Patents

Literature

125 results about "Flash smelting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flash smelting (Finnish: Liekkisulatus, literally "flame-smelting") is a smelting process for sulfur-containing ores including chalcopyrite. The process was developed by Outokumpu in Finland and first applied at the Harjavalta plant in 1949 for smelting copper ore. It has also been adapted for nickel and lead production.

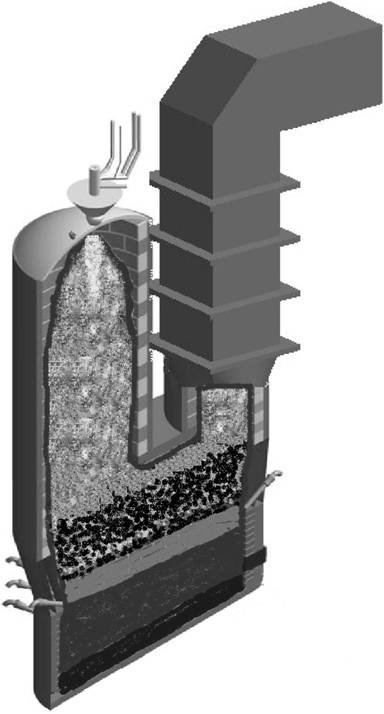

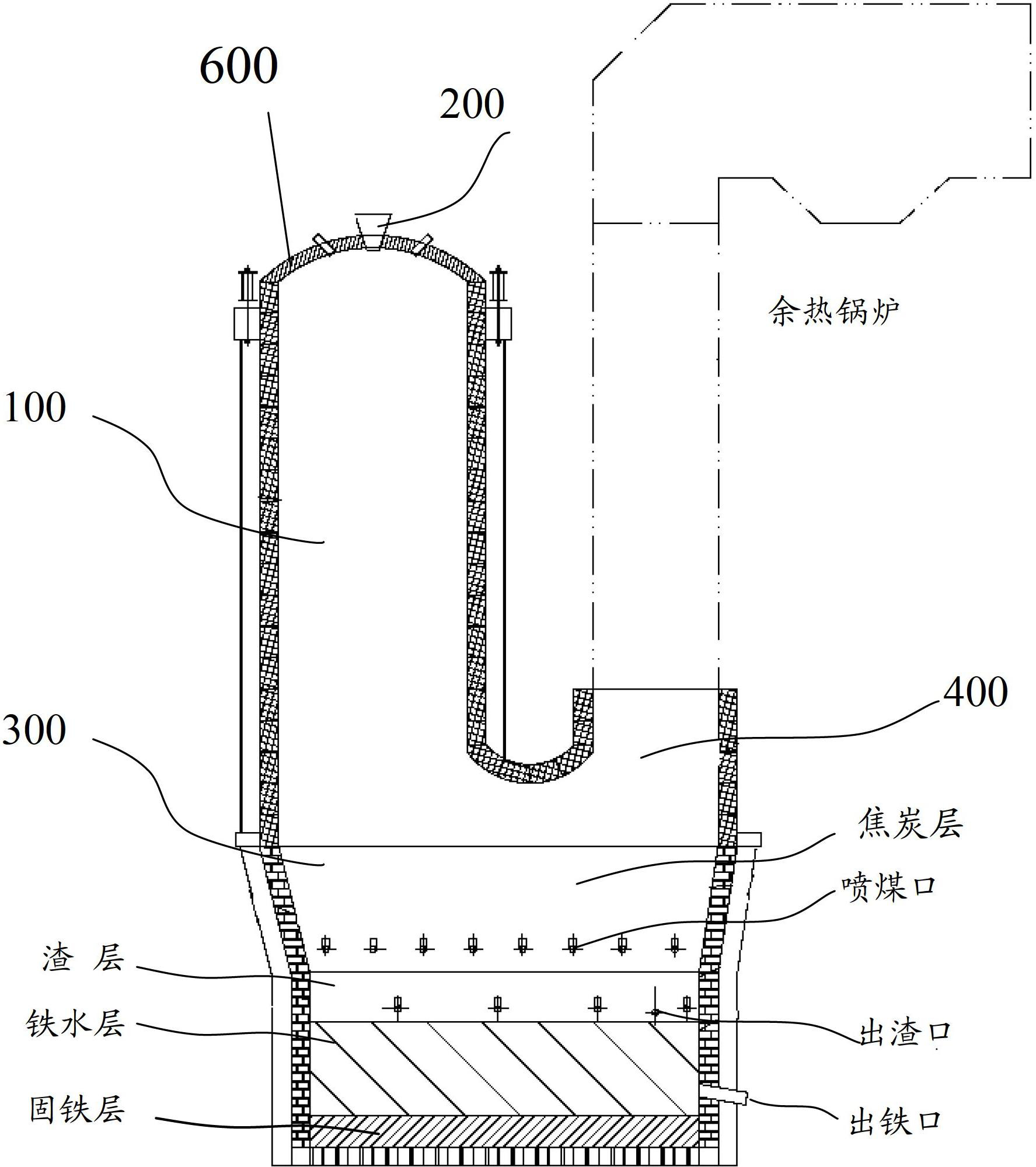

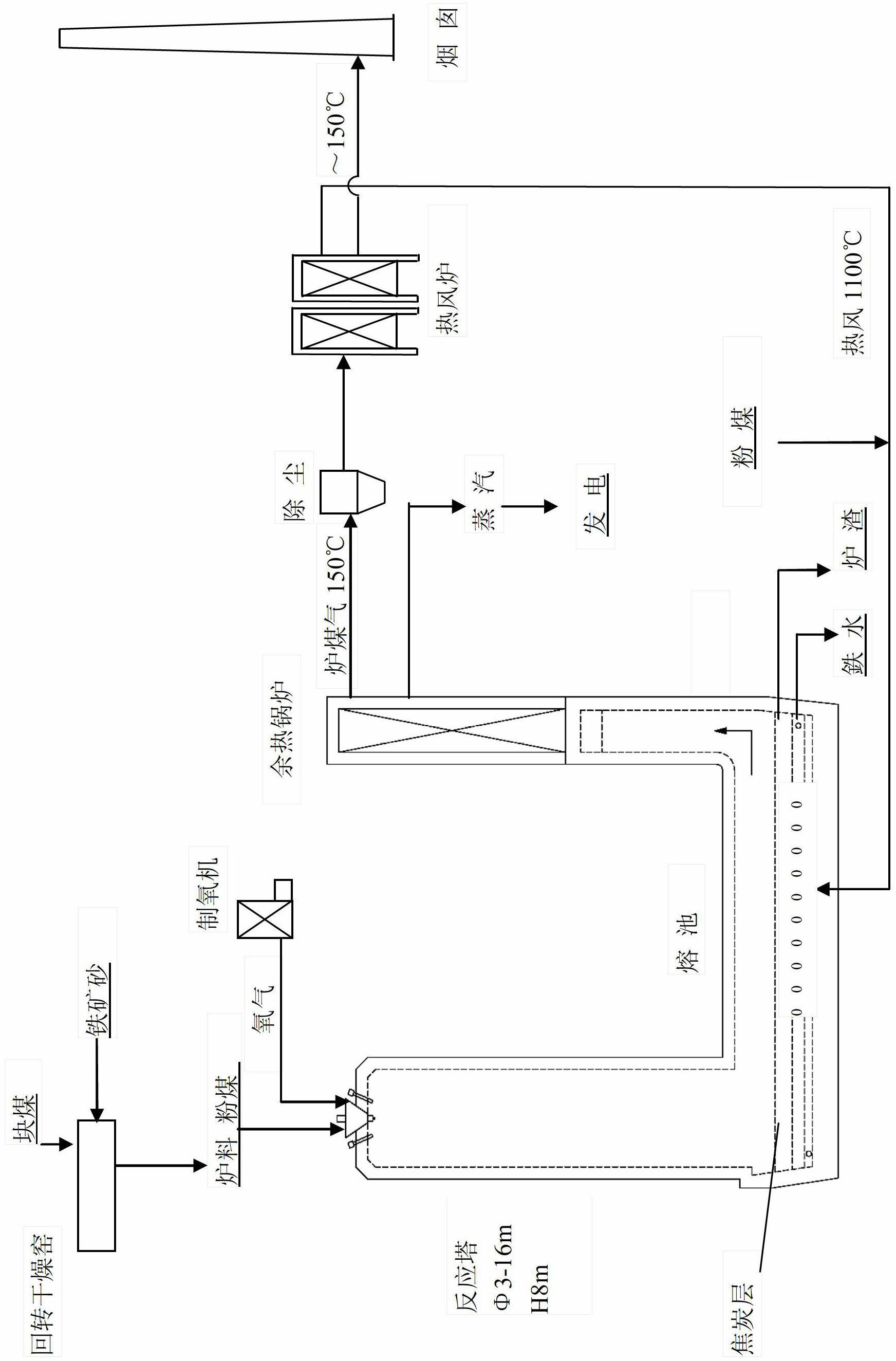

Flash smelting method of iron

The invention discloses a flash smelting method of iron. A flash smelting furnace comprises a reaction tower, a furnace charge nozzle, a molten bath and a flue, wherein a reaction space is limited in the reaction tower, the furnace charge nozzle is arranged at the top of the reaction tower, the molten bath is arranged on the lower portion of the reaction tower and used for containing melt fallen from the space of the reaction tower after reaction and for a subsequent reduction reaction of the melt, and the flue is communicated with the reaction tower through the molten bath and used for discharging flue gas generated during the reaction. The flash smelting furnace in the embodiment can be effectively used for flash smelting of the iron.

Owner:CHINA NERIN ENG

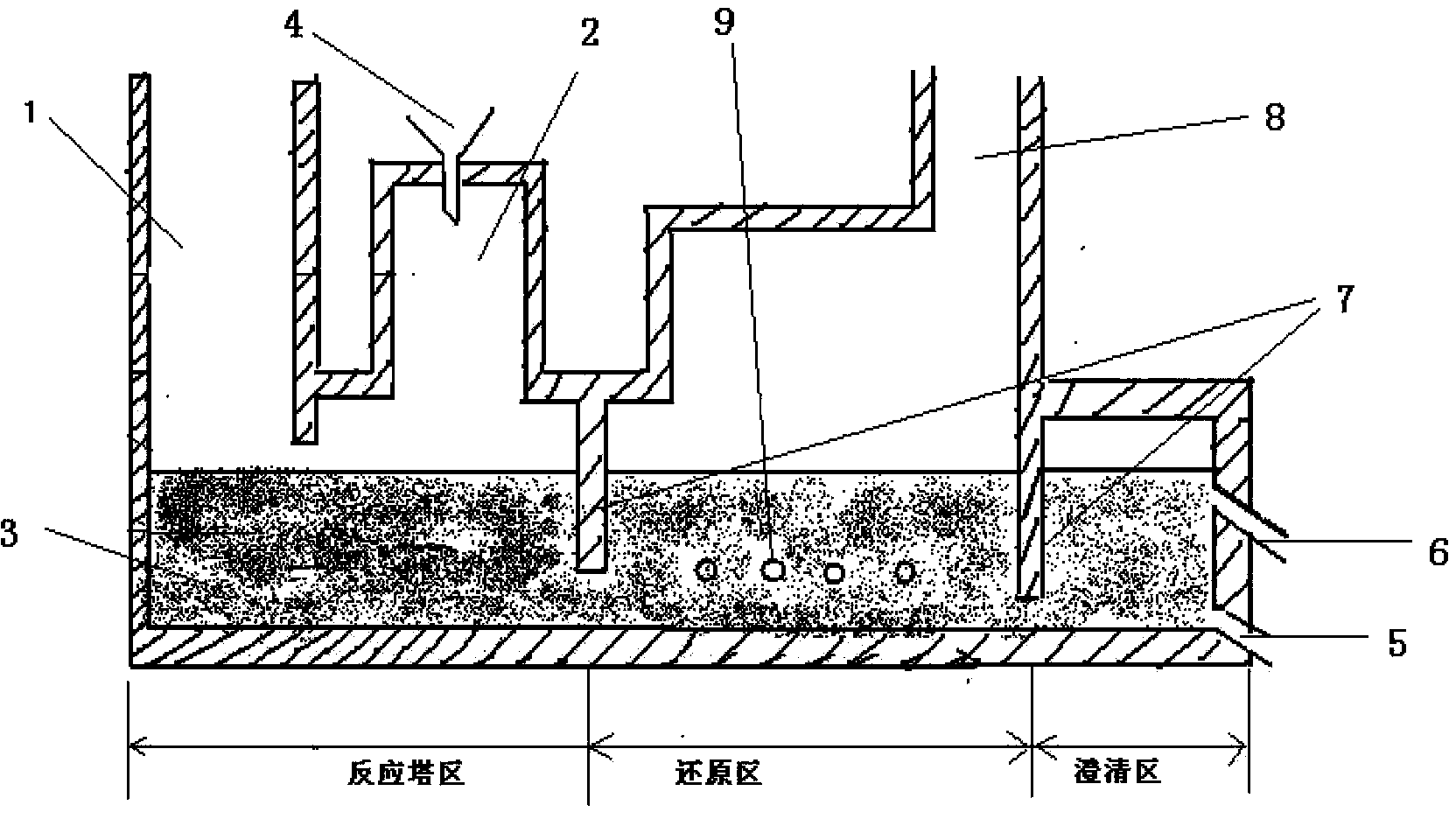

Flash smelting method and device for zinc sulfide concentrates and materials containing lead and zinc

InactiveCN103382527AMeet the requirements of smeltingTo meet the heat required for reductionEnvironmental resistanceResource utilization

The invention discloses a flash smelting method and a device for zinc sulfide concentrates and materials containing lead and zinc. The flash smelting method for the zinc sulfide concentrates and the materials containing the lead and the zinc comprises mixing the dry powder materials containing lead and zinc in proportion and spraying the mixed materials and oxygen into a smelting device from the top of a reaction tower; the smelting device is formed by three portions namely a reaction tower area, a reducing area and a clarification area which are provided with communicated bottoms; materials containing zinc achieve a oxidation sweetening reaction in the air above the reaction tower to generate into high zinc slag melt with an appropriate melting point of minus 1200 DEG C and fall into the reaction tower area; the liquid form high zinc slag melt enters into the reducing area; zinc in the high zinc slag melt is performed reduction to generate zinc steam to be collected; lead is performed reduction to be metallic lead; precious metal such as golden, silver and the like of raw materials are gathered to be precipitated at the bottom of a melt pond and discharged through a lead discharging opening. Slags which are performed reduction are discharged through a slag discharging opening, fuming processing is abandoned or further performed according to the content of the lead and the zinc. The flash smelting method and the device for the zinc sulfide concentrates and the materials containing the lead and the zinc have the advantages of being short in process, strong in material adaptability, low in energy consumption, environmentally friendly, high in resource utilization efficiency, significant for technology progress of a lead and zinc smelting industry and the like.

