Patents

Literature

442 results about "Burns temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Burns temperature, Td, is the temperature where a ferroelectric material, previously in paraelectric state, starts to present randomly polarized nanoregions, that are polar precursor cluster. This behaviour is typical of several, but not all, ferroelectric materials, and was observed in lead titanate (PbTiO₃), potassium niobate (KNbO₃), lead lanthanum zirconate titanate (PLZT), lead magnesium niobate (PMN), lead zinc niobate (PZN), K₂Sr₄(NbO₃)₁₀, and strontium barium niobate (SBN), Na₁⸝₂Bi₁⸝₂O₃(NBT).

Integrated treatment method for malodorous VOCs gas of refining devices

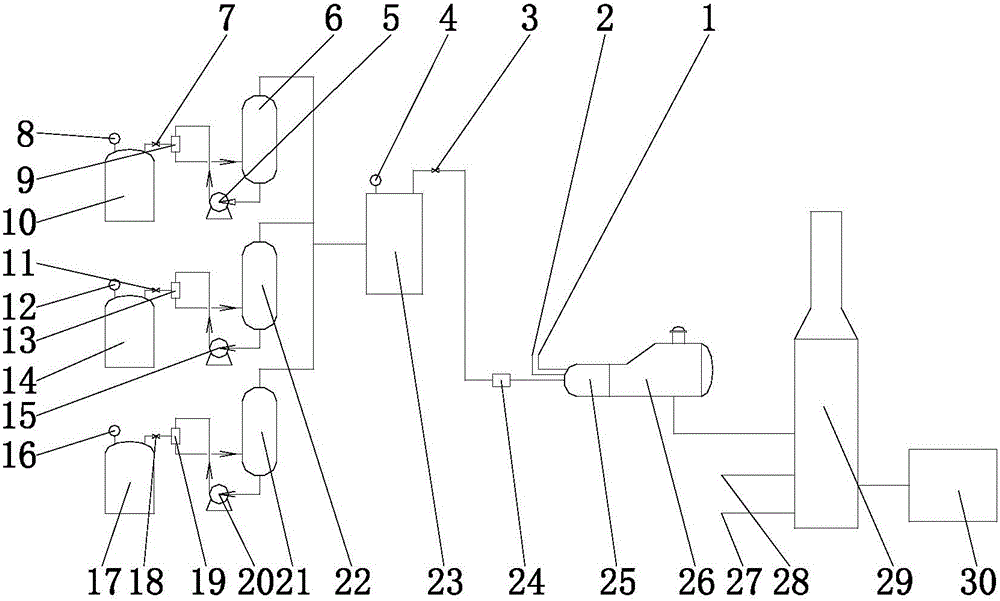

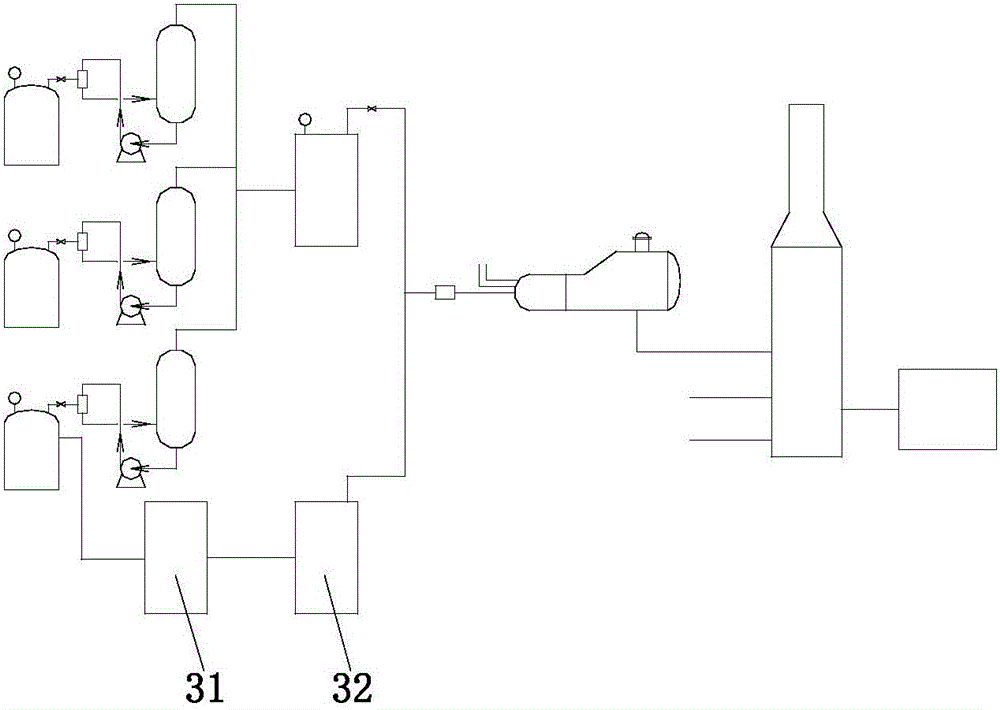

InactiveCN105841168AReduce dosageSimple processDispersed particle separationIncinerator apparatusLiquid jetBurn units

The invention discloses an integrated treatment method for unorganized emission of malodorous VOCs gas from refining and chemical equipment, which collects VOCs gas emitted from refining and chemical storage tanks including residual oil tanks, intermediate product tanks, and acid water tanks. The VOCs gas outlet of the tank is connected to the injection fluid inlet of the liquid jet vacuum pump; the working fluid inlet of the liquid jet vacuum pump is connected to the outlet of the circulation pump, and the mixed fluid outlet is connected to the gas-liquid separation tank; the inlet of the circulation pump is connected to the The liquid outlet of the gas-liquid separation device is connected; the gas outlet of the gas-liquid separation device is connected with the buffer tank; the inlet of the incineration unit is also fed with combustion-supporting gas and air in addition to the VOCs gas in the gas storage buffer tank. , VOCs gas and malodorous gas are incinerated in the incineration unit, and the incineration temperature is 800-1000°C.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

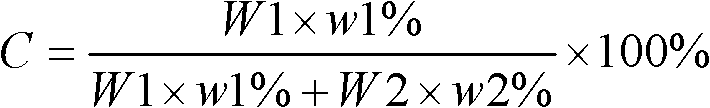

Flame retardant additive, preparation method of flame retardant additive and lithium battery

ActiveCN106785126AFlame retardantPerformance impactFinal product manufactureSecondary cells servicing/maintenanceOrganic matterFire retardant

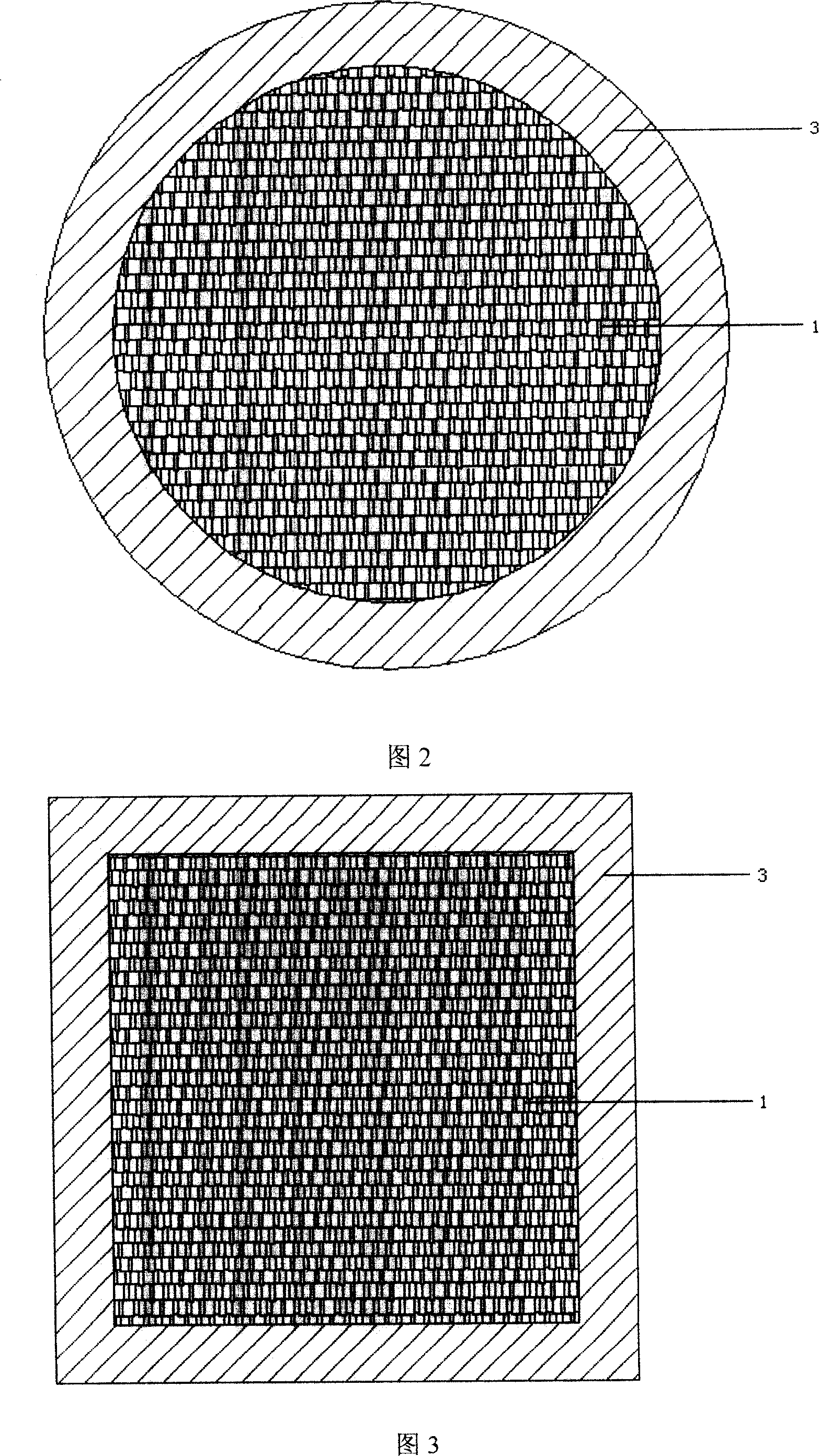

The invention discloses a flame retardant additive, a preparation method of the flame retardant additive and a lithium battery. The flame retardant additive is of a core shell structure, and comprises a flame retardant, an organic matter shell layer, an inorganic oxide shell layer or an organic and inorganic composite shell layer, wherein the organic matter shell layer, the inorganic oxide shell layer or the organic and inorganic composite shell layer is coated on the outer surface of the flame retardant; the flame retardant additive can be coated on the positive electrode and the negative electrode of the lithium battery or the surface of an isolation membrane through a bonding agent; or the flame retardant additive is added into electrolyte. When the flame retardant additive is applied to the lithium battery, the flame retardant is not directly in contact with the electrolyte of the lithium battery, so that the flame retardant cannot cause adverse influence on the performance of the lithium battery. The corresponding flame retardant additive can be selected according to the burning temperature of the electrolyte, so that the melting point of a shell layer of the flame retardant additive or the gasification temperature of the flame retardant is smaller than the burning temperature of the electrolyte; before the temperature of the electrolyte of the lithium battery reaches the burning temperature, the flame retardant is released from the shell layer, so that the flame retardant achieves a flame retardant effect; the burning or the explosion of the lithium battery is prevented; the safety of the lithium battery is improved.

Owner:QINGDAO UNIV

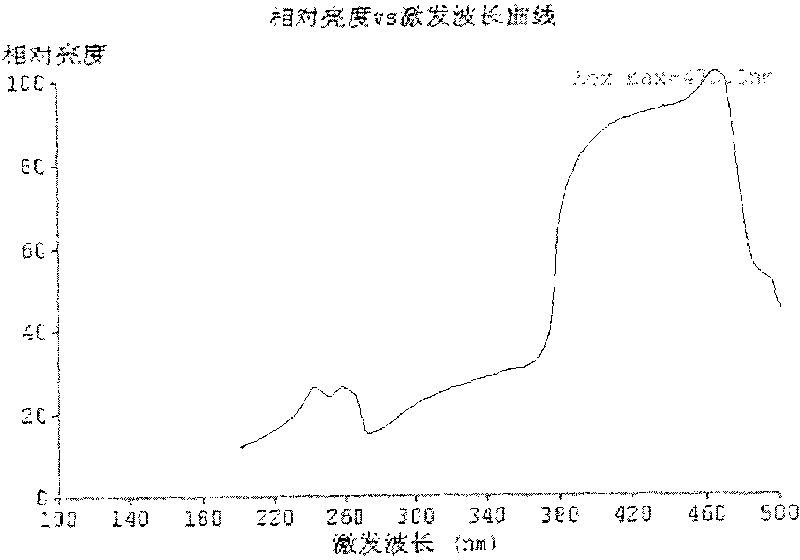

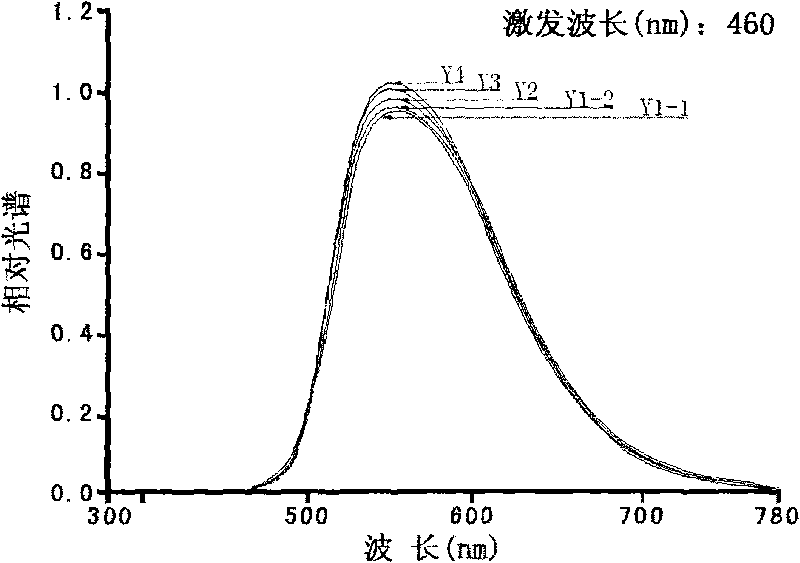

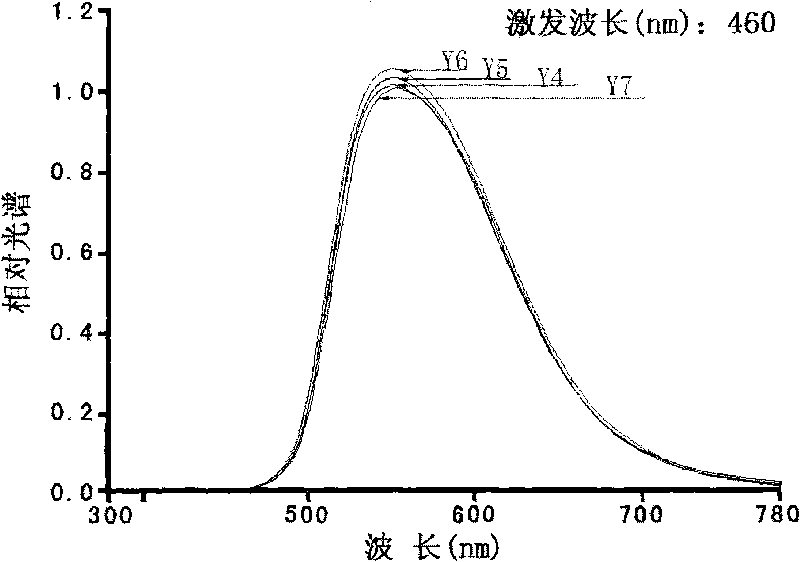

Yellow fluorescent powder used by white light LED and preparation method thereof

ActiveCN101760197ALower firing temperatureIncrease brightnessGas discharge lamp usageLuminescent compositionsCrucibleRadiance

The invention relates to a fluorescent powder used for a white light LED and a preparation method thereof. The chemical formula of the fluorescent powder is (A3-x) (Al5-2mBmCm) FnO12-n: xCe, wherein A is one or more of Y, Gd, La and Tb; B is one or more of Ti, Zr and V; C is one or two of Mn, Zn, Mg and Li; x is more than or equal to 0.03 and less than or equal to 0.1; m is more than or equal to 0.01 and less than or equal to 2; and n is more than or equal to 0 and less than or equal to 3x. The preparation method comprises the steps of coating a layer of high-temperature ceramic glaze material at the joint between a crucible cover and a crucible by using a high-temperature solid phase method and a self-pressurization sealing burning technique, putting the crucible into an atmosphere box type furnace to burn for 2 to 5 hours at 1450 to 1550 DEG C in the nitrogen atmosphere, smashing and screening after cooling so as to acquire the finished product of the fluorescent powder. The fluorescent powder of the invention has high radiance. The method of the invention can efficiently lower the burning temperature of the fluorescent powder and increase the relative brightness.

Owner:XIANGLING LED

Method for producing foam microcrystal glass by utilizing composite industrial residue and product

The invention discloses a method for producing a foam microcrystal glass by utilizing a composite industrial residue, and is characterized by comprising the following steps of: crushing different industrial residues, after mixing proportionally, grinding to raw material powder, heating, melting, quenching and drying the raw material powder, grinding to clinker powder, adding a nucleation agent, a foaming agent, a foam stabilizer, a fluxing agent and an enhancer to form a foam microcrystal batch, after pressing the batch, preheating, foaming, stabilizing the foam and annealing, sintering to obtain the foam microcrystal glass. According to the invention, burnability of the batch is remarkably improved, the burning temperature is reduced, the production cost of the foam microcrystal glass is reduced, and the method has the characteristics of abundant raw material sources, low cost, simple process, environmental friendliness, and the like. The product foam microcrystal glass has the characteristics of excellent performance quality, low volume weight, high intensity, fire protection, water tightness, corrosion resistance, no ageing, no radioactivity and the like, and is an environmental-friendly new material.

