Patents

Literature

120results about How to "Increase pulling speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

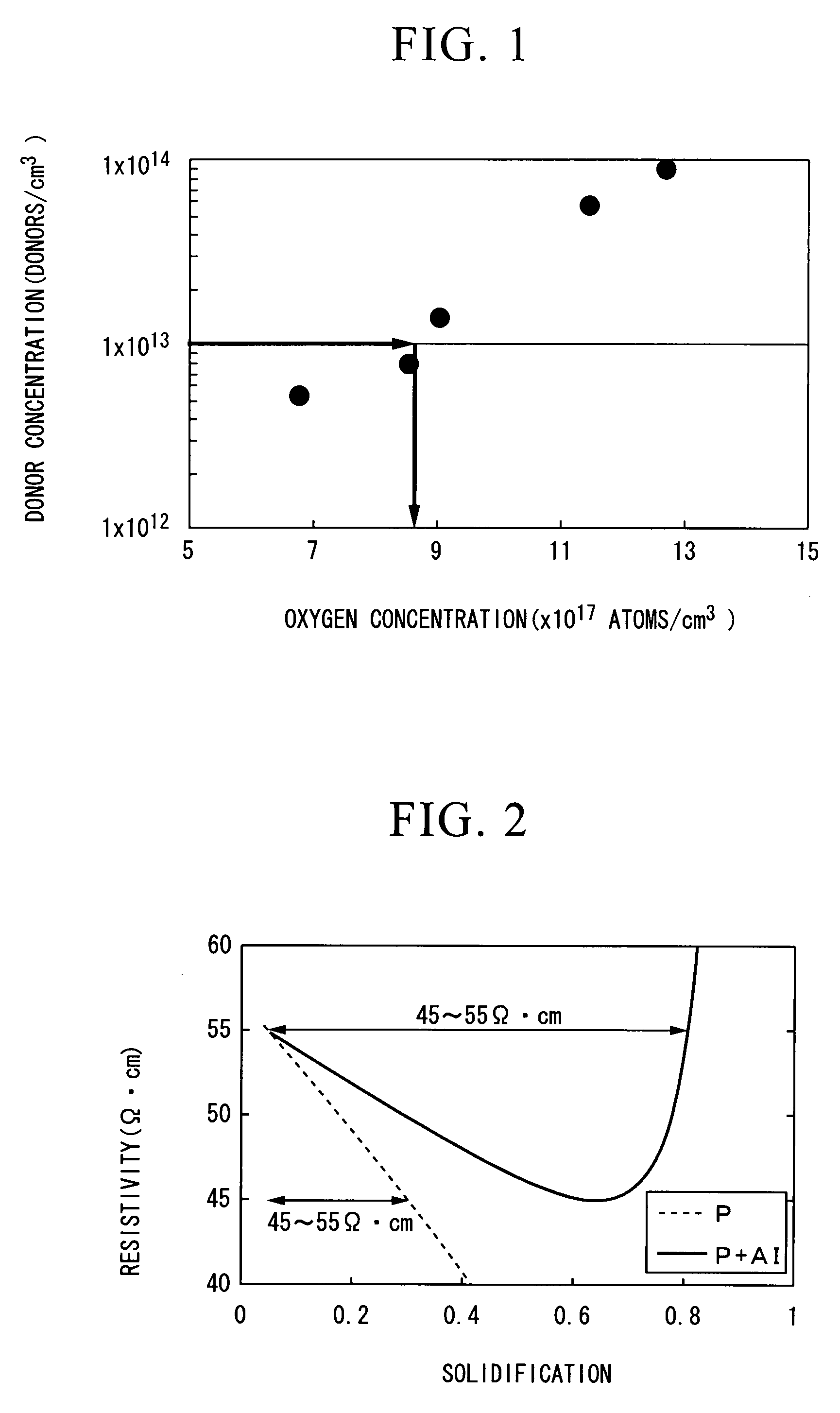

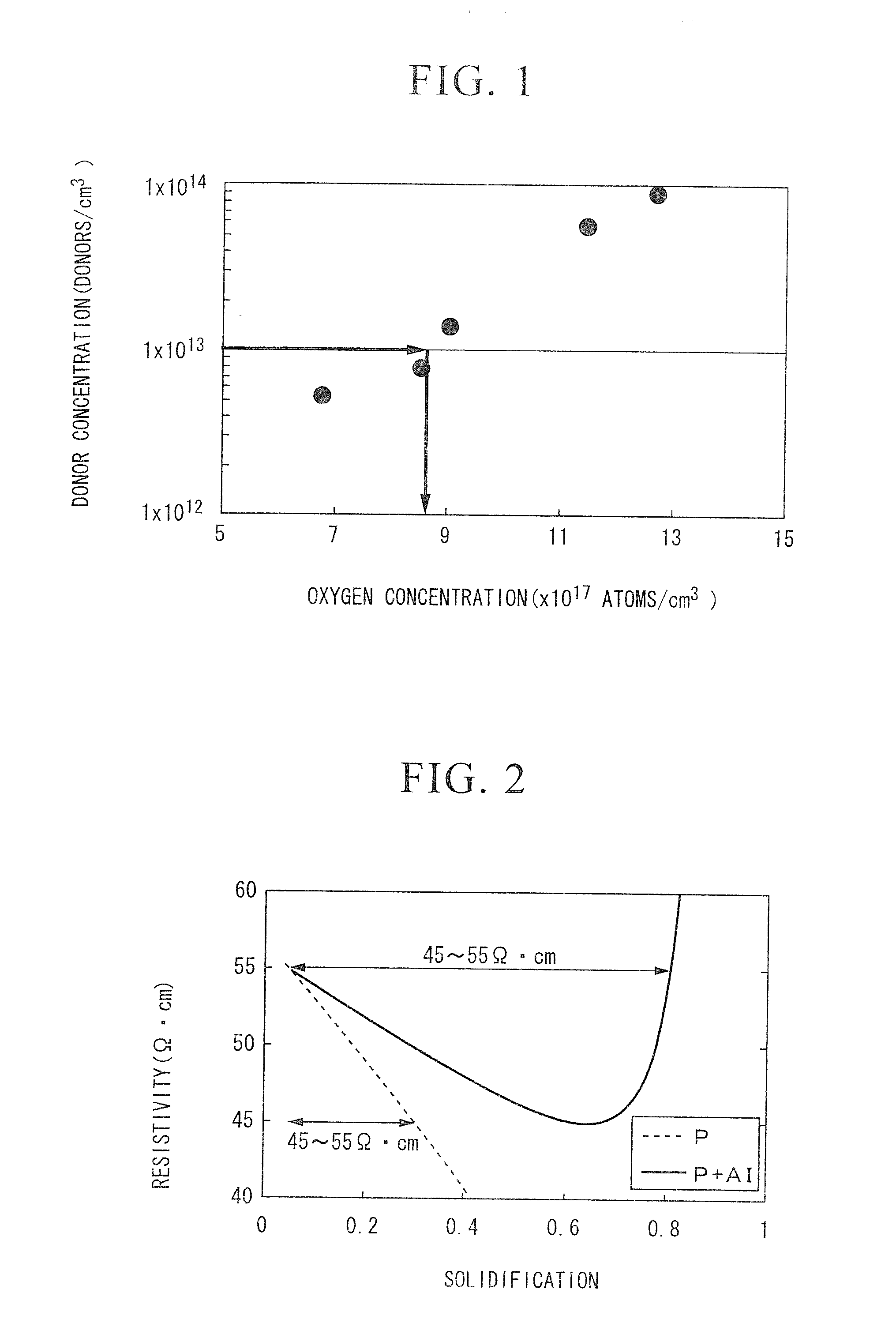

Silicon single crystal wafer for IGBT and method for manufacturing silicon single crystal wafer for IGBT

ActiveUS20070193501A1Reduce variationEasily producePolycrystalline material growthSemiconductor/solid-state device manufacturingDislocationDopant

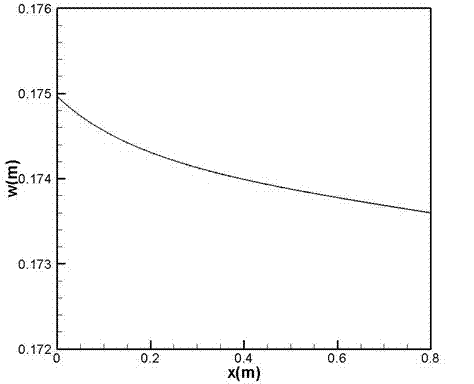

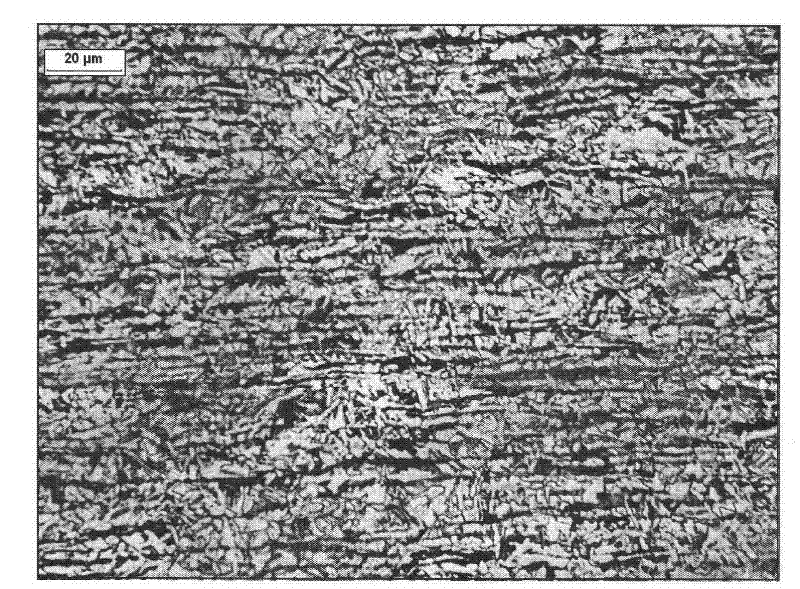

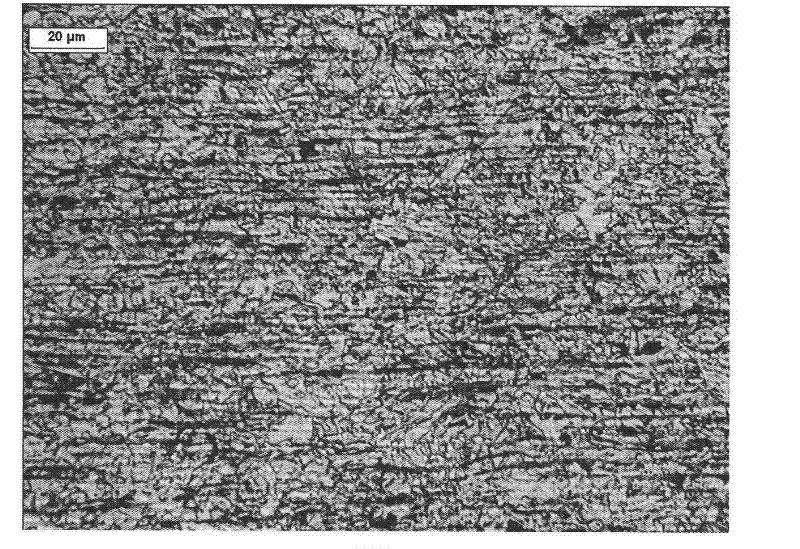

In this silicon single crystal wafer for IGBT, COP defects and dislocation clusters are eliminated from the entire region in the radial direction of the crystal, the interstitial oxygen concentration is 8.5×1017 atoms / cm3 or less, and variation in resistivity within the wafer surface is 5% or less. This method for manufacturing a silicon single crystal wafer for IGBT includes introducing a hydrogen atom-containing substance into an atmospheric gas at a hydrogen gas equivalent partial pressure of 40 to 400 Pa, and growing a single crystal having an interstitial oxygen concentration of 8.5×1017 atoms / cm3 or less at a silicon single crystal pulling speed enabling pulling of a silicon single crystal free of grown-in defects. The pulled silicon single crystal is irradiated with neutrons so as to dope with phosphorous; or an n-type dopant is added to the silicon melt; or phosphorous is added to the silicon melt so that the phosphorous concentration in the silicon single crystal is 2.9×1013 to 2.9×1015 atoms / cm3 and a p-type dopant having a segregation coefficient smaller than that of the phosphorous is added to the silicon melt so that the concentration in the silicon single crystals is 1×1013 to 1×1015 atoms / cm3 corresponding to the segregation coefficient thereof.

Owner:SUMCO CORP

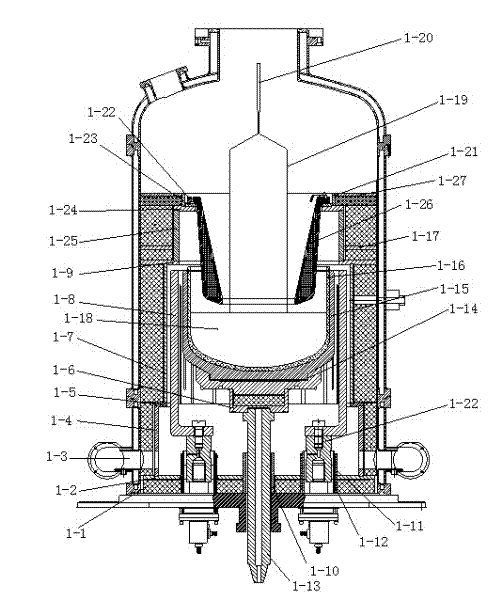

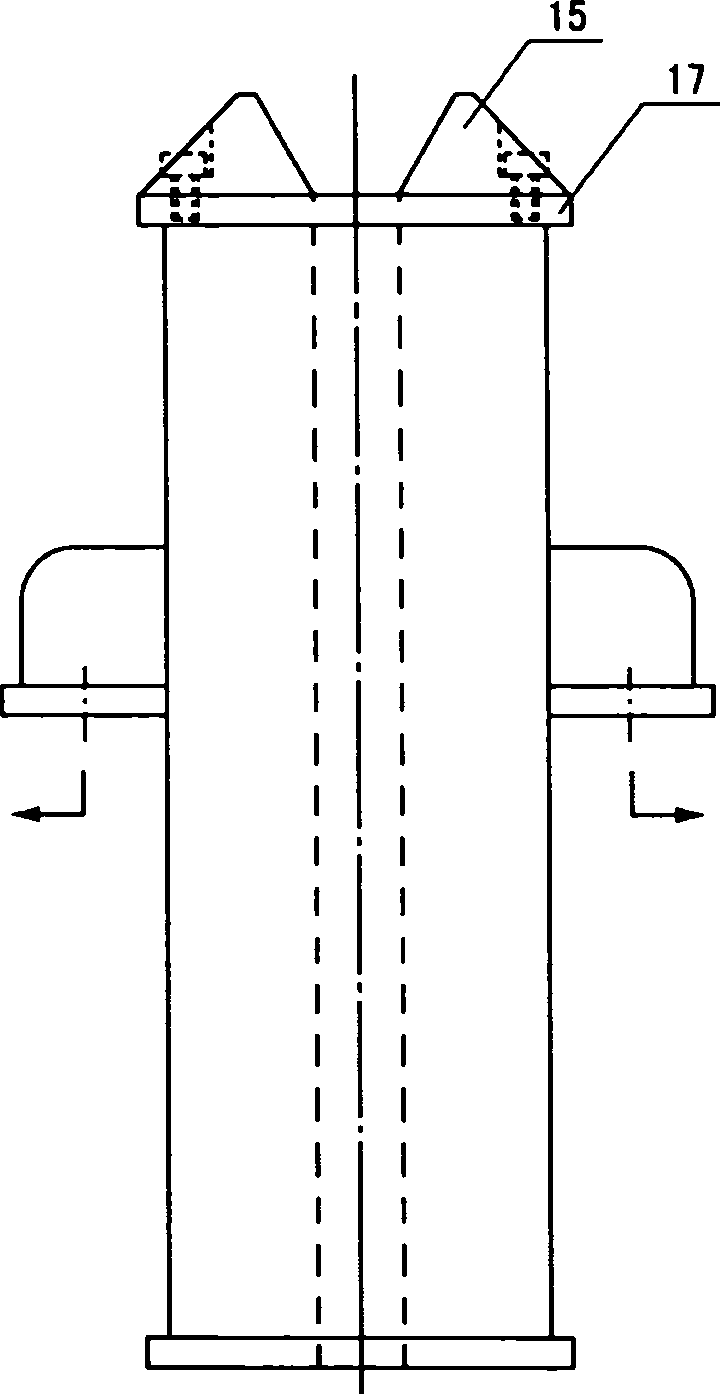

Straight-pull eight-inch silicon single crystal thermal field and production method of eight-inch silicon single crystal

InactiveCN102367588ACompact structureImprove insulation effectPolycrystalline material growthBy pulling from meltThermal insulationPhysical chemistry

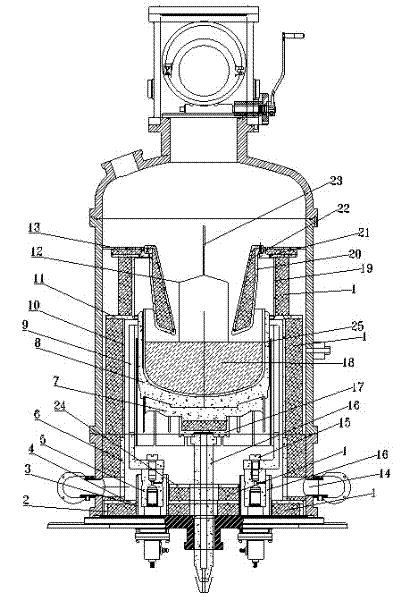

The invention discloses a straight-pull eight-inch silicon single crystal thermal field and a production method of an eight-inch silicon single crystal. The straight-pull eight-inch silicon single crystal thermal field is characterized in that a protective tray compressed sheet is arranged on a lower protective tray compressed sheet; a graphite felt is filled between the lower protective tray compressed sheet and the protective tray compressed sheet; the bottom of a main thermal insulation cylinder is clamped with a lower thermal insulation cylinder; the bottom of the lower thermal insulation cylinder is clamped with the lower protective tray compressed sheet; the bottom of the lower protective tray compressed sheet is clamped with a furnace bottom support ring; an outer guide cylinder is arranged on a guide cylinder support ring; and an inner guide cylinder is clamped on the outer guide cylinder, and a graphite felt is filled between the inner guide cylinder and the outer guide cylinder. The thermal field has compact structure and better thermal insulation property; and in the thermal field, the equal-diameter average pulling speed is improved, equal-diameter power consumption is reduced, production cost is reduced, and production efficiency is improved. The production method of the eight-inch silicon single crystal comprises: clearing and charging a single-crystal furnace, vacuumizing, smelting a material, thermally sealing, automatically seeding, shouldering, carrying out equal-diameter growing and ending. By utilizing the method, the production efficiency and yield of a product are improved.