Owner:CENT SOUTH UNIV

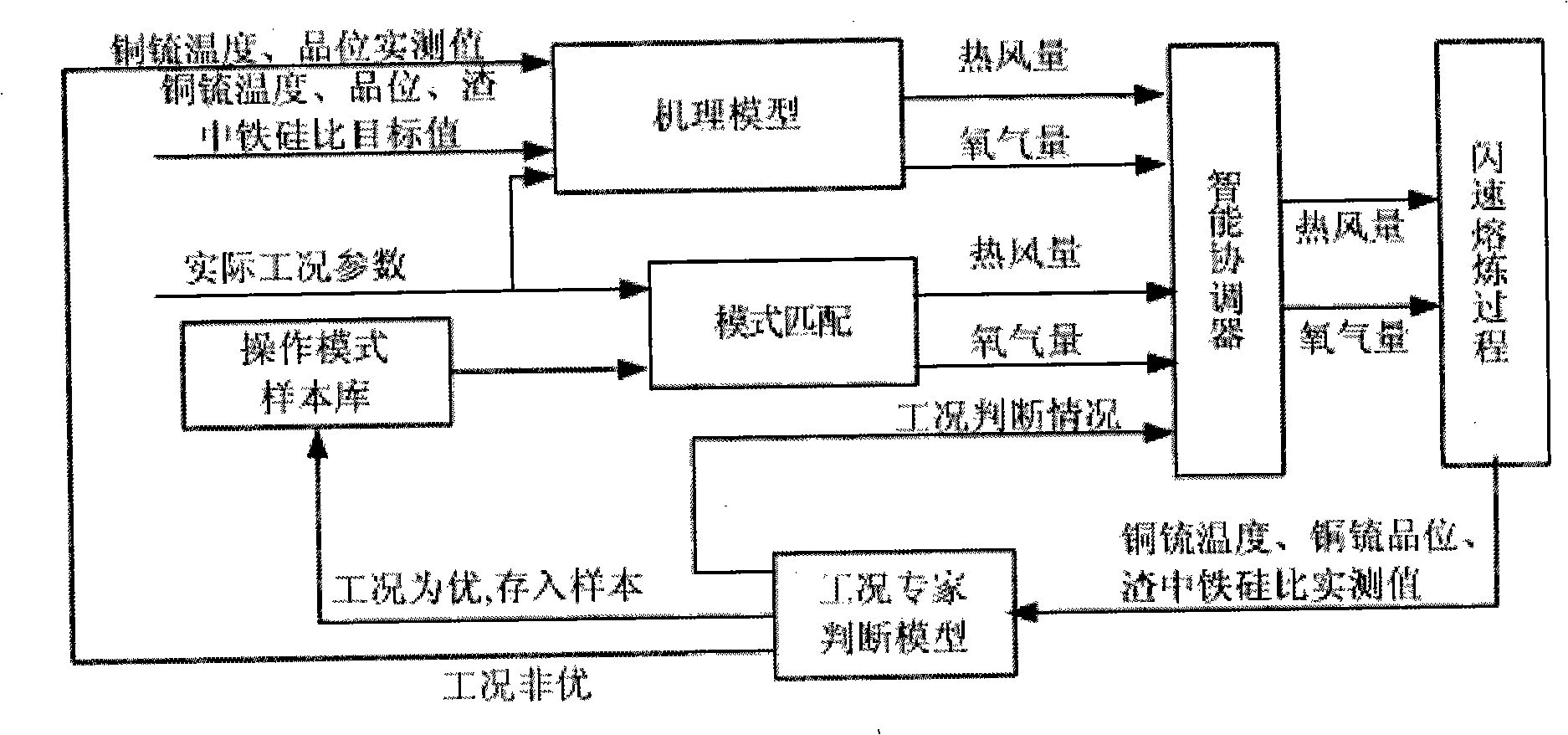

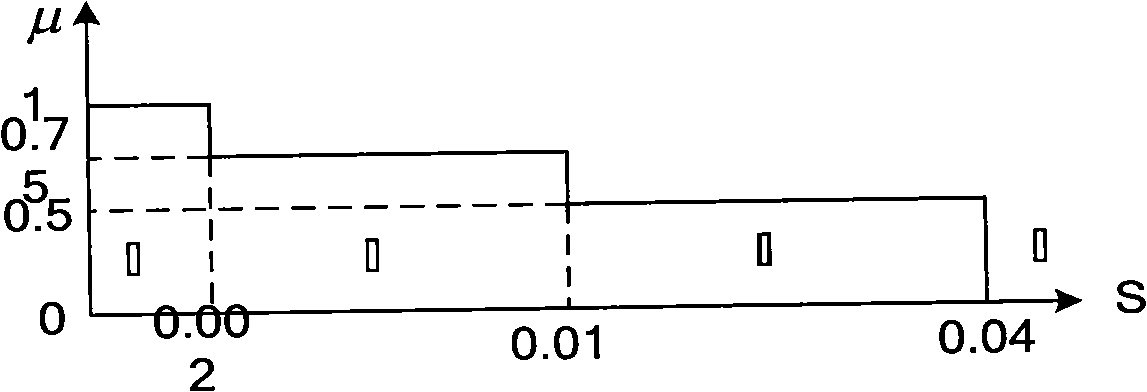

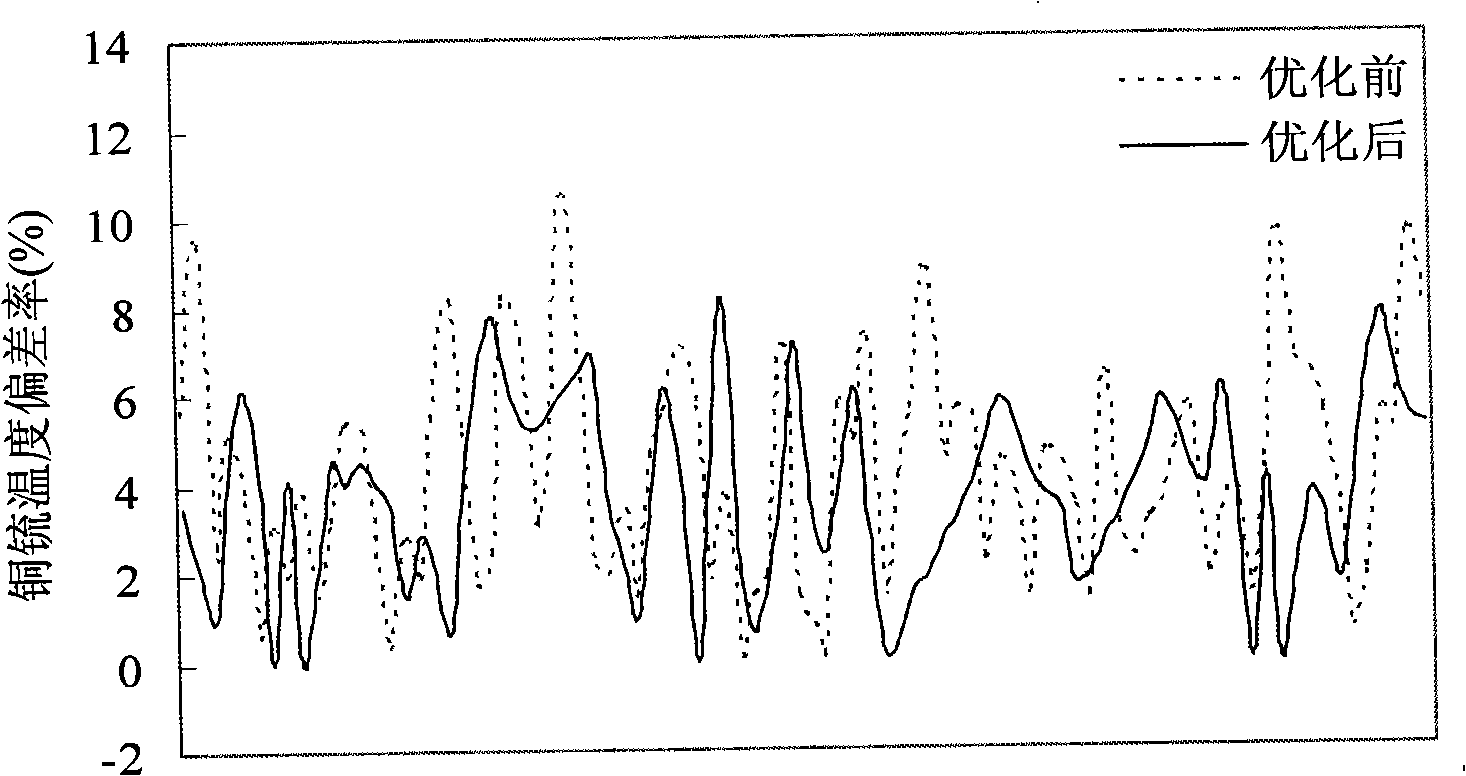

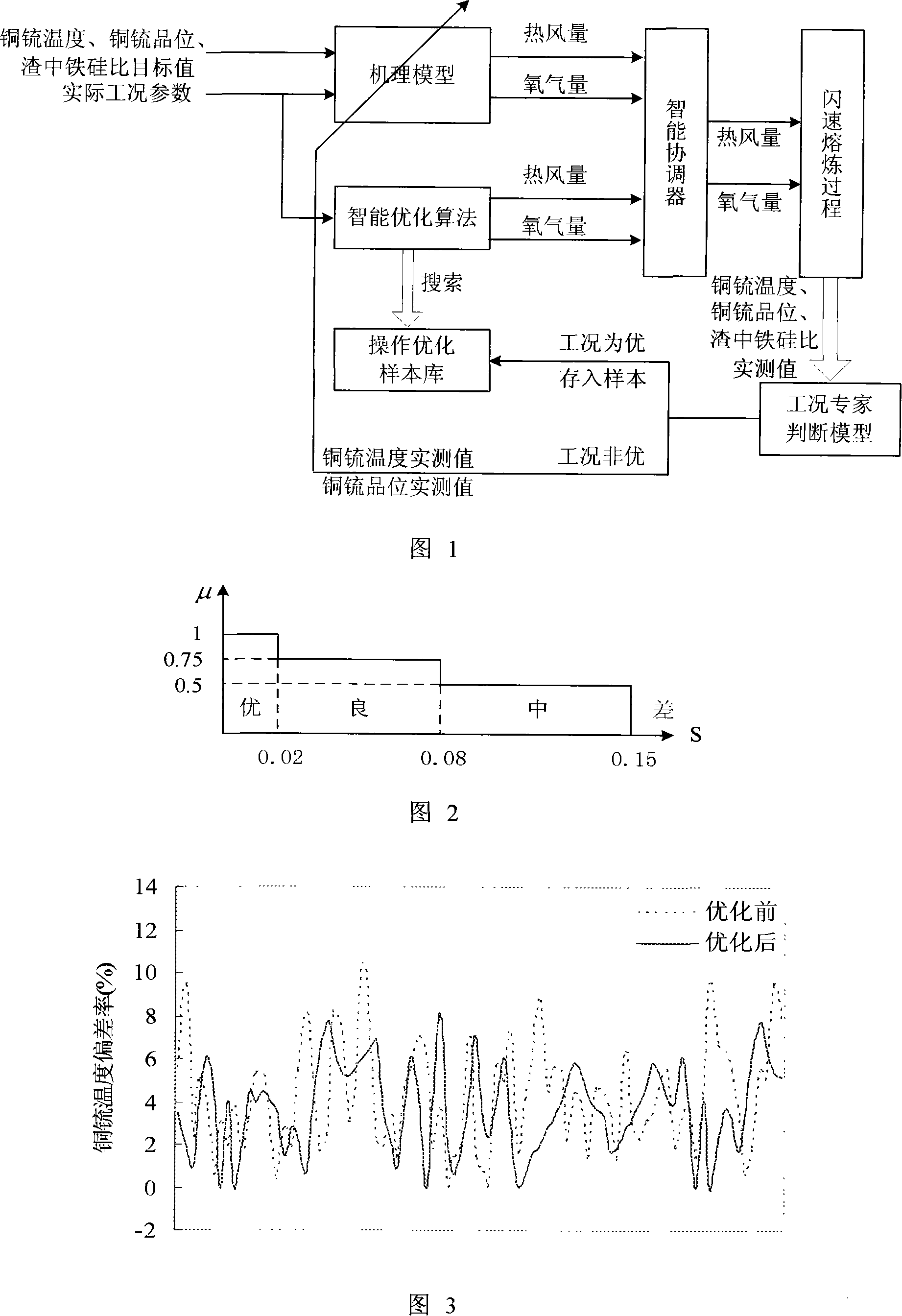

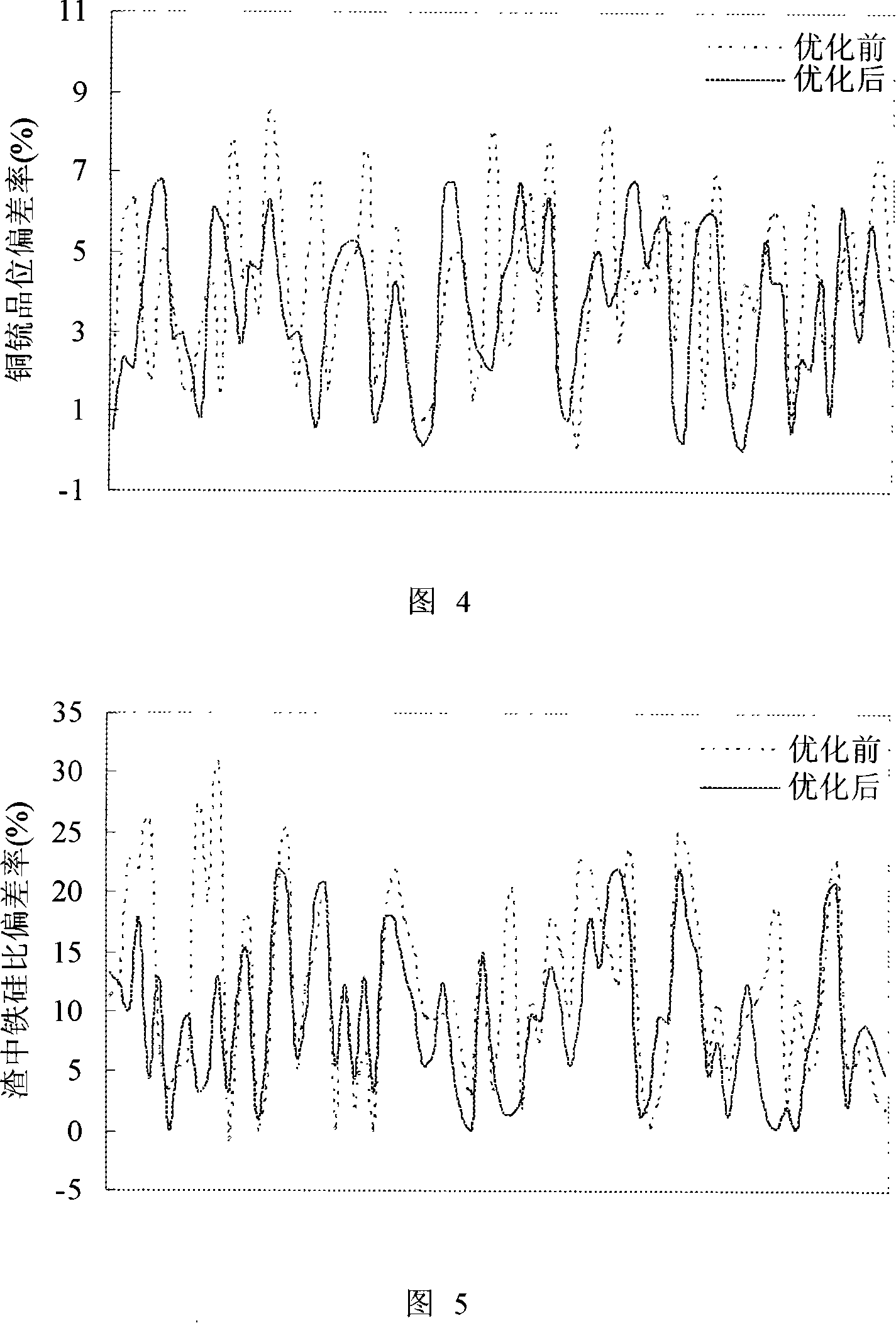

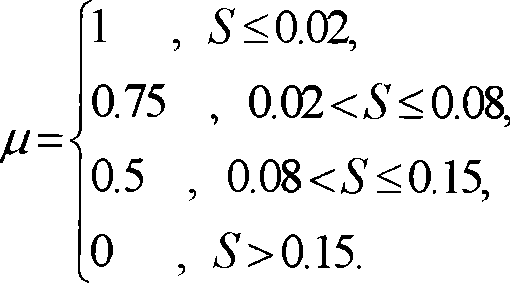

Intelligent integrated optimization method based on mode matching and balance computation

InactiveCN101353730AAchieve optimal controlRealize energy saving and consumption reductionTotal factory controlProgramme total factory controlPattern matchingFlash smelting

The invention relates to an intelligent integrated optimization method based on pattern matching and balanced computation, more particularly to a method for optimizing the operation parameter of the copper flash smelting process. The invention takes the stability of flash smelting comprehensive working condition as an optimization target, respectively establishes a mechanism model based on the balanced computation and a pattern matching intelligent optimization model based on fuzzy C average clustering, and adopts an intelligent integrated method to coordinate the optimization results of the two models. The method can obtain the optimal operation parameter of the copper flash smelting process, namely, the optimal addition amount of hot blast and oxygen of a flash furnace reaction tower, thus providing theoretical foundation and scientific optimized instruction for the adjustment of the operation parameter, and reducing the unstable working condition caused by the fluctuation of the parameter.

Owner:CENT SOUTH UNIV

Method for recycling and harmless treating of waste electronic glass

InactiveCN102199707ALess investmentLarge amount of processingProcess efficiency improvementLead smeltingSmelting process

The invention relates to a method for recycling and harmless treating of waste electronic glass, and relates to a smelting process utilizing an existing pyrometallurgical lead smelting method to treat various lead-containing glass substances generated after discarding of televisions and computers of which cathode ray tubes are displays. The method provided by the invention is characterized by crushing discarded electronic glass, mixing and proportioning with mineral raw materials, an auxiliary agent and carbon used as a reducing agent from lead smelting process to obtain a mixed material, and spraying the mixed material with air to a flash smelting reaction furnace for flash smelting to obtain crude lead and smelting slag; and remixing the smelting slag with carbon used as a reducing agent in a depletion electric furnace for further reducing to obtain slag with lead content lower than 2%. The method provided by the invention can effectively treat lead-containing dangerous solid wastes, and has the advantages of low treatment cost, high treatment capacity and no generation of secondary pollutants; the raw materials have high adaptability; and the generated smelting slag can be effectively utilized.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

