Brushless motor

A motor and core technology, applied in the magnetic circuit shape/style/structure, electromechanical devices, magnetic circuit rotating parts, etc., can solve problems such as poor steering feel, reduce the air gap, reduce the cogging torque, The effect of low cogging torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

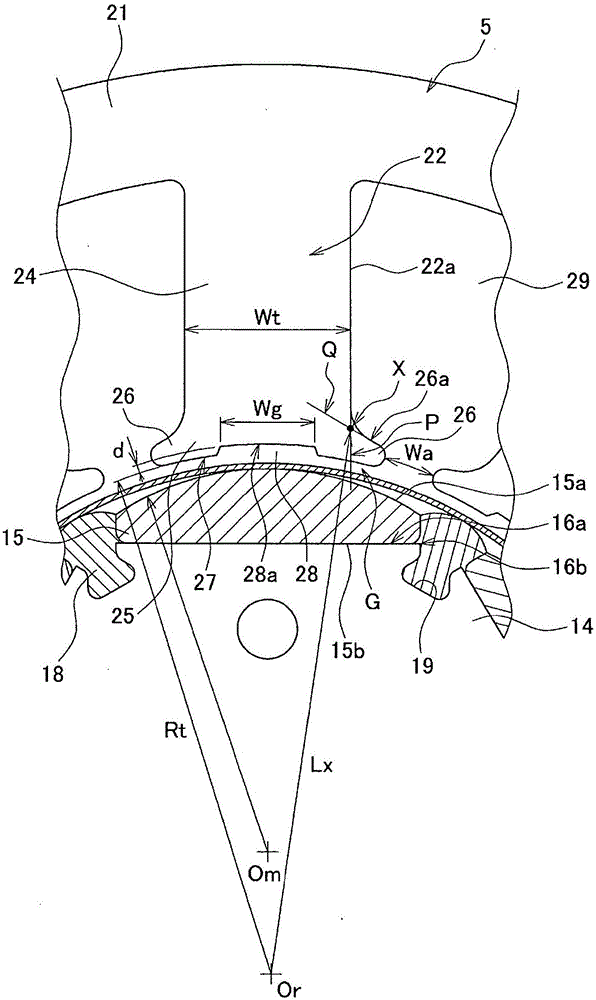

[0027] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. An object of the following embodiments is to provide a brushless motor with high torque and low cogging torque that minimizes the reduction in torque and reduces the cogging torque.

