Patents

Literature

154results about How to "Flexible temperature adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

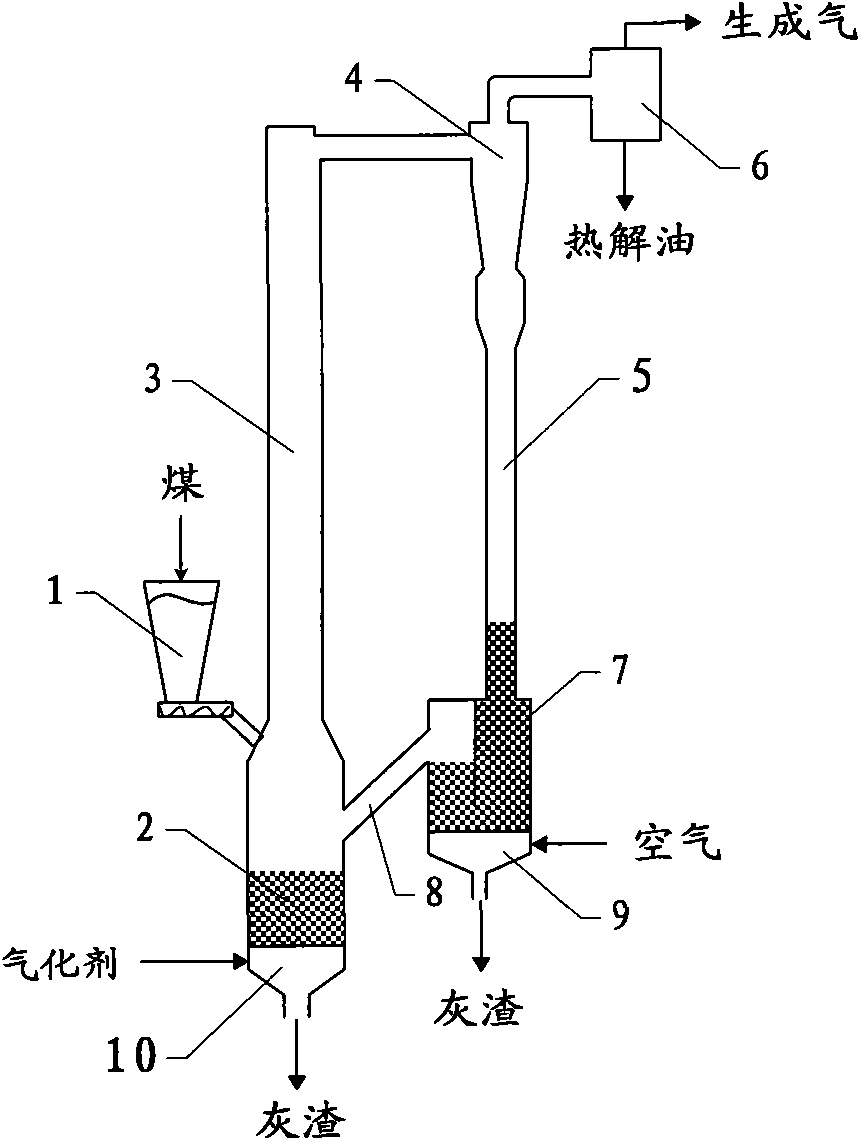

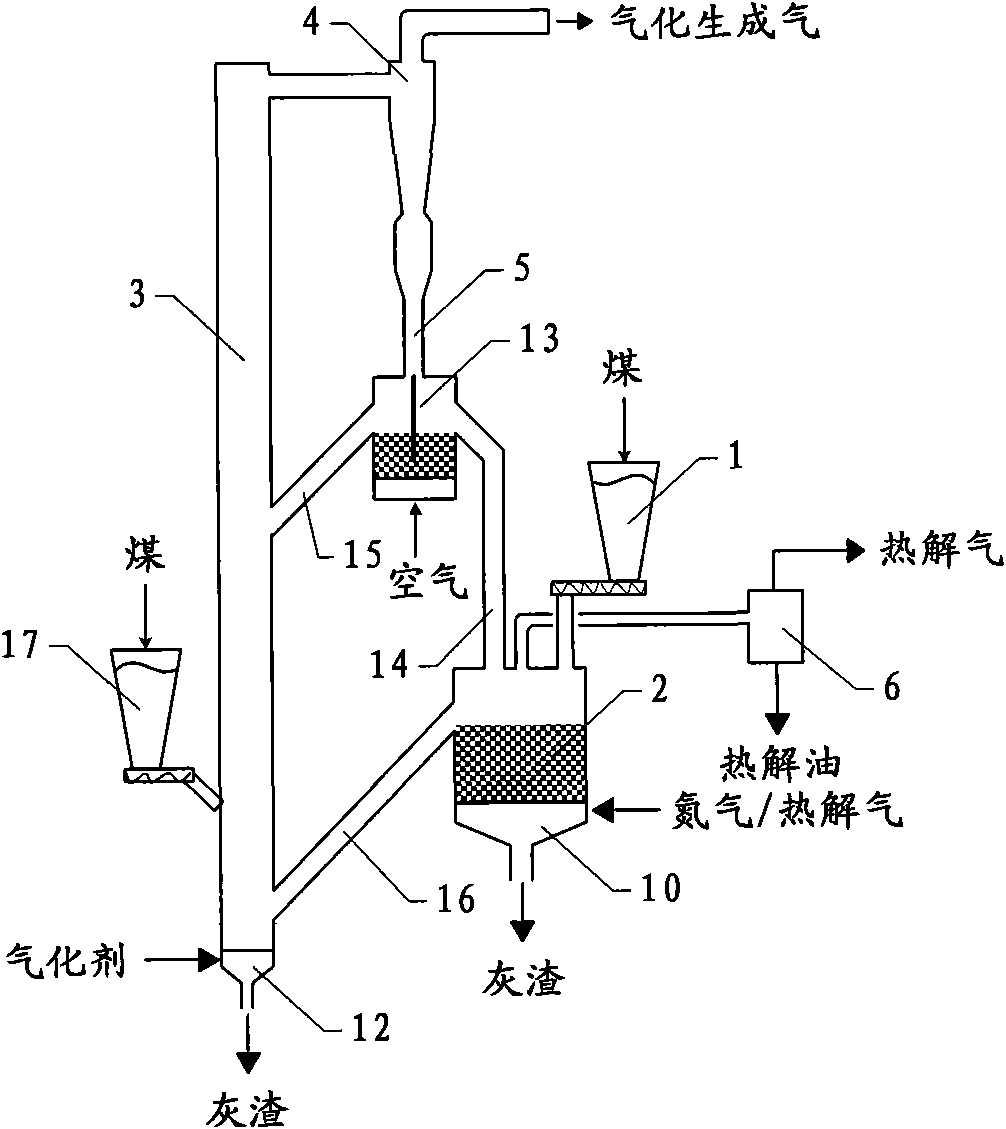

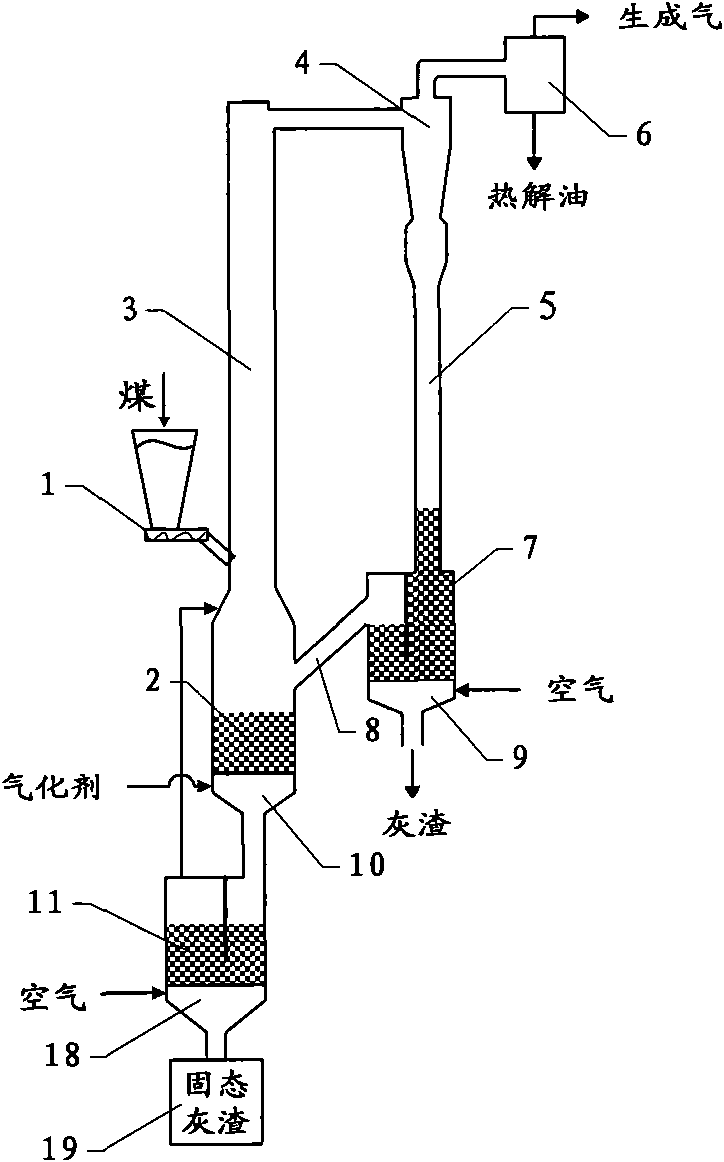

Method and device for utilizing high value through pyrolysis and gasification of coal

ActiveCN101781583ARealize joint productionFast pyrolysisLiquid hydrocarbon mixture productionCombined combustion mitigationOrganic structureFluidized bed

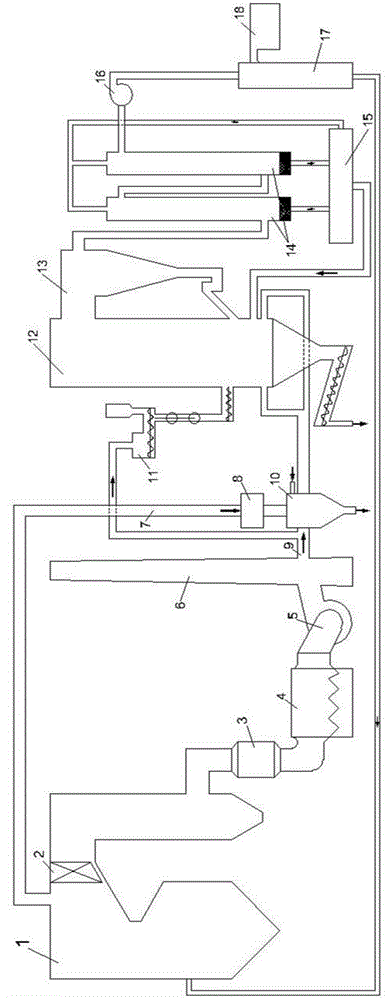

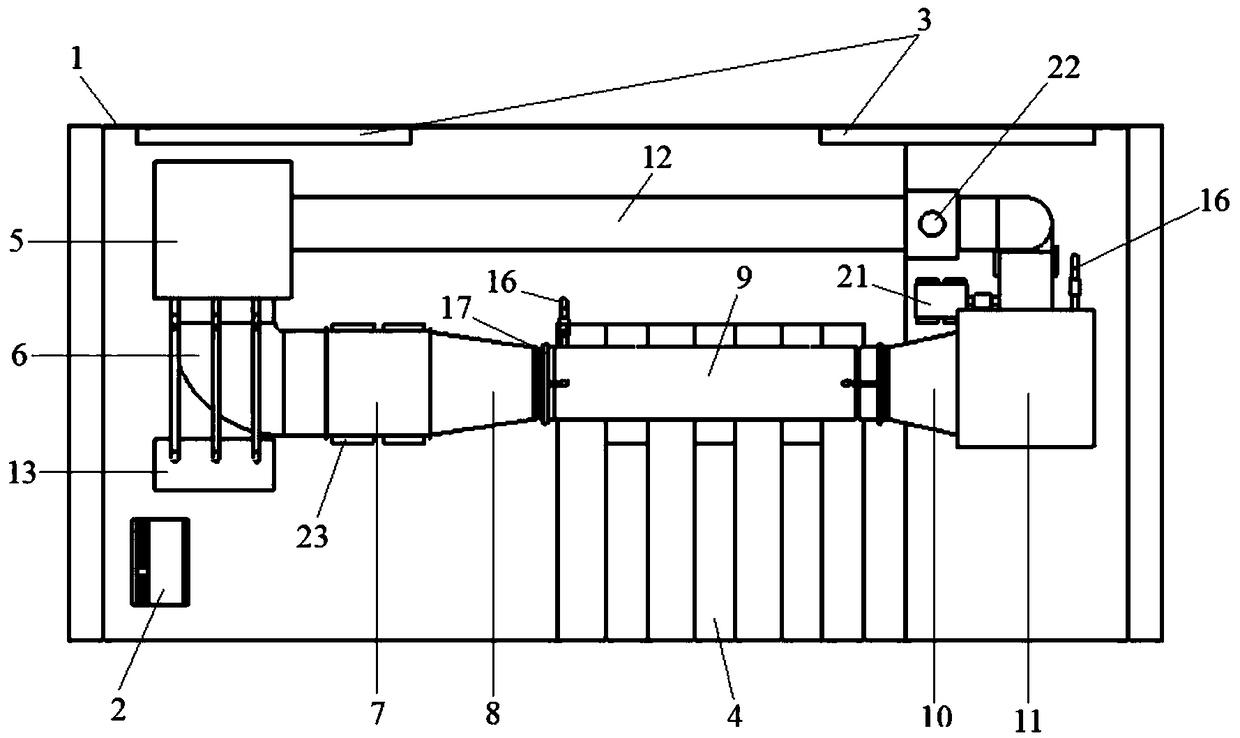

The invention relates to a method and a device for utilizing high value through pyrolysis and gasification of coal. The pyrolysis and gasification processes of the coal are separated in a mode of coupling a dilute phase conveying bed and a dense phase fluidized bed; and the coal is partially or wholly pyrolyzed before gasification, and co-production of pyrolysis gas, gasification generated gas and pyrolysis oil is realized. The dilute phase conveying bed and the dense phase fluidized bed can be coupled in two modes, namely upper-lower coupling and left-right coupling, and are applied to treating the coal in wide particle diameter distribution. High-value organic structures in the coal can be extracted before the gasification of the coal, and the utilization value of the coal is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

