Industrial production device and method for producing nanometer SiO2 rice hull ash

A technology of nano-silica and production equipment, applied in the direction of silica, silicon oxide, nanotechnology, etc., can solve problems such as limitation, energy waste, and inability to continuously feed materials, so as to ensure reaction conditions and solve volume limitations , the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention adopts conventional production equipment and preparation technology, and the present invention will be further described below in conjunction with the accompanying drawings.

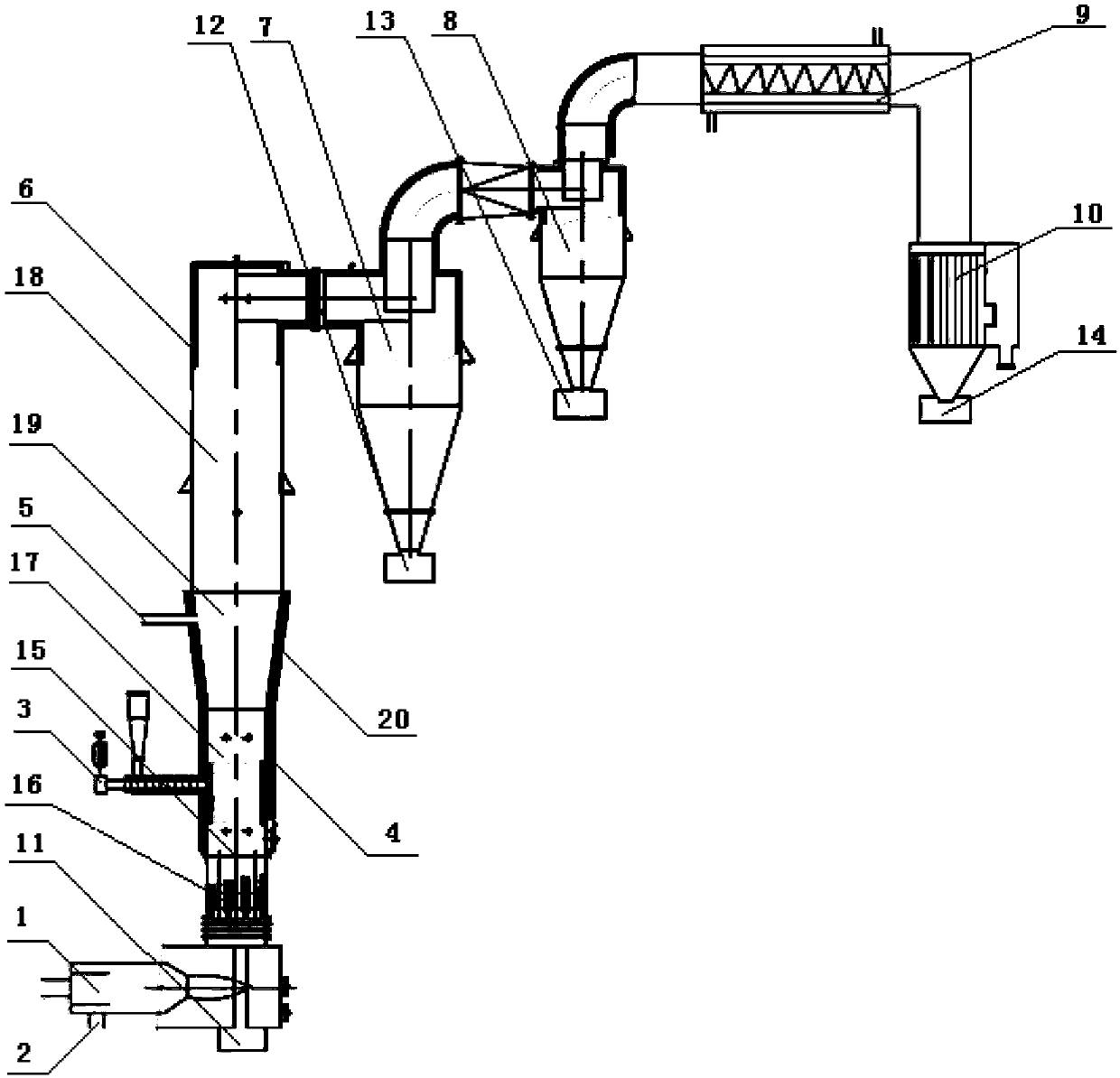

[0026] figure 1 is the nanostructured SiO of the present invention 2 Schematic diagram of the rice husk ash production plant. like figure 1 As shown, the boiler of the present invention is a fluidized-bed boiler 6 with a variable-section furnace. The upper part of the fluidized-bed boiler 6 is provided with a dilute-phase zone 18, and the diameter of the dilute-phase zone is 920mm; the lower part of the furnace is provided with a dense-phase zone 17. The diameter of the dense-phase zone is 620mm; the middle part of the furnace is provided with a variable cross-section zone 19, and the vertical angle of the variable cross-section zone 19 is 12.5°; the total height of the fluidized bed boiler 6 is 6m, and the lining of the furnace is made of anti-corrosion refractory material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com