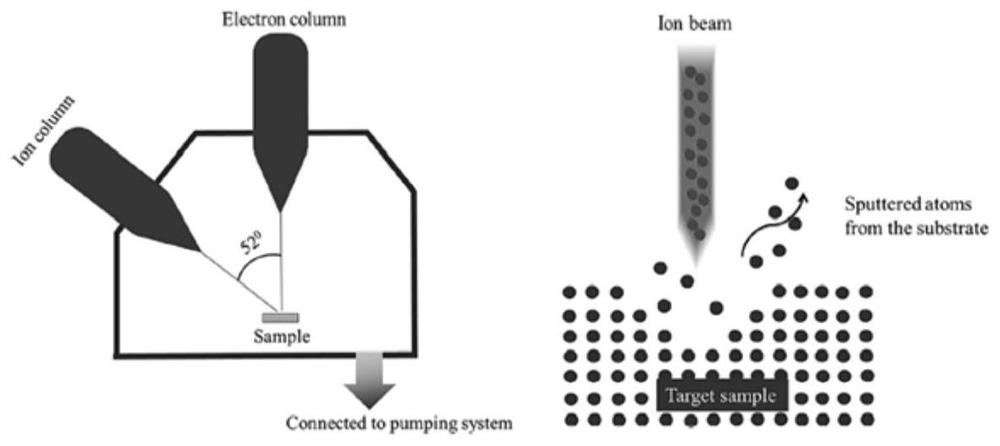

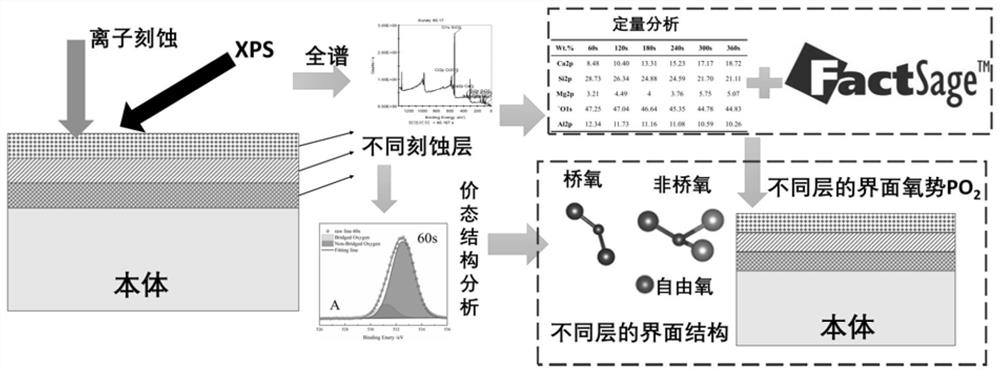

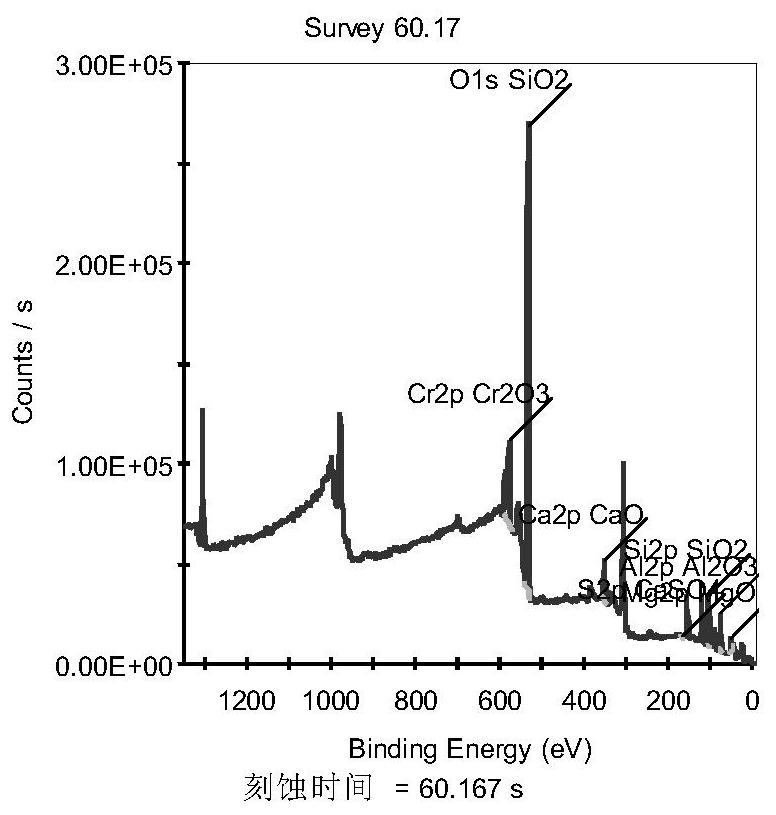

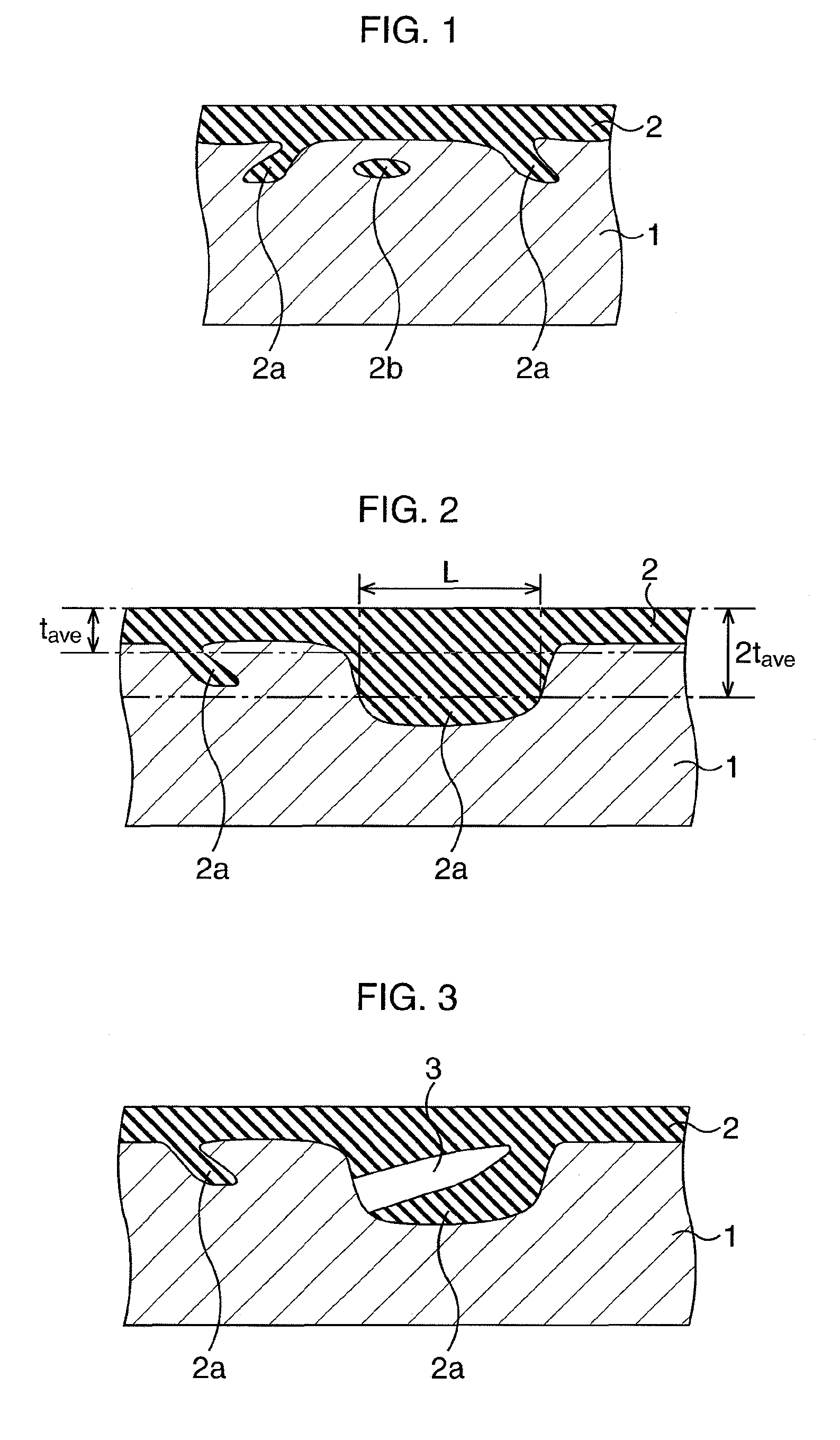

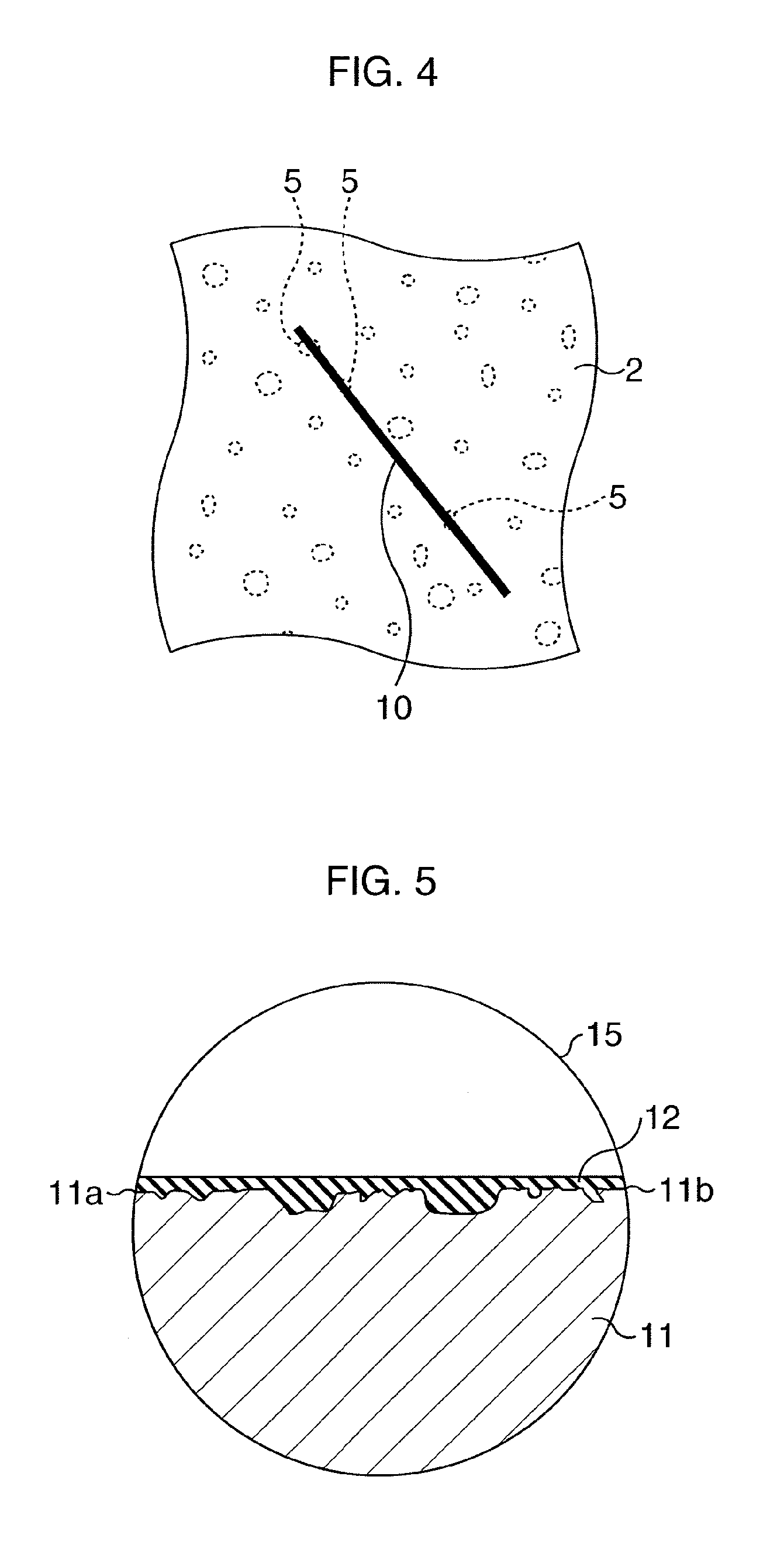

Method for directly obtaining oxygen potential and structure of material interface

ActiveCN112763527AEasy to implementImprove portabilityMaterial analysis using wave/particle radiationComputational materials scienceChemical physicsOxygen potential

The invention discloses a method for directly obtaining oxygen potential and structure of a material interface, and belongs to the technical field of material interface research. The method comprises the following steps of: etching the surface of a fresh solid sample to form a to-be-detected sample interface; carrying out XPS detection on the to-be-detected sample interface by using an Al K alpha or Mg K alpha X-ray to obtain an X-ray photoelectron spectroscopy full spectrum and a target element high-resolution spectrum; according to full-spectrum quantification and high-resolution spectrogram fitting processing, obtaining element quantitative information and valence state distribution information of the to-be-detected sample interface; performing multivariate thermodynamic calculation according to the element quantitative information of the interface to obtain the interface oxygen potential of the to-be-detected sample interface; obtaining the structure information of the to-be-detected sample interface according to the valence state distribution information; and according to the etching information, obtaining structure changes of different depths. The method solves the problem that the interface oxygen potential and the interface structure are difficult to directly obtain.