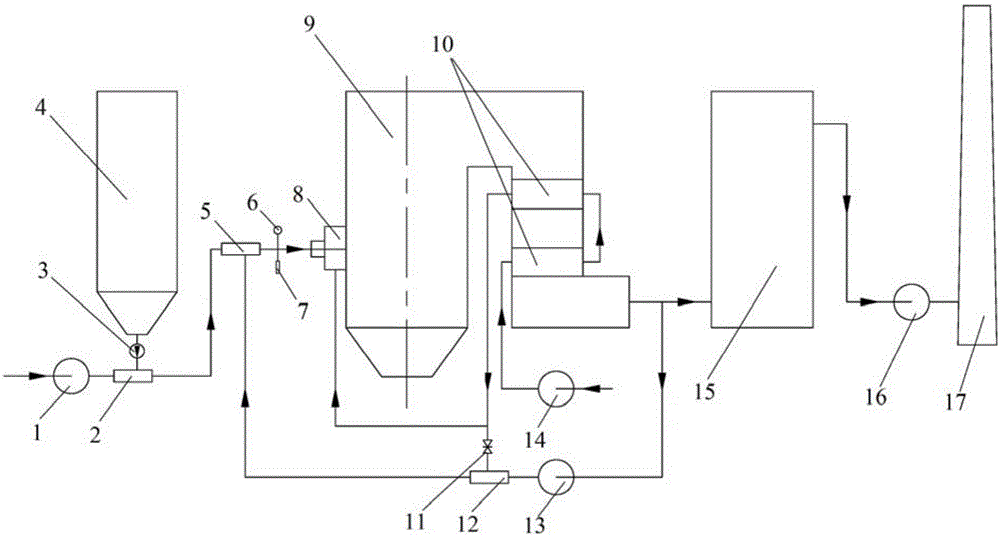

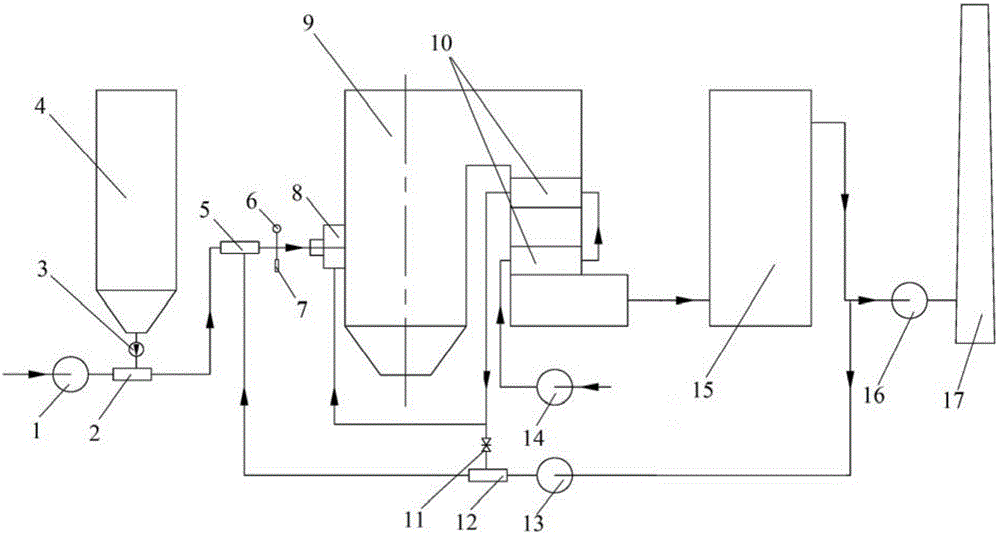

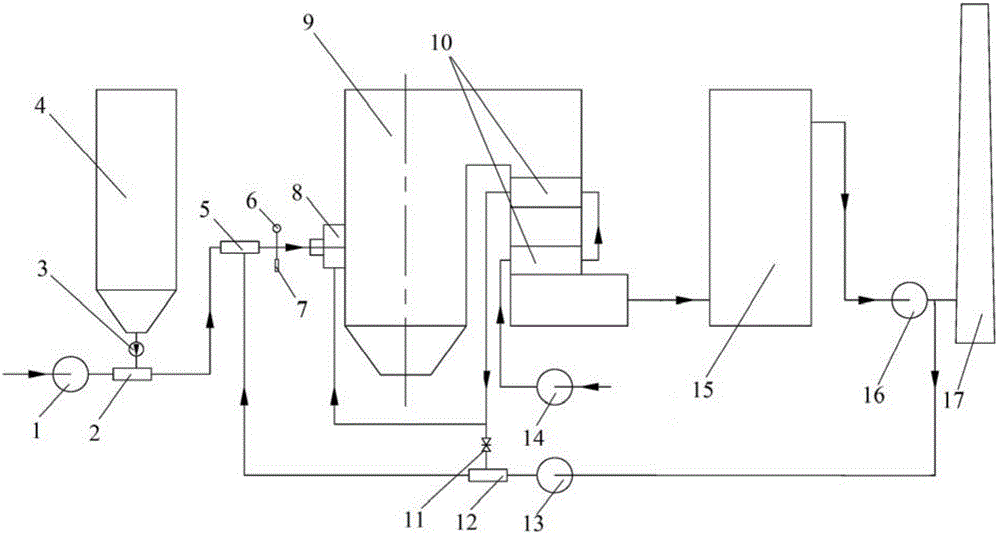

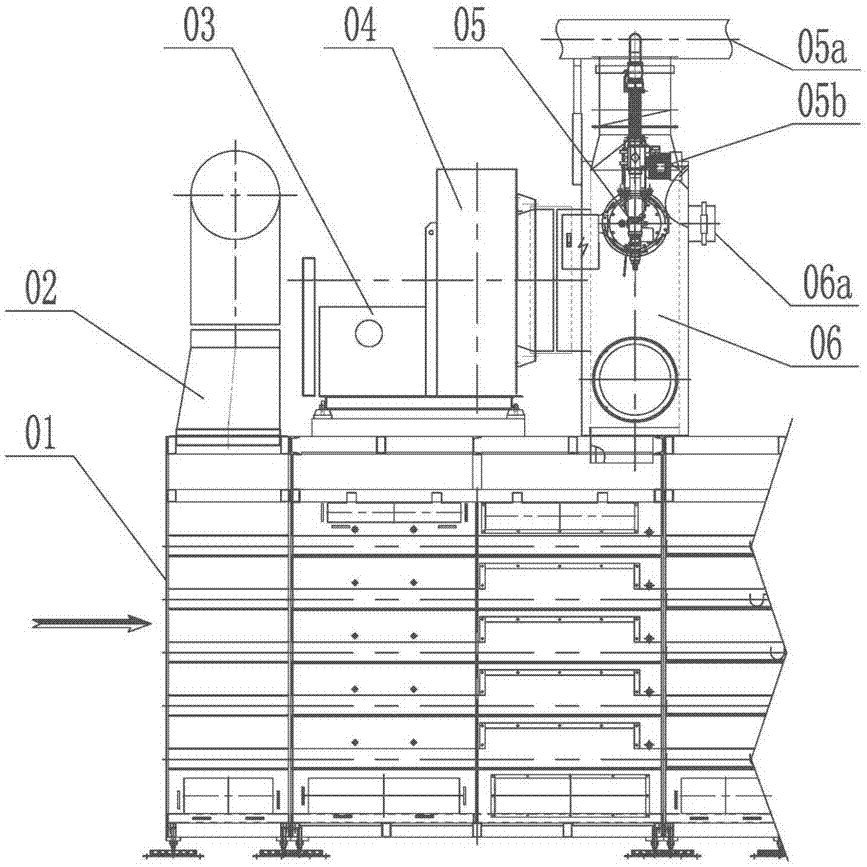

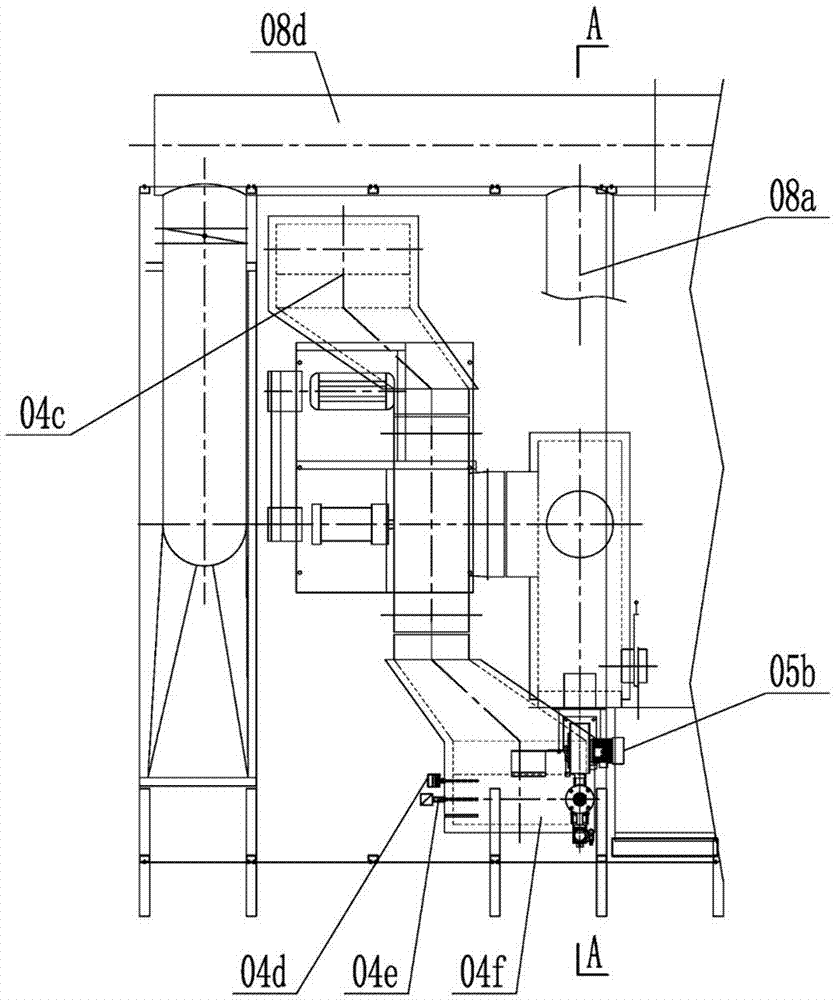

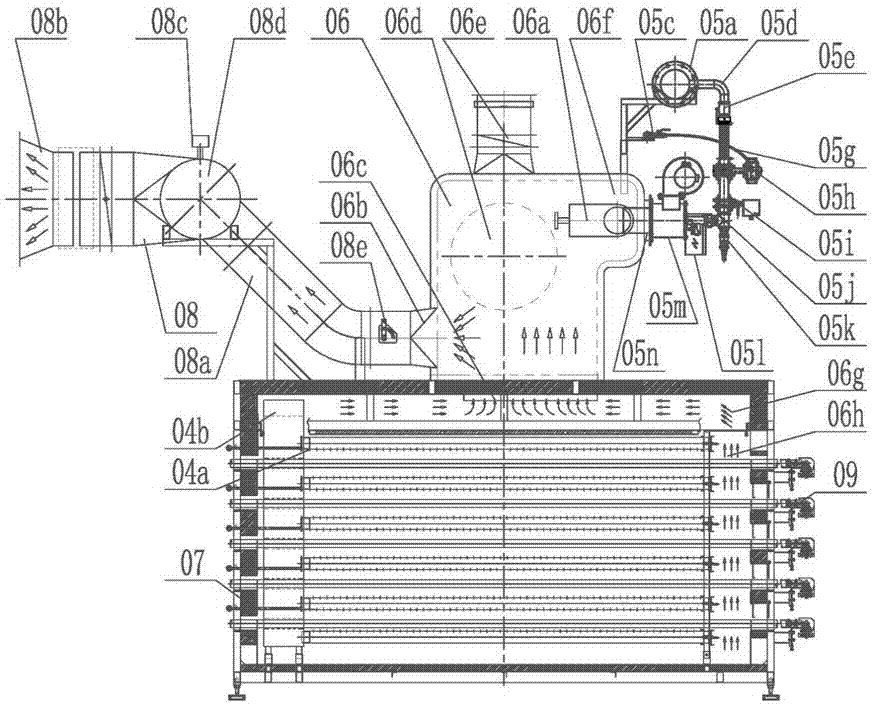

Industrial pulverized coal boiler exhaust gas recycling low-nitrogen combustion method and system

ActiveCN106247368AReduce NOx formation and emissionsReduce pollutionFluidized bed combustionFluegas recirculationExhaust gasProcess engineering

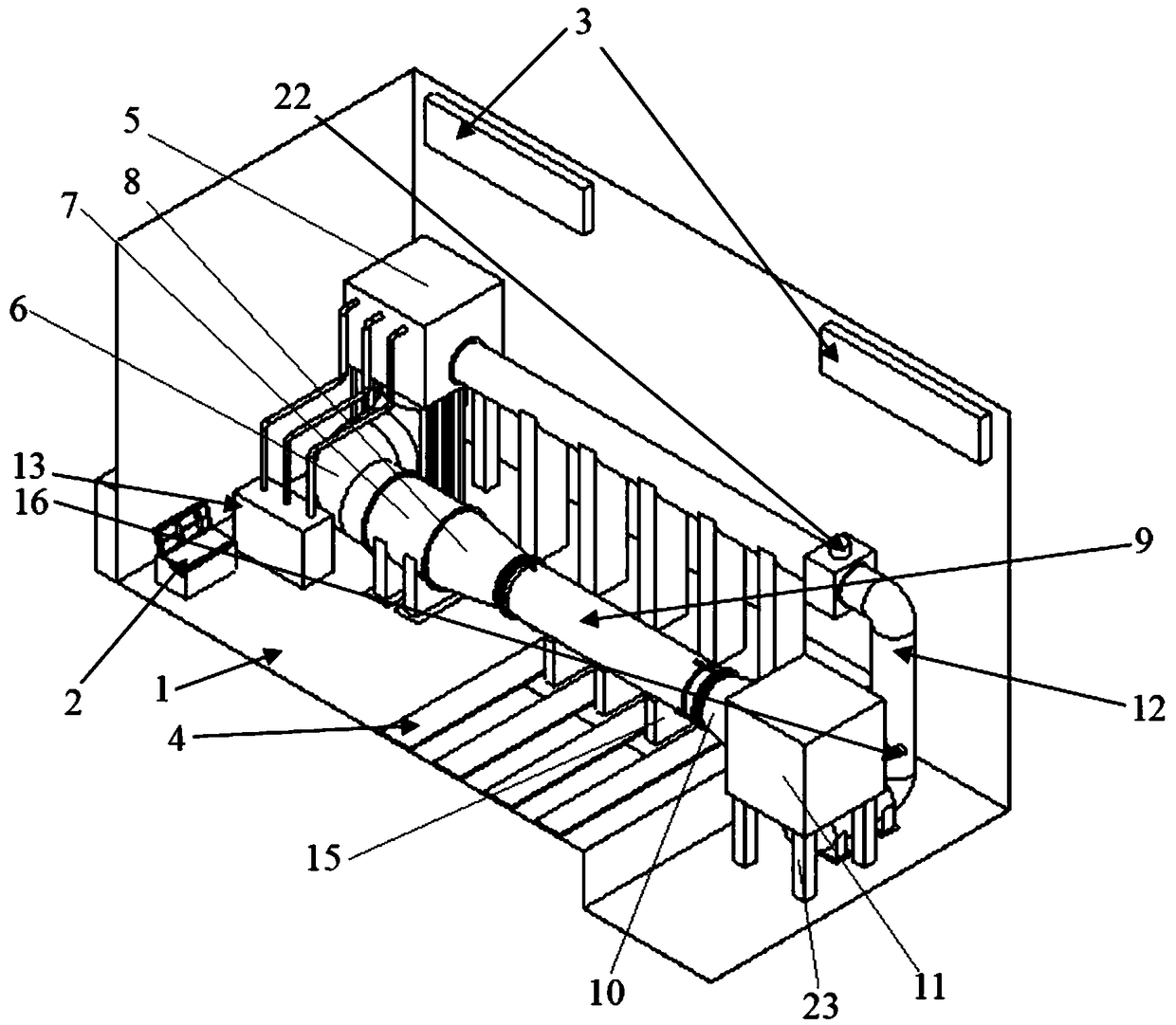

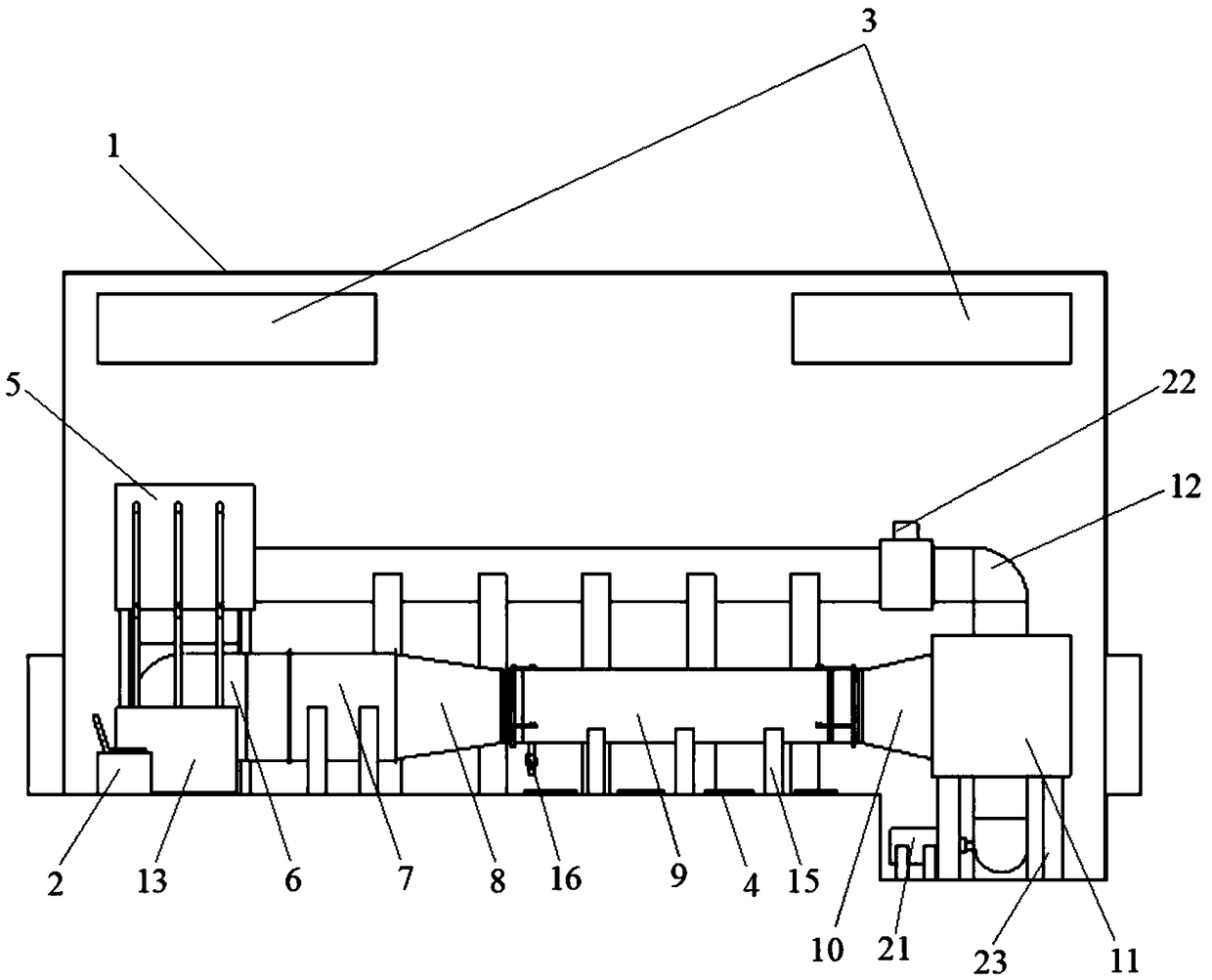

The invention discloses an industrial pulverized coal boiler exhaust gas recycling low-nitrogen combustion method. The method includes: using a part of exhaust gas extracted by a recycling fan as circulation exhaust gas, mixing the circulation exhaust gas and a part of high-temperature secondary wind, and then mixing the exhaust gas, the high-temperature secondary wind and a primary wind with pulverized coal; adjusting the amount of the extracted circulation exhaust gas according to the detected oxygen content of the mixed gas of the three kinds of gas, and then adjusting the oxygen content of pulverized coal airstreams entering a combustor; and adjusting the amount of the high-temperature secondary wind mixing with the circulation exhaust gas according to the detected temperature of the mixed gas of the three kinds of gas, and then adjusting the temperature of gas entering the combustor. The invention also discloses an industrial pulverized coal boiler exhaust gas recycling low-nitrogen combustion system which includes a primary fan, a first mixer, a boiler, a recycling fan, a second mixer and a secondary fan, wherein the boiler includes a combustor, a boiler chamber and an air pre-heating device, and an oxygen content meter and a thermometer are arranged between the first mixer and the combustor. The method and the system can improve the stability of pulverized coal combustion on the premise of an equal emission reduction effect.

Owner:SHANGHAI JIAO TONG UNIV

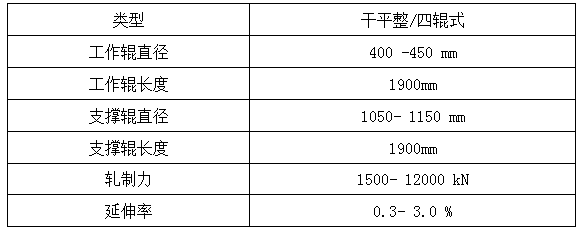

Tinning substrate for deep-punching food can and production method thereof

The invention relates to a steel metallurgical material, in particular to a tinning substrate for deep-punching food cans and a production method thereof. The tinning substrate comprises the following chemical element compositions in percentage by weight: less than or equal to 0.04% of C; less than or equal to 0.02% of Si, 0.20-0.25% of Mn, less than or equal to 0.02% of P, less than or equal to 0.018% of S, 0.005-0.040% of Als, and the balance iron and unavoidable inclusion. The production method comprises the following processes: smelting, continuous casting, heating, hot rolling, cooling and reeling, pickling and cold rolling, and annealing and leveling, wherein the heating temperature is 1210 DEG C, the primary rolling temperature is 1100-1150 DEG C, the final rolling temperature is 890+ / -10 DEG C, the reeling temperature is 560+ / -15 DEG C, the annealing temperature is 670-690 DEG C, and others are performed as conventional processes. The invention has small production control difficulty, low cost, stable performance and high can manufacturing percent of pass, and is suitable for manufacturing deep-punching food cans and can covers with more complex transformation.

