Central vortex column flash smelting process

A flash smelting and vortex technology, which can be used in rotary drum furnaces, crucible furnaces, furnaces, etc., and can solve problems such as limited

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

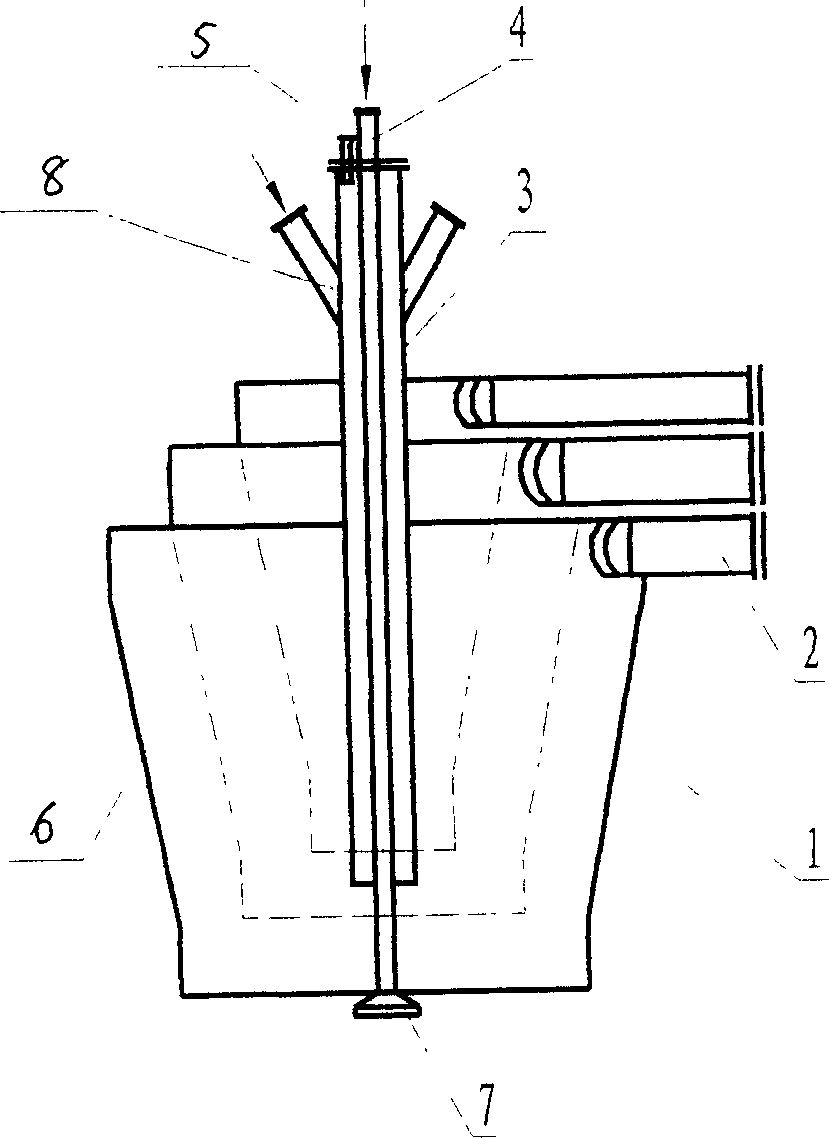

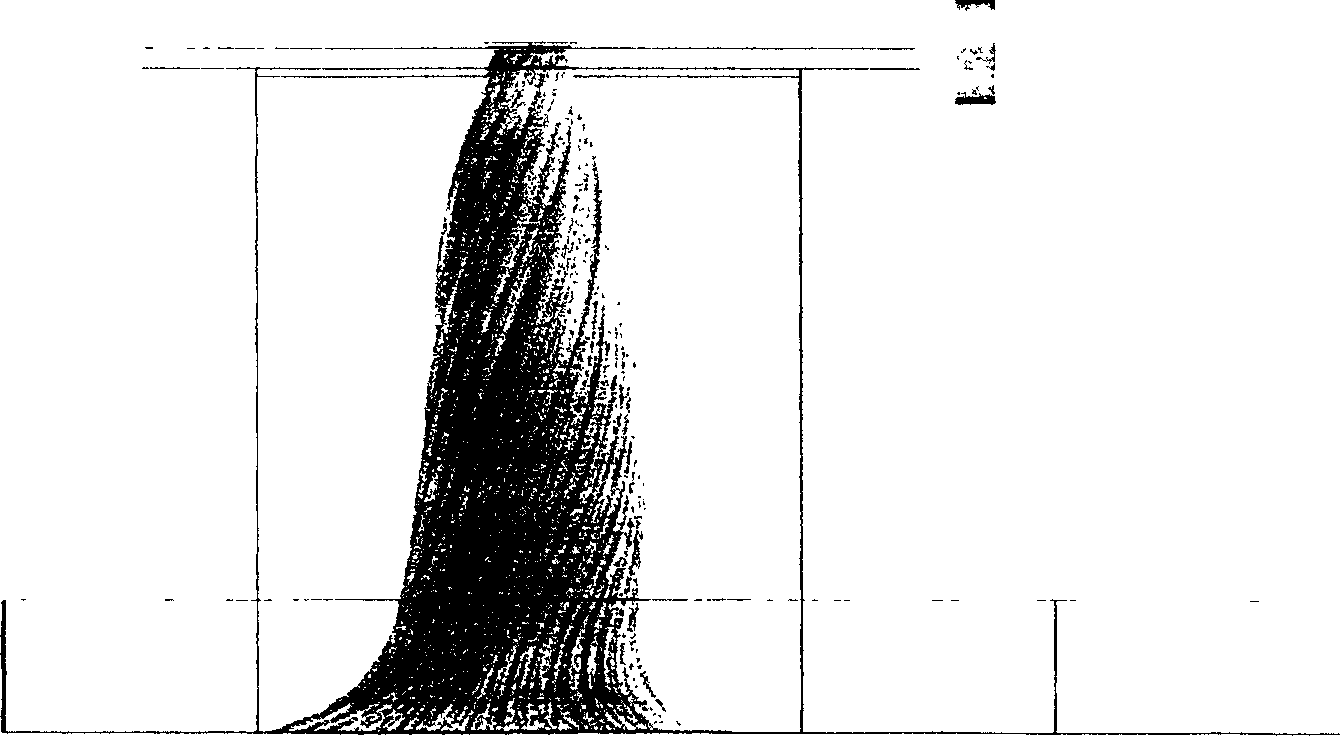

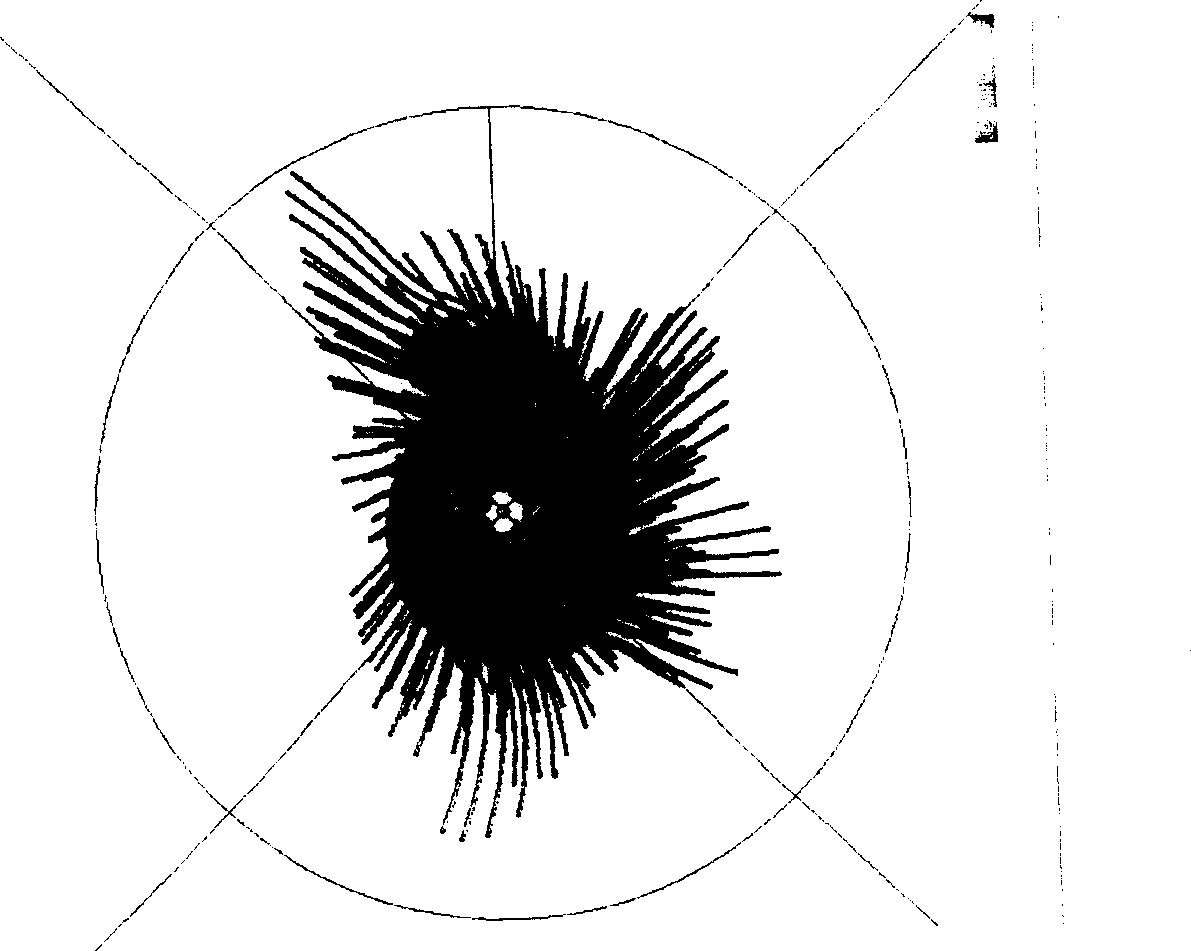

[0011] A central vortex column flash smelting process. The equipment of this process is composed of a reaction tower, a sedimentation tank and an ascending flue. The nozzle is the power source for generating the vortex column. The nozzle includes an air chamber 1 and an air inlet pipe 2; the air chamber 1 is Conical shape, the interior is vertically divided into several concentric vortex chambers 6 that are not connected to each other at the upper part and converge at the lower part. The vortex chamber at the center of the passing air cavity is fixedly connected with the upper part of the vortex chamber. The atomizing air pipe 4 is fixed in the center of the concentrate chute 3 and passes through the concentrate chute 3. The lower end of the air pipe 4 is provided with an umbrella-shaped dispersing cone. 7. There are spray holes in the horizontal direction on the dispersing cone, and the upper part of the concentrate chute is equipped with an ore inlet pipe 8 and an air pipe 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com