Flotation method for reducing content of magnesium oxide in copper-nickel concentrate

A magnesium oxide and concentrate technology, applied in flotation, solid separation, etc., can solve the problems of furnace body leakage, fluidity reduction, smelting furnace nodulation, etc., and achieve the effect of enhancing efficiency and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

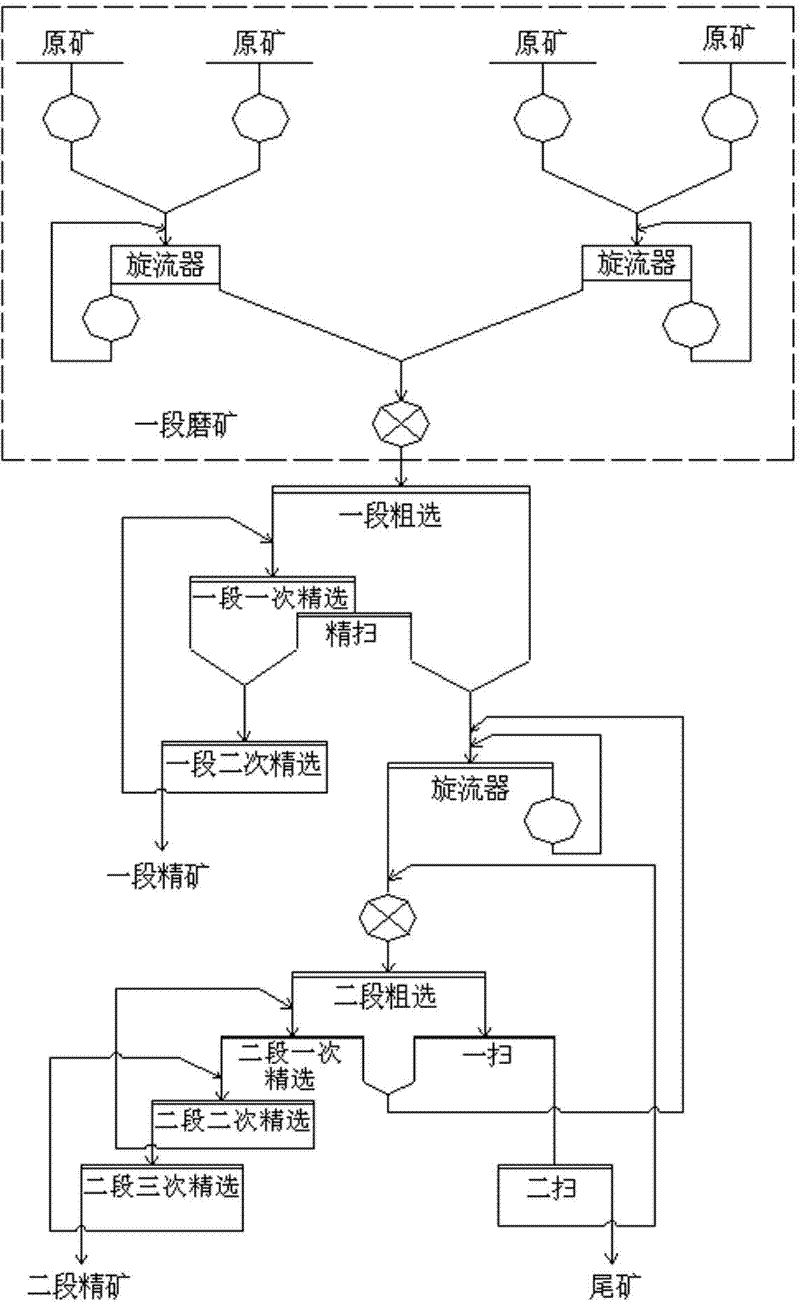

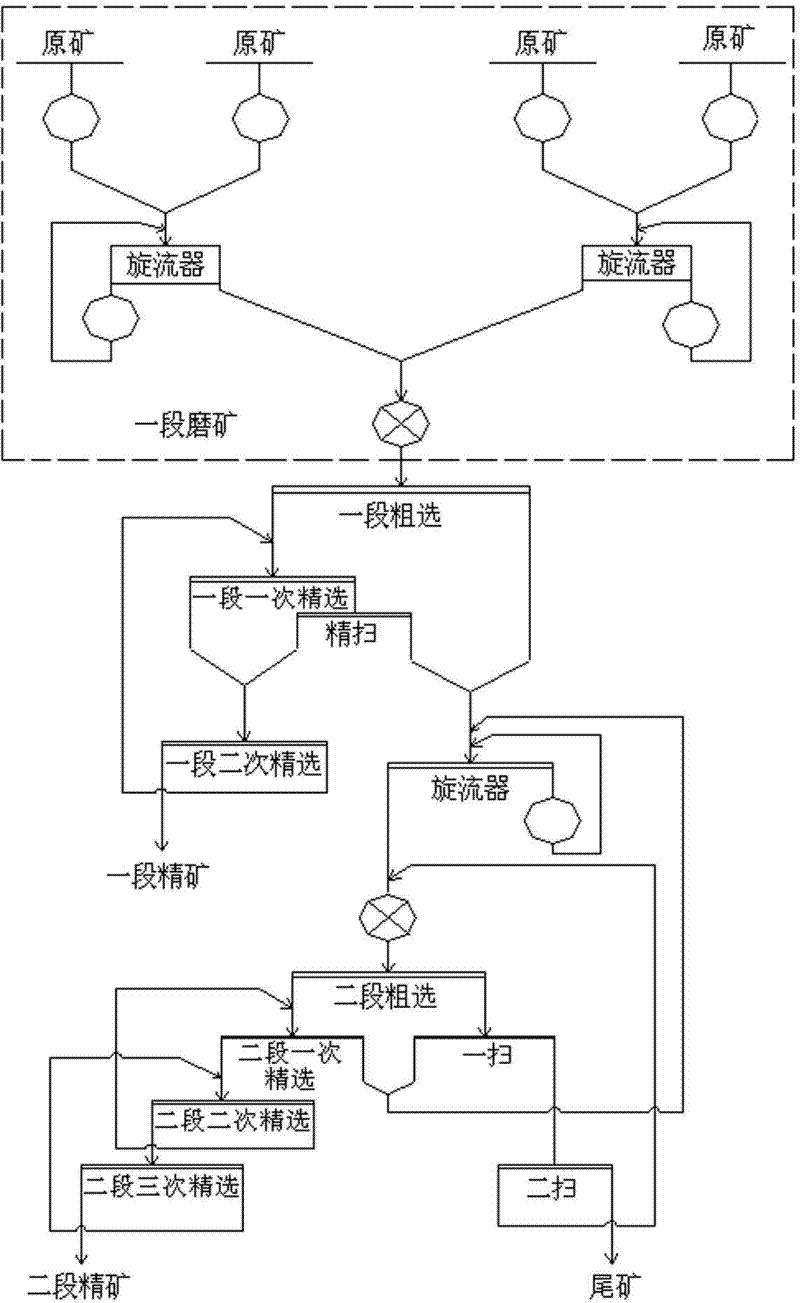

Embodiment 1

[0037] Use the existing grinding device to grind the raw ore for one stage, and add ammonium sulfate at a rate of 0.683kg of ammonium sulfate per ton of raw ore, and add ammonium sulfate during the one-stage grinding process. The percentage reaches 65% of the total weight of the pulp, and when the weight percentage concentration of the pulp is 28%, a stage of rough separation is carried out to obtain a stage of rough separation concentrate and a stage of rough separation tailings; water is added to the stage of rough separation concentrate, and the formed The concentration of the weight percentage of the pulp is 15%, and it is selected once for one stage, and the aeration volume during the selection is 0.4m 3 / m 2Min, to obtain a section of primary concentrate concentrate and a section of primary concentrate tailings; perform fine sweeping on a section of primary concentrate tailings to obtain fine sweep concentrate and fine sweep tailings; combine a section of primary concent...

Embodiment 2

[0040] Use the existing grinding device to grind the raw ore for one stage, and add 1kg of ammonium sulfate per ton of raw ore, add ammonium sulfate during the one-stage grinding process, when the weight percentage of the ore particles in the grinding slurry with a particle size