Owner:TANGSHAN GUOFENG IRON & STEEL

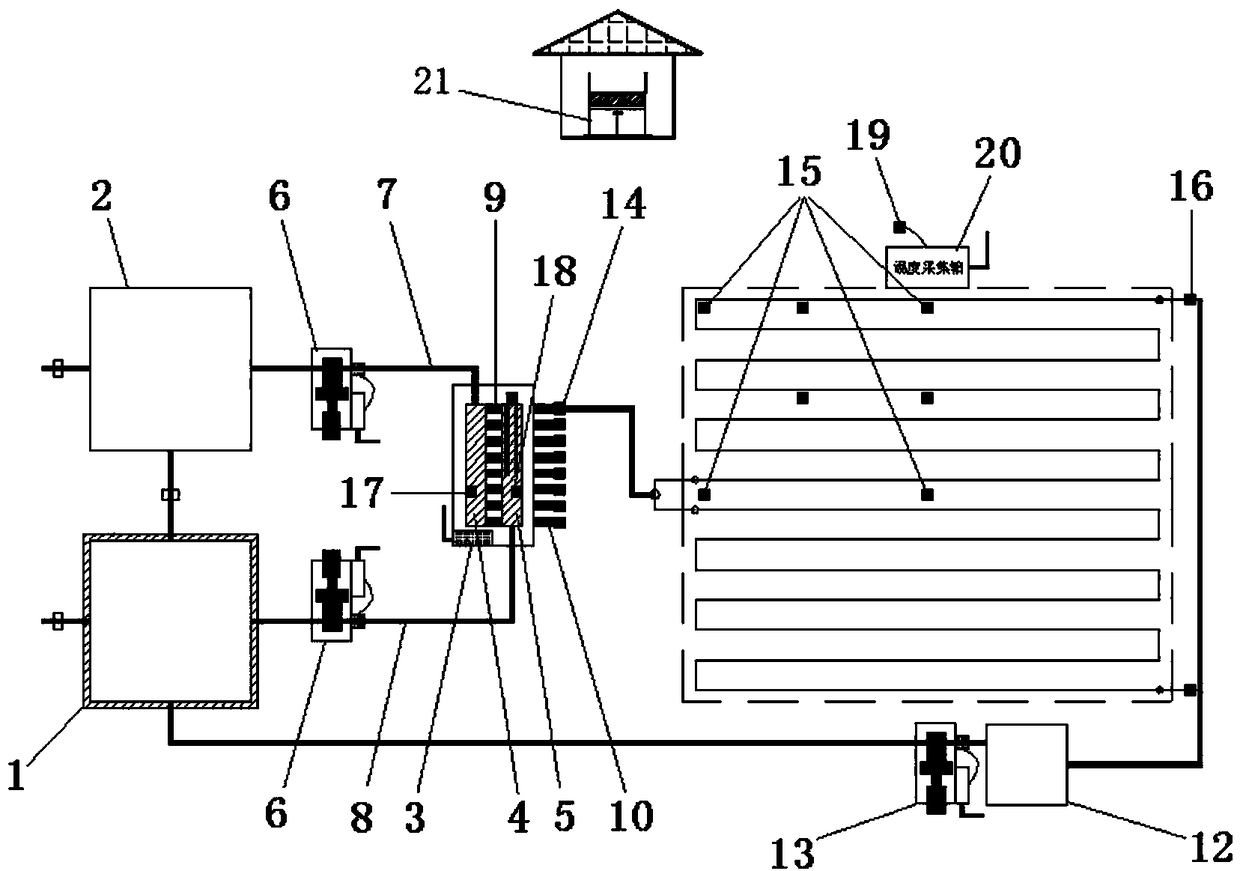

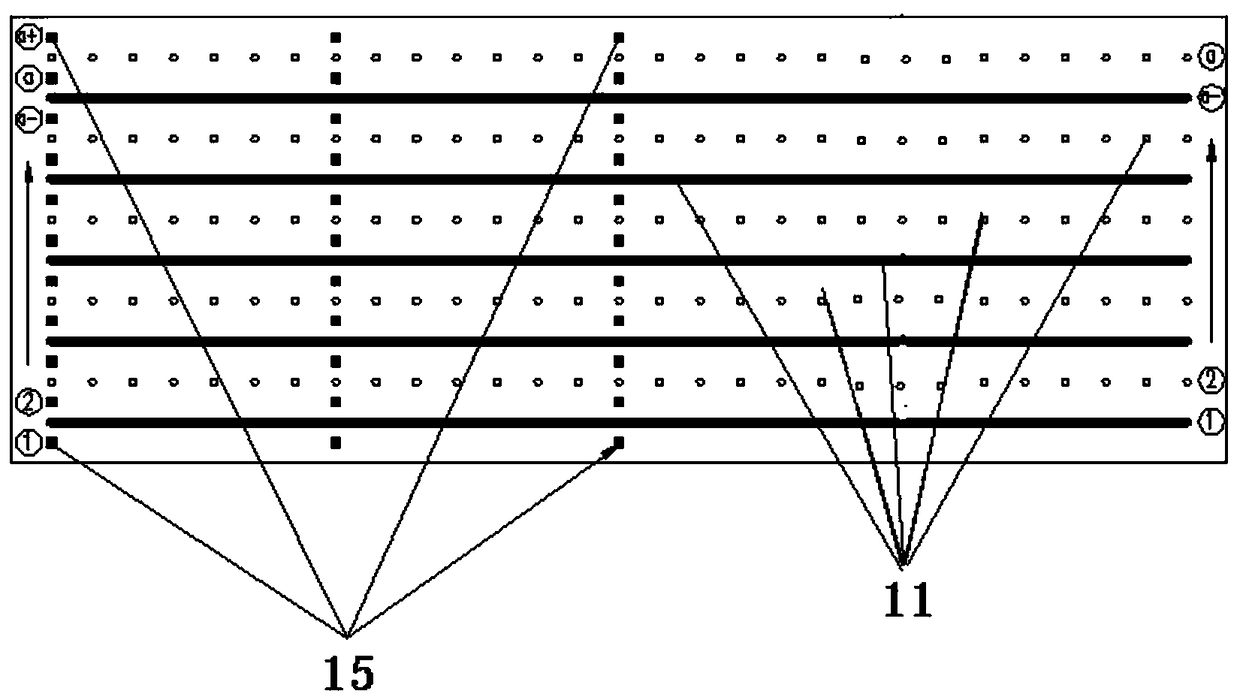

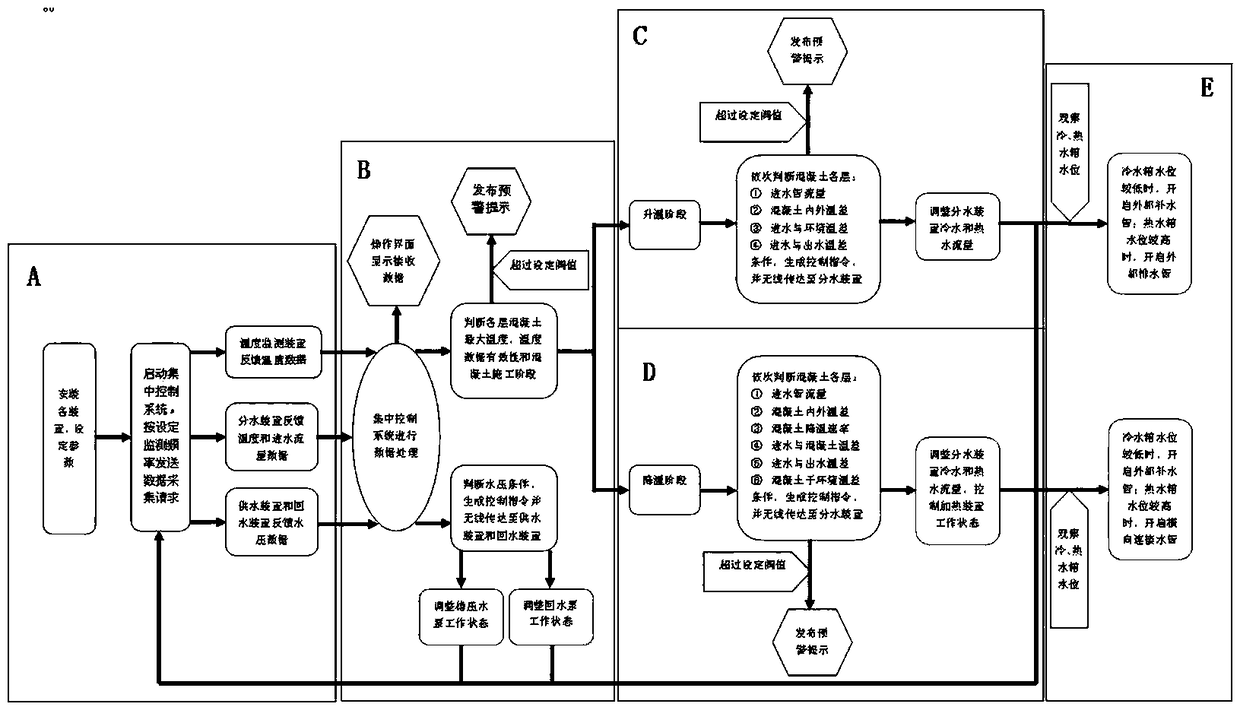

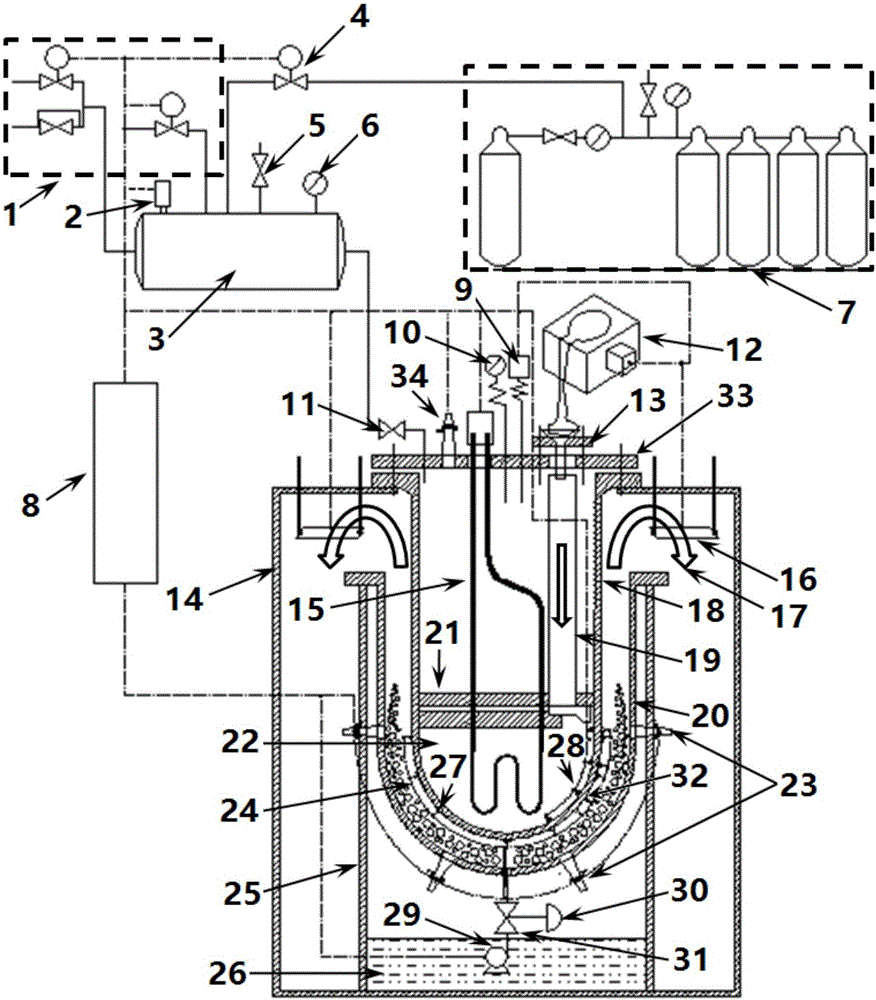

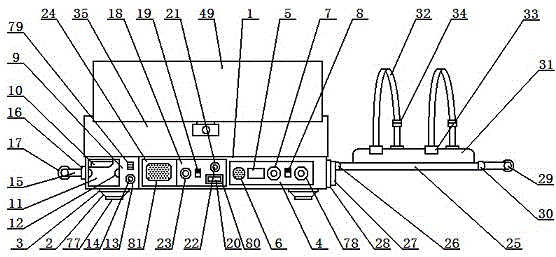

Mass concrete temperature intelligent monitoring and controlling device and method

InactiveCN109471468AControl the maximum temperatureControl cooling rateTemperatue controlPressure stabilizationData acquisition

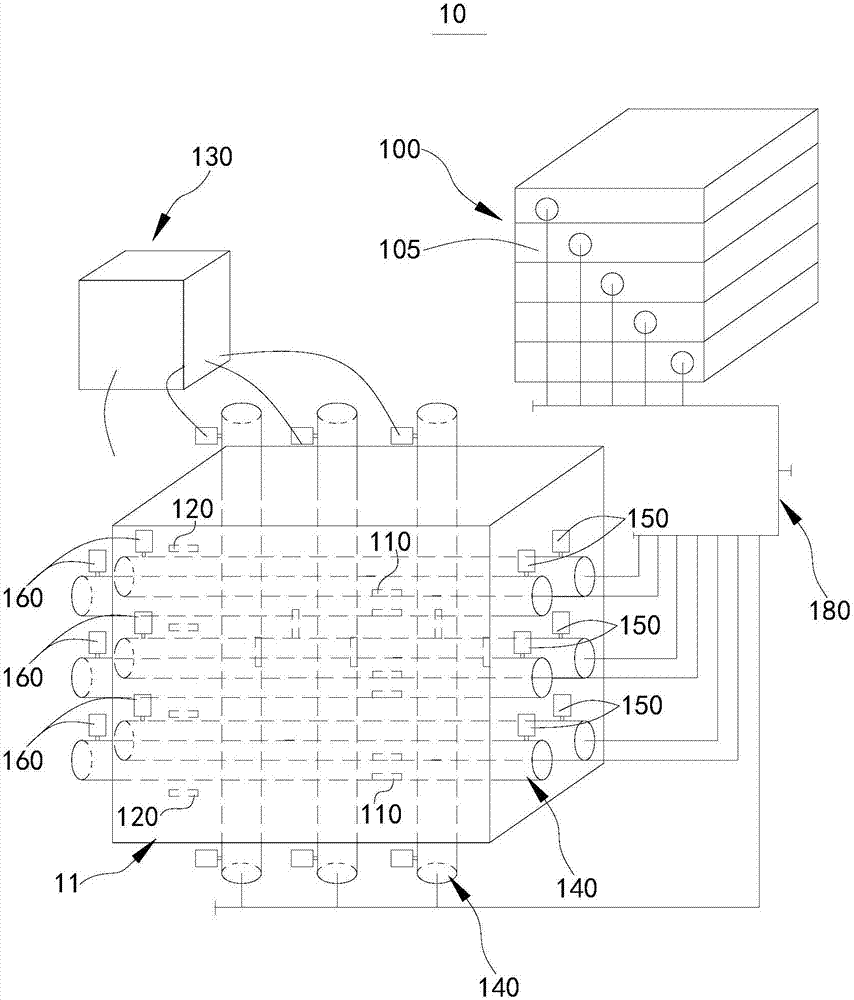

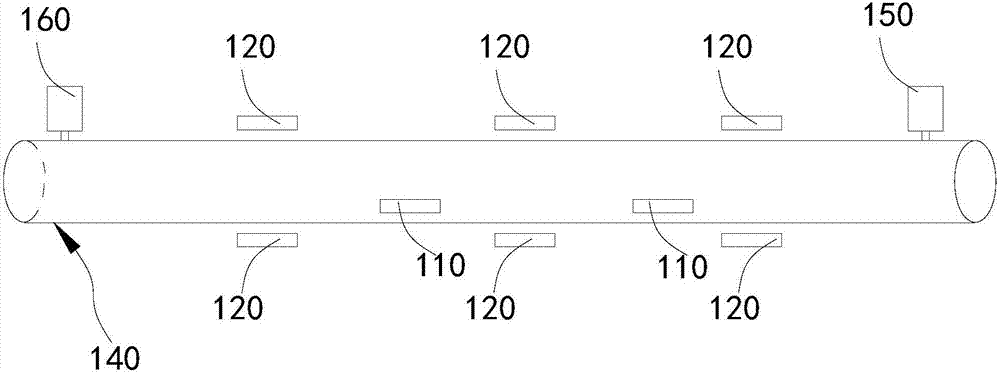

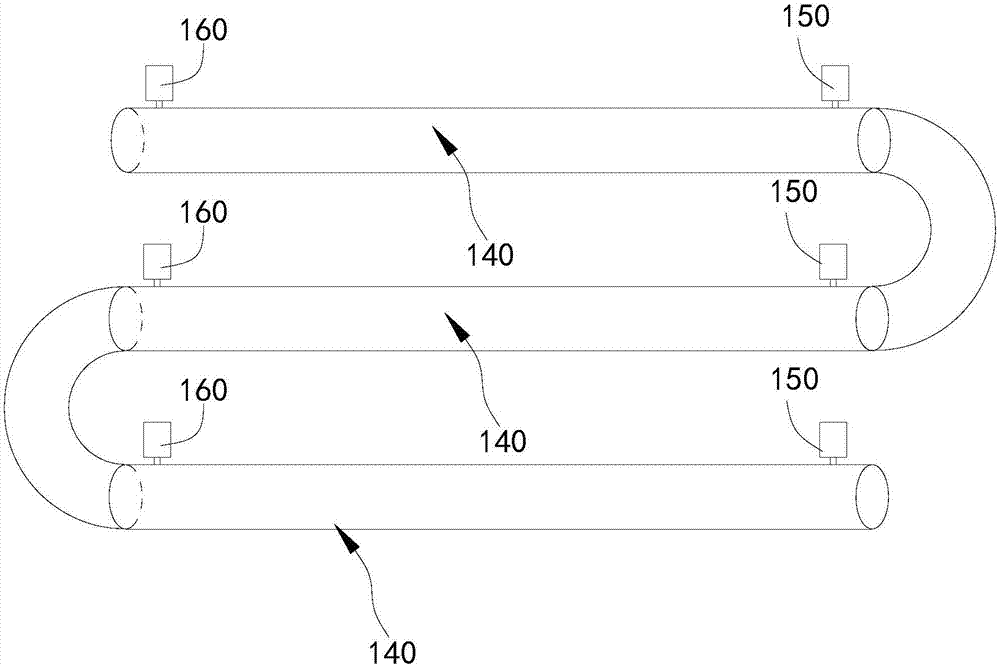

The invention discloses a mass concrete temperature intelligent monitoring and controlling device, which comprises a circulating pipeline formed by sequentially connecting a water supply device, a water distribution device, a concrete cooling system and a water return device, wherein the concrete cooling system is internally provided with a temperature monitoring device; and a centralized controlsystem which is respectively connected with the water supply device, the water distribution device, the concrete cooling system and the water return device. The concrete cooling system comprises a cooling water pipe arranged in the concrete. Usage of the device comprises a concrete cooling system setting step, a monitoring device setting step, a water distribution device setting step, a water supply device setting step, a water return device setting step, a mass concrete construction preparation step, a data acquisition step, a water supply pressure stabilization step, an alarm step, a hot water tank drainage step and a cold water tank water replenishing step. By the adoption of the mass concrete temperature intelligent monitoring and controlling device, water supply pressure can be stabilized, different water inlet temperatures and flow rates of each layer can be dynamically adjusted, temperature field change in the mass concrete can be developed according to a target of temperature control, and an alarm function is equipped, so that the problems that a temperature difference of each region of the mass concrete is too large and cracks are easy to generate are solved.