Owner:东方电气集团峨嵋半导体材料有限公司

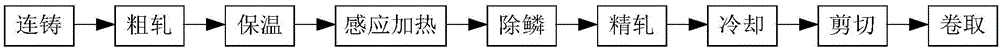

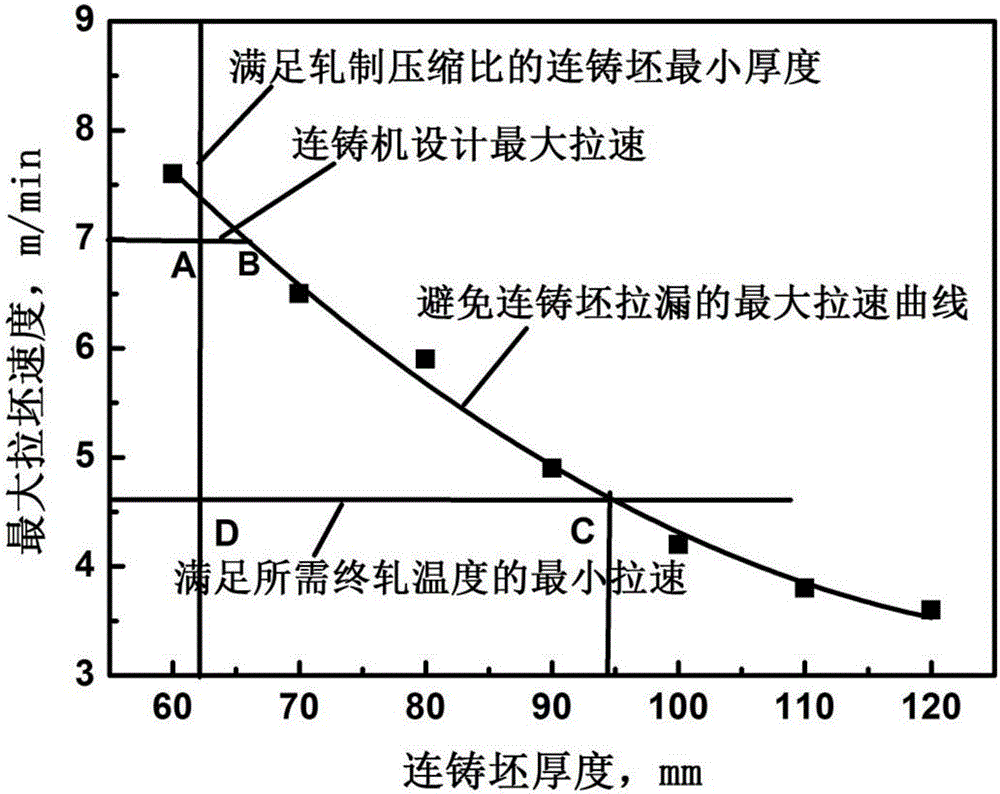

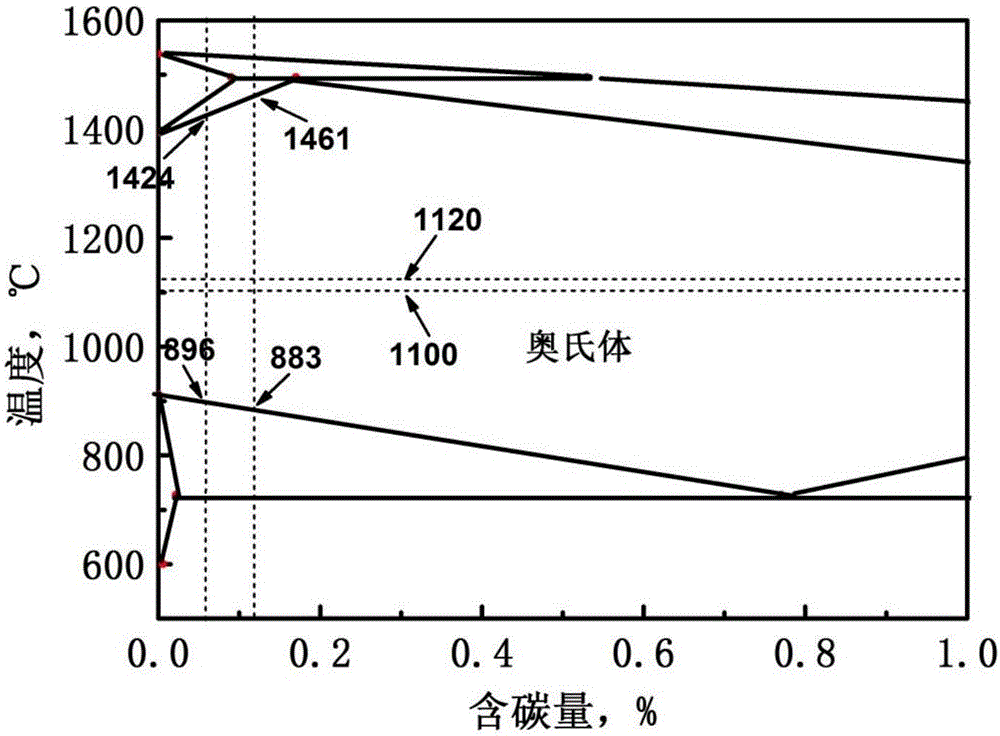

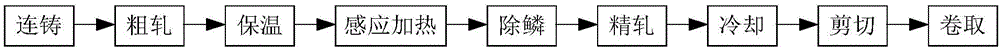

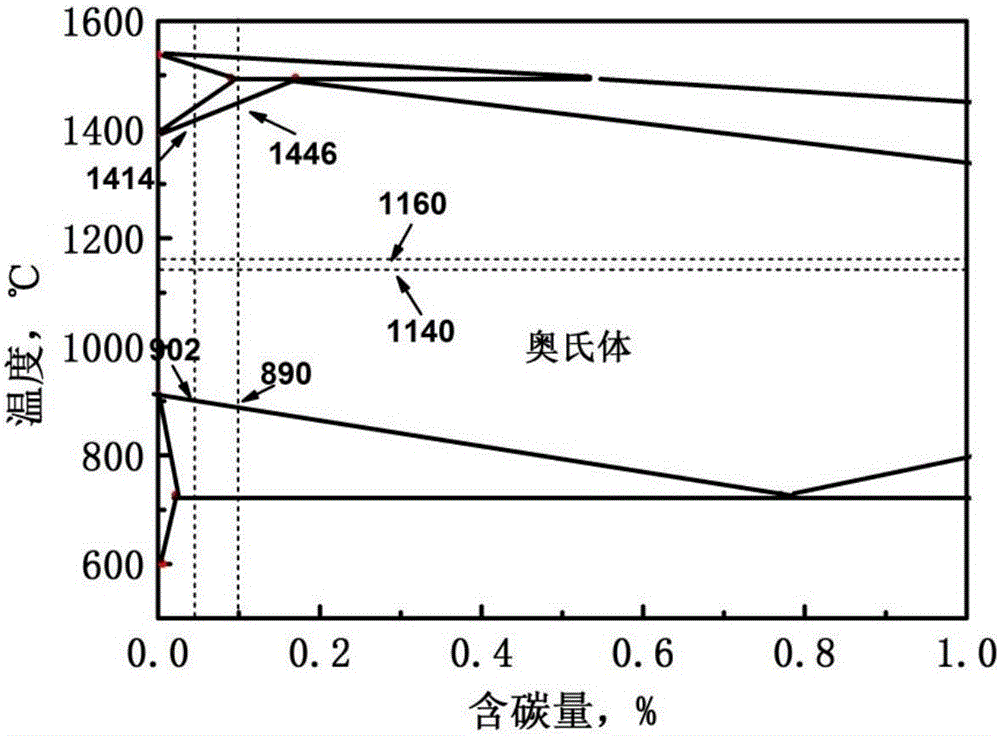

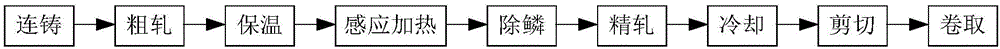

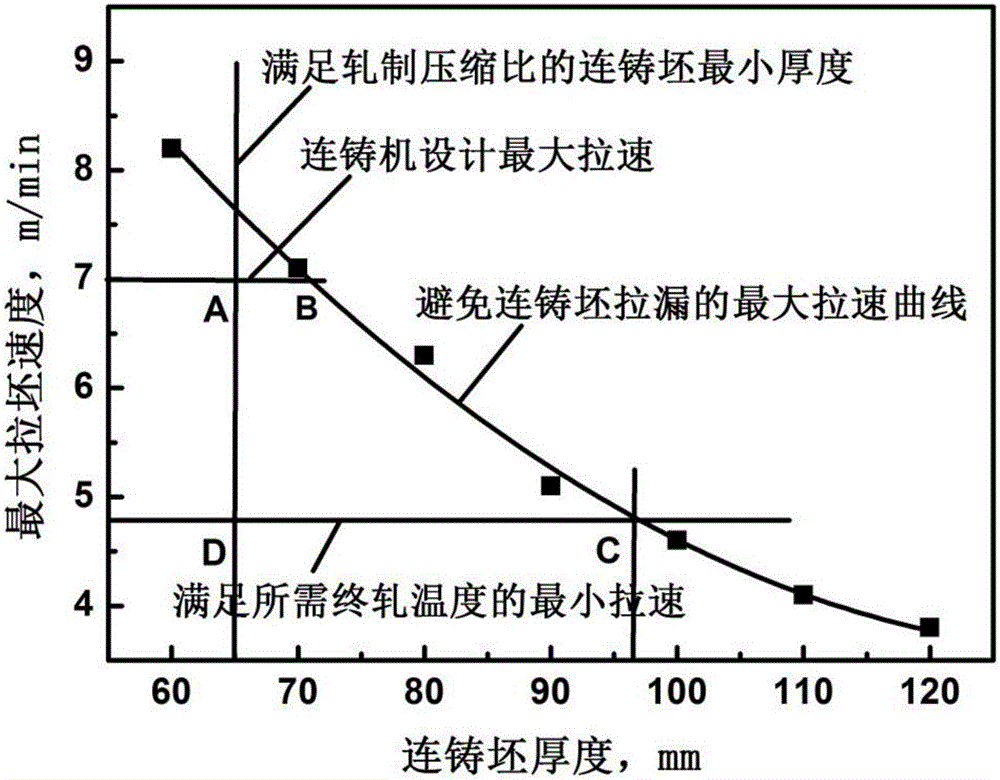

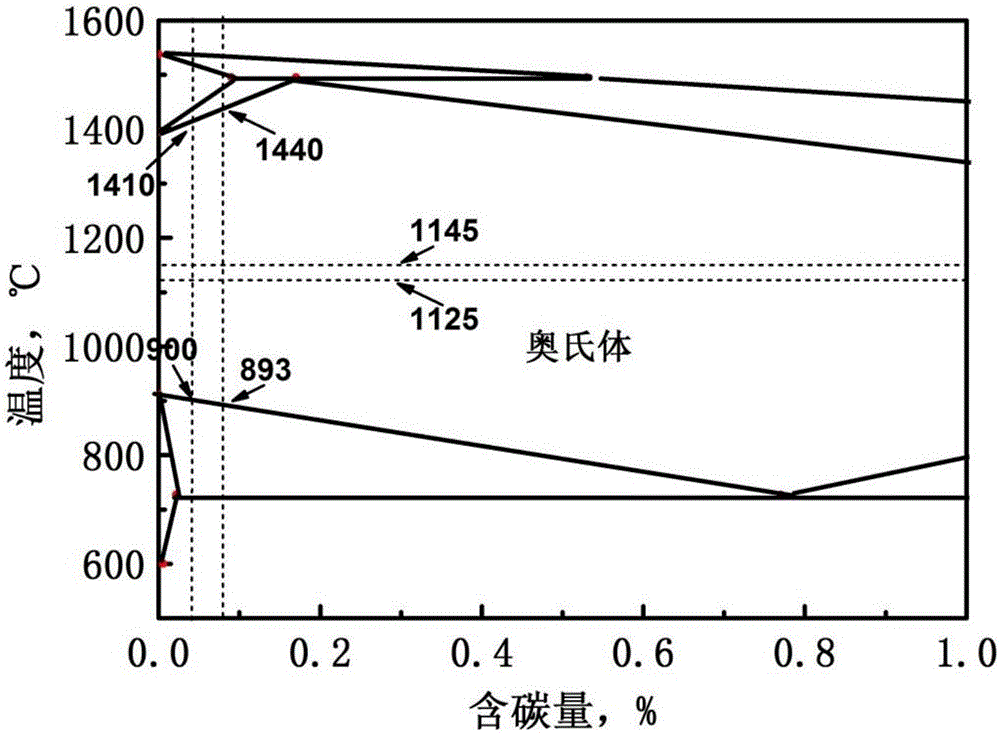

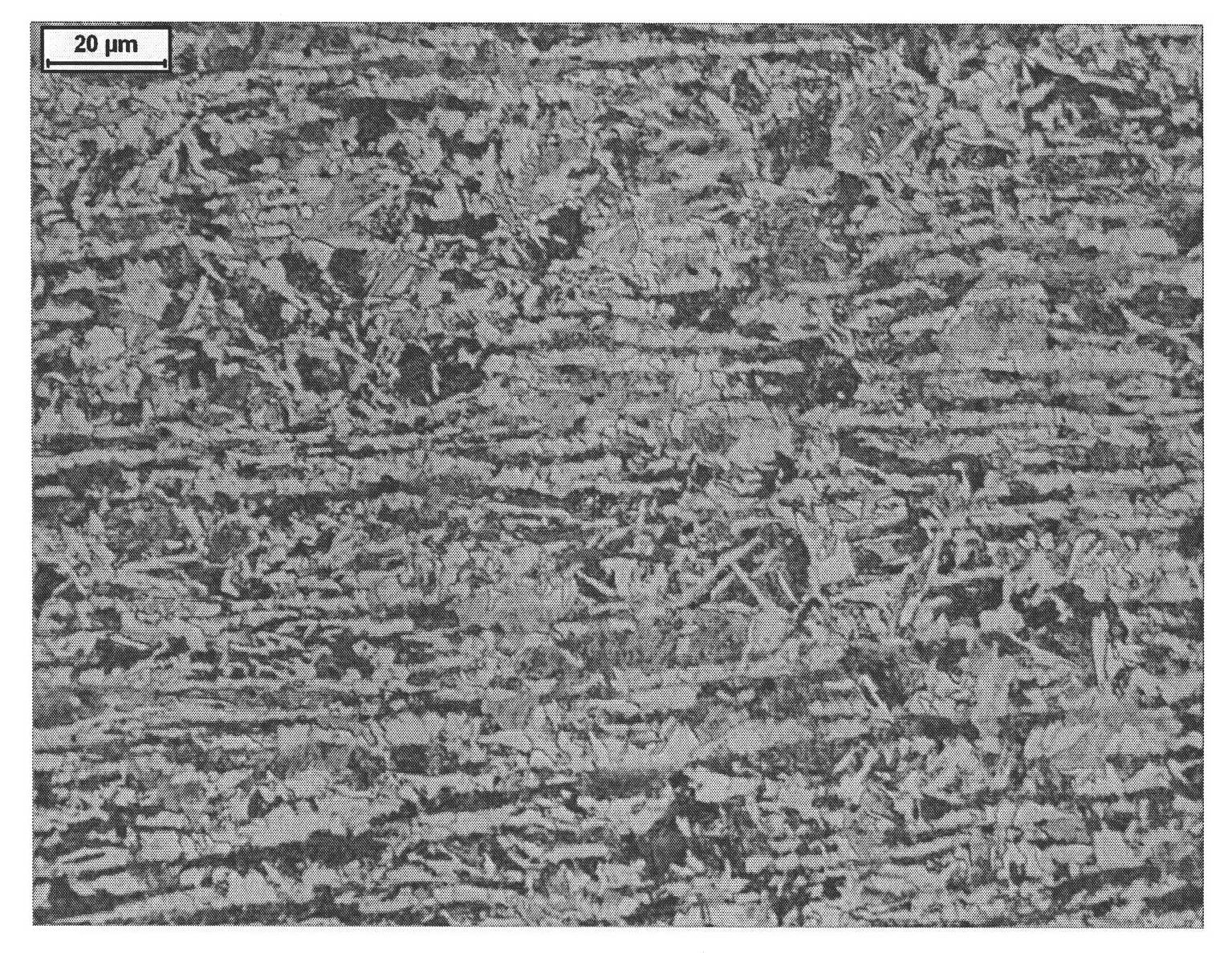

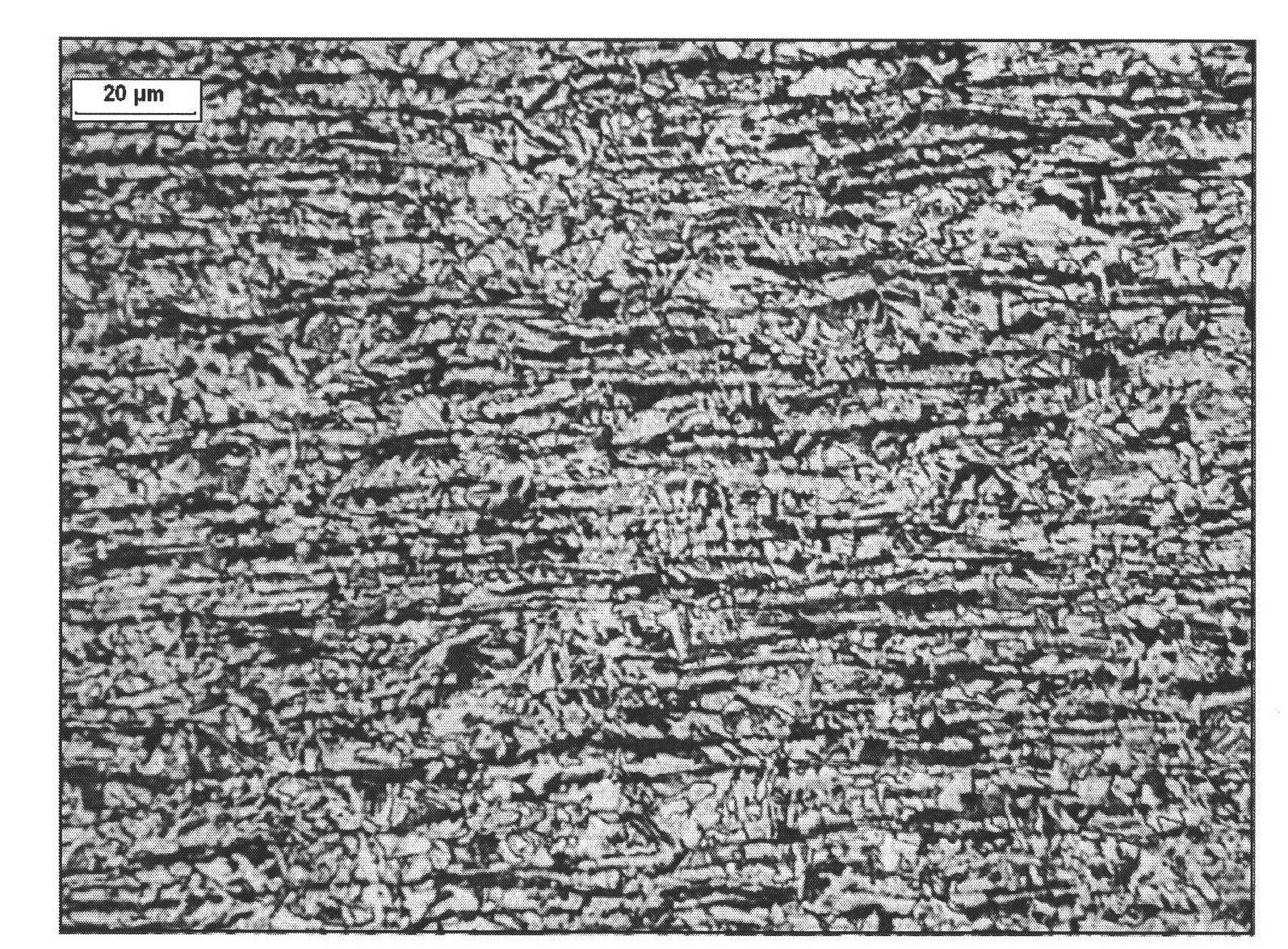

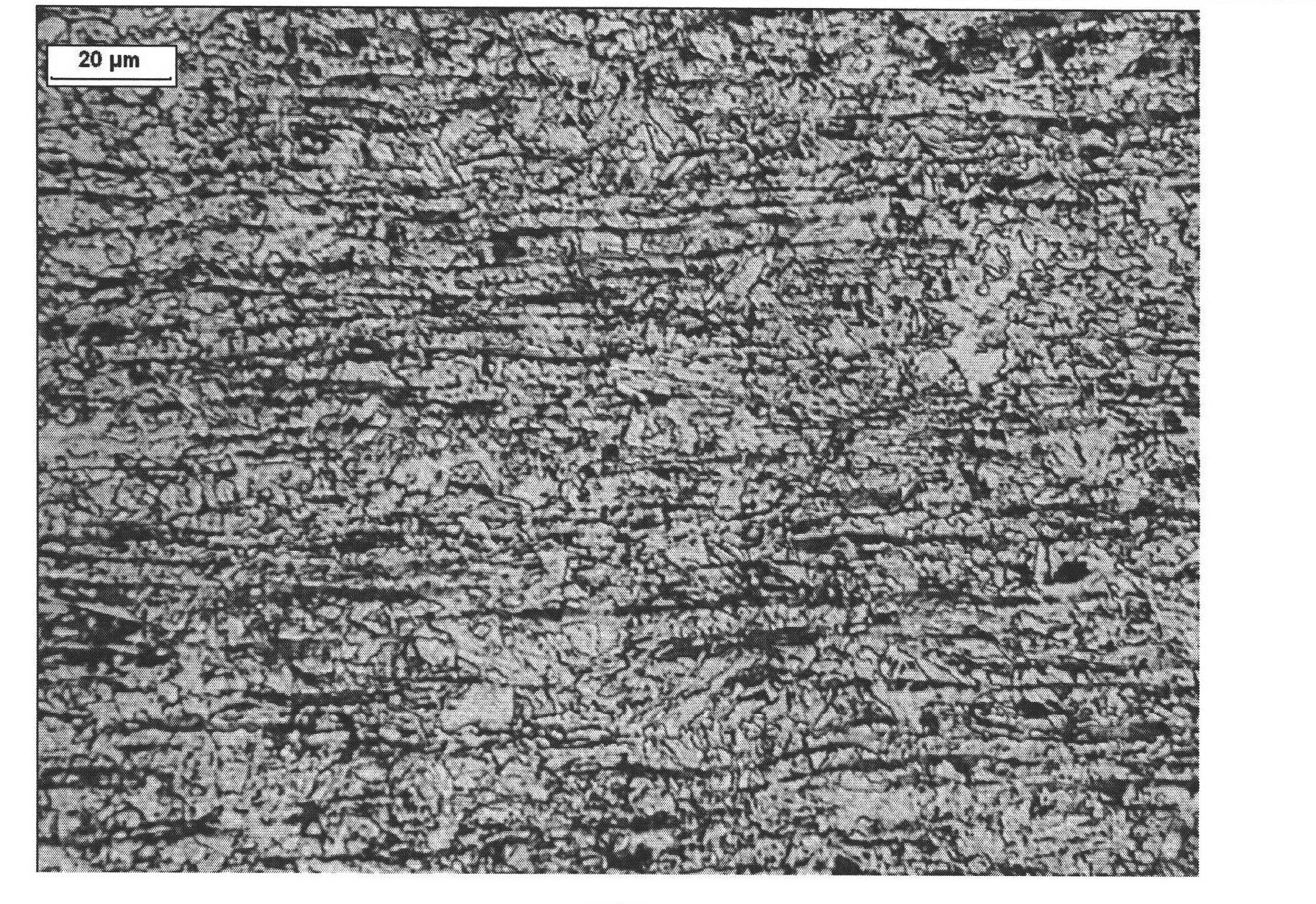

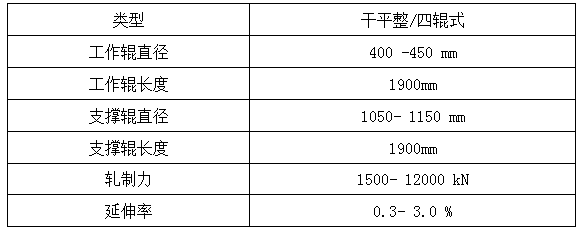

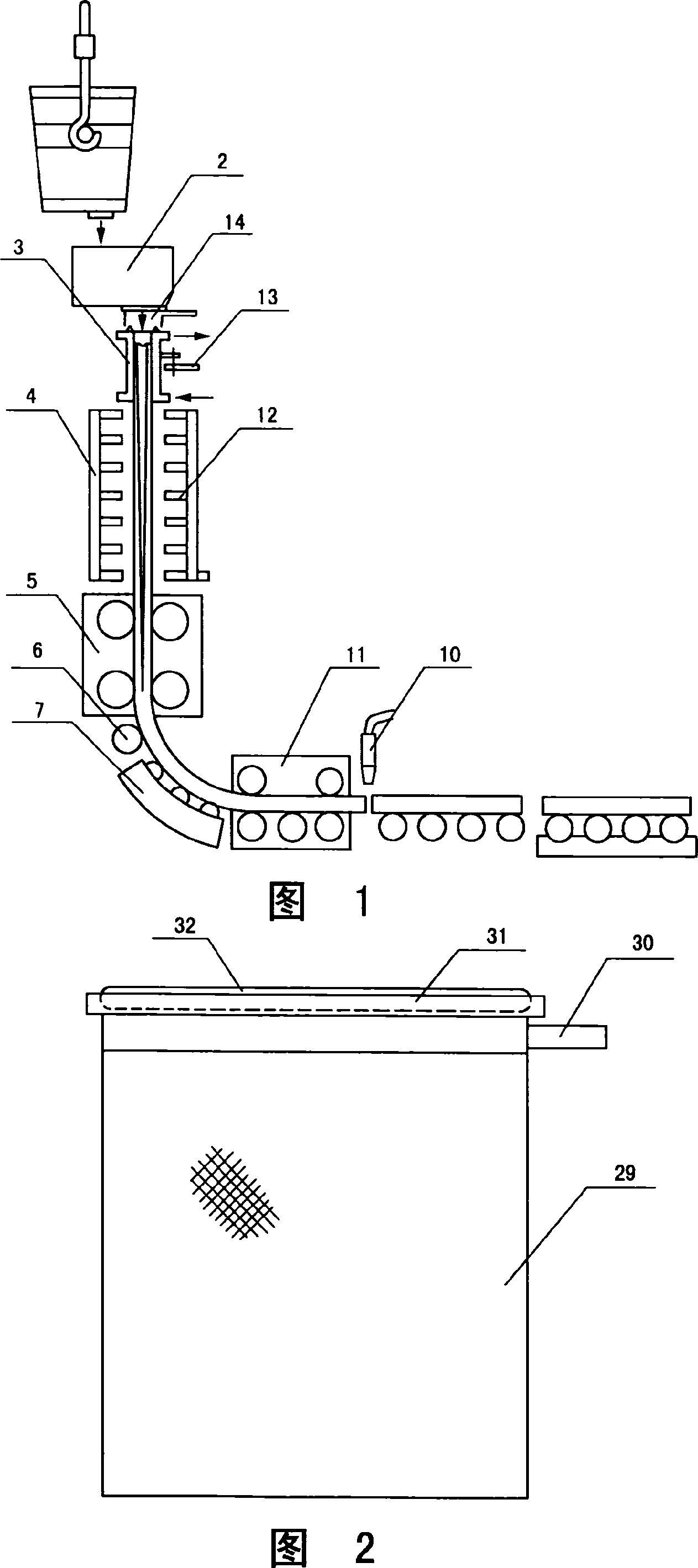

Method for producing thin-gauge dual-phase steel by applying thin slab continuous casting and rolling process

ActiveCN106734200ARealize the demand of "replacing cold with heat"Stable productionTemperature control deviceWork treatment devicesThin slabHigh pressure water

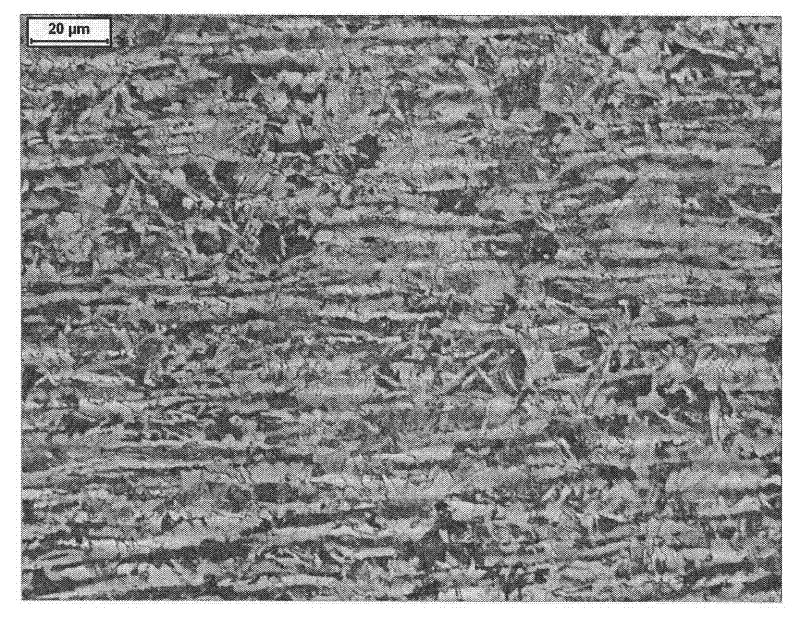

The invention relates to a method for producing thin-gauge dual-phase steel by applying a thin slab continuous casting and rolling process. The method comprises the steps: continuously casting molten steel to form a continuous casting slab with the width of 1300-1600mm and the thickness of 62-94mm; then, sequentially carrying out rough rolling, heat insulation by a heat insulation cover, induction heating, high-pressure water scale removal and finish rolling to obtain ultrathin strip steel with the width of 1300-1600mm and the thickness of 1.5-1.8mm; and finally, carrying out controlled cooling, coil-by-coil shearing and coil winding. A finished product of the thin-gauge dual-phase steel has the yield strength of 370-390MPa, the tensile strength of 590-630MPa and the elongation rate of larger than or equal to 15%. By using the method, hot-rolled thin-gauge dual-phase steel of which the size precision, slab shape precision and comprehensive mechanical property can meet requirements can be stably produced.

Owner:WISDRI ENG & RES INC LTD

Method for producing ultrathin low-carbon steel by use of thin slab casting and rolling process

ActiveCN106583453AStable productionRealize the demand of "replacing cold with heat"Roll force/gap control deviceTemperature control deviceThin slabHigh pressure water

The invention relates to a method for producing ultrathin low-carbon steel by use of a thin slab casting and rolling process. The method comprises the following steps: continuously casting molten steel into a continuous cast billet with the width of 1,300-1,600 mm and the thickness of 60-100 mm; then sequentially conducting rough rolling, heat preservation by a heat holding cover, induction heating, high-pressure water phosphorus removal and finish rolling to obtain ultrathin strip steel with the width of 1,300-1,600 mm and the thickness of 0.8-1 mm; and finally, performing controlled cooling, roll-dividing cutting and roll take-up. A produced ultrathin low-carbon steel end product has the yield strength of 250-310 MPa, the tensile strength of 350-400 MPa and the ductility of larger than or equal to 35%. By adoption of the method, stable production of hot-rolled ultrathin low-carbon steel with the thickness of 0.8-1 mm can be realized, the dimensional accuracy, the flatness accuracy and the comprehensive mechanical property can be improved, the demand for 'replacement of cold product by hot product' is met and the production cost is lowered.

