Flash smelting technology for copper or nickel sulfide ore concentrate

A sulfide concentrate and flash smelting technology, applied in crucible furnaces, electric furnaces, rotary drum furnaces, etc., can solve the problems of limited energy consumption, pollution treatment capacity, etc., and achieve high efficiency, low investment, economical construction and operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

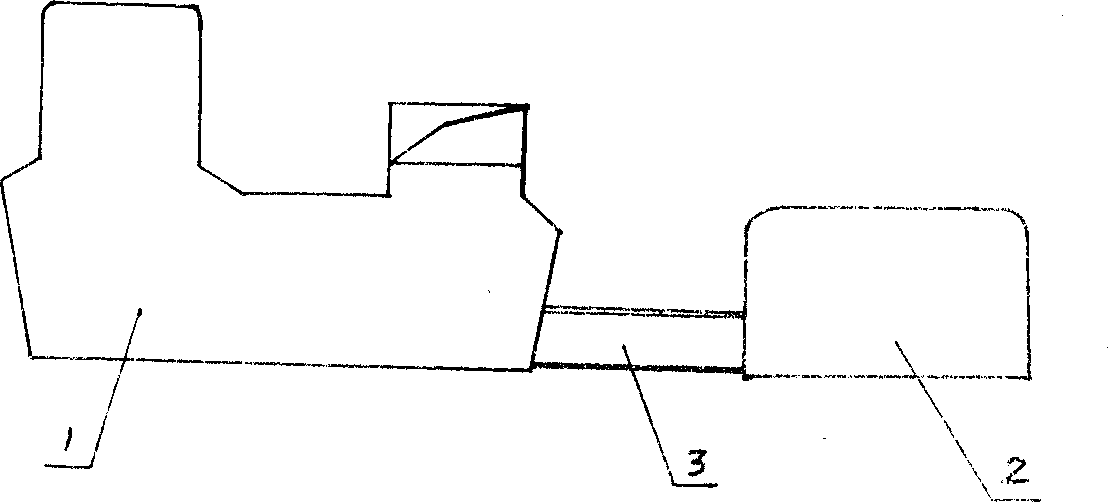

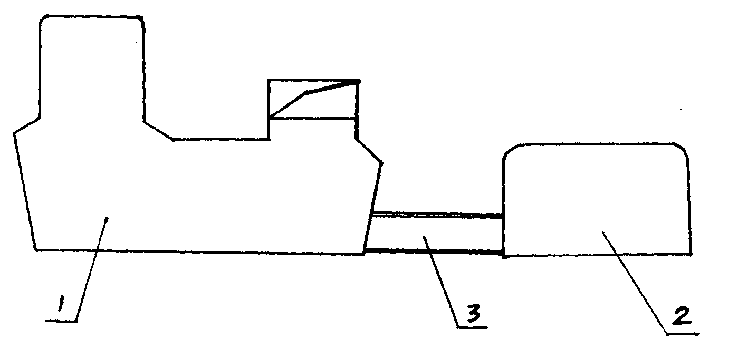

[0007] In the copper and nickel sulfide concentrate flash smelting metallurgical process of the present invention, a launder 3 is arranged between the flash smelting furnace 1 and the top-blown bath blowing furnace 2, and one end of the launder 3 is connected with the outlet of the flash smelting furnace 1 , and the other end is connected to the top-blown melting pool blowing furnace 2. After the copper and nickel sulfide concentrates are deeply dried, they are first suspended in a conventional stationary flash smelting furnace and oxidized by oxygen-enriched air to obtain liquid copper matte Or nickel matte, and then the liquid copper matte or nickel matte directly enters the conventional fixed top-blown molten pool blowing furnace through the launder and is further oxidized by oxygen-enriched air or pure oxygen to obtain blister copper or nickel matte.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com