Method for composite smelting of copper concentrate flash-molten bath and outokumpu flash furnace

A flash furnace and copper concentrate technology, which is applied in furnaces, electric furnaces, rotary drum furnaces, etc., can solve the problems of insufficient use of hearth area and low intensity of metallurgical process, so as to improve production capacity and reduce slag content Copper, the effect of improving properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

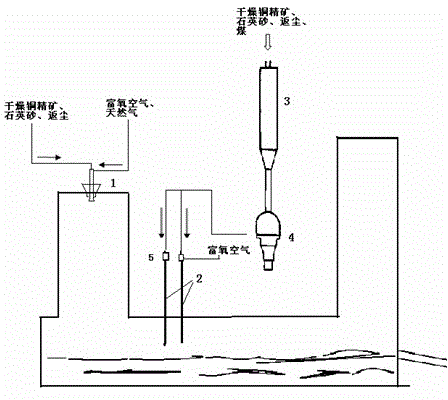

[0014] The flash-melting pool composite smelting method of copper concentrate in this embodiment, the smelting process of this embodiment is carried out in an Outokumpu flash furnace, and the Outokumpu flash furnace of this embodiment is as follows figure 1 As shown, the design of the furnace body of the reaction tower, the configuration of the metering and adding system of solid materials, the design of the concentrate nozzle, and the configuration of the fuel gun all remain unchanged from the original design of the flash smelting; the copper concentrate and dust returned by the reaction tower , flux and other solid materials and their processing capacity remain unchanged; the process control methods of heat balance and material balance remain unchanged. Install 6~10 air-material high-speed spray guns on the top of the sedimentation tank at the outlet of the reaction tower, and insert them into the sedimentation tank from the top of the sedimentation tank, 300~500mm away from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com