Owner:WISDRI ENG & RES INC LTD

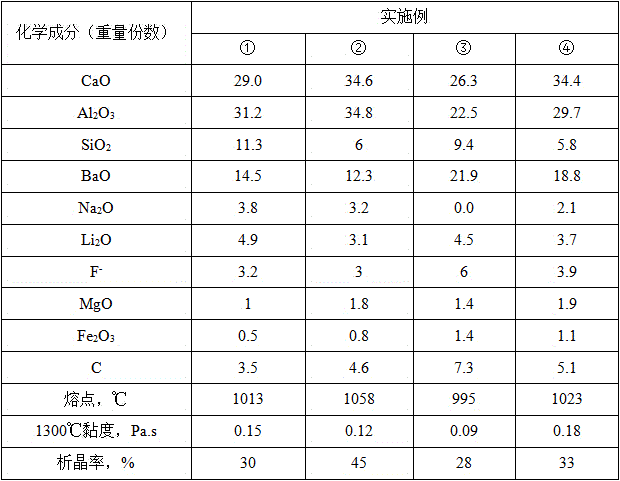

Protective slag of large-profile round billet continuous-casting crystallizer and method for preparing same

The invention discloses a protective slag of a large-profile round billet continuous-casting crystallizer and a method for preparing same. The protective slag comprises the following components by weight percentage: 27-33% of SiO2, 24-30% of CaO, 1-3% of MgO, not more than 2% of Fe2O3, 5-10% of Al2O3, 4-9% of Na2O, 1-4% of F, 0.5-2.5% of MnO and 15-20% of C (solid). The components of the protective slag of the continuous casting crystallizer are selected according to the regions of fake siliceous lime in a three-element system CaO-SiO2-Al2O3; out of the components for composing the protectiveslag, the CaO is taken as a main alkaline material, the SiO2 is taken as a main acid material, the Na2O, the CaF2 and the Li2O are taken as main flux agents, and the carbon component is taken as a framework material and a fusing speed controlling agent. By organic combination of the basic materials and the flux agents, the chemical components of the protective slag are adjusted, so as to adjust the physico-chemical indexes of the protective slag, such as fusing temperature, viscosity, crystallization performance, absorbing and including capability, heat conducting capability and the like and meet the requirements of keeping normal slag consumption, thickness of liquid slag layer and reasonable heat conducting amount under a special profile condition, thus ensuring the thickness of the billet shell at the outlet end of the crystallizer and realizing non-gluing continuous casting production.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Preliminary melting type continuous casting crystallizer protecting slag and preparation thereof

The invention belongs to the field of auxiliary materials for smelting steel, in particular to a covering slag for a pre-melting continuous casting crystallizer. The weight percentage components of the covering slag are as follows: 31 to 36 percent of SiO2, 30 to 35 percent of CaO, 2 to 5 percent of MgO, not more than 1.5 percent of Fe2O3, 2 to 5 percent of Al2O3, 8 to 11 percent of Na2O, 5 to 8 percent of F, 0.8 to 1.5 percent of Li2O, 3 to 6 percent of C and the rest are unavoidable impurities. The covering slag has a good liquidity and spreadability, can uniformly cover the surface of molten steel, has no piling phenomenon, and has the advantages of active slag surface, uniform melting and no caking phenomenon. The invention has a better insulating performance and has no cold steel agglomerated on the liquid surface; can ensure a casting blank to be fully lubricated so as to realize a high pulling rate; has a stable performance after absorbing the impurities and can realize stable and smooth continuous manufacture; avoids the steel leakage phenomenon, improves the casting blank quality and can lead the longitudinal crack of a plate blank and the angle part cross crack to be reduced by more than two third averagely; the invention has a low cost and is convenient for popularizing.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Method for producing 65Mn hot rolled steel plate

InactiveCN101773930AImprove product qualityUniform tissue performanceMetal rolling arrangementsContinuous rollingSmelting

The invention discloses a method for producing a 65Mn hot rolled steel plate, which comprises the steps of smelting, refining, thin slab casting, soaking, high pressure water descaling, hot continuous rolling, cooling and reeling based on the process of thin slab casting and rolling. The molten steel superheat temperature is T superheat (30 DEG C <T superheat < / = 45 DEG C), the charging temperature of casting blanks is T charging (900 DEG C < / = T charging < / = 1050 DEG C), the final rolling temperature is T final (850 DEG C < / = T final < / = 950 DEG C), the reeling temperature is T reeling ( 550 DEG C < / = T reeling < / = 650 DEG C), the liquid core pressure of casting blanks is L pressure (2 < / = L pressure < / = 20mm), and the depth of a single-surface decarburized layer is 0.3 to 0.9 percent of the depth of the steel plate. The chemical constitutes of molten steel after being alloyed in a refining process comprise 0.62-0.70 wt.% of C, 0.17-0.37 wt.% of Si, 0.90-1.20 wt.% of Mn, less than or equal to 0.035 wt.% of P, less than or equal to 0.035 wt.% of S, less than or equal to 0.25 wt.% of Cr, less than or equal to 0.25 wt.% of Ni and the balance of Fe and inevitable impurities. The 65Mn hot rolled steel plate produced in the method has the characteristics of uniform structure property, high thermal stability and high strength, and the quality of the 65Mn hot-rolled steel plate is obviously improved.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

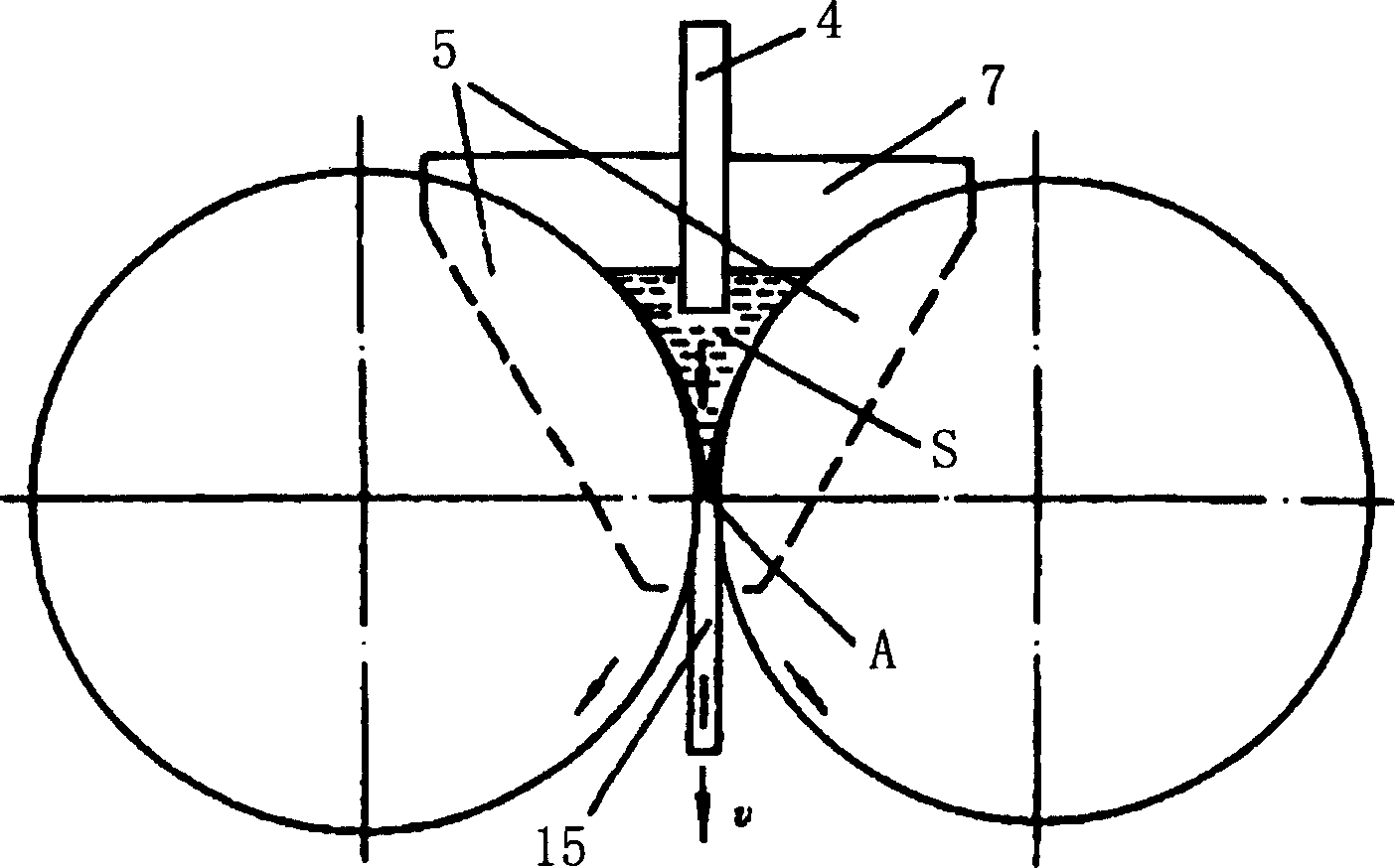

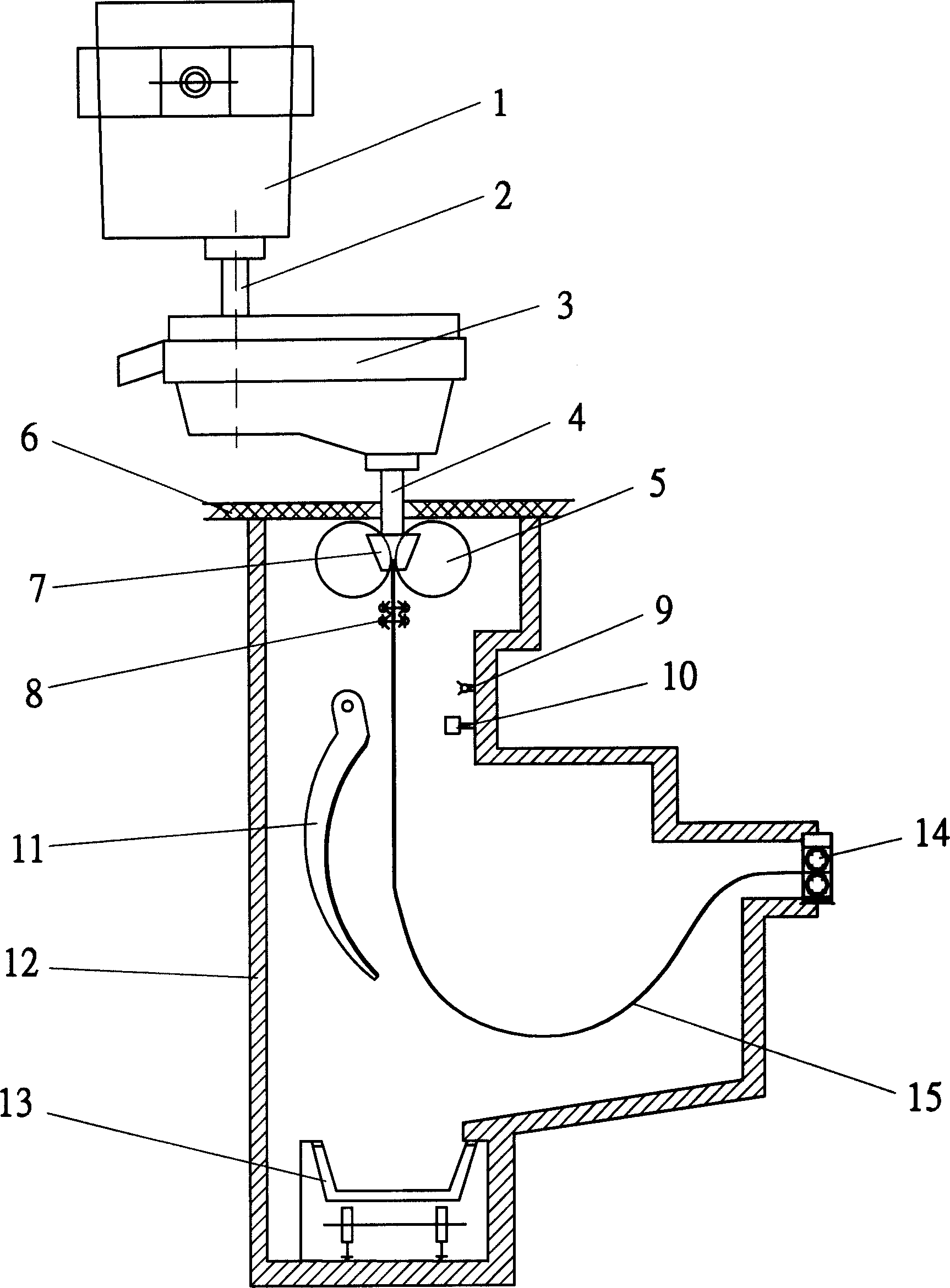

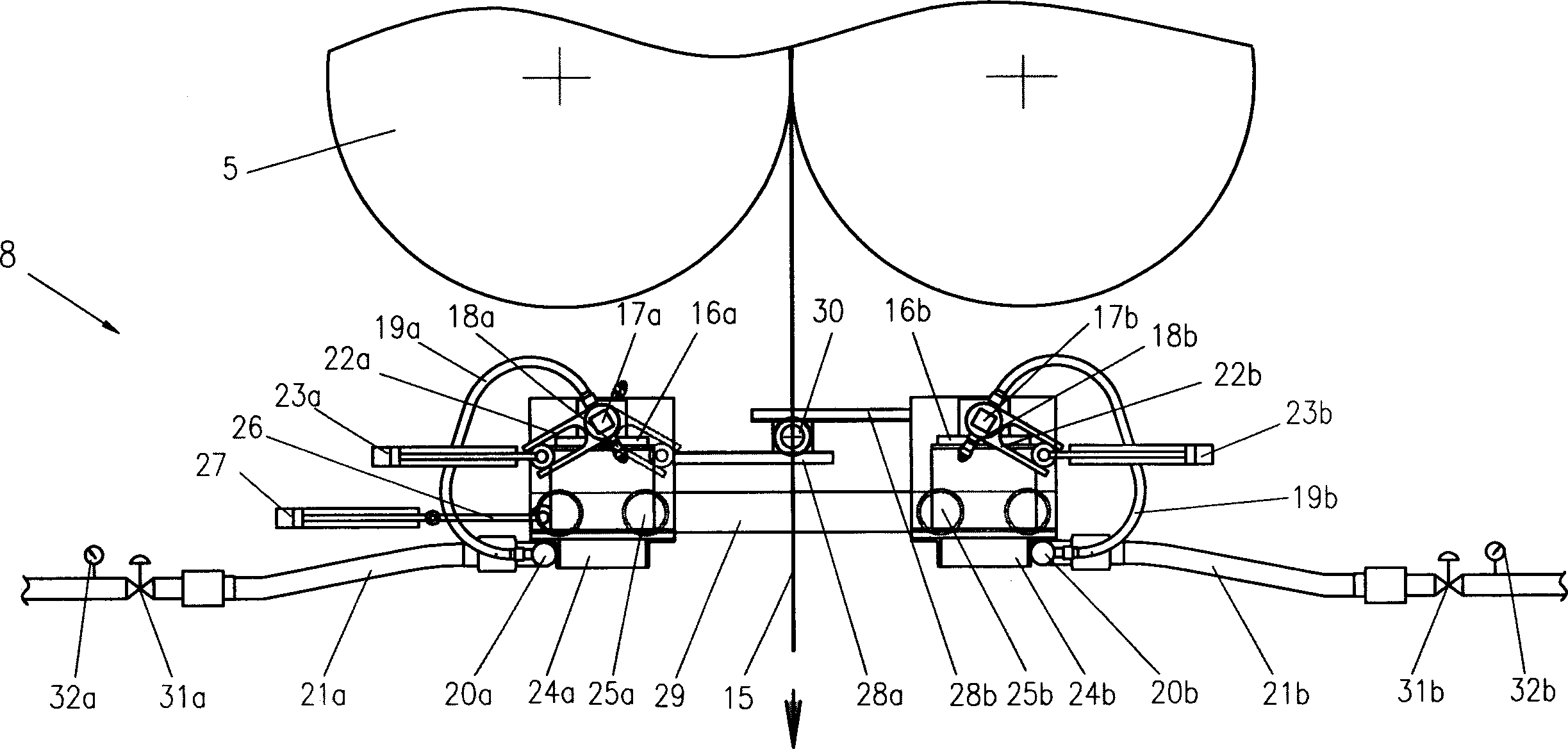

Thin-belt continuous casting method and apparatus

InactiveCN1472019AFlexible process controlEasy to operateMetal rolling arrangementsProduction rateMolten bath

A conticasting technology for thin steel band includes such steps as filling molten steel in the molten bath formed by crystallizing rollers, cooling and slight rolling by crystallizing rollers, blowing gas onto both surfaces of cast band for forced cooling, hot rolling, controlled cooling and winding. Its apparatus is composed of two blowing mechanisms, connecting-rod driver unit and synchronizing unit. Its advantages are high quality of product and high productivity.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for using thin slab continuous casting and rolling technology for producing thin-specification, low-alloy and high-strength steel

ActiveCN106734201AIncreasing the thicknessIncrease pulling speedRoll force/gap control deviceTemperature control deviceDouble phaseThin slab

The invention relates to a method for using a thin slab continuous casting and rolling technology for producing thin-specification, low-alloy and high-strength steel. Molten steel is continuously cast into a continuous casting blank with the width being 1300 mm to 1600 mm and the thickness being 65 mm to 96 mm; then rough rolling, heat insulation cover heat insulation, induction heating, high-pressure water scale removing and finish rolling are conducted in sequence, and ultrathin strip steel with the width being 1300 mm to 1600 mm and the thickness being 1.3 mm to 1.6 mm is obtained; and finally the strip steel is controlled to be cooled, shorn in different rolled and are coiled into rolls. The yield strength of the thin-specification double-phase steel finished product ranges from 380 MPa to 430 MPa, the tensile strength ranges from 530 MPa to 610 MPa, and the elongation is larger than or equal to 25%. By means of the method, stable production of hot rolled thin-specification, low-alloy and high-strength steel with the thickness being 1.3 mm to 1.6 mm can be achieved, the size precision, the plate shape precision and the comprehensive mechanical performance are improved, the requirement for replacing cold with hot is met, and the production cost is reduced.

Owner:WISDRI ENG & RES INC LTD

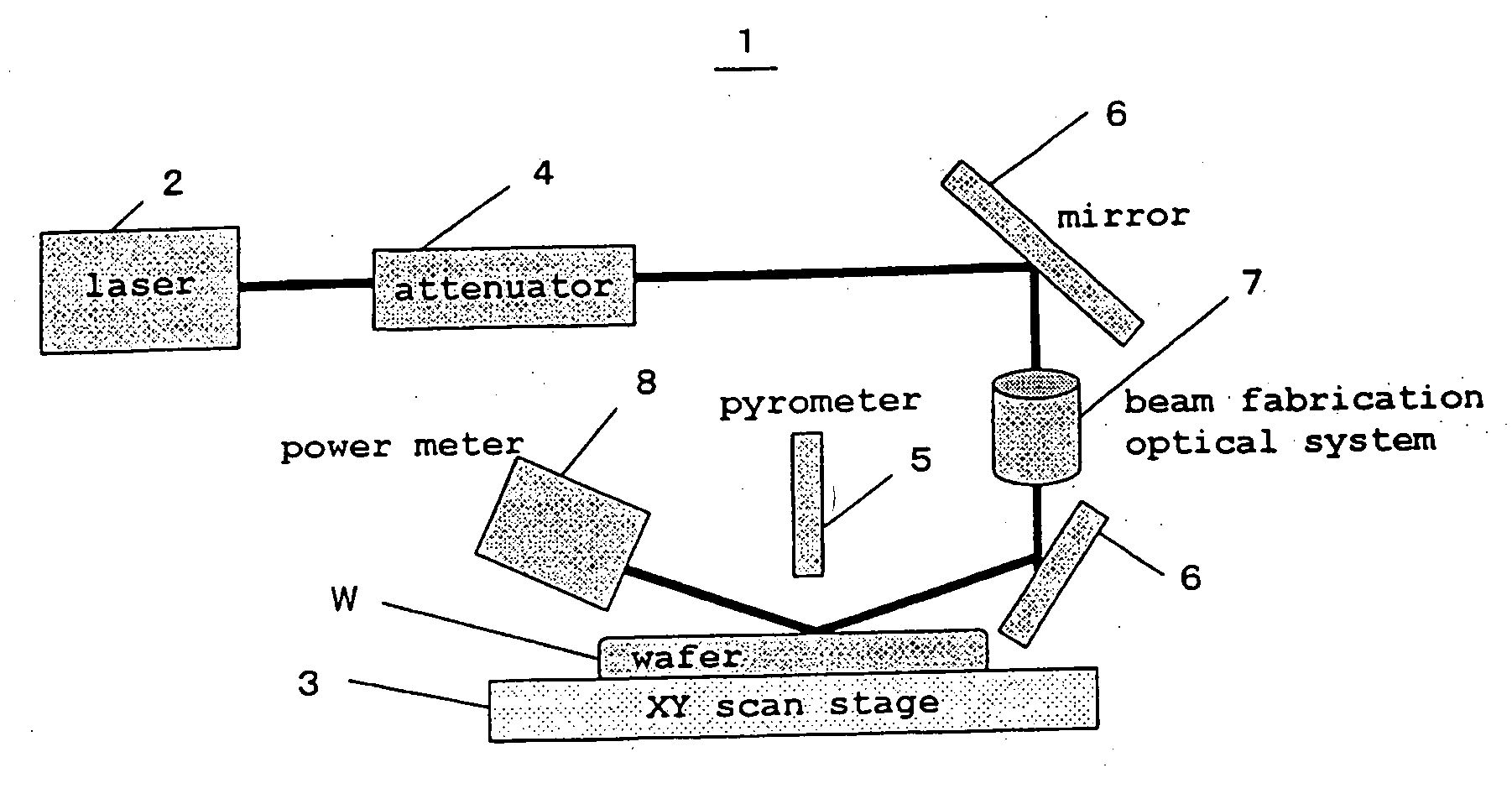

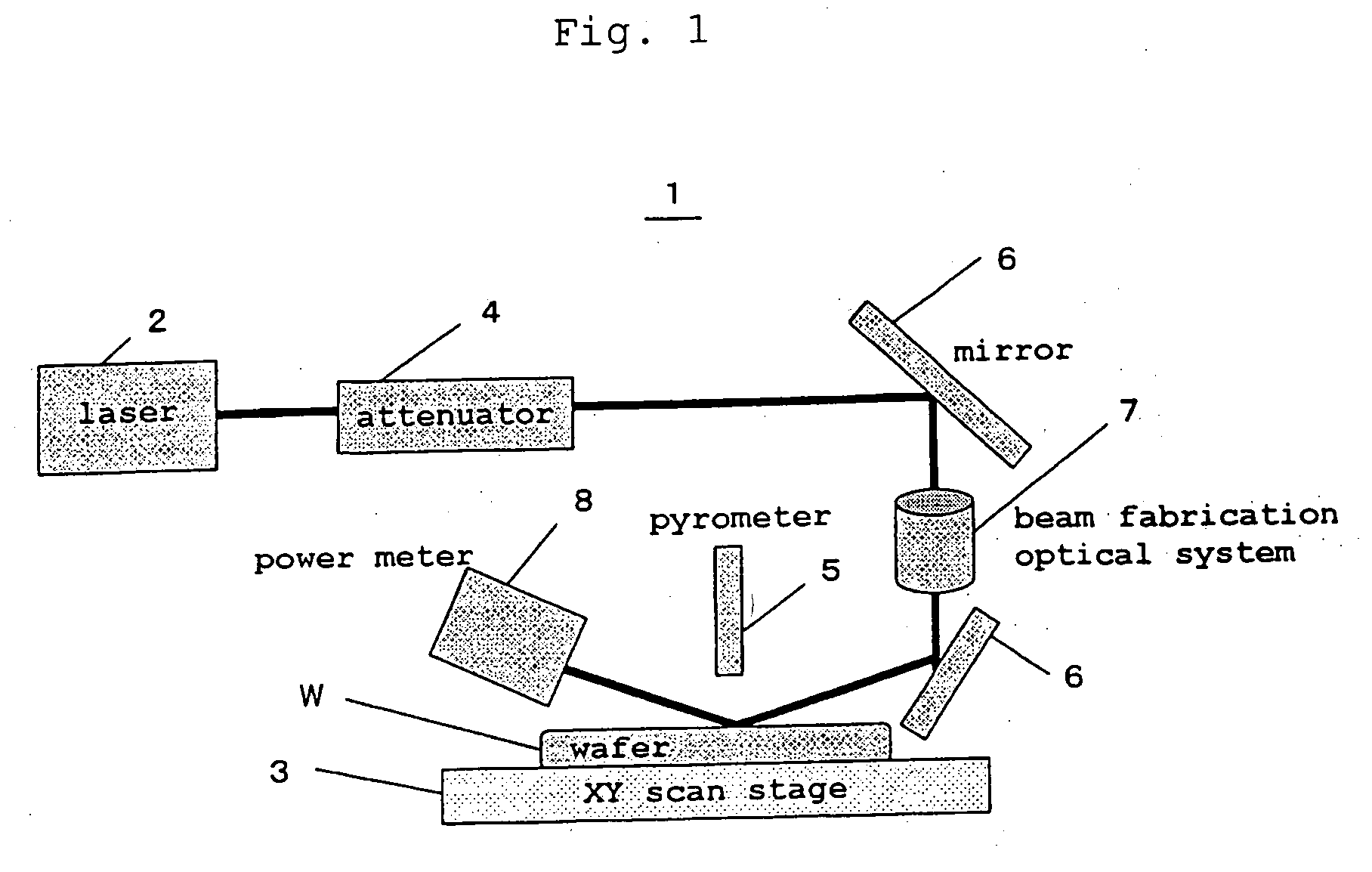

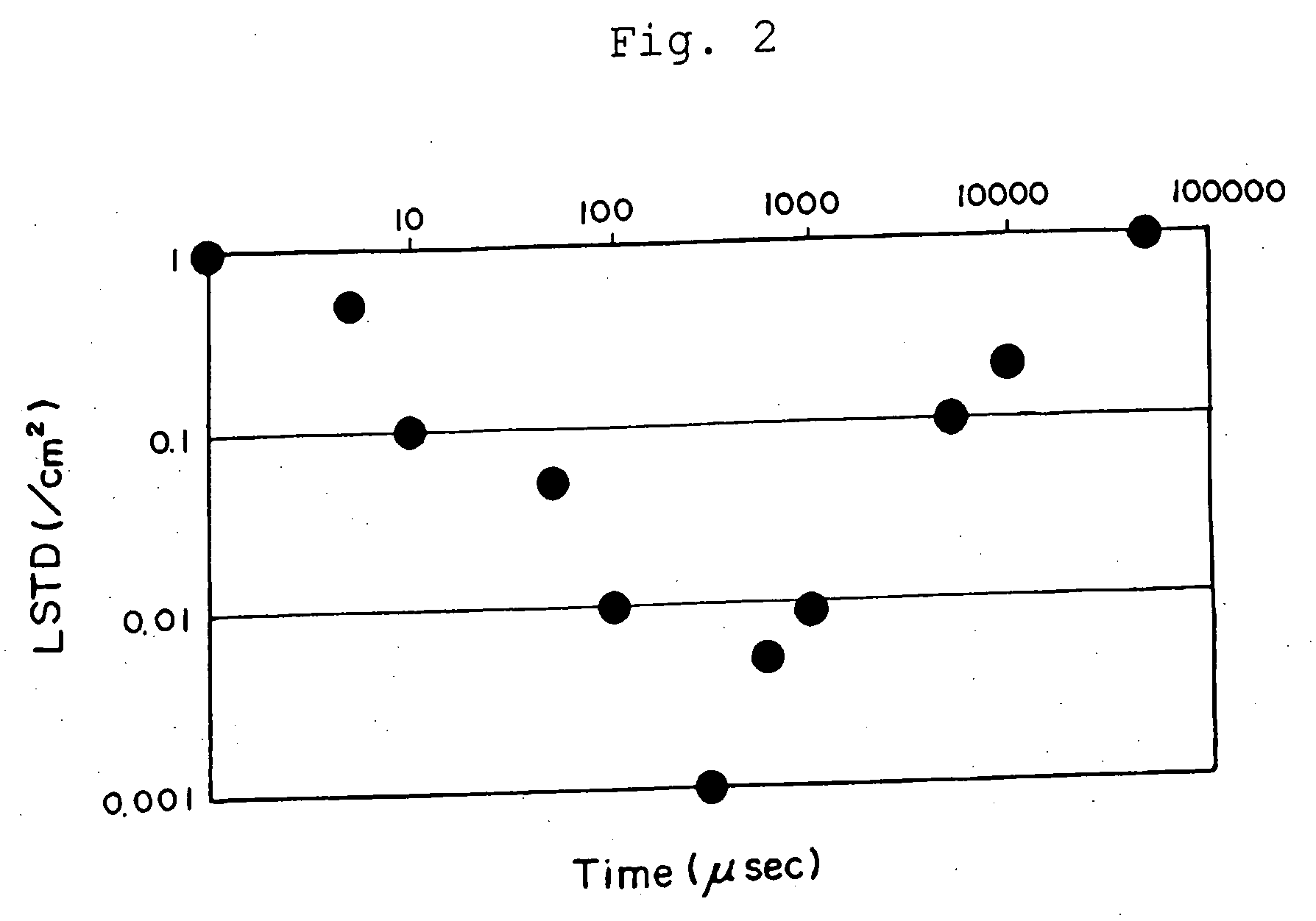

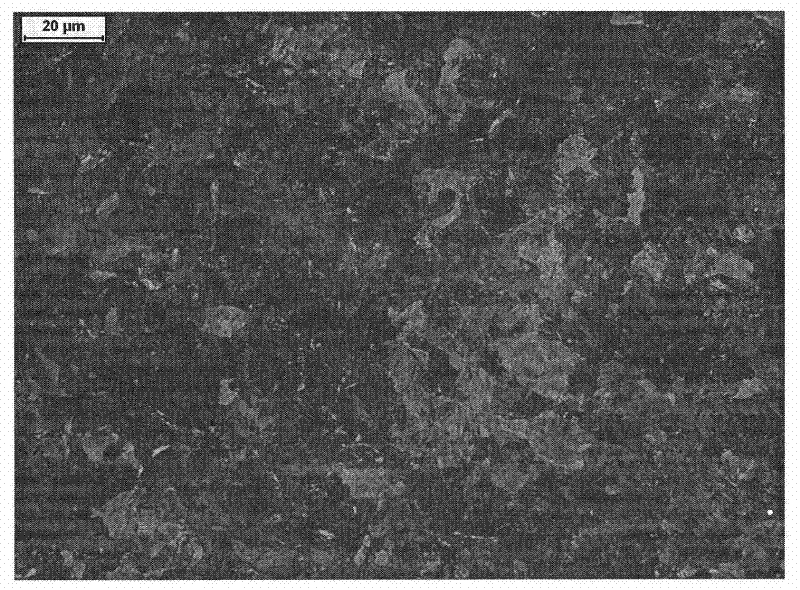

Method of manufacturing silicon wafer

ActiveUS20070059904A1Improve productivityIncrease pulling speedPolycrystalline material growthAfter-treatment detailsProduction rateWafering

The present invention provides a method of manufacturing a silicon wafer where a defect does not exist at a wafer surface layer part on which a device is formed, without affecting productivity and production costs of the wafer. An ingot of a silicon single crystal is grown by way of Czochralski single crystal pulling method, this silicon single crystal ingot is sliced to produce a wafer, then a surface layer of the wafer is annealed for between 0.01 microseconds and 10 seconds (inclusive) by means of a laser spike annealing apparatus such that a temperature of a wafer surface layer part is between 1250° C. and 1400° C. (inclusive).