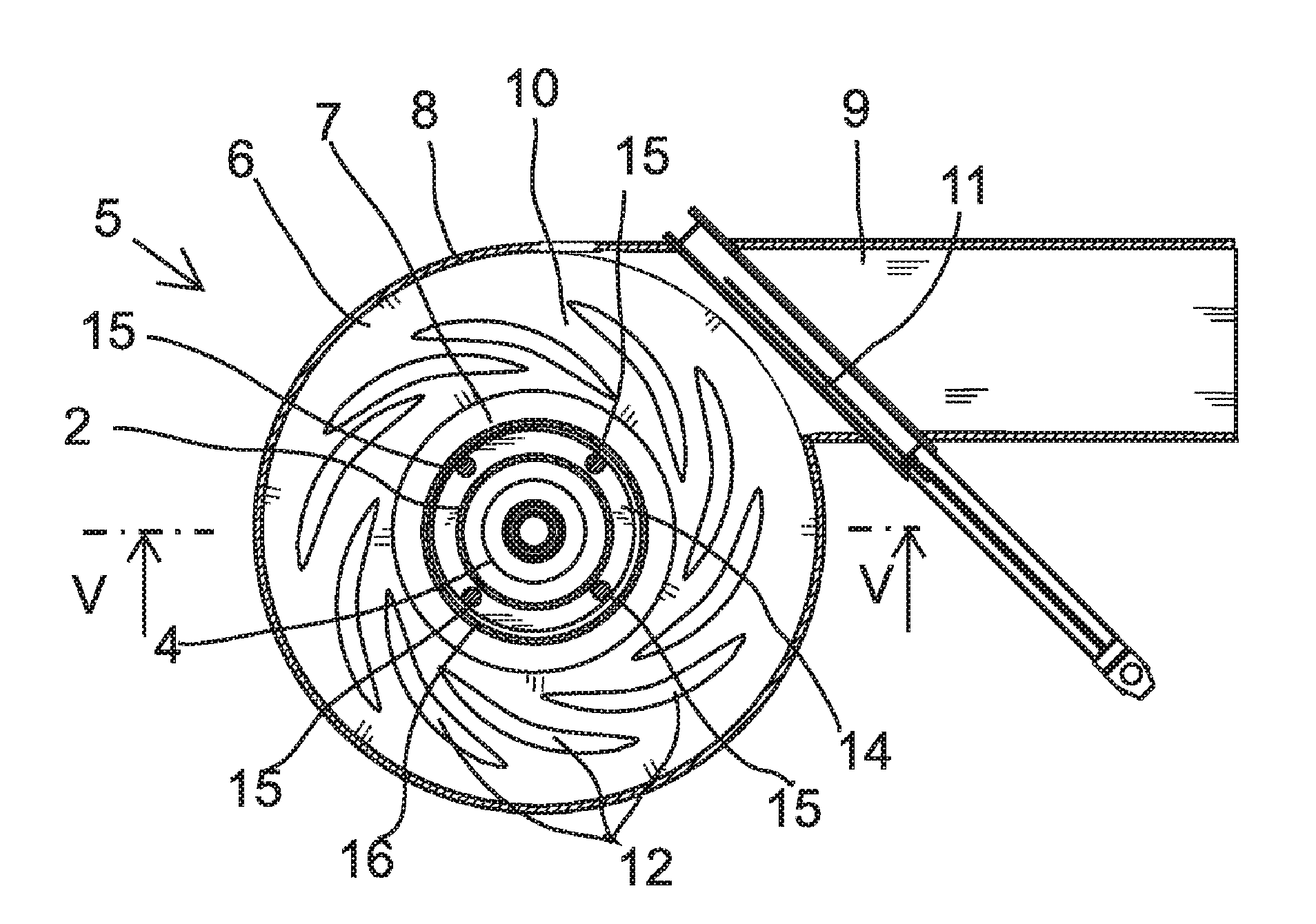

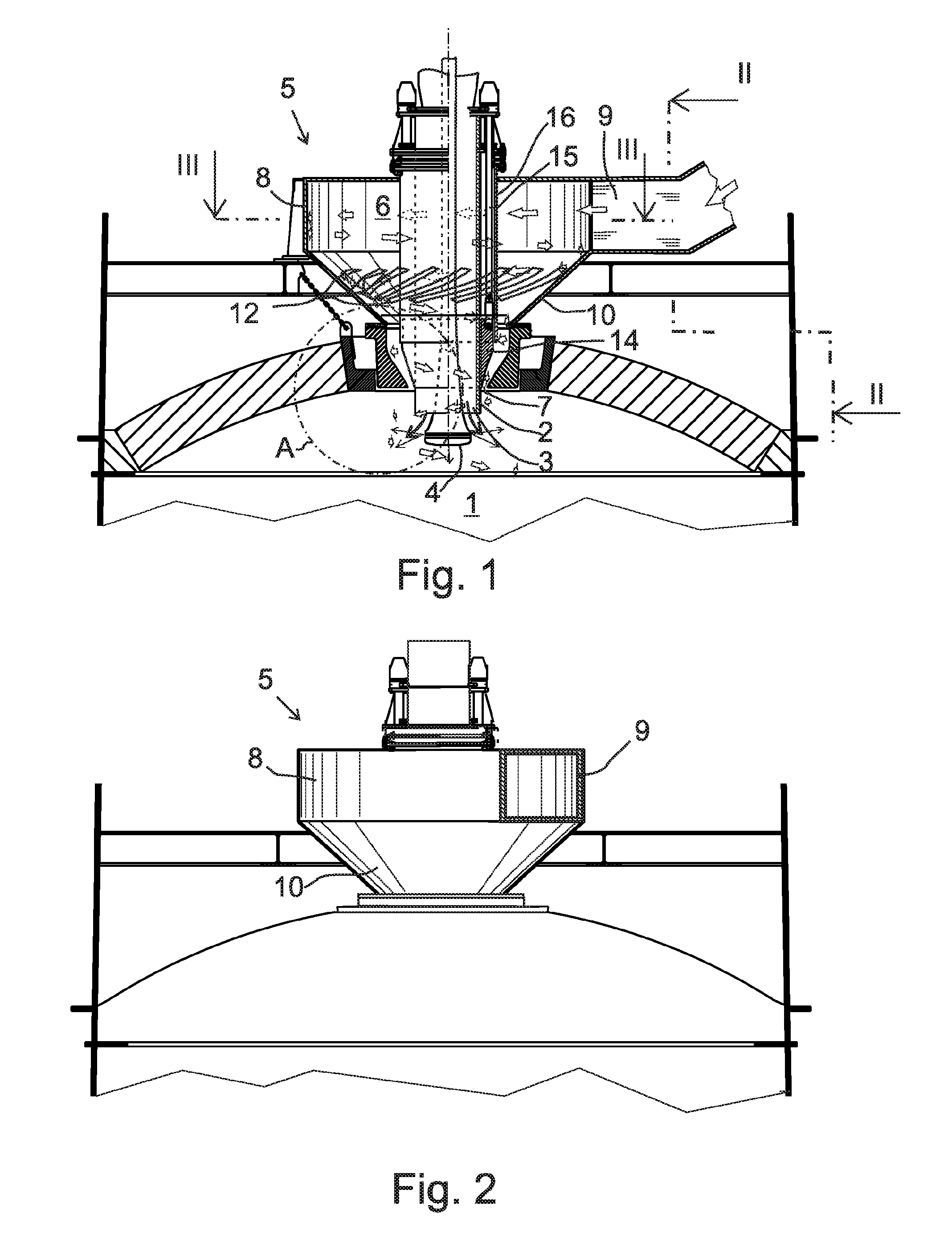

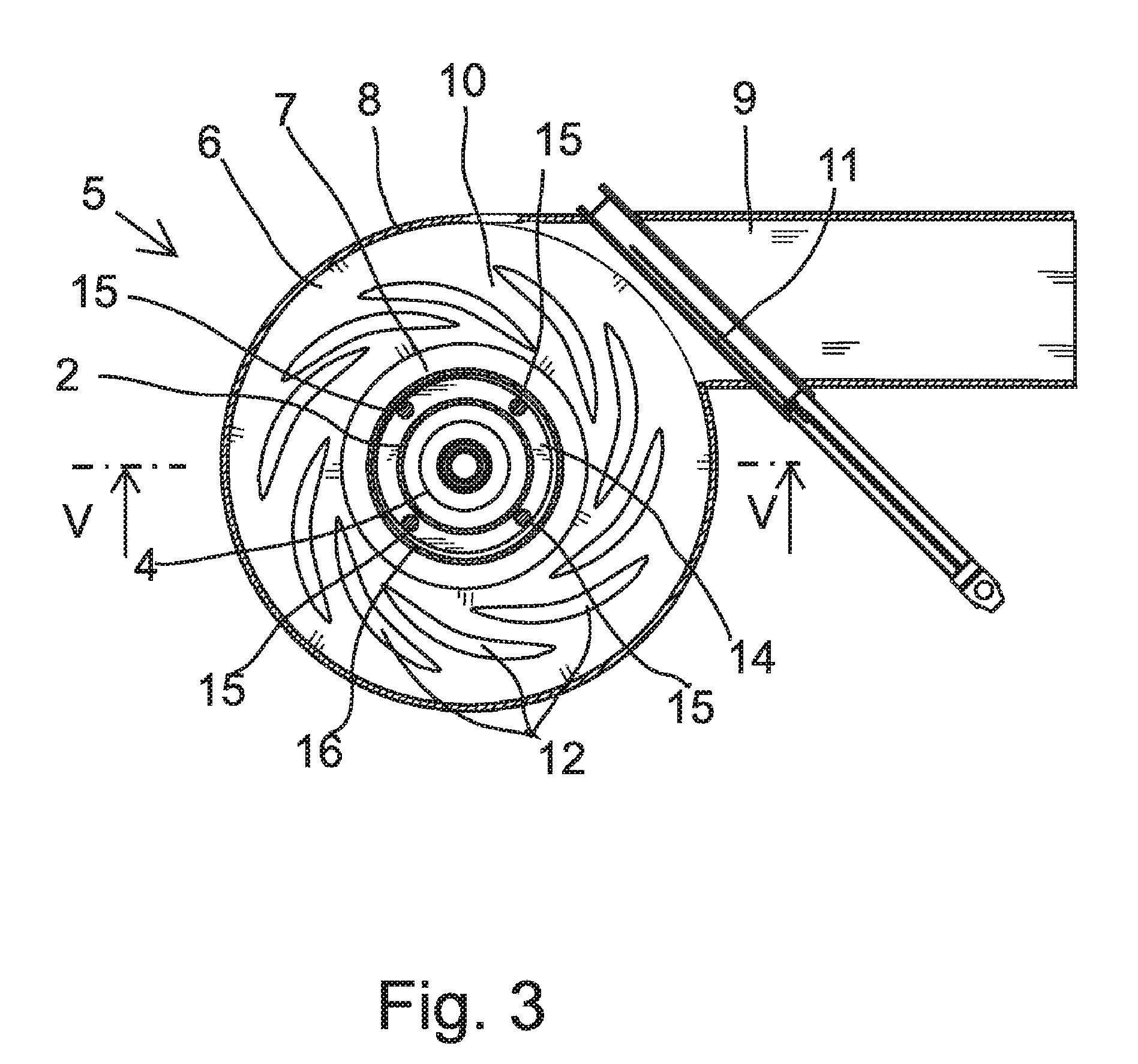

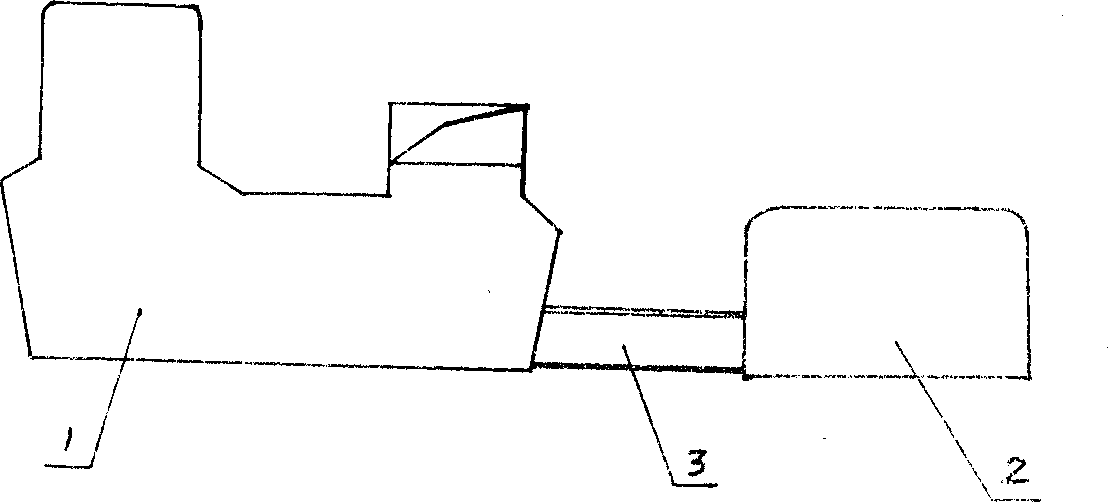

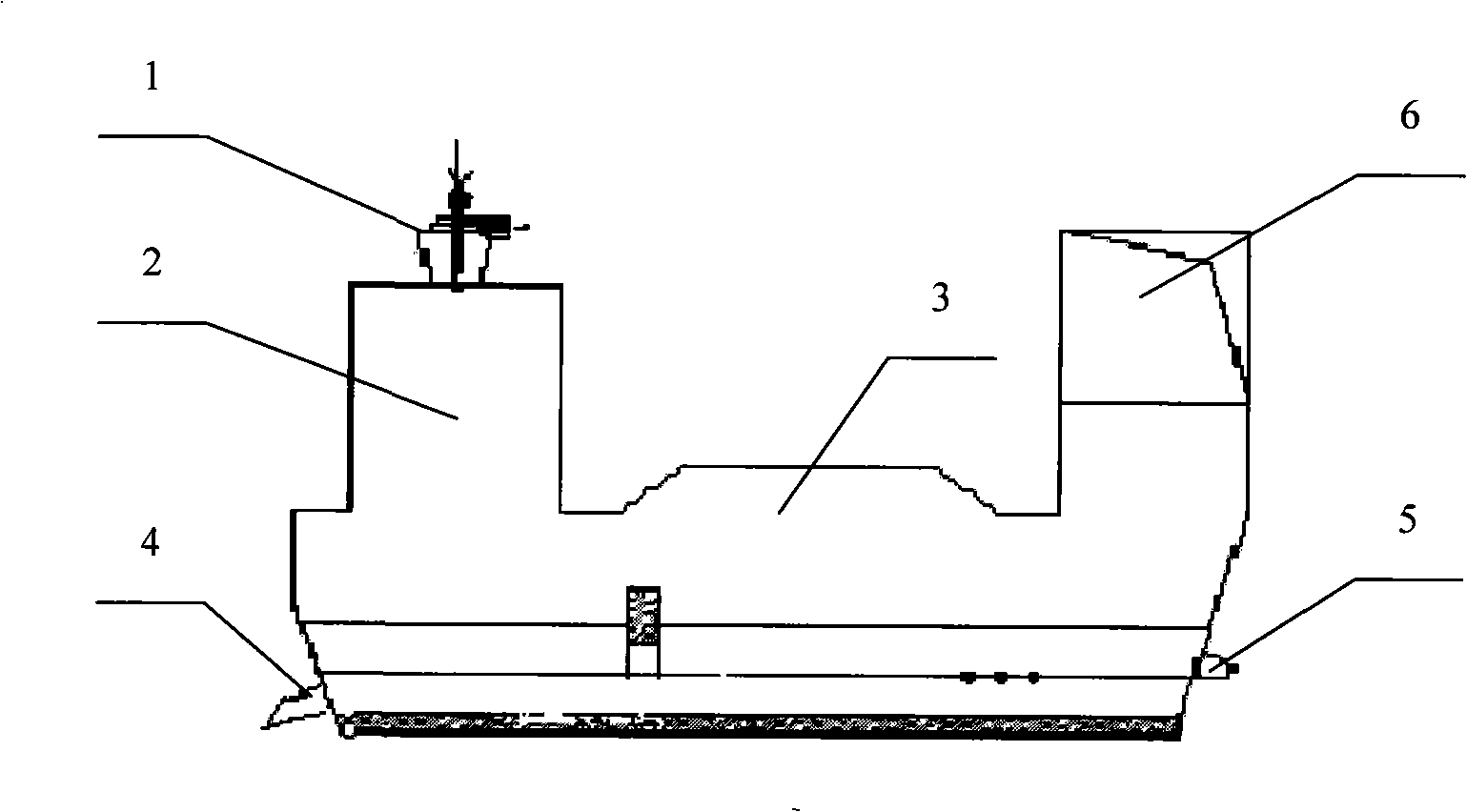

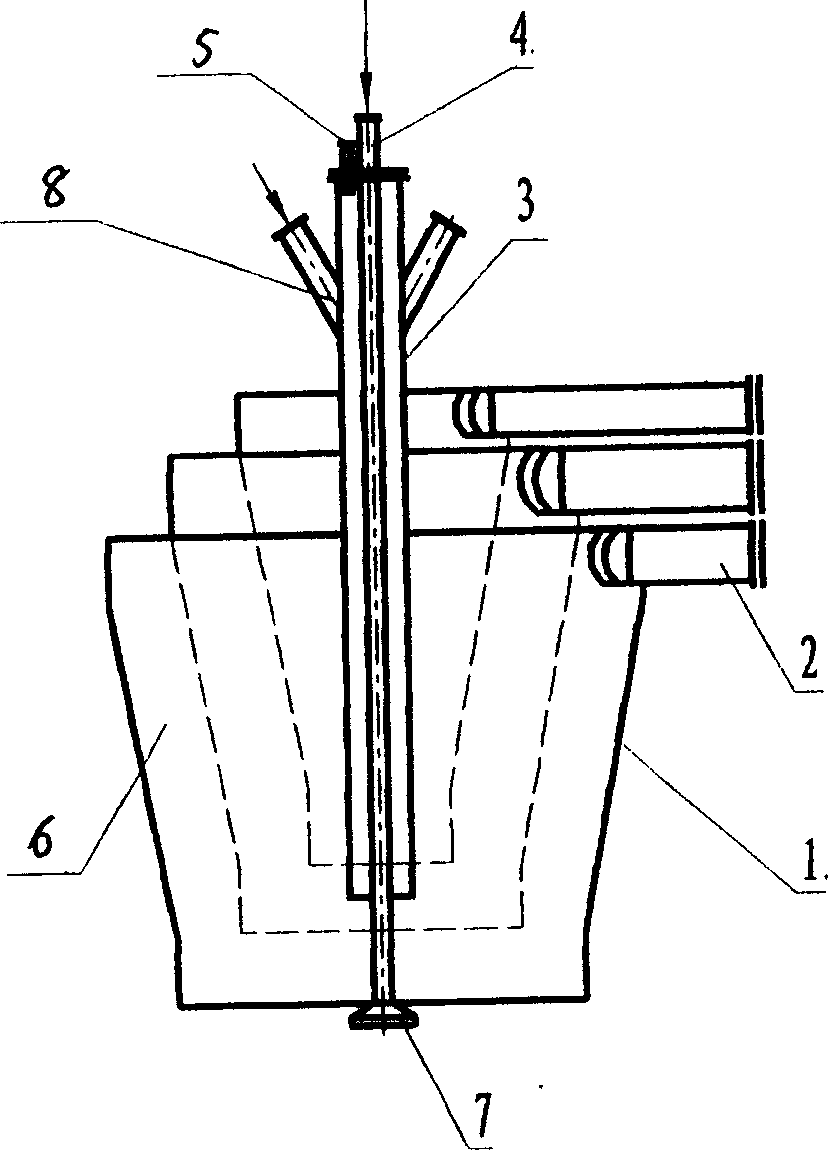

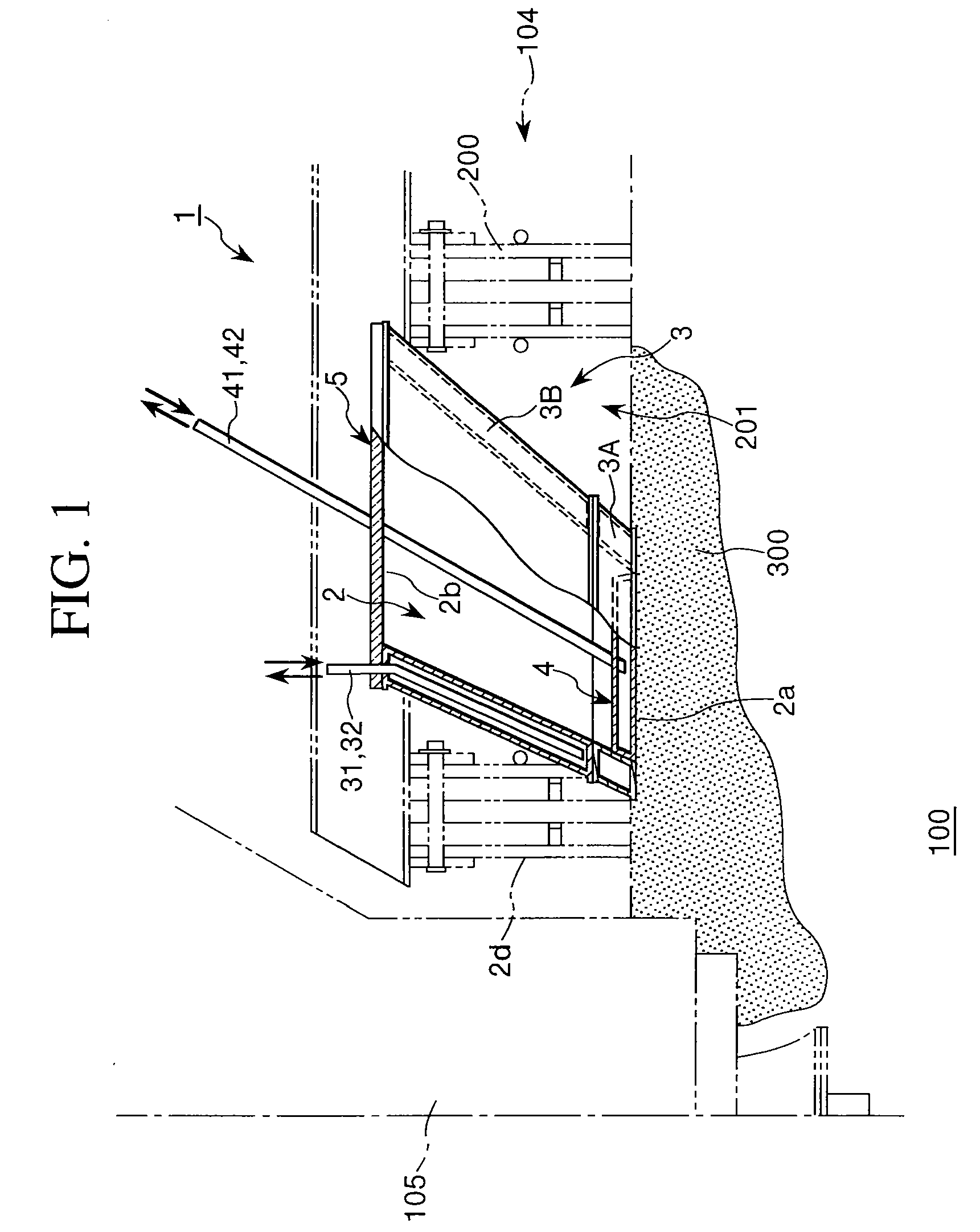

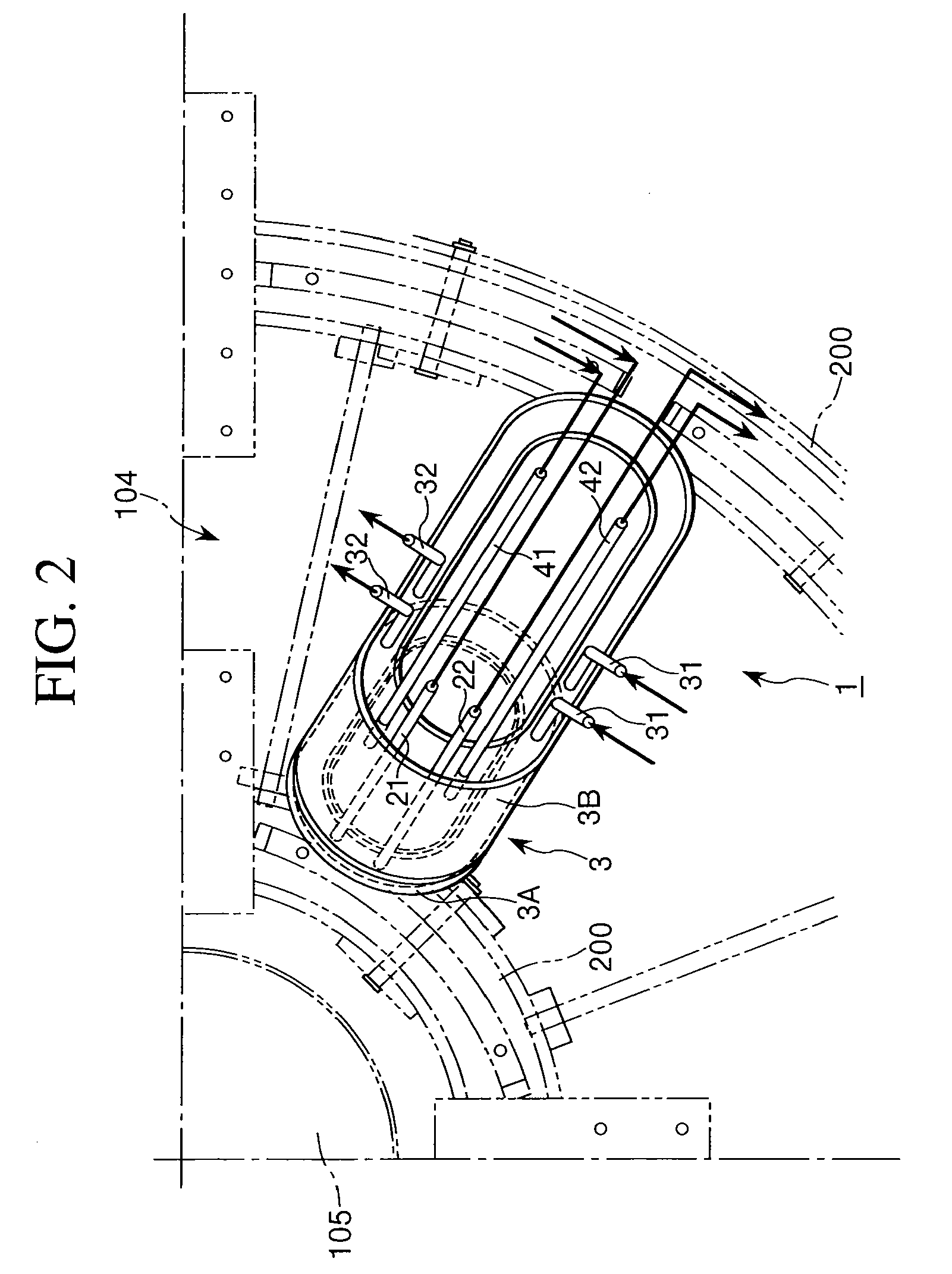

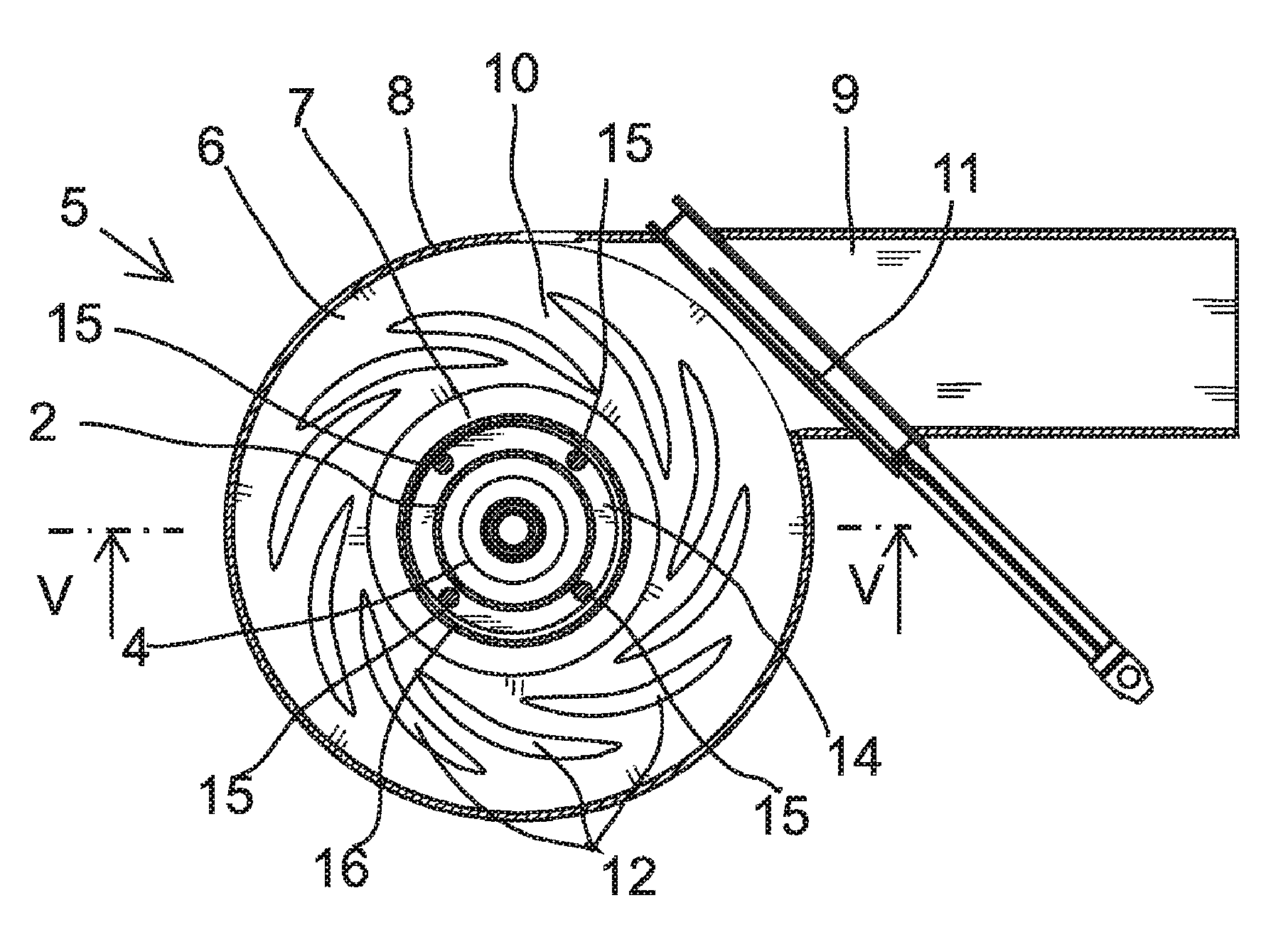

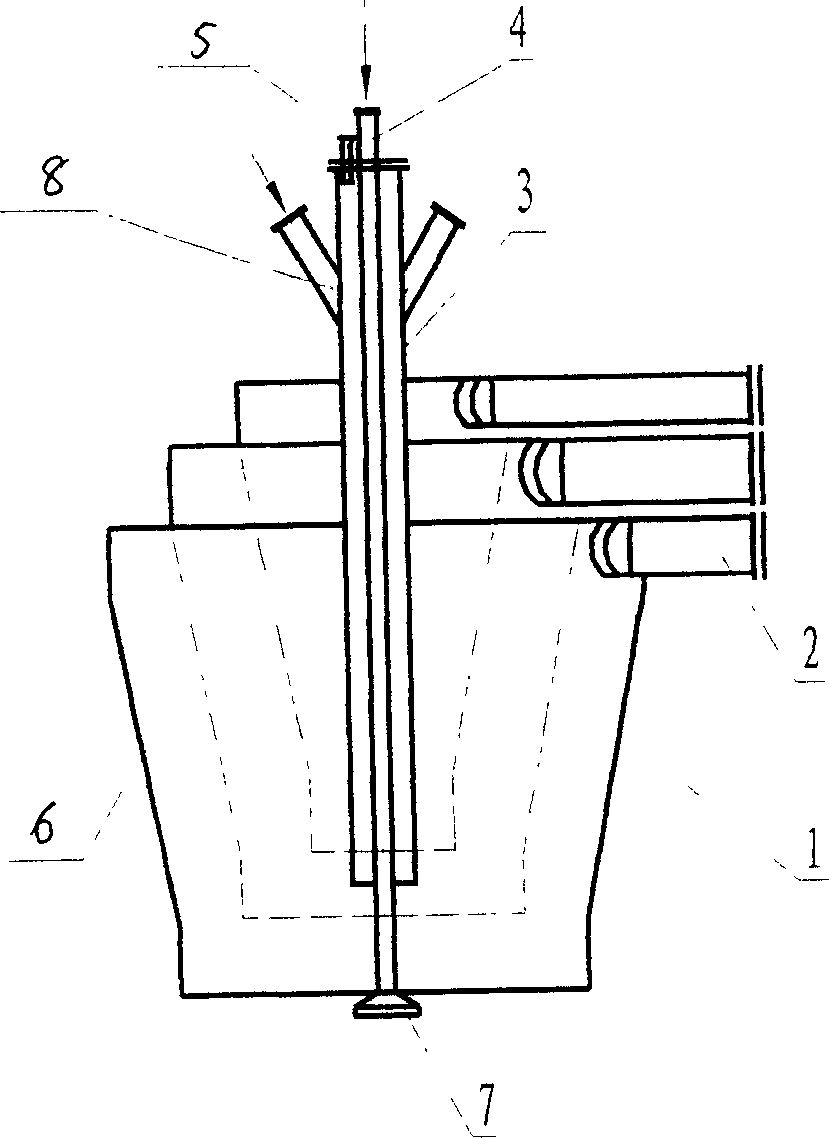

Concentrate burner

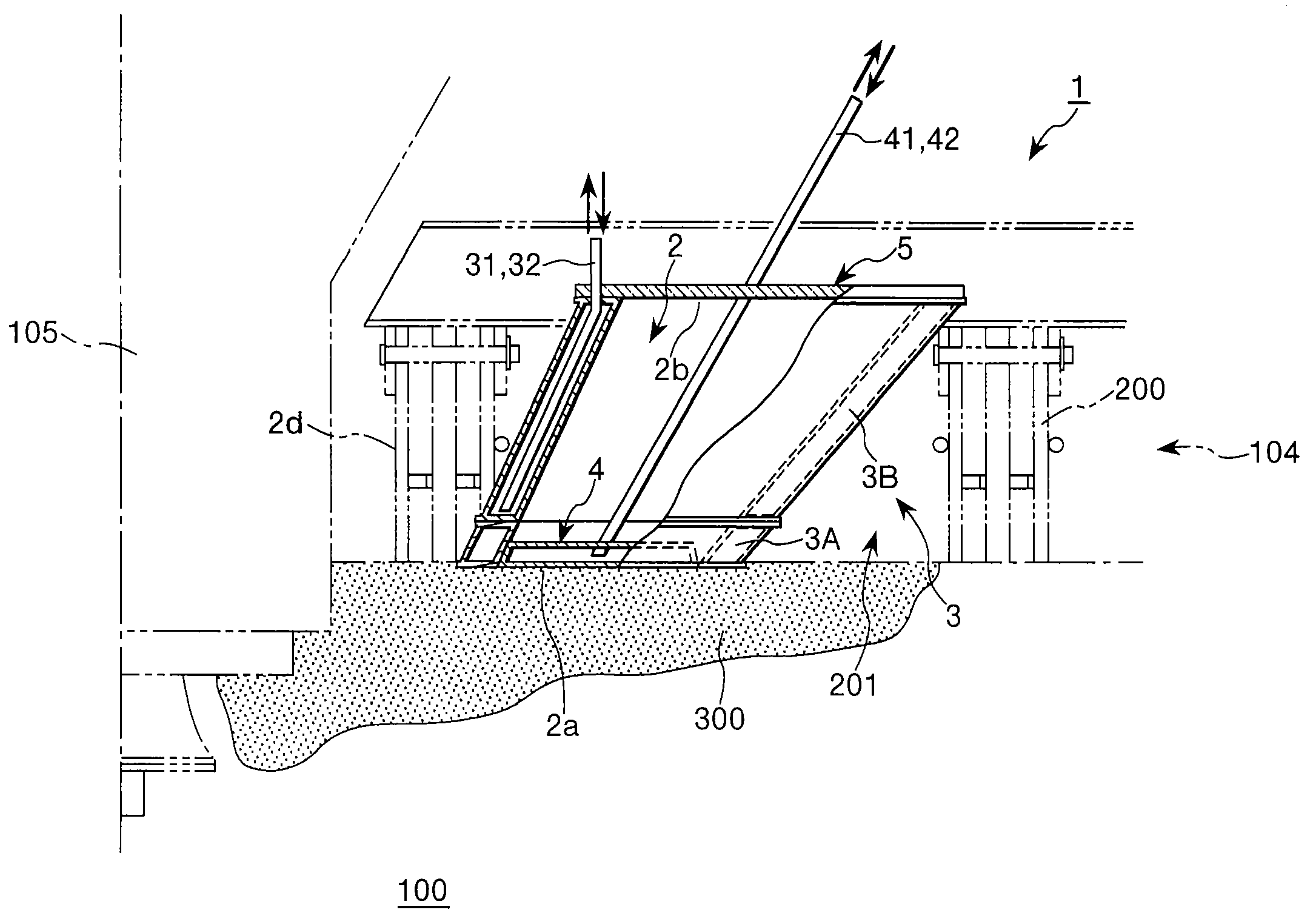

InactiveUS20100207307A1Easy to disassembleOptimal swirl angleTuyeresBell-and-hopper arrangementCombustorInlet channel