Owner:UNIV OF SCI & TECH BEIJING

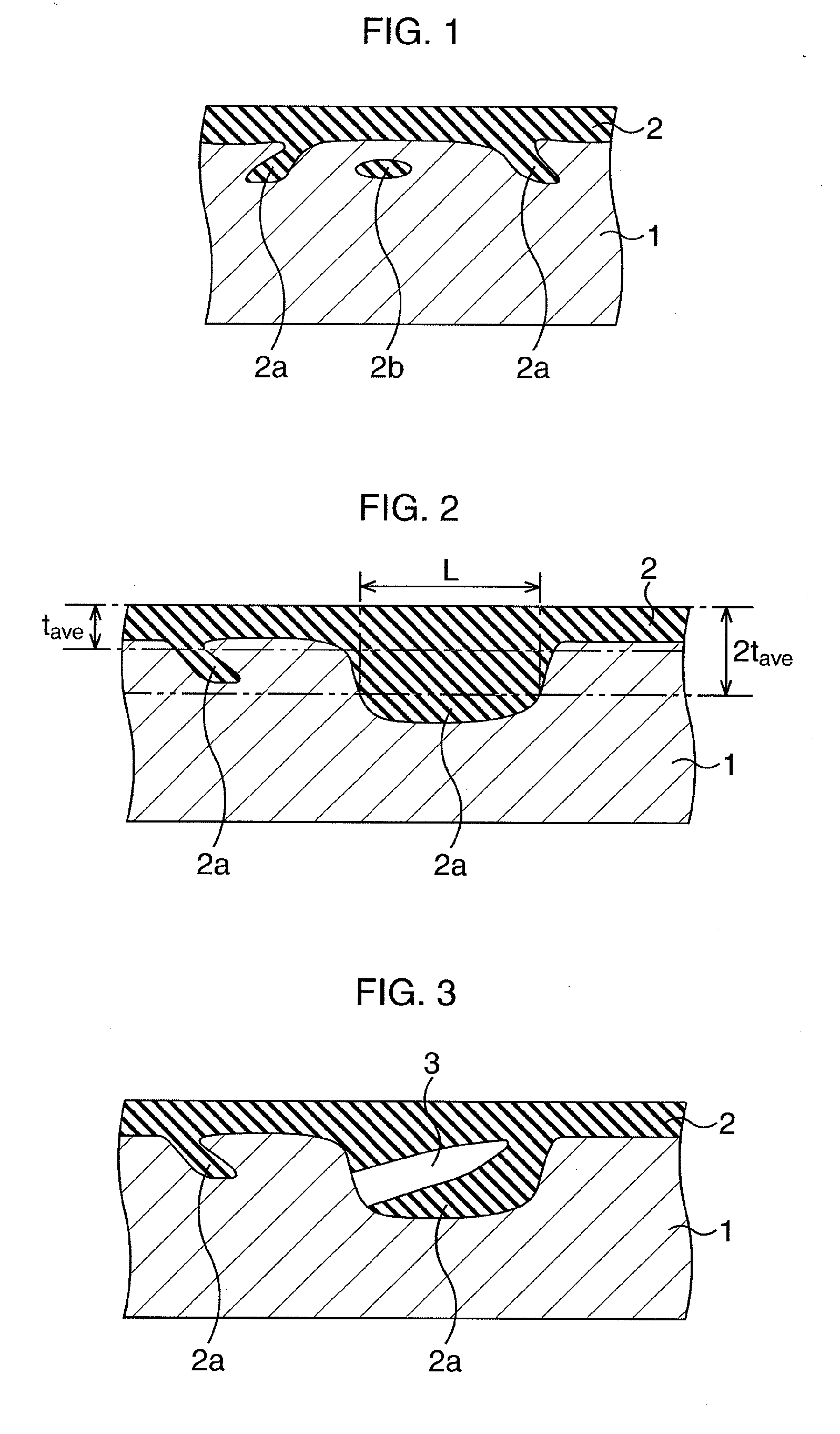

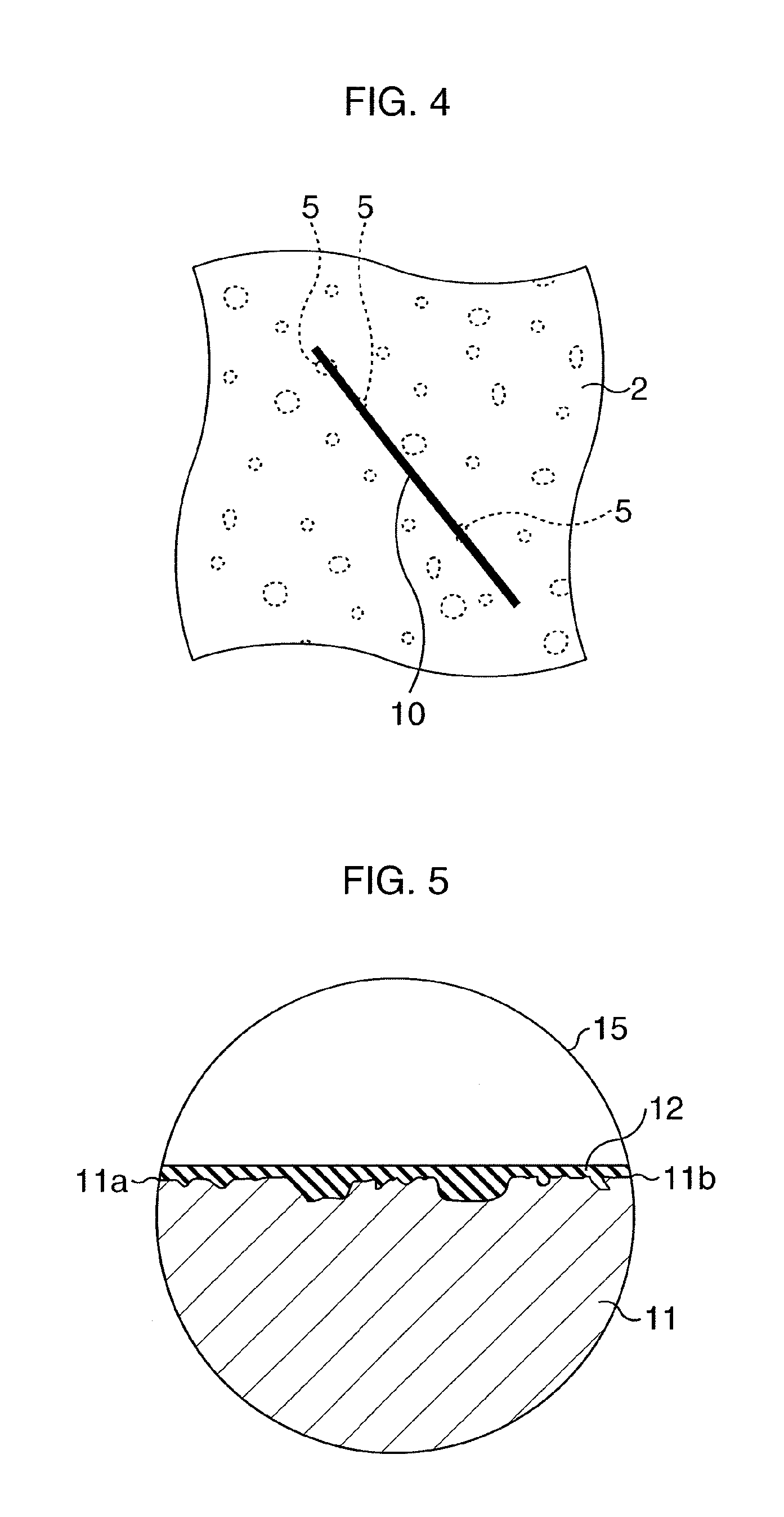

Grain-oriented electrical steel sheet and manufacturing method thereof

ActiveUS8920581B2Inhibition defectStable productionLayered productsSolid state diffusion coatingElectrical steelSheet steel

Nitriding process of a steel strip is performed. Next, annealing is performed to form a forsterite based glass coating film at a surface of the steel strip. Heating is performed up to 1000° C. or more in a mixed gas atmosphere containing H2 gas and N2 gas, and a rate of N2 gas is 20 volume % or more, next, the atmosphere is switched into H2 gas atmosphere at the temperature of 1000° C. or more and 1100° C. or less, when the annealing is performed. An oxygen potential P (H2O) / P (H2) is set to be 0.05 to 0.3 when the temperature is 850° C. or less during the heating in the mixed gas atmosphere.