Owner:GUIZHOU BRIDGE CONSTR GROUP +1

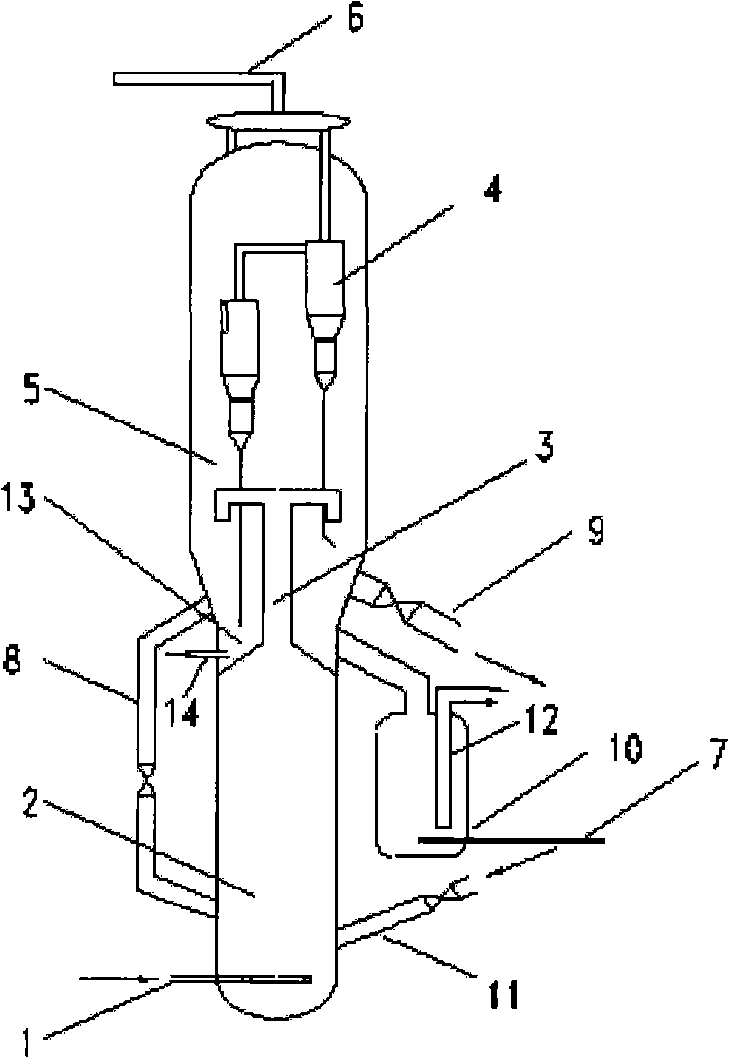

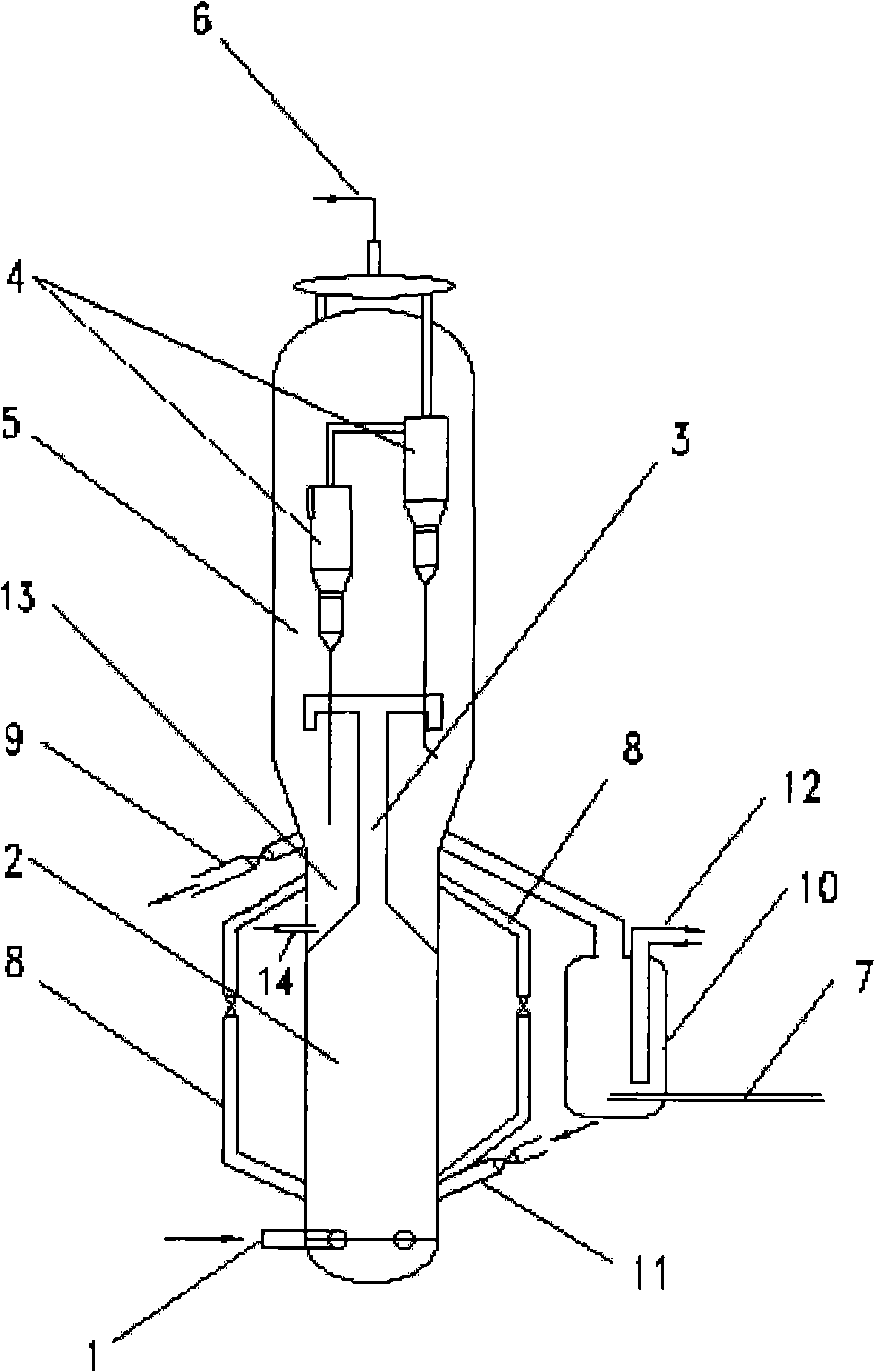

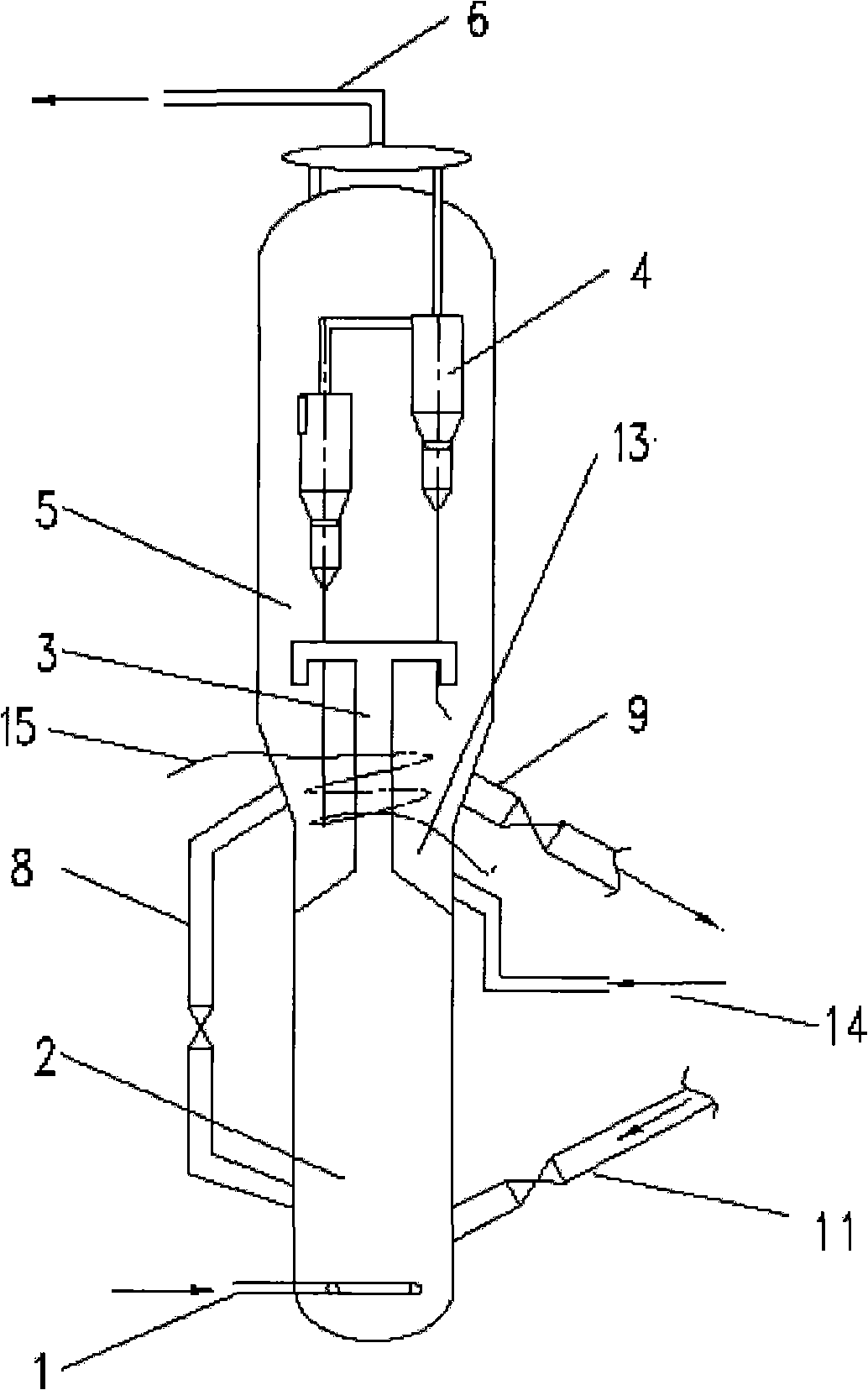

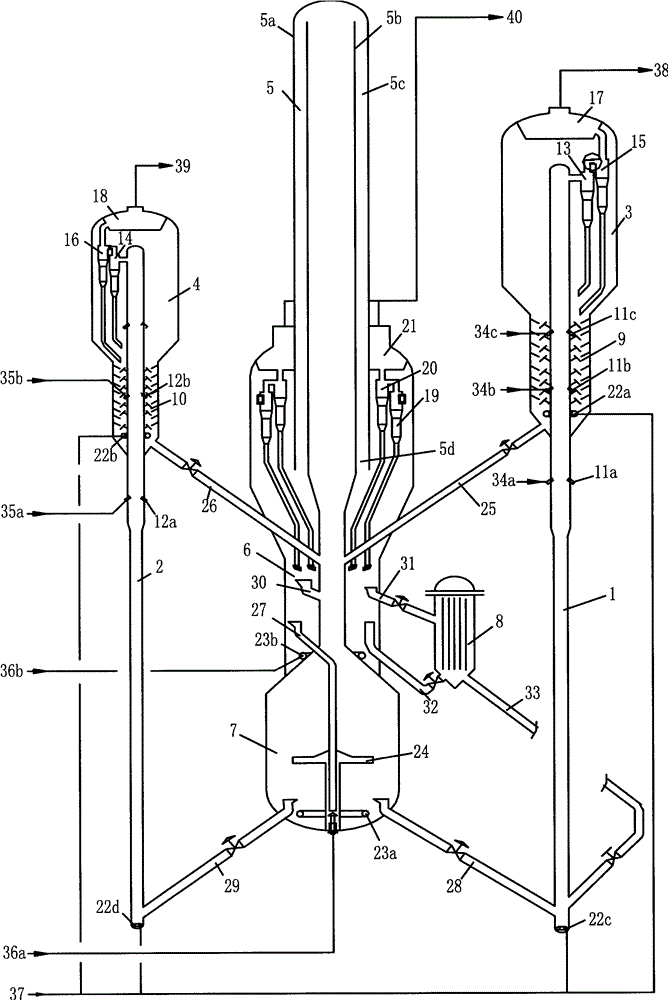

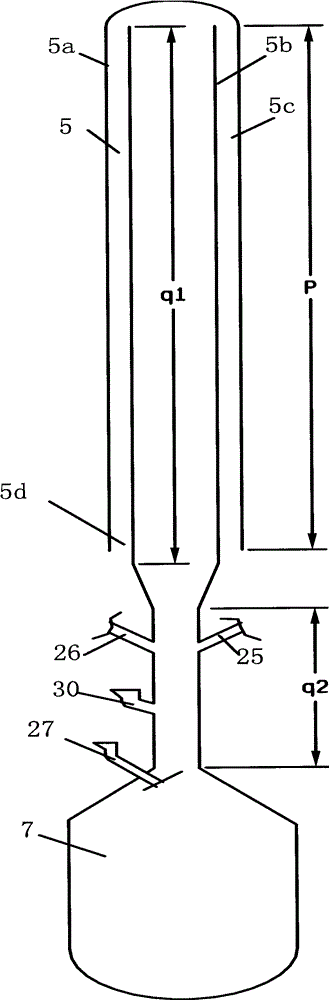

Method for producing low carbon olefinic hydrocarbon from methanol or dimethyl ether

ActiveCN101357874AHigh densityFlexible temperature adjustmentMolecular sieve catalystsHydrocarbon from oxygen organic compoundsFluidized bedDimethyl ether

The invention discloses a method for producing light olefins by methanol or dimethyl ether, which mainly solves the problems in the prior art that the yield of the light olefins is low, the temperature of a reactor is difficult to be controlled, and the mixture of catalyst in reaction area is not even. The technical proposal solves the problems and comprises the following steps: a. a fast fluidized bed reactor is provided; b. the raw materials comprising methanol or dimethyl ether are sent into the fast bed reaction area of the reactor and are contacted with the catalyst, and under effective conditions, the raw materials are converted into product logistics comprising ethylene and propylene; c. after the product logistics are separated, most part of the catalyst are sent to the second dense phase stripping area; d. the entrained product logistics are eliminated in a way that the catalyst in the second dense phase stripping area is contacted with stripping medium; e. after the processes of stripping and heat removal, the catalyst is divided into at least two parts, one of the at least two parts is sent back to the bottom of the fast bed reaction area, and the second part is sent to a regenerator. The method can be used for the industrial production of the light olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing non-spangle galvanized plate based on sheet billet continuous casting and rolling heat-based raw material and pickling galvanization continuous production line

ActiveCN108480416AFlexible temperature adjustmentShorten the lengthHot-dipping/immersion processesFurnace typesAcid washingContinuous casting

The invention relates to a method for producing a non-spangle galvanized plate based on sheet billet continuous casting and rolling heat-based raw material and a pickling galvanization continuous production line. The method comprises the following steps of totally-headless sheet billet continuous casting and rolling, pickling, smoothing, heating, non-spangle galvanization, finishing, passivation and coiling to form a non-spangle hot-galvanized roll. By means of the method, the non-spangle continuous pickling hot-galvanized plate with the specification being (0.8-4.0)*(900-1650) mm is producedin a hot rolling manner, the technological process is shortened, energy is saved, a product is good in surface quality, high in size precision and stable in performance, the production cost is lowered, parts of cold-rolling base material galvanized products can be replaced by the product, and the blank of heat-based continuous pickling galvanizing production is filled up.

Owner:RIZHAO BAOHUA NEW MATERIAL CO LTD

Rapid-mixing tubular flame burner with axial jet function

InactiveCN105627317APrevent flashback or even explosionFlexible temperature adjustmentBurnersVolumetric Mass DensityEngineering

The invention relates to a rapid-mixing tubular flame burner with an axial jet function. The burner comprises a burner body and an axial jet device. A cyclone mixing cavity is formed in the burner body. The burner body further comprises at least two airflow inlets communicating with the cyclone mixing cavity in the tangential direction of the cyclone mixing cavity. According to the burner, fuel and an oxidizing agent are injected into the burner from tangential thin-slot inlets evenly distributed in the circumference correspondingly, and backfire and even explosion can be prevented under the conditions that the flow speed is low or the oxygen concentration is high and even pure oxygen exists. According to the burner, a large-density low-temperature unburned gas film is formed on the inner wall of a quartz glass tube through the aerodynamic characteristic, and a flame area inside the quartz glass tube is wrapped, so that heat transfer between flames and the wall surface is reduced, heat loss is effectively reduced, the heat utilization rate is high, a high temperature can be easily obtained, and the flame cutting quality and the yield of nano-particles synthesized through the flames are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Rapid carburizing heat treatment technology of driving gear for automobile differential mechanism

The invention provides a rapid carburizing heat treatment technology of a driving gear for an automobile differential mechanism. The rapid carburizing heat treatment technology comprises the following steps of 1, heating, 2, intensive carburization, 3, diffusion, 4, quenching, 5, cleaning and 6, tempering. According to the treatment technology, the carburizing period is obviously shortened, production efficiency is improved, the yield is increased, the energy-saving effect is achieved, the carburizing cost is obviously reduced, and economical benefits are significantly improved.

Owner:JIANGSU BAOJIE FORGING

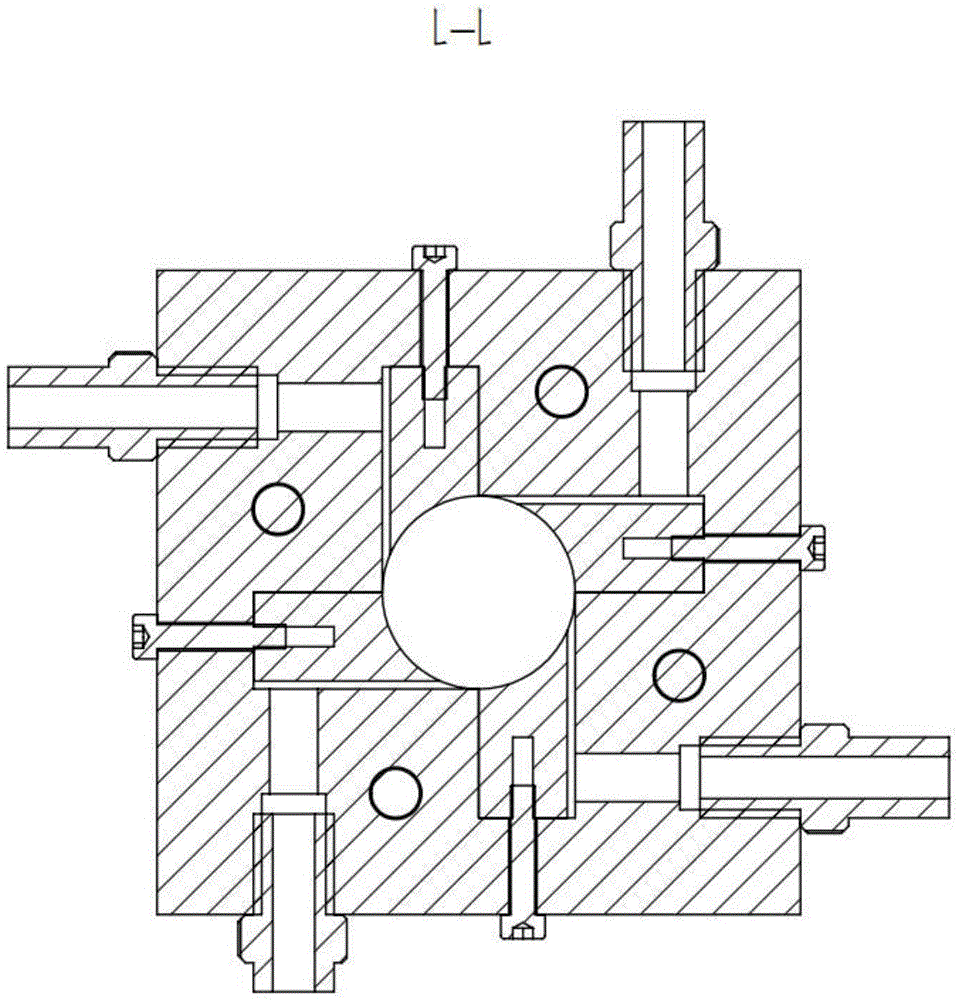

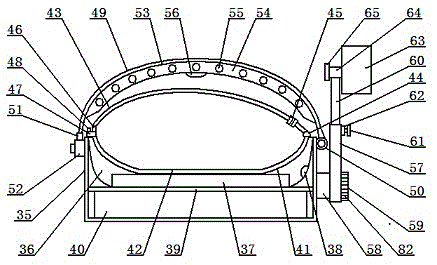

Safety testing system used for reactor pressure vessel under serious accident condition

ActiveCN106251919ADifferent cooling effectsHeating evenlyNuclear energy generationNuclear monitoringReactor pressure vesselEngineering

The invention provides a safety testing system used for a reactor pressure vessel under a serious accident condition. The safety testing system comprises a heater and a containment vessel, wherein a lower end enclosure of the containment vessel is at a suspension state, an overflow tower is arranged below the containment vessel, a spherical end enclosure of the overflow tower is at a suspension state, a reservoir for storing cooling water is arranged below the overflow tower, the lower end enclosure of the whole containment vessel is soaked in the cooling water, the heater is arranged in the containment vessel and is used for evenly heating a melt in the containment vessel at the constant temperature or at the varied temperature, the melt is poured into the containment vessel through a pouring channel at the top part of the containment vessel, the cooling water in the overflow tower is heated and boiled under the action of high temperature of the melt, a boiling tank and a steam flow are formed in the overflow tower, the containment vessel and a pressure device are connected through a pipeline and a valve, a pair of gas supply devices are connected on the pressure device, and the pressures of the gas supply devices are adjusted by the pressure device. According to the safety testing system used for the reactor pressure vessel under the serious accident condition, the failure process of the containment vessel at the high temperature gradient under the serious accident condition is simulated, and the maximum pressure value allowed in the containment vessel is acquired.