Owner:GLOBALWAFERS JAPAN

Method for producing 30CrMo hot rolled steel plate

InactiveCN101773929AImprove product qualityImprove qualityMetal rolling arrangementsHigh pressure waterHigh pressure

The invention discloses a method for producing a 30CrMo hot rolled steel plate, which mainly comprises the steps of smelting, refining, thin slab casting, soaking, high pressure water descaling, hot continuous rolling, cooling and reeling based on the process of thin slab casting and rolling. The withdrawing speed of continuous casting is S withdrawing (3.5m / min < / = S withdrawing < / = 5.5m / min), the charging temperature of casting blanks is T charging (900 DEG C < / = T charging < / = 1050 DEG C), the final rolling temperature is T final (830 DEG C < / = T final < / = 930 DEG C), the reeling temperature is T reeling ( 520 DEG C < / = T reeling < / = 620 DEG C), and the depth of a single-surface decarburized layer is 0.2 to 1.2 percent of the thickness of the steel plate. The chemical constitutes of molten steel after being alloyed in a refining process comprise 0.26-0.34 wt.% of C, 0.17-0.37 wt.% of Si, 0.40-0.70 wt.% of Mn, less than or equal to 0.035 wt.% of P, less than or equal to 0.035 wt.% of S, 0.80-1.10 wt.% of Cr, 0.15-0.25 wt.% of Mo and the balance of Fe and inevitable impurities. The 30CrMo hot rolled steel plate produced in the method has the characteristics of uniform structure property, high thermal stability and high strength, and the quality of the 30CrMo hot-rolled steel plate is obviously improved.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

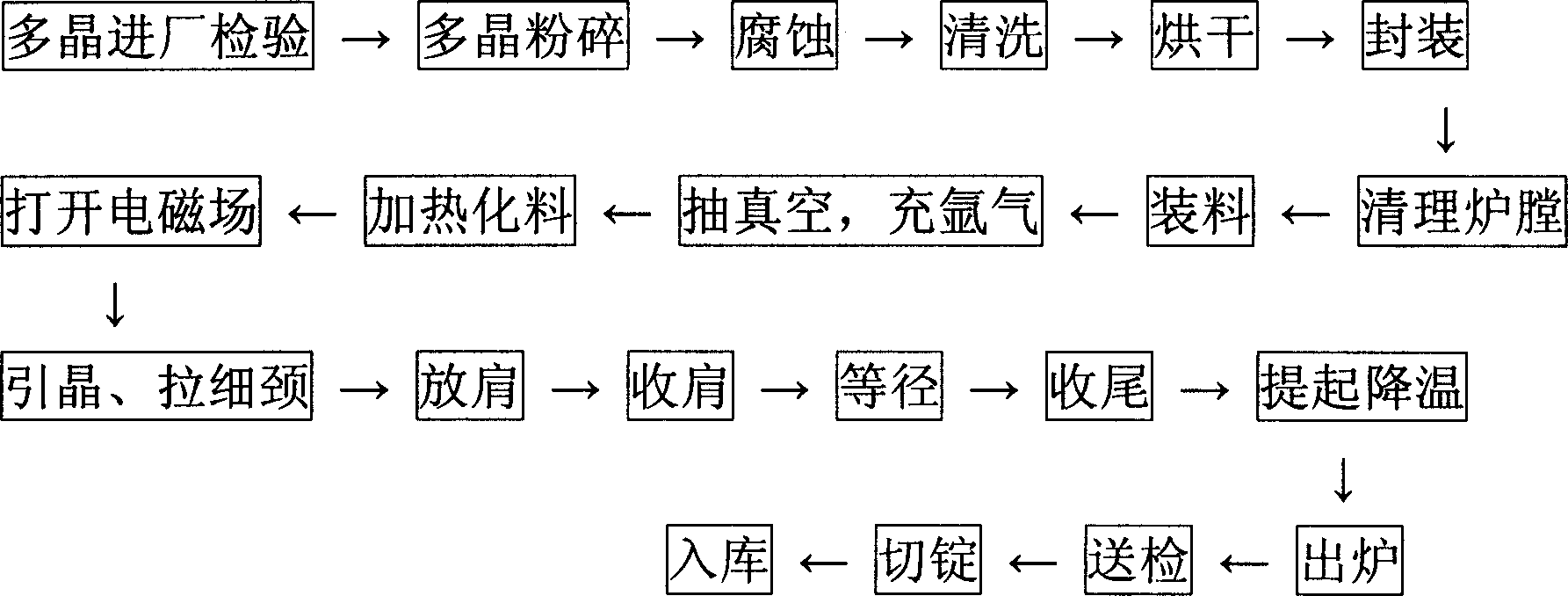

Process for preparing magnetic Czochralski silicon monocrystal

InactiveCN1763265AIncrease pulling speedPolycrystalline material growthBy pulling from meltDrawing neckElectromagnetic field

The present invention relates to monocrystal silicon, and is especially the preparation process of monocrystal silicon drawn via Czochralski method in magnetic field for semiconductor devices. The preparation process includes the following steps: smelting polycrystalline material; applying magnetic field and increasing current gradually to 35 A; rotating crucible in 1-8 rpm and rotating seed crystal at 12-16 rpm after the magnet field reaches 1200 GS and regulating crucible position; and drawing neck via regulating seed crystal stroke to zero, rotating crystal raise potentiometer and raising drawing speed to 16 inch / hr. The monocrystal silicon thus prepared has homogeneous radial distribution of resistivity and high quality.

Owner:TIANJIN HUANOU SEMICON MATERIAL TECH CO LTD

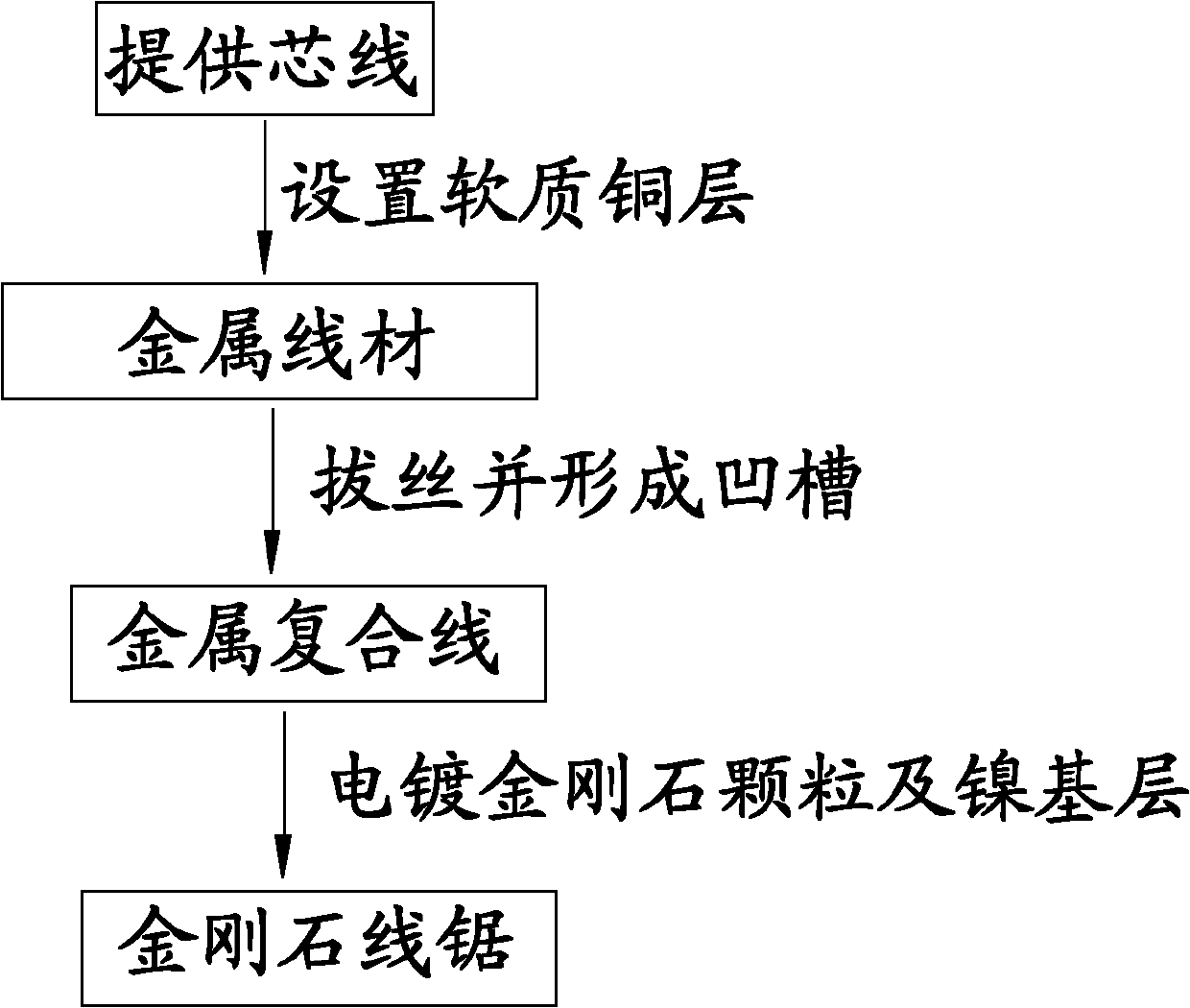

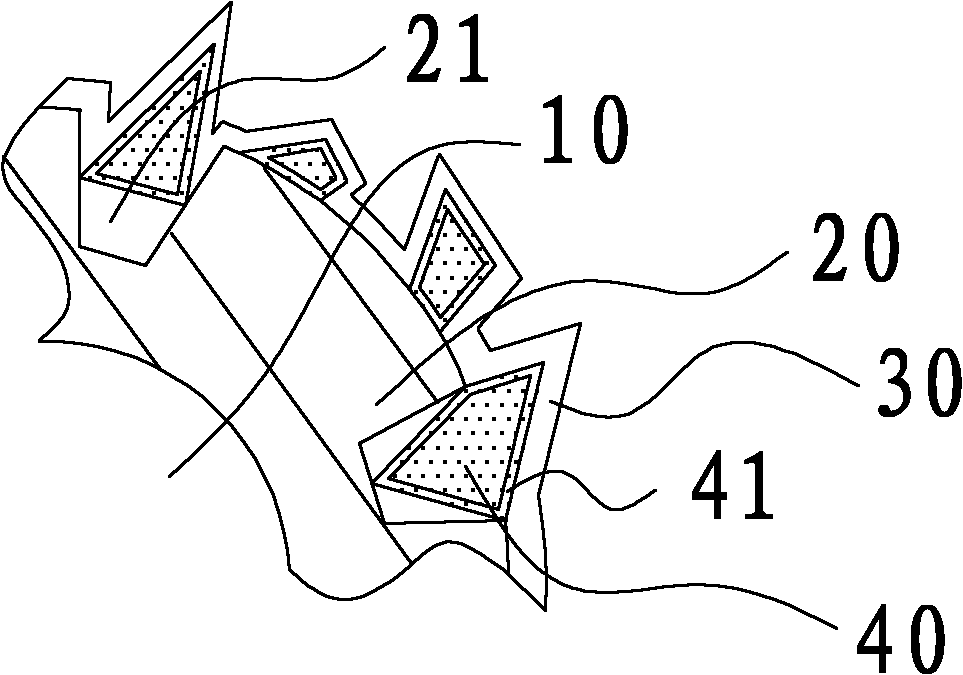

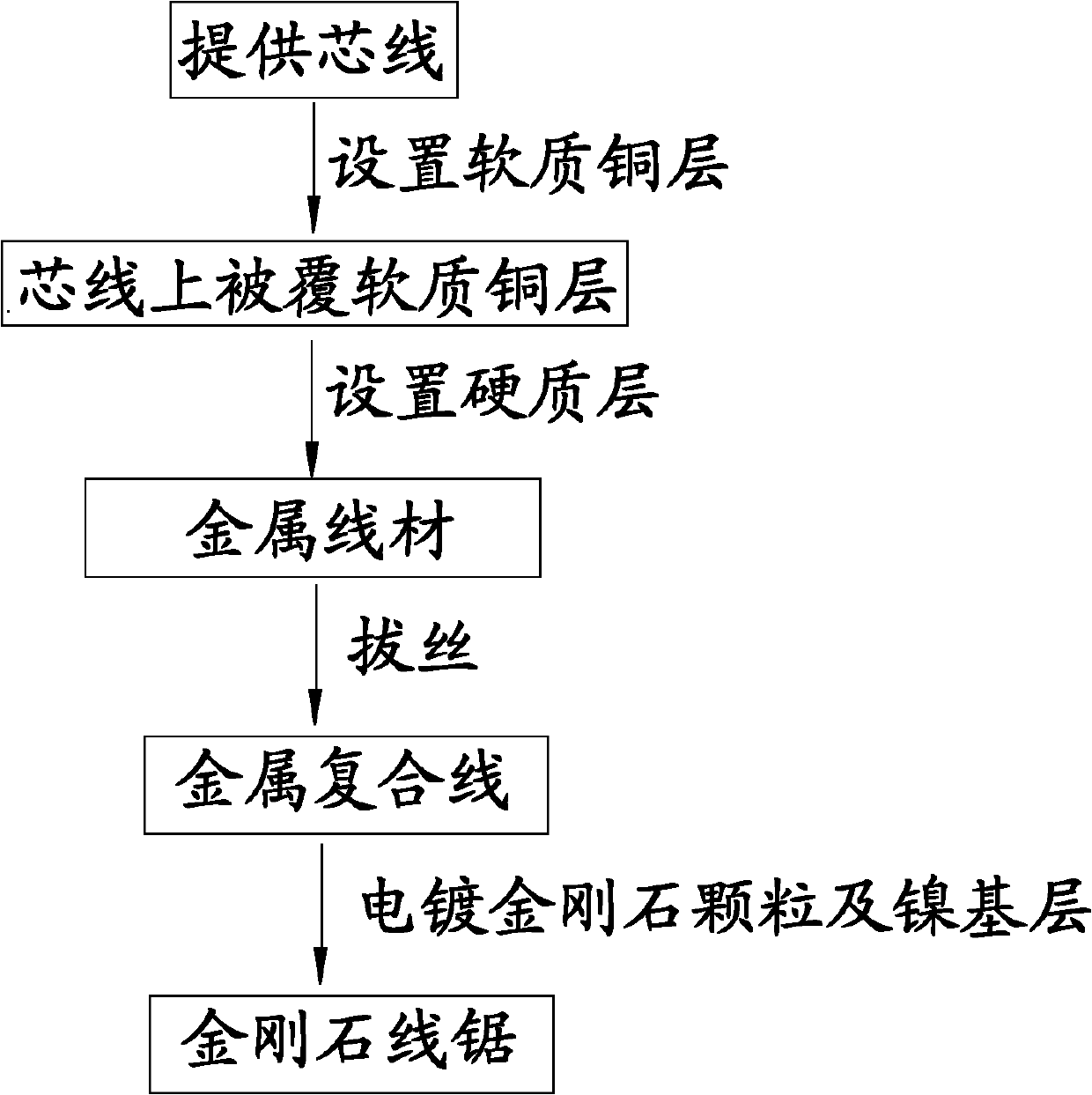

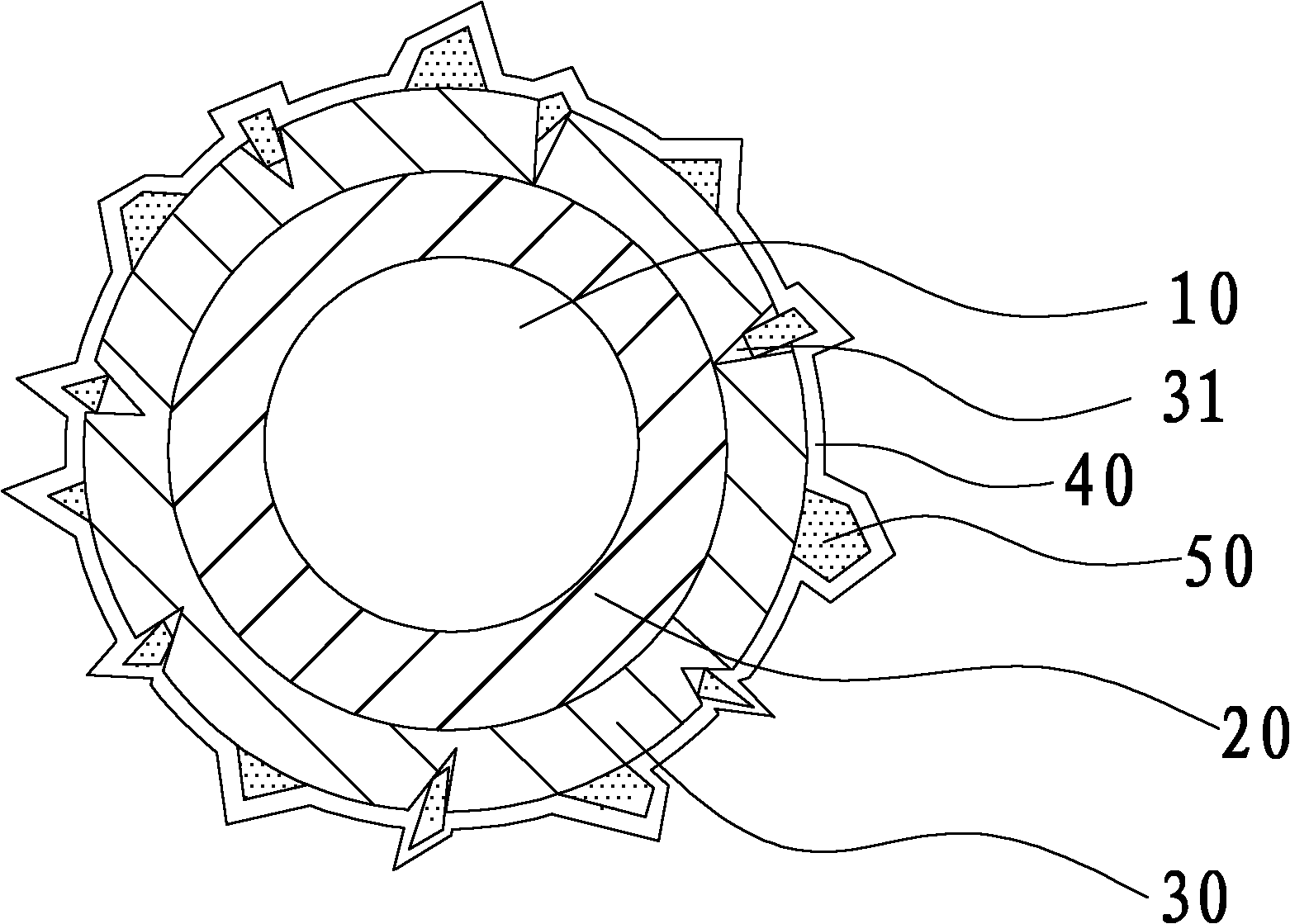

Diamond fret saw and manufacture method thereof

ActiveCN102166792AImprove processing efficiencyImprove adhesionHot-dipping/immersion processesElectrolytic coatingsDiamond wire sawNickel alloy

The invention discloses a diamond fret saw and a manufacture method thereof. The diamond fret saw comprises a metal base line body and diamond particles embedded on the surface of the metal base line body, wherein the metal base line body comprises a core body, a sand-planting layer and a nickel base layer, wherein the core body consists of carbon steel and has a diameter of 0.1-0.4mm; the sand-planting layer covers the surface of the core body and has a thickness of 0.001-0.04mm; and the nickel base layer covers the surface of the sand-planting layer and has a thickness of 0.001-0.05mm, the nickel layer comprises nickel or a first nickel alloy, the first nickel alloy comprises one or more of Co, W, Fe, Al, Mo, Nb, Si, Ti, V, Y or Zr, and a groove is formed on the surface of the sand-planting layer and is internally provided with the diamond particles. By using the diamond fret saw disclosed by the embodiment of the invention, because the sand-planting layer with the groove covers outside a steel wire, processing rate of electroplating the diamond particles can be increased and service life of the diamond fret saw can be remarkably prolonged.

Owner:盛利维尔(常州)金属材料有限公司

Method for producing non-spangle galvanized plate based on sheet billet continuous casting and rolling heat-based raw material and pickling galvanization continuous production line

ActiveCN108480416AFlexible temperature adjustmentShorten the lengthHot-dipping/immersion processesFurnace typesAcid washingContinuous casting

The invention relates to a method for producing a non-spangle galvanized plate based on sheet billet continuous casting and rolling heat-based raw material and a pickling galvanization continuous production line. The method comprises the following steps of totally-headless sheet billet continuous casting and rolling, pickling, smoothing, heating, non-spangle galvanization, finishing, passivation and coiling to form a non-spangle hot-galvanized roll. By means of the method, the non-spangle continuous pickling hot-galvanized plate with the specification being (0.8-4.0)*(900-1650) mm is producedin a hot rolling manner, the technological process is shortened, energy is saved, a product is good in surface quality, high in size precision and stable in performance, the production cost is lowered, parts of cold-rolling base material galvanized products can be replaced by the product, and the blank of heat-based continuous pickling galvanizing production is filled up.

Owner:RIZHAO BAOHUA NEW MATERIAL CO LTD

Crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of crystallizer covering slag

The invention provides a crystallizer covering slag for continuously casting high-manganese high-aluminum steel and preparation method of the crystallizer covering slag. The covering slag is prepared from the following components in parts by weight: 20-38 parts of CaO, 20-35 parts of Al2O3, 5-18 parts of SiO2, 10-22 parts of BaO, 2-7 parts of Li2O, 5-12 parts of F<->, 1-4 parts of MgO, 2-8 parts of C and Fe2O3 which is less than or equal to 2 parts. According to the preparation method disclosed by the invention, wollastonite, limestone, quartz sand, fluorite, bauxite, barium carbonate, magnesia, soda, lithium carbonate and carbonaceous materials are used as raw materials, and the covering slag is prepared through the following steps of: calculating of consumption, melting, smashing, fine grinding, drying and granulation. The covering slag disclosed by the invention has the characteristics of being low in reactivity and good in property stability, the lubrication and the thermal transmission of casting blanks can be effectively coordinated and controlled, the smooth performing of the continuous casting process of the high-manganese high-aluminum steel can be guaranteed, high-manganese high-aluminum steel continuous casting blanks with excellent surface quality are cast, and multi-heat continuous casting can be realized.