Owner:NIPPON STEEL CORP

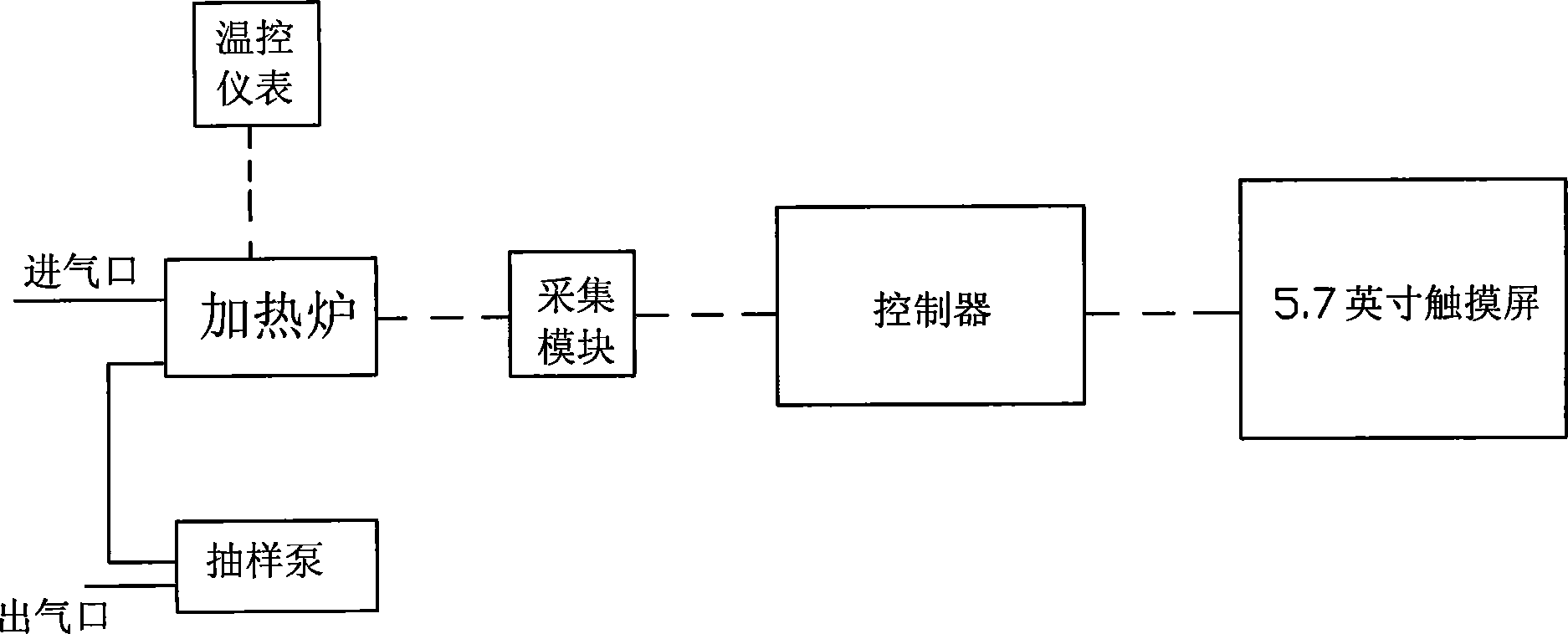

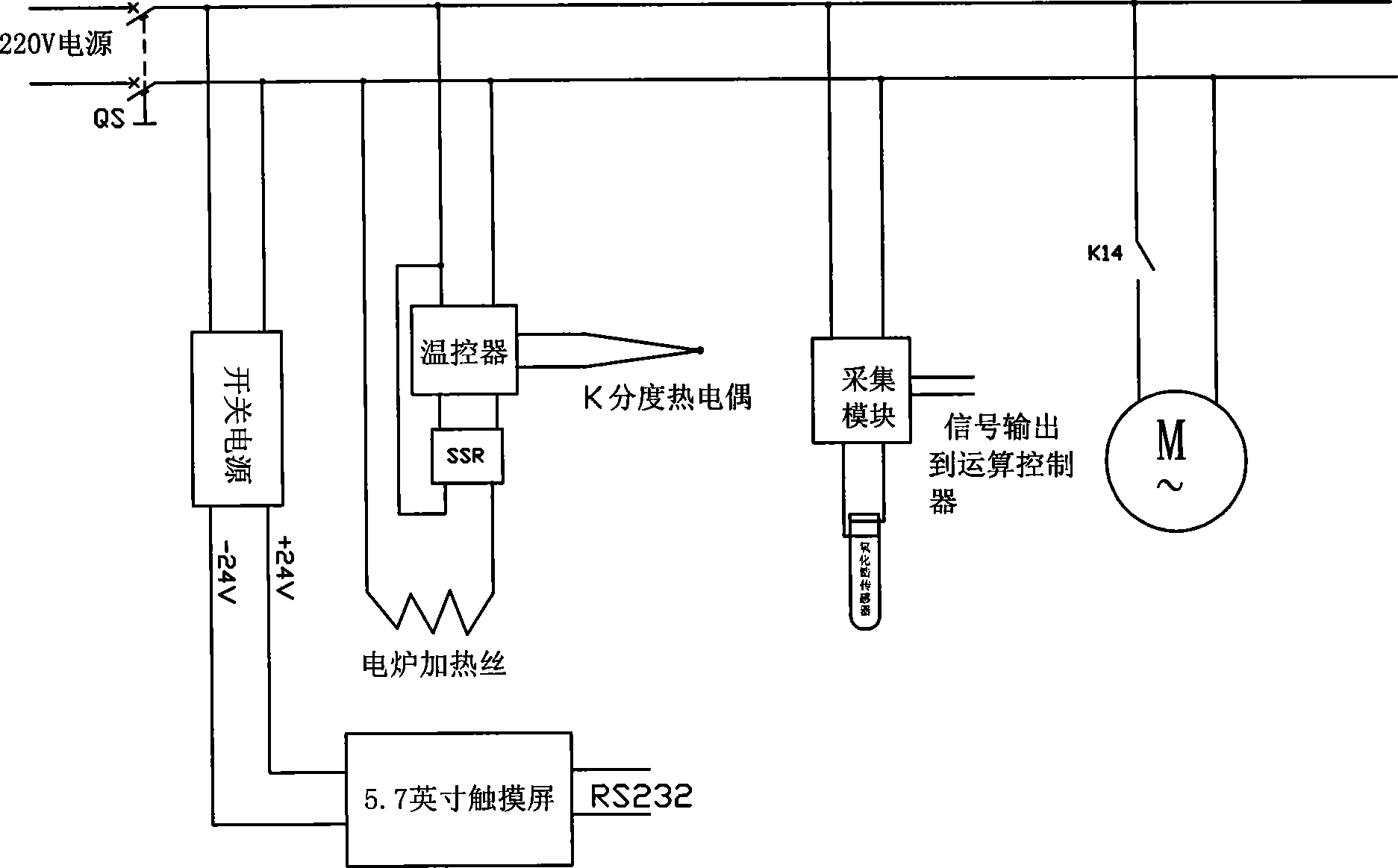

Zirconium oxide analyzer

ActiveCN101246139AEasy to operateReduce labor costsMaterial analysis by electric/magnetic meansElectric arc furnaceDisplay device

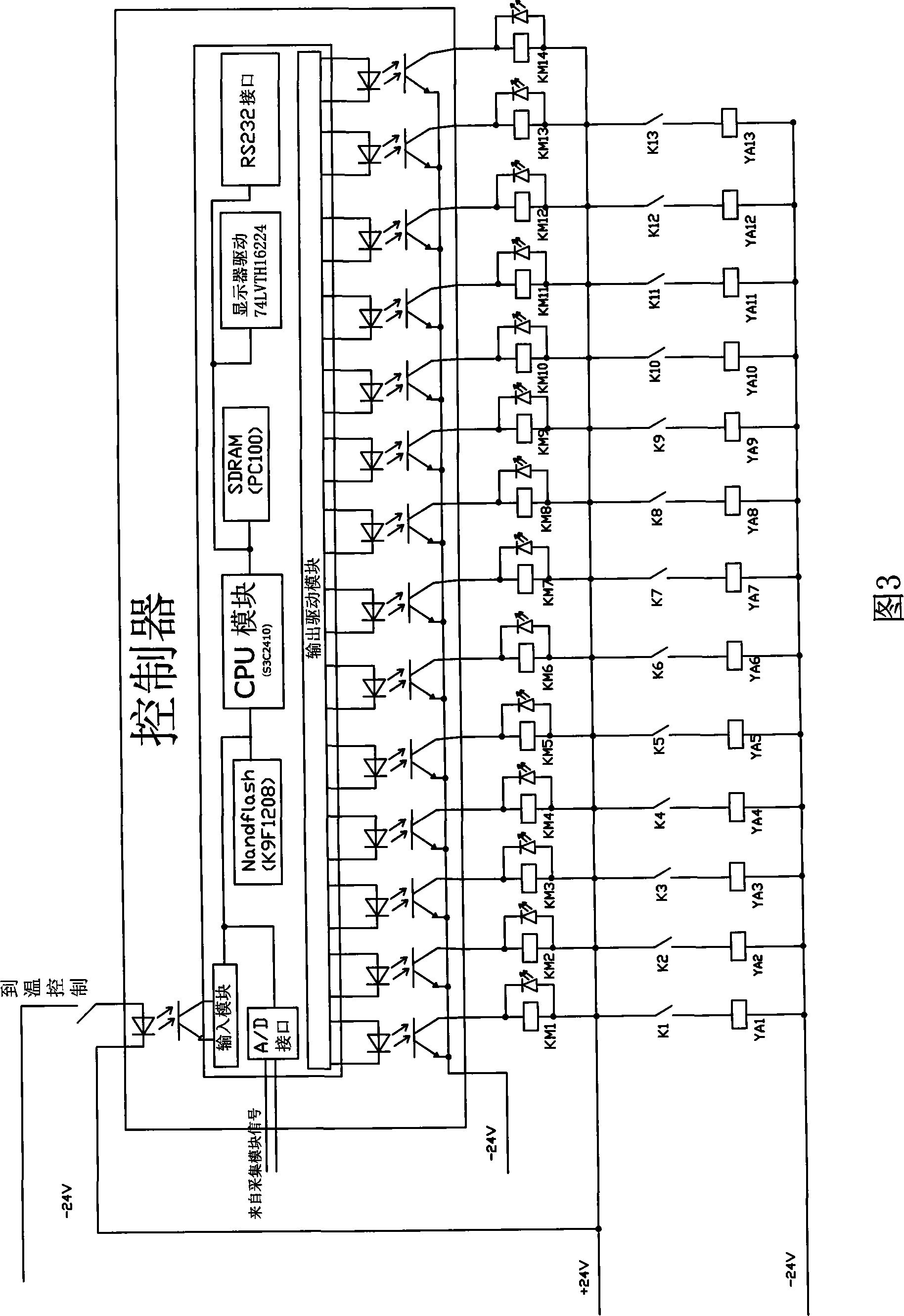

The present invention discloses a zirconium oxide analyzer, a plurality of points of gases to be measured is connected to the electromagnetic valve through a copper pipe, a plurality of points of electromagnetic valve is assembled to a pipeline, the gas in the pipeline enters into the zirconium oxide pipe in the heating furnace and is outputted by the suction pump when the flowmeter has controlled the flow capacity of the gas; when the electromagnetic valve and suction pump begin to work simultaneously, the temperature controlled instrument heats the electric heating furnace filled with zirconium oxide pipe, at this time the oxygen potential generated by the zirconium oxide pipe is inputted into the controller after the amplifying processing of the data collecting module, the controller executes calculating and processing to the collected signal and at last outputs the calculated result to the display. In the invention the operation is convenient and the running is reliable, when the operator inputs the atmosphere value into the device according to the technological requirement the device can automatically circulating-monitors timely and records the testing result at the condition of not being observed by man.

