Run-flat tire

A technology for run-flat tires and tires, applied in tire parts, tire sidewalls, transportation and packaging, etc., can solve problems such as uneven rigidity and undesired ride comfort, improve ride comfort, and suppress temperature The effect of raising and improving run-flat durability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

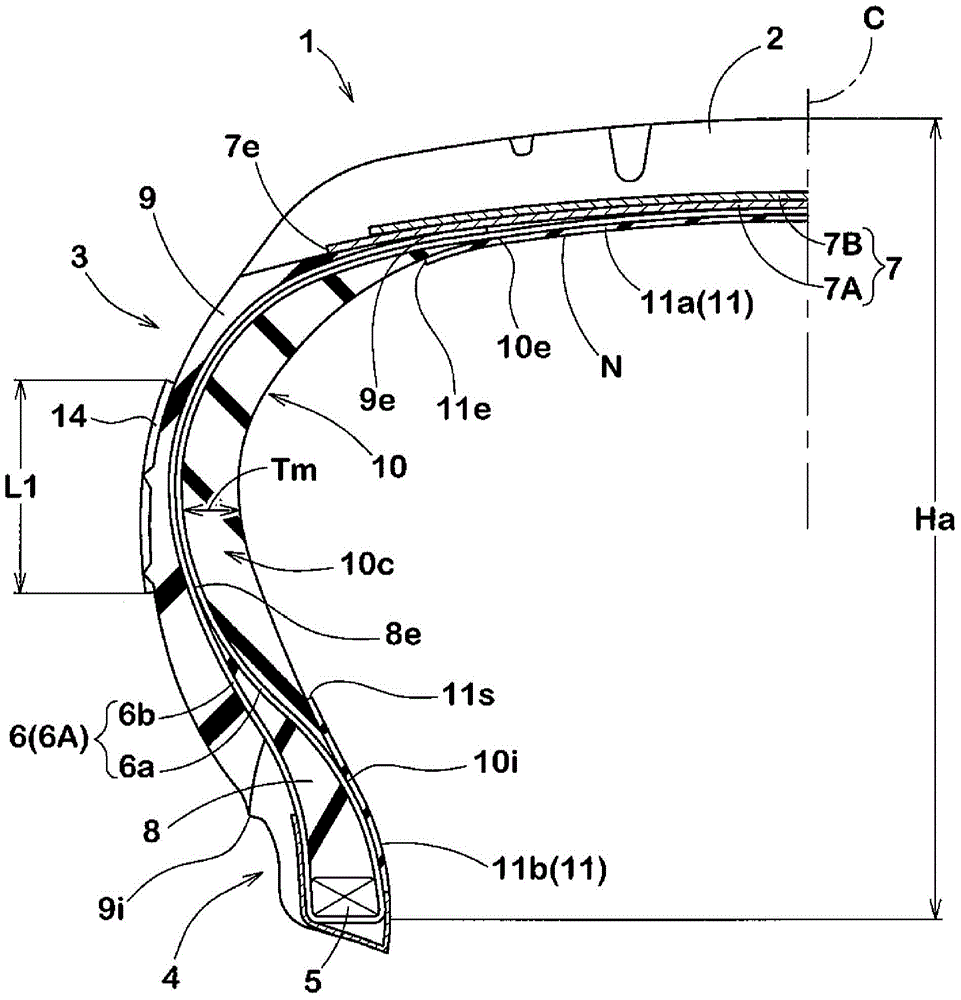

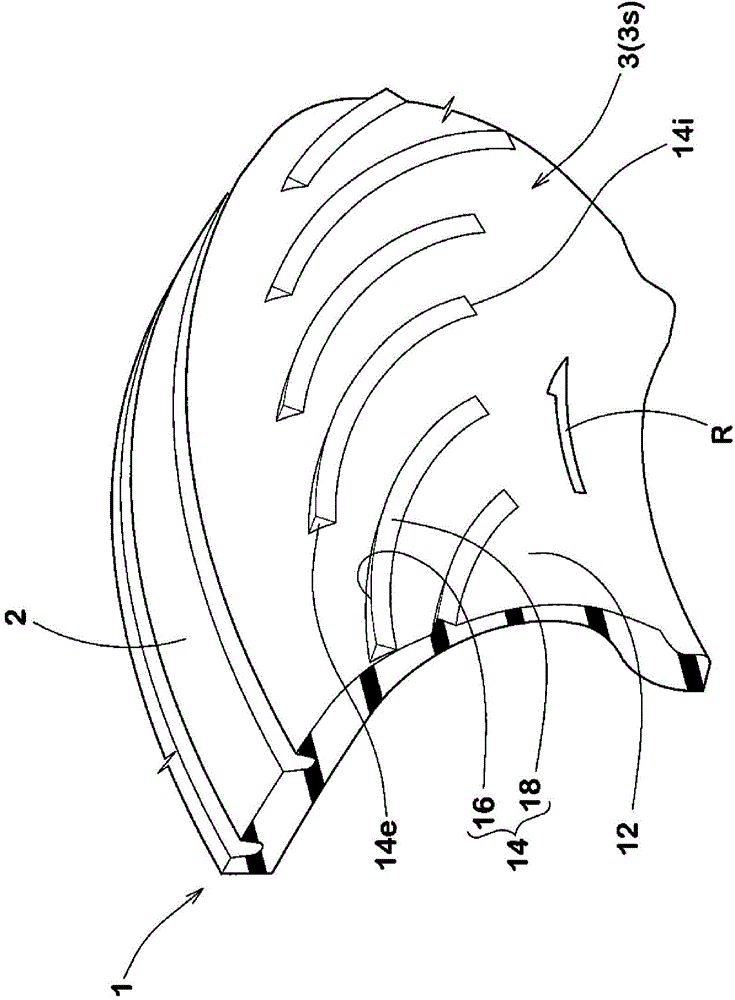

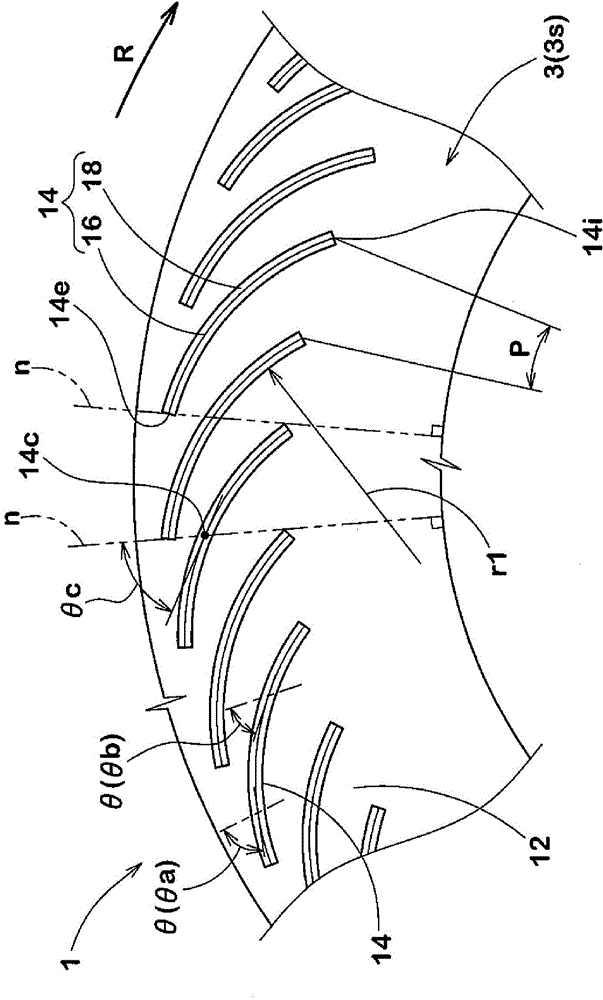

[0069] have figure 1 Run-flat tires with a size of 225 / 55R17 of the basic structure were produced according to the specifications in Table 1, and the run-flat durability and ride comfort performance of each trial tire were tested. In addition, the main common specifications or test methods of each trial tire are as follows.

[0070] Complex elastic modulus E* of sidewall reinforcing rubber layer: 9.0MPa

[0071] Loss tangent tanδ of sidewall reinforced rubber layer: 0.03

[0072] Complex elastic modulus E* of sidewall rubber: 4.0MPa

[0073] Protrusion height H1 of convex part: 2.5mm

[0074] Width W1 of convex part: 2.5mm

[0075] The angular pitches of the protrusions in Comparative Example 2 and Comparative Example 3 are the same.

[0076] The test method is as follows.

[0077]

[0078] Using a cylindrical driving tester, the test tire was driven under the following conditions, and the running distance until the tire made noise was measured. The results are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com