Owner:CHONGQING UNIV

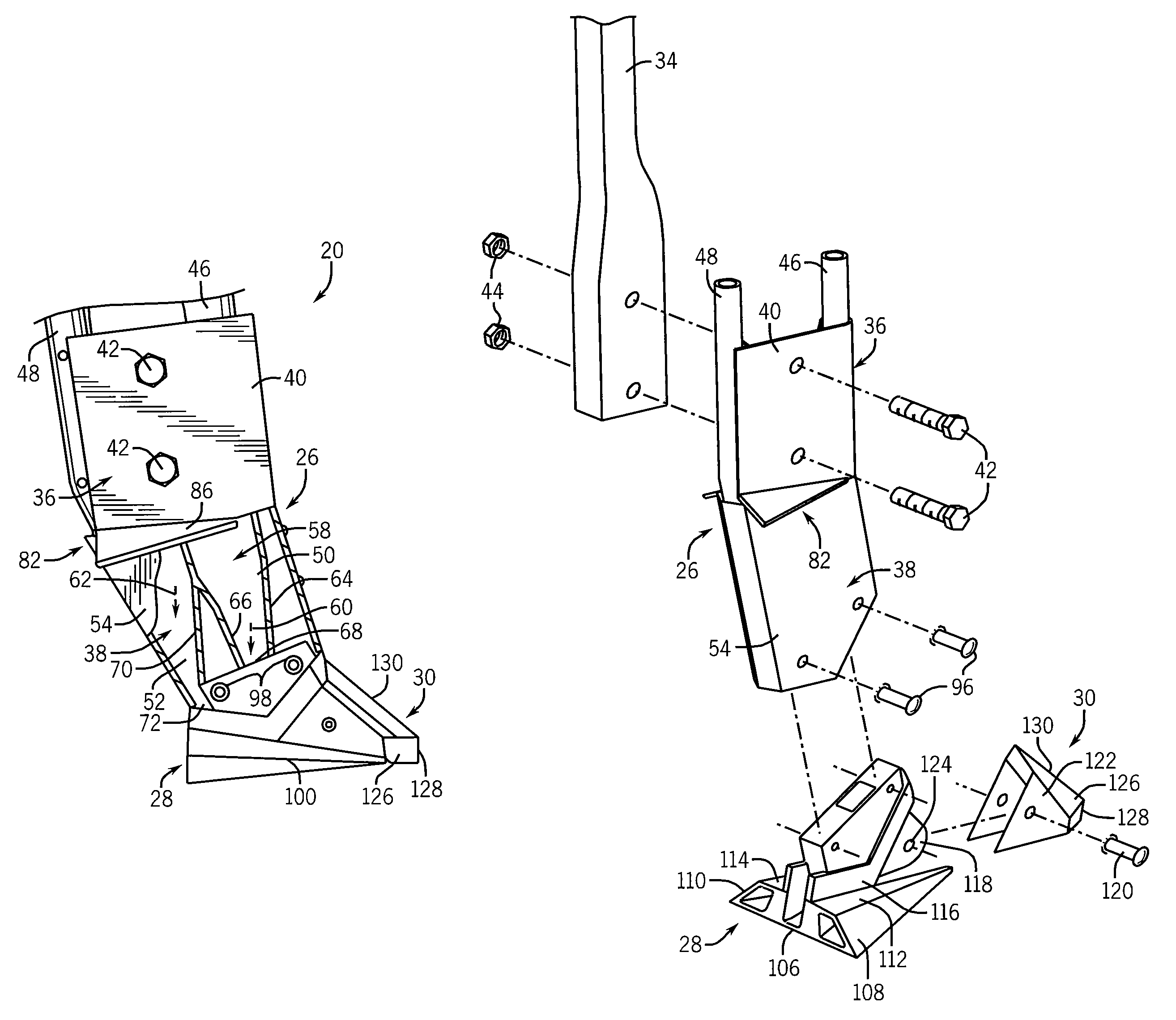

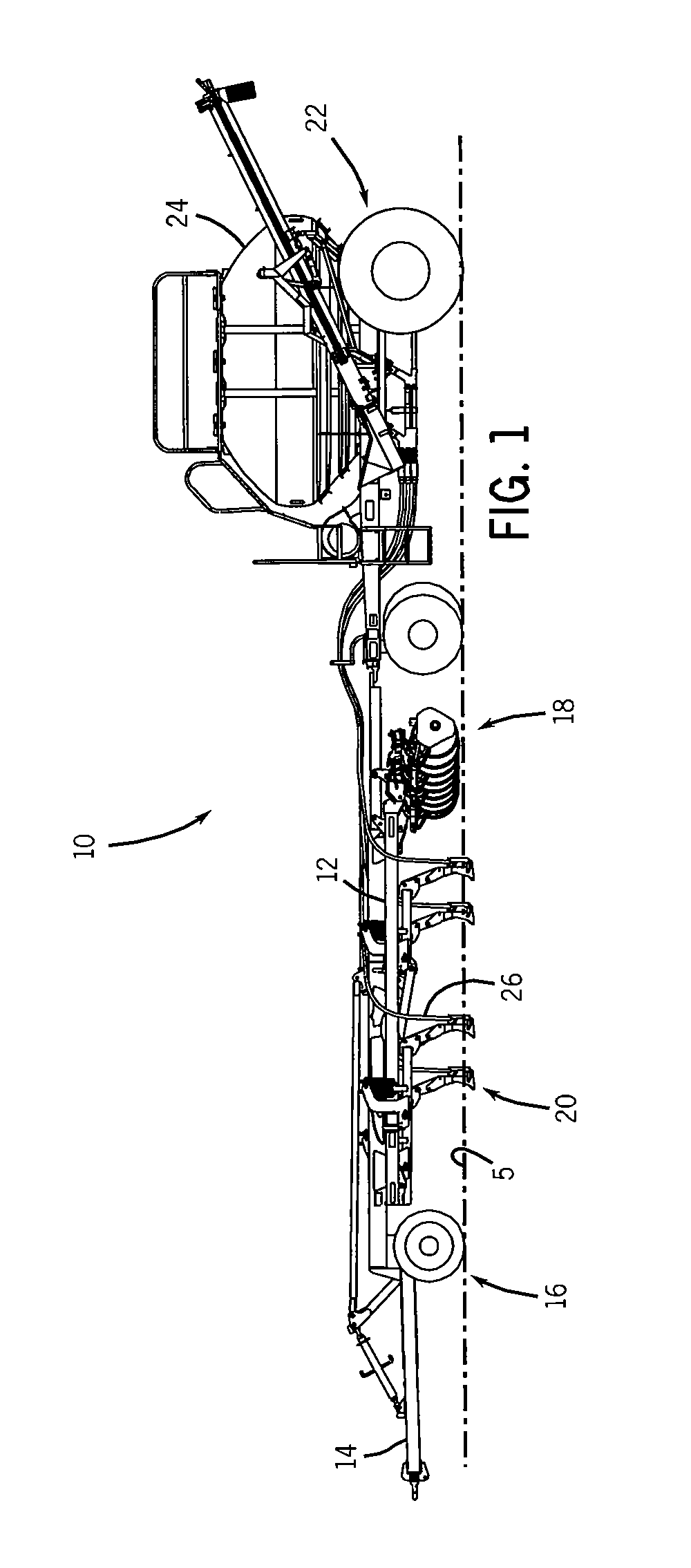

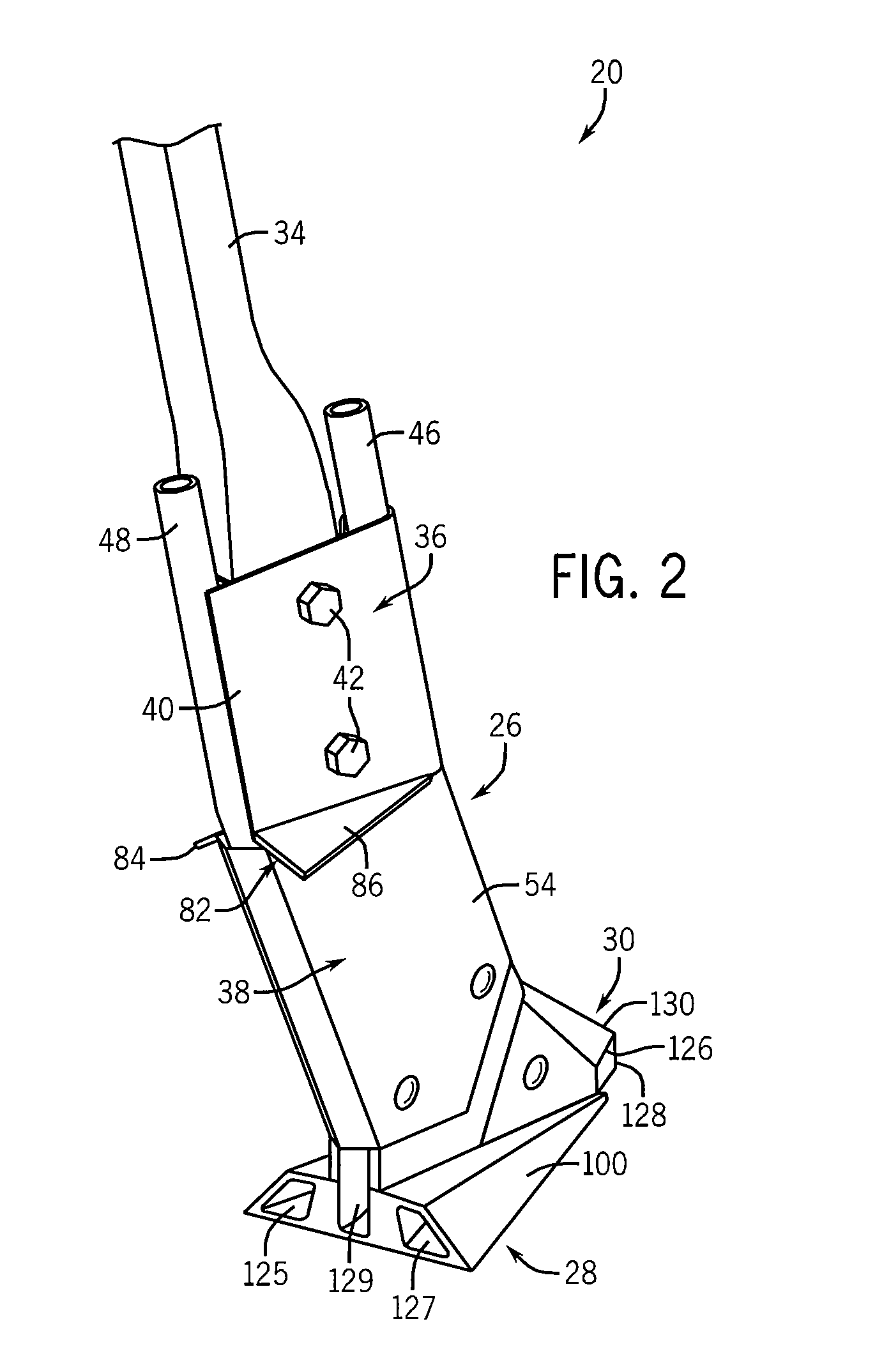

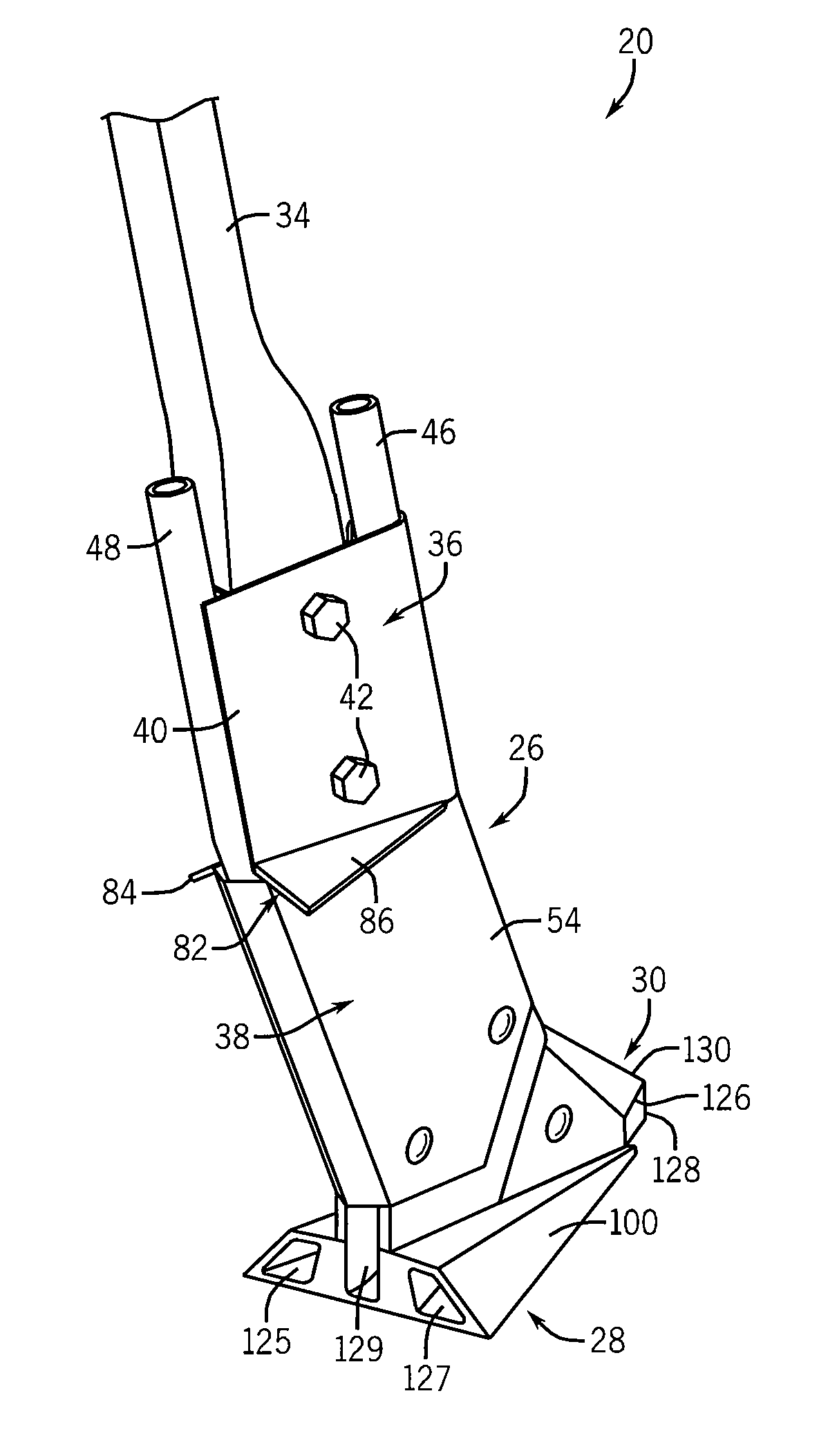

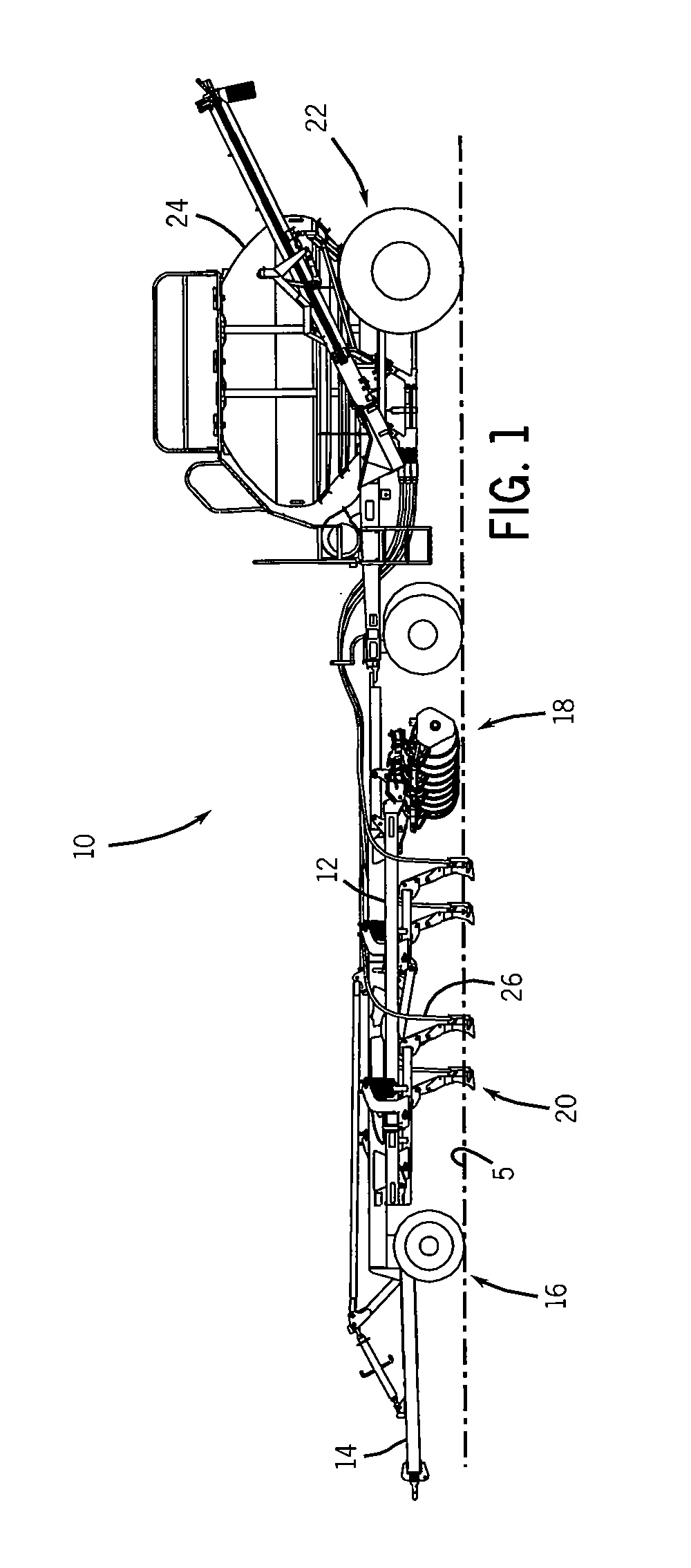

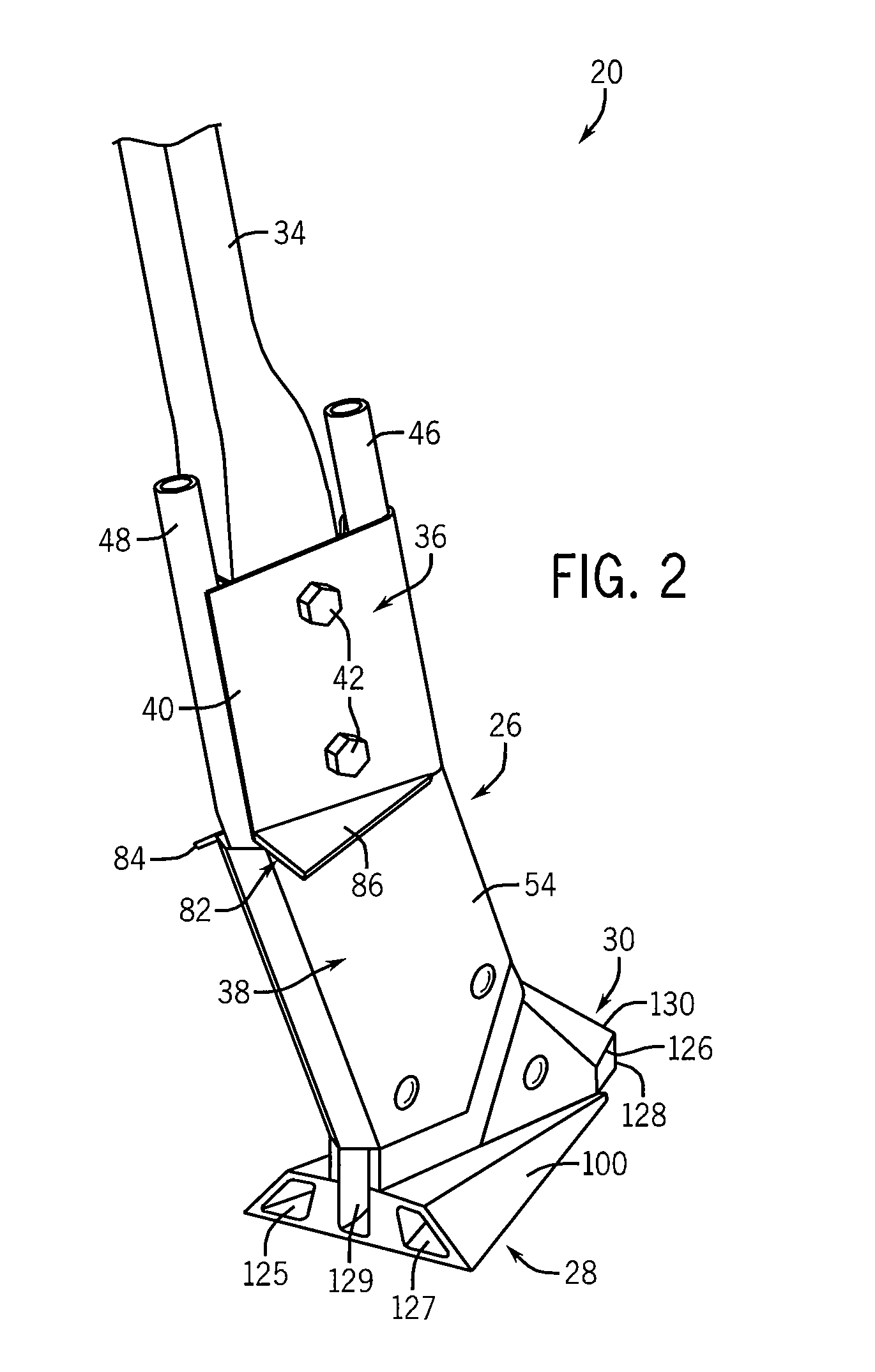

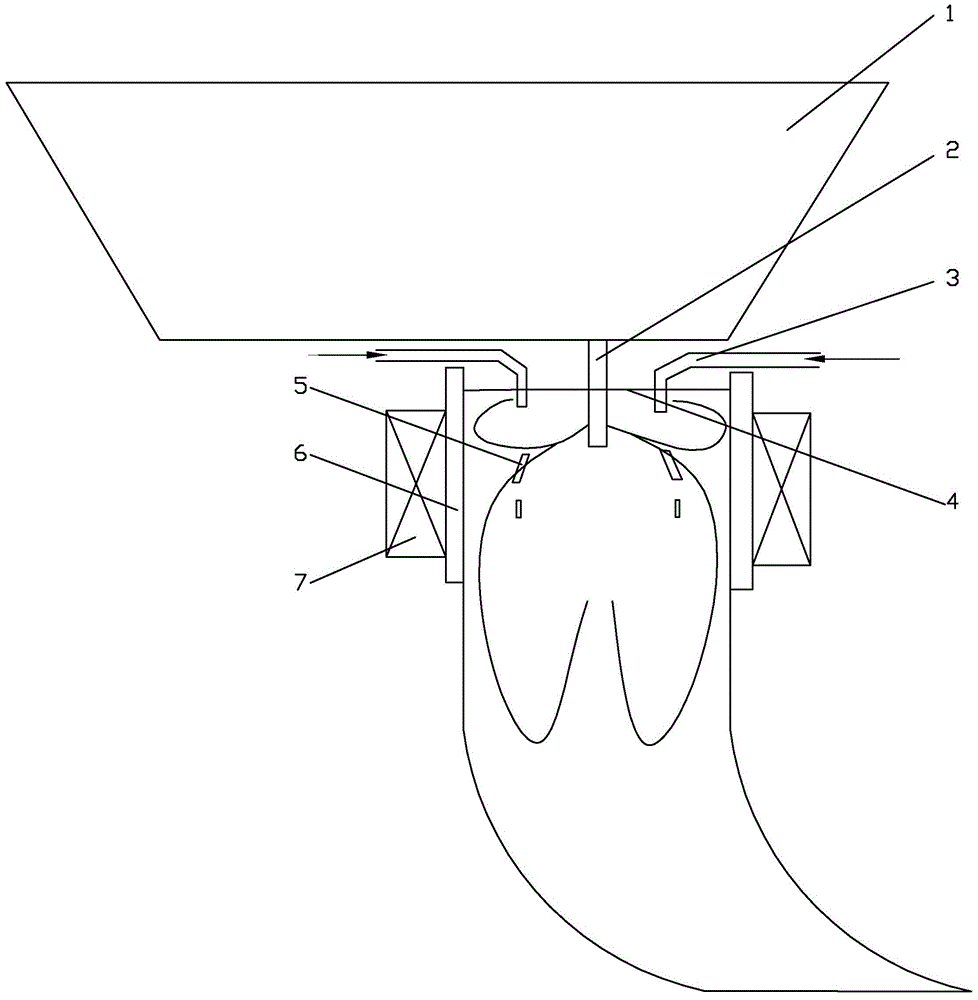

Soil opener for higher travel speeds

A soil opener has a frog mount adapted to be coupled to a shank or other mounting member of a farm implement. A spreader is removably coupled to the frog mount and includes forward and rearward product delivery channels that are intended to be flow-coupled to product delivery tubes or hoses of the farm implement. A tip is removably coupled to the spreader. The leading edges of the frog mount, the spreader, and the tip, as well as the geometry between these components are such that draft is minimized even when the soil opener is pulled through the soil at higher speeds, e.g., excess of 5 mph. The soil opener may be equipped with an optional soil gathering module.

Owner:CNH IND CANADA

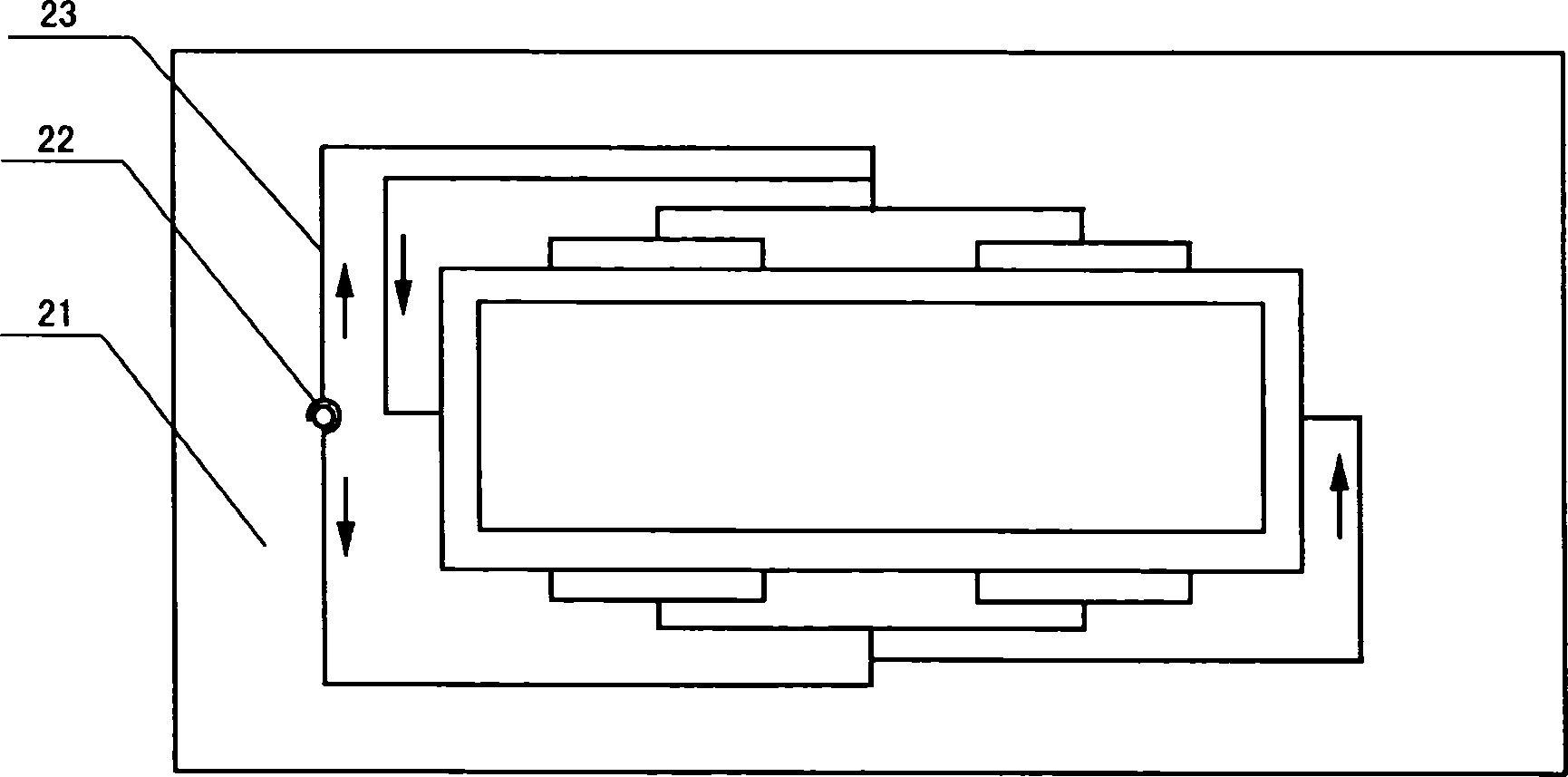

CZ Czochralski method mono-crystal furnace graphite thermal field structure

InactiveCN101560691AImprove reflectivityGood insulation performanceBy pulling from meltThermal insulationCzochralski method

The invention discloses a CZ Czochralski method mono-crystal furnace graphite thermal field structure, which comprises a thermal shielding and a gas stream guidance device. Athermal shielding outer layer (3) and a thermal shielding inner layer (1) are arranged on the thermal shielding and the gas stream guidance device. A gap is arranged between the thermal shielding outer layer (3) and the thermal shielding inner layer (1). Due to the adoption of the technical proposal as well as the adoption of the reflection angle of an inclined plane, the reflectivity of thermal radiation is increased; and the gaps between the thermal shielding outer layer and the thermal shielding inner layer at the middle and lower part of the thermal shielding are added, therefore, graphitic carbon felt is filled, and the heat insulation effect of the thermal shielding is increased. The structure leads the traditional 20-inch thermal sealed field to maintain the drawing condition under 1420 DEG C needing to consume 70-75kw / h heat to reduce to 60-65kw / h heat, thus saving more than 10% energy. The structure fills 2-3 layers of graphitic carbon felt to increase the thermal insulation and change the longitudinal temperature gradient of crystals during the growth of mono-crystals. Besides, the drawing speed is increased by 0.05mm / min, the production capacity of equipment is improved and the production cost is reduced.