Owner:ZHEJIANG UNIV OF TECH

Substrate for strapping band

The invention belongs to the field of ferrous metallurgy materials, in particular relates to a substrate for a strapping band and a production method thereof. The substrate comprises the following chemical components in percentage by weight: 0.14-0.20 percent of C, 0.17-0.37 percent of Si, 0.55-0.75 percent of Mn, less than or equal to not more than 0.035 percent of P,0.01-0.04 percent of AL and the balance of Fe and inevitable impurities, wherein the tensile strength is not less than 7850Mpa, the elongation percentage is not less than 8 percent and the repeated bending times is not less than 8. In the production method, the smelting steps comprises the specific steps of molten iron pretreatment sulfur removal station, top and bottom combined blown converter, LF (Low Frequency) steel ladle refining and slab continuous casting,; the hot rolling steps comprises the specific steps of heating, rough rolling, hot rolling, finish rolling, laminar cooling and reeling; and the cold rolling steps comprises the specific steps of acid pickling, cold rolling and heat treatment. The steel grade has reasonable mixture ratio of chemical components and higher product strength, elongation percentage and repeated bending times compared with national standard. The production method of the substrate can ensure the chemical organization and physical performance of the steel grade.

Owner:TANGSHAN GUOFENG IRON & STEEL

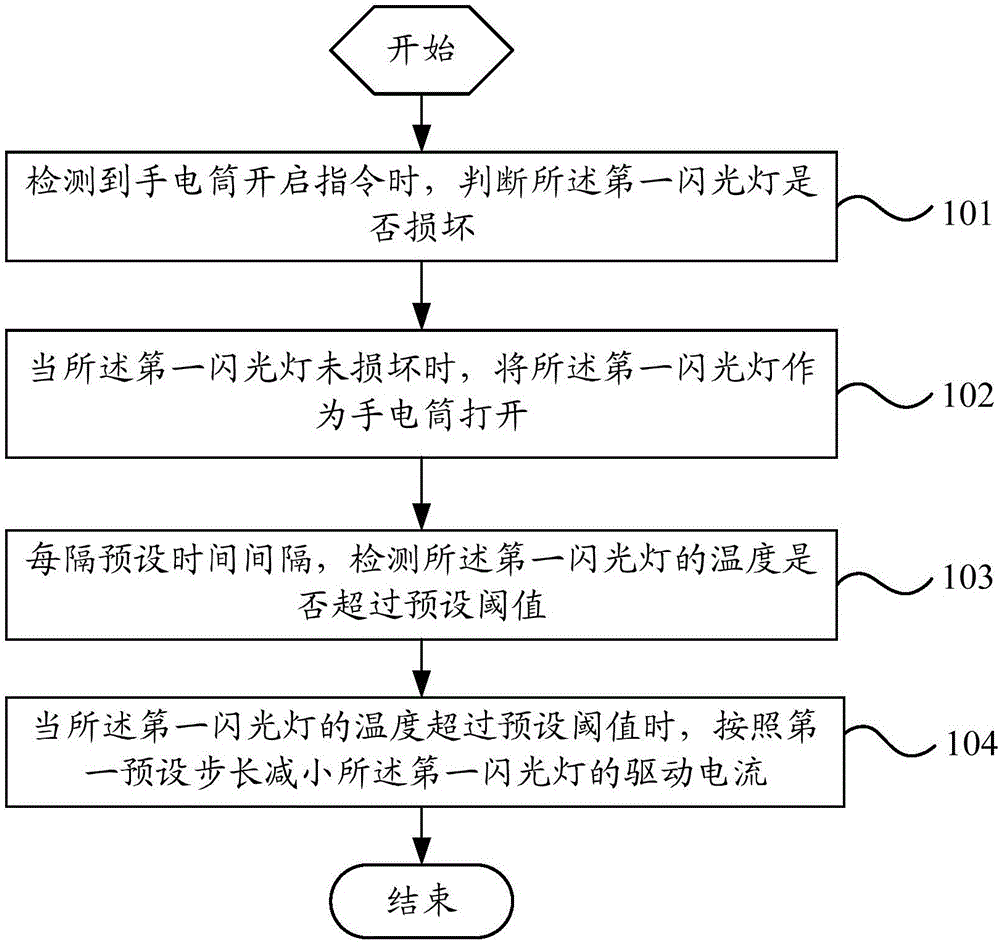

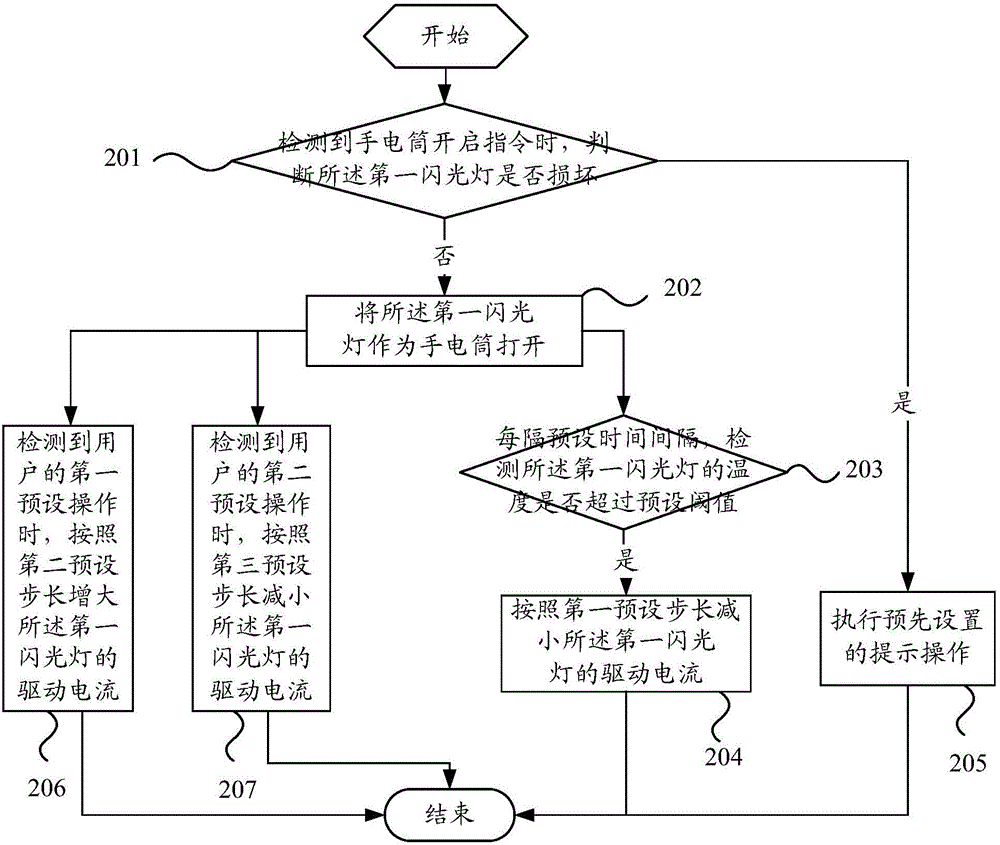

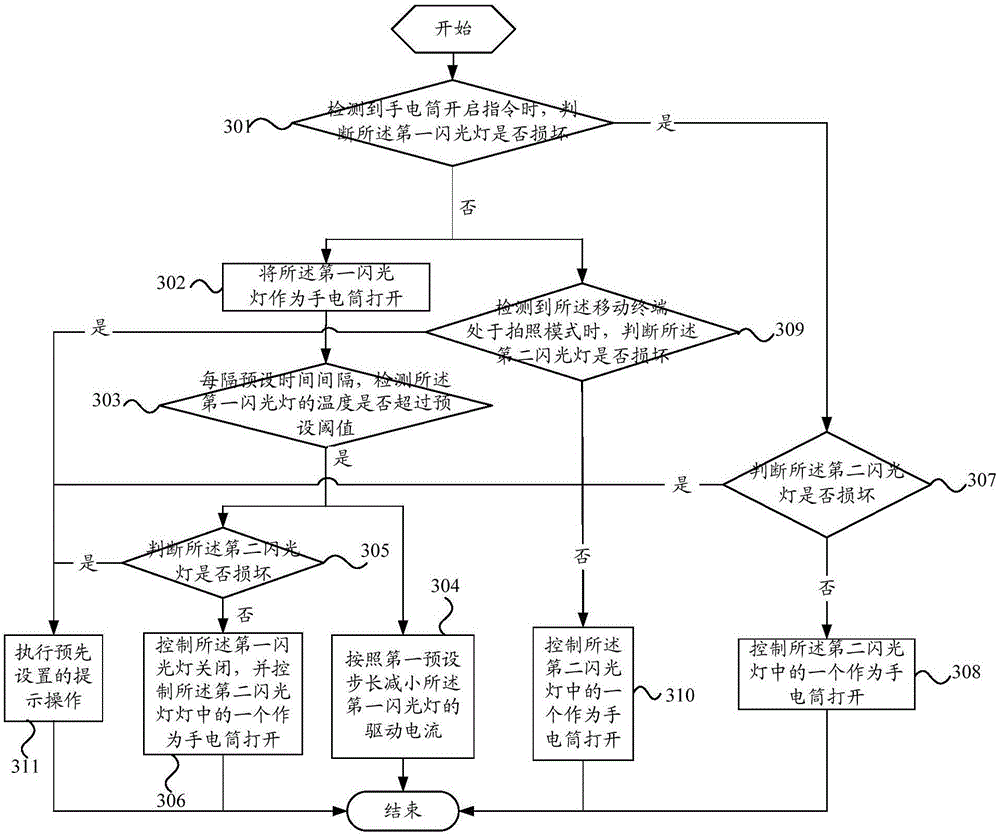

Method for controlling flash lamp of mobile terminal and mobile terminal

ActiveCN106535434ASmall driving currentAvoid damageElectric light circuit arrangementEnergy saving control techniquesDriving currentFlashlight

The invention provides a method for controlling a flash lamp of a mobile terminal and a mobile terminal. A first flash lamp is arranged on the mobile terminal, and the method includes judging whether the first flash lamp is damaged when a flashlight opening instruction is detected; switching on the first flash lamp as a flashlight when the first flash lamp is not damaged; detecting whether the temperature of the first flash lamp exceeds a preset threshold value at preset time intervals; and reducing driving current of the first flash lamp according to a preset step length when the temperature of the first flash lamp exceeds the preset threshold value. Thus, the method for controlling the flash lamp of the mobile terminal can monitor whether the temperature of the flash lamp exceeds the preset threshold value in real time after the flash lamp is switched on as a flashlight, thereby flexibly adjusting the driving current, solving the problem that after the flashlight is used for a long time, the flash lamp is damaged due to too high temperature, and improving usage experience of a user.

Owner:VIVO MOBILE COMM CO LTD

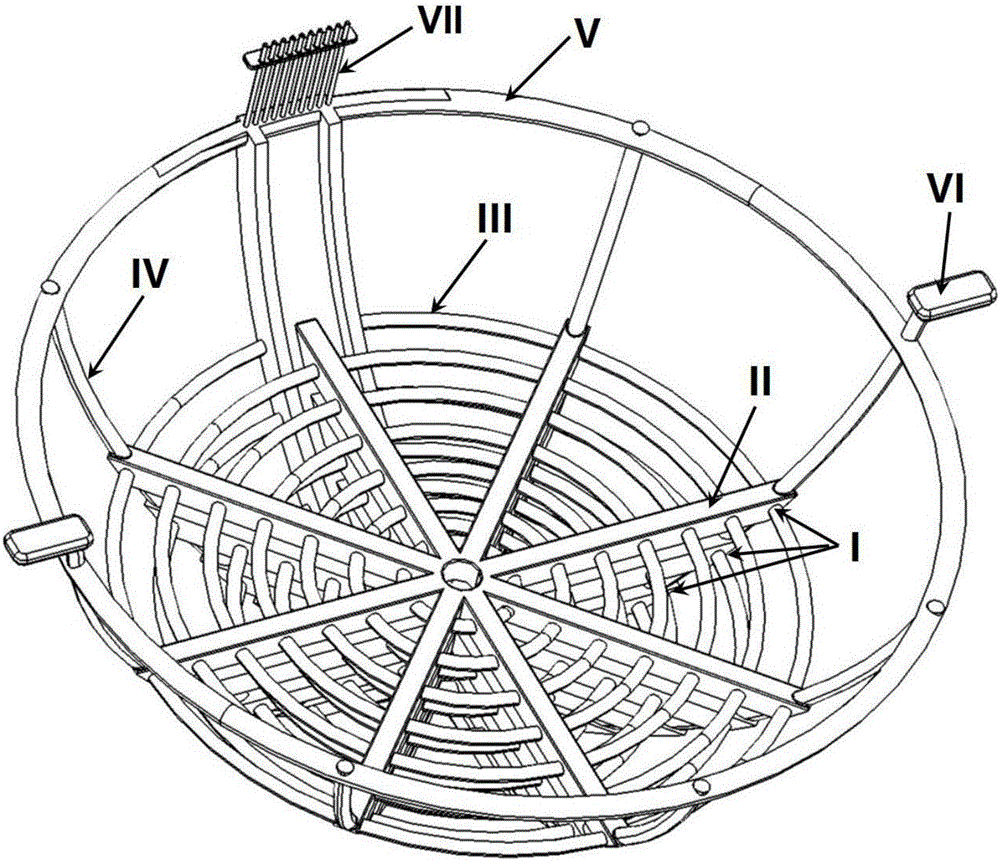

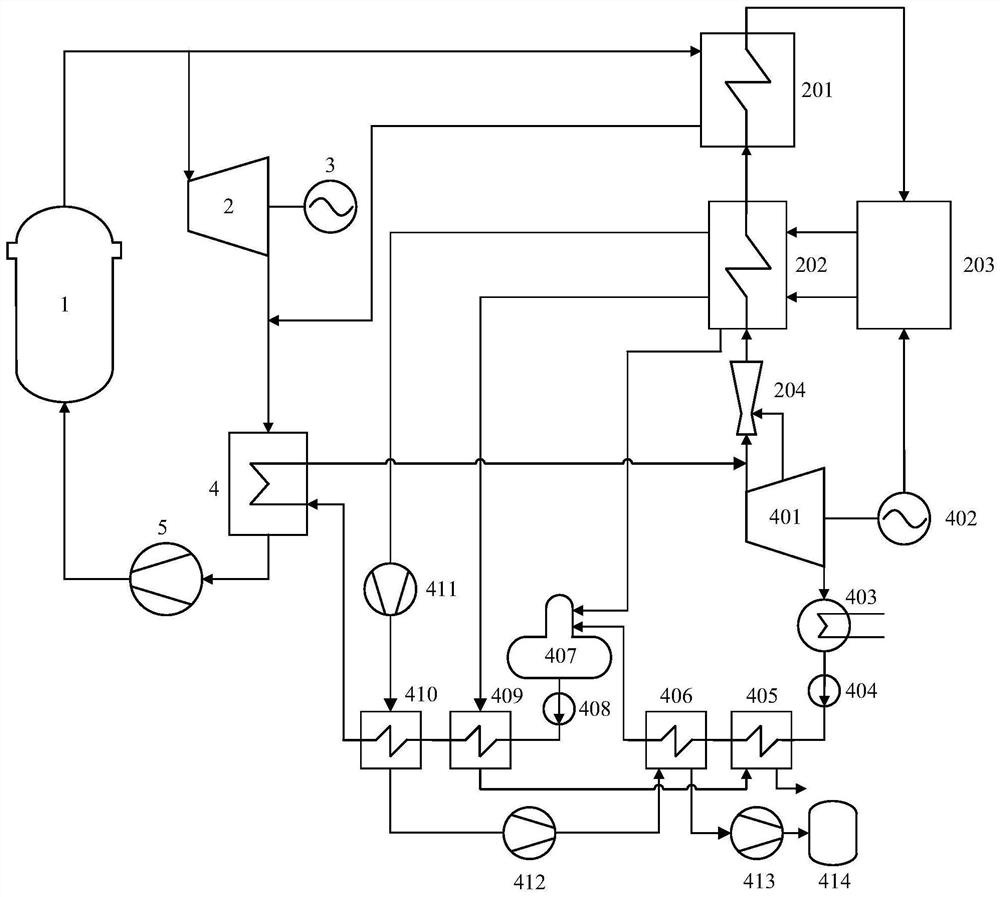

Nuclear energy power generation hydrogen production comprehensive utilization system

ActiveCN113503191AImprove energy efficiencyImprove efficiencyCellsEnergy inputChemistryBrayton cycle

The invention discloses a nuclear energy power generation hydrogen production comprehensive utilization system. The system comprises a helium-steam combined power generation system, a high-temperature solid oxide water electrolysis hydrogen production system, a waste heat recycling system and a hydrogen compression storage system, wherein the helium-steam combined power generation system is used for generating power through a high-temperature helium Brayton cycle and a steam Rankine cycle and outputting steam to the high-temperature solid oxide water electrolysis hydrogen production system, and the high-temperature solid oxide water electrolysis hydrogen production system is used for electrolyzing the steam to generate hydrogen, oxygen and steam; and the hydrogen is input into a regenerative heater of the steam Rankine cycle for waste heat recycling, and the hydrogen after heat release is input into the hydrogen compression storage system. According to the principle of gradient utilization of energy, the helium-steam combined cycle power generation system is adopted for a nuclear energy high-temperature gas cooled reactor, the power generation system and the high-temperature solid oxide water electrolysis hydrogen production system are coupled, and the energy utilization efficiency is improved.