Owner:MIANYANG KAIYUAN MAGNETIC MATERIAL

Method for producing high-grade niobium concentrate from niobium rough concentrate

ActiveCN112301236AEasy to operateSolve industrial application development problemsProcess efficiency improvementSlagNiobium

The invention discloses a method for producing high-grade niobium concentrate from niobium rough concentrate. The method comprises the following steps that the niobium rough concentrate, a slag formerand a reducing agent are mixed and proportioned according to the mass ratio of 100: (0-50): (2-25); wherein the quantity of the slag former is not 0; the obtained ingredients are put into a smeltingfurnace to be smelted, and iron-containing alloy, furnace slag and smoke are produced through smelting; the oxygen potential in the furnace and the mass ratio of CaO / SiO2 are adjusted to a proper range by controlling the composition of ingredients and the oxygen potential in the furnace and monitoring the components of a smelting product and the recovery rate of iron; wherein the recovery rate ofFe in the iron-containing alloy is controlled to be 10%-55%, and the CaO / SiO2 mass ratio of the slag is controlled to be 0.3-0.7; the produced slag is discharged into a cinder ladle, and cooling and crystallizing are carried out; and then fine grinding is conducted after crushing, obtained slag powder is treated through a beneficiation process, and high-grade niobium concentrate is obtained. The method is simple in process, easy to operate and low in cost, and the niobium rough concentrate can be used for producing high-grade niobium concentrate.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

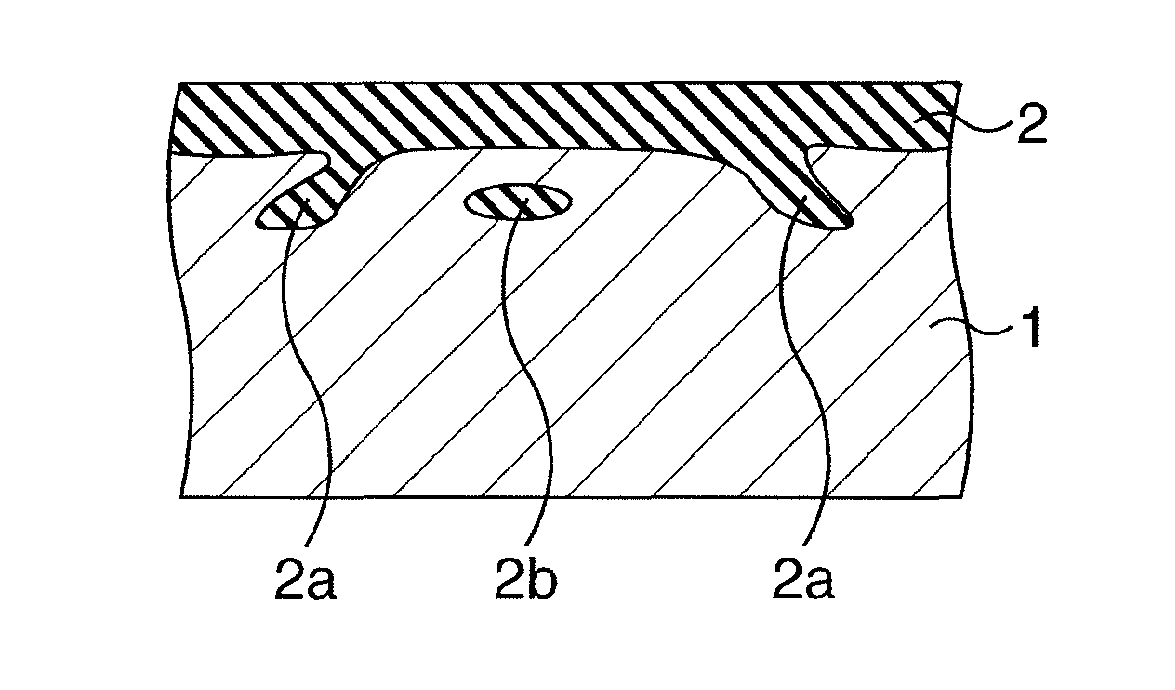

Method for improving high heat input welding performance of thick steel plates

ActiveCN102191429BIncrease the amount of controlPrecise control of initial oxygen positionHeat-affected zoneSheet steel

The invention discloses a method for improving the high heat input welding performance of thick steel plates. The method comprises the following steps of: 1) smelting and casting to obtain an ingot, wherein deoxidants are added in the deoxidation process of molten steel, the adding sequence of the deoxidants is Mn and Si, Al, Ti, and Ca, a Mg deoxidant is added in the casting process of the molten steel, and the initial oxygen potential during the deoxidation of Mg is accurately controlled by adding Fe2O3 powder into a casting ingot mould; and 2) rolling and cooling. In the method, microfine dispersive distribution and Mg-containing inclusions, which are formed by adding the deoxidants in the deoxidation process of the molten steel and adding the Fe2O3 powder into the casting ingot mould to accurately control the oxygen potential during the deoxidation of the Mg, can inhibit the growth of austenite grains in a welding heat affected zone, and promotes the growth of ferrite in the grains, so that the high heat input welding performance of the thick steel plates is greatly improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Melting method for dephosphorization under reducing atmosphere for high phosphate ore

This invention discloses a method for dephosphorization of high-phosphorus ore by melt reduction. The high-phosphorus ore smelting capacity of the present melt reduction process depends on the oxygen potential of furnace slag, and is very low generally. The method in this invention comprises: mixing high-phosphorus ore, carbon reductant, quicklime and fluorite, adding into a temperature field, and melting. The ratio of carbon in carbon reductant to iron in high-phosphorus ore is 140-350 kg C / ton Fe. The ratio of CaO in quicklime to SiO2 in high-phosphorus ore is 1.6-3.0. The weight ratio of fluorite to high-phosphorus ore is 5-20%. The diameters of high-phosphorus ore are below 6 mm. The diameters of carbon reductant are below 0.5 mm. The diameters of quicklime and fluorite are below 6 mm. The temperature of the temperature field is 1300-1500 deg.C.

Owner:武钢集团有限公司

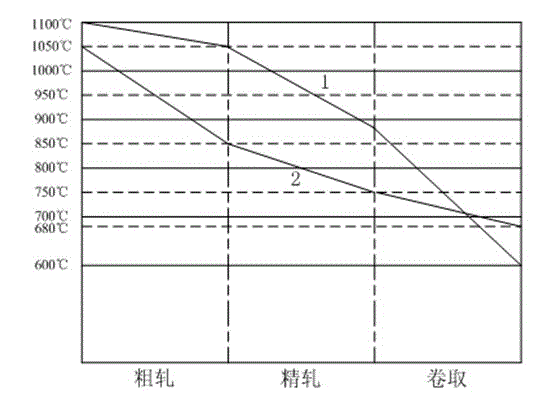

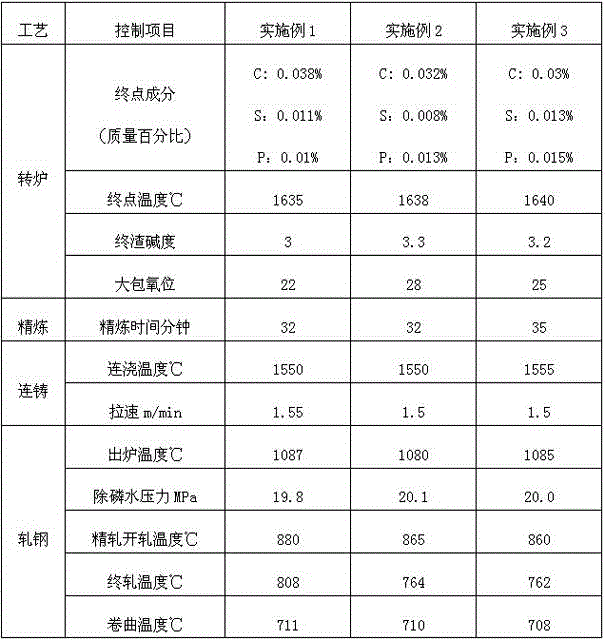

Production process for middle-width hot rolling strip steel for cold rolling

InactiveCN102941227AAvoid rolling in the two-phase zone of hot rolling and finishing rollingImprove mechanical propertiesMetal rolling arrangementsSlagStrip steel

The invention relates to a production process for middle-width hot rolling strip steel for cold rolling, and belongs to the technical field of hot continuous rolling of the metallurgical industry. The technical scheme is as follows: the production process comprises the steps of furnace rotating, refining, continuous casting and steel rolling; the final components include not more than 0.05% of C, not more than 0.013% of S and not more than 0.015% of P, the final temperature is 1630-1650 DEG C, the final slag basicity R is more than or equal to 3, and the ladle oxygen potential is less than or equal to 30 ppm; and the refining time is longer than 30 minutes, the continuous casting temperature is 1545-1560 DEG C, the pulling rate is 1.5 m / min plus / minus 0.05 m / min, the heating temperature is 1100-1200 DEG C, the descaling water pressure is 18 MPa, the finish rolling openning temperature is 850-880 DEG C, the final rolling temperature is more than or equal to 750 DEG C, and the crimp temperature is 700 plus / minus 20 DEG C. The production process has the positive effects that the hot rolling and the finish rolling in a two-phase region are avoided, the mechanical property of a product is optimized, the requirements of the next procedure are met, and the product quality is guaranteed.

