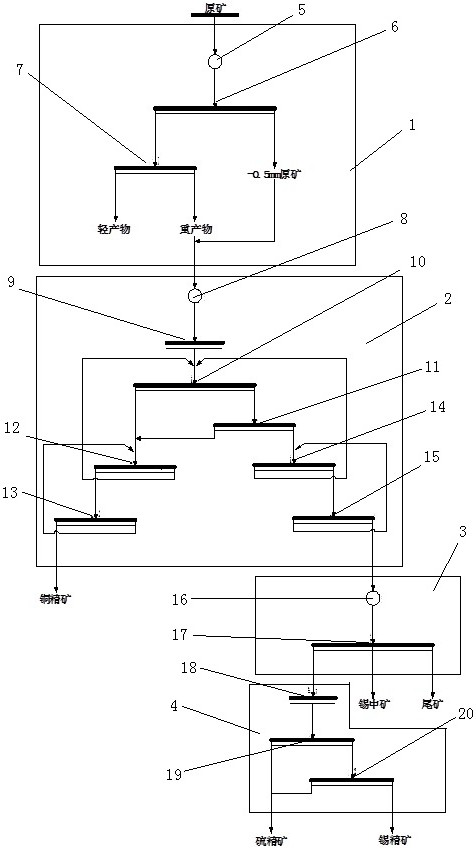

Copper-tin ore separation process

A separation and process technology, applied in the field of copper-tin ore separation process, can solve the problems of grinding cost, high cost management cost of flotation reagents, difficulty in realizing the maximum comprehensive recovery of valuable metals, and difficulty in ensuring the economic benefits of enterprises, etc. , to achieve the effect of reducing production cost, high selection grade and saving storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A copper-tin ore raw ore: Cu grade 0.85%, Sn grade 0.38%, Ag grade 45.30g / t, main metal minerals are chalcopyrite, cassiterite, pyrite, a small amount of sphalerite, non-metallic minerals such as quartz, Sericite, feldspar, calcite, kaolinite, etc. are the main ones.

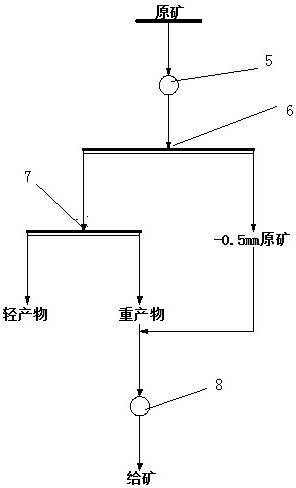

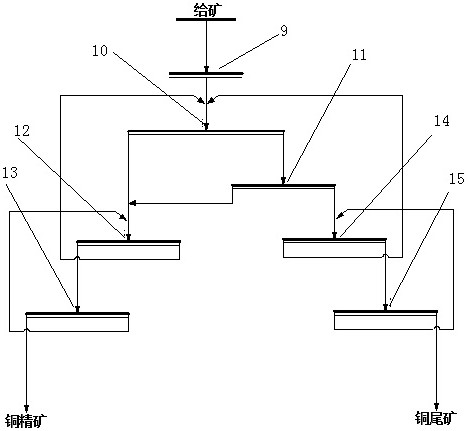

[0043] Use the copper-tin ore sorting system to process the ore, and the specific steps are as follows:

[0044] Feed the raw ore into the crusher 5, crush it to -15mm, and sieve it through the grading screen 6 to obtain two grades of -0.5mm and +0.5mm~-15mm, and feed the ore with the grade of +0.5mm~-15mm into the Dense medium cyclone 7, with an inlet pressure of 0.14MPa and a combined density of 2.15g / cm 3 Sorting under conditions to obtain heavy products and light products, and then the heavy products and -0.5mm particle size raw ore are combined and fed into the first ball mill 8.

[0045] Grind the ore to -0.074mm to account for 75%, adjust the mass concentration of the pulp to 40%, feed it into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com