Hyperbolic-type crystallizer copper pipe

A mold copper tube, hyperbolic technology, applied in the field of mold copper tube, can solve the problems of air gap thickness reduction, difficult to obtain large gradient, increase mold heat transfer effect, etc., to achieve the effect of increasing the casting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

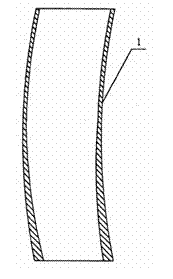

[0033] Notes in the figure: 1. Mold copper tube 2. Copper tube wall 3. Hyperbolic surface

[0034] According to the taper curve obtained in the content of the invention, we take a certain crystallizer copper tube as an example to illustrate the specific implementation of the invention. The main parameters of the continuous casting machine using the mold copper tube are as follows:

[0035] Casting machine type: full arc

[0036] Casting machine radius: 8m

[0037] Number of streams: 5 streams

[0038] Flow spacing: 1250mm

[0039] Billet section size: 170mm×170mm

[0040] Mold copper tube height: 900mm (effective height 800mm)

[0041] Casting steel type: Q235

[0042] Cooling water flow:

[0043] Design pulling speed:

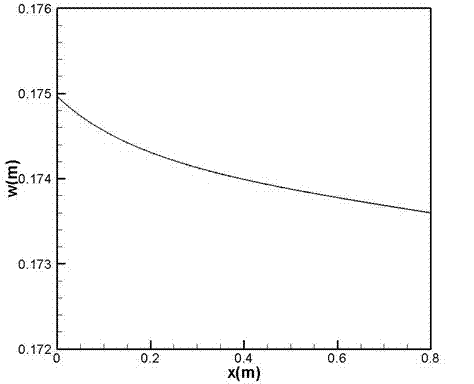

[0044] Assuming that half of the shrinkage of the crystallizer cavity is z, the taper curve formula [1] is integrated to obtain the change law of z along the length of the crystallizer, which is expressed as follows:

[0045] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com