Tailing pre-discarding method for andalusite ore separation

A technology of andalusite ore and andalusite, which is applied in the pre-tailing field of andalusite ore beneficiation, can solve the problems of low efficiency, large loss of fine-grained andalusite ore, and unsuitable implementation, so as to reduce transportation costs and increase concentrate production. High quality and resource utilization rate, high removal rate of gangue minerals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

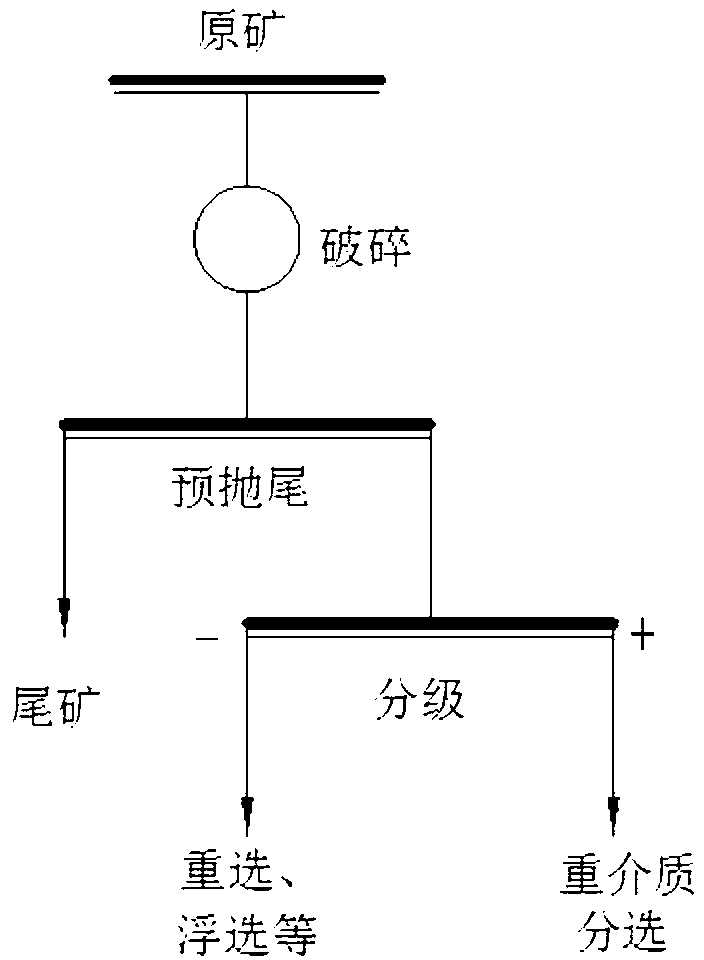

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, but of course the following examples should not be construed as limiting the present invention.

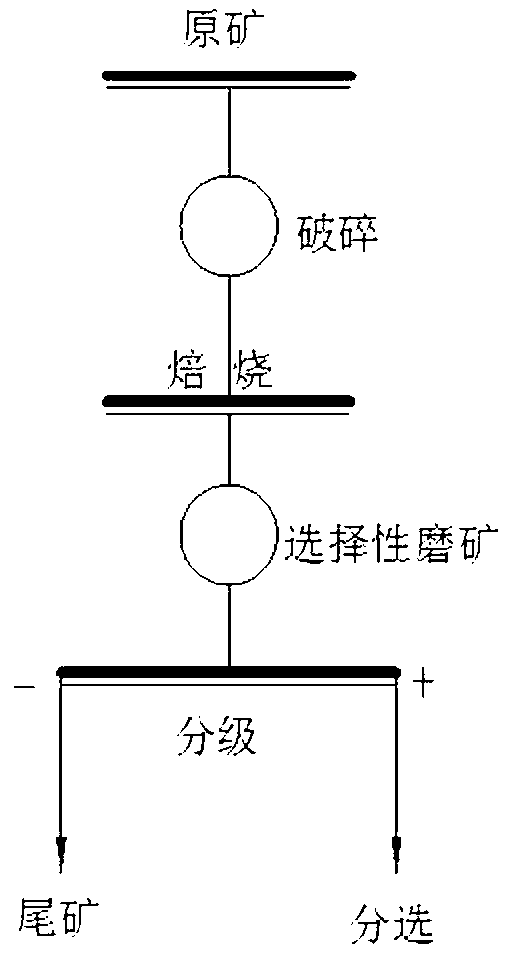

[0020] Such as figure 2 Shown, the present invention provides a kind of tailing method of andalusite ore beneficiation in advance, and it comprises the steps:

[0021] 1) Crushing the andalusite raw ore until the particle size is less than or equal to 20mm;

[0022] 2) Roast the crushed material in a high-temperature furnace for 10-20 minutes at a temperature of 700-900°C, and then pass air into the cooling bed to quickly cool the material to room temperature;

[0023] 3) The cooled material is subjected to dry selective grinding, and the grinding product is classified by dry method to remove the tailings, and the remaining material is sent to the subsequent beneficiation operation for separation and purification.

[0024] The cooling bed in step 2) of the present invention uses air a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com