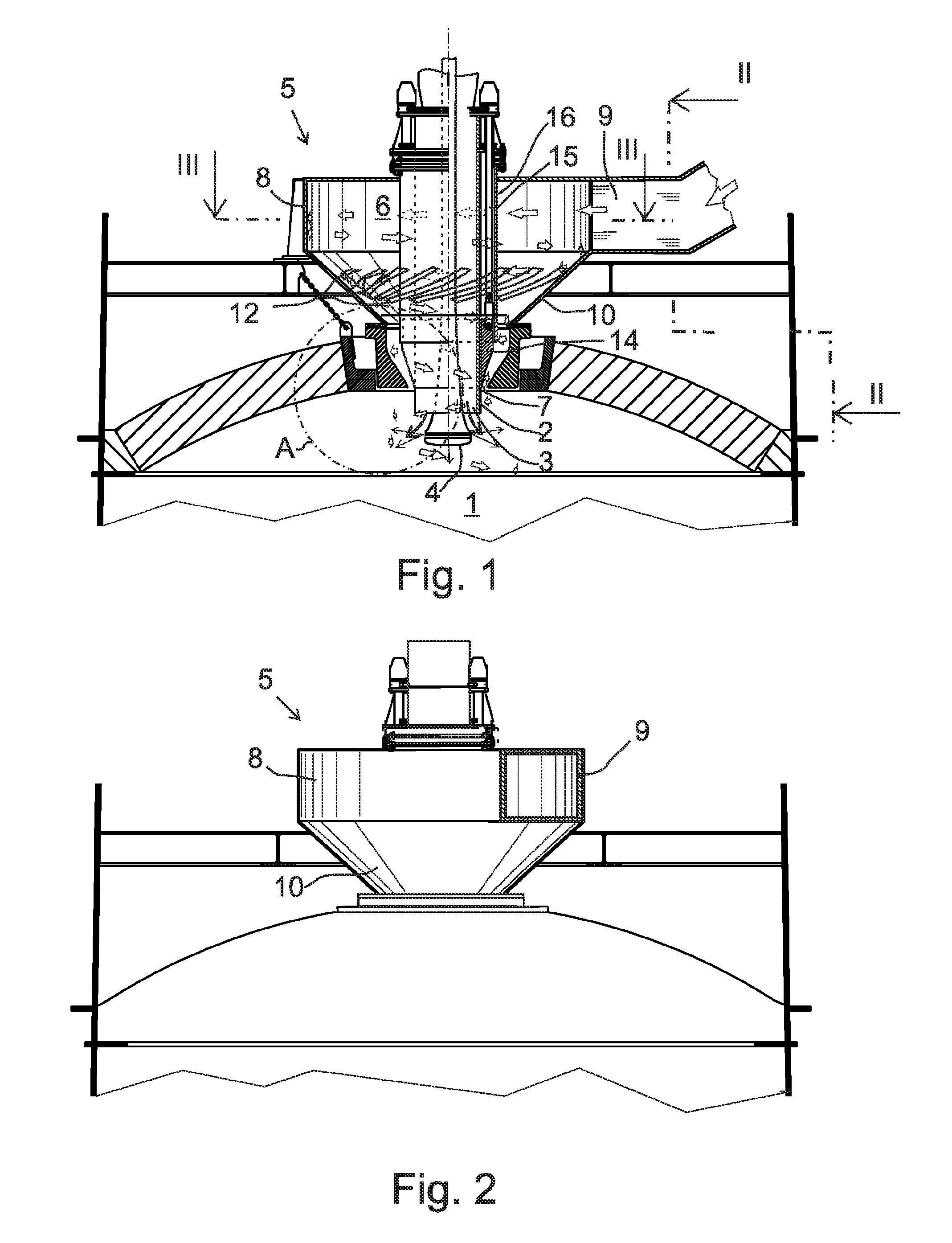

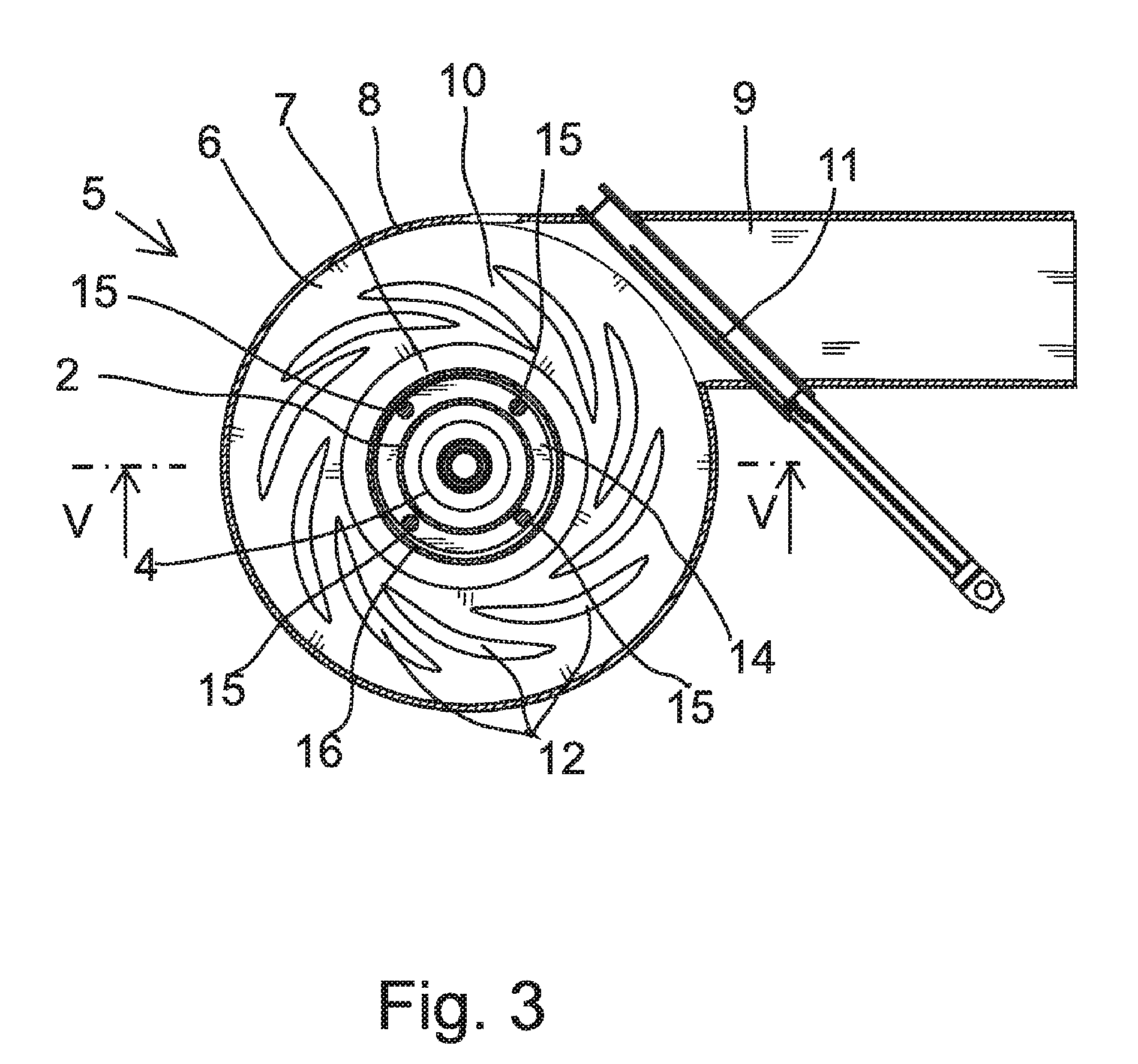

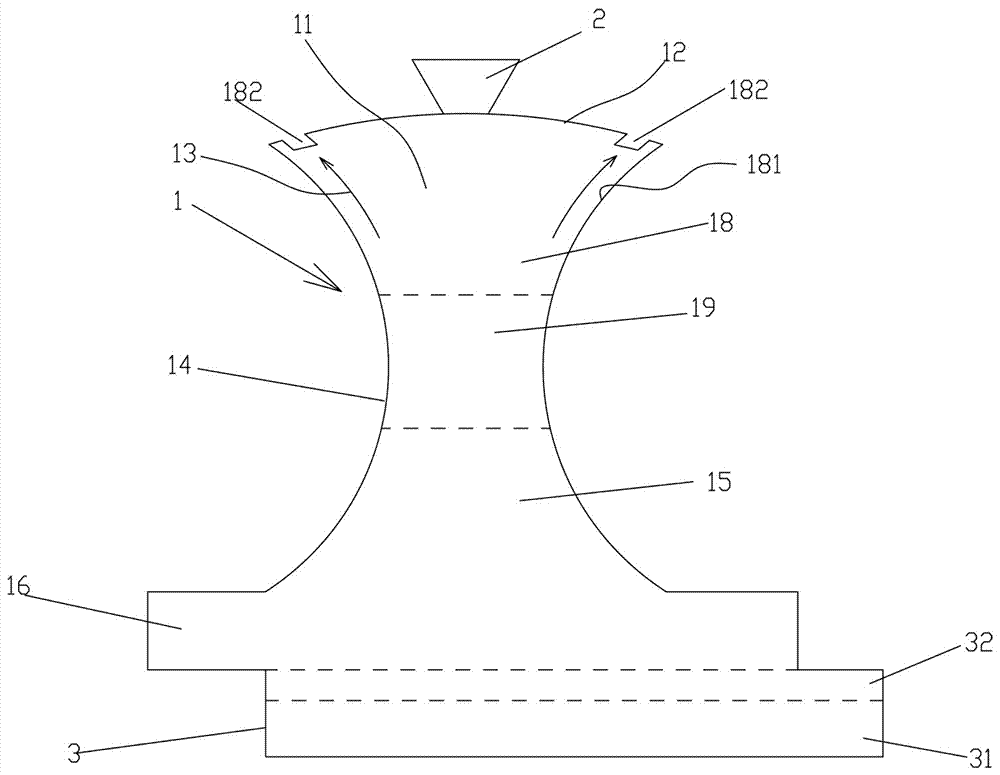

A concentrate burner for feeding a pulverous concentrate mixture and reaction gas into the reaction shaft (1) of a flash smelting furnace. The concentrate burner includes a feeder pipe (2) for feeding the concentrate mixture into the reaction shaft (1), the orifice (3) of the feeder pipe opening to the reaction shaft, a dispersing device (4), which is arranged concentrically inside the feeder pipe (2) and which extends to a distance from the orifice inside the reaction shaft (1) for directing dispersing gas to the concentrate mixture flowing around the dispersing device. For feeding the reaction gas into the reaction shaft (1), a gas supply device (5) includes a reaction gas chamber (6), which is located outside the reaction shaft and opens to the reaction shaft (1) through an annular discharge orifice (7) that surrounds the feeder pipe (2) concentrically for mixing the reaction gas discharging from the discharge orifice with the concentrate mixture discharging from the middle of the feeder pipe, the concentrate mixture being directed to the side by means of the dispersing gas. The reaction gas chamber (6) comprises a turbulent flow chamber, to which an inlet channel (9) opens tangentially for directing the reaction gas to the reaction gas chamber in a tangential direction. In the inlet channel (9), an adjusting member (11) is arranged for adjusting the cross-sectional area of the reaction gas flow.

Owner:OUTOTEC OYJ

Flash smelting technology for copper or nickel sulfide ore concentrate

InactiveCN1376804AUpscalingImprove efficiencyRotary drum furnacesCrucible furnacesMelting tankFlash smelting

A flash smelting technology for copper sulfide-nickel sulfide ore concentrate features that a flowing channel is arranged between flash smelting furnace and top-blowing smelting furnace. Said ore concentrate in suspended state is oxidized by oxygen-enriched air in flash smelting furnace, and then directly flows through said flowing channel into the top-blowing smelting furnace, where it is further oxidized by oxygen-enriched air or pure oxygen to obtain coarse copper or nickel. Its advantages are high efficiency, low energy consumption, and low cost.

Owner:CHINA NERIN ENG

Copper flash smelting operation parameter optimization method

The invention provides a method for optimizing operation parameters in the flash smelting of copper. The invention is aimed at the optimization of the stability in comprehensive operation condition in flash smelting, sets up a mechanism model and an intelligent optimizing model based on a fuzzy C mean clustering chaos pseudo parallel genetic algorithm, and carries out coordinated outputting for the optimized result of the two models by way of intelligent integration. The method can get the optimal operation parameters in the flash smelting of copper, that is, the optimal charge of hot blast and oxygen in a reaction tower of a flash smelting furnace.

Owner:CENT SOUTH UNIV

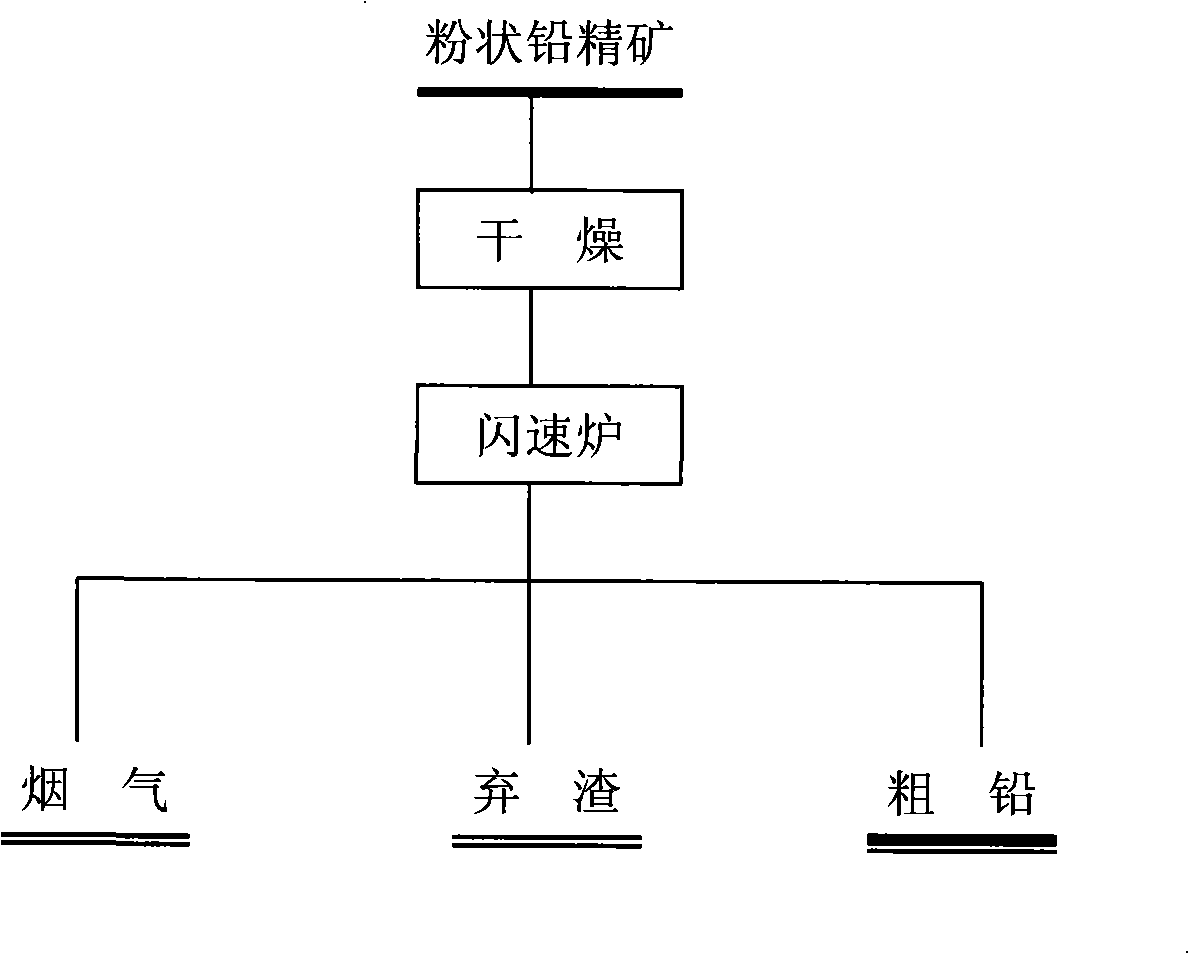

Flash smelting method for lead

The invention relates to a lead flash smelting method, belonging to the nonferrous metal field. The technique comprises the following steps that: the dried powder lead sulphide ore concentrate and the oxygen are injected into the space of a high temperature reaction tower and are in a floating state, the input amount of the oxygen is controlled to ensure that the oxidation rate of the lead sulphide ranges from 60 to 80 percent, the oxidization process of the lead sulphide is finished, the generated fused mass falls on a sedimentation tank below the reaction tower; the lead matte and the furnace slag are generated continuously by the interreaction and the reduction reaction of the lead oxide and the lead sulphide and are discharged from a lead discharging port and a slag discharging port respectively after the carilification, the furnace slag with low lead content can be discarded or is processed further; the flue gas enters an afterheat boiler through a flue and is sent to a device of recycling sulfur. The method has short flow and great productivity as well as safe production, saves energy, protects the environment, uses the resources effectively and is continuous and sanitary and stable.

Owner:YUNNAN METALLURGICAL GROUP +1

Method for processing complex nickel raw material by utilizing flash smelting system

InactiveCN102888519AImprove dehydration efficiencyHigh recovery rateRotary drum furnacesCrucible furnacesLead smeltingSmelting process

The invention provides a method for processing a complex nickel raw material by utilizing a flash smelting system. The method comprises steps as follows: (1) drying wet concentrates: dewatering and drying wet copper-nickel mixed concentrate containing 8-12% of water until the water content is less than 0.3%; (2) mixing materials: mixing dried concentrate with quartz powder and pulverized coal; (3) feeding into a furnace for reacting: uniformly mixing the mixed material with oxygen-enriched air, and feeding into a reaction column of a flash smelting furnace by virtue of a concentrate nozzle for smelting and reacting, and then transferring the produced low-nickel flow to the next process; (4) blowing in a converter; and (5) slowly cooling, and separating. The method provided by the invention has the adaptability to raw materials higher than that of conventional nickel smelting technology and is simple in smelting process; and furthermore, little valuable metal is contained in the waste smelting slag, high recovery rate of the metal in smelting is achieved, and low energy consumption is ensured.

