Intelligent integrated modelling approach based on operating condition judgment

A modeling method and predictive model technology, applied in the direction of instrumentation, adaptive control, control/regulation system, etc., can solve the problems of complex structure and operation of flash furnace, difficulty in detecting matte grade, high temperature in the furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

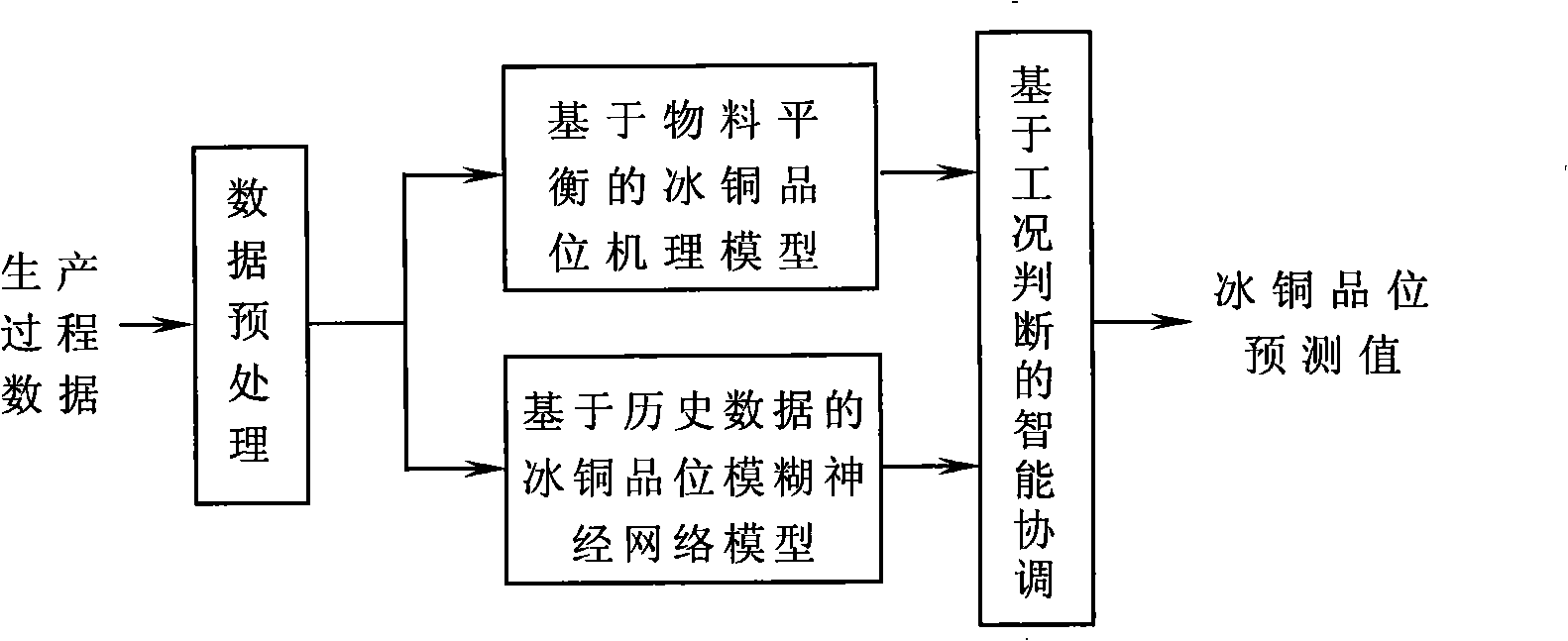

AI Technical Summary

Problems solved by technology

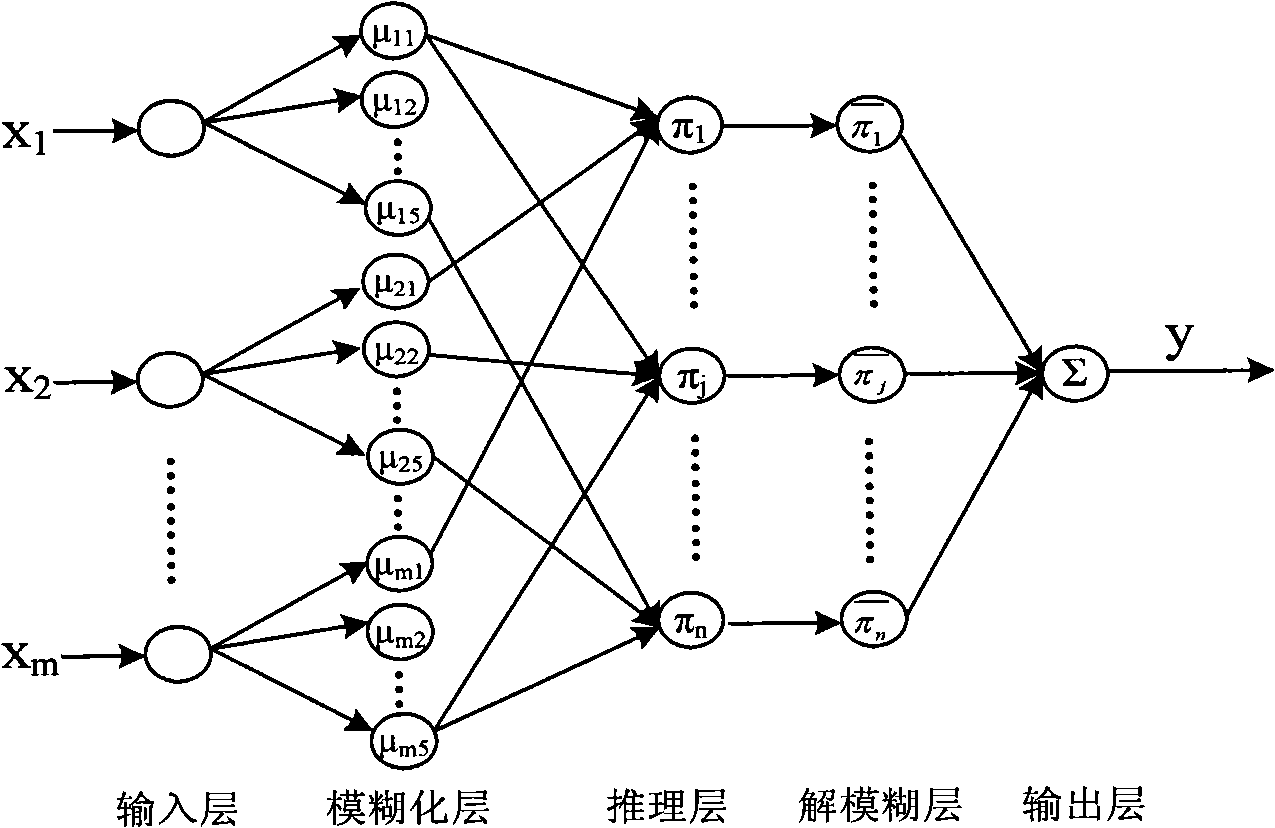

Method used

Image

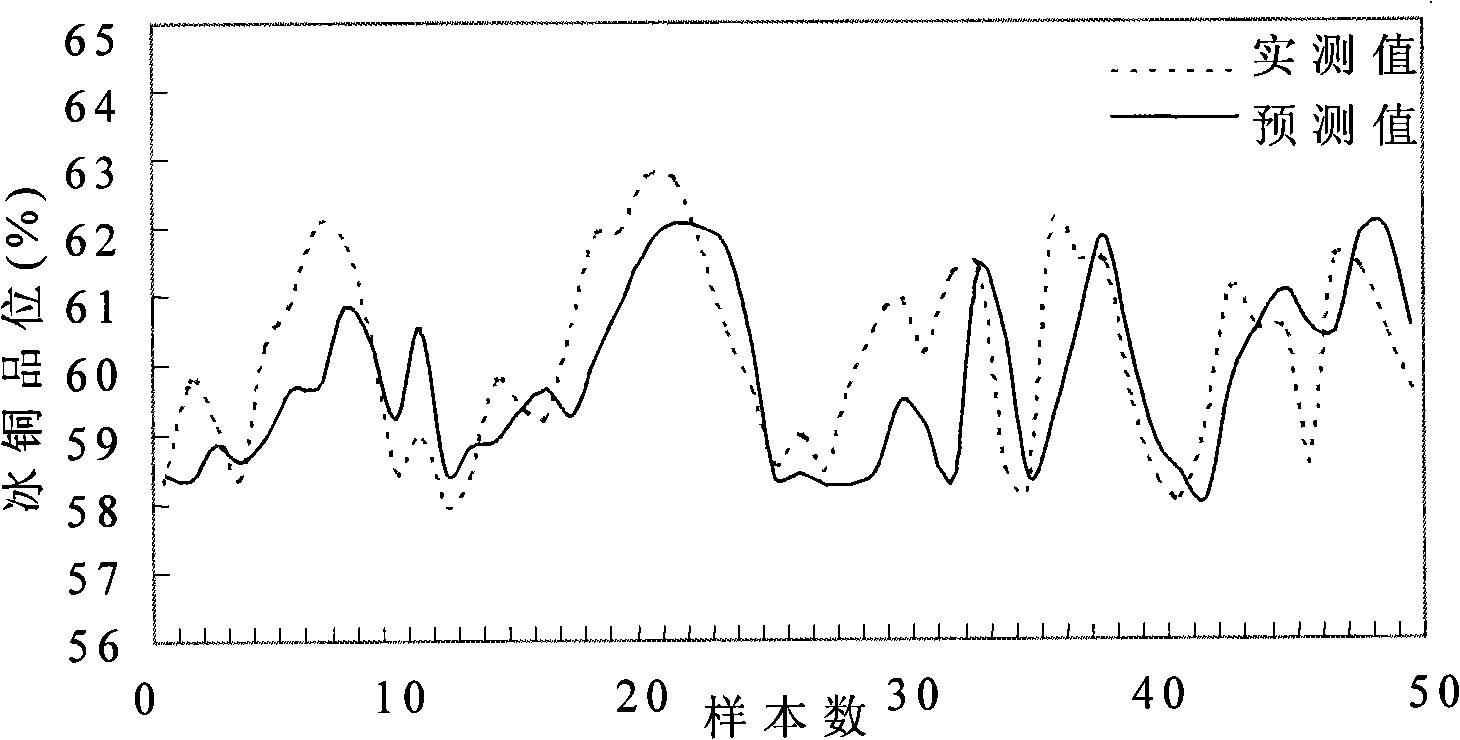

Examples

Embodiment 1

[0017] The specific steps of establishing the matte grade prediction model are as follows:

[0018] Step 1: Acquisition of relevant data

[0019] In order to predict the matte grade, it is necessary to select some data that has a great influence on the matte grade and can be obtained in real time as input, and calculate the matte grade through model calculation. Through the analysis of the process mechanism of the copper flash smelting process, it is known that the main factors affecting the grade of matte include the chemical composition of the materials entering the furnace, the air volume and oxygen volume during the smelting process.

[0020] Furnace feed materials include: concentrate, slag concentrate, indeterminate material, silicate ore, converter soot, converter boiler soot, dry soot, boiler soot, electric dust collector soot; its main components are iron, copper, sulfur, oxygen and di Silica, obtained by chemical analysis every four hours. In general, the compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com