Flash smelting method for lead

A flash smelting and lead sulfide technology, applied in the field of non-ferrous metals, to achieve the effect of reducing the amount of high-temperature flue gas, large production capacity, and efficient utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

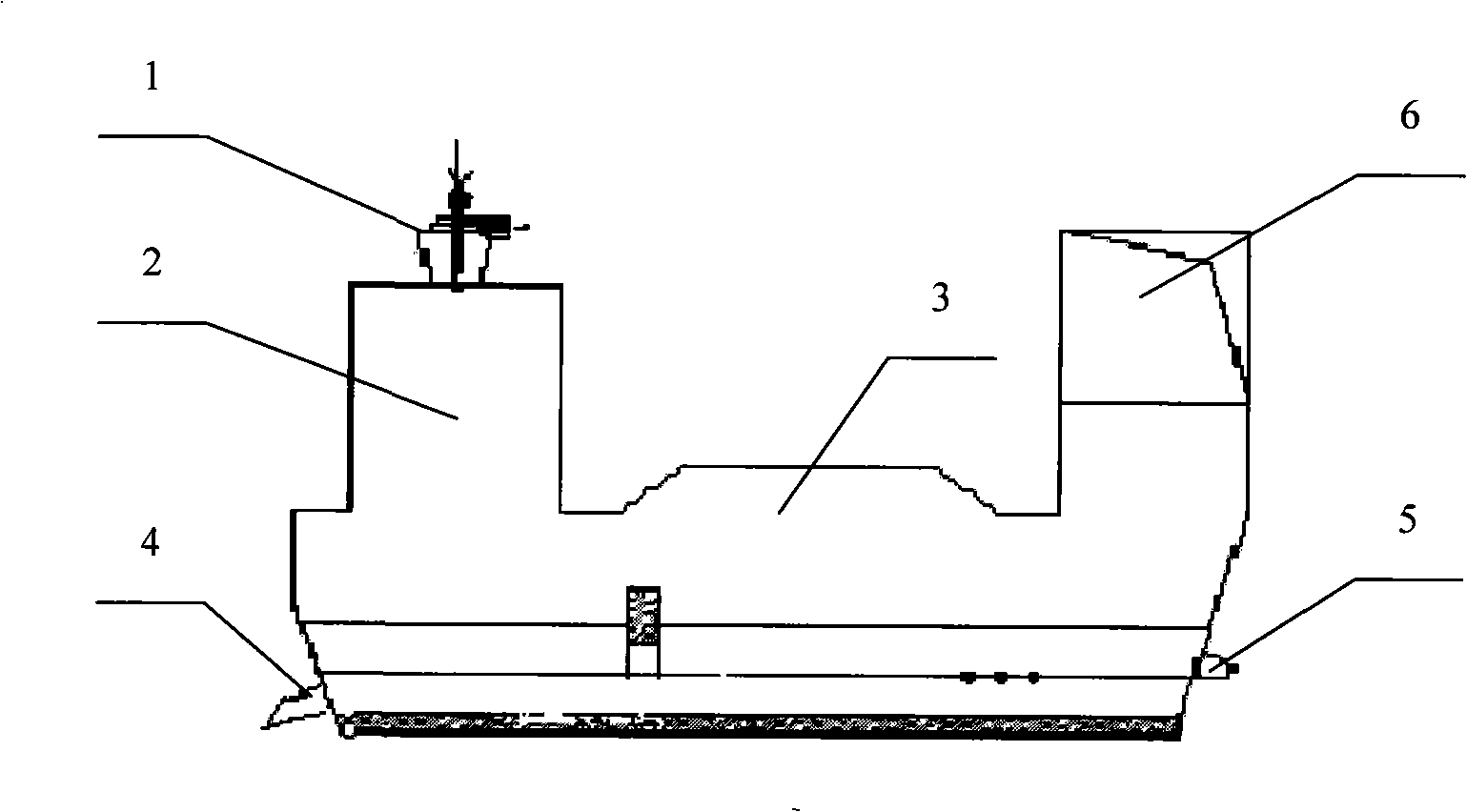

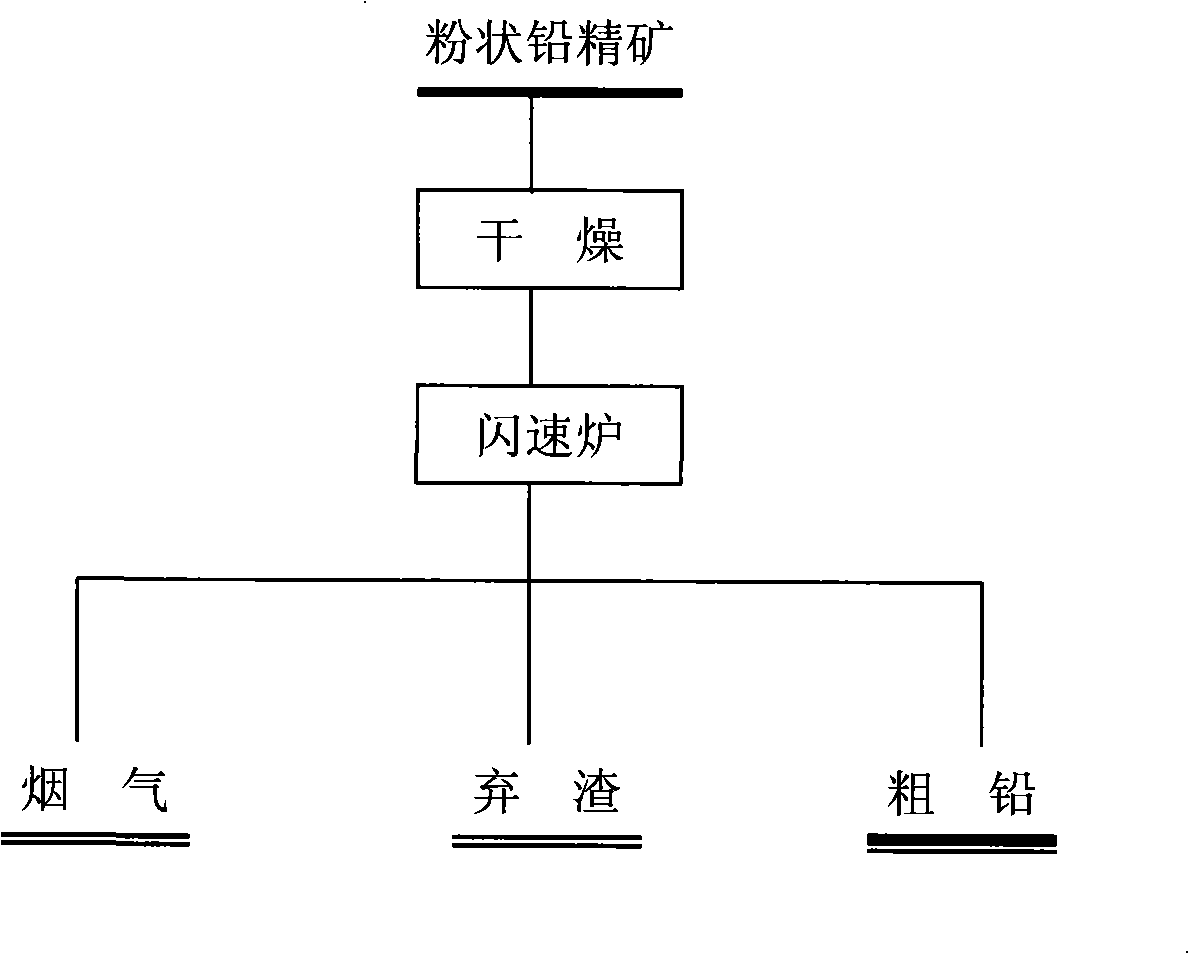

[0021] (1) Spray the powdered lead sulfide concentrate with 8% water content before drying and 0.3% water content after drying with oxygen containing 50% oxygen and 25°C air supply temperature into the space of a high-temperature reaction tower 2 through nozzle 1, forming In the floating state, the input amount of oxygen is controlled so that the oxidation rate of lead sulfide is 60%, the oxidation process of lead sulfide is completed, and the generated melt falls in the sedimentation tank 3 below the reaction tower 2;

[0022] (2) Through the interactive reaction and reduction reaction of lead oxide and lead sulfide, 98% of crude lead and slag are continuously generated; silver is enriched in crude lead, and the recovery rate of silver is 97%;

[0023] (3) crude lead and slag are respectively discharged from the lead outlet 4 and the slag outlet 5 after being clarified and stratified in the sedimentation tank 3, and the slag contains 4% lead and is discarded;

[0024] (4) The...

Embodiment 2

[0026] (1) Spray the powdered lead sulfide concentrate with 8% water content before drying and 0.3% water content after drying with 60% oxygen and 25°C air supply temperature into the space of a high-temperature reaction tower 2 through nozzle 1, forming In the floating state, the input amount of oxygen is controlled, so that the oxidation rate of lead sulfide is 80%, the oxidation process of lead sulfide is completed, and the generated melt falls in the sedimentation tank 3 below the reaction tower 2;

