Method for coordinated disposal of waste lead-containing glass through lead smelting

A co-processing and lead smelting technology, applied in the direction of improving process efficiency, can solve the problems of heavy metal pollution, waste of lead resources, etc., and achieve the effects of avoiding waste, improving recovery rate, and solving heavy metal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

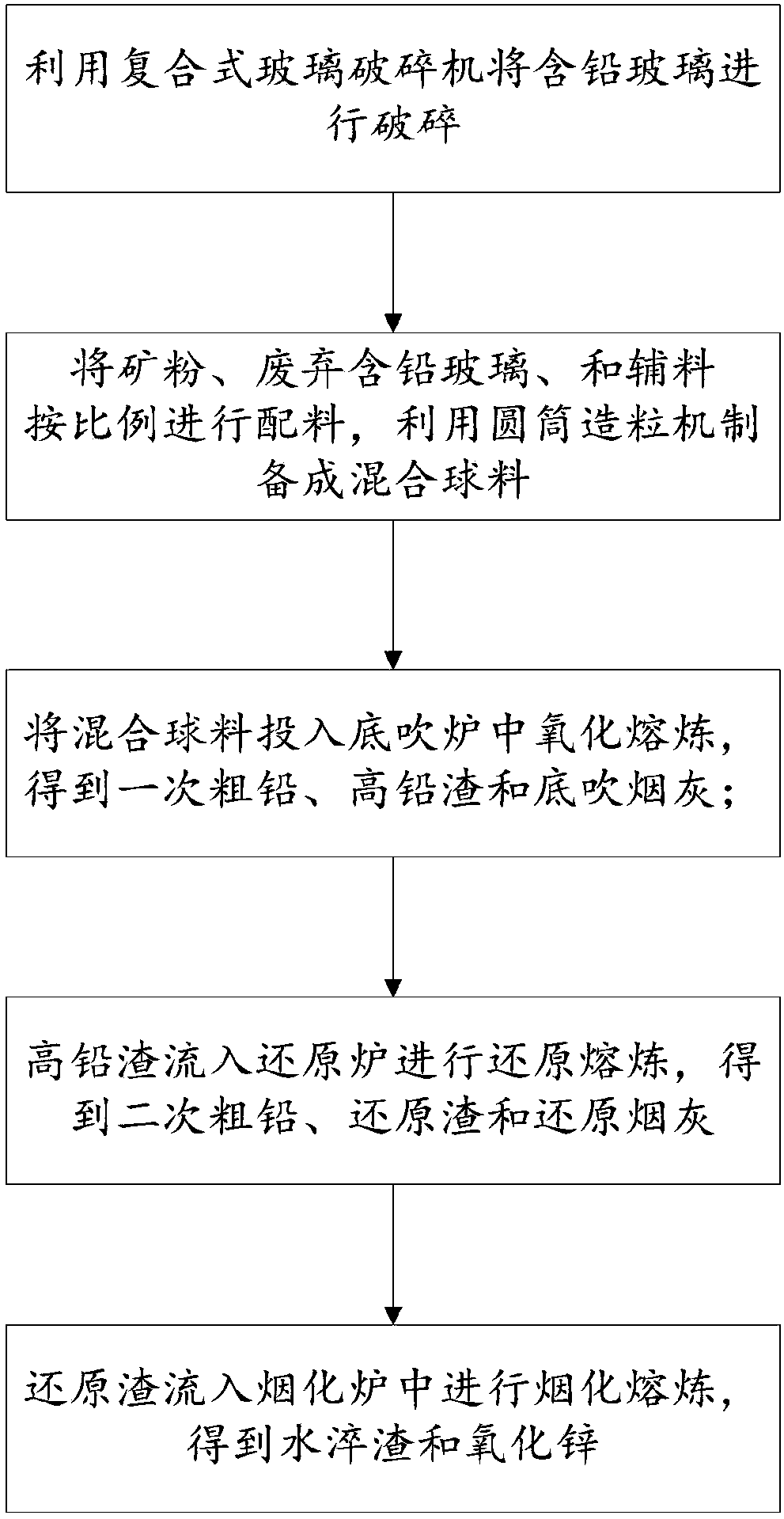

Method used

Image

Examples

Embodiment

[0034] What needs to be understood is that the main components of leaded glass are lead oxide and other silicates. In view of the fact that quartz sand needs to be added to the bottom blowing furnace to make slag during the melting process, leaded glass can be added as a "solvent", and after melting and slagging reaction Then flow into the reduction furnace for reduction smelting. In the bottom-blown furnace, PbO participates in bottom-blown smelting to produce primary lead, SiO 2 Participate in slagging reaction, the reaction formula is as follows:

[0035] 2PbO+PbS=3Pb+SO 2

[0036] xPbO+ySiO 2 =xPbO·ySiO 2

[0037] FeO+SiO 2 =FeO·SiO 2

[0038] CaO+SiO 2 =CaO·SiO 2

[0039] In the reduction furnace, lead silicate and lead ferrite react with C / CO to produce secondary crude lead. The reaction formula is as follows:

[0040] 2PbO SiO 2 +2FeO+C=2Pb+2FeO·SiO 2 +CO 2

[0041] 2PbO SiO 2 +2CaO+C=2Pb+2CaO·SiO 2 +CO 2

[0042] In summary, from the analysis of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com