Owner:苏州新苏化工机械有限公司

Nanometer composite silicon brick and preparation method thereof

The invention relates to a nano-sized composite silica brick and a production method thereof. The invention is characterized in that: raw materials and binder of the silica brick are as follows: silica granules and fine powders, waste silica brick granules, calcium carbonate nanoparticles, iron oxide nanoparticles, silicon dioxide nanoparticles, fluorite powders, lime and sulfite pulp wastes. The production method is based on the existing production process of the silica brick, and introduces compound nanopowders in optimal proportions in the production process of the silica brick after high-efficiency dispersion, to produce nano-sized composite silica bricks. With the addition of nanopowders, the performance of silica brick is significantly improved, and manifested as follows: 1) the particle size fraction is more reasonable, the accumulation is compact and the texture is uniform; 2) the slurry has good plasticity and moldability and the production efficiency is improved; 3) the burning temperature is decreased to 20 DEG C, thus realizing energy conservation and discharge reduction; 4) the tridymite is superior in crystallization conversion and has low content of quartz residues; 5) the number of closed pores is increased, the number of opened pores are reduced, the porosity is reduced, and the strength and refractoriness under load are increased; and 6) the final product has good appearance, smooth end surface and good bonding property, and the rate of qualified products is increased.

Owner:ZHENGZHOU UNIV +1

High-temperature domestic porcelain metallic bright glaze and product decorated by same

The invention relates to a high-temperature domestic porcelain metallic bright glaze and a product decorated by the same. The bright glaze produced by using natural mineral raw materials and industrial pure raw materials comprises the following materials by weight percent: 10-25 percent of potassium feldspar, 10-30 percent of albite, 0-35 percent of quartz, 0-10 percent of barium carbonate, 0-10 percent of wollastonite, 0-10 percent of kaolin, 0-5 percent of zinc oxide, 1-10 percent of aluminum oxide, 1-10 percent of bone ash, 1-5 percent of purple clay and 10-35 percent of ferric phosphate, and the glaze is obtained by mixing, ball-milling and screening the raw materials. The fabrication technology of the glaze is basically the same as the common porcelain glaze, the cost is low, not only can the pure color be guaranteed through redesigning of the formula of the glaze, but also the burning temperature of the glaze is increased to 1380 DGE C, so that the decoration effect of domestic porcelain is greatly enriched, and the high-temperature domestic porcelain metallic bright glaze has wide application prospect.

Owner:HUNAN KARPERY INDAL +1

High-efficiency industrial gas

InactiveCN101892102ARaise the combustion temperatureImprove combustion efficiencyGaseous fuelsGas flame welding apparatusIndustrial gasPropane gas

The invention discloses a high-efficiency industrial gas which comprises the raw materials: industrial propane gas with the purity higher than 95% (weight percent), and liquid-phase synergistic additive accounting for 0.3-1.0% (weight percent) of the industrial propane gas. By adding a little liquid-phase synergistic additive into the propane gas, the high-efficiency industrial gas remarkably improves the burning temperature and efficiency; meanwhile, the liquid-phase synergistic additive of the high-efficiency industrial gas has low corrosivity for a container and good volatility.

Owner:BEIJING DATONG HONGYE TECH DEV

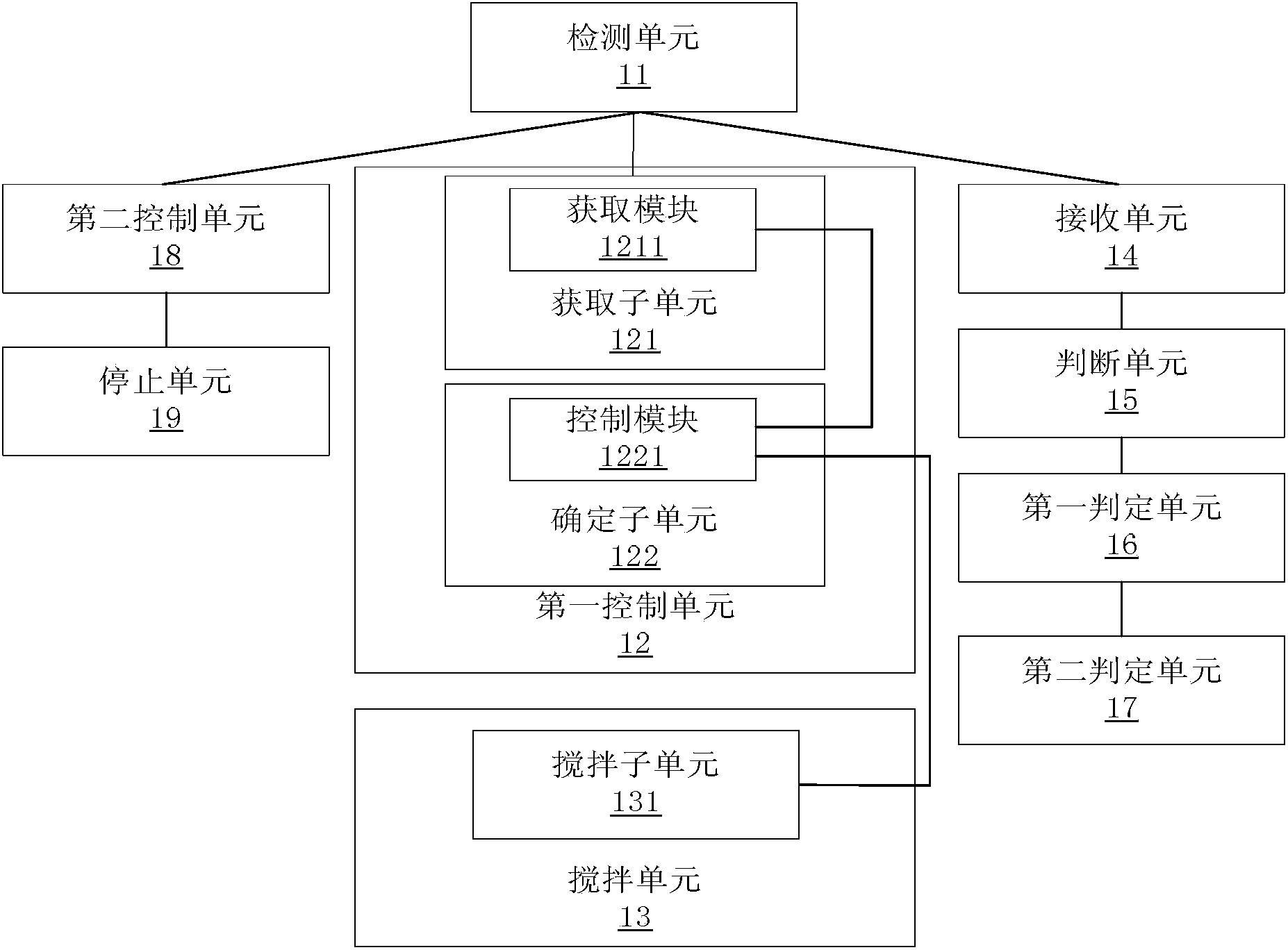

Method for controlling soybean milk making, soybean milk machine, method for making bean curd, and bean curd machine

ActiveCN103425153AAvoid burnt smellSolve the problem of prone to burnt phenomenonAuxillary controllers with auxillary heating devicesBeverage vesselsAnimal scienceSlurry

The invention discloses a method for controlling soybean milk making, a soybean milk machine, a method for making bean curd, and a bean curd machine. The method for controlling soybean milk making includes the steps of detecting the temperature of soybean milk fluid in the soybean milk making process, and controlling the power of a heater to decrease along with the rising of the temperature of the soybean milk fluid. Through the method for controlling soybean milk making, due to the fact that the heating power of the heater is adjusted according to the real-time temperature, the heating power can be lowered before the temperature of the soybean milk fluid reaches the burnt temperature, the burnt phenomenon is effectively prevented, and the phenomenon that the soybean milk fluid has a burnt taste is avoided. Therefore, the problem that in the prior art, the burnt phenomenon easily appears when the soybean milk machine works and the bean curd machine works is solved, and the aim of enabling the burnt effect not to appear in the soybean milk making process is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Fire suppressing gas generator composition

InactiveUS20020137875A1Increase volumeReduce the temperatureOther chemical processesFire extinguisherElastomerParticulates

A fire suppressing gas generator composition which has a low burn temperature which provides an adjustable mass flow rate, which provides high inert gas yields upon combustion, which generates flame suppressing gasses during composition, which provides exhaust gas with low particulate content, and which is suitable for use in pellet form. The gas generator composition of the invention generally comprises a high nitrogen content solid, preferably 5-amino tetrazole, and potassium perchlorate or other oxidizer salt in an amount sufficient to allow flameless deflagration of the high nitrogen contant solid. The composition of the invention also preferably comprises a flame inhibitor precursor such as perbrominated aromatic compound, an elastomeric binder, a powder pressing modifier or enhancer such as mica, and an electrostatic charge suppressant such as graphite.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

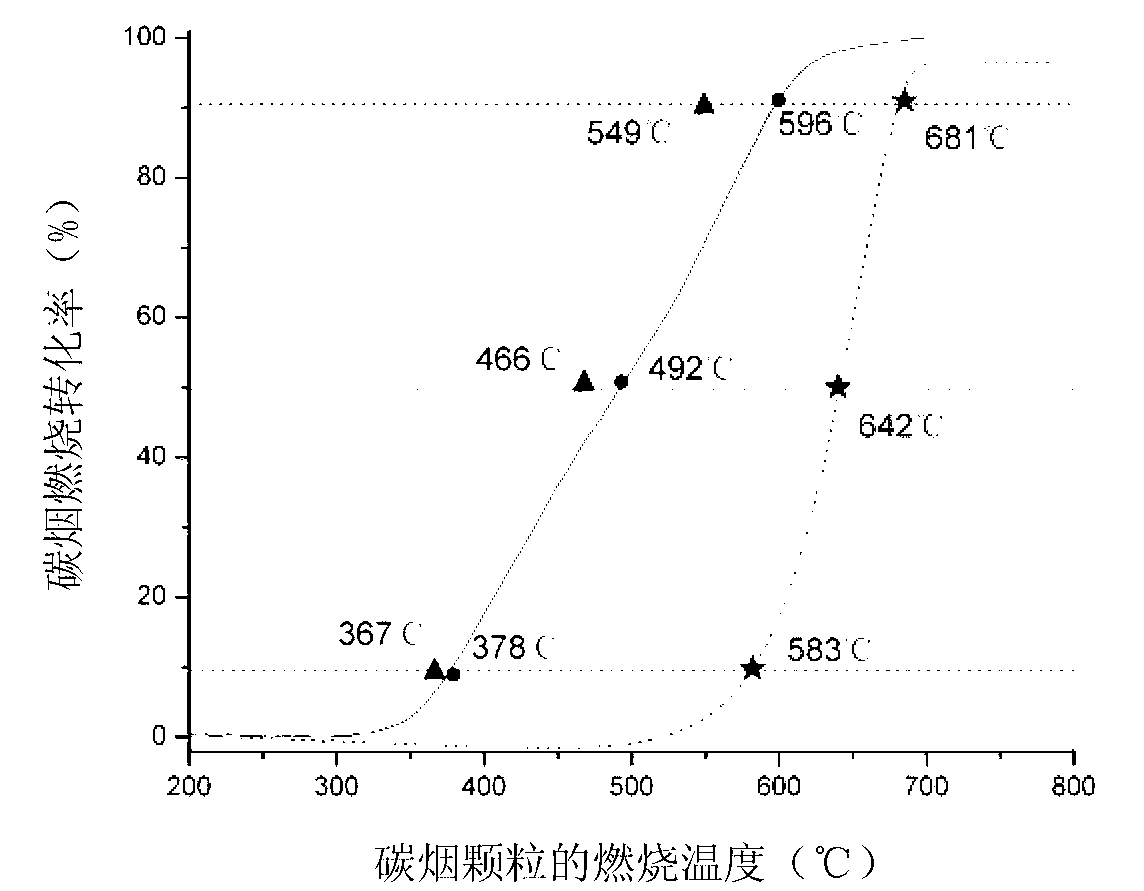

Composite rear earth pyrochlore-type oxide catalyst for catalyzing burning for removing soot of diesel vehicle and preparation method thereof

InactiveCN101879445AHigh selectivityThe synthesis process is simpleDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare earthPyrochlore

The invention provides a composite rear earth pyrochlore-type oxide catalyst for catalyzing burning for removing soot of a diesel vehicle and a preparation method thereof, belonging to the technical field of a tail gas cleaning catalyst of the diesel vehicle. The expression formula of the composite metal oxide is A2B2-xMxO7, wherein A is La, B is Sn, M is Mn, Fe, Co, Ni or Cu. The invention adopts a coprecipitation method to prepare the catalyst, the preparation process is simple, and the cost is low. The preparation method comprises the following steps: mixing metal nitrate and tin tetrachloride solution; adjusting the pH value by ammonia solution; drying the obtained deposit; and roasting the deposit at the high temperature to obtain the composite rear earth pyrochlore-type oxide catalyst. Under the effect of the catalyst, a simulation diesel vehicle exhausts, the burning temperature of the soot particles is lowered to the exhaust range of the diesel vehicle, and the speed of the soot oxidation rate is improved. The catalyst is a useful catalyst for removing the pollution of soot particles of the diesel vehicle.

Owner:UNIV OF JINAN

Supported silver catalyst for reducing soot particle burning temperature and preparation method

InactiveCN103212414AStrong oxidation activityGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater basedCerium(IV) oxide

The invention discloses a supported silver catalyst for reducing soot particle burning temperature and a preparation method, relating to catalysts. The catalyst comprises an active component and a carrier, wherein the active component is silver; the carrier is cerium dioxide or cerium-based composite oxide; the supported amount of silver is 1-20% of the weight of the carrier; and the cerium-based composite oxide has the general formula of Ce1-xMxOy, and M is rare-earth metal. The carrier is prepared by adding a surfactant as a template into a cerium-based solution through a hydrothermal precipitation method. The catalyst is prepared by introducing a complexing auxiliary agent into a water-based silver nitrate solution, evaporating to dryness and baking. The prepared catalyst has excellent oxidative activity in the process of soot burning, is capable of reducing the temperature of soot T50 from 642 DEG C to about 400 DEG C to reach the operating temperature range of a diesel engine, and reaches and exceeds various types of reported soot particle burning catalysts under the same evaluation conditions.

Owner:XIAMEN UNIV

High-purity corundum pouring material containing nano calcium carbonate and preparation method thereof

The invention relates to a high pure corundum castable material containing nanometer calcium carbonate and a preparation method thereof. Based on the present commonly used corundum castable material, by adding nanometer calcium carbonate powder as well as adopting efficient dispersant and suitable mixing technology, the invention prepares corundum castable material that contains nanometer calcium carbonate. The invention solves the disadvantage of low strength of the present high pure corundum castable material in low and middle temperature, more particularly, the strength in about 800 DEG C. Furthermore, the variation of the burnt cool strength of the corundum castable material containing nanometer calcium carbonate from 800 DEG C to 1600 DEG C is comparatively small, and the cool strength and hot strength are both higher than those of the corundum castable material containing cement with the same content of CaO. The corundum castable material that contains nanometer calcium carbonate and is prepared by the utility model can be widely applied to such industries fields as iron and steel, nonferrous metals, ceramics and petrochemical etc. The invention can also be applied to fireproof materials products cast, molded and burnt by a porous brick etc., which can greatly reduce the burnt temperature and save energy.

Owner:ZHENGZHOU UNIV

Apparatus for incinerating rice husk and producing SiO2 rice husk ash with nano structure therefor