Owner:TANGSHAN JIANLONG IND CO LTD

Method for synergistically and deeply removing oxygen in metal titanium by super-oxyphilic metal and calcium

ActiveCN112095021AReduce oxygen activityImprove removal effectProcess efficiency improvementTitaniumChloride

The invention discloses a method for synergistically and deeply removing oxygen in metal titanium by super-oxyphilic metal and calcium. The method comprises the following steps: filling specific positions of a reactor with materials such as super-oxyphilic metal, anhydrous calcium chloride, a titanium raw material and a calcium reducing agent; and carrying out distillation-deoxidation and disassembly-cleaning so as to stably reduce the oxygen content of titanium to be smaller than 100 ppm. The super-oxyphilic metal has extremely high oxygen affinity, and oxygen in calcium chloride fused salt can be subjected to solid solution or forms oxide, so that extremely low oxygen potential is created, and the thermodynamic problem of deep deoxidation is solved; and the calcium chloride fused salt has high fluidity and high solubility to the calcium reducing agent and calcium oxide, so that the kinetics problem of deoxidation is solved. Through organic combination of purification and deoxidationof Ca, deep, efficient and stable removal of oxygen in the metal titanium is realized. The method disclosed by the invention is simple and easy to implement, good in oxygen removal effect and free ofsecondary pollution, and the product meets the use requirements in the fields of target material manufacturing, optical coating, electronic element manufacturing and the like.

Owner:GRIMAT ENG INST CO LTD +1

Grain-oriented electrical steel sheet and manufacturing method thereof

ActiveUS20110209798A1Inhibition defectStable productionSolid state diffusion coatingThin material handlingSheet steelElectrical steel

Nitriding process of a steel strip is performed. Next, annealing is performed to form a forsterite based glass coating film at a surface of the steel strip. Heating is performed up to 1000° C. or more in a mixed gas atmosphere containing H2 gas and N2 gas, and a rate of N2 gas is 20 volume % or more, next, the atmosphere is switched into H2 gas atmosphere at the temperature of 1000° C. or more and 1100° C. or less, when the annealing is performed. An oxygen potential P (H2O) / P (H2) is set to be 0.05 to 0.3 when the temperature is 850° C. or less during the heating in the mixed gas atmosphere.

Owner:NIPPON STEEL CORP

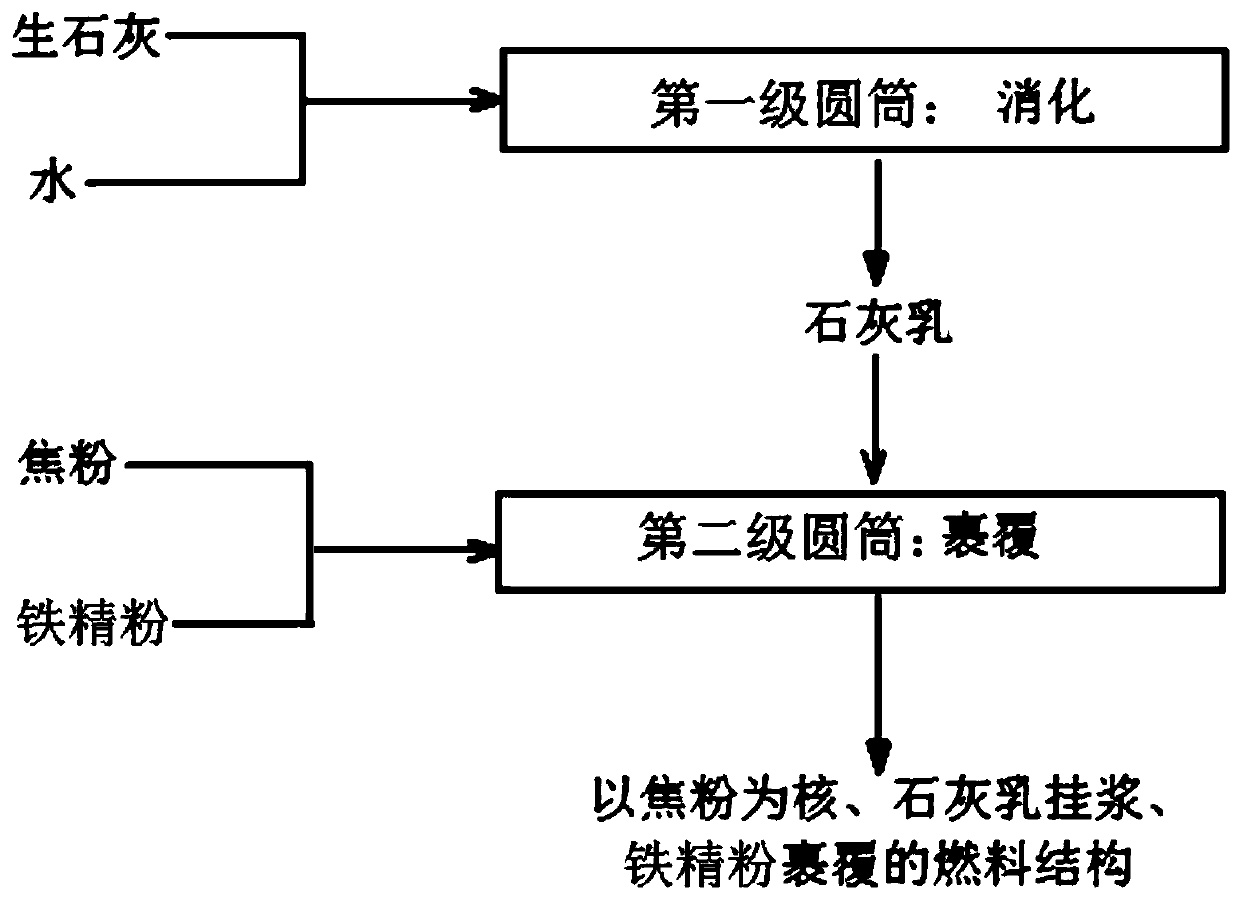

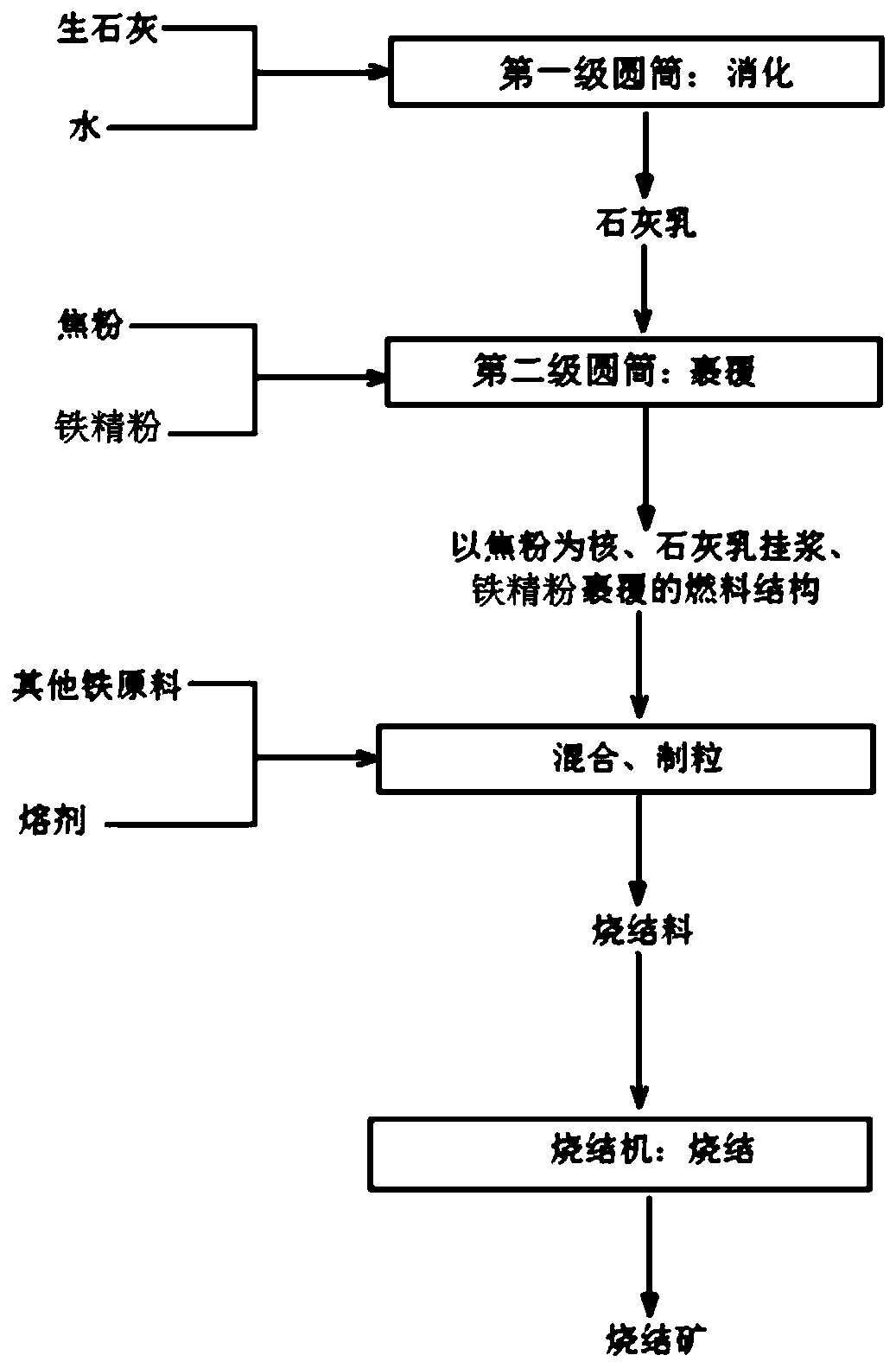

Coke powder pretreatment process for sintering and iron ore sintering process and system