Owner:SOUTH CHINA UNIV OF TECH

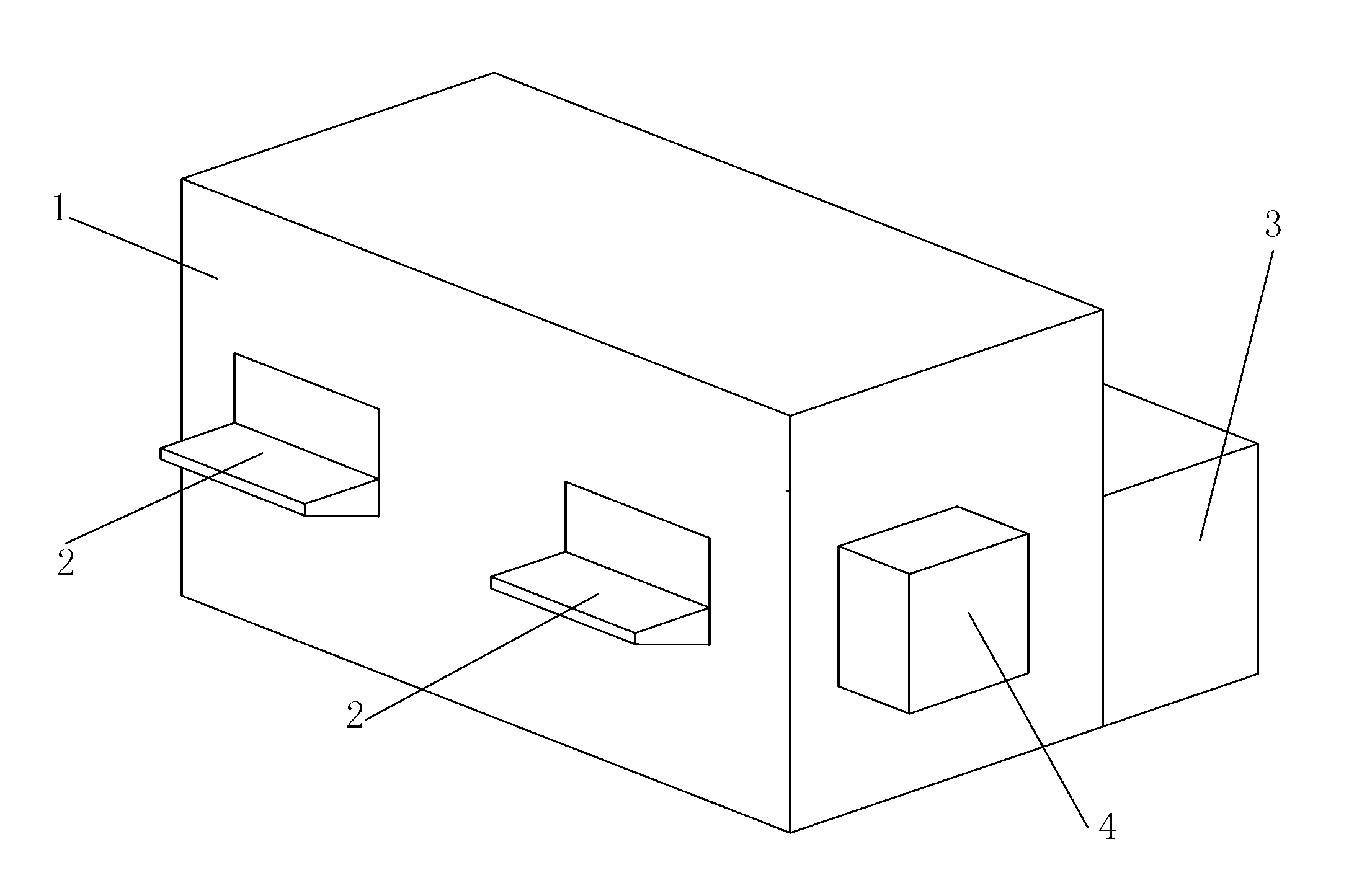

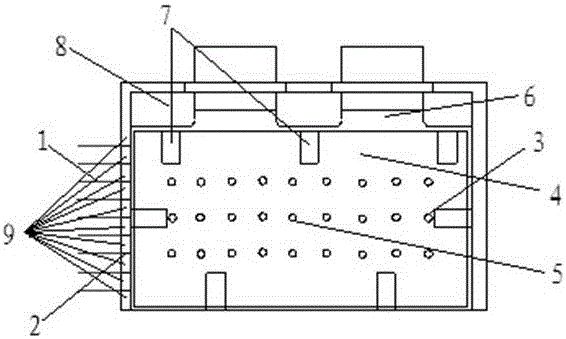

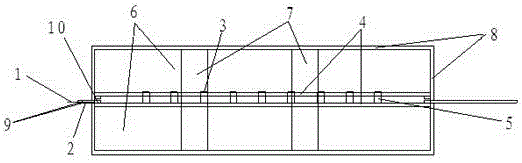

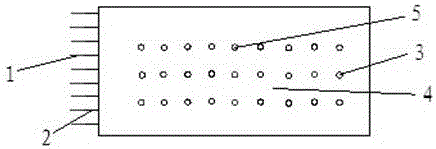

Blood storage bank system and access control method

InactiveCN103309255AEnsure safe handlingPrecise control of refrigeration temperatureData processing applicationsProgramme control in sequence/logic controllersData informationEngineering

The invention provides a blood storage bank system and an access control method. The problems of high refrigeration energy consumption, medical accidents caused by human error defects, low working efficiency, high labor intensity and the like of the conventional manual storage and management of a blood bank are solved. The blood storage bank system comprises a storage tank with a cold storage cavity, wherein the storage tank is provided with storage windows and taking windows; a material shelf is arranged in the storage tank; advancing mechanical arms are arranged on the material shelf; the storage tank is communicated with heat exchange units; temperature sensors are arranged in the cold storage cavity of the storage tank; and the heat exchange units, the temperature sensors and the mechanical arms are in control connection with a computer controller. The access control method comprises the following steps of 1) scanning stored blood bags; 2) inputting data information; 3) storing the blood bags under control; 4) making blood bag taking records; 5) taking out the blood bags under control; 6) locking the windows; 7) regulating and controlling cold storage temperature; and 8) giving an alarm when the temperature is abnormal. According to the system and the method, the blood bank is automatically monitored, the safe access and use of the blood bank is ensured, and the cold storage temperature is accurately controlled.

Owner:QINGDAO AUCMA ULTRA LOW TEMPERATURE FREEZING MACHINES

Method for producing soft pack batteries based on measurable battery internal temperature device

ActiveCN106711512ARealize direct temperature measurementSimple flat structure designFinal product manufactureThermometers using electric/magnetic elementsElectrical resistance and conductanceShort-circuit test

The invention relates to the technical field of battery production, and in particular relates to a method for producing soft pack batteries based on a measurable battery internal temperature device. The method for producing soft pack batteries based on the measurable battery internal temperature device takes a test component and a main battery body as a basic device, and is characterized by comprising the following steps of: assembling the test component by encapsulating a thermistor with a double-circuit board, carrying out a path test, and then carrying out surface insulation treatment and drying treatment; assembling a battery core package by encapsulating the test component with a double-core, or inserting the test component into a single core package, then baking, and carrying out a short-circuit test; and combining the core packages and then entering a shell, carrying out top side sealing according to the thickness of a bare battery core, then carrying out hot and cold pressure, testing temperature data numbers, namely, correspondingly leading to a number obtained after a lead is matched with the thermistor, and carrying out data linearized processing. The method provided by the invention has the advantages that the vertical and horizontal positions of the whole test component in the core package can be flexibly adjusted, and the temperature of positive and negative plates at different depths inside the battery can be flexibly tested according to needs.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

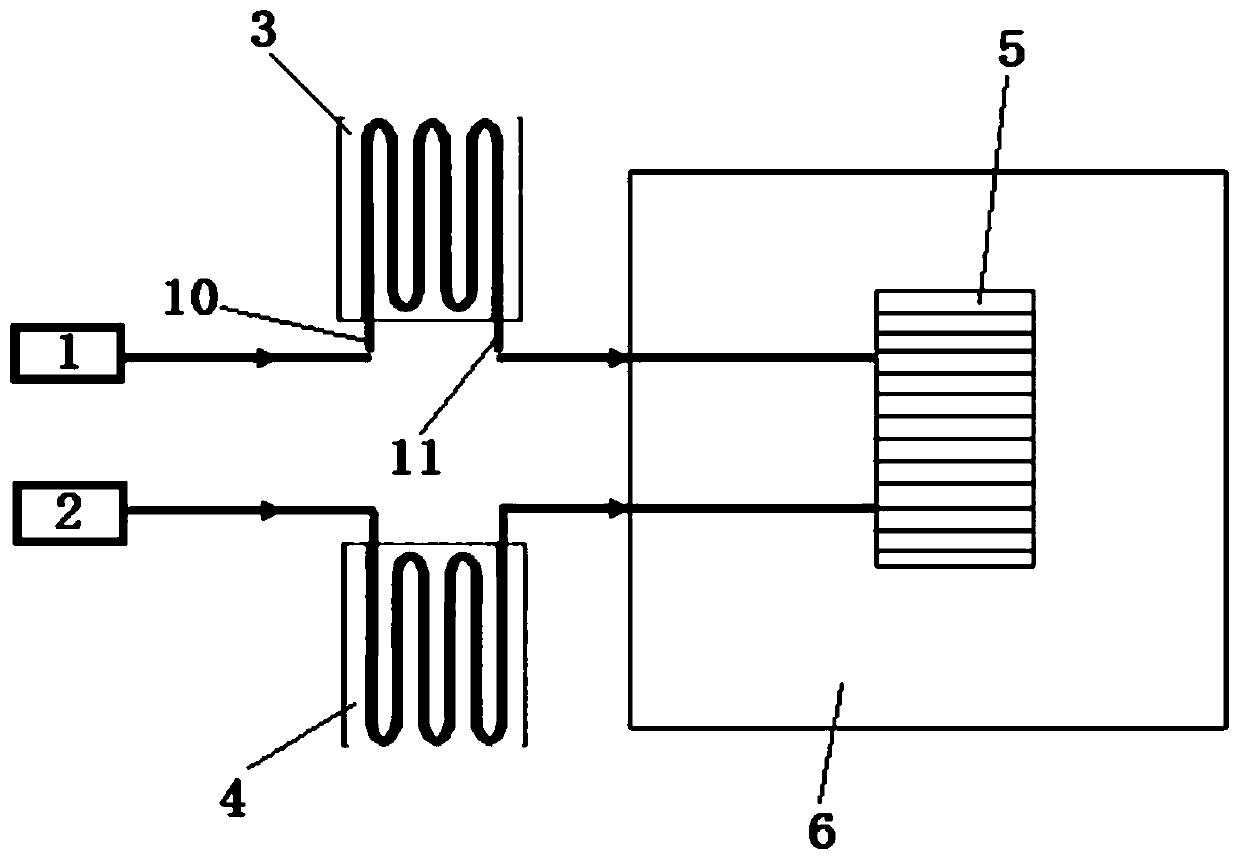

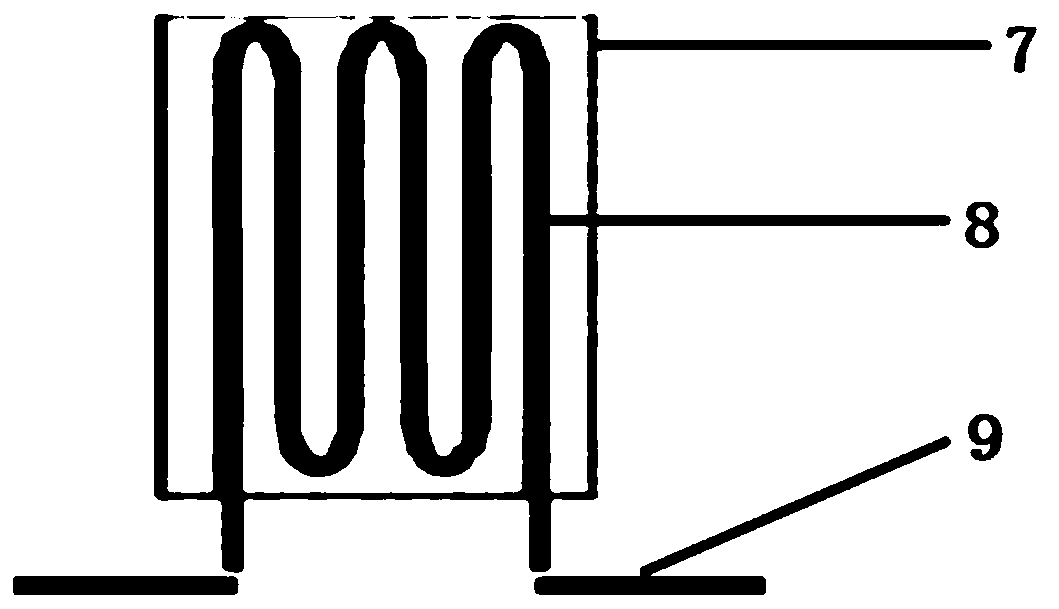

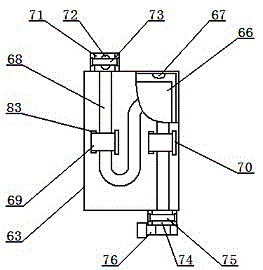

System and method for gas precooling and cooling in low-temperature starting test of fuel cell

PendingCN111490271AIncrease heat transfer areaIncrease the outer surface areaLighting and heating apparatusFuel cellsGas pipelineEvaporator

The invention relates to a system for carrying out gas precooling and cooling in a low-temperature starting test of a fuel cell. The system comprises a hydrogen pre-cooling system (3) and an air pre-cooling system (4), the hydrogen pre-cooling system (3) and the air pre-cooling system (4) are each provided with a closed environment cabin (7), a finned tube type evaporator (8) and a refrigerating device, the finned tube type evaporator (8) and the refrigerating device are arranged in the closed environment cabin (7). The finned tube evaporator (8) is provided with an air inlet (10) and an air outlet (11), and corresponding air enters the finned tube evaporator (8) from the air inlet (10) and is exhausted from the air outlet (11) after being pre-cooled. Compared with the prior art, the system has the advantages that the length of a gas pipeline is effectively reduced, gas cooling is stably achieved, the device is suitable for testing of different gas temperature requirements, and the requirement for large-span-range flow is met.

Owner:SHANGHAI SHENLI TECH CO LTD

Supercritical carbon dioxide secondary reheat coal-fired power generation boiler system

PendingCN106979512ANovel structural designHigh heat transfer efficiencyCombustion processIndirect carbon-dioxide mitigationFlueSuperheater

The invention relates to a supercritical carbon dioxide secondary reheat coal-fired power generation boiler system comprises a furnace and a flue, wherein the furnace is vertically arranged; the side wall of the furnace is formed by a cooling wall and a reheat wall; the cooling wall is positioned below the reheat wall; a burner is arranged in each of the middle part area and the lower part area of the cooling wall; the reheat wall comprises a primary reheat wall and a secondary reheat wall; the ground clearances of the primary reheat wall and the secondary reheat wall are equal or approximate; an overheater module and a reheater module are arranged in the flue in the flue gas flowing direction in a staged manner. The supercritical carbon dioxide secondary reheat coal-fired power generation boiler system has the benefits as follows: the reheat wall is novel in structural design, three-stage heat absorption and energy conversion are realized on the premise that the height of the furnace is not increased, and the furnace does not need to be designed as horizontal, and the energy utilization ratio is high; besides, by opening and closing appropriate valves, the specific combination manner of the primary reheat wall and the secondary reheat wall can be selected, that is, the heating surface area of the primary reheat wall and the secondary reheat wall can be adjusted, the temperature of the reheat working medium can be flexibly adjusted, and that the superheat degree of the reheat working medium reaches the standard can be ensured.

Owner:HUAZHONG UNIV OF SCI & TECH

System for preparing high-caloric-value biomass gasified gas by using high-temperature flue gas of oxygen-enriched combustion boiler

ActiveCN104629809AImprove energy efficiencyImprove qualityGaseous fuel feeder/distributionEnergy inputThermal energyFluidized bed gasifier

The invention discloses a system for preparing biomass gasified gas by using flue gas of an oxygen-enriched combustion boiler. The system is characterized by comprising a circulating fluidized-bed gasifier and a cyclone separator, wherein the circulating fluidized-bed gasifier is provided with a charging opening which is used for inputting a biomass material to the circulating fluidized-bed gasifier; the circulating fluidized-bed gasifier is further provided with a gas inlet which is used for inputting the flue gas of the oxygen-enriched combustion boiler; the circulating fluidized-bed gasifier is used for gasifying the biomass material under the action of the flue gas of the oxygen-enriched combustion boiler, so as to obtain the gasified gas; the cyclone separator is connected with the circulating fluidized-bed gasifier and is used for separating the gasified gas. A biomass gasification system and an oxygen-enriched combustion boiler system are used in a matched manner, and the flue gas of the oxygen-enriched combustion boiler is adopted as a gasifying agent for biomass gasification reaction, so that the energy utilization efficiency of the oxygen-enriched combustion boiler system is increased, the quality of the biomass gasified gas is improved, the whole heat energy utilization efficiency is increased, and the production cost is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Novel water tunnel experiment system for simulating real marine environment

ActiveCN109238638AAdjust the temperature arbitrarilyFlexible adjustment of flow rateHydrodynamic testingEngineeringHigh pressure water

The invention discloses a novel water tunnel experiment system for simulating a real marine environment. A guide rail is paved on a closed space foundation, a high-pressure water storage tank and a water storage cabin are built in, and the high-pressure water storage tank is connected with a high-pressure water pump station; an elbow pipeline, a stable pipeline, a shrinkage pipeline, a test pipeline and a diffusion pipeline are connected between a water outlet of the high-pressure water storage tank and a water inlet of the water storage cabin, a reflux pipeline is connected between the waterinlet of the high-pressure water storage tank and the water outlet of the water storage cabin, and the reflux pipeline is provided with a salinity adjustment subsystem; a moving device is arranged atthe bottom of the test pipeline, high-pressure valves and telescopic devices are arranged at both ends, motors are arranged on outer walls of the both ends, telescopic shafts of the motors are connected with the high-pressure valves at the located ends, and a cantilever guide rail is arranged in the test pipeline; and the test pipeline and the water storage cabin are provided with unloading drainage devices. The novel water tunnel experiment system disclosed by the invention simulates the real deep sea environment in terms of pressure, temperature, salinity and ocean current as much as possible, and can complete the key technical index test of deep sea equipment accurately, efficiently and reliably.