Owner:芜湖升阳光电科技有限公司

Silicon single crystal wafer for IGBT and method for manufacturing silicon single crystal wafer for IGBT

InactiveUS20100288184A1Little variation in resistivityIncrease pulling speedPolycrystalline material growthSemiconductor/solid-state device manufacturingDopantHydrogen atom

A method for manufacturing a silicon single crystal wafer for IGBT, including introducing a hydrogen atom-containing substance into an atmospheric gas at a hydrogen gas equivalent partial pressure of 40 to 400 Pa, and growing a single crystal having an interstitial oxygen concentration of 8.5×1017 atoms / cm3 or less at a silicon single crystal pulling speed enabling pulling of a silicon single crystal free of grown-in defects. The silicon single crystal is irradiated with neutrons so as to dope with phosphorous; an n-type dopant is added to the silicon melt; or phosphorous is added to the silicon melt so the phosphorous concentration in the silicon single crystal is 2.9×1013 to 2.9×1015 atoms / cm3; a p-type dopant having a segregation coefficient smaller than that of the phosphorous is added to the silicon melt so the concentration in the single crystal is 1×1013 to 1×1015 atoms / cm3 corresponding to the segregation coefficient thereof.

Owner:SUMCO CORP

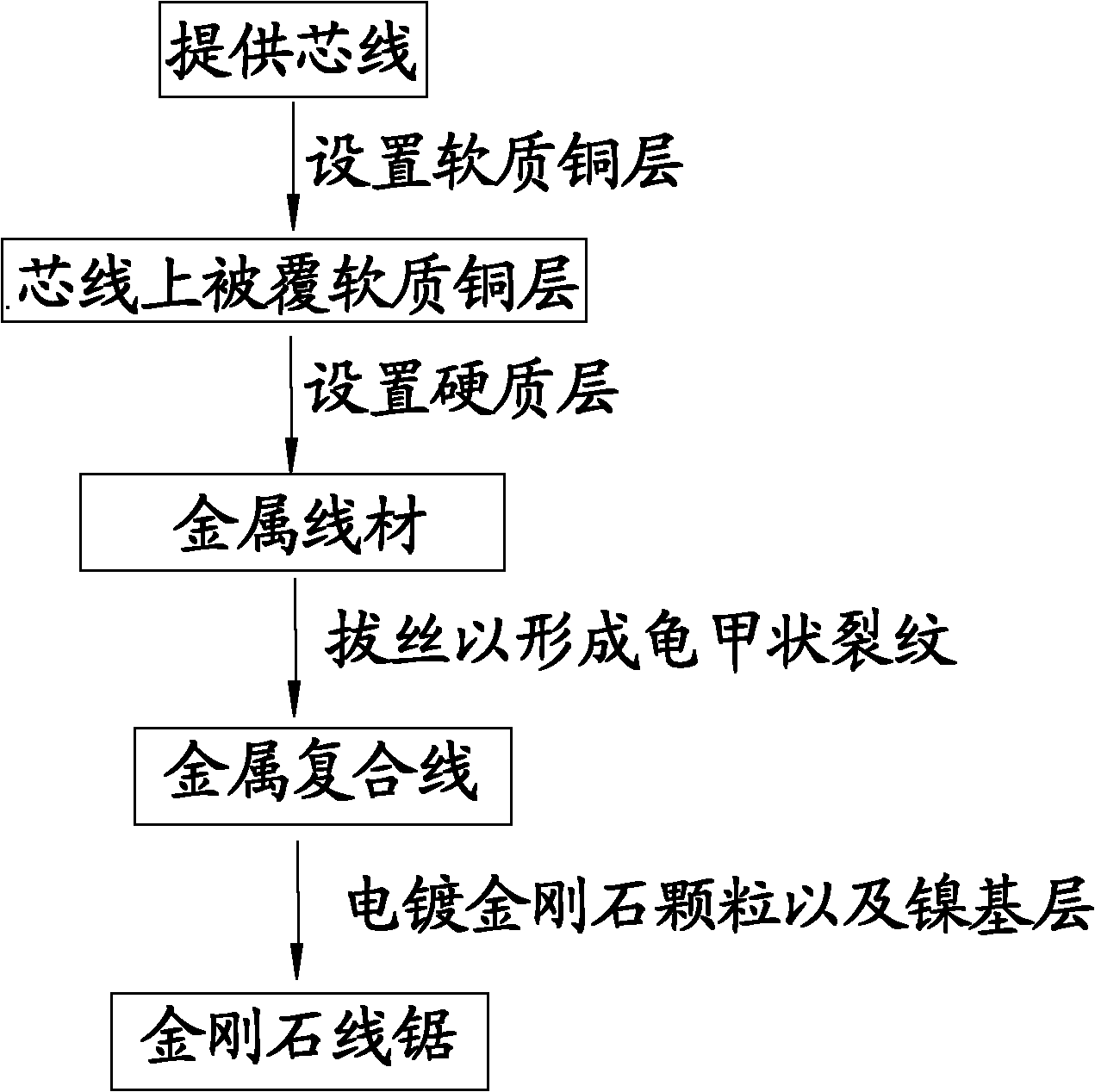

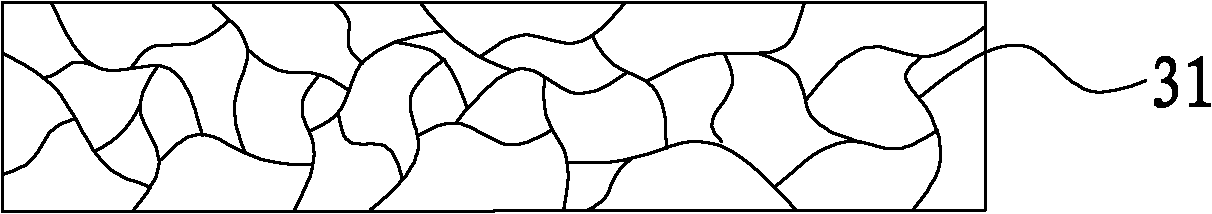

Diamond fretsaw and manufacture method thereof

The invention discloses a diamond fretsaw and a manufacture method thereof. The diamond fretsaw comprises a metal baseline body and diamond granules, wherein the metal baseline body comprises a core body, a protection layer, a sand-planting layer and a nickel base layer; the core body is made of carbon steel and has the diameter of 0.1-0.4mm; the protection layer covers the surface of the core body, has the thickness of 0.001-0.003 mm and is made of soft copper; the sand-planting layer covers the surface of the protection layer and has the thickness of 0.01-0.04mm; testudinate cracks for planting the diamond granules are formed on the surface of the sand-planting layer which comprises zinc, zinc alloy, nickel or first nickel alloy; and the nickel base layer covers the surface of the sand-planting layer, has the thickness of 0.001-0.05 mm and is made from nickel or second nickel alloy. By utilizing the diamond fretsaw provided by the embodiment of the invention, the protection layer made of soft steel covers outside a steel wire so as to resist corrosion and prevent the cracks from expanding; due to the existence of the testudinate cracks, the wire drawing yield can be improved in one aspect, the processing efficiency of electroplating can be remarkably enhanced in the other aspect and the service life of the diamond fretsaw is favorably prolonged.

Owner:盛利维尔(常州)金属材料有限公司

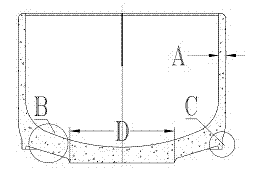

Hyperbolic-type crystallizer copper pipe

The invention relates to a hyperbolic-type crystallizer copper pipe, which is characterized in that a conical degree curve of an inner cavity of a crystallizer is a hyperbola; the conical degree curves of four surfaces are all hyperbolas; and a relative large curve gradient is close to a meniscus, so as to better meet the demand on the conical degree close to the meniscus and better adapt to the contraction of a billet shell along the longitudinal direction of the crystallizer, thereby further reducing the thickness of a clearance along the longitudinal direction of the crystallizer, better eliminating the harmful effect of the clearance, promoting a heat transfer effect of the whole crystallizer and meeting the demand on high pulling speed of the crystallizer copper pipe.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

Method for producing 30CrMo hot rolled steel plate

InactiveCN101773929BImprove billet qualityImprove uniformityMetal rolling arrangementsStructure propertyThin slab

The invention discloses a method for producing a 30CrMo hot rolled steel plate, which mainly comprises the steps of smelting, refining, thin slab casting, soaking, high pressure water descaling, hot continuous rolling, cooling and reeling based on the process of thin slab casting and rolling. The withdrawing speed of continuous casting is S withdrawing (3.5m / min < / = S withdrawing < / = 5.5m / min), the charging temperature of casting blanks is T charging (900 DEG C < / = T charging < / = 1050 DEG C), the final rolling temperature is T final (830 DEG C < / = T final < / = 930 DEG C), the reeling temperature is T reeling ( 520 DEG C < / = T reeling < / = 620 DEG C), and the depth of a single-surface decarburized layer is 0.2 to 1.2 percent of the thickness of the steel plate. The chemical constitutes of molten steel after being alloyed in a refining process comprise 0.26-0.34 wt.% of C, 0.17-0.37 wt.% of Si, 0.40-0.70 wt.% of Mn, less than or equal to 0.035 wt.% of P, less than or equal to 0.035 wt.% of S, 0.80-1.10 wt.% of Cr, 0.15-0.25 wt.% of Mo and the balance of Fe and inevitable impurities. The 30CrMo hot rolled steel plate produced in the method has the characteristics of uniform structure property, high thermal stability and high strength, and the quality of the 30CrMo hot-rolled steel plate is obviously improved.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