ActiveCN111548834AReduce generationFacilitate reverse reductionSolid fuelsWaste based fuelIron powderSolid fuel

The invention provides a pretreatment process of coke powder for sintering, which comprises the following steps: 1) conveying quick lime into a first-stage cylinder, spraying water into the first-stage cylinder, and digesting the quick lime in the first-stage cylinder to obtain lime milk; and 2) conveying the lime milk obtained in the step 1) into a second-stage cylinder, conveying the coke powderand the fine iron powder into the second-stage cylinder at the same time, and mixing the lime milk, the coke powder and the fine iron powder in the second-stage cylinder to form a fuel structure which takes the coke powder as a core and is coated with lime milk slurry and the fine iron powder. The combustion environment of the solid fuel in the sintering process of the coke powder is improved; sothat on one hand, the oxygen potential in a peripheral gas film during combustion of the coke powder is reduced, and an N element in the fuel is inhibited from being oxidized into NOx; and on the other hand, a calcium ferrite substance is rapidly formed on the surface of the coke powder, and generated NOx is promoted to be reversely reduced into N2.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

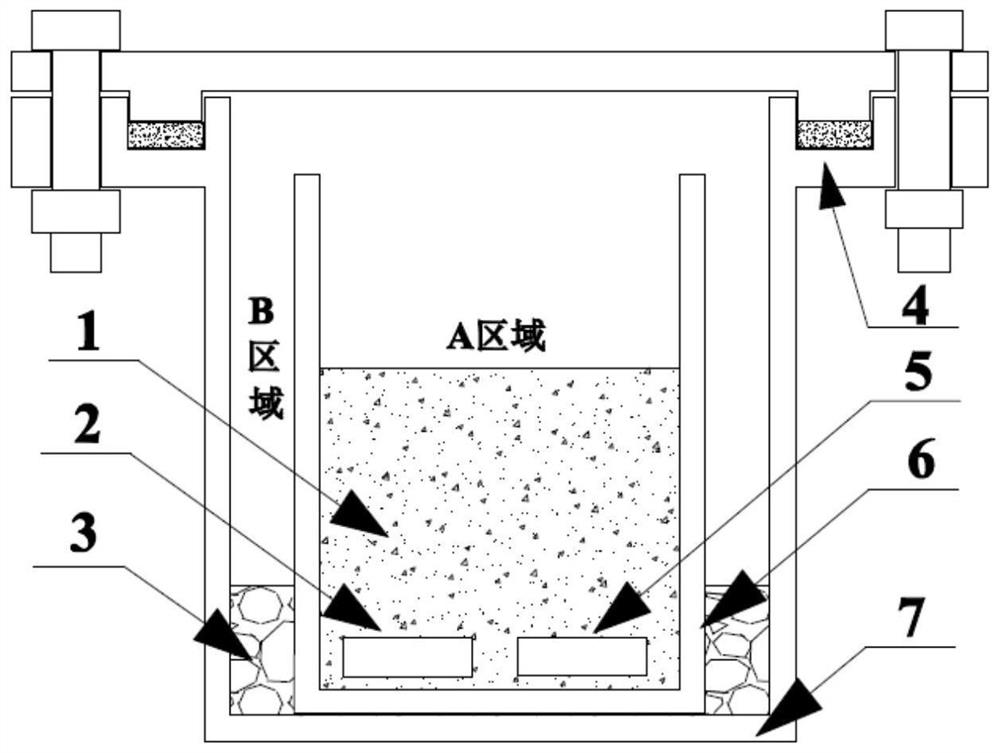

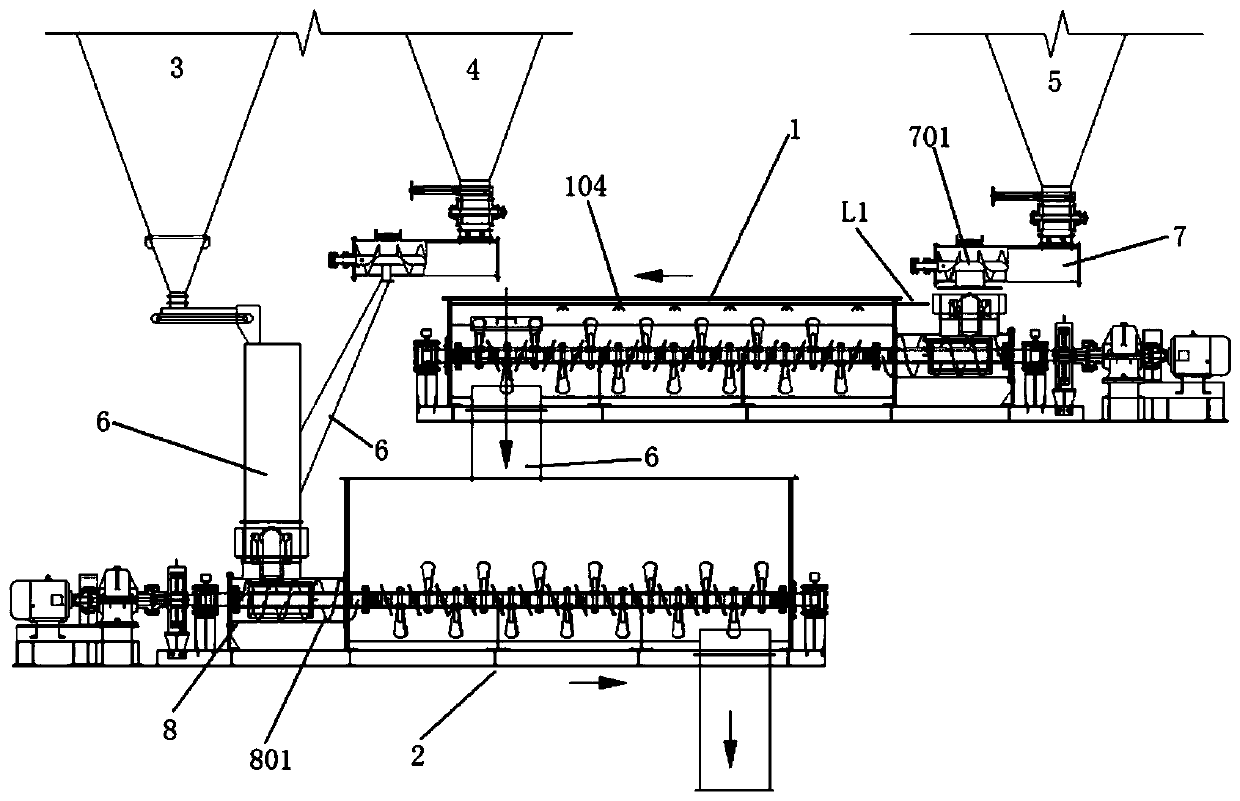

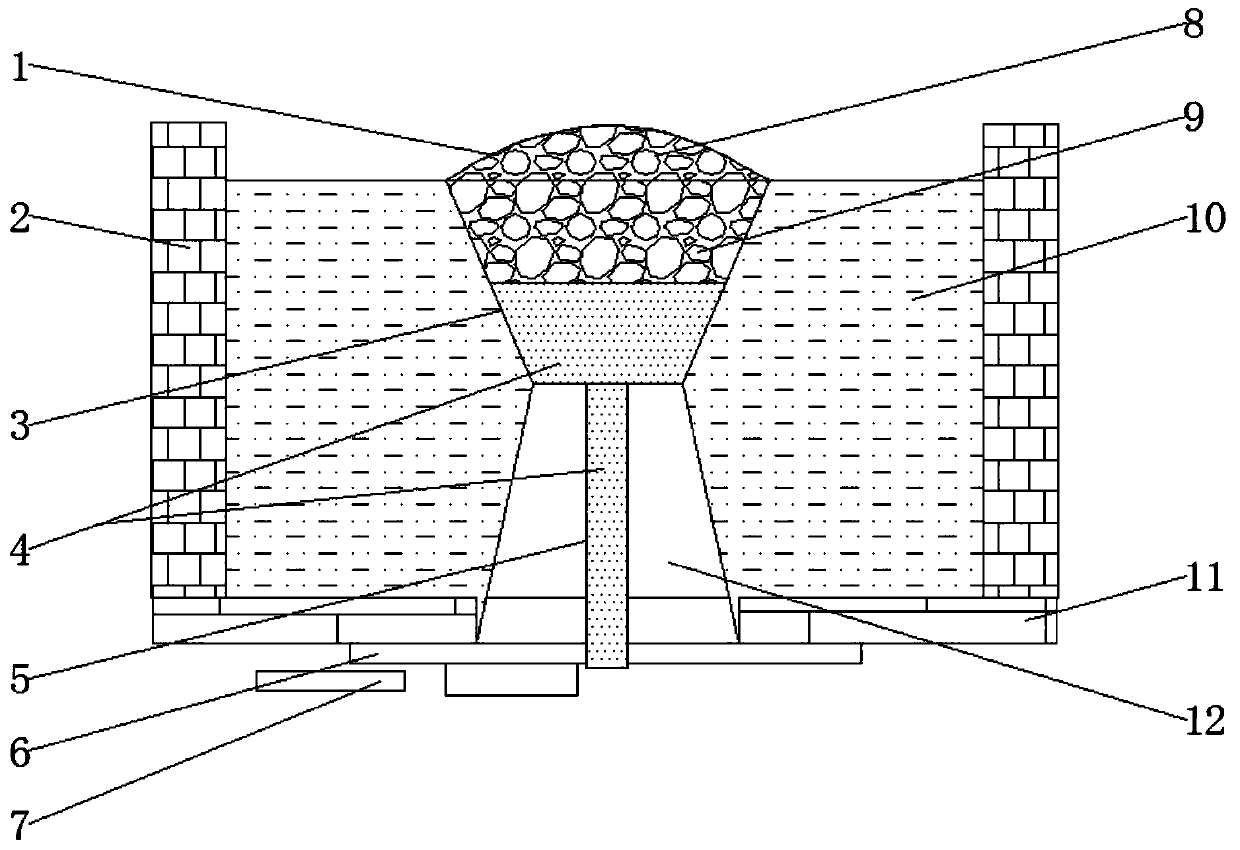

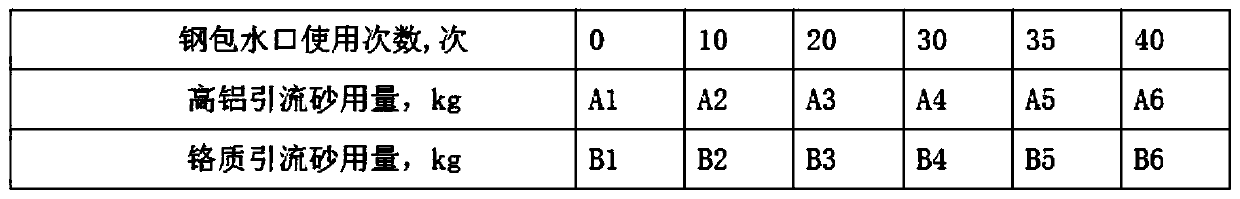

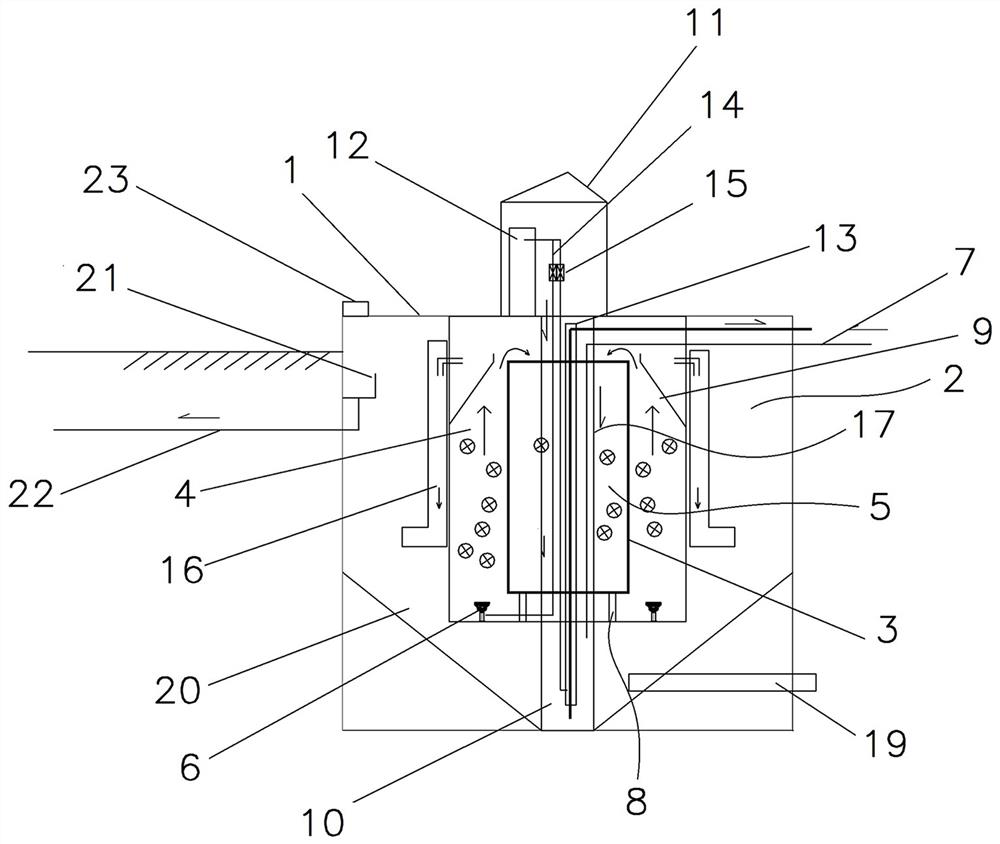

Ladle filler sand filling method conducive to increasing cleanliness of IF (interstitial-free) steel

The invention discloses a ladle filler sand filling method conducive to increasing cleanliness of IF (interstitial-free) steel, and relates to the technical field of liquid steel purification. A ladlefiller sand filling structure conducive to increasing cleanliness of IF steel comprises ladle bottom bricks, wherein a ladle walls is arranged at bottoms of the ladle bottom bricks; an upper ladle slide plate is arranged at the bottom of the ladle wall; a lower ladle slide plate is arranged below the upper ladle slide plate. According to the ladle filler sand filling method conducive to