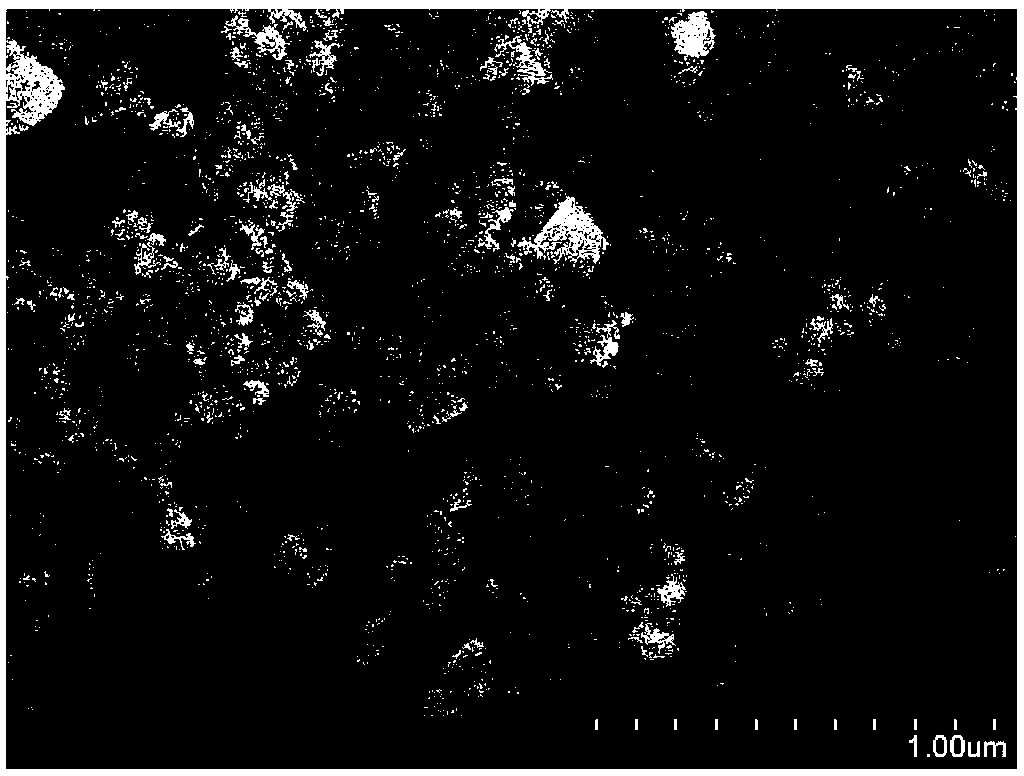

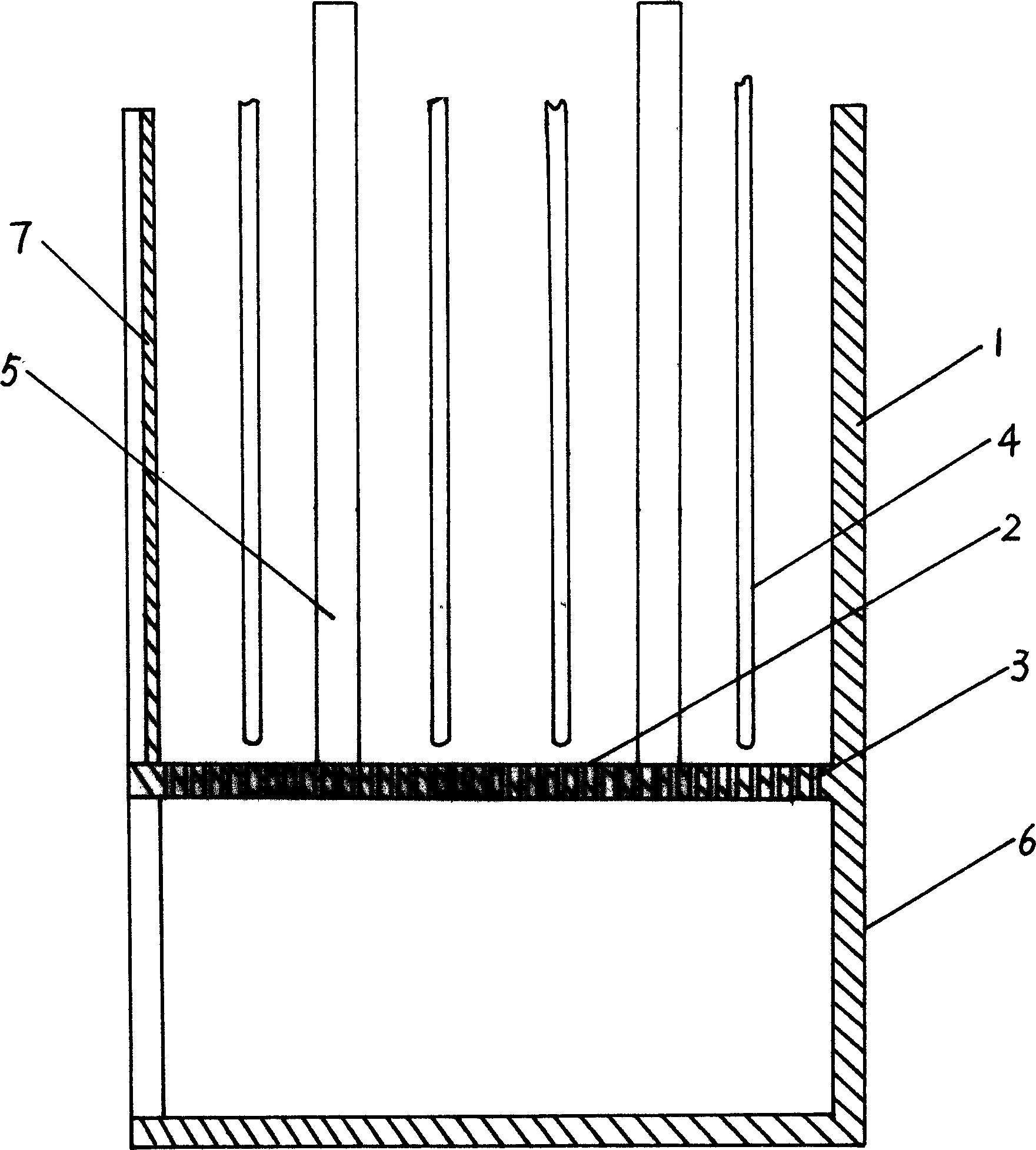

InactiveCN1559897ASolve the problem of limited stack volumeEfficient take awaySilicaSolid waste disposalHigh strength concreteNano structuring

The invention is a rice hull burning device and the nano structural SiO2 rice hull ashes produced by it, and the device includes a burning container, where the bottom board is distributed with many small hole, the inside of the container is distributed with heat exchange water pipes, it regulates the distribution density of these water pipes to control the burning temperature under 600 deg.C in the rice hulls, thus able to ensure the produced rice hull ashes are nano structural rice hull ashes, using the produced heat energy in burning course, and simultaneously solving the problem of limitation to the bulk of a rice hull pile; the produced nano structural SiO2 rice hull ashes contain many about 50 nm-sized SiO2 particles loosely bound together and many holes, where the content of SiO2 exceeds 90%, and has superhigh activity of volcanic ash and strong reinforcement action on ordinary concrete and high-strength concrete, and when the quantity of replacing the cement is 5-20%, can heighten the pressive strength of high-strength concrete by above 10MPa.

Owner:JINAN UNIVERSITY

Composite cigarette filter tip capable of improving mouthfeel of novel cigarette and application thereof

ActiveCN107772530ASolve the deformationSolve the collapseTobacco smoke filtersManufacturing technologyEngineering

The invention relates to the technical field of tobacco manufacturing, in particular to a composite cigarette filter tip capable of improving mouthfeel of a novel cigarette and an application thereof.The composite cigarette filter tip capable of improving mouthfeel of the novel cigarette is obtained by composition of at least one solid section and at least one cigarette tow section. One or multiple hole channels are arranged in the solid section. As for a novel cigarette product, a tobacco section does not burn and generates smoke by depending on heat sources and other effects. The heating temperature is far lower than the burning temperature of a conventional cigarette. Hole channels arranged in the solid section help minimize the obstruction and interception effects of the filter tip upon smoke, reduce the loss of smoke in the filter tip and improve smoke concentration. Additionally, the hole channels in the solid section are filled with fragrant particles or coated with fragrant layers. When a user smokes the novel cigarette, the cigarette filter tip draws close to the tobacco section so that temperature goes high. Therefore, fragrant components are released at high temperatureto increase aroma concentration and enrich smoke. As a result, the mouthfeel of the novel cigarette is effectively improved.

Owner:CHINA TOBACCO GUIZHOU IND

Preparation of low temperature metal-lustrous glaze for ceramic

InactiveCN101348330AImprove metallic luster effectThe function of promoting crystallizationCeramicMetal

The invention belongs to the porcelain glaze material technical field, in particular to a porcelain glaze material and a method for manufacturing the same. In the invention, quartz, kaolin, red lead, feldspar and calcium carbonate are evenly mixed and calcined at a high temperature of between 1,250 and 1,400 DEG C to generate a glassy material, and the glassy material is crushed into particles with the particle diameter of between 200 and 250 meshes, and is mixed with particle coloring metal oxides to manufacture the porcelain glaze material. The invention better considers the two technical problems of improving the metal luster effect and lowering the burning temperature of glaze materials; moreover, the invention has the advantages of simple process, low cost and obvious energy saving effect.

Owner:SICHUAN BAITA XINLIANXING CERAMIC GROUP

Blank for manufacturing bakeware ceramic products, and corresponding glaze and manufactured products thereof

InactiveCN101348362AAvoid environmental pollutionChange the phenomenon of monotonous color patternClaywaresFritCalcite

The invention discloses blank for preparing ceramic products such as baking pans, etc., relative glaze and the finished ceramic product. The blank comprises kaolin, talc, feldspar and limestone; in addition, the blank also comprises waste glass, the weight of which against the total weight of the blank is between 10 and 28 percent; the glaze comprises low-temperature clinker, feldspar, quartz and calcite; the blank is used to make the ceramic body, the surface of the ceramic body is coated with the glaze and burned at a temperature of between 1060 and 1150 DEG C, and the ceramic products such as baking pans, etc. can be obtained. The invention fully utilizes the waste glass, the burning temperature is low, the prepared ceramic product undergoes the quenching after being burned at a temperature of 280 DEG C and the quench cracking does not occur, and after the burning and the quenching, no fog dot exist on the glaze.

