Apparatus for incinerating rice husk and producing SiO2 rice husk ash with nano structure therefor

An incineration device and a nanostructured technology are applied in the field of nanostructured SiO2 rice husk ash, which can solve the problems that the heat of the rice husk is not utilized, the production scale is limited, and the volume cannot be too large, so as to solve the problem that the accumulation volume of the rice husk is limited. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

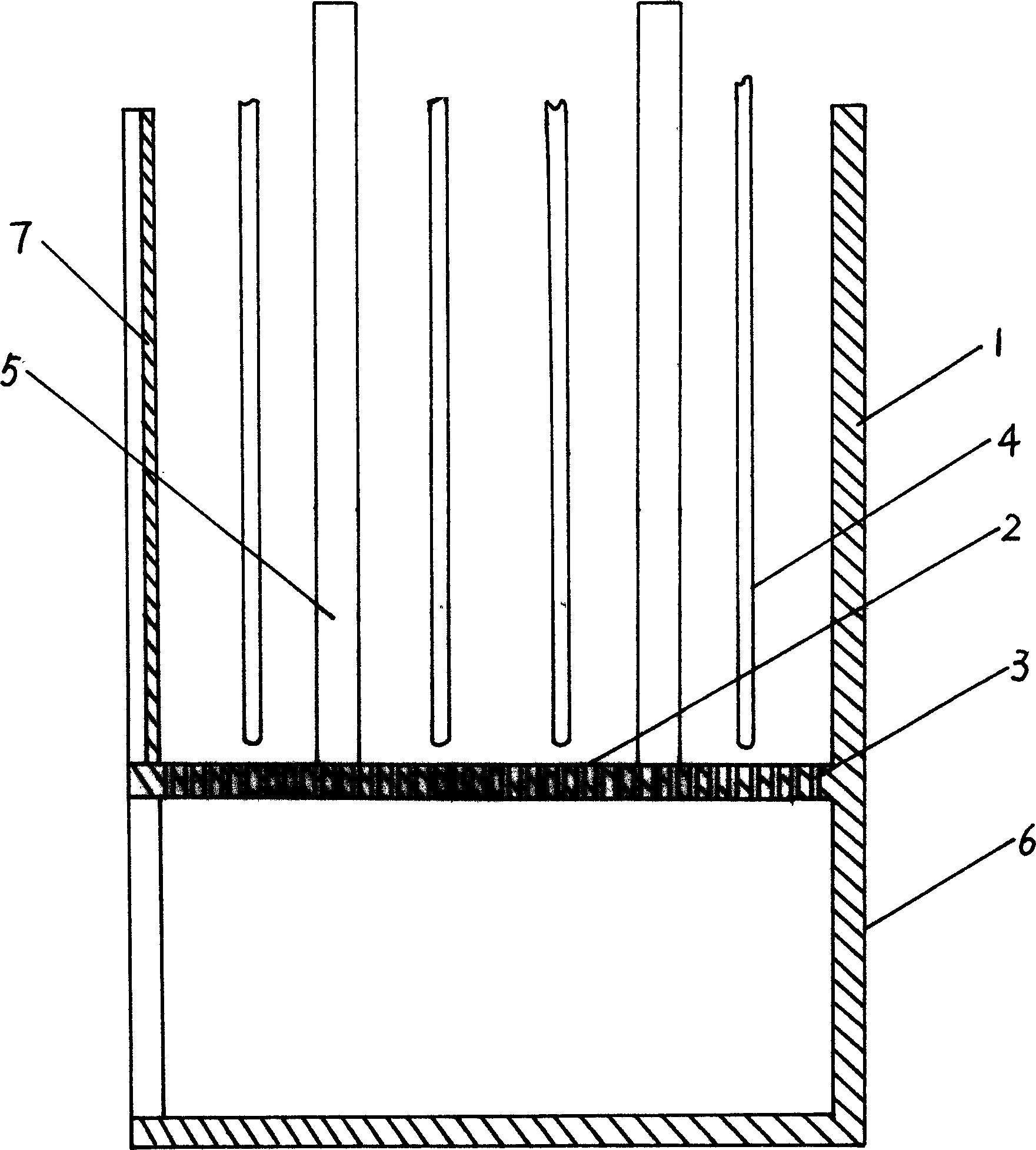

[0016] Such as figure 1 As shown, the rice husk incineration device of the present invention includes an incineration container 1, and the bottom plate 2 of the container 1 is made of materials such as steel plates. One or more than one chimney 5, the lower part of the bottom plate 2 is provided with a supporting shell 6, the inner space of the lower supporting shell 6 forms a fire space to facilitate ignition, and the side wall of the container 1 is provided with an openable gate 7, the container 1 is distributed with heat exchange water pipe 4, one end of water pipe 4 is closed and extends to bottom plate 2, and the other end is drawn from container 1 to connect with other heat exchange devices (such as boilers that can generate hot water or steam or generate electricity). During use, rice husks are piled up in the incineration container ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com