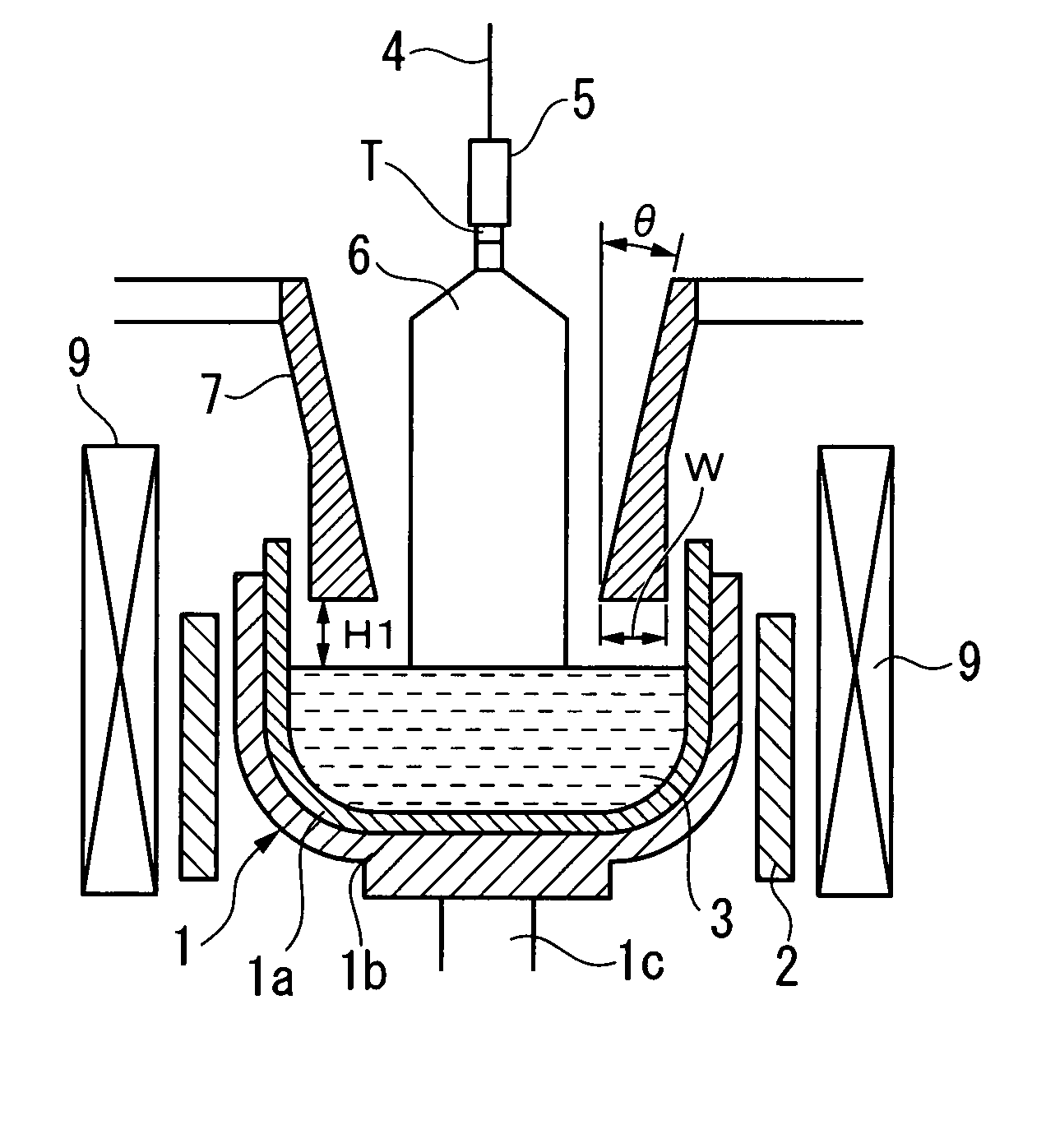

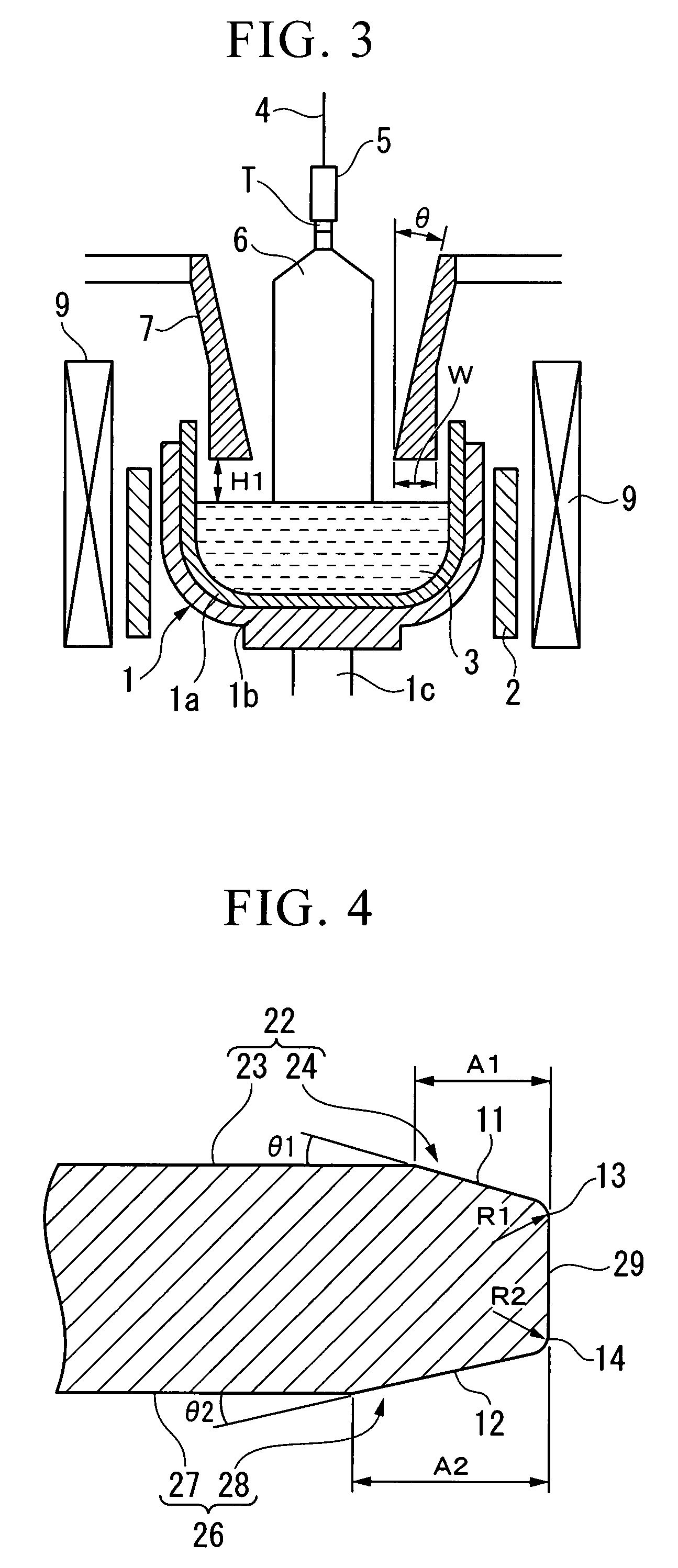

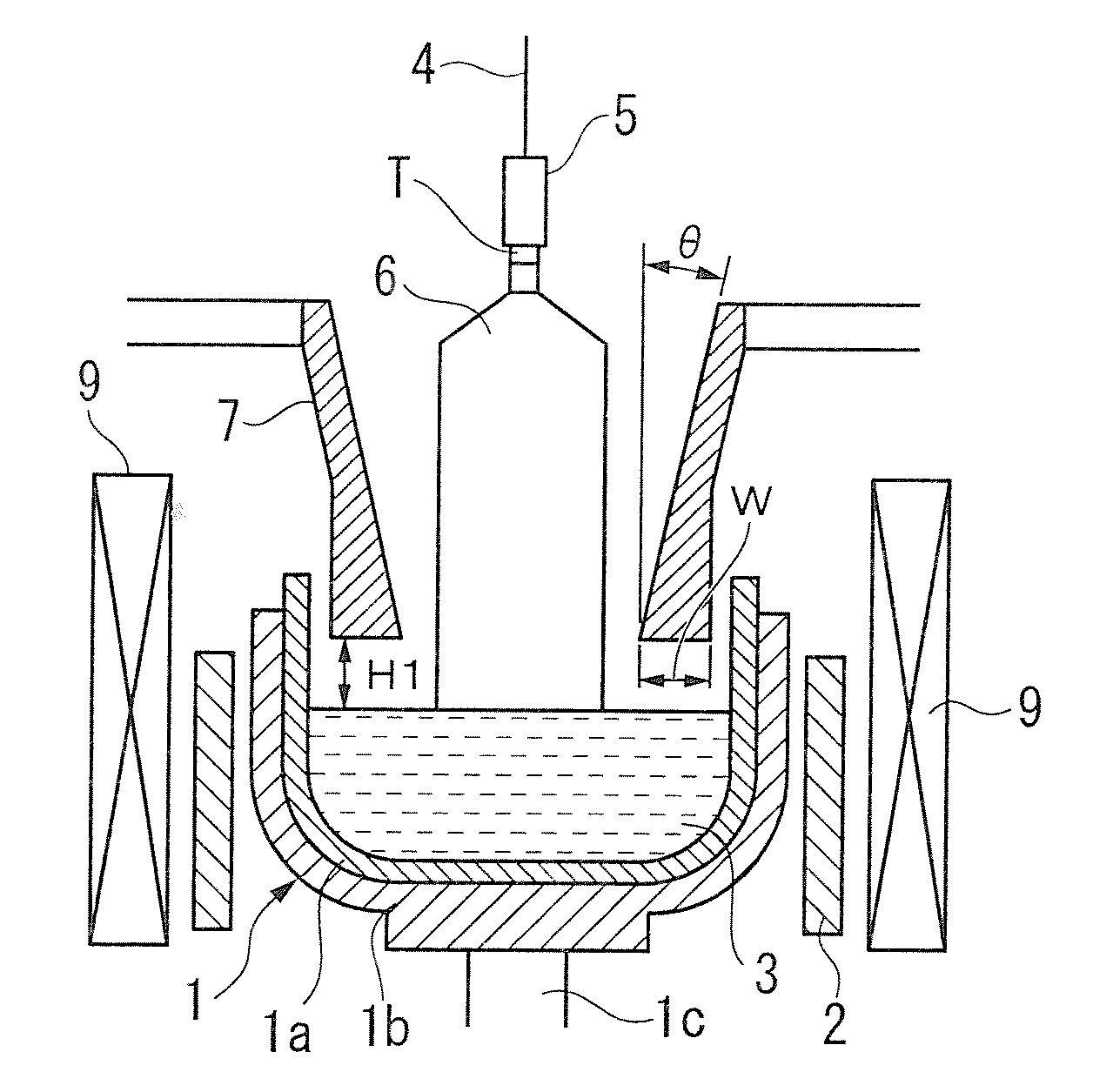

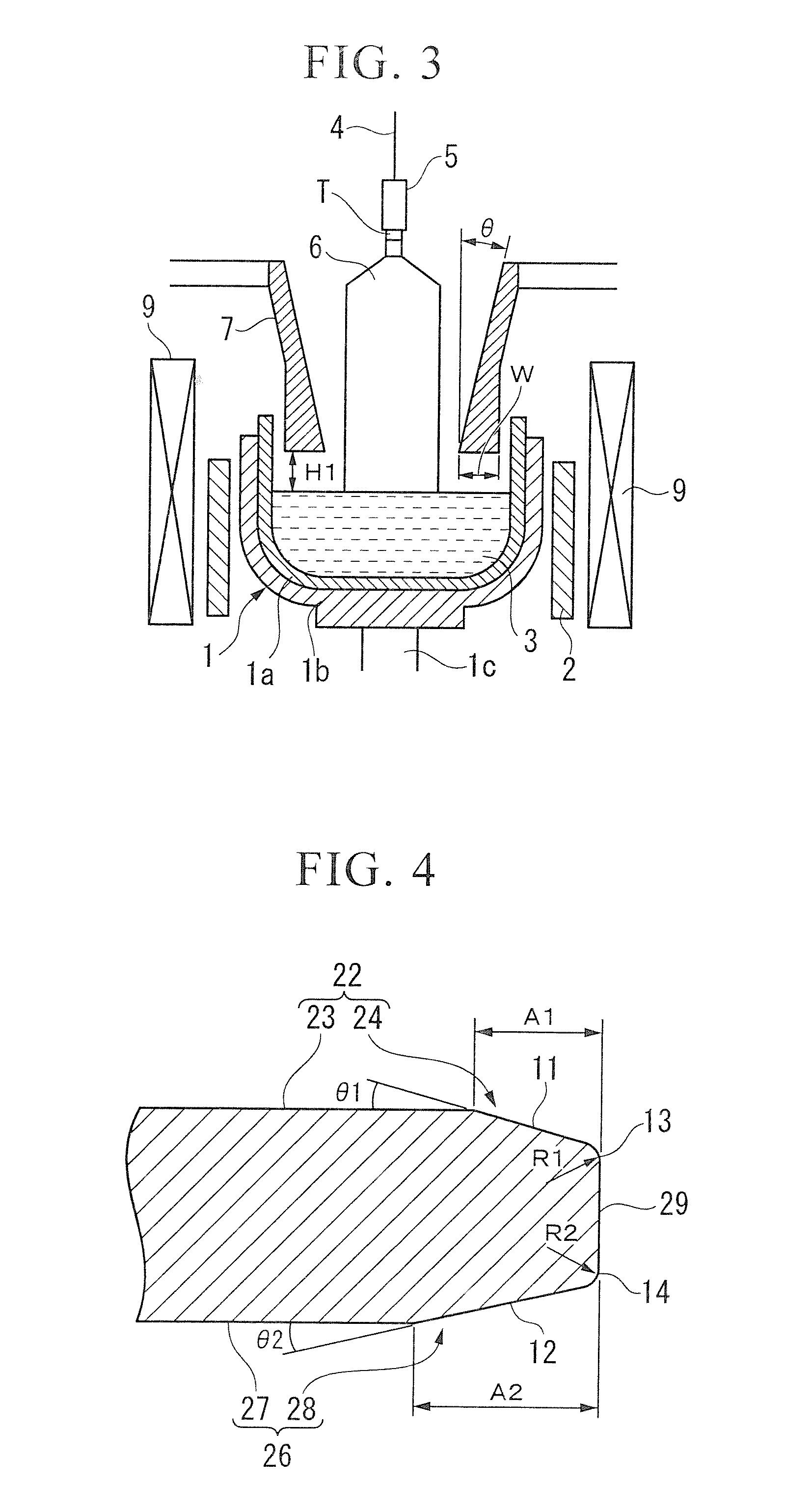

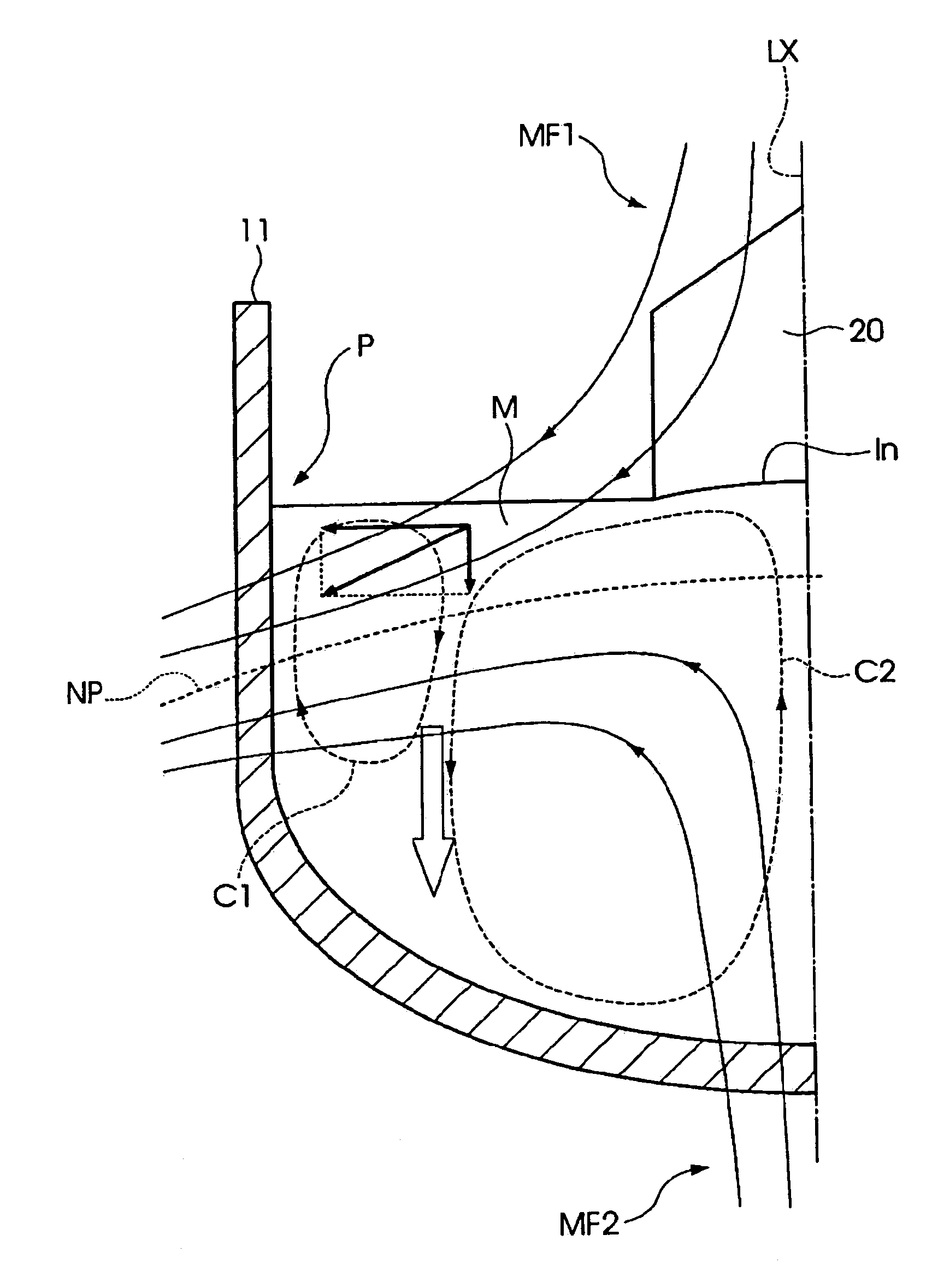

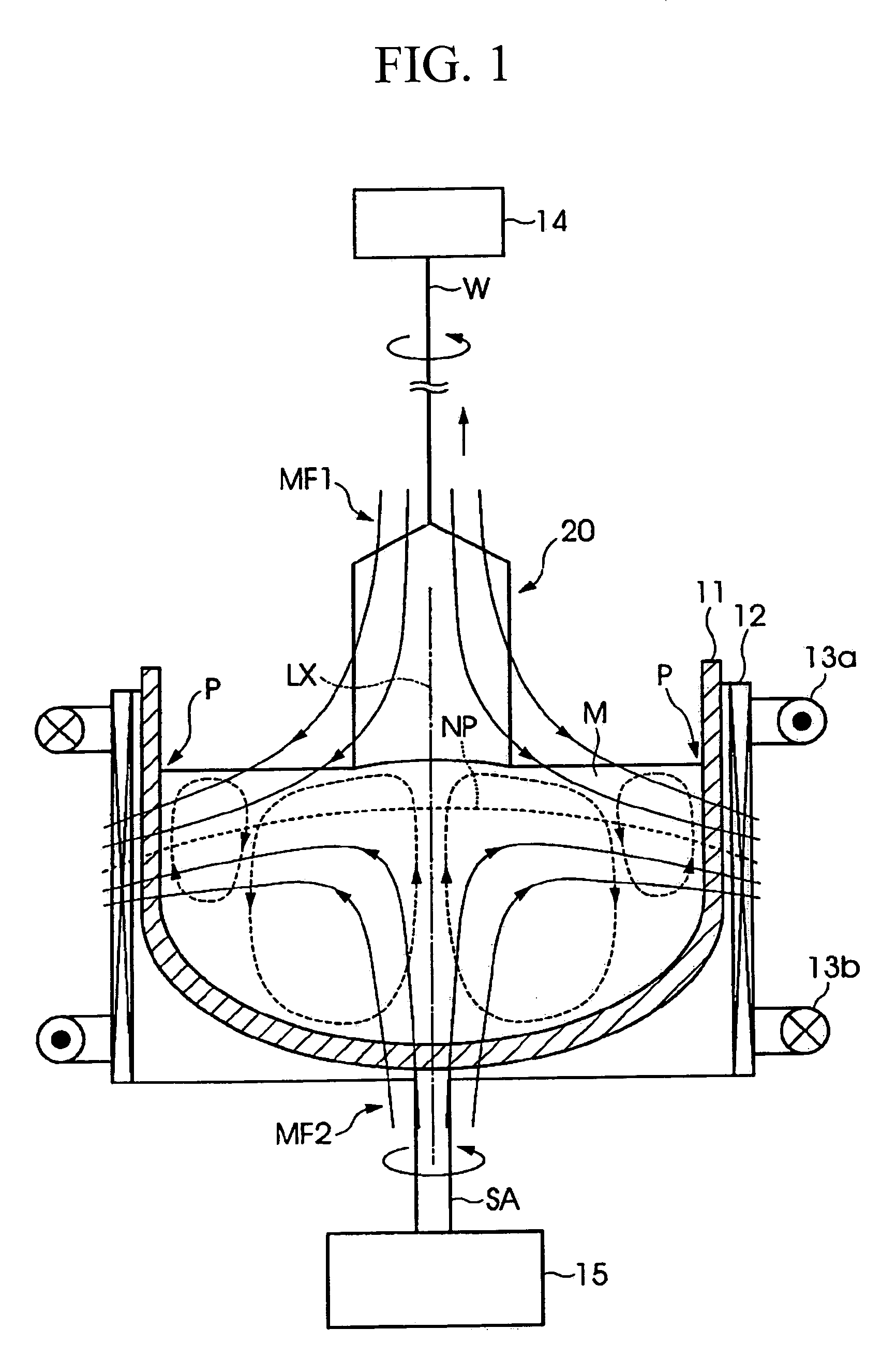

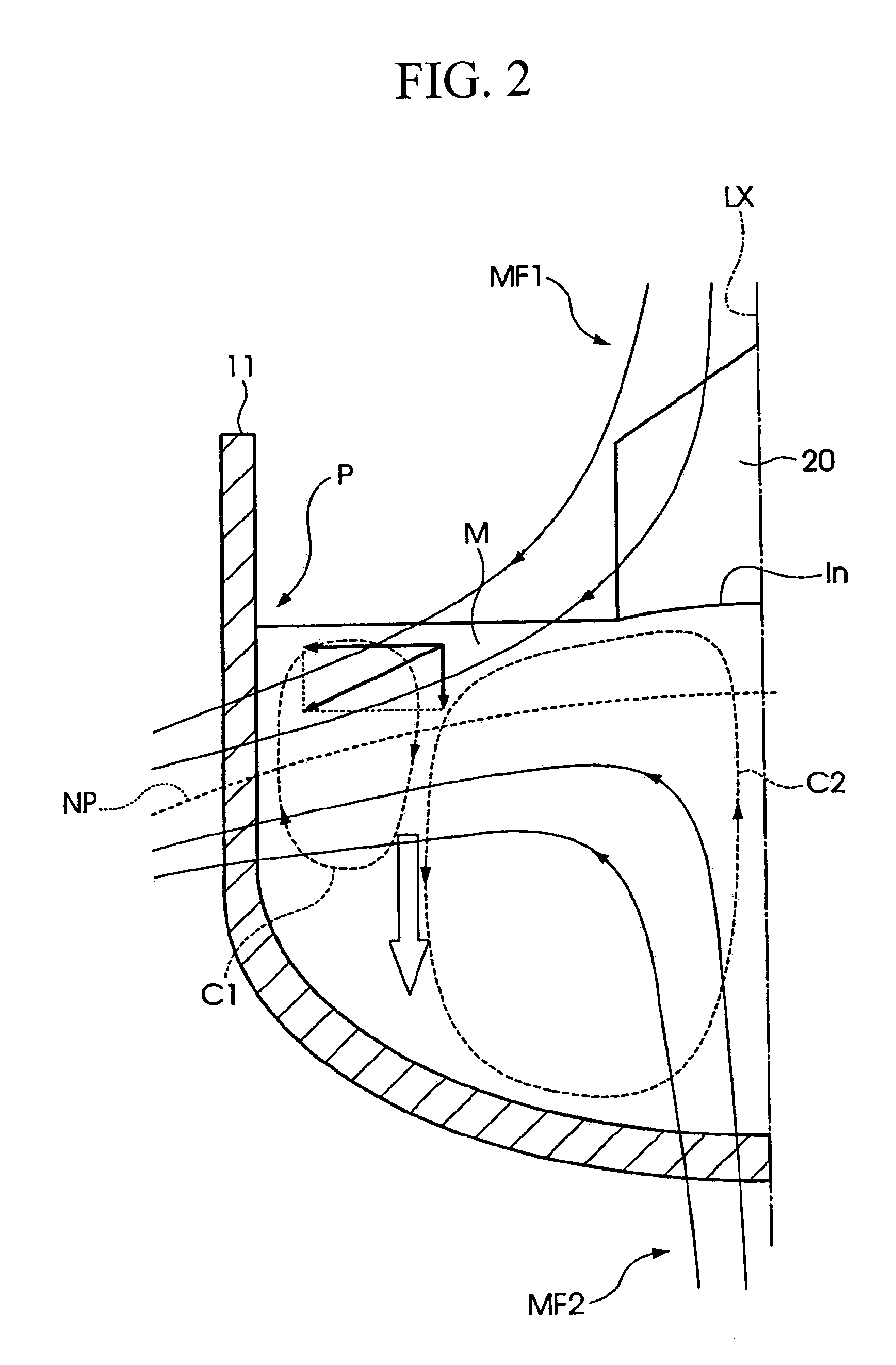

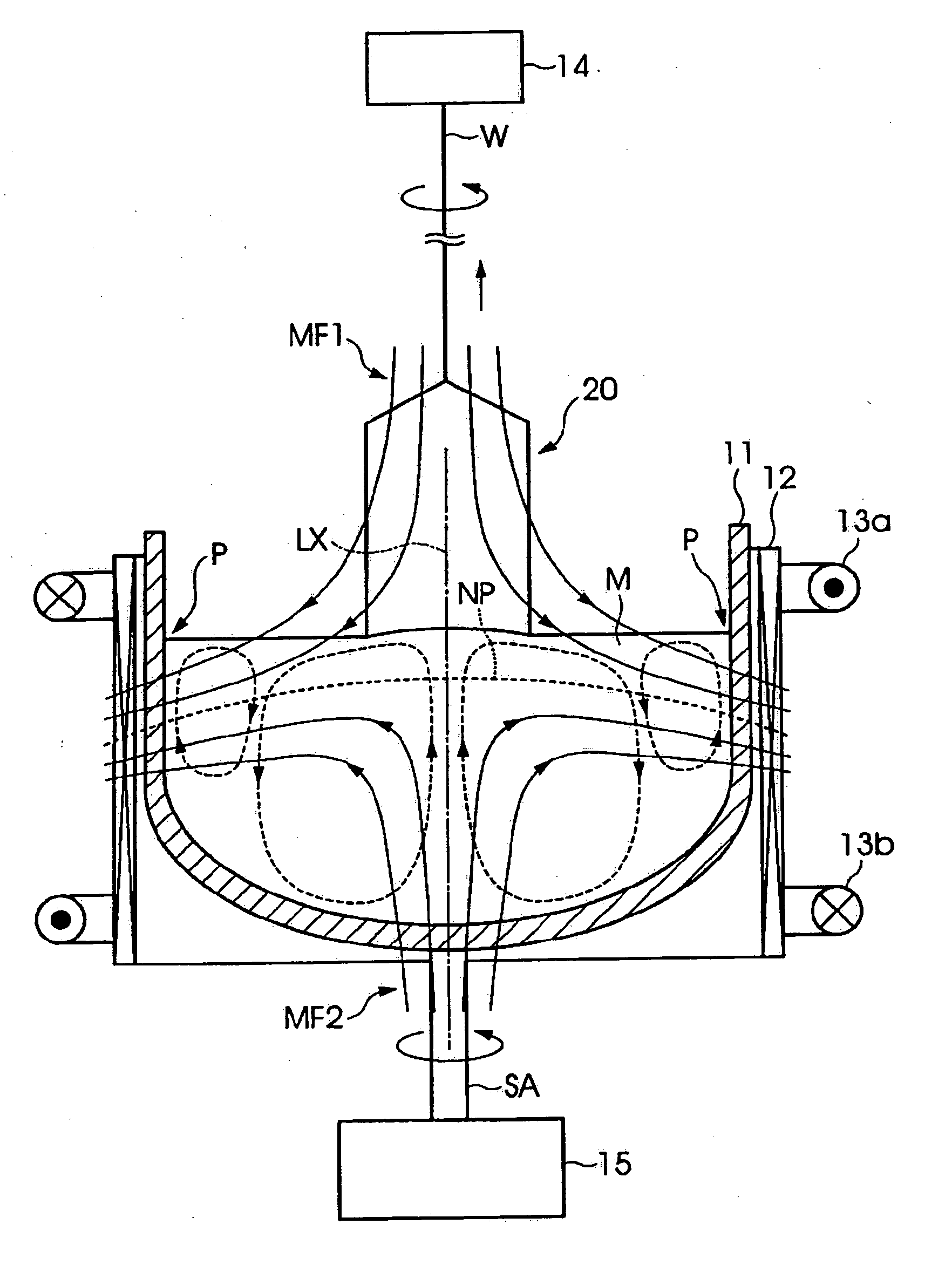

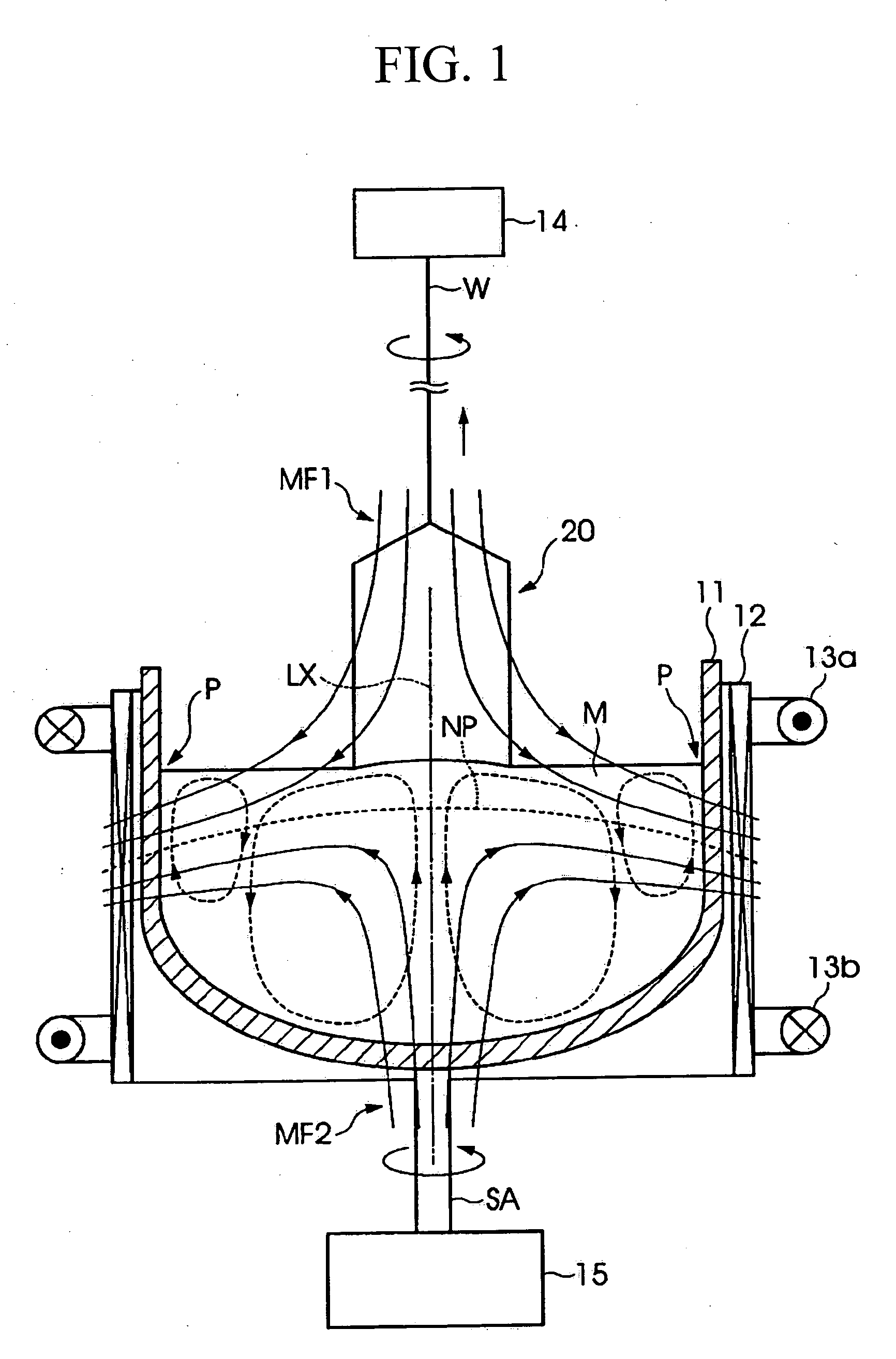

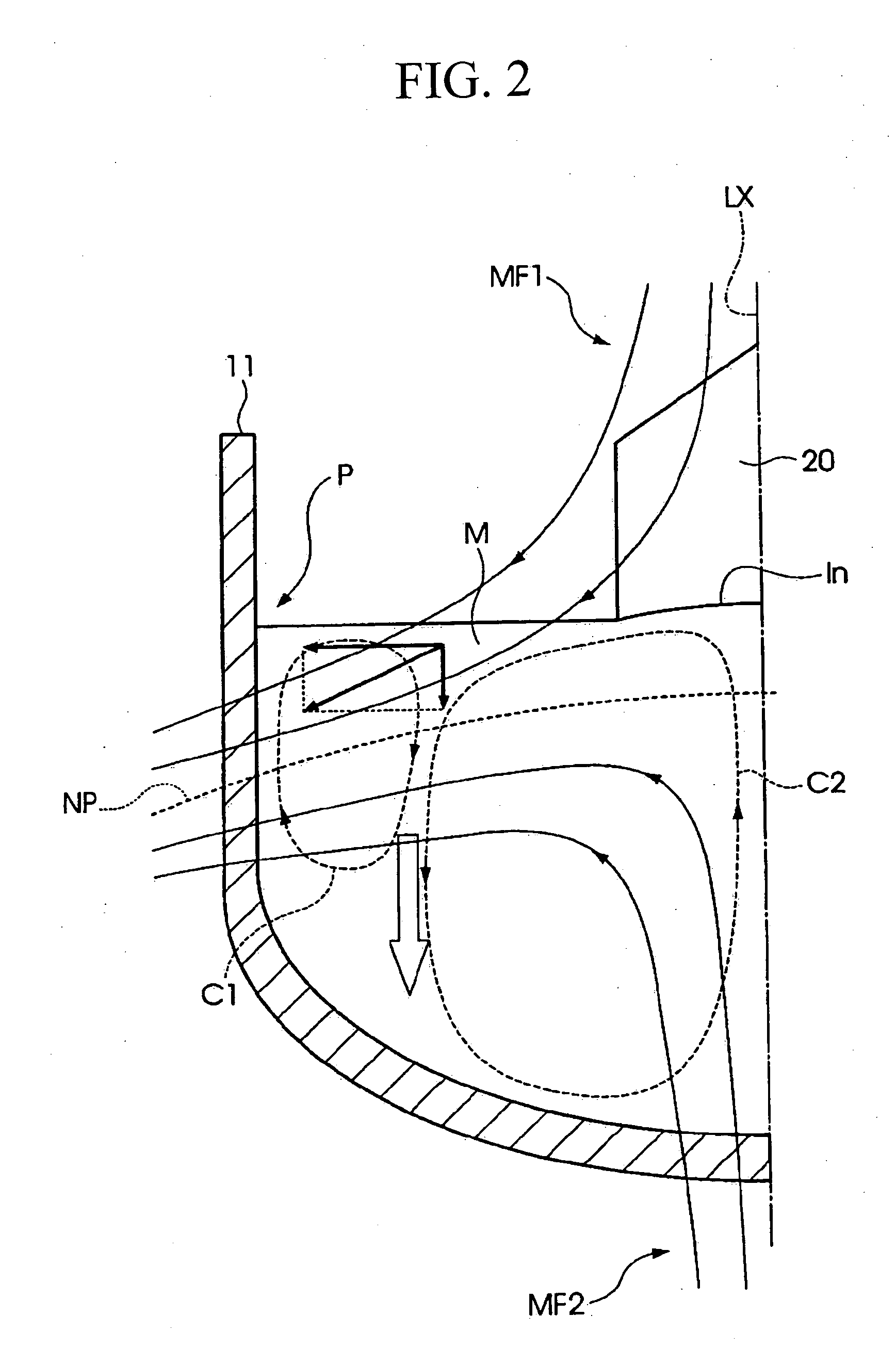

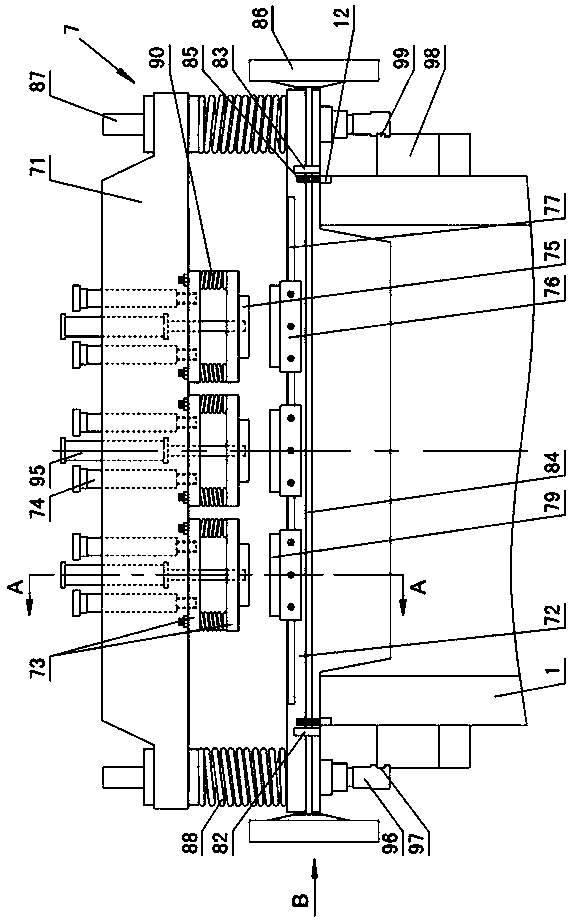

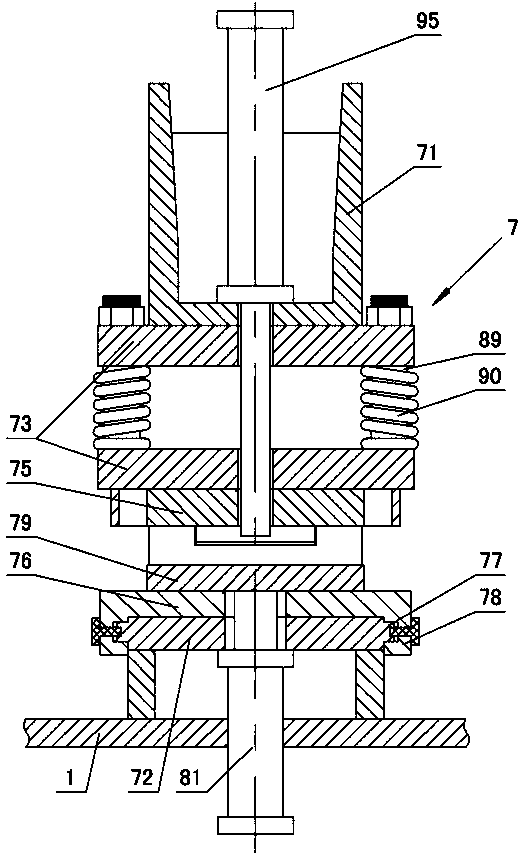

Apparatus and method for producing single crystal, and silicon single crystal

ActiveUS7300518B2Improve efficiencyHigh degreeAfter-treatment apparatusPolycrystalline material growthCrucibleSingle crystal

The invention provides an apparatus for producing a single crystal, and a method for producing a silicon single crystal using the same. An apparatus for producing a single crystal includes a heating device which heats polycrystalline silicon raw material held in a crucible to form silicon melt, and a pulling up device which grows a silicon single crystal while pulling it up from the silicon melt accompanied with rotation. By providing the apparatus with a magnetic field generation unit which applies to the silicon melt a cusp magnetic field a shape of neutral plane of which is symmetric around the rotation axis of the silicon single crystal and is curved in the upward direction, various conditions for producing a silicon single crystal having a defect free region is relaxed, and a silicon single crystal having a defect free region is produced at high efficiency.

Owner:SUMCO CORP

Soil Opener For Higher Travel Speeds

A soil opener has a frog mount adapted to be coupled to a shank or other mounting member of a farm implement. A spreader is removably coupled to the frog mount and includes forward and rearward product delivery channels that are intended to be flow-coupled to product delivery tubes or hoses of the farm implement. A tip is removably coupled to the spreader. The leading edges of the frog mount, the spreader, and the tip, as well as the geometry between these components are such that draft is minimized even when the soil opener is pulled through the soil at higher speeds, e.g., excess of 5 mph. The soil opener may be equipped with an optional soil gathering module.