Owner:CHAOZHOU XIONGJIA PORCELAIN MFG

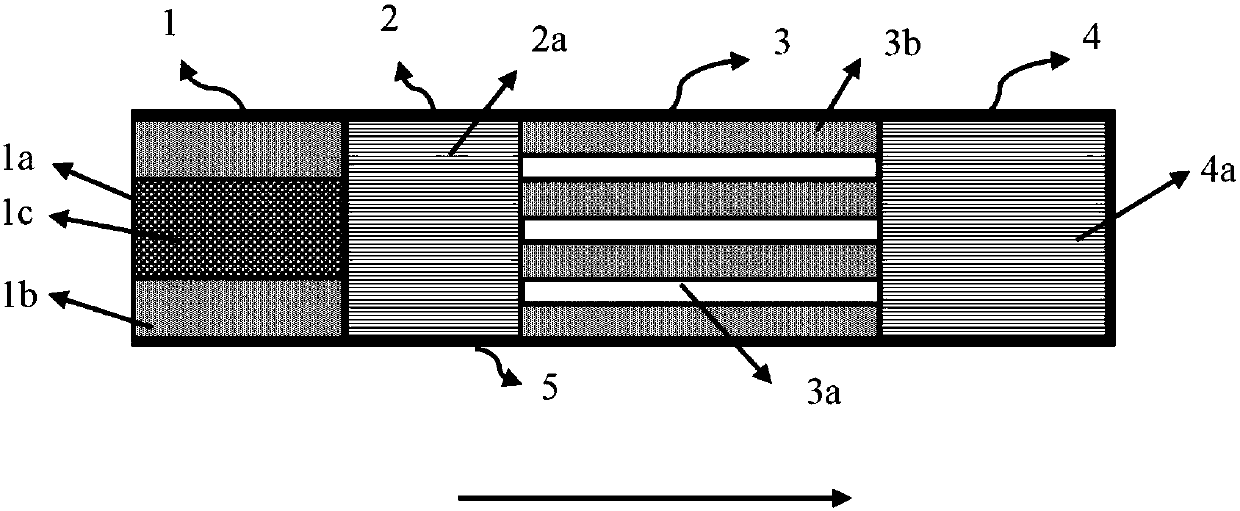

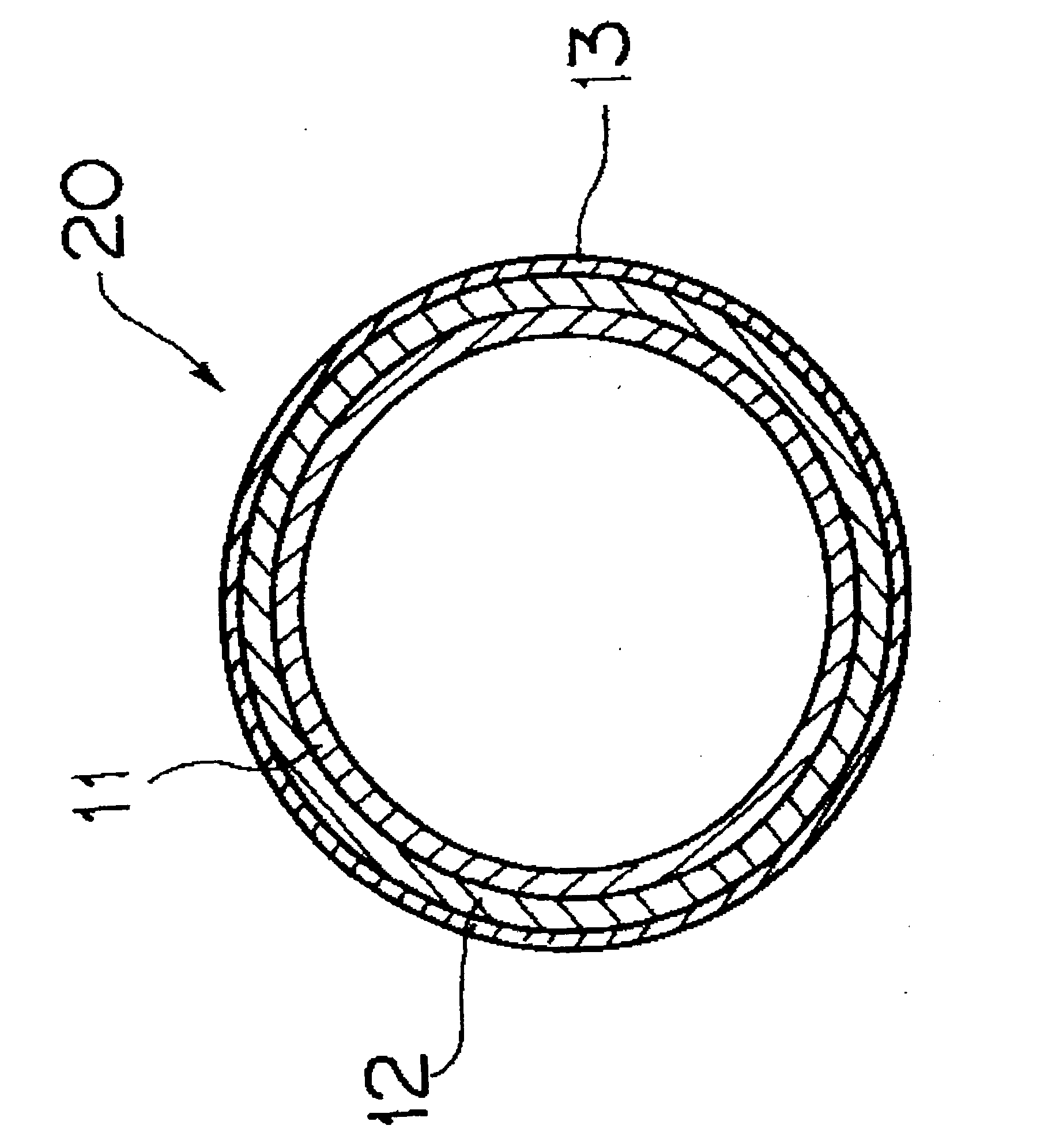

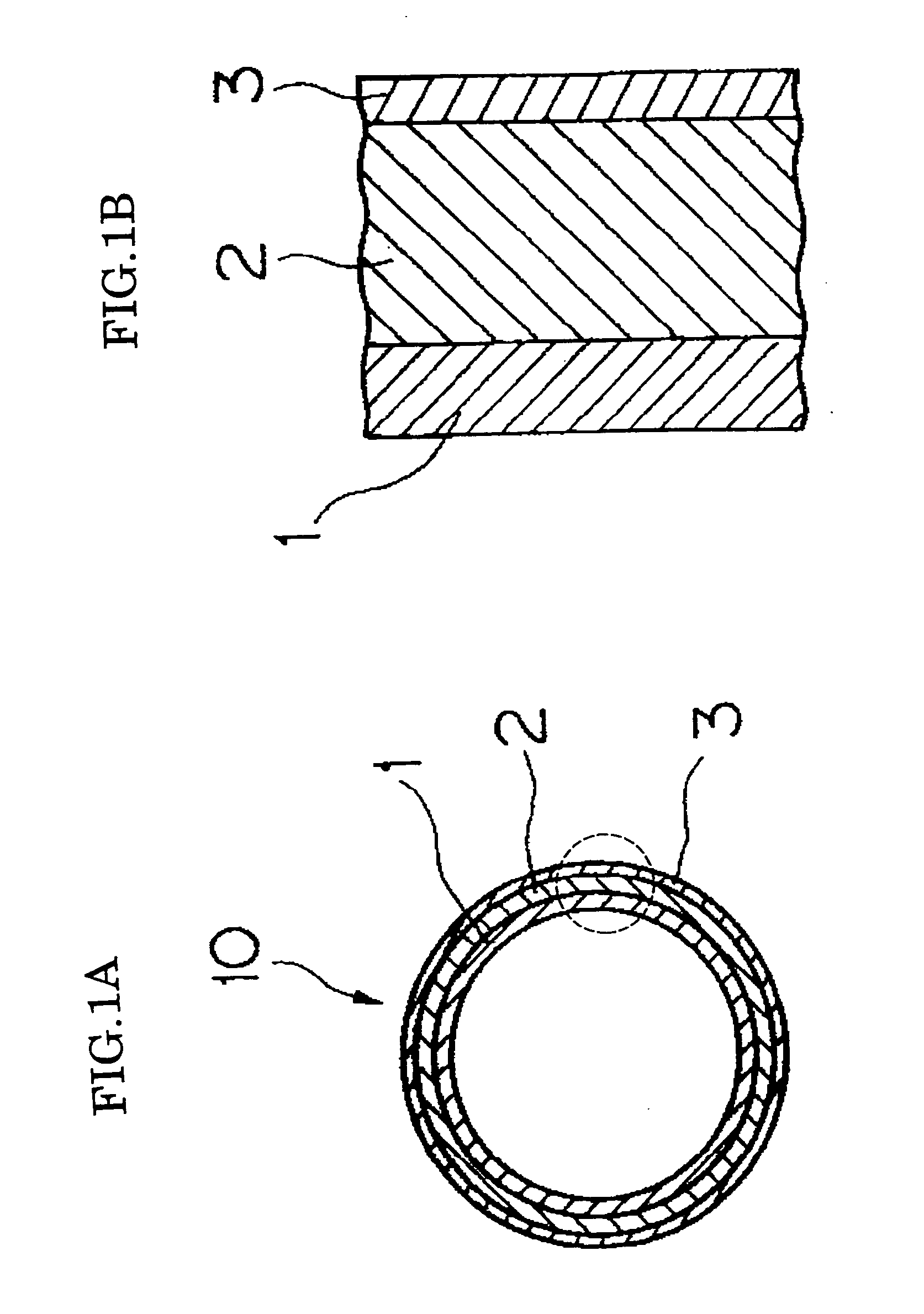

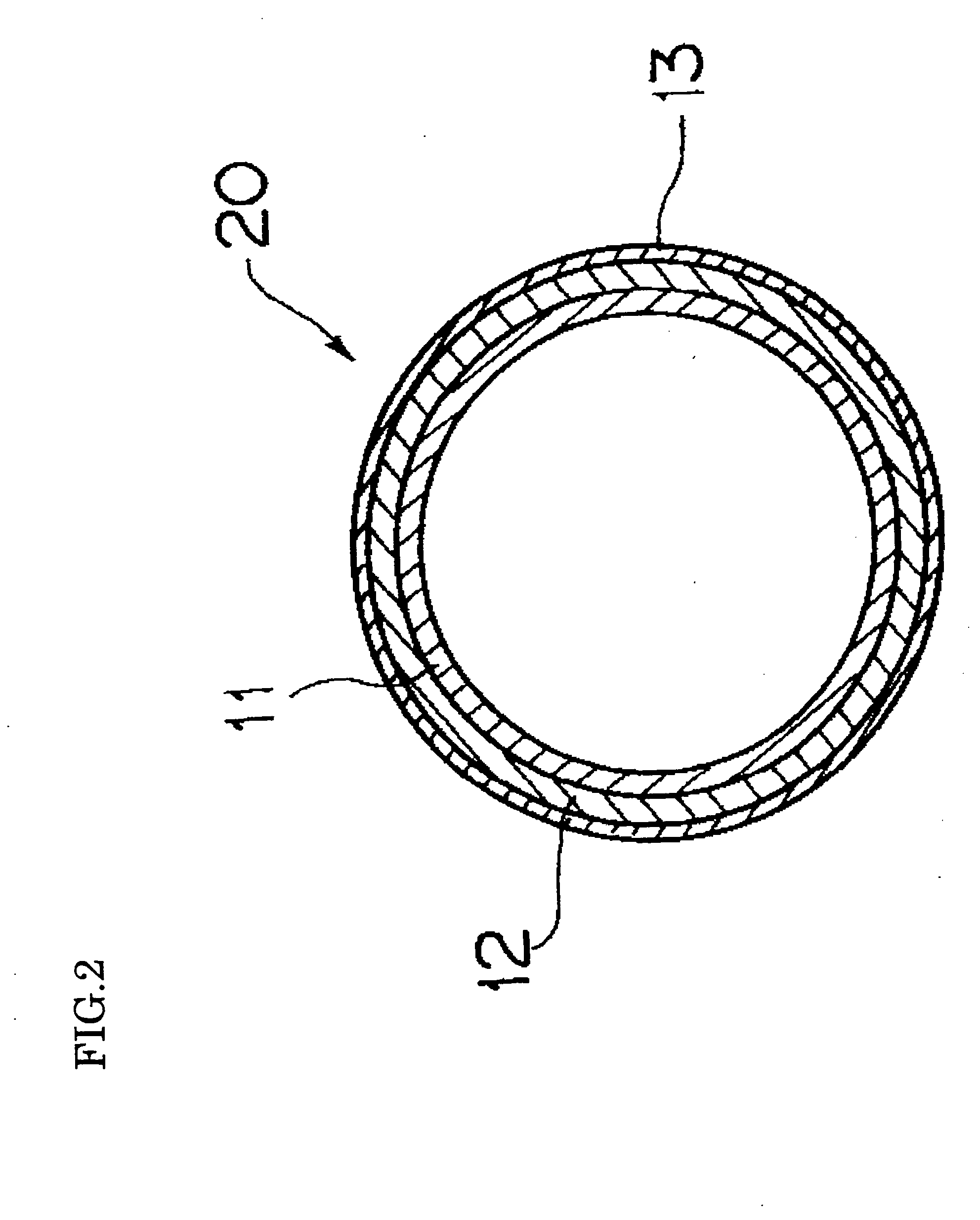

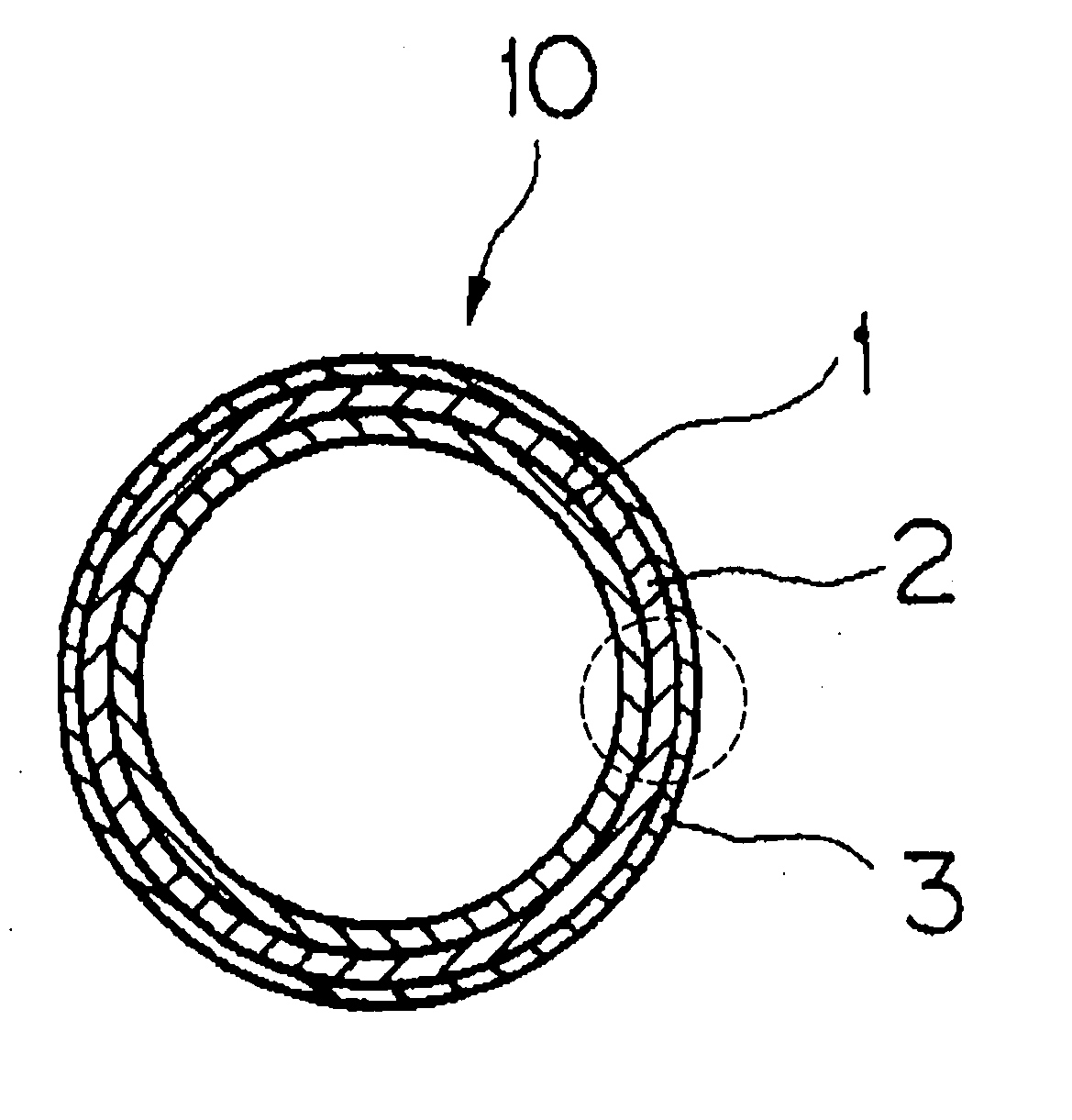

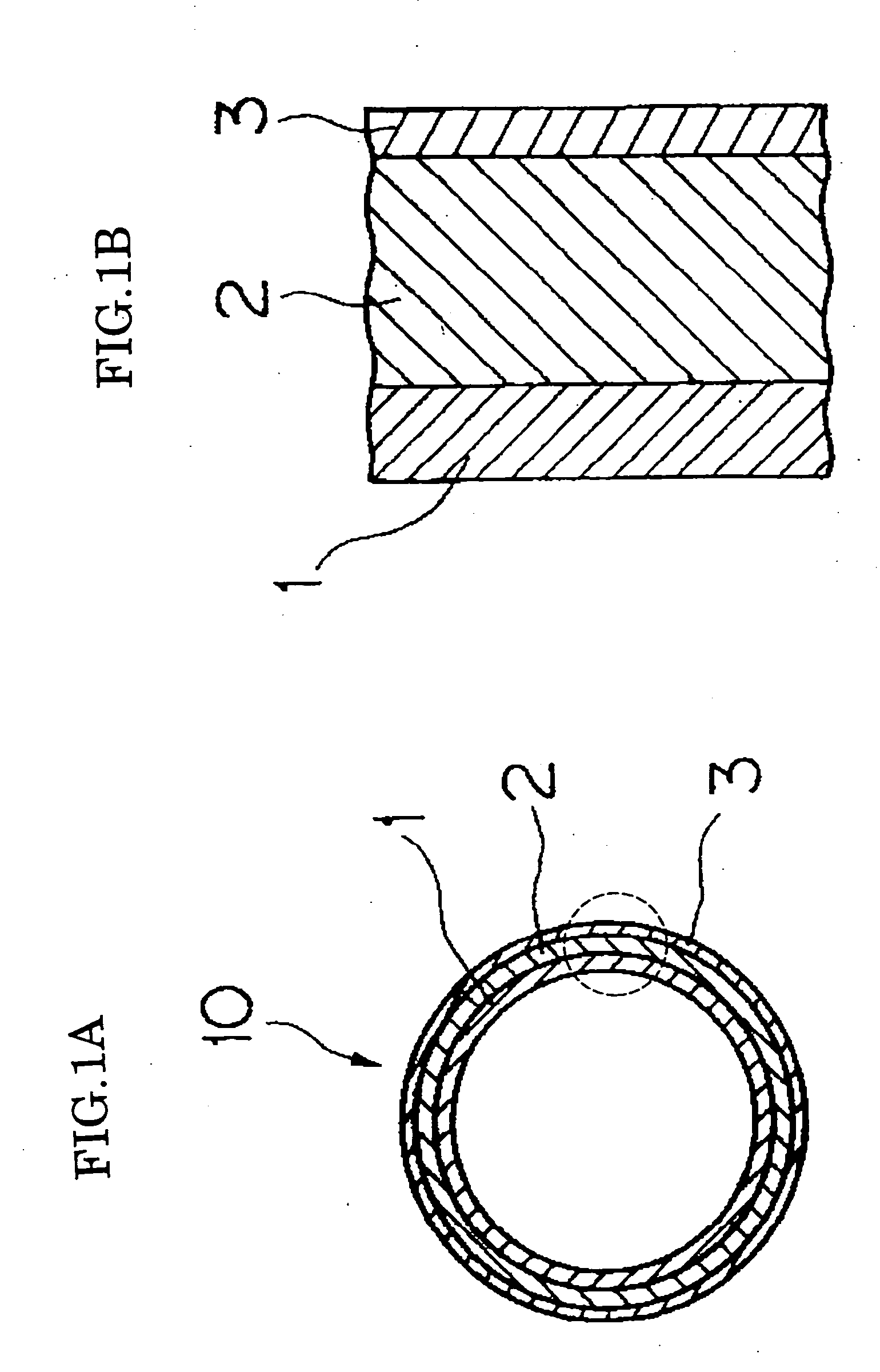

Fixing member, method for producing it, and image forming apparatus comprising the fixing member

In a fixing member (10) in which an elastic layer made of heat-resistance synthetic rubber and a releasing layer made of fluorocarbon resin are sequentially provided on a substrate, a melting point of the fluorocarbon resin constituting the releasing layer (3) is set to be at least 20° C. lower than a temperature for starting an oxidation of the heat-resistance synthetic rubber constituting the elastic layer (2), and the releasing layer (3) is burned by a temperature which is higher than the melting point of the fluorocarbon resin constituting the releasing layer (3), and a burning temperature which does not exceed the starting temperature for the oxidation of the heat-resistance rubber constituting the elastic layer (2).

Owner:RICOH KK

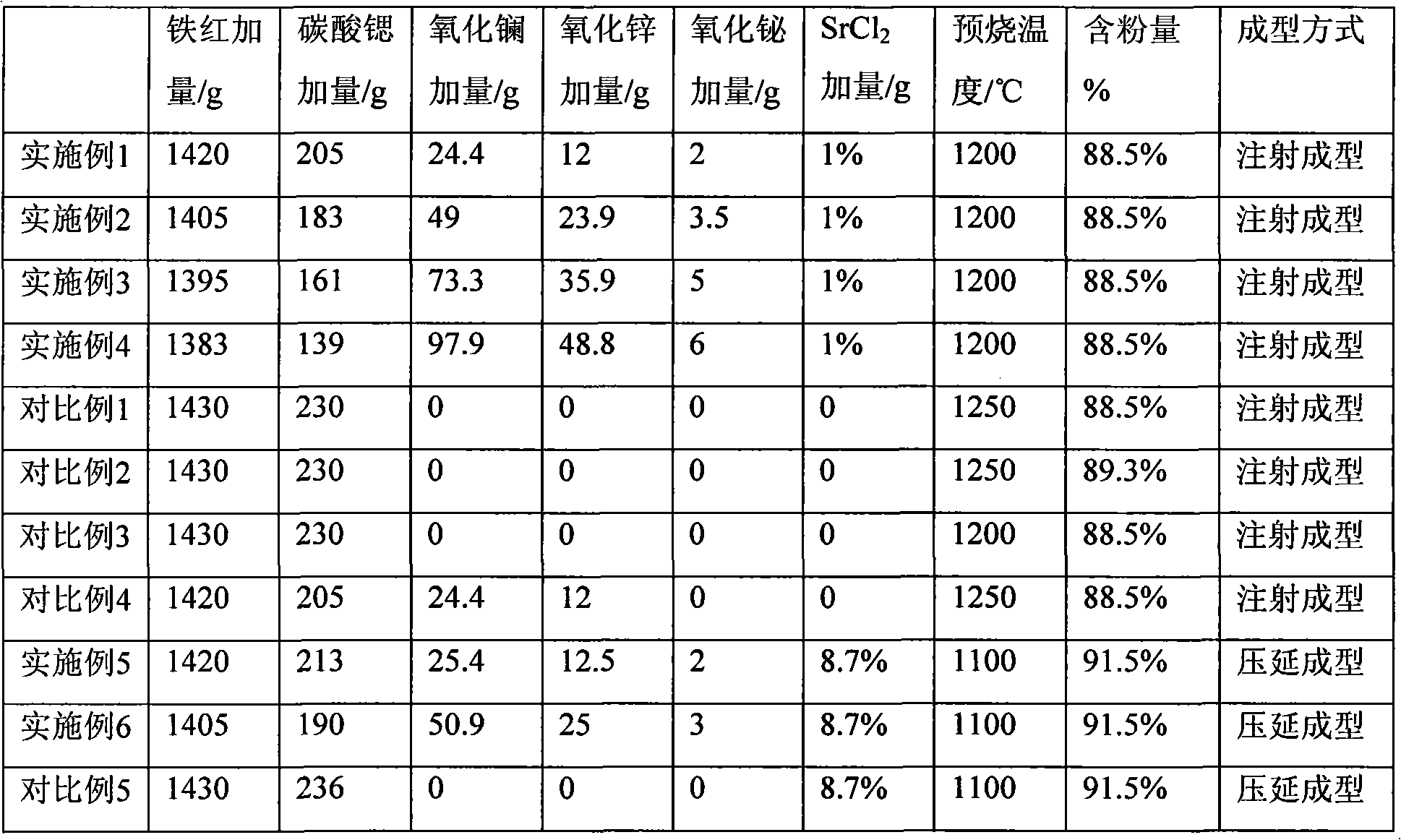

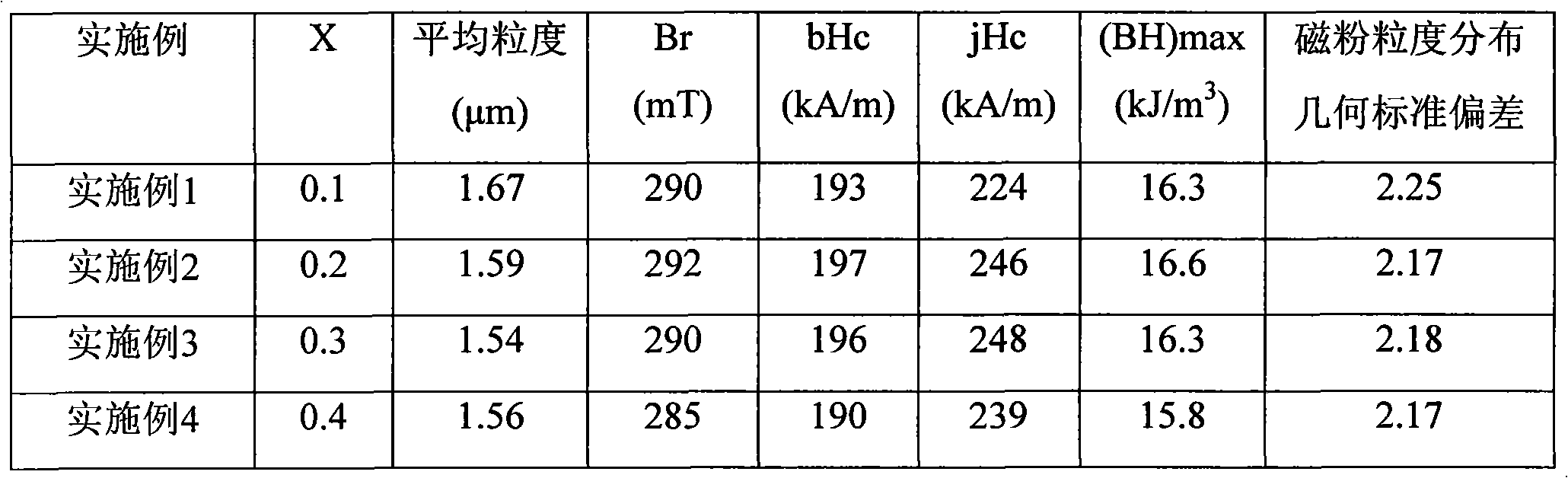

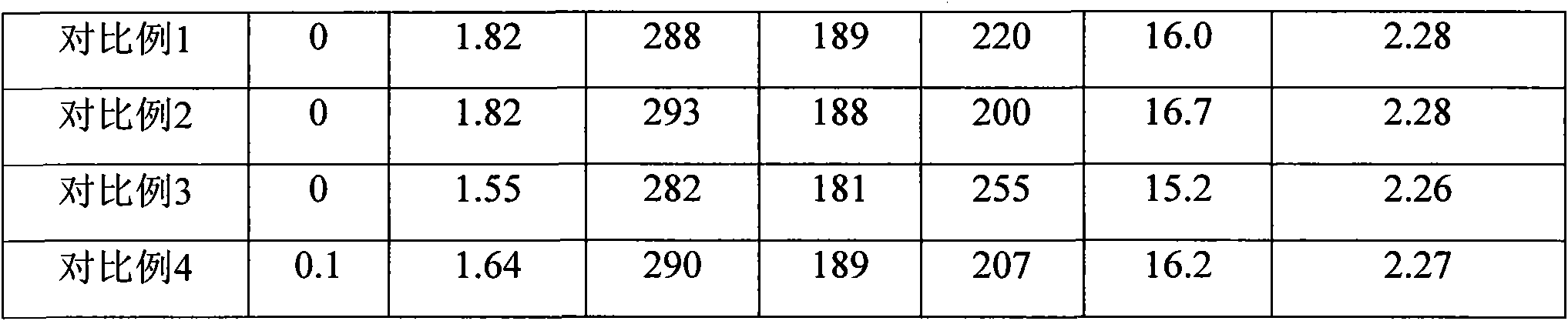

Bonded ferrite magnetic powder, preparation method thereof and bonded permanent magnet

ActiveCN101894648AControl growthControl particle size distributionInductances/transformers/magnets manufactureMagnetic materialsStrontiumChloride

The invention discloses bonded ferrite magnetic powder, a preparation method thereof and a bonded permanent magnet, which belong to the technical field of magnetic materials. The magnetic powder comprises a principal phase with the molecular formula of (M1-xLax)O.n(Fe1-yZnyBiz)2O3, wherein M denotes at least one of strontium and barium; x, y, z and n denote mole ratios, and meets x=2mn(y+z); x is 0.01 to 0.40; z / y is more than or equal to 0.01 and less than or equal to 0.3; n is 5.50 to 6.40; and m is 0.90 to 1.10. The invention also provides the preparation method for the bonded ferrite magnetic powder, and the bonded permanent magnet. Bismuth oxide is added in certain proportion in a material mixing process, and chloride is added in certain proportion as a fluxing agent in the material mixing process, so the reduction of pre-burning temperature and control over the growth of crystal grains and the grain size distribution of the magnetic powder are realized, and the prepared magnetic powder is endowed with the advantages of high Br and high jHc.