increasing cleanliness of IF steel, after automatic casting of a ladle, ladle filler sand flows in a tundish with molten steel, and most sand remains as slag in tundish top slag after movement in an impact zone, so that oxidizability of the slag is improved; the rise of oxygen potential in the slag is positively correlated with oxygen potential in the liquid steel, and thus, oxygen content in the liquid steel can also increase after chromium-based ladle filler sand enters the top slag; the increase of the oxygen content in the tundish molten steel indicates the increase of oxide inclusion.

Owner:MAANSHAN IRON & STEEL CO LTD

Vertical oxidation ditch micro-power water treatment system

ActiveCN111777178AImprove processing efficiencySmall footprintTreatment with aerobic and anaerobic processesSustainable biological treatmentWater treatment systemPower equipment

The invention belongs to the technical field of environmental protection, and particularly relates to a vertical oxidation ditch micro-power water treatment system, which is provided with an oxidationditch area and a sedimentation tank area so as to achieve aeration circulation treatment and standing sedimentation simultaneously, and effectively improves the sewage treatment efficiency; a partition plate extending in the vertical direction is adopted to divide the oxidation ditch area into an aerobic zone and an anoxic zone of which the bottoms are communicated; wherein an aeration pipe for providing oxygen is arranged at the bottom of the aerobic zone, when a water inlet pipe and the aeration pipe work, liquid in the aerobic zone is driven by oxygen potential energy to surge upwards andgo over the upper end of the partition plate to converge in the anoxic zone to circulate, and then an oxidation ditch circularly flows in a vertical plane is formed. According to the present invention, the circulation power of the oxidation ditch comes from the residual energy of the aerated gas, so that the power equipment required by the circulation is eliminated, and the advantages of energy saving, environmental protection, small space occupation and compact structure are achieved.

Owner:国威环境工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com