Owner:CNH IND CANADA

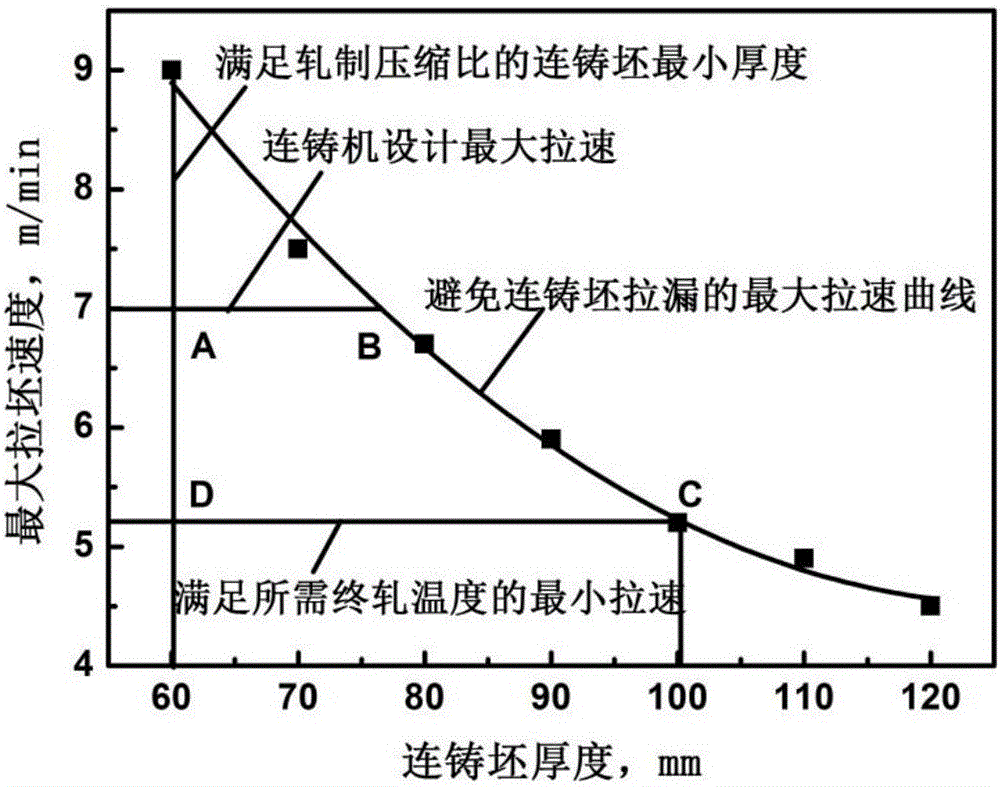

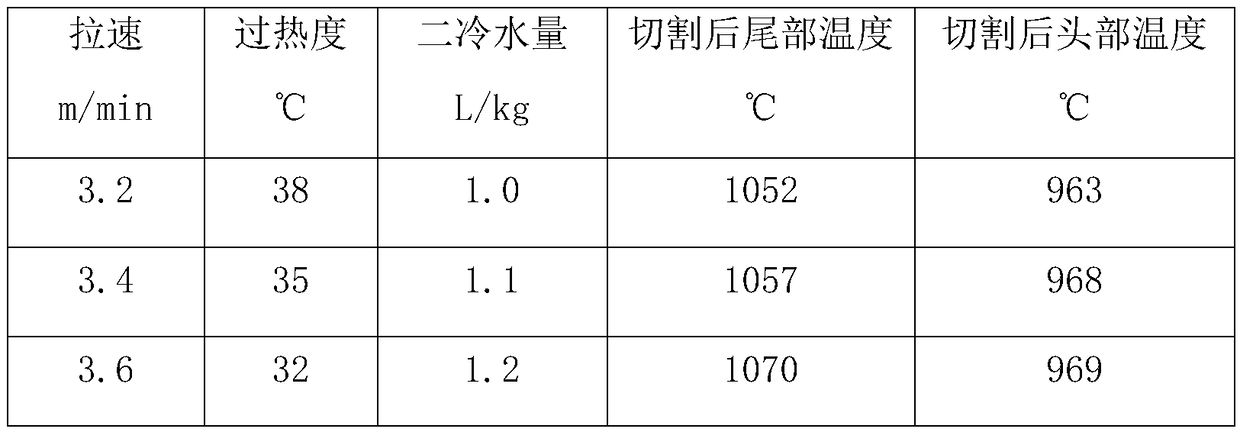

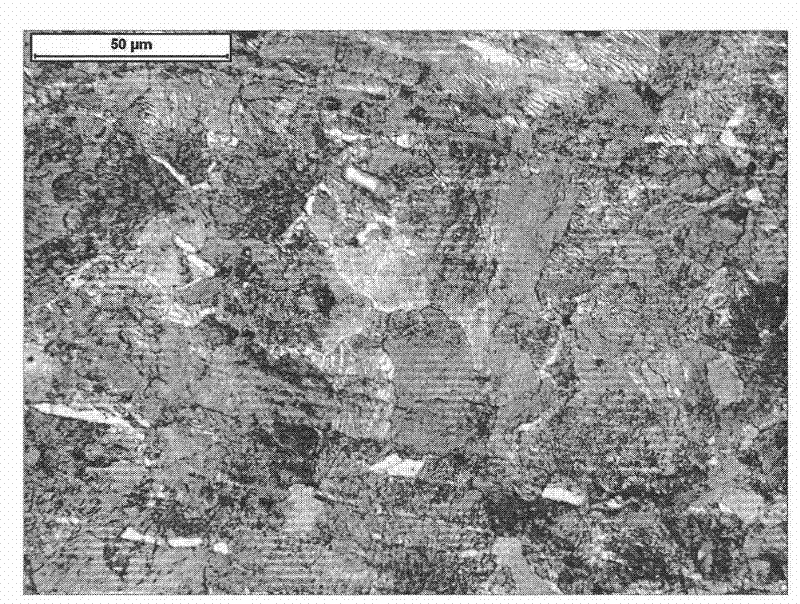

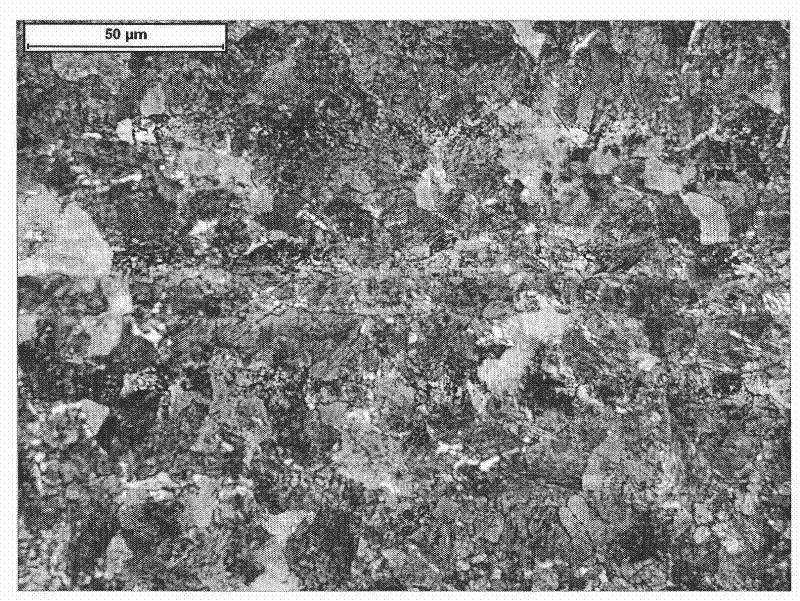

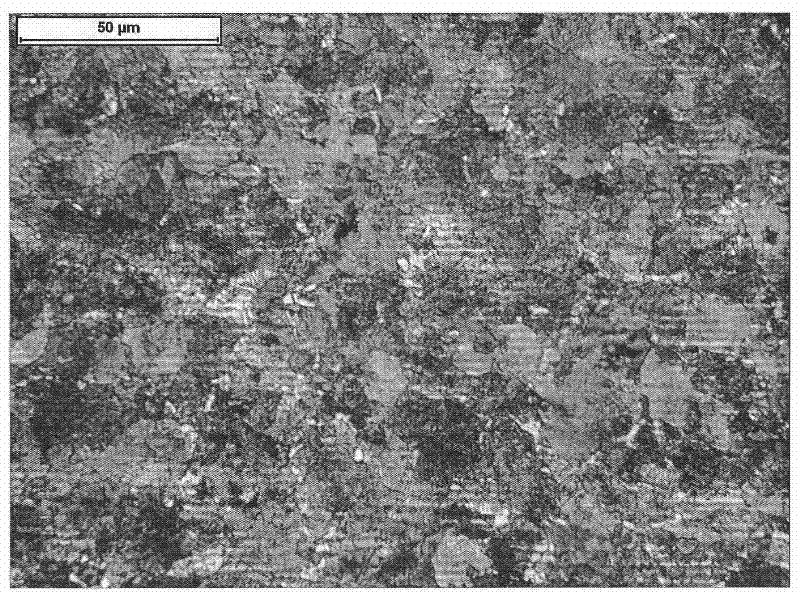

High casting speed continuous casting method of small billet directly rolled from long product

InactiveCN109465412AIncrease pulling speedIncrease the surface temperature of the slabSteelmakingTemperature control

A high casting speed continuous casting method of a small billet directly rolled from a long product belongs to the technical field of steelmaking and continuous casting. The specific steps and parameters of the method are as follows: the cross section size of the small billet involved in the method is 130mm*130mm-160mm*160mm, the basic circular arc radius range of a continuous casting machine is8-11m; the casting speed of the continuous casting machine is controlled; [P] less than or equal to 0.0250wt% in steel is controlled; the molten steel temperature and the superheat degree of a tundish, the cooling water flow of a crystallizer are controlled, and secondary cooling adopts automatic water distribution, and the like; and the temperature of a casting blank is controlled after the casting blank is cut so as to complete the method. The method has the advantages of meeting the requirement of a direct rolling process through temperature control of the casting blank, effectively reducing the production cost, and laying a foundation for the successful application of the long product direct rolling technology in industrial production.

Owner:SHOUGANG CORPORATION

Method for producing 65Mn hot rolled steel plate

InactiveCN101773930BAdd depthImprove billet qualityMetal rolling arrangementsLiquid coreStructure property

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Apparatus and method for producing single crystal, and silicon single crystal

ActiveUS20060107889A1Increase pulling speedHigh gradientPolycrystalline material growthBy zone-melting liquidsNeutral planeMonocrystalline silicon

Owner:SUMCO CORP

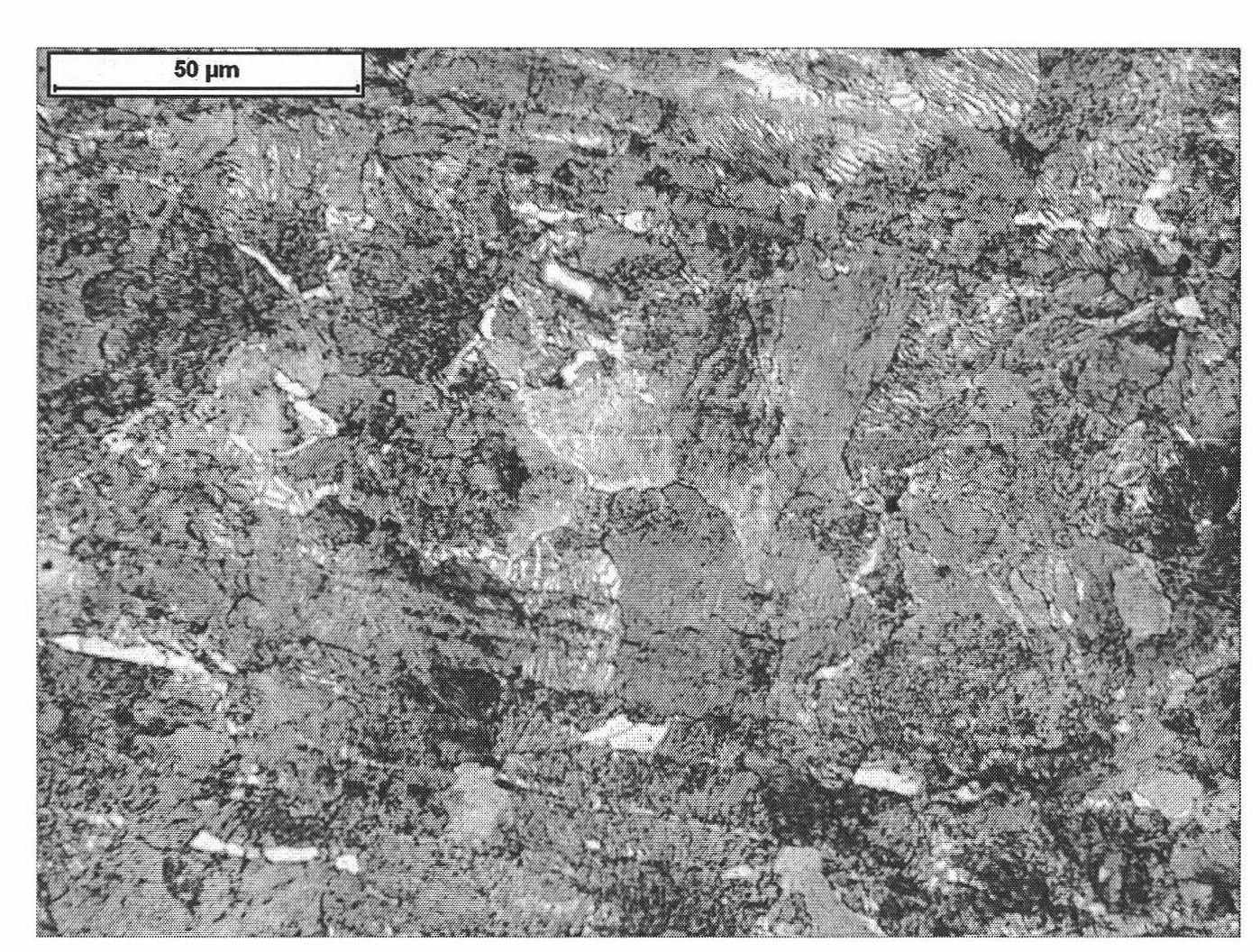

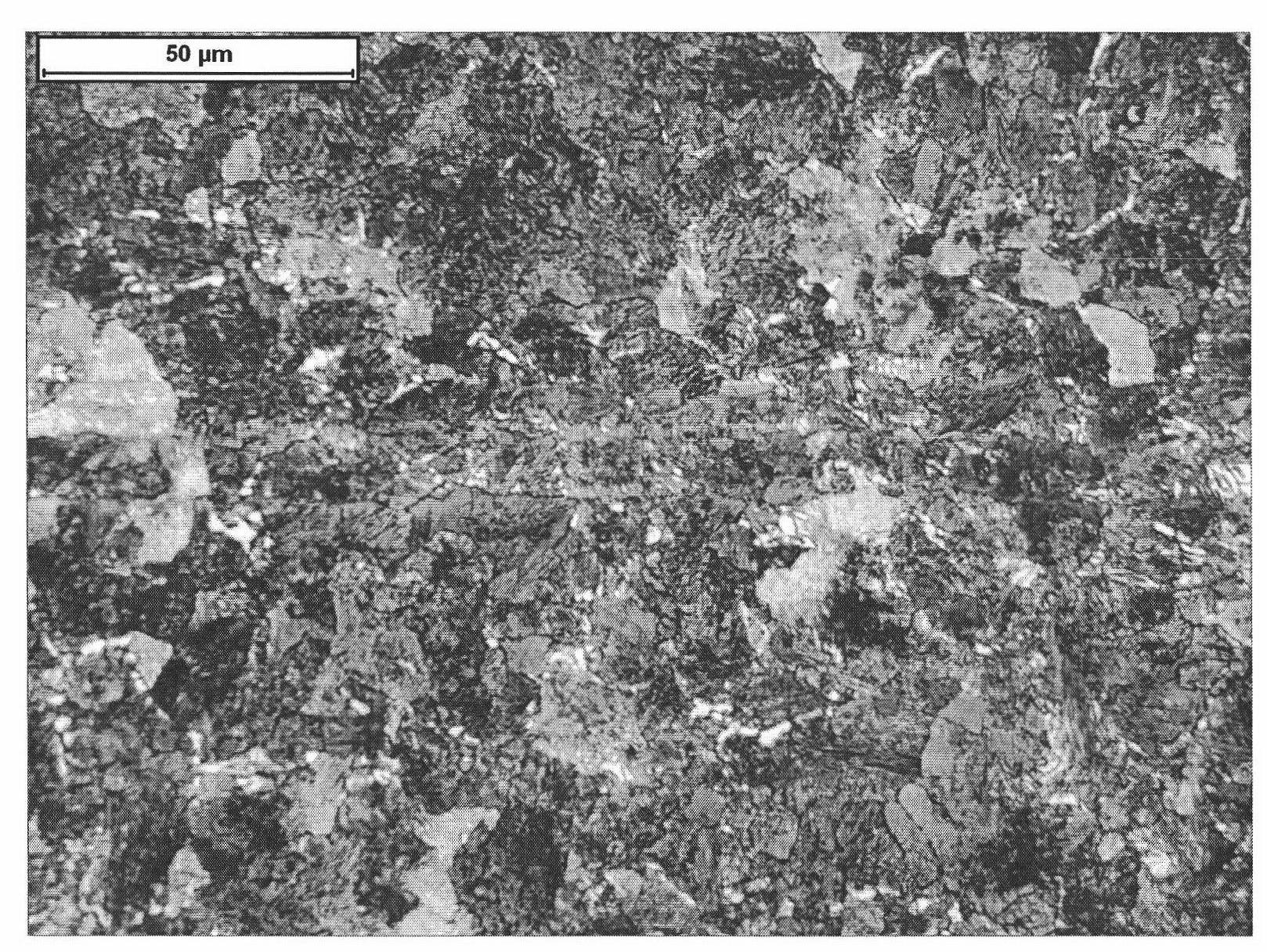

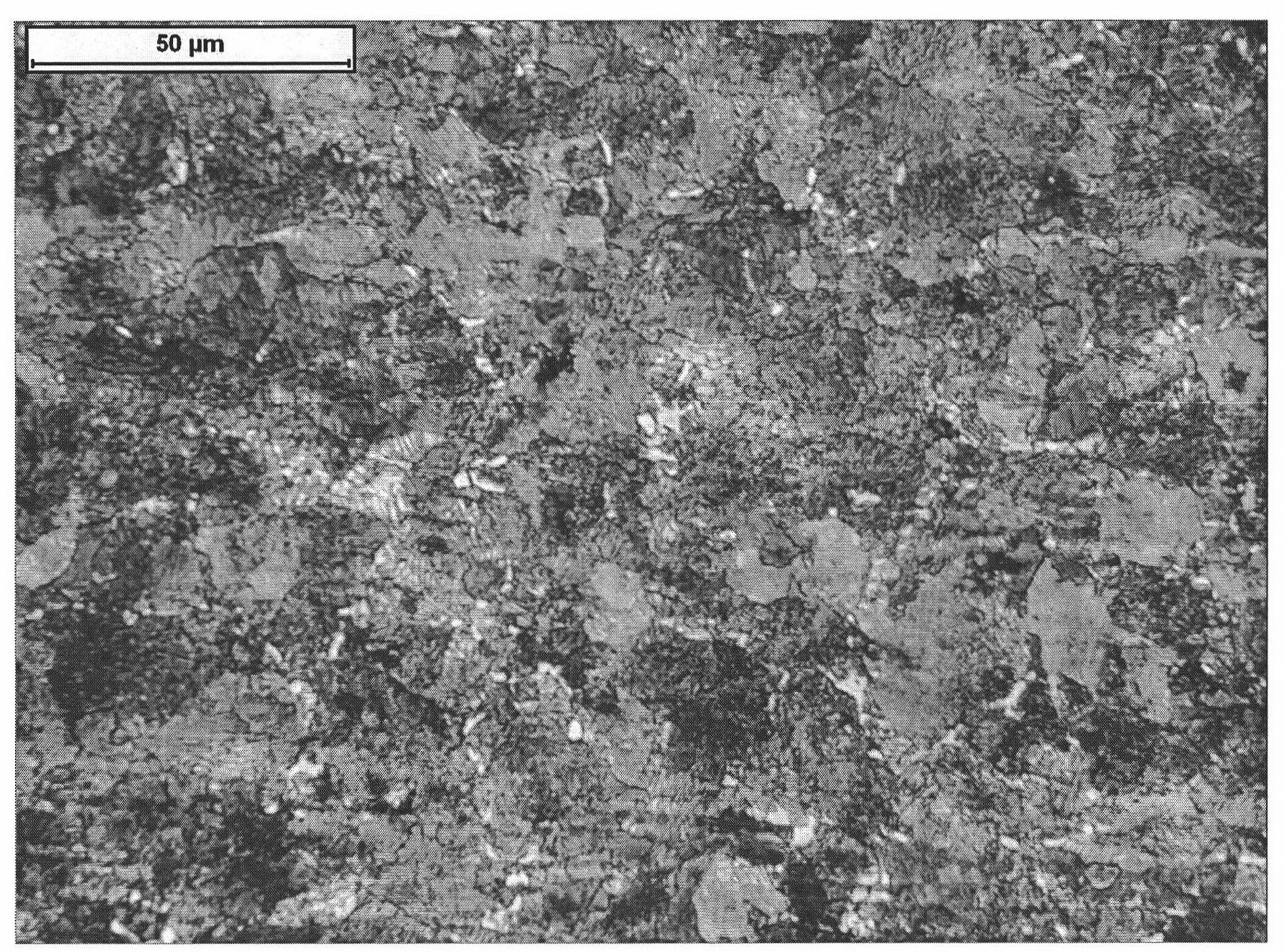

Method for improving internal quality of casting blank by composite intervention

Provided is a method for improving internal quality of casting blank by composite intervention. The method comprises following steps: 1), machining pure iron or steel with the approximate content of steel grades to be an easily-melted cold bodies moving with molten steel and then drying; 2), baking feeding guide pipes which are made by refractory material and immersing them into a crystallizer below the molten steel surface; aligning feeding guide pipe openings to the center of steel streams as for round and square billets; utilizing two guide pipes for plate blank and distributing them on two sides of a wide surface of the crystallizer; 3), continuously injecting the dried cold bodies into a high-temperature region of a molten pool of the crystallizer, adding the cold bodies in the amount of 0.8-1.3% of casting blank; adopting the crystallizer to electromagnetically stir during the continuous casting process. The method for improving internal quality of casting blank by composite intervention has following beneficial effects: cold bodies are fed into the crystallizer such that superheat and temperature gradient of molten steel during mass production of continuous casting; the solidification structure of casting blank is improved; quality flaws of the internal quality of the casting blank is reduced; the temperature field of the crystallizer is improved; and therefore the purposes of increasing equiaxial crystal ratio and improving internal quality of the casting blank are fulfilled.

Owner:BAOSHAN IRON & STEEL CO LTD

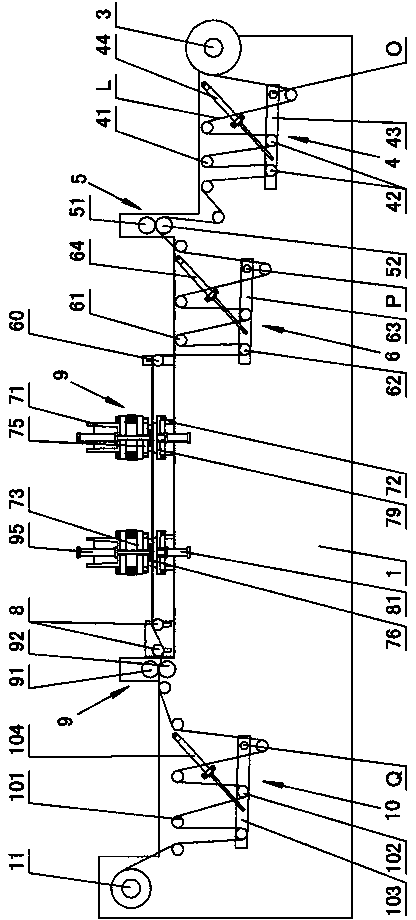

Biodegradation mulching film punching machine

Provided is a biodegradation mulching film punching machine. The biodegradation mulching film punching machine is characterized in that the punching machine comprises a machine base, and the machine base is sequentially provided with a feeding roller, a first feeding tensioning roller set, front regulation type clamping rollers, a second feeding tensioning roller set, a feeding guide roller, a punching mechanism, a discharging guide roller, rear regulation type clamping rollers, an output tensioning roller set and a material rolling roller from feeding to discharging; the material rolling roller is driven by power; the first feeding tensioning roller set comprises a first feeding upper tensioning roller and a first feeding lower tensioning roller; the front regulation type clamping rollers comprise the upper front clamping roller and the lower front clamping roller; the second feeding tensioning roller set comprises a second feeding upper tensioning roller and a second feeding lower tensioning roller; the regulation type clamping rollers comprise the upper rear clamping roller and the lower rear clamping roller; the output tensioning roller set comprises an upper output tensioning roller and a lower output tensioning roller.

Owner:TAIZHOU HUANGYAN ALPHA PACKAGING FILM

Method for producing 75Cr1 hot-rolled sheet steel

InactiveCN101745535AEnsure fatigueImprove uniformityTemperature control deviceMetal rolling arrangementsPorosityChemical composition

The invention provides a method for producing high-quality 75Cr1 hot-rolled sheet steel based on the continuous thin slab casting and rolling process, which mainly adopts the following process flow: smelting, refining, continuous thin slab casting, soaking, hot continuous rolling, cooling and coiling. The superheat T of molten steel is larger than 30 DEG C and less than or equal to 45 DEG C, the charging temperature T of the cast slab is larger than or equal to 900 DEG C and less than or equal to 1050 DEG C, the finish rolling temperature T is larger than or equal to 850 DEG C and less than or equal to 950 DEG C, the coiling temperature T is larger than or equal to 550 DEG C and less than or equal to 630 DEG C, and the drawing speed S of continuous casting is larger than or equal to 3.5m / min and less than or equal to 5.5m / min; mold flux casting is adopted; and the chemical composition of molten steel is as follows: 0.70 percent to 0.80 percent by weight of C, 0.20 percent to 0.45 percent by weight of Si, 0.60 percent to 0.90 percent by weight of Mn, 0.025 percent by weight or less of P, 0.025 percent by weight or less of S, 0.30 percent to 0.60 percent by weight of Cr and 0.02 percent to 0.08 percent by weight of V. When the method is adopted to produce the 75Cr1 hot-rolled sheet steel, the segregation, porosity and cracks of the cast slab are reduced, and the 75Cr1 hot-rolled sheet steel is characterized by uniform microstructure and properties and high fatigue resistance.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Continuous steel billet casting process and apparatus

The present invention discloses continuous steel billet casting method and apparatus. The method is setting inert gas protected area with certain inert gas pressure maintained between the pouring basket and the crystallizer of the continuous casting apparatus. The continuous steel billet casting apparatus includes a pouring basket, a crystallizer, a vibration mechanism, a secondary cooling area, a withdraw unit, a bending unit, an curved track and a straightener. Between the pouring basket and the crystallizer, is set one inert gas protecting cover with cylindrical cover, sliding sleeve and gas inlet. The present invention can raise the quality of the thin steel billet and avoid the blocking of the inlet of the crystallizer cause by molten steel.

Owner:江苏兴利来特钢有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com