Owner:TIANJIN UNIV

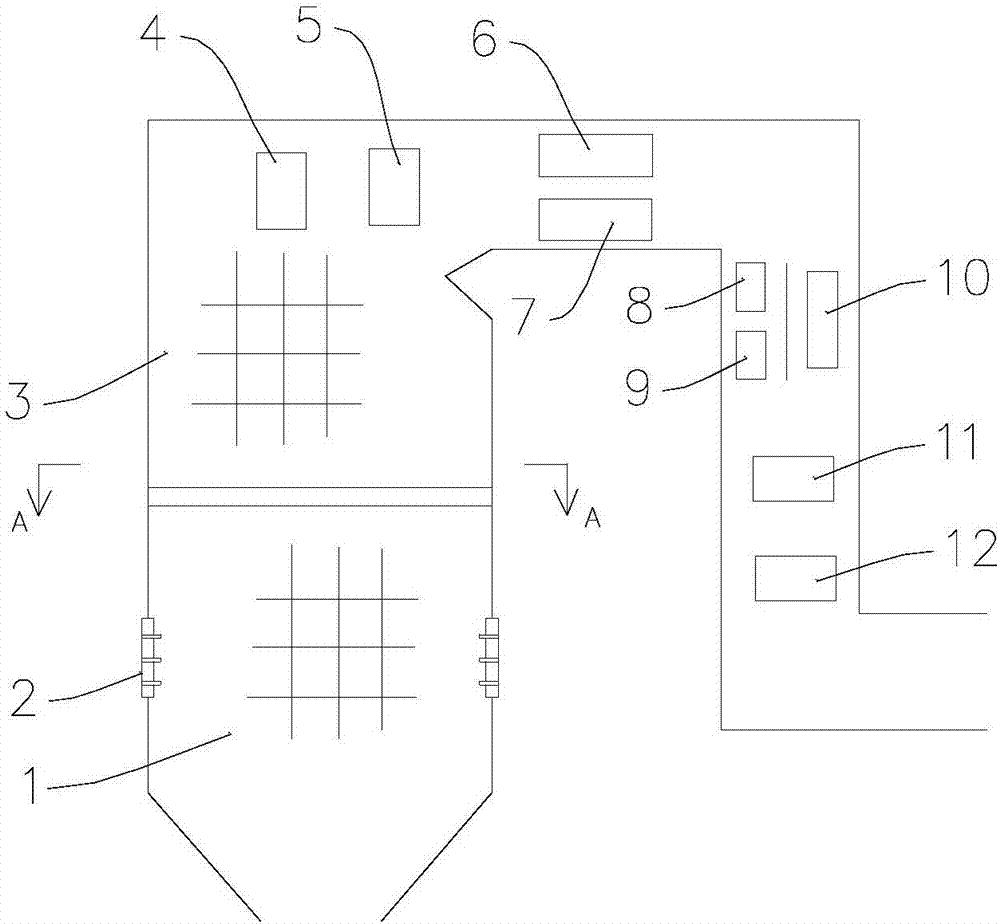

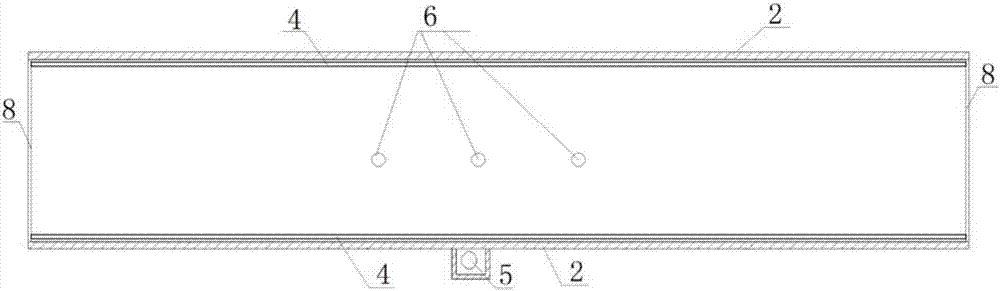

Mass concrete temperature control equipment and temperature control method

ActiveCN107268631AGuarantee product qualityEnsure safetyTemperatue controlFoundation engineeringWater storageTemperature control

The invention relates to the field of building and civil engineering, and discloses mass concrete temperature control equipment and a temperature control method. The mass concrete temperature control equipment and the temperature control method aim to solve the problem that related arts are not excellent in effect. The mass concrete temperature control equipment comprises a water tank, a control device, a plurality of branch water pipes, a plurality of first temperature sensors and a plurality of second temperature sensors; the branch water pipes, the first temperature sensors and the second temperature sensors are located in concrete; the water tank has a plurality of water storage spaces which are separated from one another for accommodating fluids at different temperatures; first regulating valves connected to the control device are arranged at inlets of the plurality of branch water pipes; the first regulating valves, the first temperature sensors and the second temperature sensors are connected to the control device; the quantity of the first temperature sensors is greater than that of the branch water pipes and the quantity of the second temperature sensors is greater than that of the branch water pipes; and the first temperature sensors are arranged in the corresponding branch water pipes and the second temperature sensors are arranged around the outer walls of the branch water pipes in concrete.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

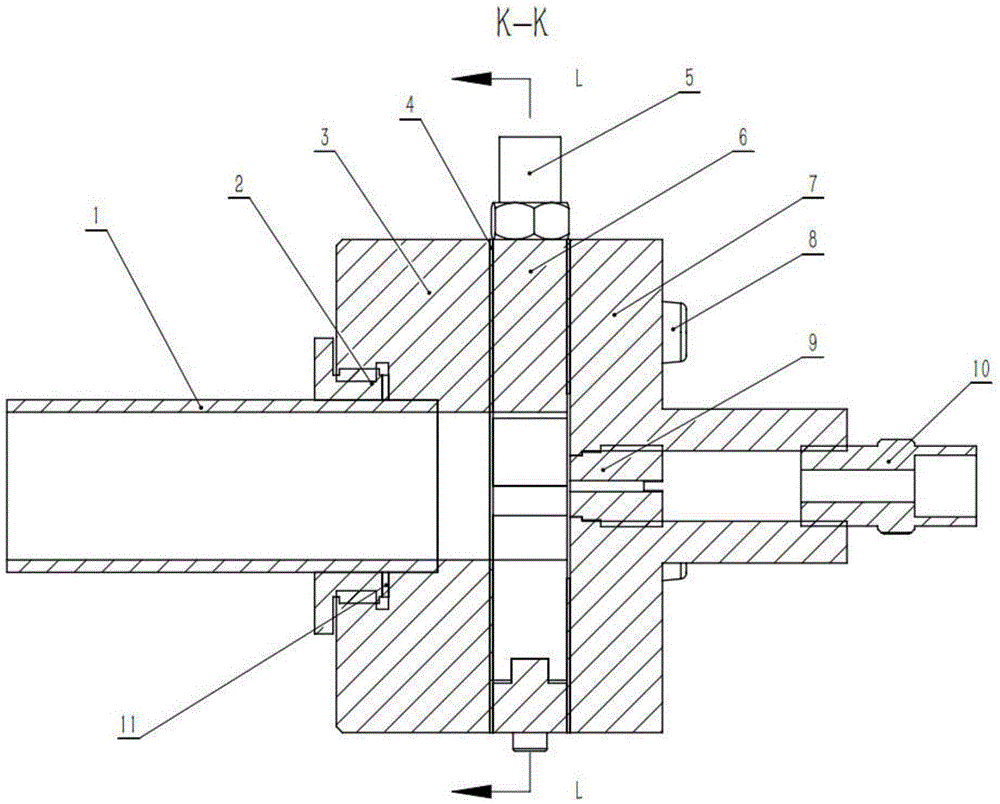

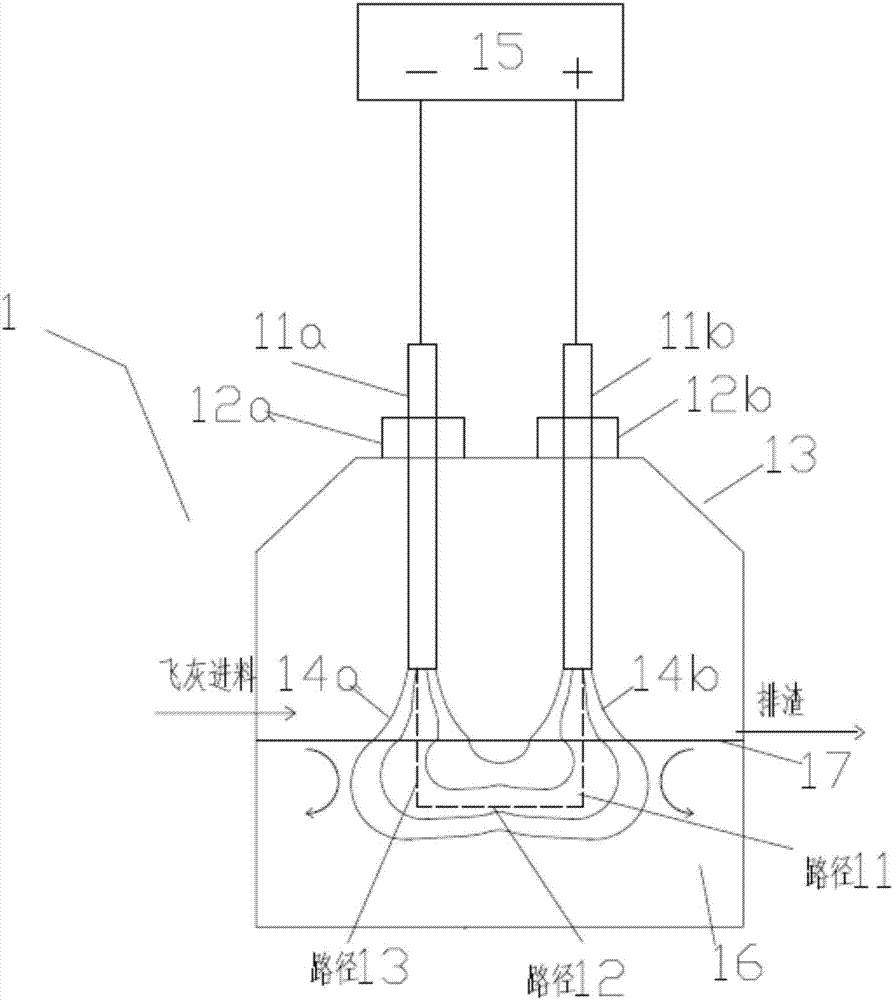

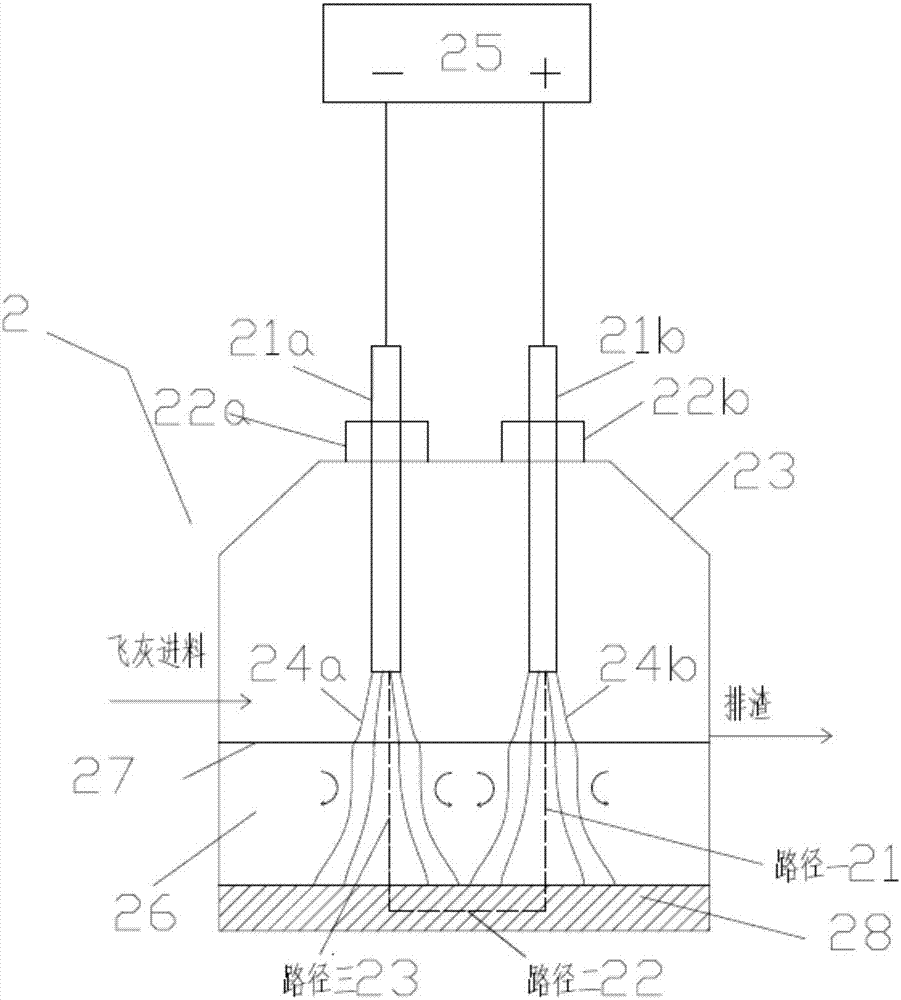

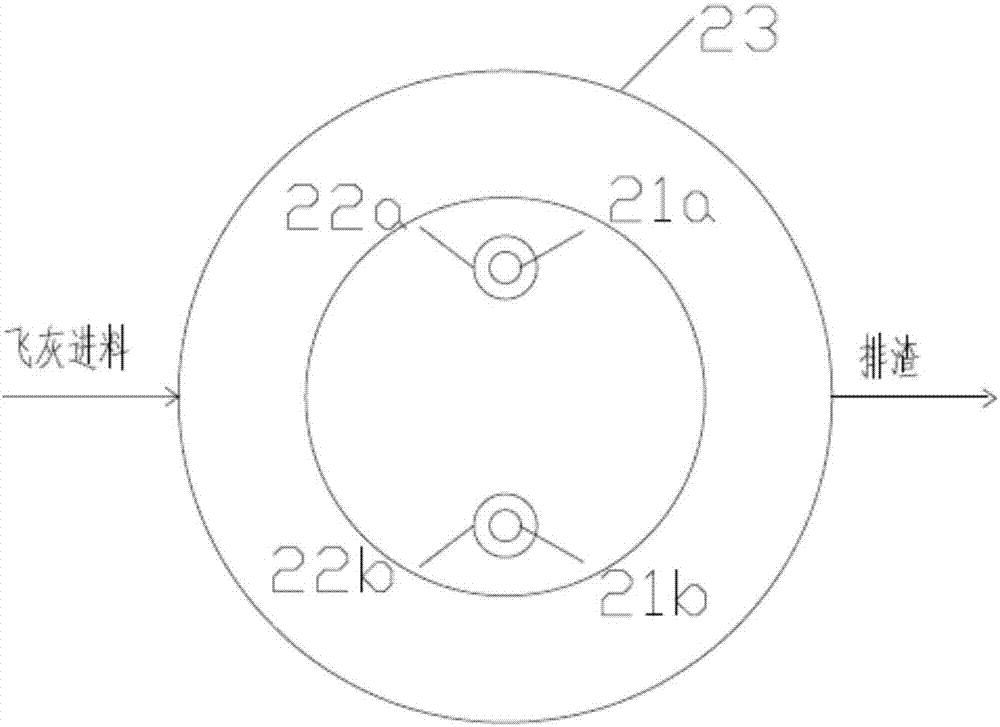

Novel double-electrode direct-current arc system for melting wastes

ActiveCN107020293AAchieve fusionMaximize Melting RateSolid waste disposalTransportation and packagingSlagCurrent distribution

The invention discloses a novel double-electrode direct-current arc system for melting wastes. The novel double-electrode direct-current arc system solves the technical problem of technical defects existed in an existing double-electrode arc technology aiming at the background technology. The adopted technical scheme is characterized in that the novel double-electrode direct-current arc system for melting the wastes comprises a melting furnace, a melting furnace body provided with a fly ash feed inlet and a slag discharge opening, double electrodes vertically inserted into the furnace body, and two lifting systems which are in one-to-one correspondence to the double electrodes and used for adjusting the heights of the double electrodes relative to the surface of a melting pool, wherein the space between the double electrodes vertically inserted into the furnace body is more than two times larger that the height of the melting pool; the two electrodes are connected onto a negative pole and a positive pole of a direct-current power supply; a furnace bottom conductive piece is arranged at the bottom part of the furnace body; and the conductivity of the furnace bottom conductive piece is more than two orders of magnitude higher than the conductivity for melting the wastes. The novel double-electrode direct-current arc system for melting the wastes has the advantages that current distribution in the melting pool is improved, and the fly ash melting pool can be more effectively melted.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Temperature-adjustable children transfusion fixing device

InactiveCN105559958ARelieve painReduce difficultyRestraining devicesInfusion devicesDisplay deviceEngineering

The invention relates to a temperature-adjustable children transfusion fixing device, and belongs to the technical field of medical appliances. According to the technical scheme, the device comprises a fixed seat, wherein supporting legs are arranged on the lower side of the fixed seat, and are connected with the fixed seat by virtue of a support fixing connector; an adjustment panel is arranged on the front side of the fixed seat; a comprehensive temperature display is arranged on the front side of the adjustment panel; a voice prompter is arranged on the left side of the comprehensive temperature display; and a temperature adjustment knob is arranged on the right side of the comprehensive temperature display. The temperature-adjustable children transfusion fixing device is simple in structure, convenient to use and good in fixing effect, and can be used for flexibly adjusting temperature, so that pains of children can be effectively relieved, and difficulty of medical staff transfusion can be alleviated.

Owner:蒋成霞

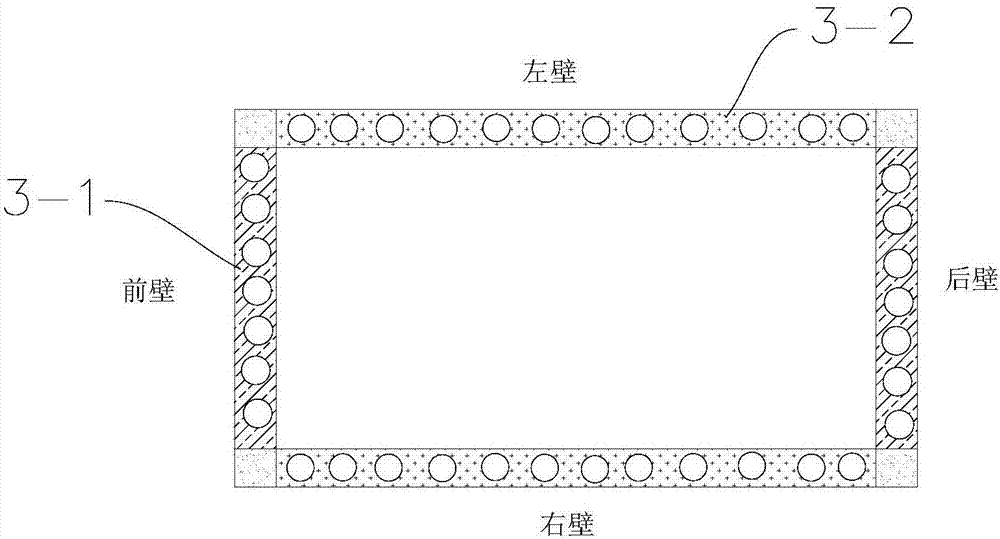

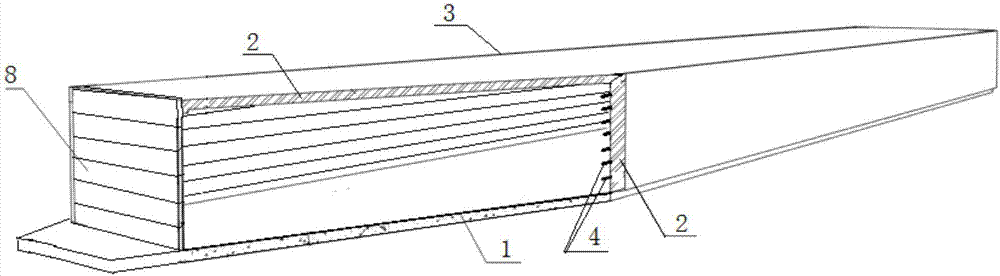

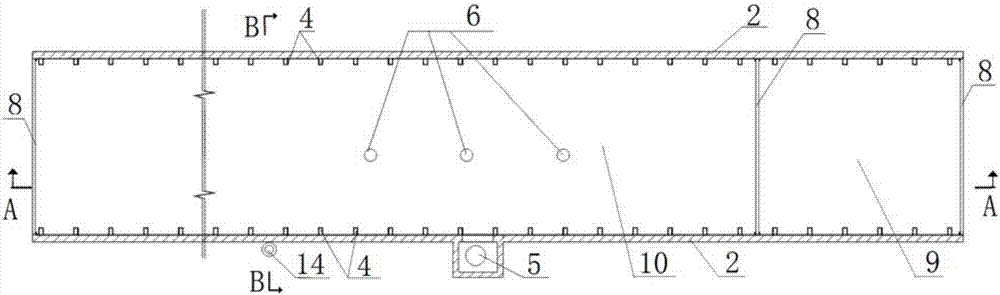

Stereoscopic maintenance tunnel for precast concrete members

PendingCN107081845AContinuous and uniform productionIncrease in sizeCeramic shaping apparatusAssembly lineEngineering

The invention discloses a stereoscopic maintenance tunnel for precast concrete members. The stereoscopic maintenance tunnel comprises a long-bar-shaped tunnel body surrounded by a base and a shell. A plurality of layers of tracks penetrating through the tunnel body are distributed at the two sides of the inside of the tunnel body. Heating equipment used for generating steam is arranged inside the tunnel body. Two end openings of the tunnel body are both provided with openable and closeable isolation gates allowing mold platens carried with the precast members to pass through. A closed steam curing chamber containing a plurality of layers of tracks is installed inside the tunnel body. The stereoscopic maintenance tunnel for the precast concrete members is reasonable in structural design, capable of achieving assembly-line-type maintenance, high in maintenance amount, capable of saving energy and high in efficiency.