Owner:JINCHUAN GROUP LIMITED

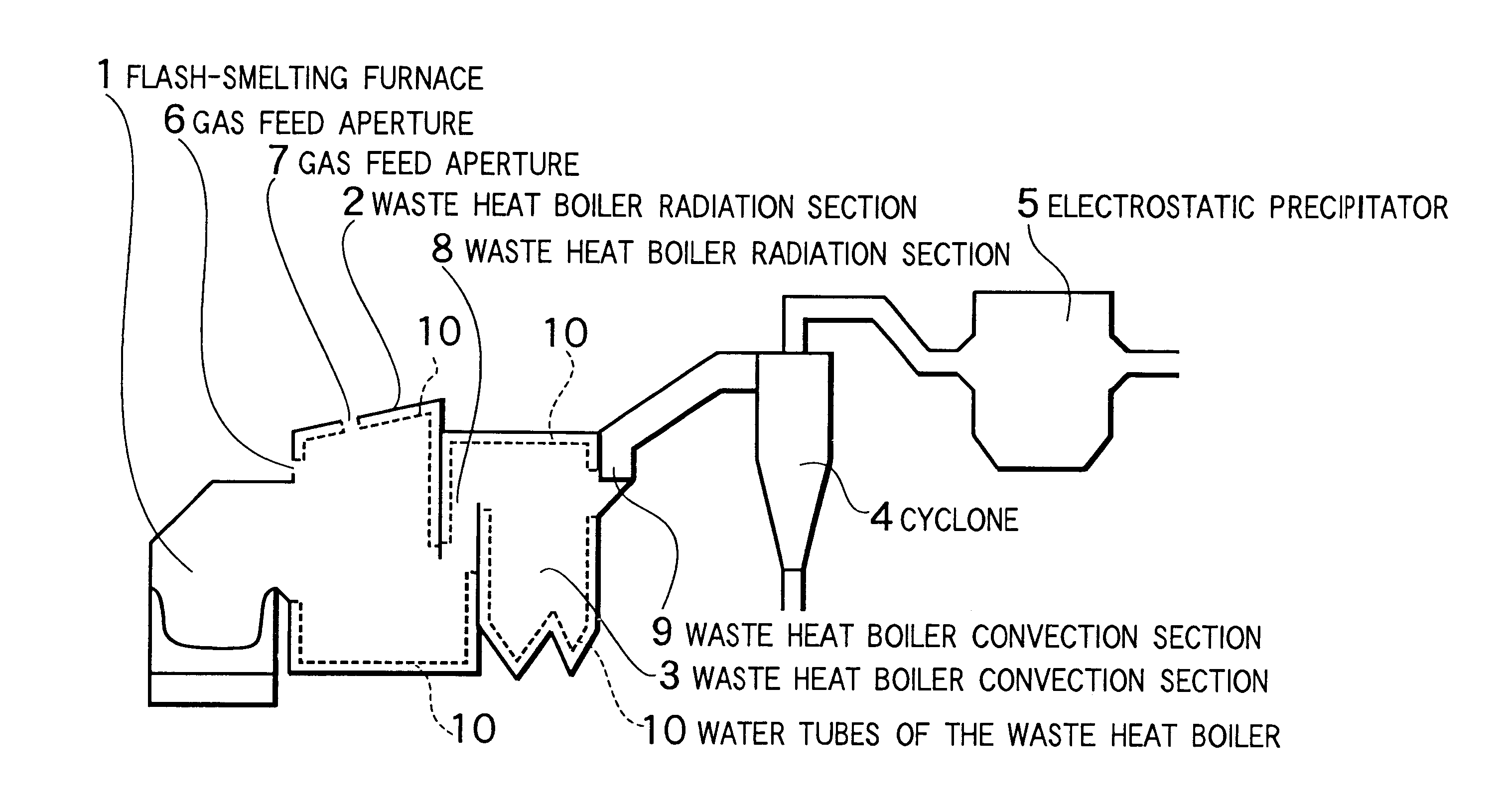

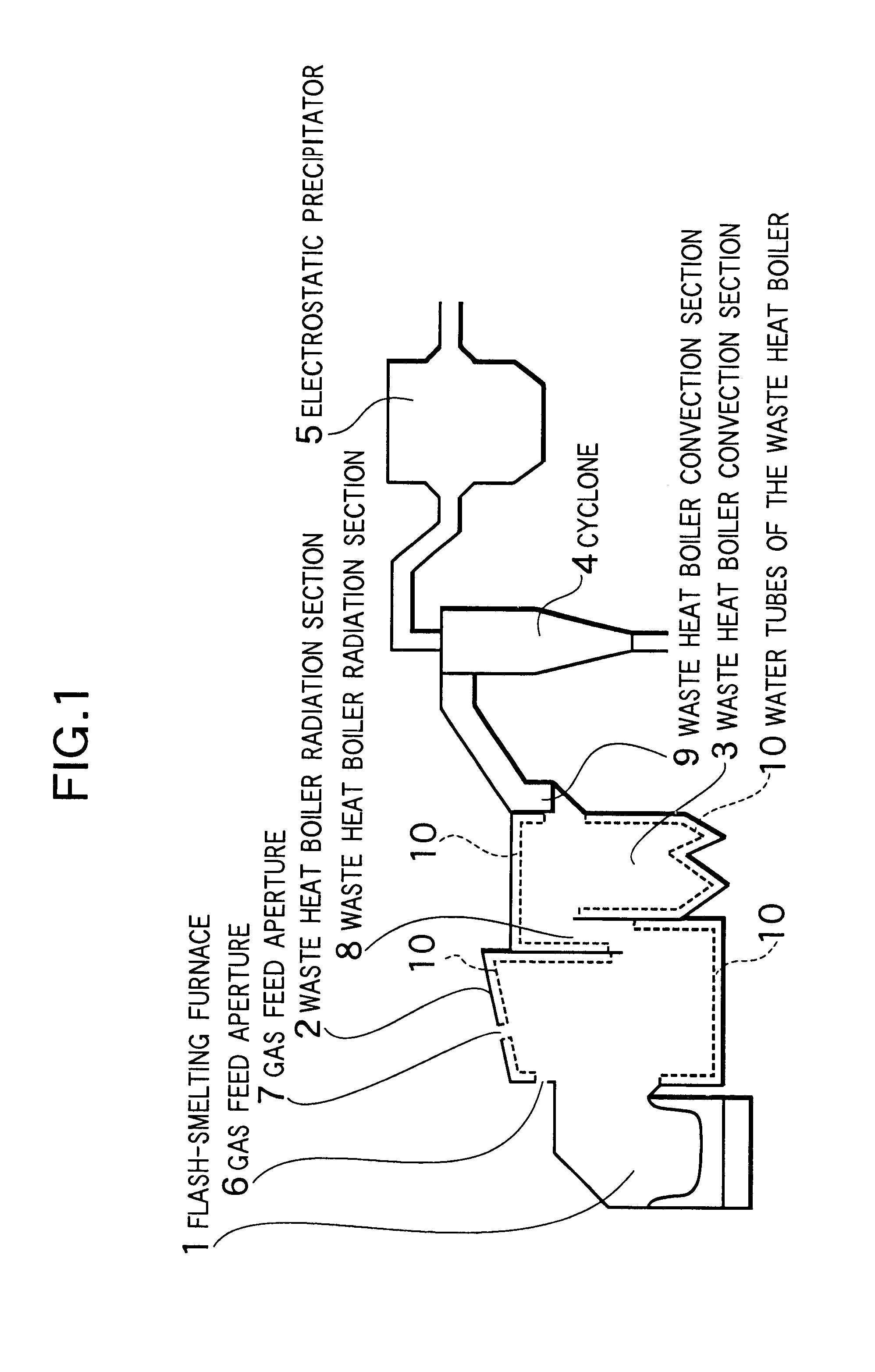

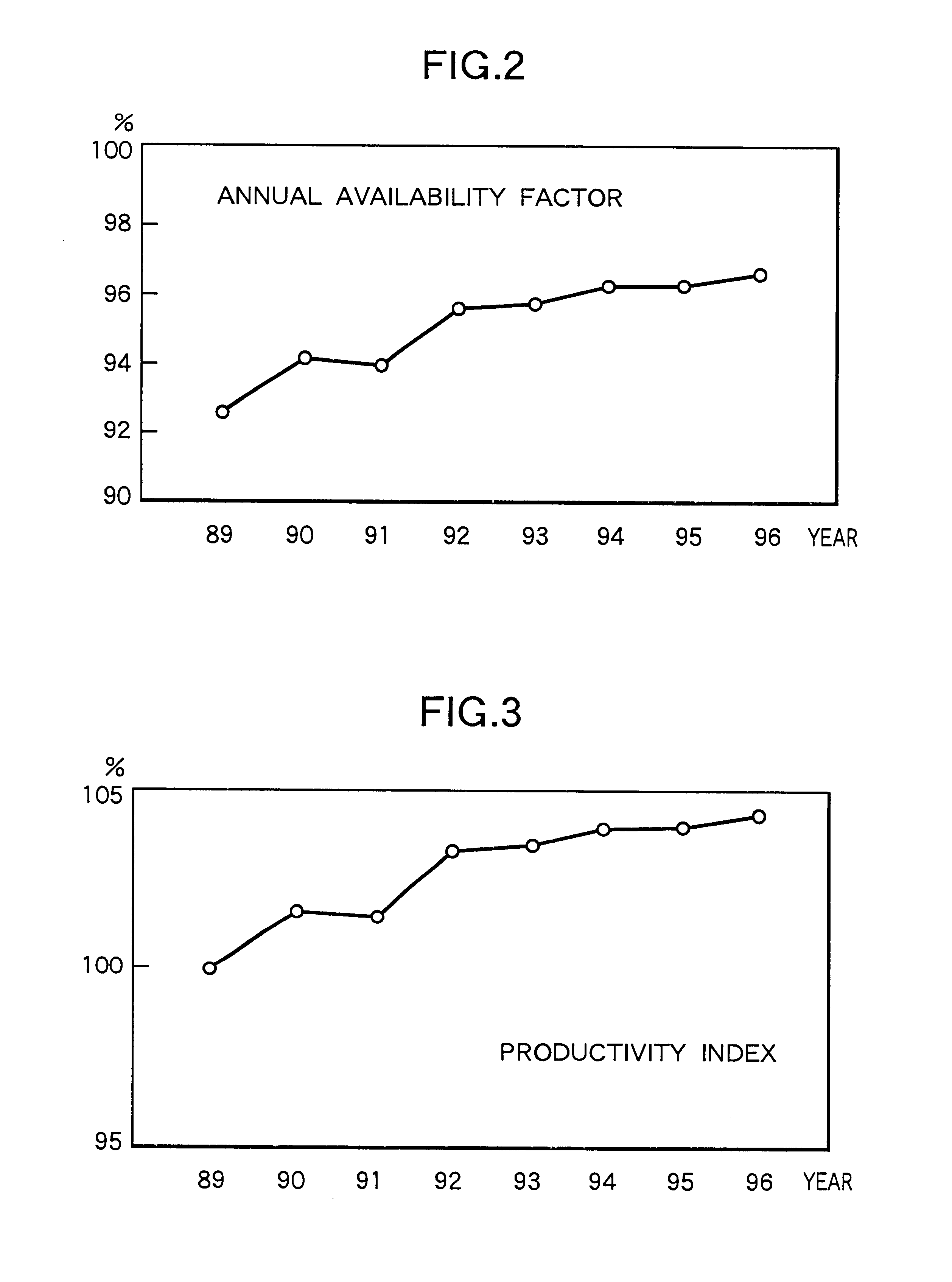

Method for operating waste heat boiler in flash-smelting furnace

In a copper flash-smelting works, forced oxidation of dust is prevented, adhesion of dust to a boiler water tube is reduced, and on-line ratio and productivity index is improved. The temperature at the WHB radiation section outlet is greatly reduced and the atmosphere within the WHB radiation section is controlled by blowing the mixed gas of nitrogen gas and air from the feed aperture established in the wall into the boiler radiation section of the waste heat boiler of the flash-smelting furnace in a copper flash-smelting works.

Owner:DOWA METALS & MINING CO LTD +1

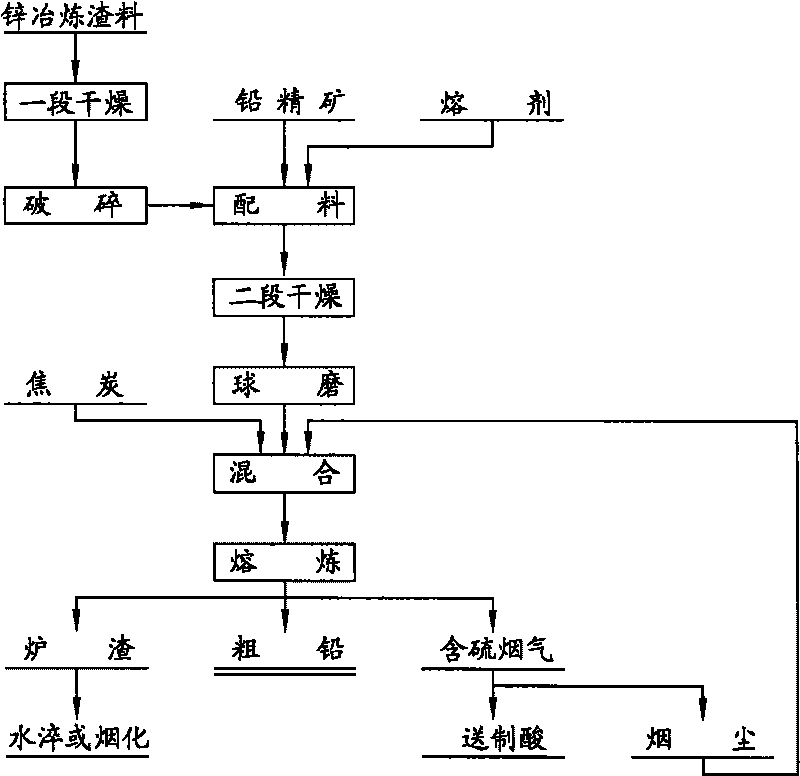

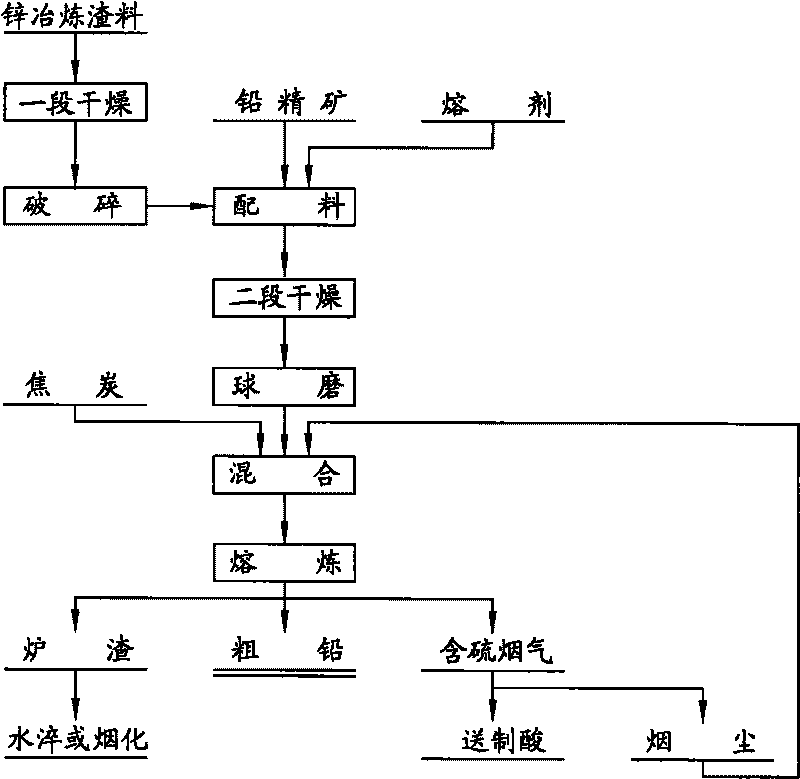

Direct lead smelting method for processing zinc smelting slag by matching

ActiveCN101705366AMeet energy consumptionEliminate polluted environmentProcess efficiency improvementLead smeltingFlash smelting

The invention discloses a direct lead smelting method for processing zinc smelting slag by matching. The method comprises the following steps of: drying zinc smelting slag at the first stage; batching the zinc smelting slag together with raw materials and solvents containing lead to obtain a lead-containing furnace charge with stable components; drying at the second stage and then ball milling; uniformly mixing the furnace charge with reducing agent coke and smelting return dust respectively according to preset measurements, and continuously adding the obtained mixed powder from an oxygen nozzle so as to ensure that the mixed powder enters a lead smelting furnace together with pure oxygen to carry out flash smelting and respectively obtain crude lead and secondary zinc oxide; sending slag into a fuming furnace for blowing or water quenching; and sending gas fume containing sulphur into a sulfuric acid system. The lead smelting method has short technological process and strong raw material adaptability and can smelt low-grade furnace charges containing more than 25 percent of Pb, and meanwhile, a large amount of the zinc smelting slag can be processed by matching. The lead smelting method can produce all crude lead in a metallurgical furnace, and the content of lead in the slag can be controlled to be below 3.5 percent without adopting a blast furnace or other devices to carry out high lead slag reduction. The lead smelting method belongs to true lead smelting or one-step lead smelting.

Owner:CINF ENG CO LTD

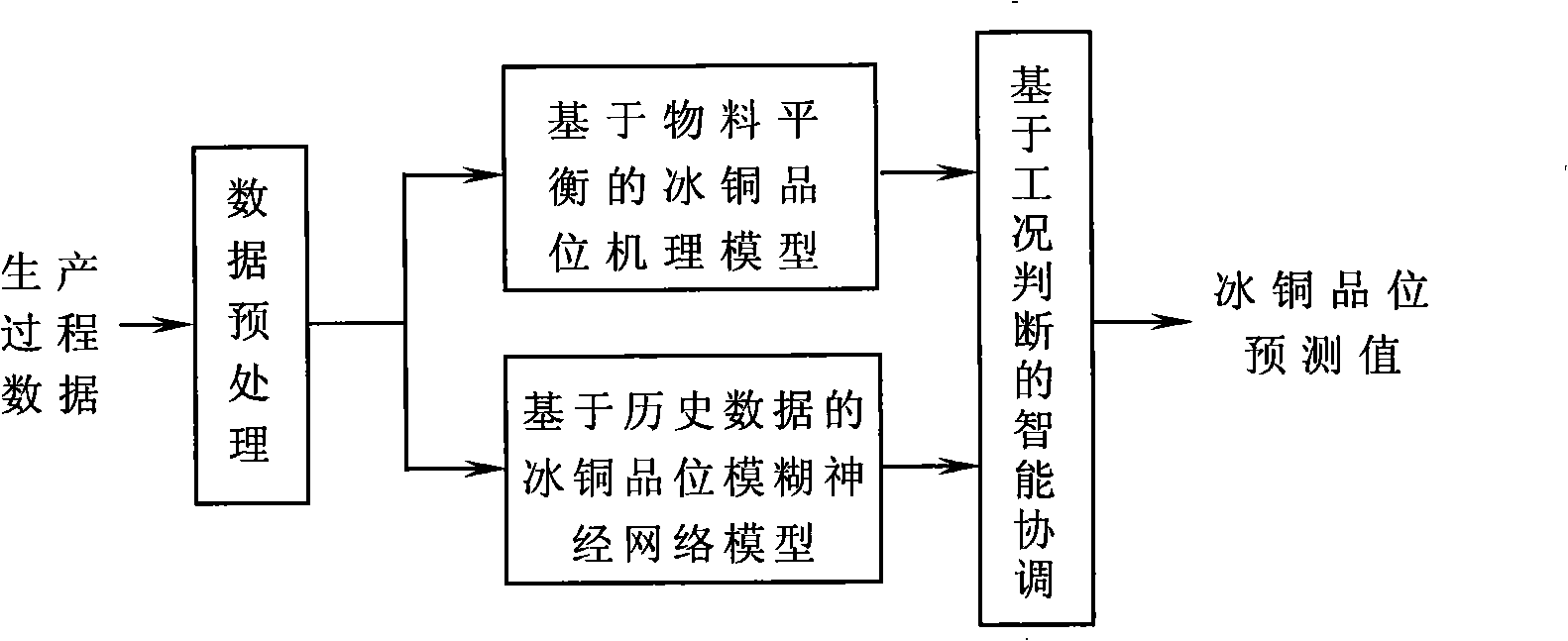

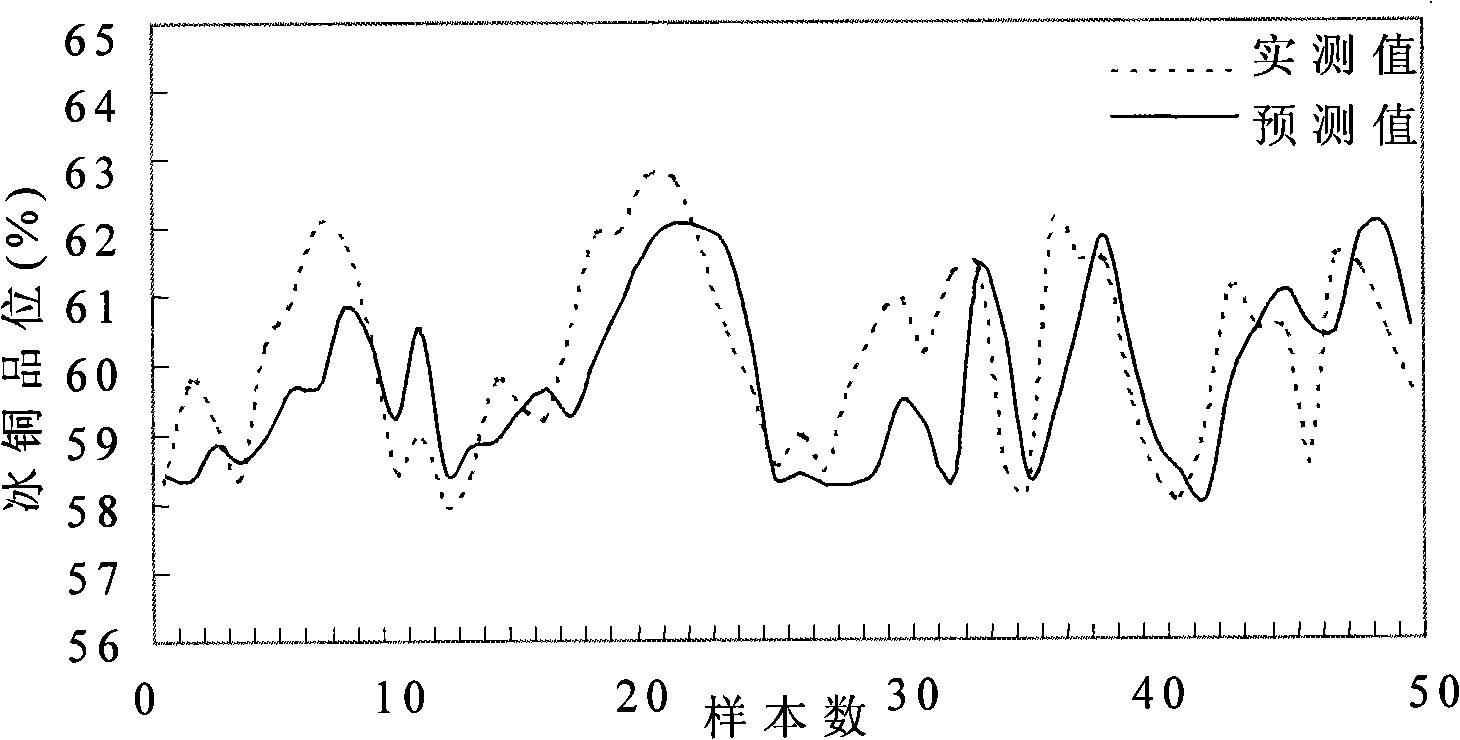

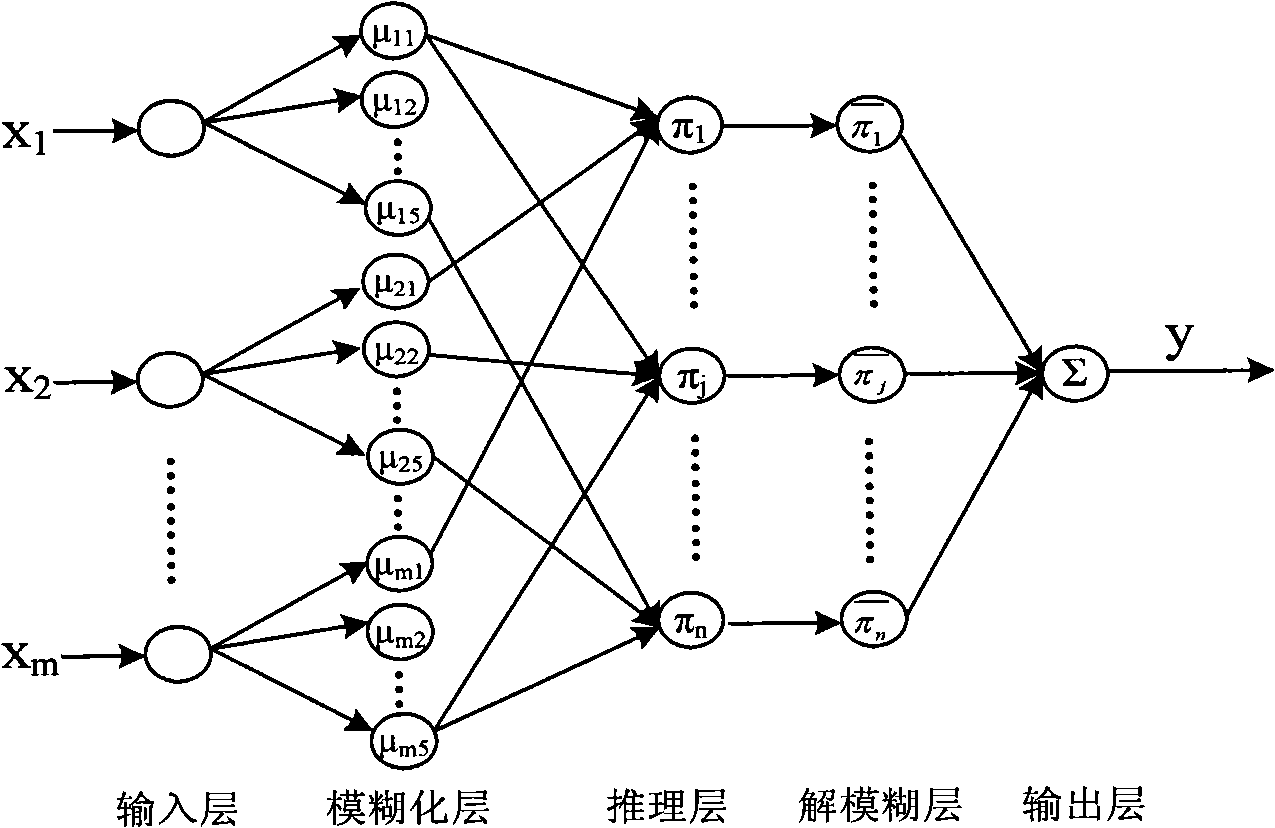

Intelligent integrated modelling approach based on operating condition judgment

The invention relates to an intelligent integrated modeling method based on working condition judgment, which establishes a matte grade prediction model based on the working condition judgment during the flash smelting process. The invention selects the ingredient, blast volume and oxygen demand of material sent into a furnace as the input of a model after analyzing copper flash smelting production technology and relevant factors influencing matte grade to predicate the matte grade. Firstly, a mechanism model of the matte grade is established based on material balance, a fuzzy neural network model of the matte grade is established by utilizing historical data, and on the basis, the integrated prediction model of the matte grade is established by adopting an intelligent coordination strategy on the basis of the judgment of the working condition stability situation. By utilizing the model, the problem of difficult online detection of the matte grade is effectively solved, and the prediction of the matte grade is realized, thus having important significance to the realization of the optimized instruction of the copper flash smelting process.

