Method for producing non-spangle galvanized plate based on sheet billet continuous casting and rolling heat-based raw material and pickling galvanization continuous production line

A thin slab continuous casting and galvanized sheet technology, which is applied in hot-dip coating process, heat treatment furnace, metal rolling, etc., can solve the problems of shortened service life of the load of the roll system, complicated process flow, and easy deviation of the strip, etc. To achieve uniform structure performance, shorten the process flow, and shorten the length of the rolling line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] DX51D+Z galvanized sheet

[0049] The process steps are: continuous casting and rolling of full-endless thin slab → pickling → leveling → heating → spangle-free galvanizing → skin pass → passivation → coiling into spangle-free hot-dip galvanized coil

[0050] The composition of the thin slab continuous casting and rolling heat-based raw material is: C≤0.06, Si≤0.044, Mn.08-0.20, P≤0.017, S≤0.006, Alt0.015-0.050, B0.0009-0.0025, thin plate Billet continuous casting and rolling thermal base material thickness: 0.8mm ~ 6.0mm.

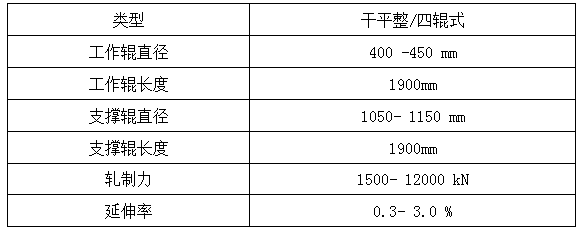

[0051] The above steps of continuous casting and rolling of full endless thin slabs are as follows: the continuous casting slab produced by the continuous casting machine directly enters the large-reduction rolling mill, and is rolled to a 12mm intermediate slab, heated to 1150°C by an induction heating furnace, descaled under high pressure, and then Enter the finishing mill for finishing rolling. After finishing rolling, the temperature: 850±20℃, ...

Embodiment 2

[0060] Steel type: SGHC

[0061] The process steps are: continuous casting and rolling of full-endless thin slab → pickling → leveling → heating → spangle-free galvanizing → skin pass → passivation → coiling into spangle-free hot-dip galvanized coil

[0062] The composition of the thin slab continuous casting and rolling heat-based raw material is: C≤0.06, Si≤0.044, Mn.08-0.20, P≤0.017, S≤0.006, Alt0.015-0.050, B0.0009-0.0025, thin plate Billet continuous casting and rolling thermal base material thickness: 0.8mm ~ 6.0mm.

[0063] The above-mentioned steps of continuous casting and rolling of full endless thin slabs are as follows: the continuous casting slab produced by the continuous casting machine directly enters the large-reduction rolling mill, and is rolled to a 15mm intermediate slab, heated to 1200°C by an induction heating furnace, and then descaled under high pressure, and then Enter the finishing mill for finishing rolling. After finishing rolling, the temperature...

Embodiment 3

[0072] S350GD+Z

[0073] The process steps are: continuous casting and rolling of full-endless thin slab → pickling → leveling → heating → spangle-free galvanizing → skin pass → passivation → coiling into spangle-free hot-dip galvanized coil

[0074] The composition of the thin slab continuous casting and rolling heat-based raw material is: C≤0.06, Si≤0.044, Mn.08-0.20, P≤0.017, S≤0.006, Alt0.015-0.050, B0.0009-0.0025, thin plate Billet continuous casting and rolling thermal base material thickness: 0.8mm ~ 6.0mm.

[0075] The above steps of continuous casting and rolling of full endless thin slabs are as follows: the continuous casting slab produced by the continuous casting machine directly enters the large-reduction rolling mill, and is rolled to a 10mm intermediate slab, heated to 1200°C by an induction heating furnace, descaled under high pressure, and then Enter the finishing mill for finishing rolling. After finishing rolling, the temperature: 850±20℃, laminar flow coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com