Owner:BEIKUANG MAGNETS FUYANG CO LTD

Fixing member, method for producing it, and image forming apparatus comprising the fixing member

InactiveUS20050095381A1Low costShaft and bearingsSynthetic resin layered productsHeat resistanceImage formation

In a fixing member (10) in which an elastic layer made of heat-resistance synthetic rubber and a releasing layer made of fluorocarbon resin are sequentially provided on a substrate, a melting point of the fluorocarbon resin constituting the releasing layer (3) is set to be at least 20° C. lower than a temperature for starting an oxidation of the heat-resistance synthetic rubber constituting the elastic layer (2), and the releasing layer (3) is burned by a temperature which is higher than the melting point of the fluorocarbon resin constituting the releasing layer (3), and a burning temperature which does not exceed the starting temperature for the oxidation of the heat-resistance rubber constituting the elastic layer (2).

Owner:KONDOH TSUNEAKI

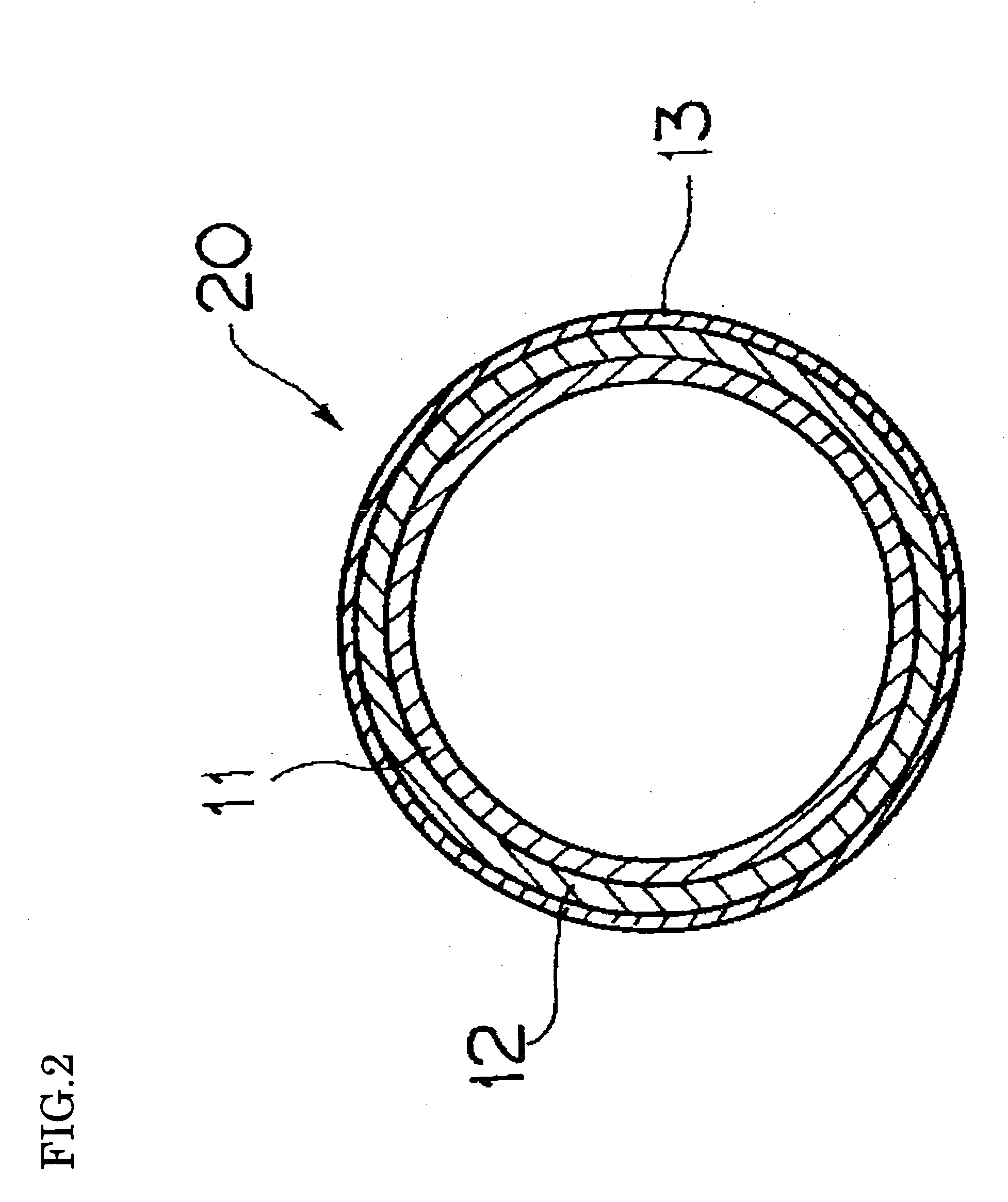

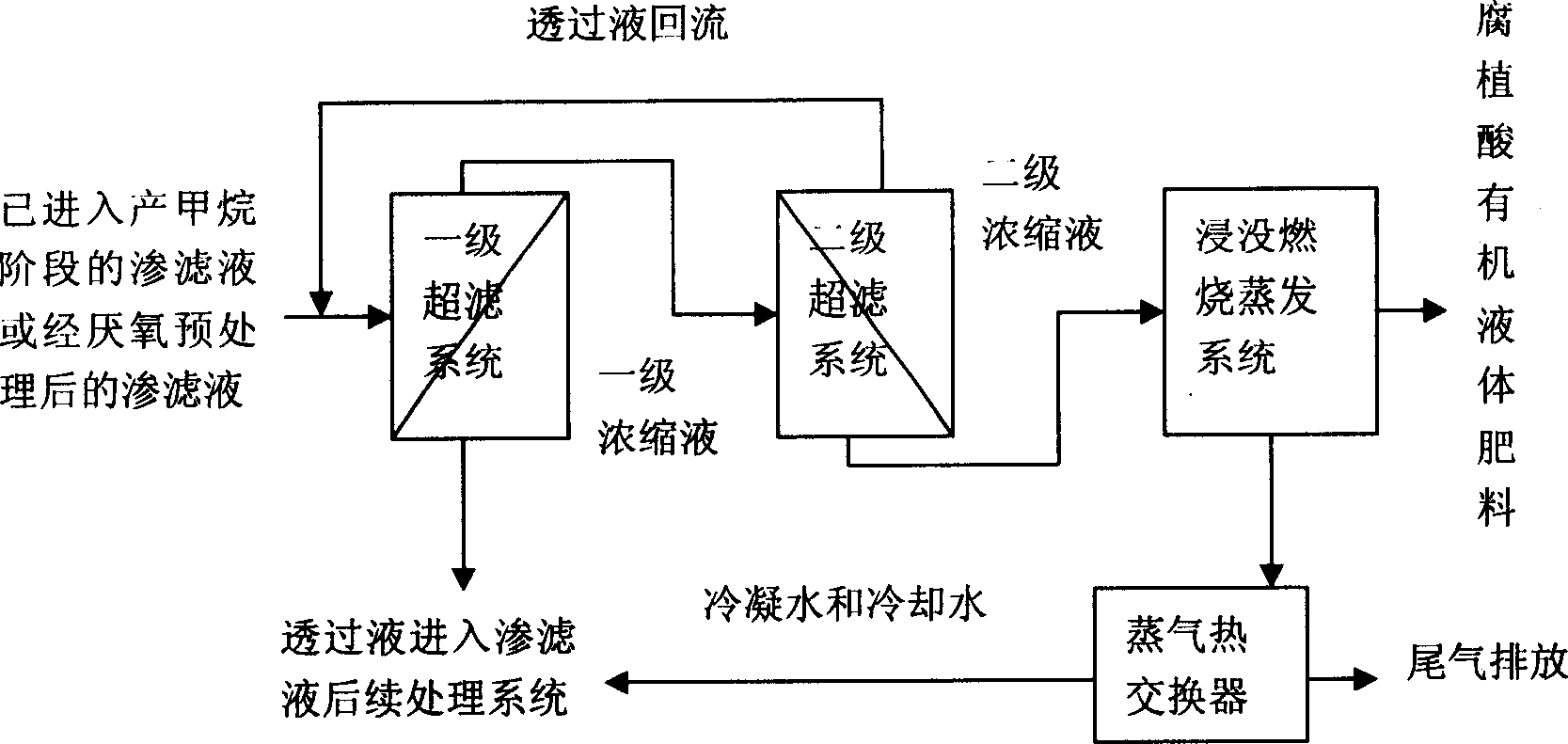

Resource process for percolation liquid of city life garbage landfill

InactiveCN1648075ASolve difficult problemsUnification of environmental benefitsBio-organic fraction processingClimate change adaptationCombustion chamberOrganic fluid

The technological process of utilizing percolation liquid from domestic garbage landfill belongs to the field of garbage treating technology. The present invention aims at raising the percolation liquid treating level to reach the exhaust standard. The technological process of utilizing percolation liquid from domestic garbage landfill includes the following steps: 1) pumping the percolation liquid to the first stage of ultrafiltering system and treating in pressure difference of 0.3-0.5 MPa, 5-10 times concentration and membrane separation to obtain the first stage of concentrated liquid; 2) pumping into the second stage of ultrafiltering system and treating in pressure difference of 1.0-1.5 MPa, 4-5 times concentration and membrane separation to obtain the second stage of concentrated liquid; and 3) treating in immersing, burning and evaporating system at burning temperature over 750 deg.c, immersing depth 0.3-0.6 m and 5-10 times concentration to obtain liquid organic fertilizer.

Owner:TSINGHUA UNIV

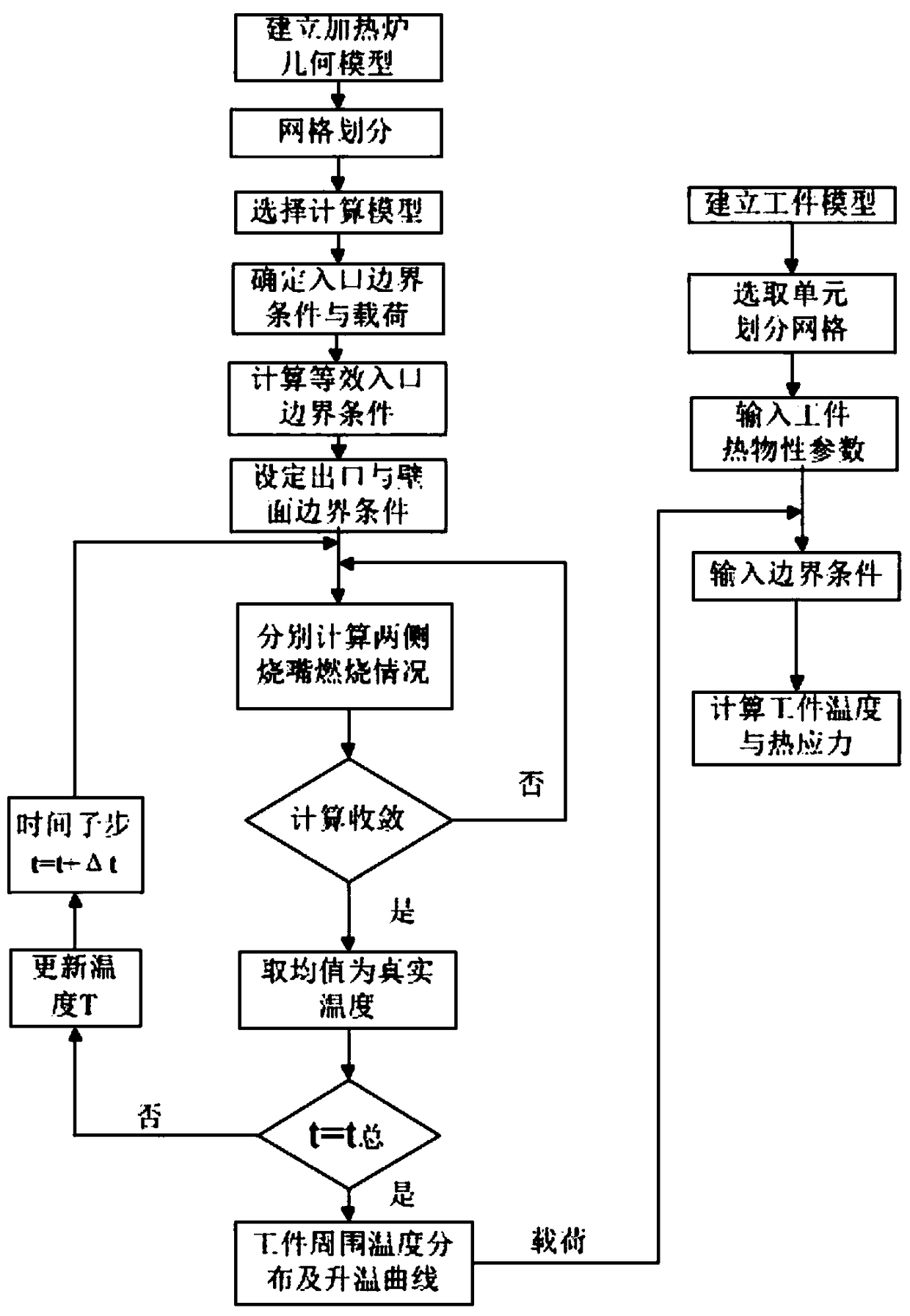

Method for analyzing regenerative heating furnace flow field and internal temperature and thermal stress of workpiece

InactiveCN108363857ASimplify the modeling processThe result is accurateDesign optimisation/simulationSpecial data processing applicationsStructural analysisModel parameters

A method for analyzing a regenerative heating furnace flow field and an internal temperature and a thermal stress of a workpiece is characterized in that the content of the method specifically comprises the following steps of (a) establishing a regenerative heating furnace geometrical model; (b) dividing a grid; (c) selecting a numerical simulation calculation model; (d) determining an entrance boundary condition, setting a model entrance condition as a speed entrance condition; (e) setting exit and wall boundary conditions; (f) respectively calculating a respective burning temperature field of burner nozzles at two sides of the heating furnace in a reversing process; (g) establishing a furnace internal processing workpiece model; (h) selecting a thermal-structural analysis unit to performgrid division on the furnace internal processing workpiece model; (i) inputting a thermophysical parameter of the furnace internal processing workpiece model; and (j) distributing the temperature field in the heating furnace into foundation and boundary conditions, and performing computational analysis on a furnace internal processing workpiece. According to the method for analyzing the regenerative heating furnace flow field and the internal temperature and the thermal stress of the workpiece, a modeling process is simple and a result is more accurate; model parameters can be adjusted according to the difference of the hating furnace and the workpiece; and the method is adapted widely.