Owner:CENT SOUTH UNIV

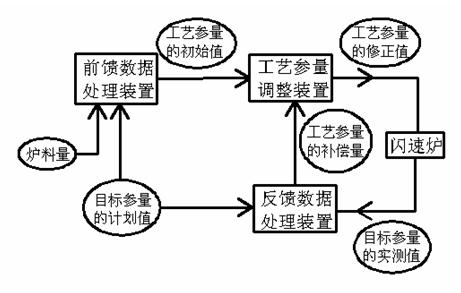

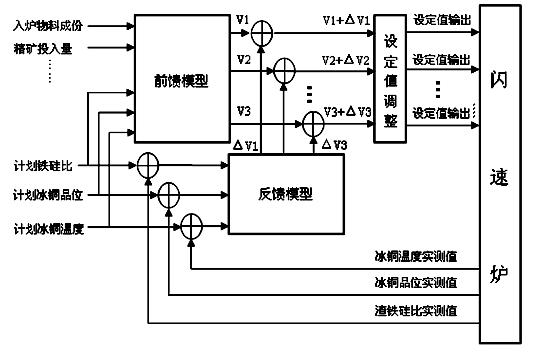

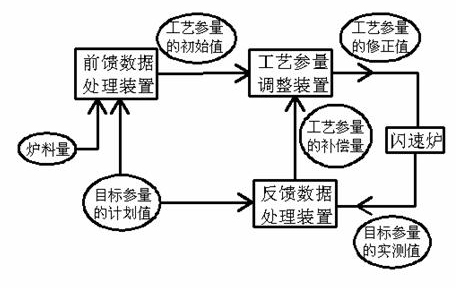

Flash smelting method and system for copper

InactiveCN102560143AHigh control precisionImprove stabilityAdaptive controlControl systemFlash smelting

The invention discloses a flash smelting method and system for copper and relates to a copper matter production technology. The flash smelting method and system are used for realizing higher control accuracy in comparison with the prior art, effectively improving the operation rate of a flash furnace and the production stability, stabilizing the grade of copper matte and leading the standard derivation of the copper matte to be reduced as well as increasing the comprehensive recovery rate of smelting. According to the technical scheme of the invention, the flash smelting method comprises a feed-forward data processing step, a feedback data processing step and a technology parameter adjustment step, wherein in the feed-forward data processing step, an initial value of the technology parameter needed for charging amount is worked out according to a planned value of a target parameter; in the feedback data processing step, a measured value of the target parameter of the flash furnace is collector, the measured value and the planned value are calculated and processed, and the compensation dosage of the technology parameter is worked out; in the technology parameter adjustment step, the initial value and the compensation dosage are combined, correction computation is carried out on the technology parameter to obtain a corrected value of the technology parameter; and a control system of the flash furnace implements a charging technology parameter according to the corrected value. The flash smelting method is mainly used for producing and purifying the copper matte, i.e. an intermediate product in copper refining.

Owner:CHINA NERIN ENG

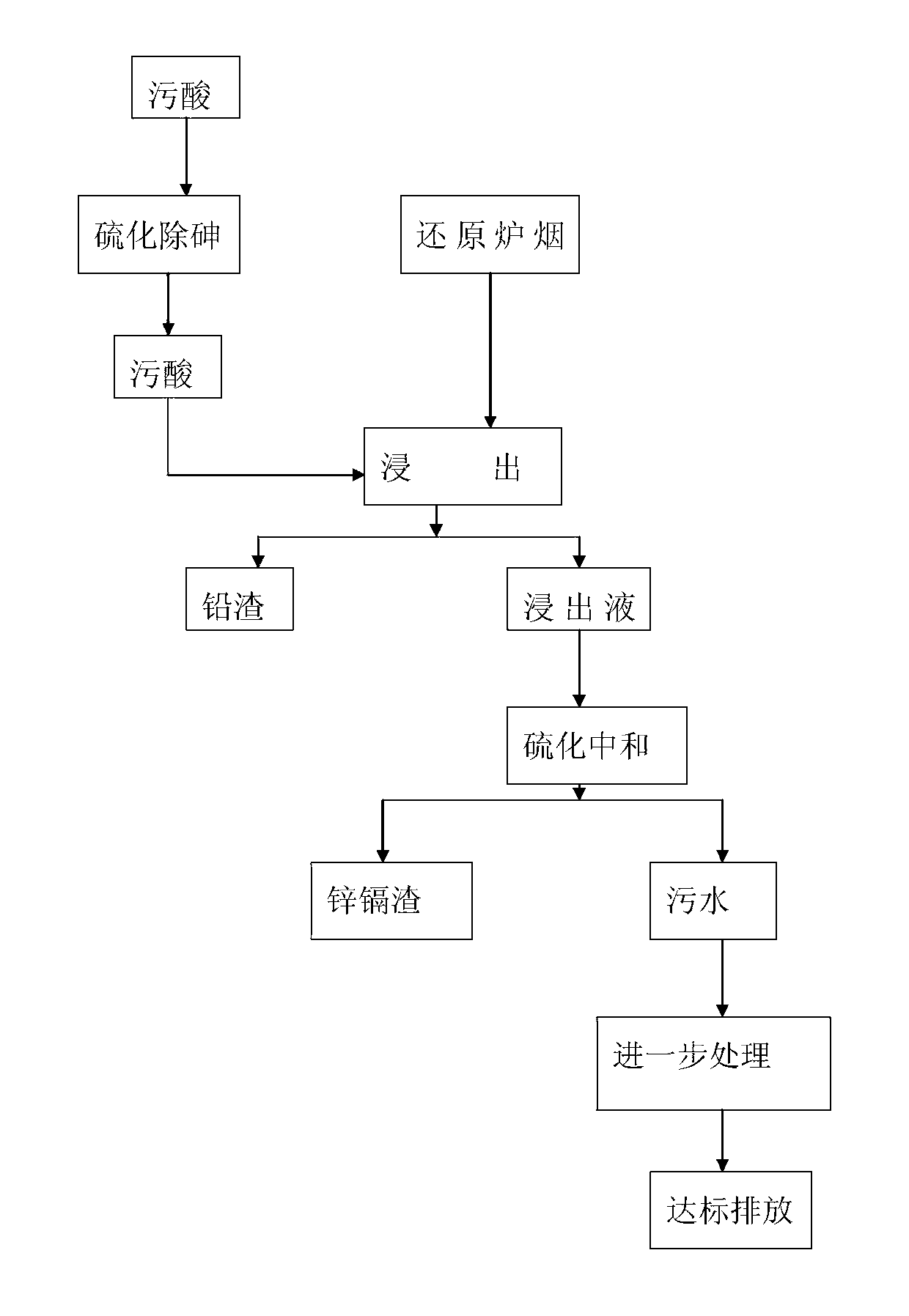

Process for recovering lead, zinc and cadmium in soot on recovery section in process of treating waste acid generated in lead smelting

InactiveCN102994764ALow running costAvoid harmProcess efficiency improvementLead smeltingNon-ferrous extractive metallurgy

The invention relates to the field of nonferrous metal smelting and particularly relates to a process for recovering lead, zinc and cadmium in soot on a recovery section in the process of treating waste acid generated in lead smelting. The soot of a reduction furnace is subjected to a leaching reaction by using arsenic sulfide removal waste acid in the lead smelting industry to generate lead slag to be recovered, and then, the leaching agent is continued to be neutralized by using sodium sulphide and sodium hydroxide to generate high-grade zinc and cadmium slag to be recovered. According to the invention, the waste acid is used for separating the lead, zinc and cadmium in the soot of the reduction furnace for lead smelting, so that the operation cost is low; the problem of production operation damage caused by circulated accumulation of the zinc and cadmium in lead smelting is solved and the pressure of a lead smelting system is relieved under the condition of low cost; and the lead slag which is low in arsenic content and suitable for being treated by a lead system and the zinc and cadmium slag which is suitable for being treated by a zinc system can be generated, and meanwhile, the waste acid is also treated, so that not only is the treatment cost of the waste acid reduced, but also the treatment difficulty is lowered.

Owner:HENAN YUGUANG GOLD & LEAD

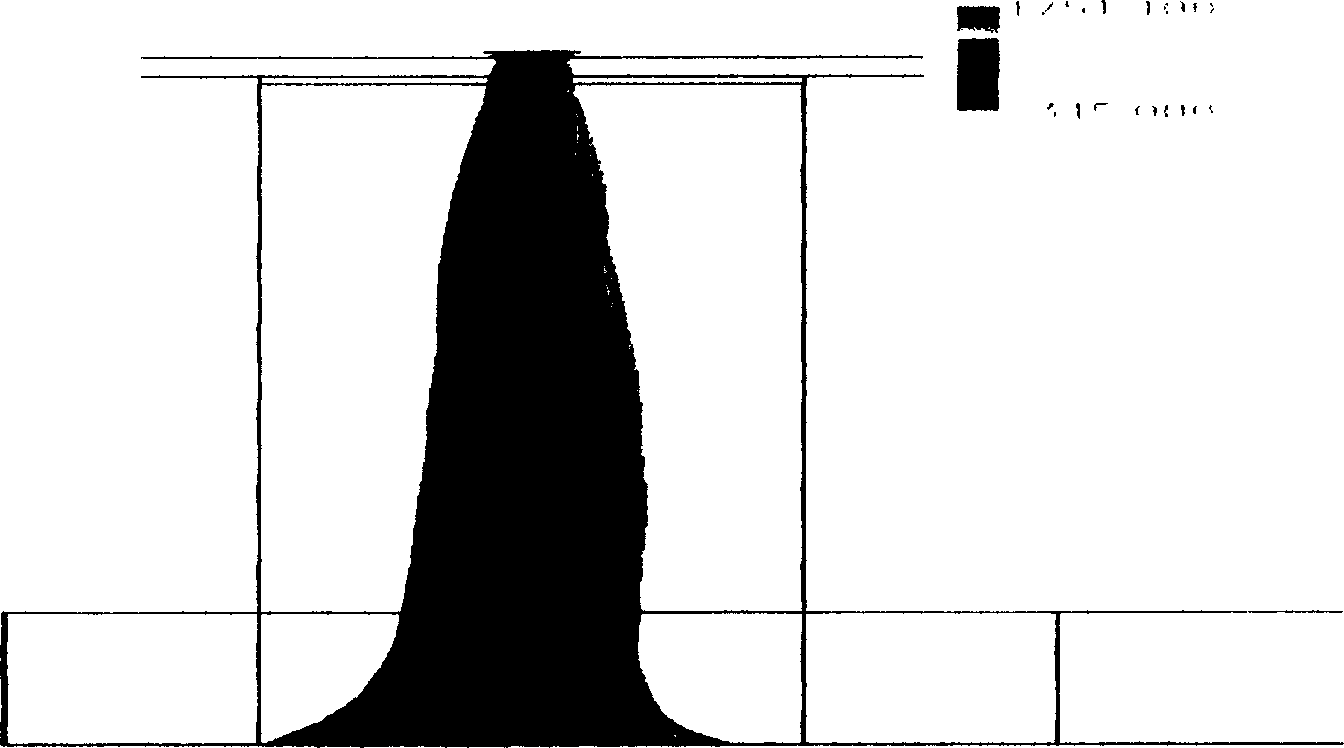

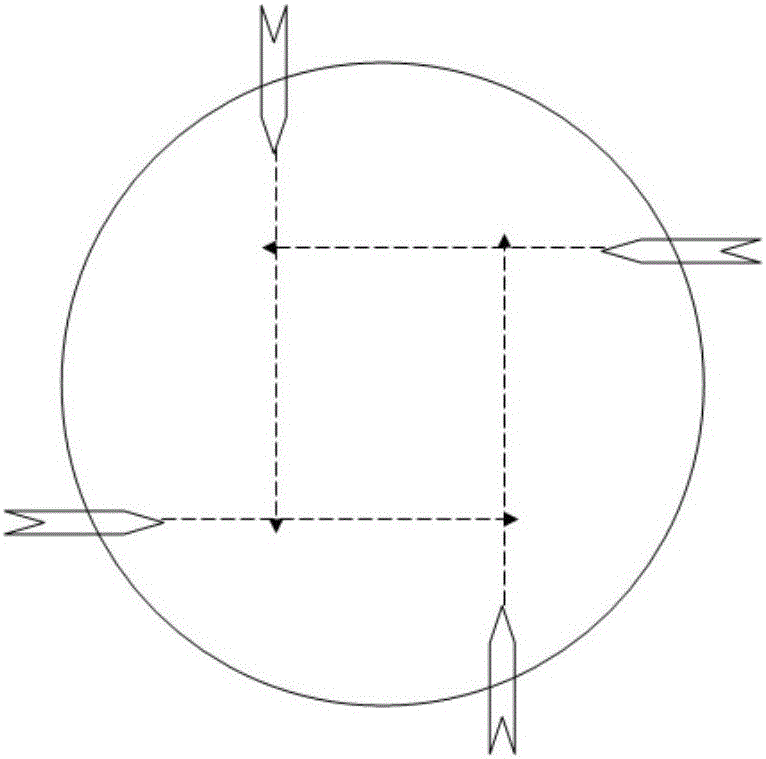

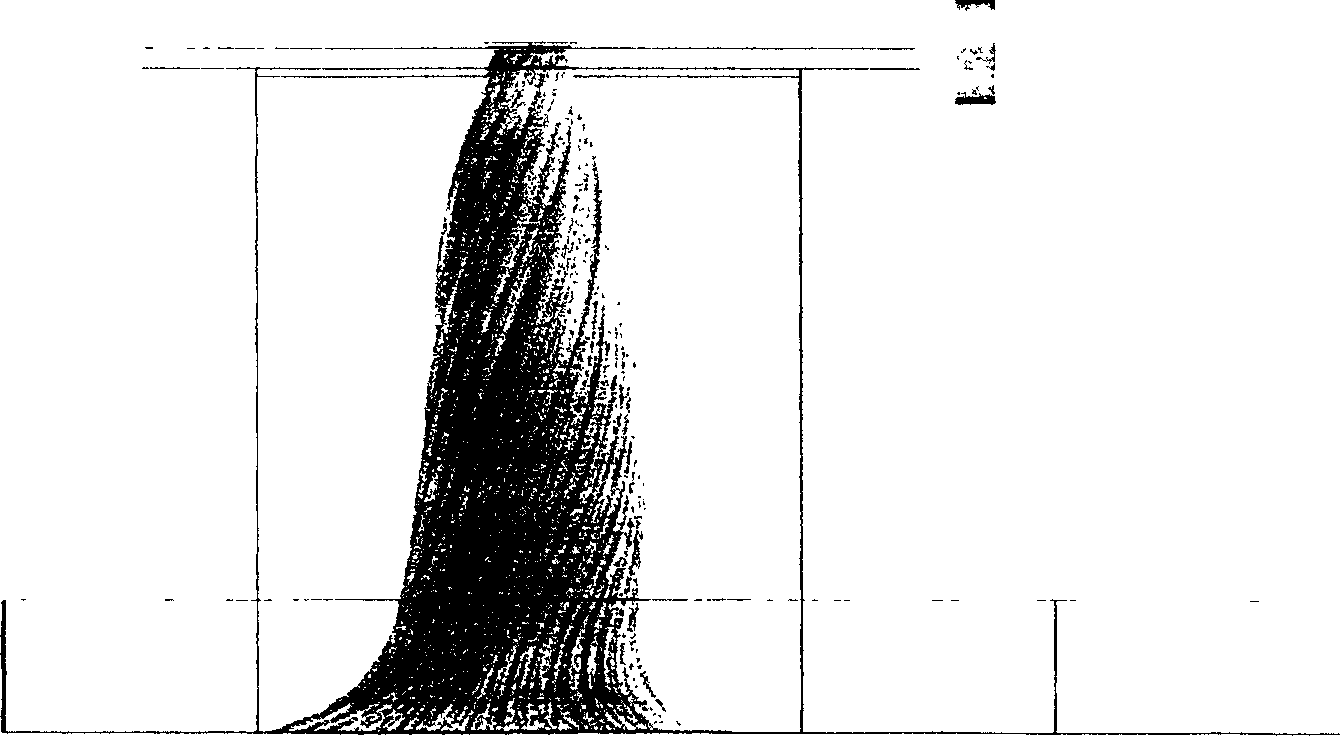

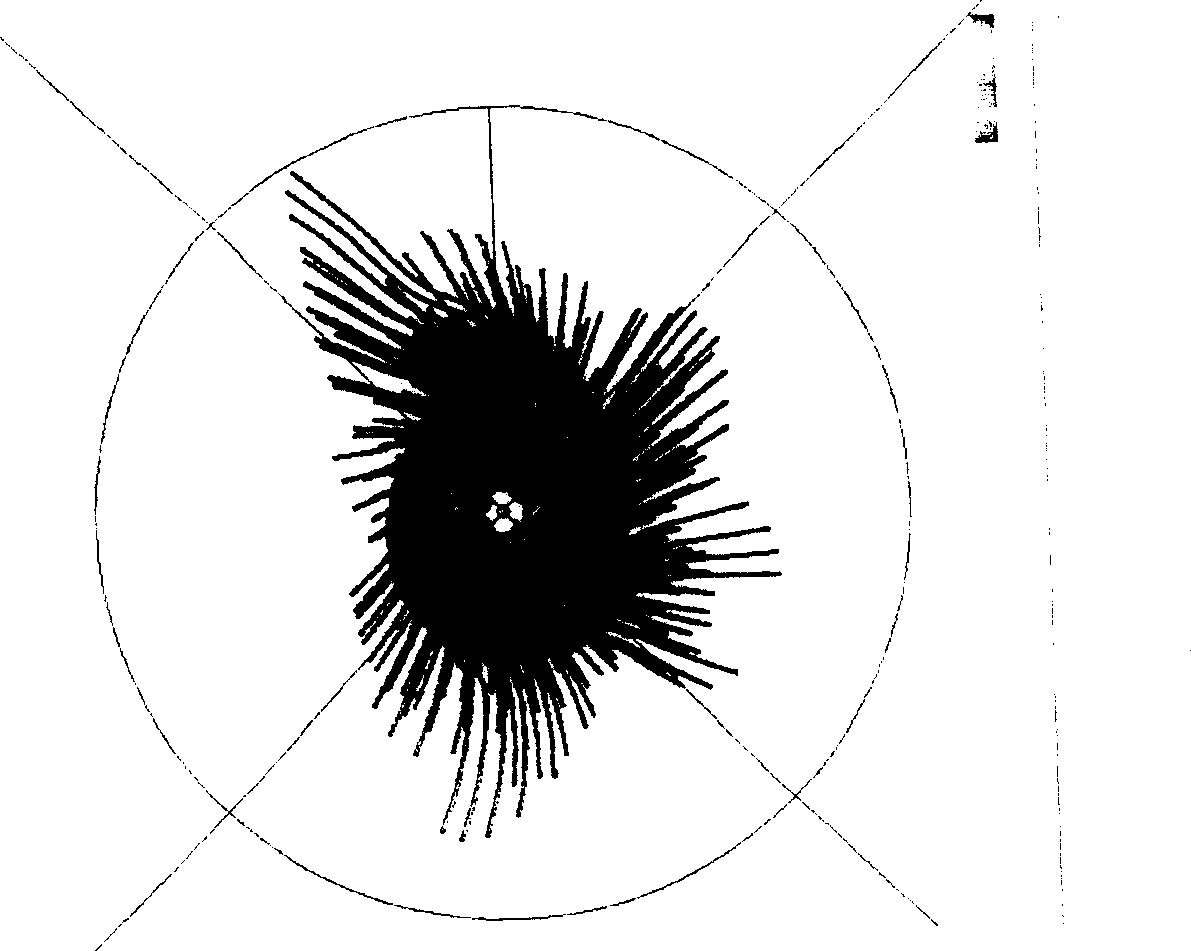

Central vortex column flash smelting process

InactiveCN1528926AReduce washoutReduce corrosionRotary drum furnacesCrucible furnacesSmelting processNuclear engineering

The invention discloses a kind of centre swirl flash quick smelting process. The process sprays the dried powder materials and oxygen into the reactor form the muzzle at the centre of the top, and forms the swirl pole high temperature reaction area along the shaft line of the reactor. There has a ring untouchable transition circle between the high temperature reaction area and the reactor wall in lengthwise. There has a ring untouchable transition circle that has particle grad, oxygen potential grad and temperature grad which weakened towards the reactor wall direction between the high temperature reaction area and the reactor wall. Because of the untouchable circle, it reduces the impact of high temperature, particles, and air, so it can protect the reactor wall.

Owner:CHINA NERIN ENG

Method for preparing iron from iron-containing slag charge by employing bath smelting and melt restoring

ActiveCN104278125AEasy drying and dehydration processMeet emptying requirementsProcess efficiency improvementInorganic ChemicalSulfur

The invention relates to a method for preparing iron from iron-containing slag charge by employing bath smelting and melt restoring, and belongs to the technical field of metallurgy. The method comprises the following steps: in a bath smelting furnace, heating iron-containing slag charge, in which the mass percent content of iron is lower than 50% and the mass percent content of sulphur is 0.07%-15%, to over 1100 DEG C in a low oxidative atmosphere to obtain a desulfurization product; heating to 1350-1450 DEG C, simultaneously adding a slag-making material and lastingly introducing an oxygen-enriched gas, and stopping introducing of the oxygen-enriched gas until the desulfurization product and slag-making material are completely co-molten; obtaining oxide melt and then adding a reducing agent; and restoring at 1450-1550 DEG C, so as to obtain cast iron of which the mass percent content of sulphur is smaller than or equal to 0.07%. The method is strong in adaptive capacity, and convenient for industrial popularization, and low-iron and high-sulphur slag charge generated in metallurgical and inorganic chemical industries is effectively recovered and utilized.