of ≤200 mesh When it reaches 70% of the total weight of the pulp and the concentration of the pulp is 31%, a stage of roughing is carried out to obtain a stage of roughing concentrate and a stage of roughing tailings; water is added to the stage of roughing concentrate and the formed pulp is controlled The weight percentage concentration is 23%, and a period of one-time selection is carried out, and the air volume during selection is 0.5m 3 / m 2 Min, to obtain a section of primary concentrate concentrate and a section of primary concentrate tailings; perform fine sweeping on a section of primary concentrate tailings to obtain fine sweep concentrate and fine sweep tailings; combine a section of primary ...

Embodiment 3

[0043] Use the existing grinding device to grind the raw ore for one stage, and add ammonium sulfate at a rate of 0.8415kg ammonium sulfate per ton of raw ore, and add ammonium sulfate during the one-stage grinding process. The percentage reaches 67.5% of the total weight of the pulp, and when the weight percentage concentration of the pulp is 25%, a stage of roughing is carried out to obtain a stage of rough concentrate and a stage of rough tailings; water is added to the stage of rough concentrate and the formed The concentration of the weight percentage of the pulp is 19%, and it is selected once for one stage, and the aeration volume during the selection is 0.45m 3 / m 2 Min, to obtain a section of primary concentrate concentrate and a section of primary concentrate tailings; perform fine sweeping on a section of primary concentrate tailings to obtain fine sweep concentrate and fine sweep tailings; combine a section of primary concentrate concentrate and The first stage of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com