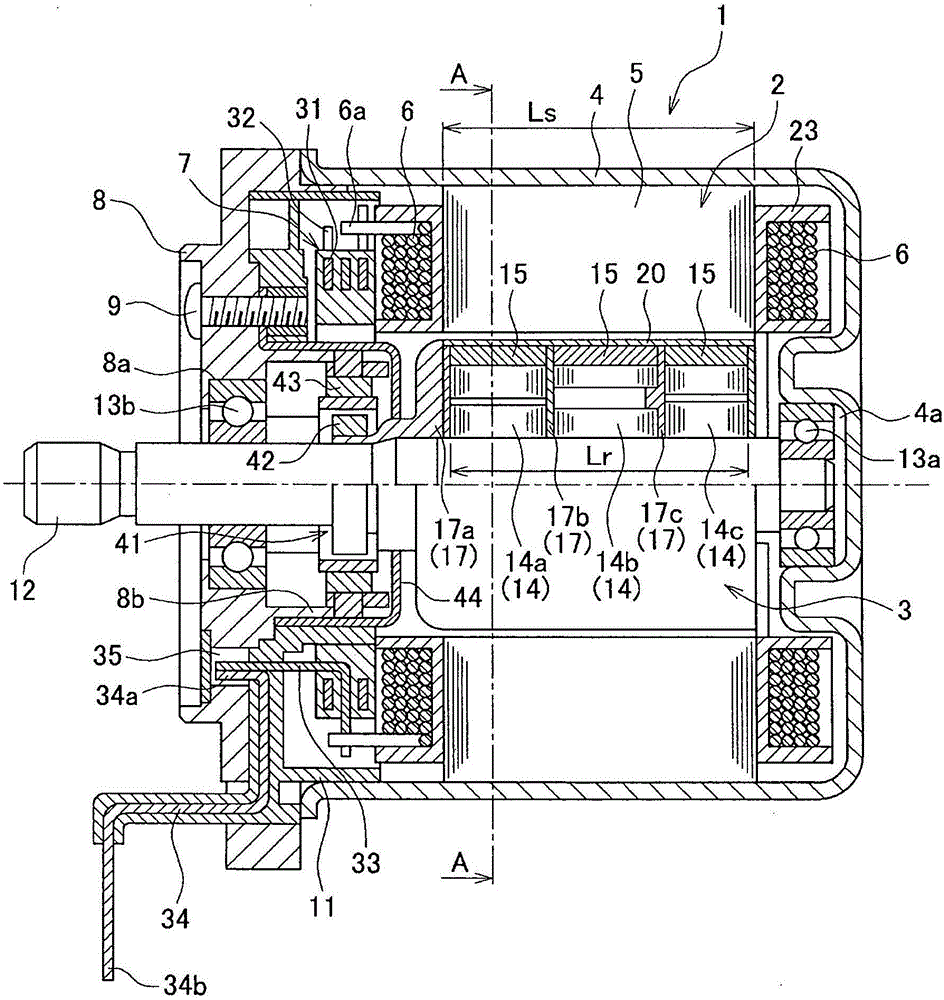

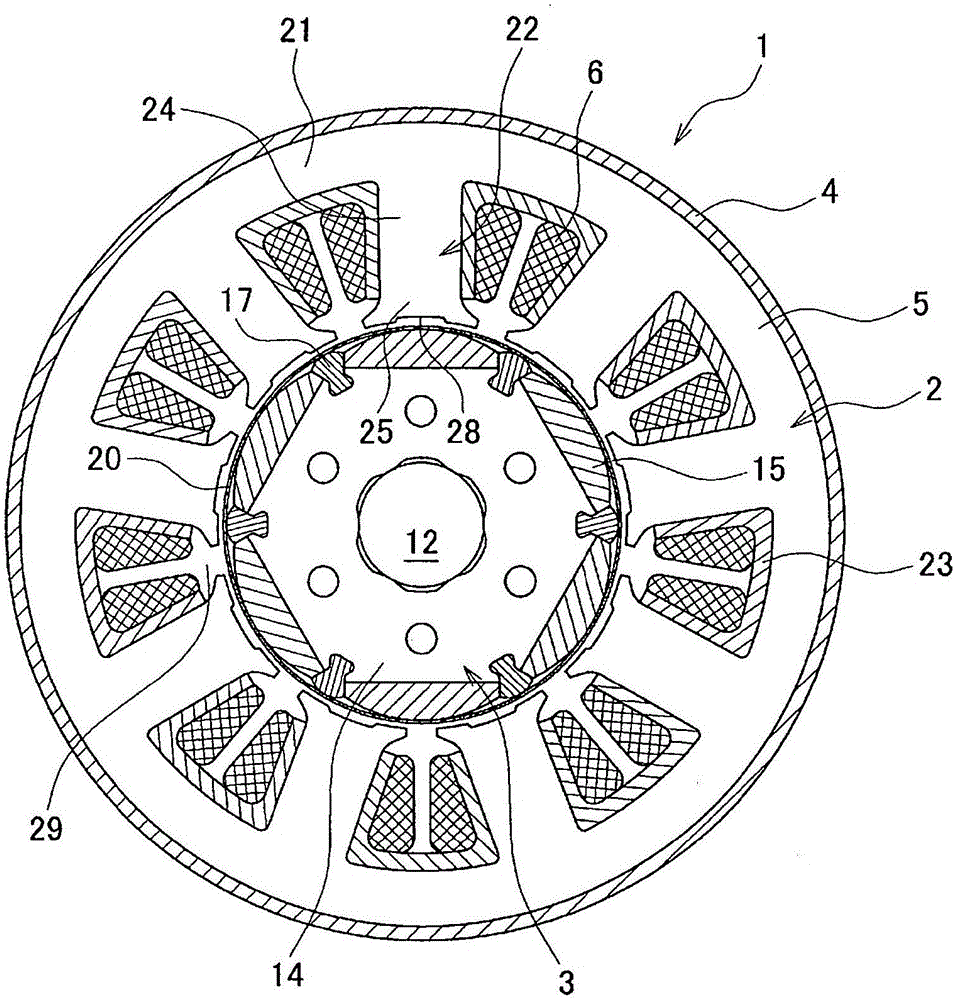

[0028] figure 1 It is a cross-sectional view showing the structure of a brushless motor 1 (hereinafter abbreviated as motor 1 ) according to one embodiment of the present invention. figure 2 is along figure 1 Sectional view of line A-A. The motor 1 is used, for example, as a power source of a steering column assist type EPS, rotates forward and reverse according to a handle operation direction, and applies motion assist force to a steering shaft of an automobile. Such as figure 1 As shown, the motor 1 has an inner rotor type structure in which a stator (fixed body) 2 is arranged on the outside and a rotor (rotating body) 3 is arranged on the inside. The motor 1 is attached to an unill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com