Owner:CENT SOUTH UNIV

Inspection hole structure for flash-smelting furnace

ActiveUS20090085263A1Growth inhibitionEasy to peelFurnace componentsBlast furnace detailsEngineeringFlash smelting

Owner:PAN PACIFIC COPPER CO LTD

Method for utilizing nickel flash smelting water-quenched slag

InactiveCN103114198AAvoid negative effectsChange grain structureProcess efficiency improvementCokeFlash smelting

The invention relates to a method for utilizing nickel flash smelting water-quenched slag. The method comprises the following steps of: sequentially preparing materials, mixing and sintering, and is characterized by the following steps: performing high-pressure rolling preprocessing on the nickel flash smelting water-quenched slag, preparing and mixing with other sintering feed, sintering and producing sintered ore. The method is characterized by comprising the following steps: I, performing high-pressure rolling preprocessing on the nickel flash smelting water-quenched slag, so that the ratio of -0.074mm is over 40 percent; II, the specific formula during material preparation comprises 5-15 parts of nickel flash smelting water-quenched slag, 10-40 parts of Australia ore powder, 10-40 parts of Shanxi Daixian ore powder, 10-20 parts of blast furnace ore return powder, 2-6 parts of limestone flour, 5-10 parts of dolomite dust, 3-9 parts of lime and 4-10 parts of coke powder; III, uniformly mixing through a two-section mixer, adding water, thus obtaining a mixture; and IV sintering. According to the sintered ore manufactured by the method, the nickel flash smelting water-quenched slag can be highly efficiently utilized.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

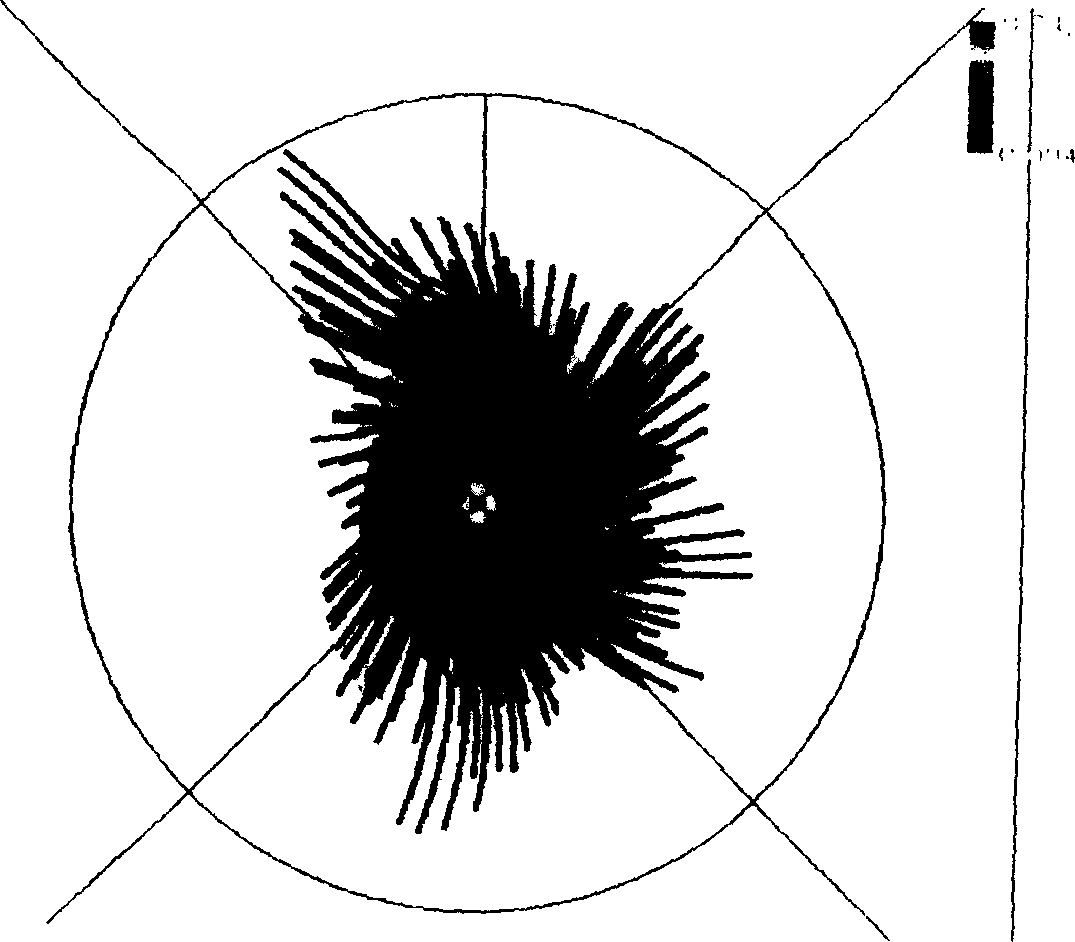

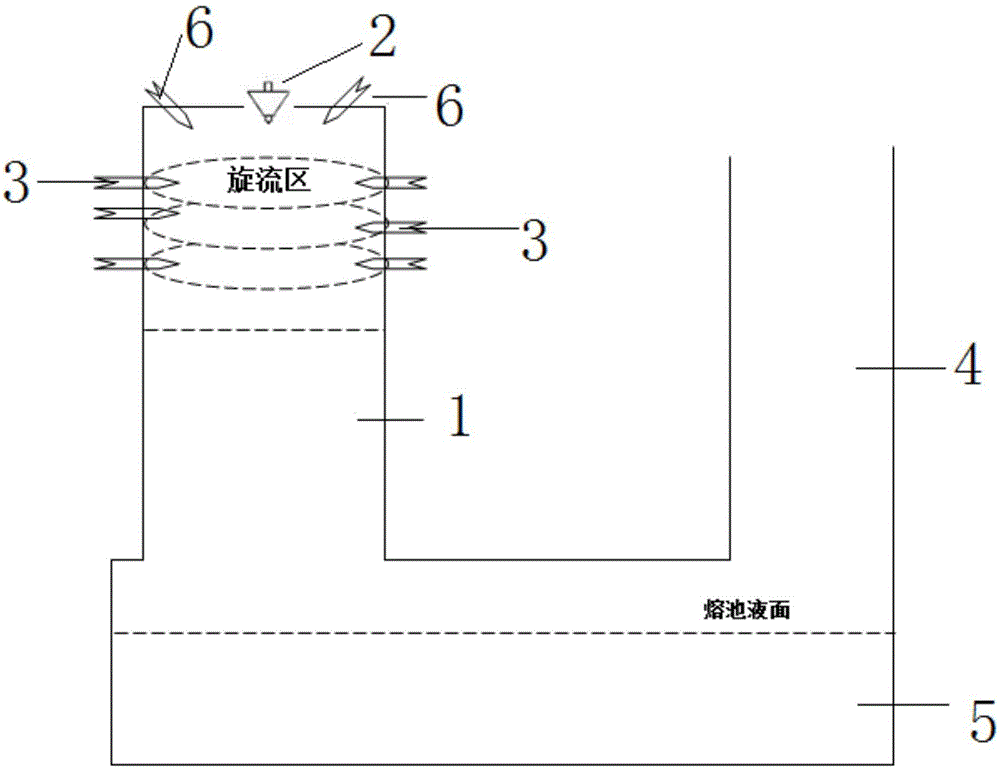

Swirling flow flash smelting process

The invention provides a swirling flow flash smelting process. The process comprises the following steps that (1) raw materials are prepared, and raw ores and fluxing agents are crushed and dried; (2) swirling flow is manufactured, an airflow guide-in device arranged on the sidewall of a reaction tower of a flash furnace is used for jetting reactant gas into the flash furnace at a high speed and brings heat in, a swirling flow area is formed in the reaction tower, and a high-temperature environment of 1000-1450 DEG C is formed in the reaction tower; (3) materials are charged; and (4) swirling flow smelting is carried out. Through the swirling flow flash smelting process provided by the invention, on one hand, the dropping track of ore powder can be lengthened, and the ore powder can make more contact with the reactant gas, so that the chemical reaction efficiency of the ore powder and the reactant gas in the space of the reaction tower is improved, the smelting efficiency of the ore powder is improved, and the utilization rate of the reactant gas is increased; and on the other hand, the dispersion effect of the ore powder can be optimized, the ore powder is orderly distributed from the center of the reaction tower to the edge according to the sizes of particles, and the situation that the materials are stacked in the center of the flash furnace is avoided.

Owner:TIANJIN FLASH IRONMAKING TECH CO LTD

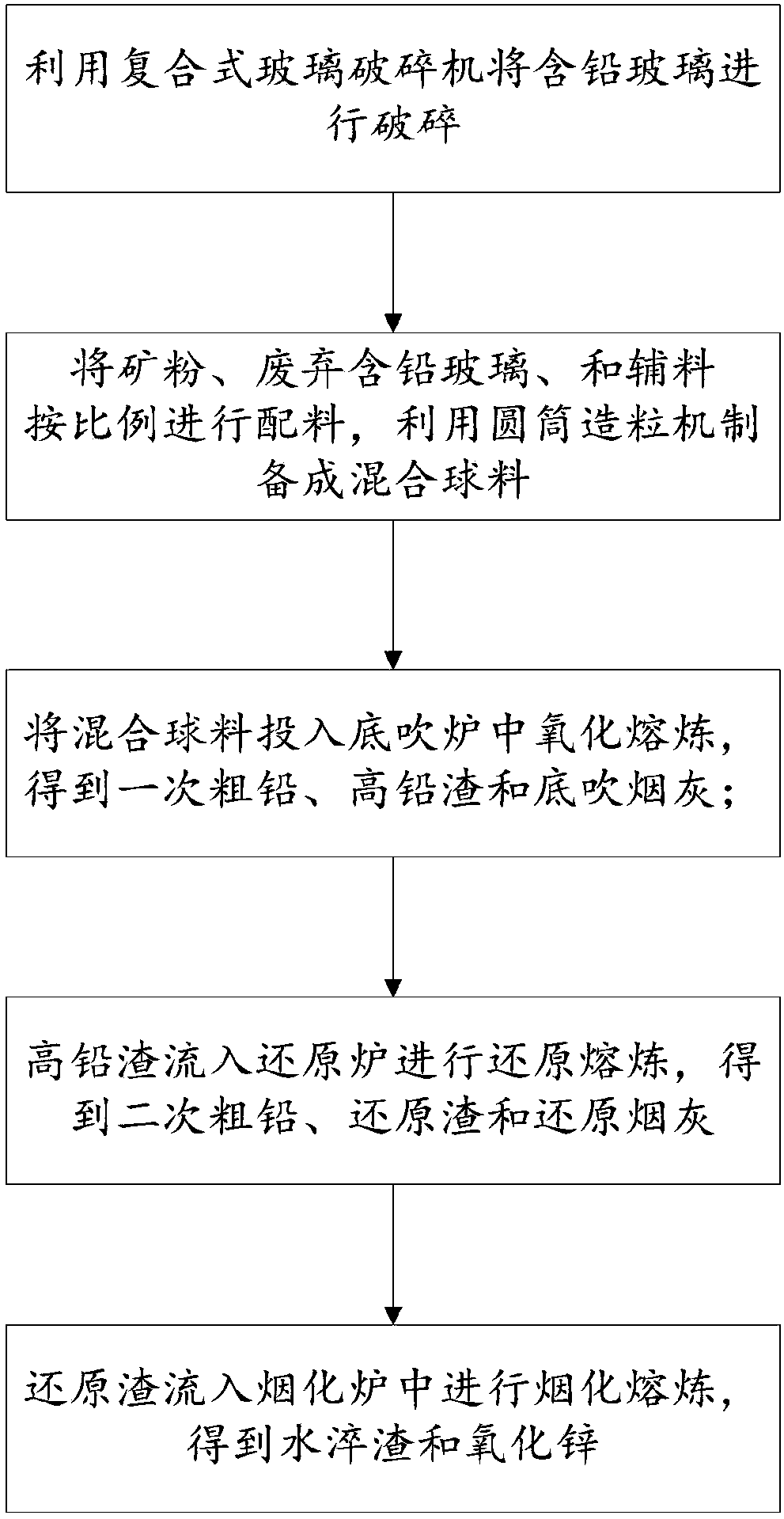

Method for coordinated disposal of waste lead-containing glass through lead smelting

InactiveCN108149019AAvoid wastingSolve pollutionProcess efficiency improvementLead smeltingFlash smelting

The invention discloses a method for coordinated disposal of waste lead-containing glass through lead smelting. The method includes the following steps of pretreatment, burdening, oxidizing smelting,reducing smelting and fuming smelting, wherein during pretreatment, a composite glass breaker is used for breaking the lead-containing glass; during burdening, ore powder, auxiliary materials and thewaste lead-containing glass are matched according to the mass proportion of 80-95: 3-15: 2-5, and are prepared into a mixed ball material through a cylinder granulator, and according to slag type control, FeO / SiO2=1.5-2.2, CaO / SiO2= 0.4-1.0, FeO / ZnO=1.1-1.3, S is controlled 15-18% or so, and the silicate degree is 0.8 or so; during oxidizing smelting, the mixed ball material is thrown into a bottom blowing furnace to be subjected to oxidizing smelting, and primary wet lead, high-lead slag and bottom blowing soot are obtained; during reducing smelting, the high-lead slag flows into a reducing furnace to be subjected to reducing smelting, and secondary wet lead, reduced slag and reduced soot are obtained; and during fuming smelting, the reduced slag flows into a fuming furnace to be subjected to fuming smelting, and water quenched slag and zinc oxide are obtained. The method for coordinated disposal of the waste lead-containing glass through lead smelting avoids waste of lead resources and solves the heavy metal pollution problem.

Owner:岷山环能高科股份公司

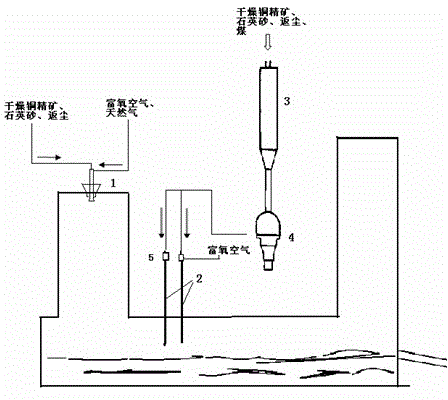

Method for composite smelting of copper concentrate flash-molten bath and outokumpu flash furnace

InactiveCN102876902AIncrease production capacityLow copperRotary drum furnacesCrucible furnacesMelting tankMolten bath

The invention discloses a method for composite smelting of a copper concentrate flash-molten bath and an outokumpu flash furnace. The method for composite smelting comprises the following steps: (1) dried copper concentrate, quartz sand, return dust, oxygen-enriched air and natural gas are injected into a reaction tower of the outokumpu flash furnace for flash smelting through a concentrate nozzle and a fuel nozzle, and then enter a sedimentation tank of the outokumpu flash furnace; (2) copper matte and slag are further generated in the sedimentation tank, and clarification separation is carried out; the slag on a melt is discharged out of the sedimentation tank through an overflow port in a sedimentation wall, so that the flash smelting is finished; and solid reducing agents are sprayed to the surface of the melt at high velocity through air or the oxygen-enriched air. By adopting the method, the yield of the outokumpu flash furnace is greatly improved, the clarification separation from the copper matte is accelerated, and the copper which is contained in the slag is reduced.

Owner:TONGLING NON FERROUS METAL GROUP CORP

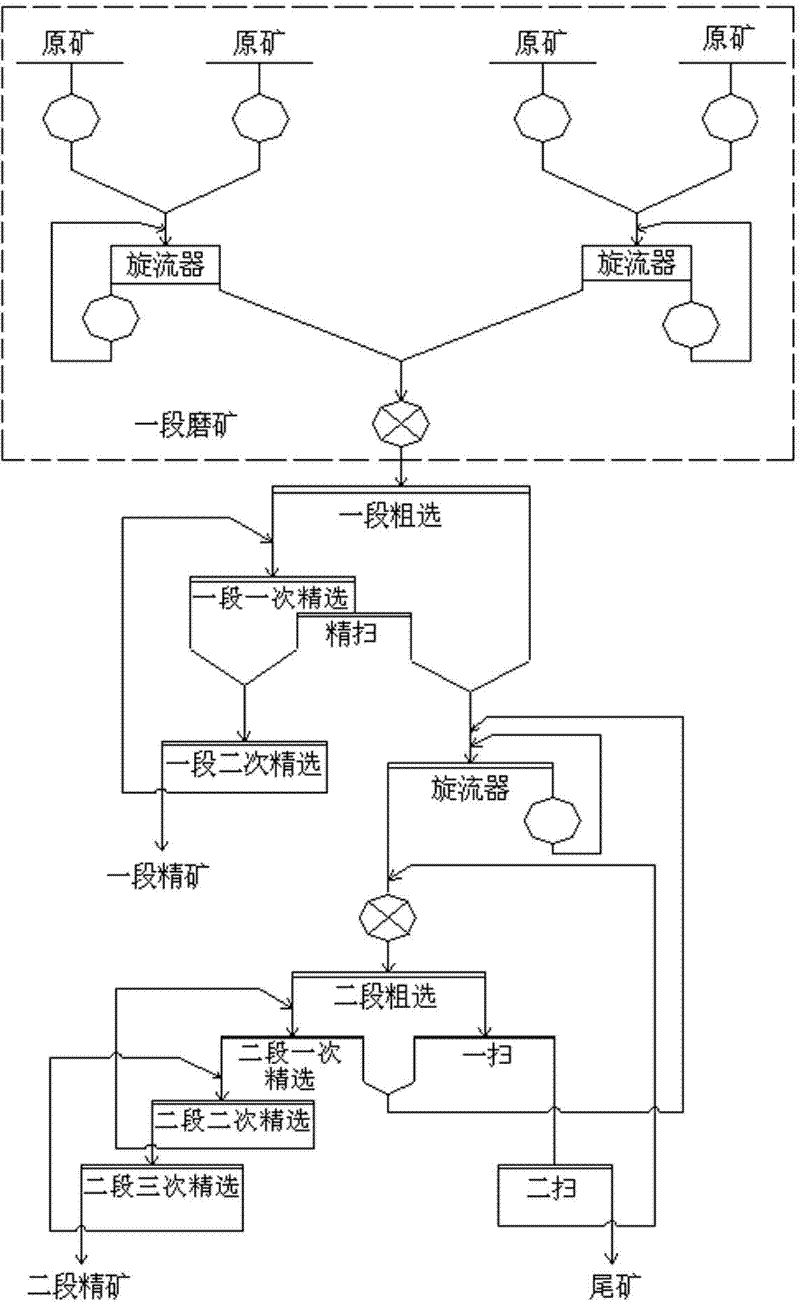

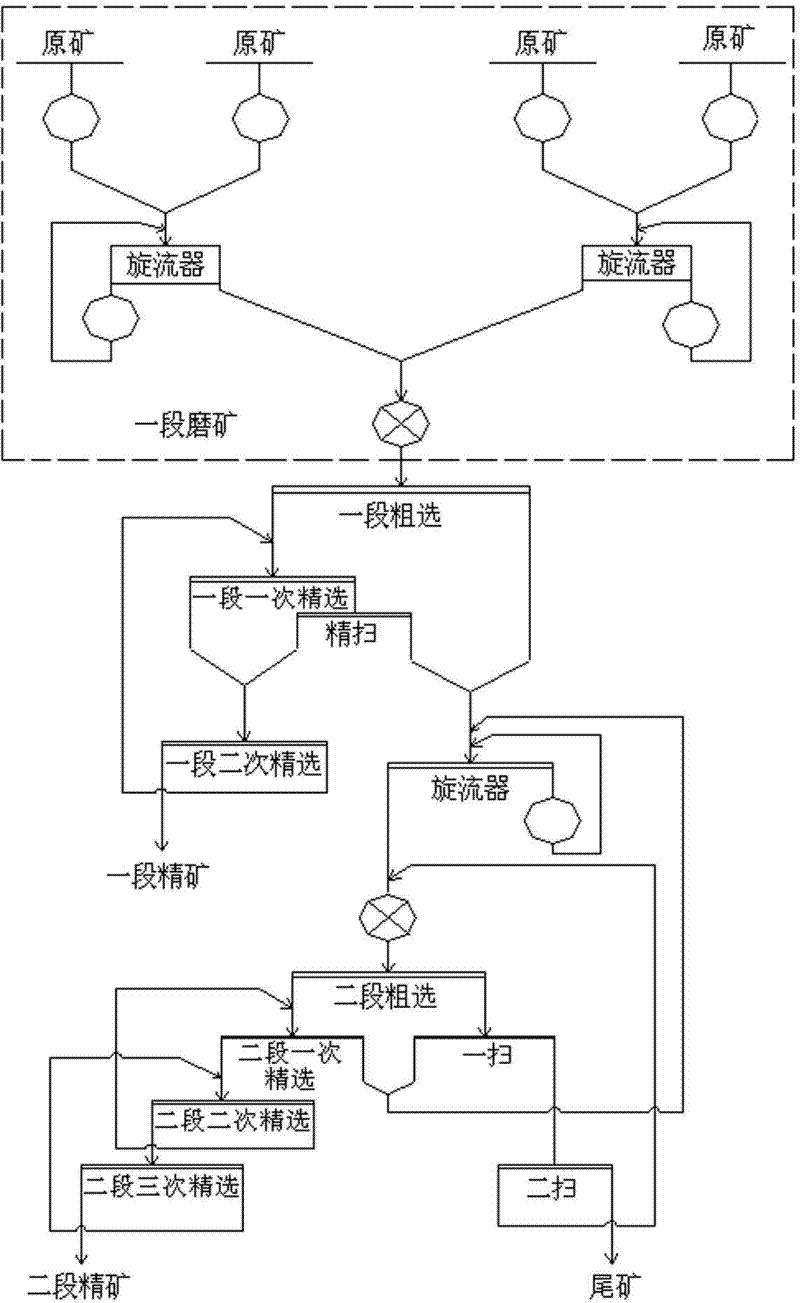

Flotation method for reducing content of magnesium oxide in copper-nickel concentrate

ActiveCN102441495AMeet the requirements of Express Selection and Early HarvestGuaranteed gradeFlotationFlash smeltingTailings

The invention discloses a flotation method for reducing the content of magnesium oxide in copper-nickel concentrate. The flotation method comprises the following steps: raw ore is ground at the first stage, primary roughing concentrate is treated through first-stage once cleaning, and first-stage cleaning tailings are scavenged; first-stage once cleaning concentrate and scavenged concentrate are treated through first-stage twice cleaning, and first-stage twice cleaning tailings are treated through first-stage once cleaning; first-stage twice cleaning concentrate is dewatered; first-stage roughing tailings and scavenged tailings are ground at the second stage, second-stage roughing tailings are treated through once scavenging, second-stage roughing concentrate is treated through second-stage once cleaning, and first-stage scavenged concentrate and second-stage once cleaning tailings are ground at the second stage; once scavenged tailings are treated through twice scavenging, and twice scavenged concentrate is treated through second-stage roughing; second-stage once cleaning tailings are treated through second-stage twice cleaning; second-stage twice cleaning tailings are treated through second-stage once cleaning; and second-stage twice cleaning concentrate is treated through second-stage third-time cleaning, second-stage third-time cleaning tailings are treated through second-stage twice cleaning, and the second-stage third-time cleaning tailings are dewatered. The flotation method adopts the mode of staged grinding and staged cleaning, and considers both the nickel grade and the nickel recovery rate in the copper-nickel concentrate, and provides acceptable material for flash smelting.

Owner:JINCHUAN GROUP LIMITED

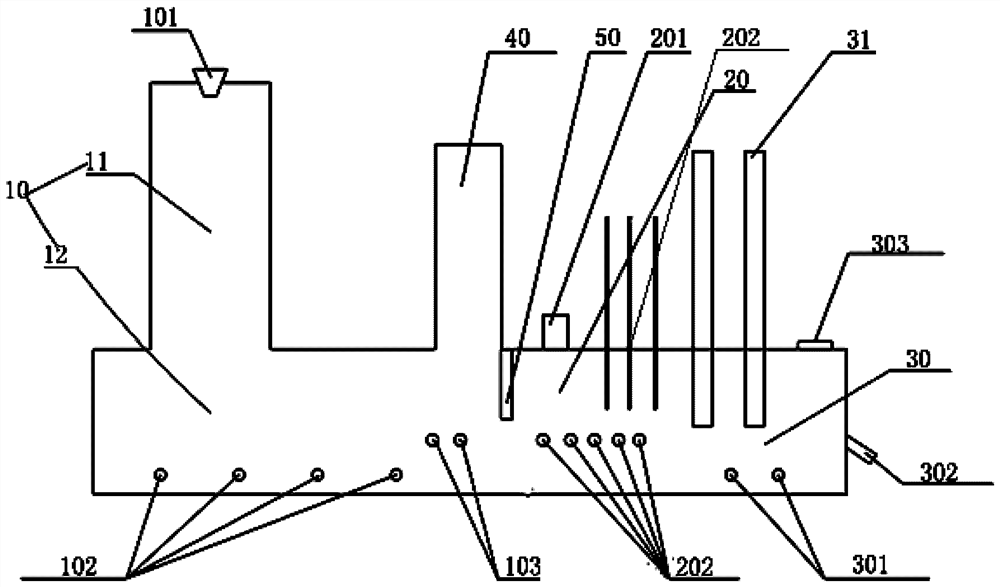

Nickel smelting device and nickel smelting method

The invention provides a nickel smelting device and a nickel smelting method. The nickel smelting device is integrated equipment and comprises a smelting area, a dilution area and a settling area which horizontally and sequentially communicate with one another, wherein the smelting area comprises a flash smelting reaction tower and a settling pond which is located below the flash smelting reactiontower and directly communicates with the flash smelting reaction tower; the flash smelting reaction tower is used for carrying out flash smelting on a nickel smelting raw material under the action offirst oxygen-enriched air to produce nickel matte containing 20-75wt% of nickel, smelting slag and smelting smoke; and the dilution area communicates with the settling pond, is provided with a plurality of first spray holes and is further provided with a plurality of first spray guns corresponding to the first spray holes one to one. The nickel smelting device can simultaneously have the excellent properties in the aspects of being short in process, good in dilution effect, low in energy consumption, free of adding of a large number of vulcanizing agents and the like in the nickel smelting process.