Owner:YANSHAN UNIV

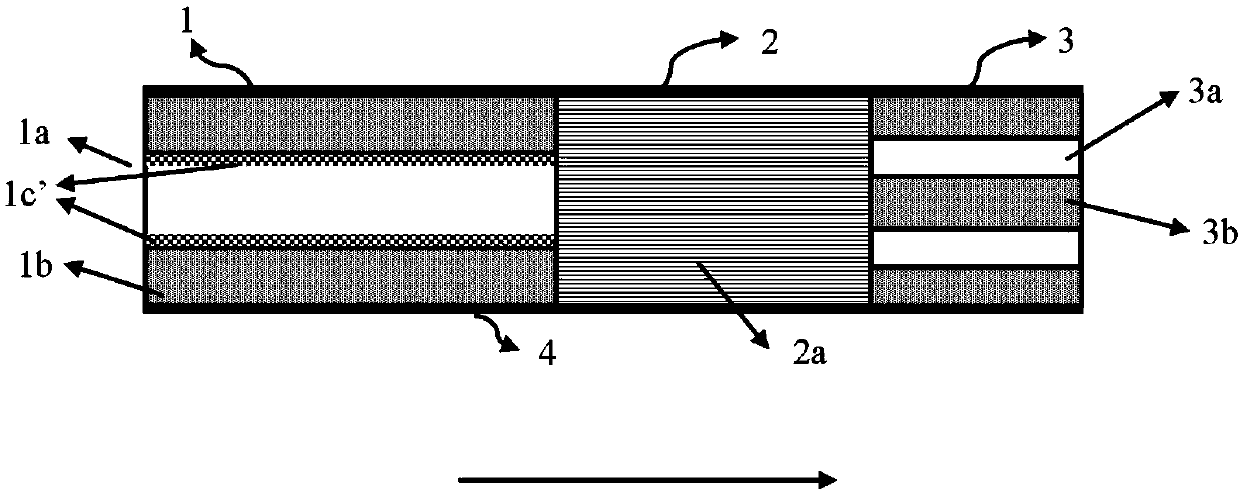

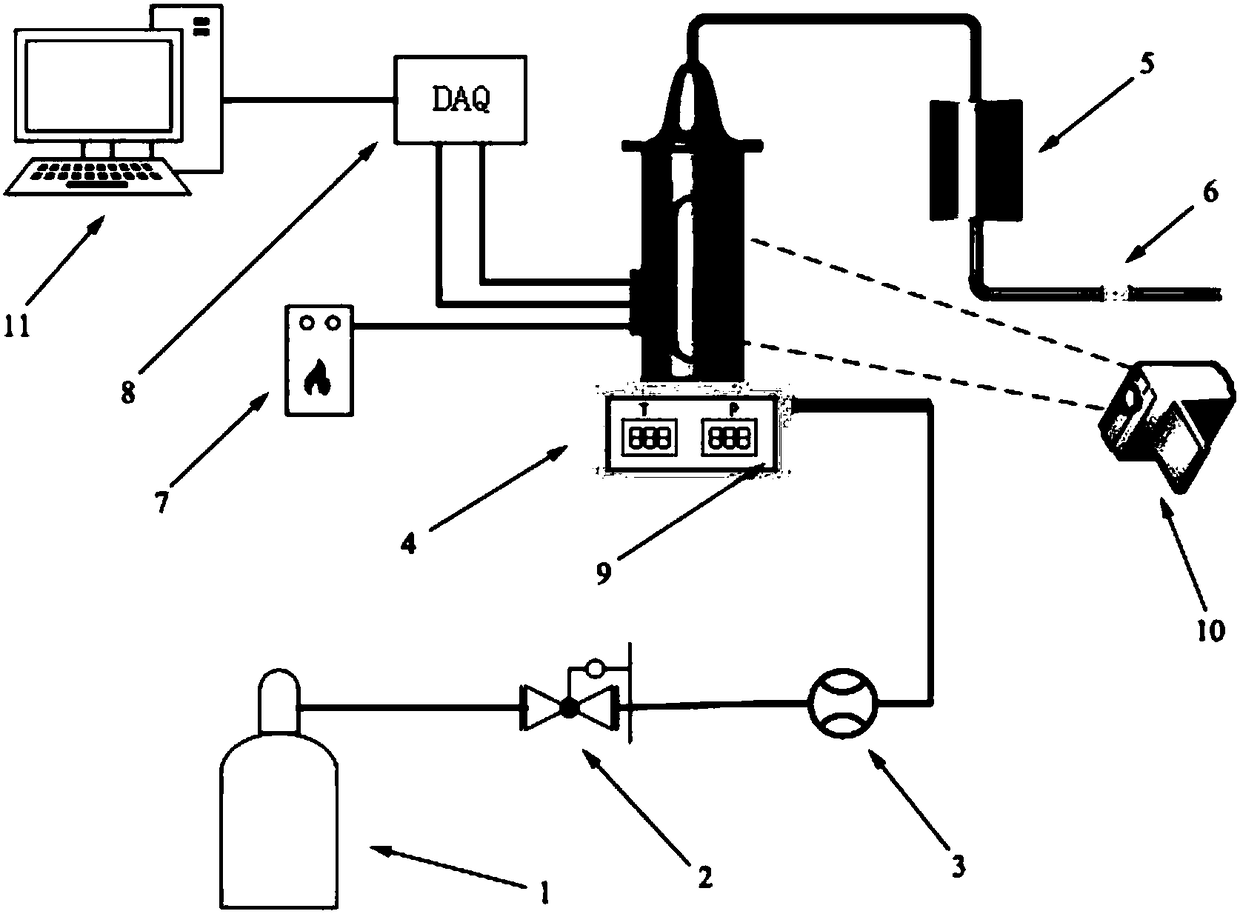

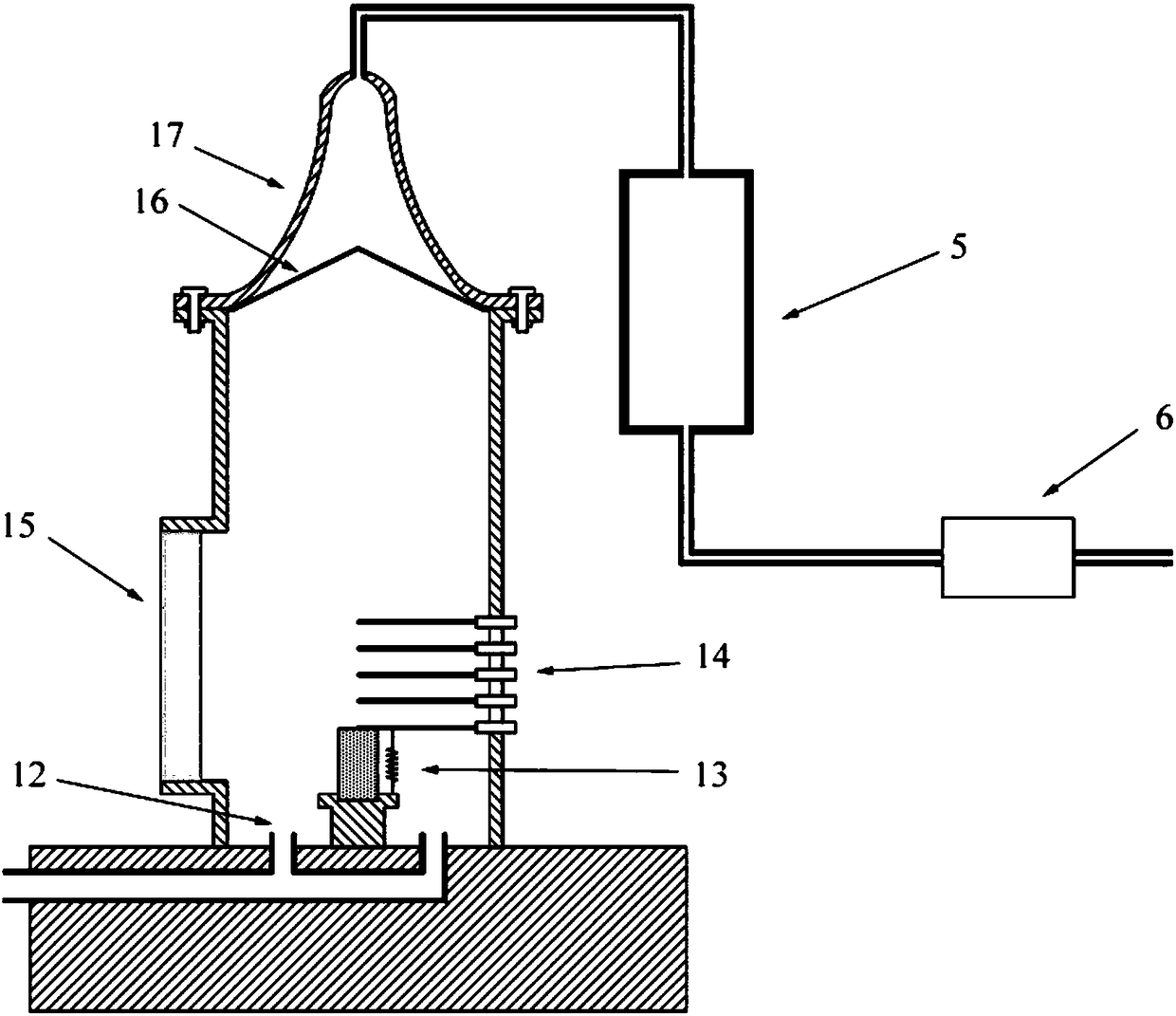

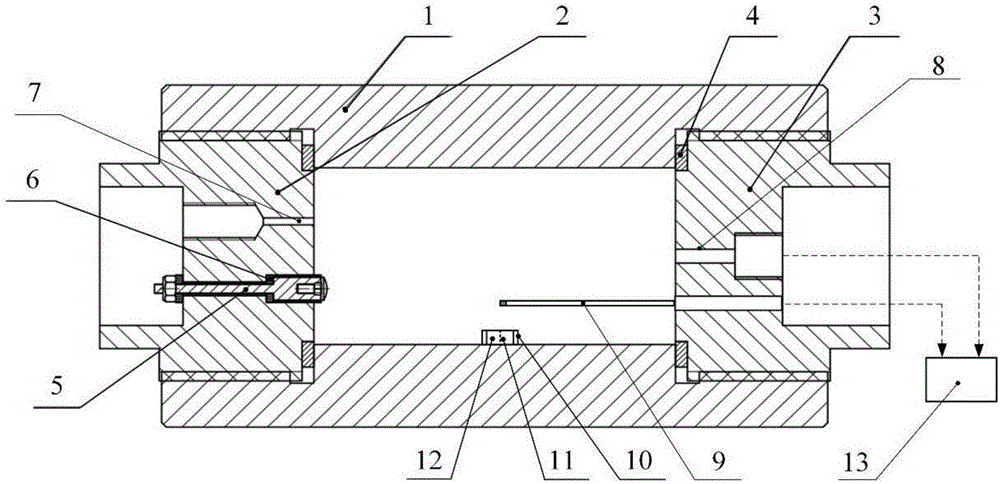

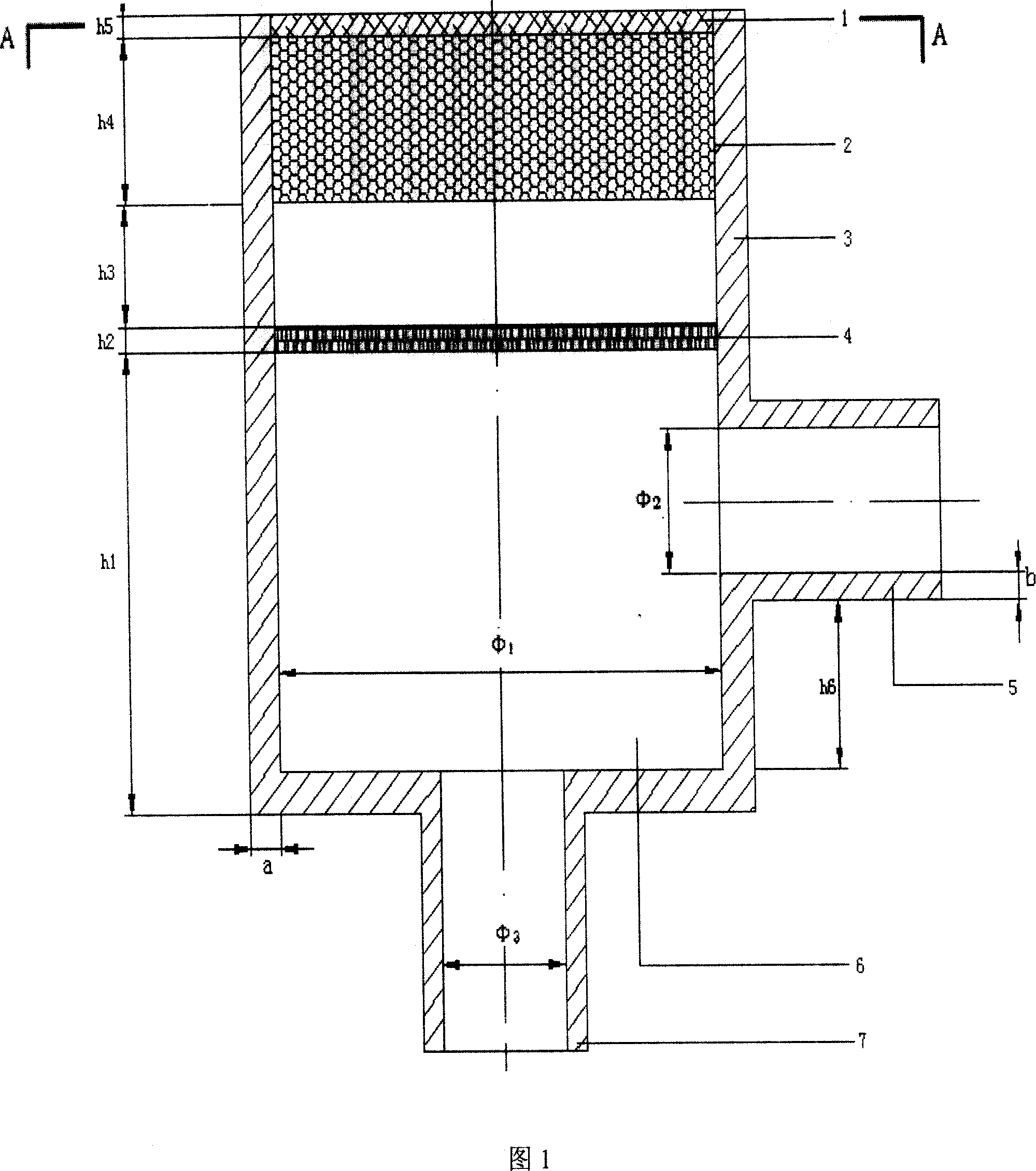

Equipment used for measuring high-pressure burning characteristic parameters of solid propellant and with observation window

PendingCN108593837AHigh precisionReliable resultsChemical analysis using combustionMaterial analysis by optical meansCombustion chamberEngineering

The invention discloses equipment used for measuring high-pressure burning characteristic parameters of solid propellant and with an observation window. The equipment comprises a high-pressure air bottle group, a pressure reducing valve, an electronic flowmeter, an igniter, a high-pressure burning chamber with the observation window, a buffer tank, a back pressure valve, a high-speed camera, an optical filter, a digital display panel, a data collection module and a computer. The high-pressure burning chamber with the observation window further comprises a shell, the observation window, a temperature sensor and a pressure sensor. Compared with the prior art, the equipment has the advantages that change of parameters such as burning speed, burning temperature and highest burning temperatureof the solid propellant under the constant pressure can be measured synchronously, the morphological characteristics of burning flame are acquired in real time, the influence of pressure on the burning process is confirmed, and the experimental support is provided for research of a high-pressure burning mechanism of the solid propellant.

Owner:UNIV OF SCI & TECH OF CHINA

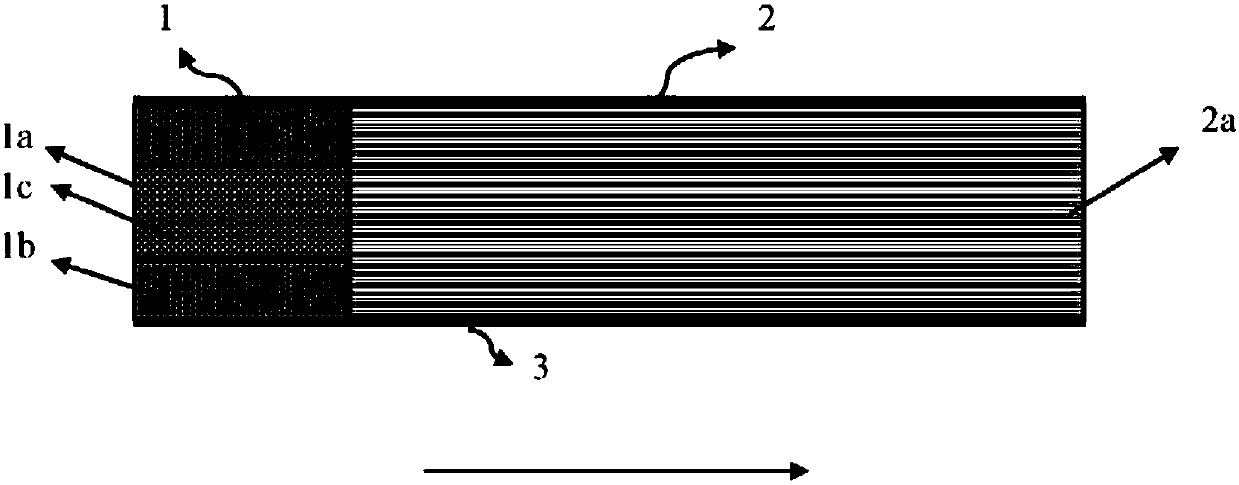

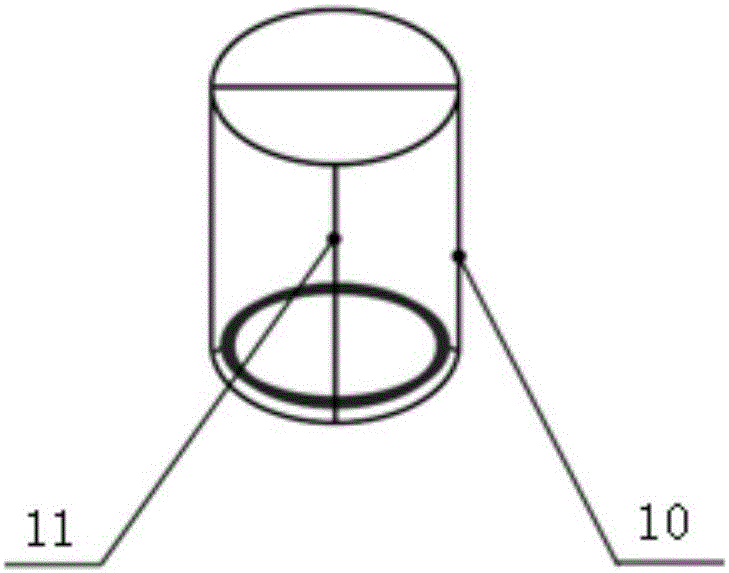

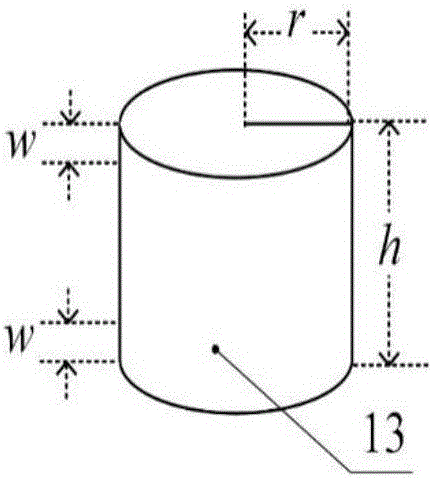

Test device for burning speed/burning temperature of solid propellant and test method thereof

ActiveCN106198849ASolve the problem of inaccurate burning rate testEliminate the effects ofChemical analysis using combustionCombustorEngineering

The invention discloses a test device for burning speed / burning temperature of a solid propellant and a test method thereof. The test device comprises a constant volume burner main body, a first plug, a second plug, an ignition electrode, a decompression valve, a temperature sensor and a pressure sensor, wherein the ignition electrode and the decompression valve are arranged on the first plug; the temperature sensor and the pressure sensor are arranged on the second plug; the constant volume burner main body has a cylindrical chamber structure; one end of the constant volume burner main body is connected with the first plug through a thread while the other end is connected with the second plug through the thread; a clamping device is arranged in the constant volume burner main body; a propellant grain is fixed in the clamping device; a data collecting processing unit is arranged on the outer side of the constant volume burner main body; the data collecting processing unit is respectively connected with the pressure sensor and the temperature sensor. The test device provided by the invention can meet the requirement of propellant energy quantitative test, can simulate the high pressure environment of solid propellant application and can acquire the burning speed and burning temperature of the propellant under high pressure state, so that a reliable design input is supplied for the research on the propellant.