[0027] (2) Through the interactive reaction and reduction reaction of lead oxide and lead sulfide, 97% of crude lead and slag are continuously generated; silver is enriched in crude lead, and the recovery rate of silver is 97.5%;

[0028] (3) crude lead and slag are respectively discharged from the lead outlet 4 and the slag outlet 5 after being clarified and stratified in the sedimentation tank 3, the slag contains 25% lead, and after the slag is reduced by the blast furnace, ...

Embodiment 3

[0031] (1) Spray the powdered lead sulfide concentrate with 8% water content before drying and 0.3% water content after drying with 70% oxygen and 25°C air supply temperature into the space of a high-temperature reaction tower 2 through nozzle 1, forming In the floating state, the input amount of oxygen is controlled so that the oxidation rate of lead sulfide is 70%, the oxidation process of lead sulfide is completed, and the generated melt falls in the sedimentation tank 3 below the reaction tower 2;

[0032] (2) Through the interactive reaction and reduction reaction of lead oxide and lead sulfide, crude lead 97.5% and slag are continuously generated; silver is enriched in crude lead, and the recovery rate of silver is 96%;

[0033] (3) Crude lead and slag are respectively discharged from lead outlet 4 and slag outlet 5 after clarification and stratification in sedimentation tank 3. The slag contains 10% lead and is sent to beneficiation after slow cooling to obtain tailings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com