Owner:CHINA ENFI ENGINEERING CORPORATION

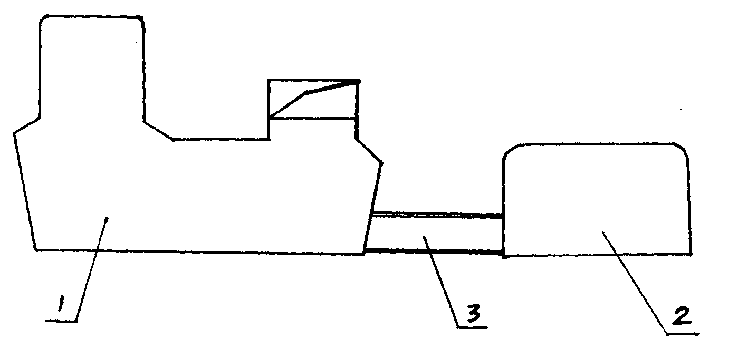

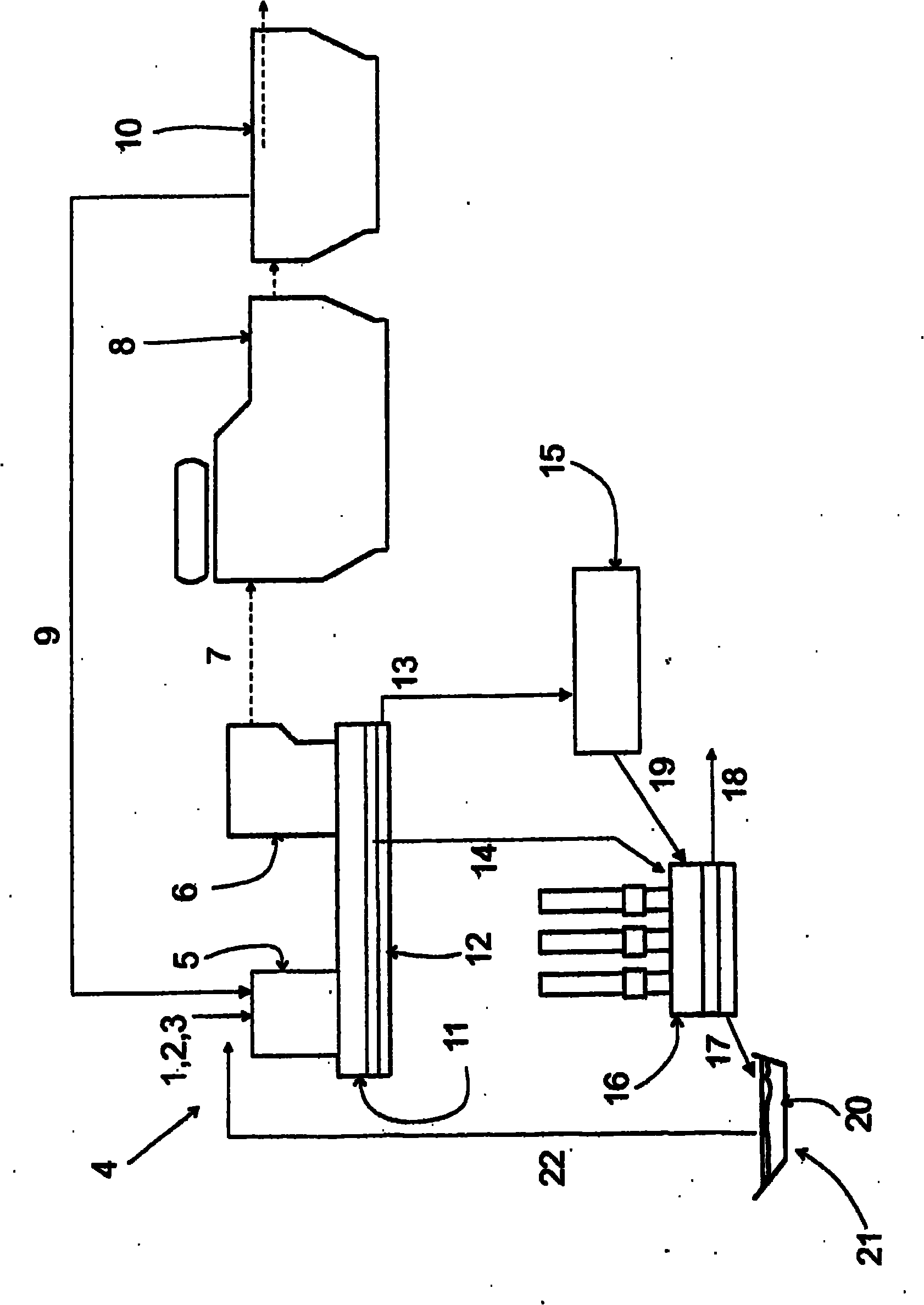

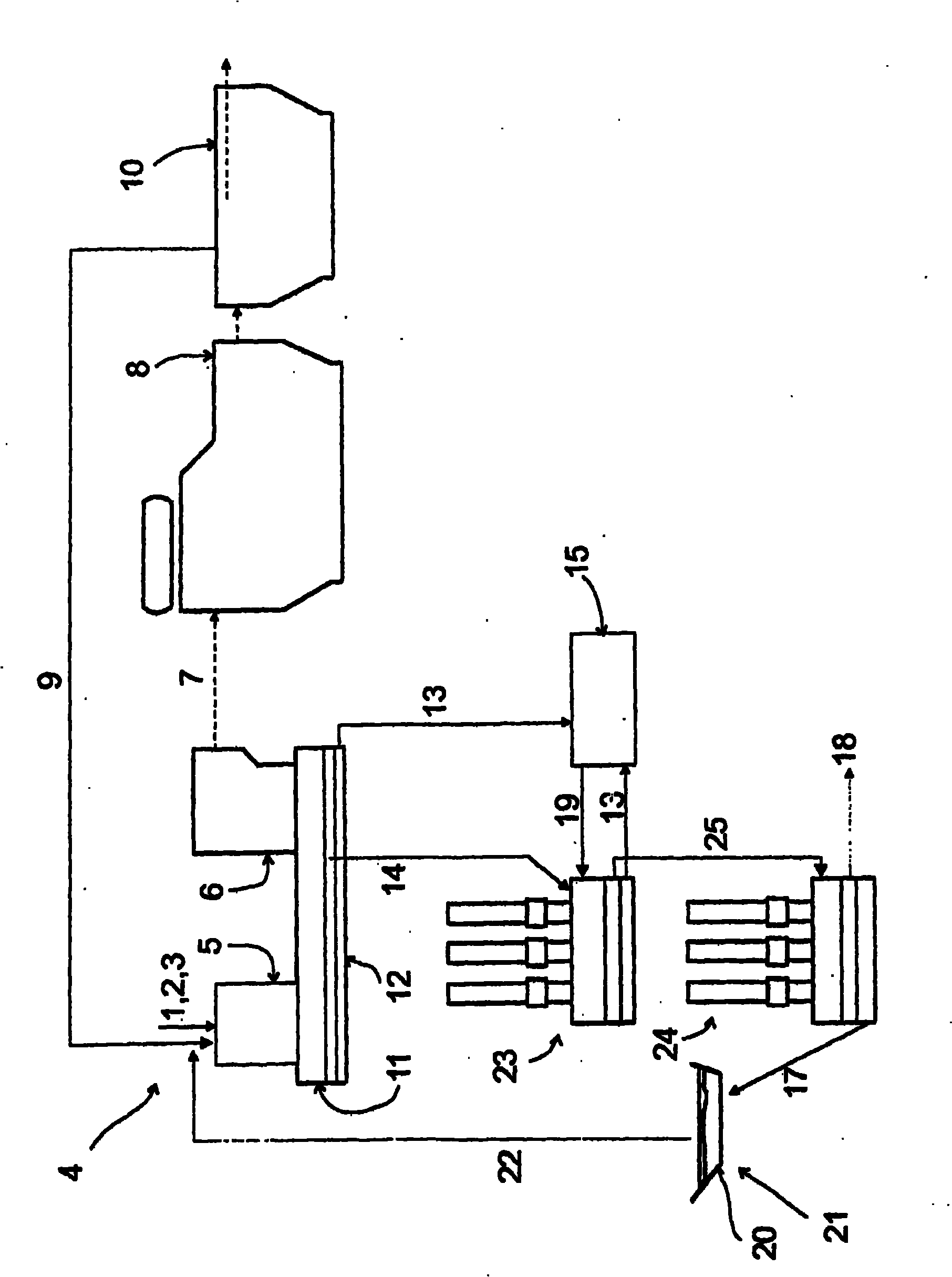

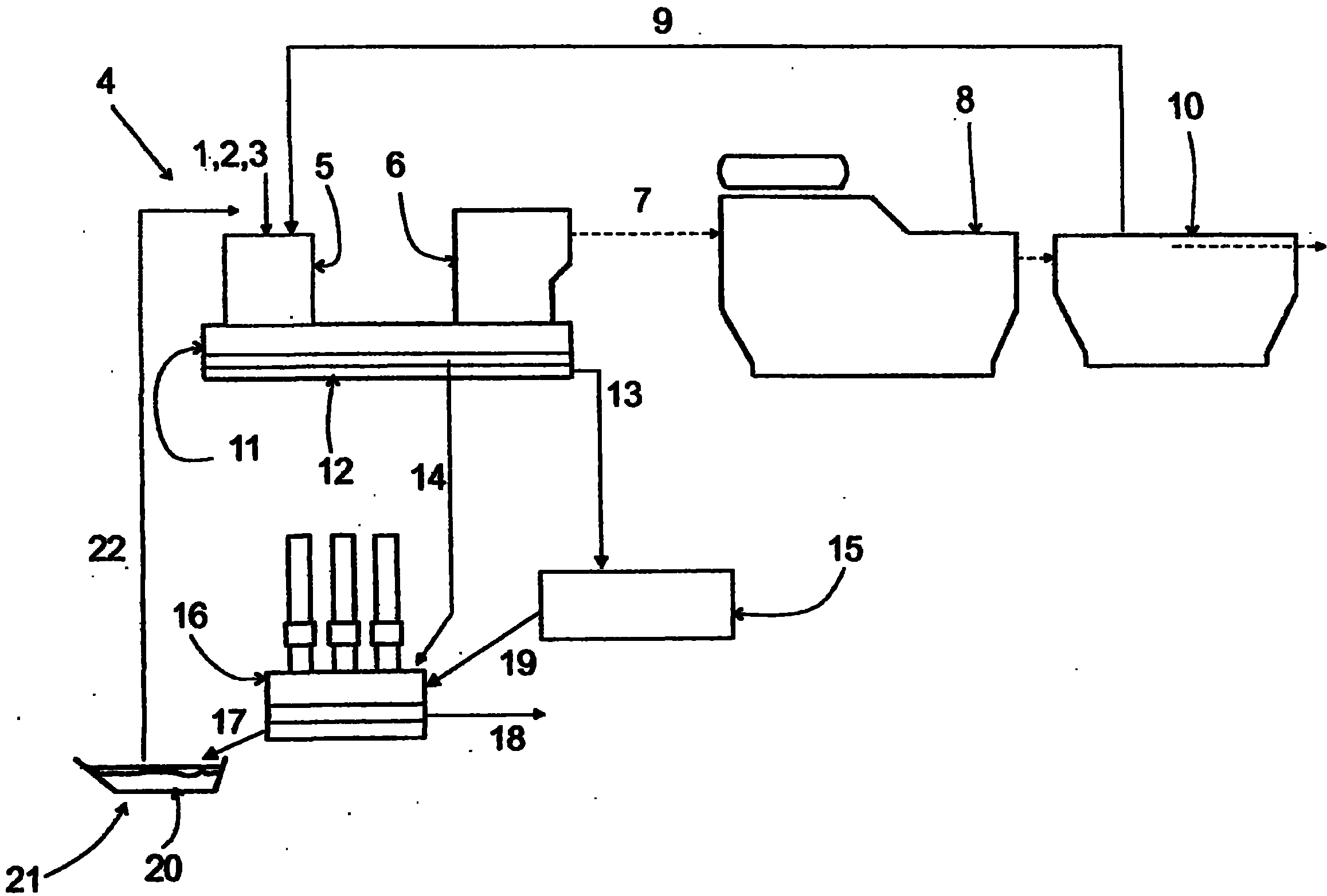

Method for refining copper concentrate

The invention relates to a method for refining copper concentrate. In the method, copper concentrate (1), flux (2) and reaction gas (3) are fed together into the reaction shaft (5) of a suspension smelting furnace (4), for instance to the reaction shaft (5) of a flash smelting furnace, and in the suspension smelting furnace (4), there are created separate phases, i.e. blister copper (13) and slag (14). In the method, slag from a suspension smelting furnace (14) is conducted into an electric furnace (16), and the slag from the suspension smelting furnace(14) is treated in the electric furnace (16) with a reduction agent, so that in the electric furnace (16), there are created separate phases, i.e. bottom metal (17) and waste slag (18); the electric furnace bottom metal (17) is removed from the electric furnace (16), the electric furnace bottom metal (17) is granulated, and there is obtained granulated electric furnace bottom metal (22); and the granulated electric furnace bottom metal (22) is fed to the reaction shaft (5) of a suspension smelting furnace (4).

Owner:METSO OUTOTEC (FINLAND) OY

Concentrate burner

InactiveUS8206643B2Good body shapeImprove flame stabilityTuyeresBell-and-hopper arrangementInlet channelCombustor

A concentrate burner for feeding a pulverous concentrate mixture and reaction gas into a reaction shaft of a flash smelting furnace. The concentrate burner includes a feeder pipe for feeding a concentrate mixture into the reaction shaft and a dispersing device for directing dispersing gas to the concentrate mixture flowing around the dispersing device. For feeding the reaction gas into the reaction shaft, a gas supply device is provided which includes a reaction gas chamber for mixing the reaction gas with the concentrate mixture, and for directing the concentrate mixture to the side by the dispersing gas. The reaction gas chamber includes a turbulent flow chamber, to which an inlet channel opens tangentially for directing the reaction gas to the reaction gas chamber in a tangential direction. In the inlet channel, an adjusting member is arranged for adjusting the cross-sectional area of the reaction gas flow.

Owner:OUTOTEC OYJ

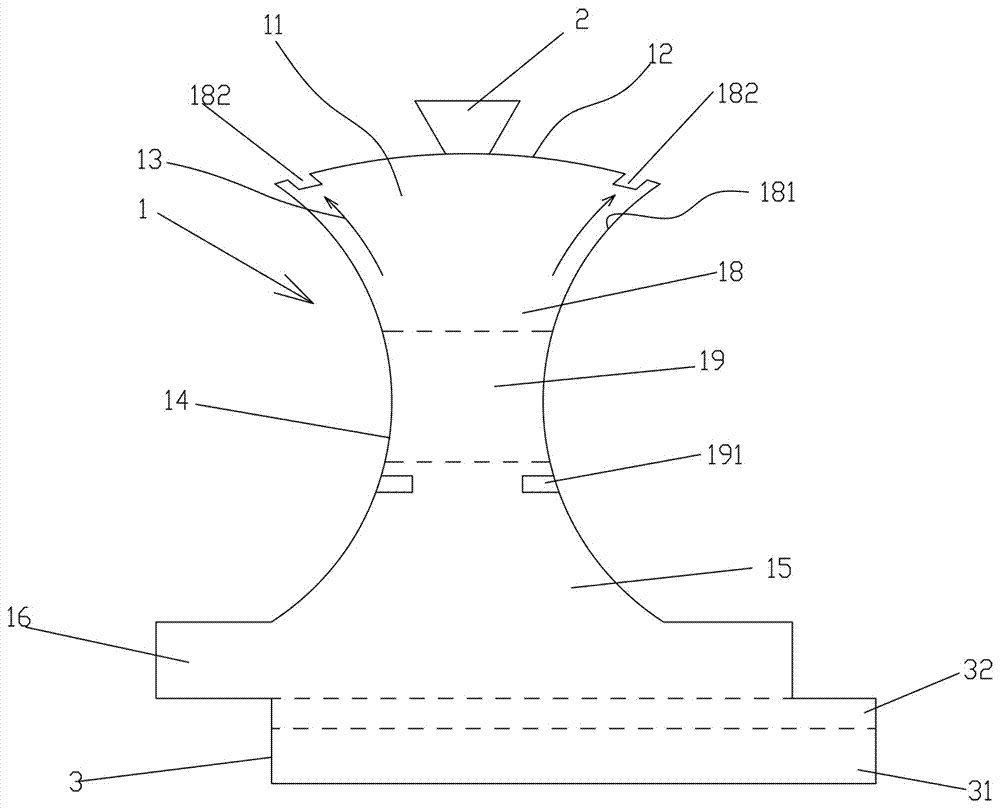

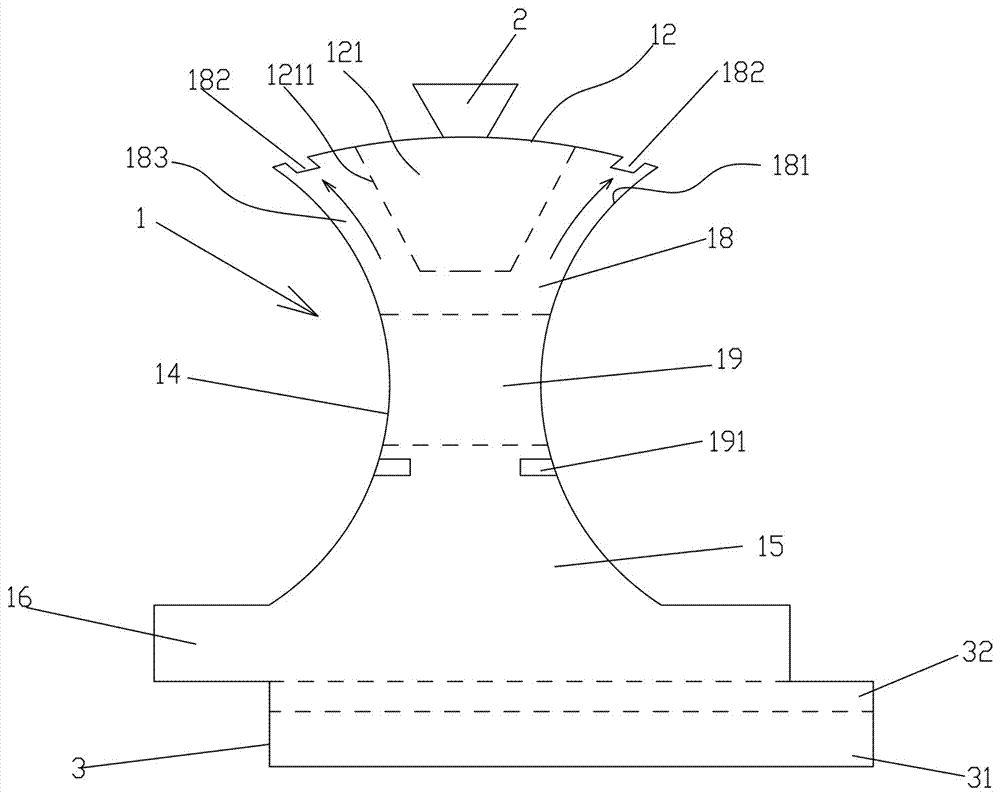

Novel flash iron smelting method and iron smelting furnace thereof

InactiveCN107881275ACompact structureAchieve a complete responseFluidised-bed furnacesReaction temperatureOxygen

The invention discloses a novel flash iron smelting method and an iron smelting furnace thereof. The iron smelting furnace comprises a reaction tower, a furnace charge nozzle and a molten pool, a reaction space is defined in the reaction tower, and the furnace charge nozzle is formed in the top of the reaction tower; the molten pool is arranged at the lower part of the reaction tower, and a towerbody of the reaction tower is of a single-sheet hyperboloid structure generated through a hyperbolic curve rotating around a main axis of the reaction tower; and the lower part of the single-sheet hyperboloid structure is provided with an inlet of fuel and oxygen-enriched gas, the fuel and the oxygen-enriched gas enter the lower part of the reaction space from the inlet, and high-valence iron oxides in iron ore are partially reduced to low-valence iron oxides and a part of metal iron, and the low-valence iron oxides and the part of metal iron fall into the molten pool. The iron smelting furnace has the advantages of compact structure and controllable reaction time and reaction temperature.

Owner:李淼

Central vortex column flash smelting process

InactiveCN1246486CReduce washoutReduce corrosionRotary drum furnacesCrucible furnacesSmelting processNuclear engineering

The invention discloses a kind of centre swirl flash quick smelting process. The process sprays the dried powder materials and oxygen into the reactor form the muzzle at the centre of the top, and forms the swirl pole high temperature reaction area along the shaft line of the reactor. There has a ring untouchable transition circle between the high temperature reaction area and the reactor wall in lengthwise. There has a ring untouchable transition circle that has particle grad, oxygen potential grad and temperature grad which weakened towards the reactor wall direction between the high temperature reaction area and the reactor wall. Because of the untouchable circle, it reduces the impact of high temperature, particles, and air, so it can protect the reactor wall.

Owner:CHINA NERIN ENG CO LTD

Method for comprehensively utilizing calcium and sulfur resources of industrial gypsum

ActiveCN111285390AIncrease the concentration of sulfur dioxideEfficient use ofCalcium/strontium/barium sulfatesMagnesium/calcium/strontium/barium sulfides/polysulfidesNonferrous metalSmelting process

The invention discloses a method for comprehensively utilizing calcium and sulfur resources of industrial gypsum, and belongs to the technical field of comprehensive utilization of solid waste resources of industrial gypsum. The method is based on a calcium sulfate pyrolytic reaction mechanism and copper and lead nonferrous metal smelting industrial production conditions; industrial gypsum low-temperature semi-reduction is provided to generate a mixture of CaSO4 and CaS; the prepared semi-reduction product is applied to the flash smelting process of non-ferrous metals such as copper and lead,achieving organic combination with a non-ferrous smelting process; sulfur dioxide generated by high-temperature pyrolysis of CaSO4 and CaS in the semi-reduction product can improve the concentration of sulfur dioxide in a smelting system, a sulfuric acid product is prepared, calcium oxide provides a slagging flux required by smelting, and efficient utilization of industrial gypsum sulfur-calcium resources is achieved. According to the method, the industrial gypsum is digested without generating secondary waste residues, and meanwhile, the calcium and sulfur resources can be fully and reasonably utilized.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Method for smelting of ore from Carlin-type gold deposit

The invention discloses a method for smelting of ore from a Carlin-type gold deposit, and relates to a method for smelting extraction of gold from a Carlin-type gold deposit. The method is characterized in that during smelting, ore from a Carlin-type gold deposit is added into a lead smelting raw material for smelting to form crude lead rich in gold and silver; and gold and silver are separated and recovered from the crude lead. The method for smelting of ore from a Carlin-type gold deposit comprises the following steps of mixing ore from a Carlin-type gold deposit and one or more of oxygen-rich lead flash smelting raw materials such as lead concentrate, residues from wet zinc smelting, lead-containing residues from wet copper smelting or lead precious metal system residues, and carrying out self-heating smelting oxidation and reduction treatment on the mixture to obtain waste residues and crude lead rich in gold and silver, wherein the waste residues are utilized for manufacture of cement and recovery rates of gold and silver are greater than 99.5%.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Overhaul method for semi-hot state of flash smelting furnace

ActiveCN102147192ASolve the problem of partial cold repairShorten the timeLinings repairFluidised-bed furnacesWater useMetallurgy

The invention discloses an overhaul method for semi-hot state of a flash smelting furnace, which comprises the following steps of: (1) manufacturing a water-cooled baffle; (2) cooling a furnace body and carrying out heat insulation to the furnace body; (3) dividing the flash smelting furnace and isolating by the water-cooled baffle; (4) cooling a cold repair area to room temperature, and cooling a hot-state area to 700 DEG C; (5) overhauling an erosion area in the cold repair area; and (6) sealing the flash smelting furnace after overhauling, naturally warming, lifting the isolating water-cooled baffle for warming, warming the whole furnace body to 800-850 DEG C and keeping constant temperature for 1-2 days after the cold repair area is warmed to 600-700 DEG C, then warming to the feed temperature and finally finishing overhauling. The overhaul method has the advantages that the maintenance cycle is shortened, the maintenance material is saved, the production is ensured, and the economic benefit is improved.

Owner:JINLONG COPPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com