Owner:UNIV OF SCI & TECH OF CHINA

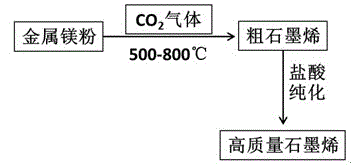

Method using carbon dioxide as raw material to prepare high-quality graphene

The invention discloses a method using carbon dioxide as a raw material to prepare high-quality graphene. The method comprises the following steps: (1) putting magnesium powder into a tube-type high-temperature furnace, and raising temperature to the 500-800 DEG C of burning temperature of magnesium powder under the protection of carbon dioxide with 90.00-99.99 percent of purity and 50-75 ml / min of flow; after achieving the 500-800 DEG C of burning temperature of magnesium powder, increasing the flow of carbon dioxide to 100-300 ml / min, reacting for 20-60 minutes at high temperature, regulating the flow of carbon dioxide to 70-75 ml / min, and cooling to room temperature to obtain coarse graphene powder; and (2) pouring the obtained coarse graphene powder into a hydrochloric acid solution with concentration of 1-10 mol / L, magnetically stirring for 40-80 minutes, filtering, cleaning to neuter with deionized water, then putting into a drying oven and drying at the temperature of 100-150 DGE C. The method is simple, fast, safe and environmentally-friendly, the prepared graphene can be directly used in mechanical property reinforced phases of composite materials or drug carrier with benzene rings and is applied to the fields of light, electricity, chemistry, physics and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

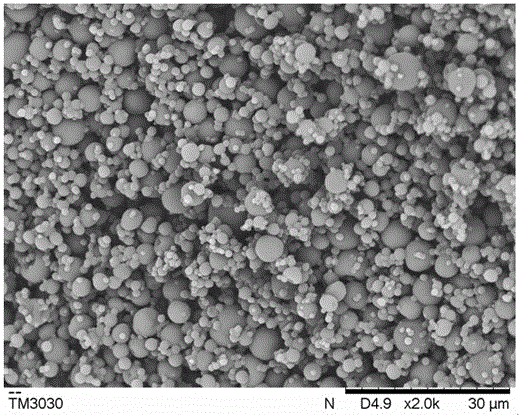

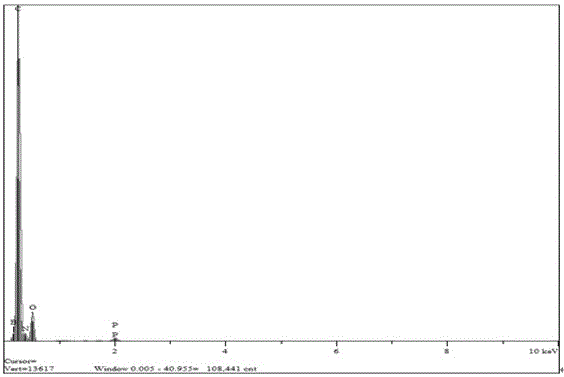

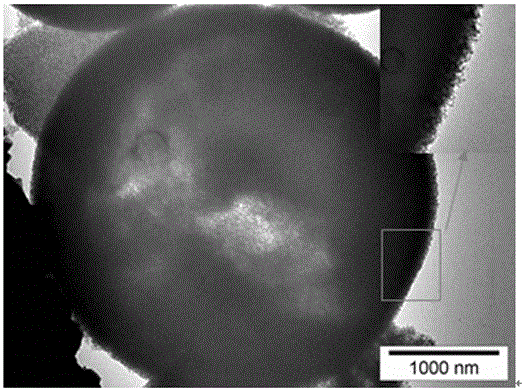

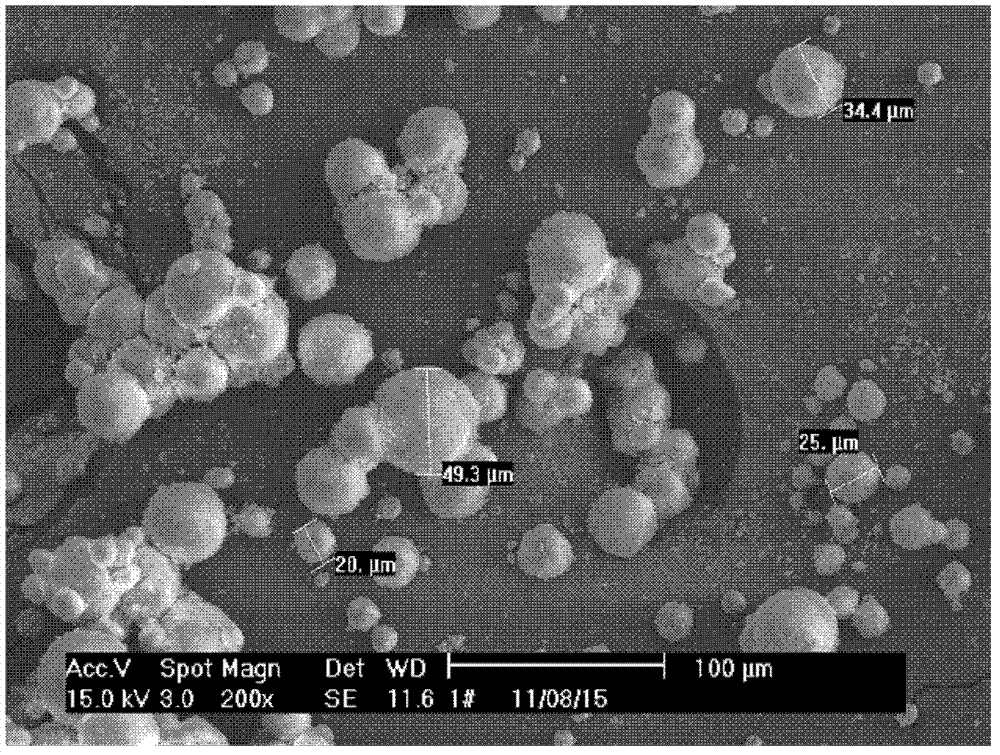

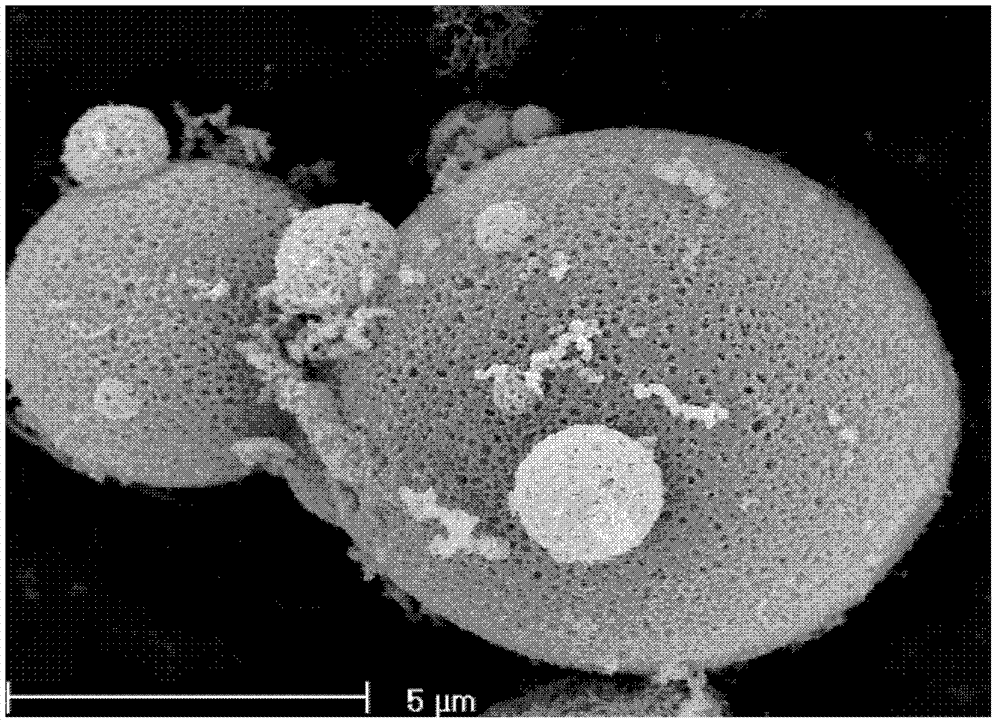

Porous silica microsphere preparation method

ActiveCN103086381AIncrease hole sizeEasy to prepareSilicaNanotechnologyTotal solid contentPolymer science

The invention discloses a porous silica microsphere preparation method, which comprises: mixing a template structure and a completely-vulcanized silicone rubber emulsion, carrying out spray drying, and burning to prepare porous silica microspheres, wherein the completely-vulcanized silicone rubber emulsion is prepared through carrying out irradiation on an organic silicone polymer emulsion or a copolymer emulsion, the template structure is a completely-vulcanized silicone rubber emulsion-free completely-vulcanized rubber emulsion, the solid content in the template structure is 2-50% of the total solid content in the mixed emulsion, a burning temperature is 250-1200 DEG C, and a burning time is 10-600 min. The porous silica microsphere preparation method has characteristics of simpleness and low equipment cost, wherein the formed hole is large.

Owner:CHINA PETROLEUM & CHEM CORP +1

Metal fiber and porous ceramic media surface burner

InactiveCN1995814AExpand the adjustment rangeReduce sulfide contentGaseous fuel burnerMetal fiberAlloy

The invention relates to a metallic fiber and multi-hole ceramic dielectricsurface burner, belonging to heat energy engineering technology area. The burner comprises burner shell, gas pipeline and air pipeline. In the empty cavity constituted by the burner shell, metallic fiber medium in combustion zone and ceramic medium in preheat zone are set from upper to lower in turn and two medium are tightened together. The material of metallic fiber medium in combustion zone is made of Fe-Cr-Al alloy and the material of ceramic medium in preheat zone is made of zirconia or silicon carbide. Compared with ordinary surface burner, the invention can prevent tempering effectively, improve the adjustable range of fuel and air and improve burning temperature in certain range so as to improve thermal efficiency. The burner in invention can burn natural gas, liquefied petroleum gas and mixed gas so on, also burn air fuel with low thermal value which is approached to 1000kcal / m3.

Owner:NORTHEASTERN UNIV

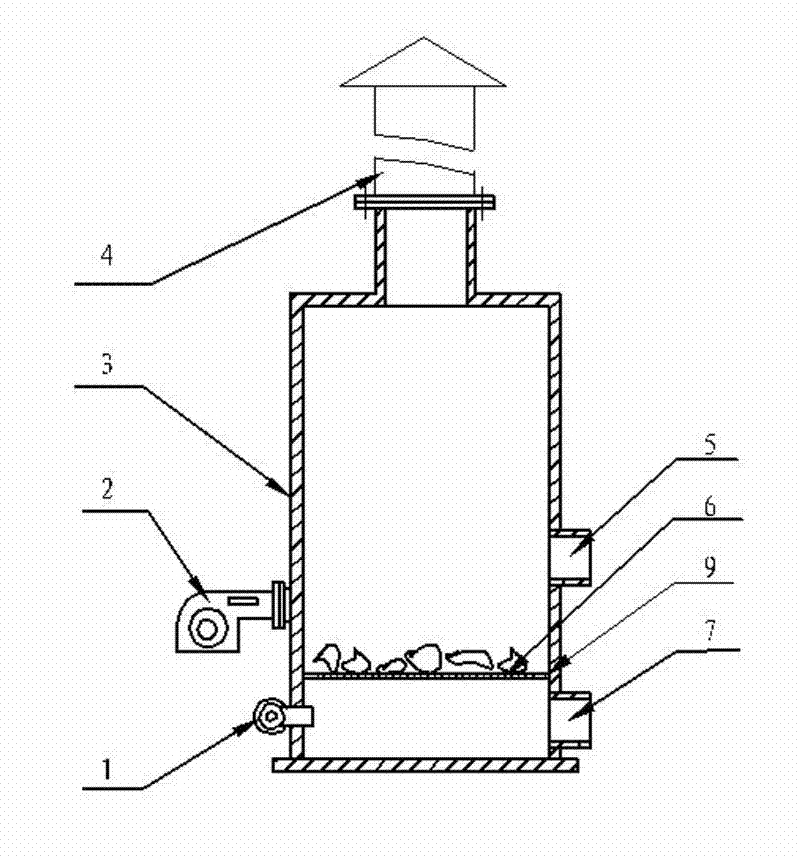

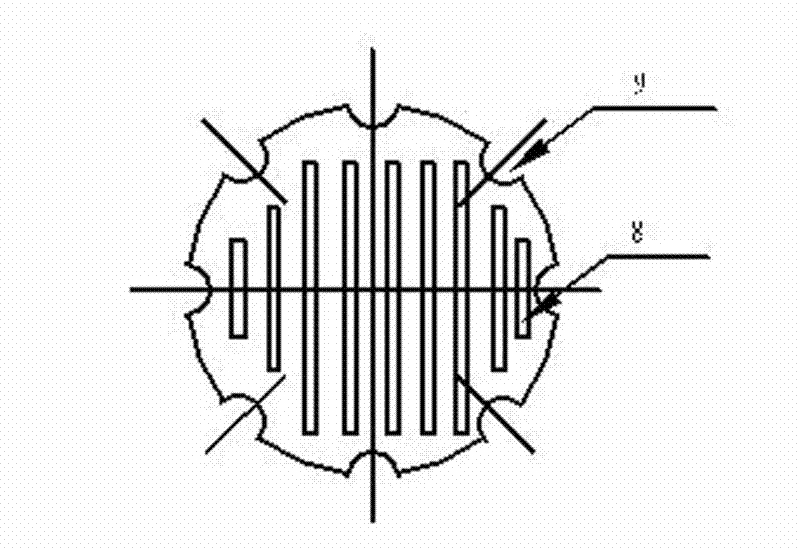

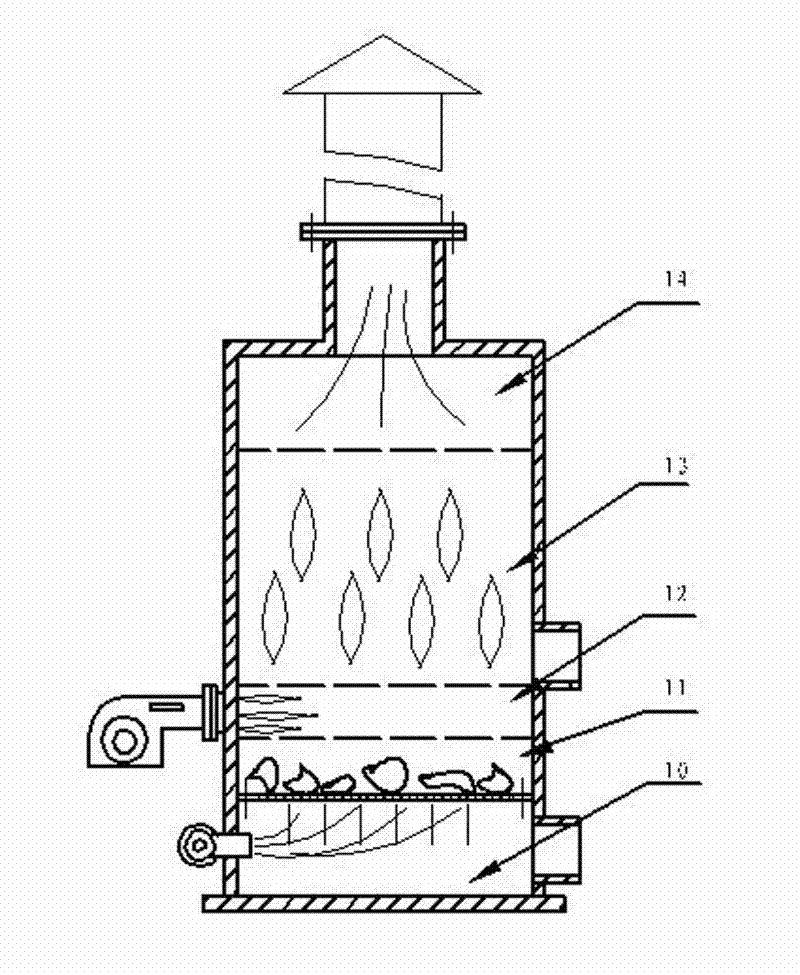

Waste incinerator

InactiveCN102226526ARealize incineration treatmentSufficient oxygen supplyIncinerator apparatusOxygenIncineration

The invention relates to a small-size waste incinerator which comprises a furnace body, a fan, a burner, a garbage inlet, a fire grate, a slagging port and a chimney. The fire grate of the waste incinerator is provided with an ash hole and a hot air hole, and can be used for directly carrying out the burning process on garbage which is not be subjected to early-stage stoving and spraying processes, a hearth can be ensured to have enough oxygen to supply in any case, and a fusion layer is arranged between the fire grate and the lighting flame, the hearth burning temperature and the burning efficiency can be effectively improved and reasonable burning working conditions can be achieved; and the formation of harmful gases such as dioxin and the like can be effective controlled, and the high efficient non-toxic non-smelly waste incineration dispose is realized.

Owner:FUJIAN NANPING JIAHE BOILER MFG

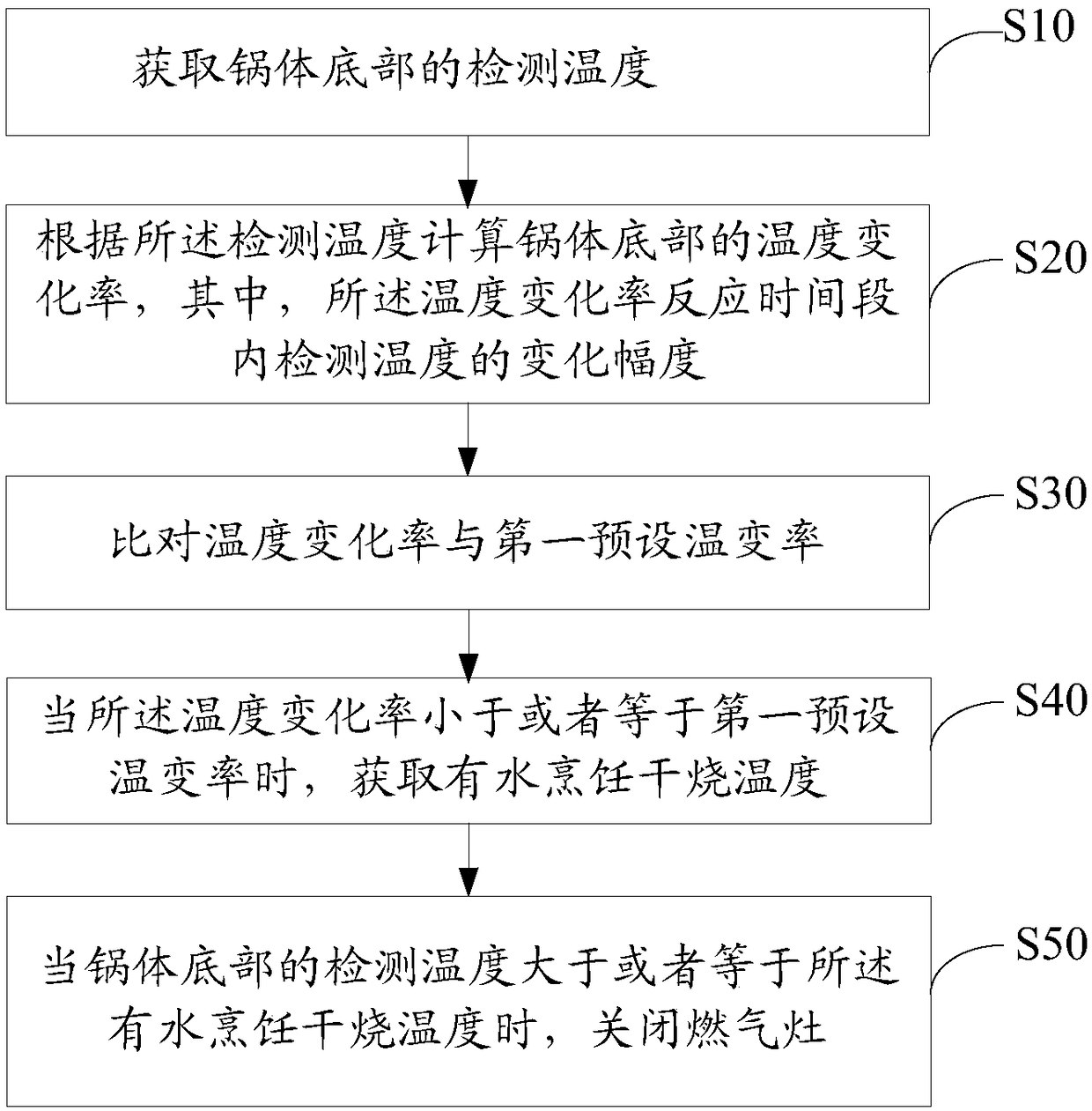

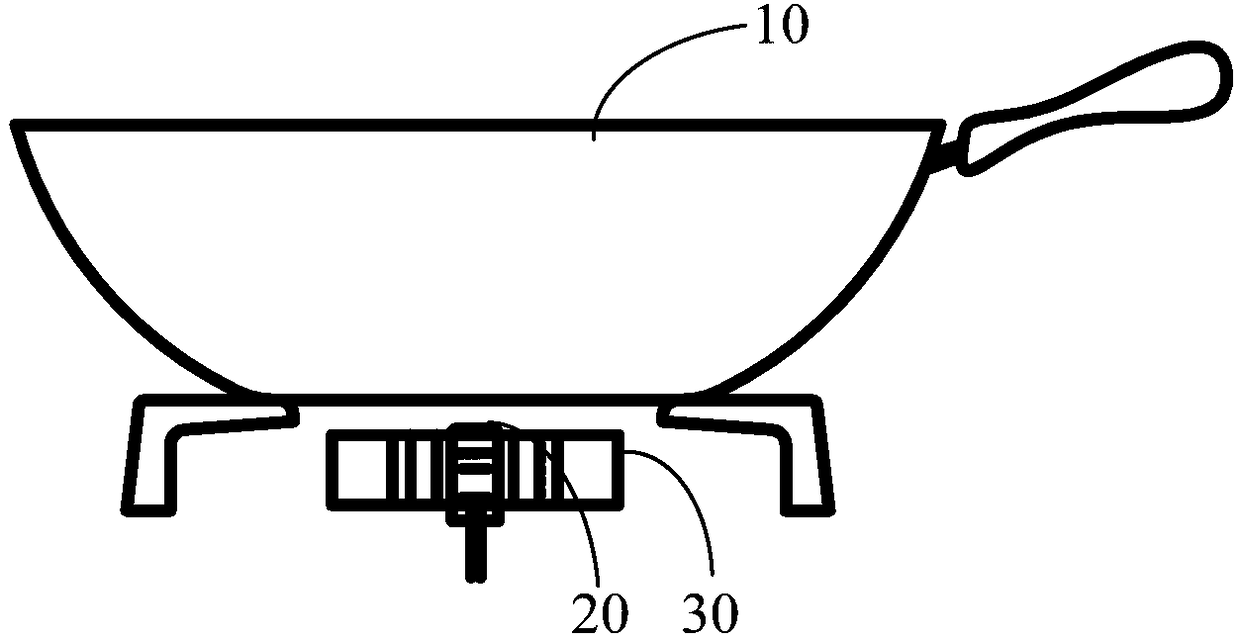

Control method of gas stove and gas stove

ActiveCN108253463AHigh control precisionDomestic stoves or rangesLighting and heating apparatusGas cooking stoveGas stoves

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

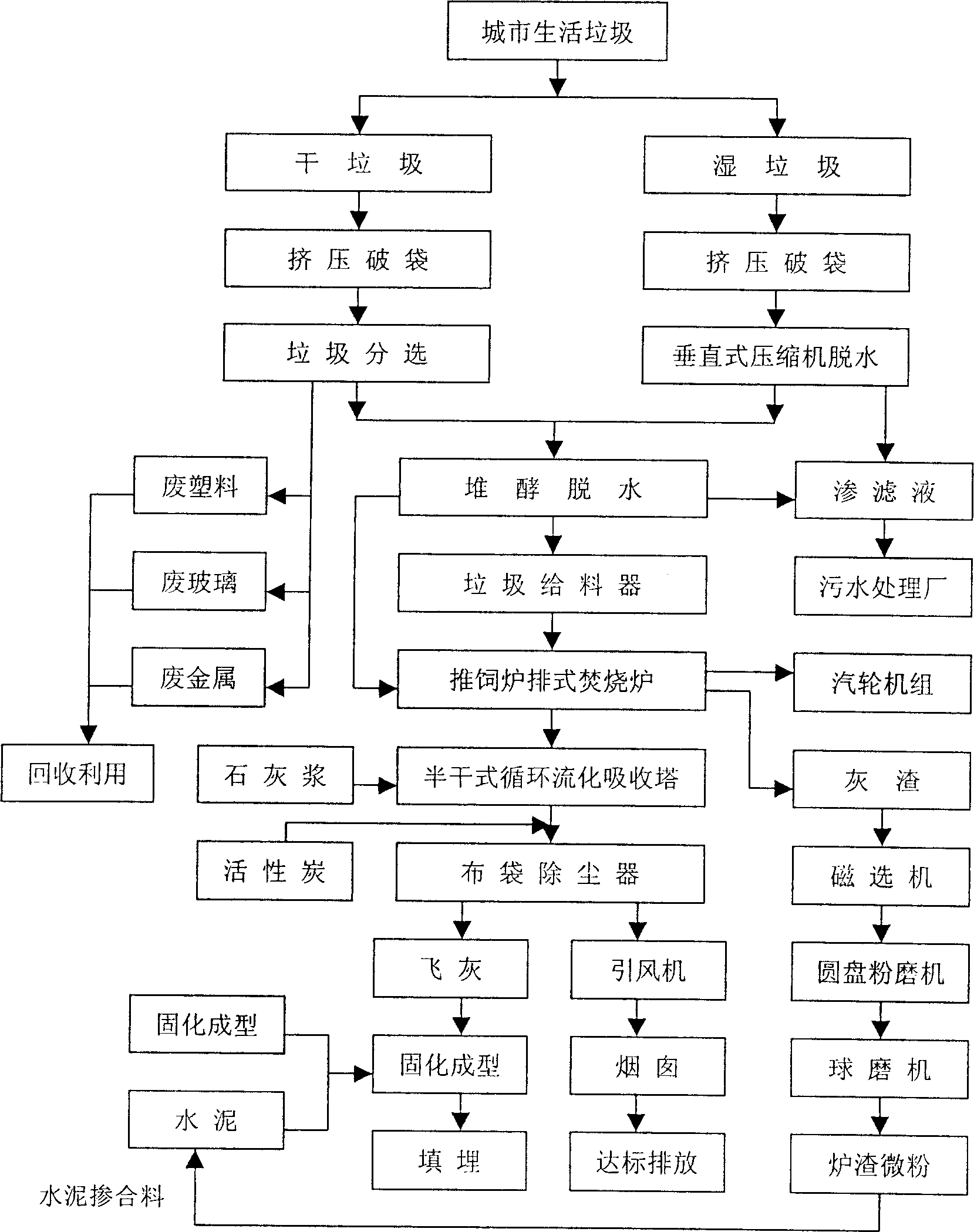

A comprehensive treatment process for urban domestic garbage

InactiveCN1864876AReduce moisture contentHigh calorific valueSolid waste disposalTotal efficiencySlag

The invention relates to an integrated method for processing municipal life waste, which comprises: collecting and classifying, separating, mechanically dewatering, fermenting and dewatering, burning, treating smoke, and collecting the slag to be used. Wherein, the dry waste after classifying and collecting can be separated into waste metal, waste glass and waste plastic, to be directly used; the wet waste via dewatered by compressing vehicle, mechanically compressed dewatered and fermenting dewatered can reach more 25% of dewatering total efficiency; the low-level caloricity of waste wet base is improved to 5990kg / kJ; the burning temperature is kept at 950-1050Deg. C, with high caloricity recycle rate; and the burning smoke has lower contents of dust, hydrochloride, heavy metal and dioxins; the smoke processing system has lower cost; and the slag has stable property, which can be used as cement blending material after magnetically selection and secondary grinding, or replace some cement. The invention can realize the integrated utilization of slag.

Owner:ZHEJIANG UNIV

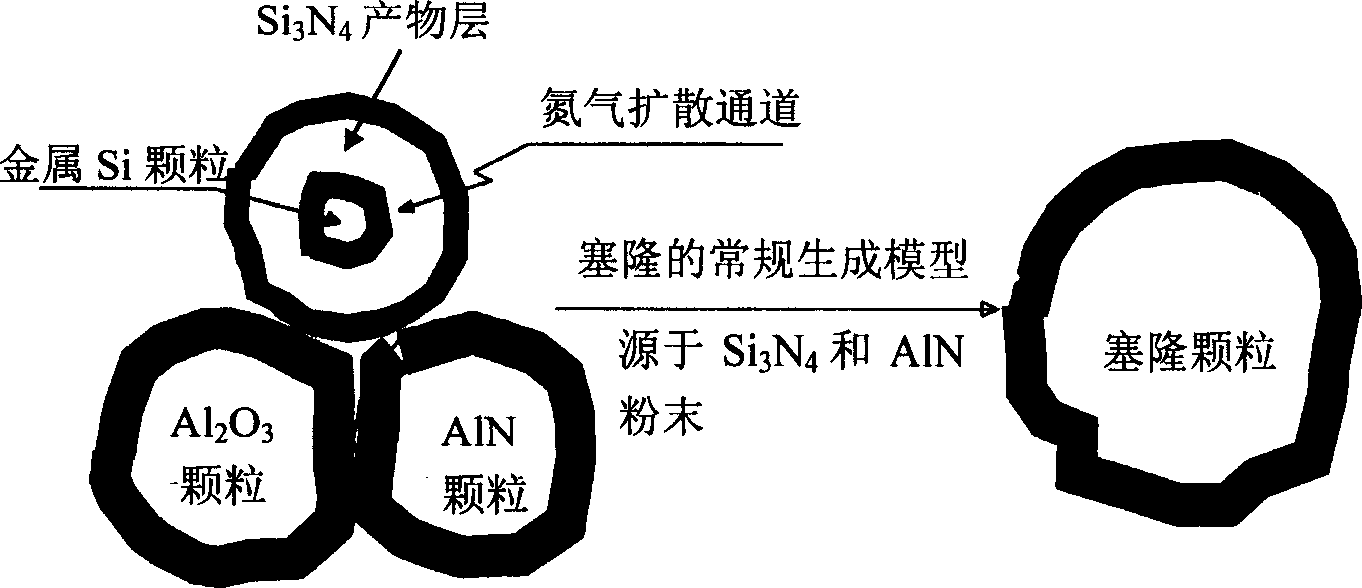

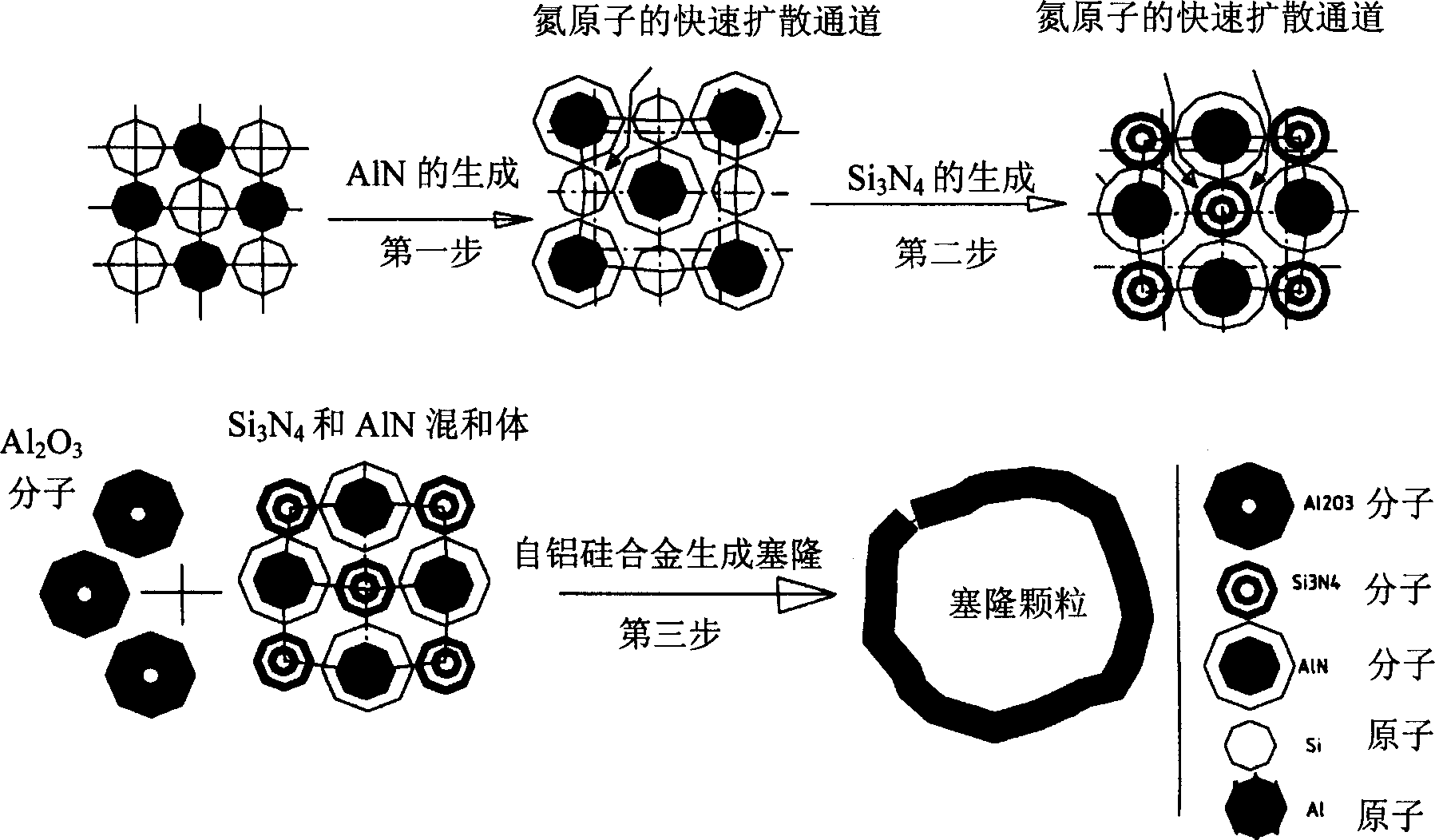

Sialon combined fireproof material containing aluminum silicon alloy

A fireproof material containing aluminum-silicon alloy. the material contains 60-75úÑ corumdum aggregate, 10-20úÑ fine corumdum powder, 5-15úÑ fine powder of aluminum-silicon alloy, 1.5-5úÑ clay, 5-12úÑ aluminum oxide. The fine powder of aluminum-silicon alloy is formed by melting or sintering metallic aluminum and metallic silicon. Due to introduction of fine powder of aluminum-silicon alloy, in producing corundum brick, the coupling phase could be quickly formed, the coupling strength between the coupling phase and brown corumdum aggregate will be improved. Compared the burning temperature of 1500degree C in the conventional process, the burning temperature of the invention is reduced to about 1430degree C , which improves the capacity of resisting rupture and high temperature.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com