Owner:刘祥锦

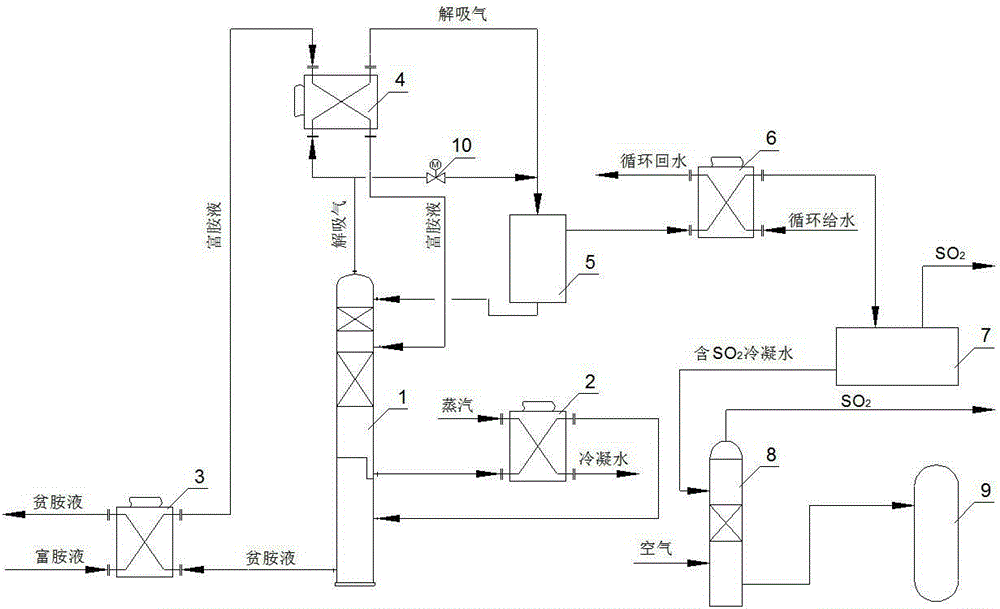

Organic amine wet flue gas desulphurization and desorption system with high-efficiency and low-energy consumption

ActiveCN105233689AReduce usageReduce cooling water consumptionDispersed particle separationReboilerChiller

The invention relates to an organic amine wet flue gas desulphurization and desorption system with high-efficiency and low-energy consumption. The desorption system comprises a desorber, a reboiler, a lean / rich amine liquid heat exchanger, a rich amine heater, a primary separator, a condensation cooler, a secondary separator, a desorption tower, an amine liquid purifying system and an electric regulating valve. A high-temperature saturated steam containing SO2 (desorbed gas for short) at the top of the desorber is directly used as a secondary heating medium of a rich amine liquid, so that the rich amine liquid entering the tower is at bubble point temperature; an integrated process system comprising step-by-step condensation cooling waste heat utilization of the high temperature desorbed gas, charging of the rich amine liquid at bubble point temperature, and backflow of a condensation liquid at bubble point temperature is used, so that effective reuse of the waste heat andreduced amounts of cooling water and heating steam are realized, the SO2 desorption efficiency of the desorber is improved, and the energy-saving effect is substantial.

Owner:TONGLING NON FERROUS METAL GROUP CORP +1

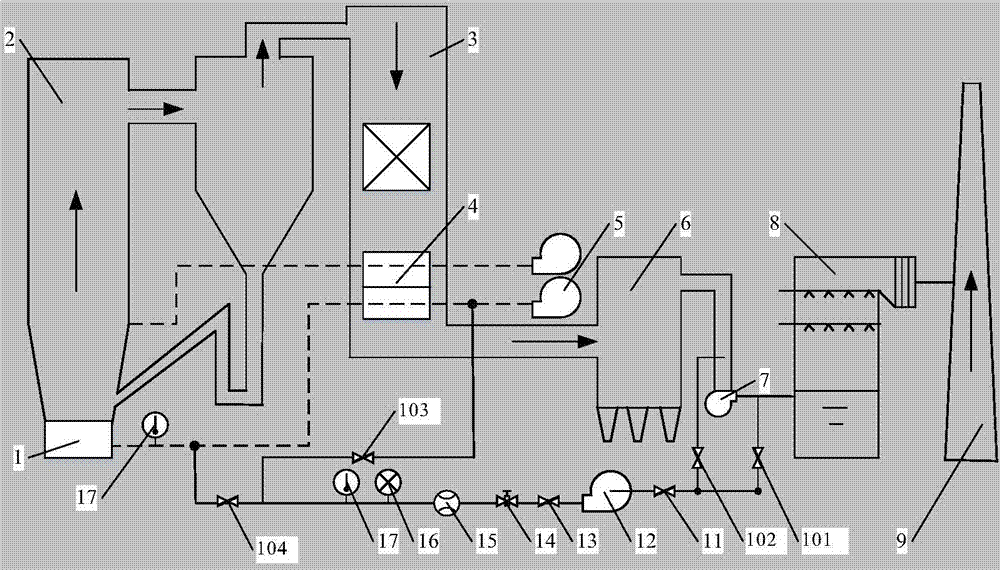

Flue gas recirculation method and flue gas recirculation system capable of reducing NOx emission of circulating fluidized bed boiler

PendingCN106969351AEmission reductionLower operating bed temperatureFluidized bed combustionApparatus for fluidised bed combustionAir volumeFlue gas

The invention discloses a flue gas recirculation method capable of reducing the NOx emission of a circulating fluidized bed boiler. Low-temperature flue gas after dust removal treatment and before wet desulphurization is pressurized, mixed with primary air and conveyed to an air chamber in the bottom of a hearth, and the amount of the primary air for fluidization is reduced and the proportion of secondary air is increased in the case of ensuring the invariable total amount of fluidizing air, so that the staged combustion characteristic of the secondary air is enhanced, and the NOx generated by combustion in the boiler is reduced. The invention further provides a flue gas recirculation system capable of reducing the NOx emission of a circulating fluidized bed boiler. The flue gas recirculation system comprises a recirculation pipeline, a recirculation fan, a valve, a flue gas flow meter, a flue gas pressure measurement component, a flue gas temperature measurement component and the like. The system is capable of remarkably lowering the running bed temperature of the circulating fluidized bed boiler, and better realizing air staging needed for low-nitrogen combustion, thereby greatly reducing the NOx emission of the circulating fluidized bed boiler. In addition, the system is capable of being used in combination with an SNCR or SCR technology, and further reducing the NOx emission of the circulating fluidized bed boiler.

Owner:HUANENG CLEAN ENERGY RES INST

Energy-saving drying kiln using common wind pipe as combustion chamber

PendingCN107131741ALow costSimple structureDrying gas arrangementsDrying machines with progressive movementsCombustion systemCombustion chamber

The invention discloses an energy-saving drying kiln using a common wind pipe as a combustion chamber. The energy-saving drying kiln comprises a drying kiln body, a heat supply system, a combustion system, a wet sucking system and a transmission system; the drying kiln body comprises at least one standard module section; each standard module section forms an independent circular heating system; the circular heating system comprises a square wind pipe; the square wind pipe is provided with a kiln afterheat inlet, a cold wind distribution port, a combustor connecting pipe, a heat supply outlet and a wet discharge port; the kiln afterheat inlet is connected with a kiln afterheat pipe; the cold wind distribution port is connected with the cold wind pipe; the combustor connecting pipe is connected with the combustion system; the heat supply outlet is connected with the heat supply system; hot wind combusted by the combustion system is mixed with kiln afterheat and cold wind by the circular heating system, and then, is fed above and below adobes in the transmission system through the heat supply system for drying; and dried moisture is discharged into atmosphere by the wet sucking system. The energy-saving drying kiln can realize effective drying of adobes to achieve the supply and sucking balance, and is more obvious in energy saving effect.

Owner:DLT TECH CO LTD

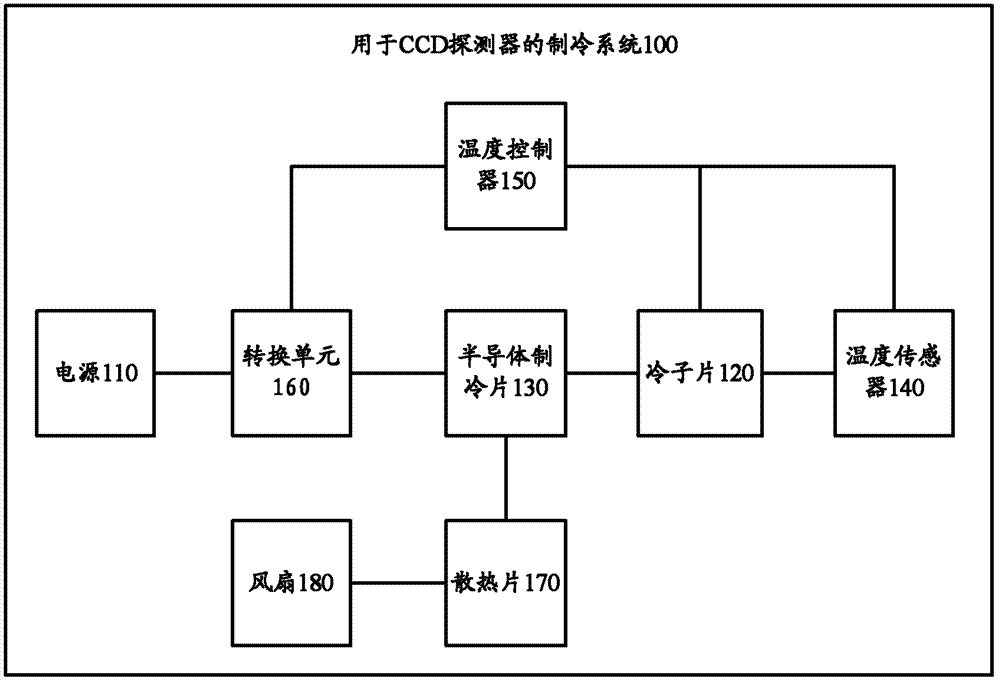

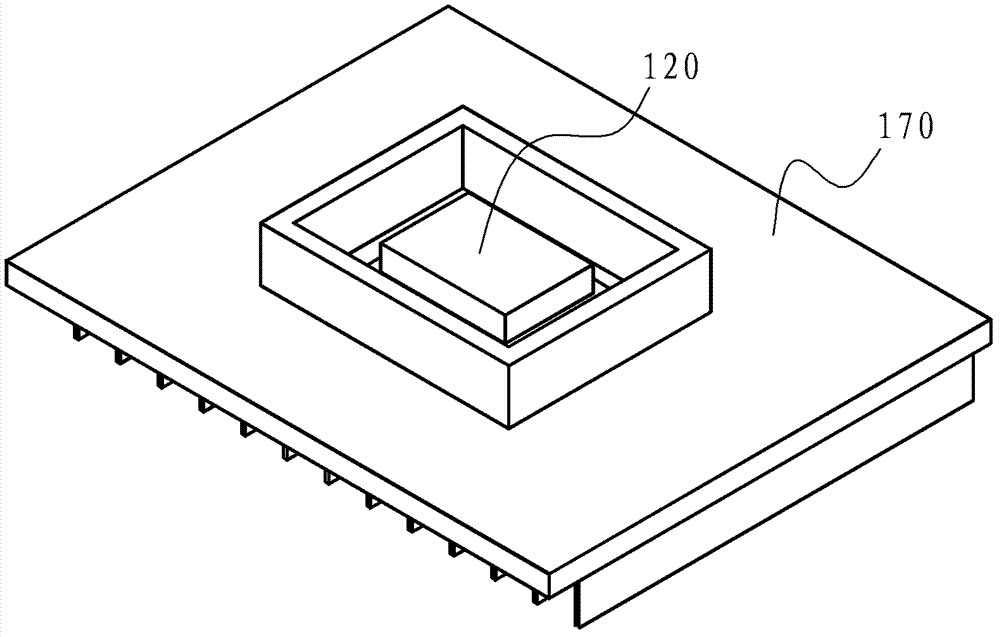

Refrigerating system for CCD (Charge Coupled Device) detector

InactiveCN102820273AReduce the temperatureFlexible and adjustable temperatureSemiconductor/solid-state device detailsSolid-state devicesControl signalEngineering

The invention provides a refrigerating system for a CCD (Charge Coupled Device) detector, which comprises a cold plate, a semiconductor refrigerating sheet, a temperature sensor, a temperature controller and a conversion unit, wherein the cold plate is provided with a first face, a second face and a side wall; the cold face of the semiconductor refrigerating sheet is contacted with the first face of the cold plate, and the cold face cools the CCD detector through the second face of the cold plate; the temperature sensor is used for detecting the current temperature of the cold plate and outputting a temperature indicating signal; the temperature controller reads the current temperature of the cold plate according to the temperature indicating signal and compares the current temperature with the first predetermined temperature to obtain a control signal; and the conversion unit is used for adjusting the current temperature of the cold face to the first predetermined temperature selectively by supplying power to the semiconductor refrigerating sheet through a power supply according to the control signal. According to the refrigerating system, the temperature of the CCD detector can be freely controlled, so that influence of high temperature on the CCD detector is reduced. In addition, the temperature of the CCD detector is ensured to change stably through the cold plate, so that the service life of the CCD detector is prolonged.

Owner:北京中科美伦数字技术股份公司

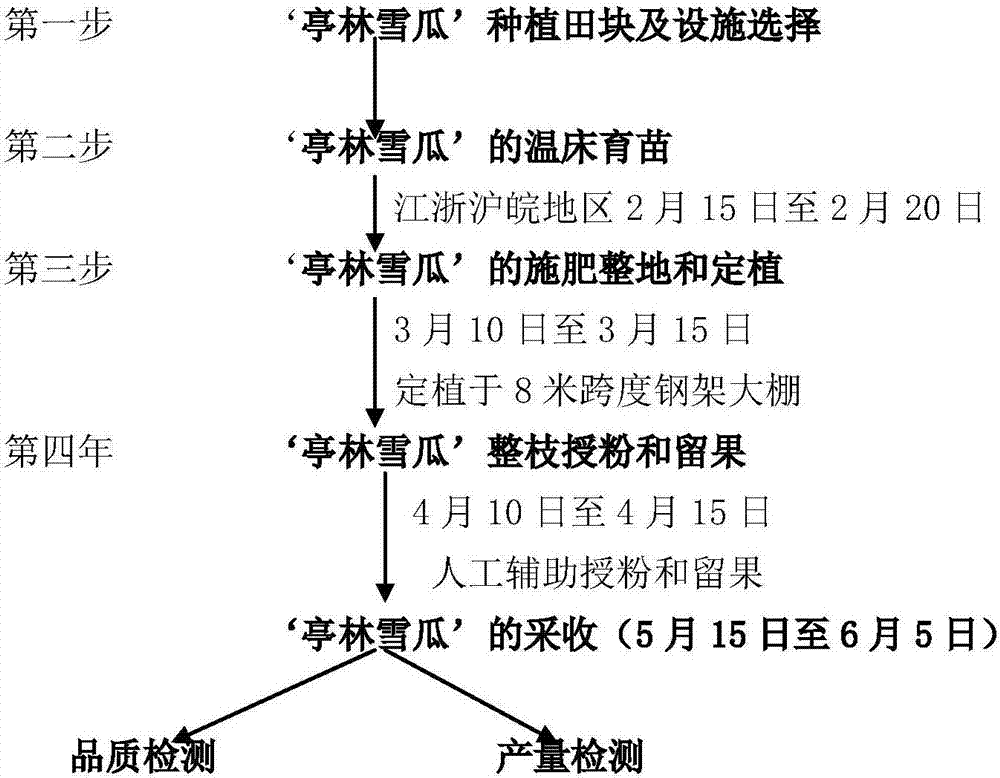

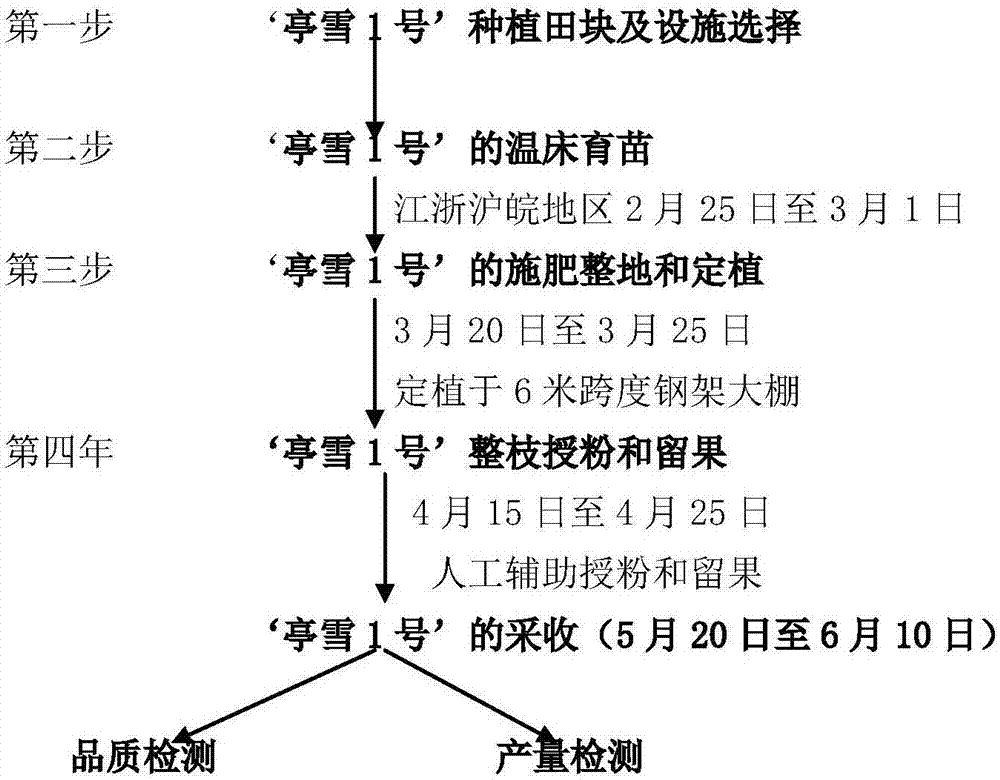

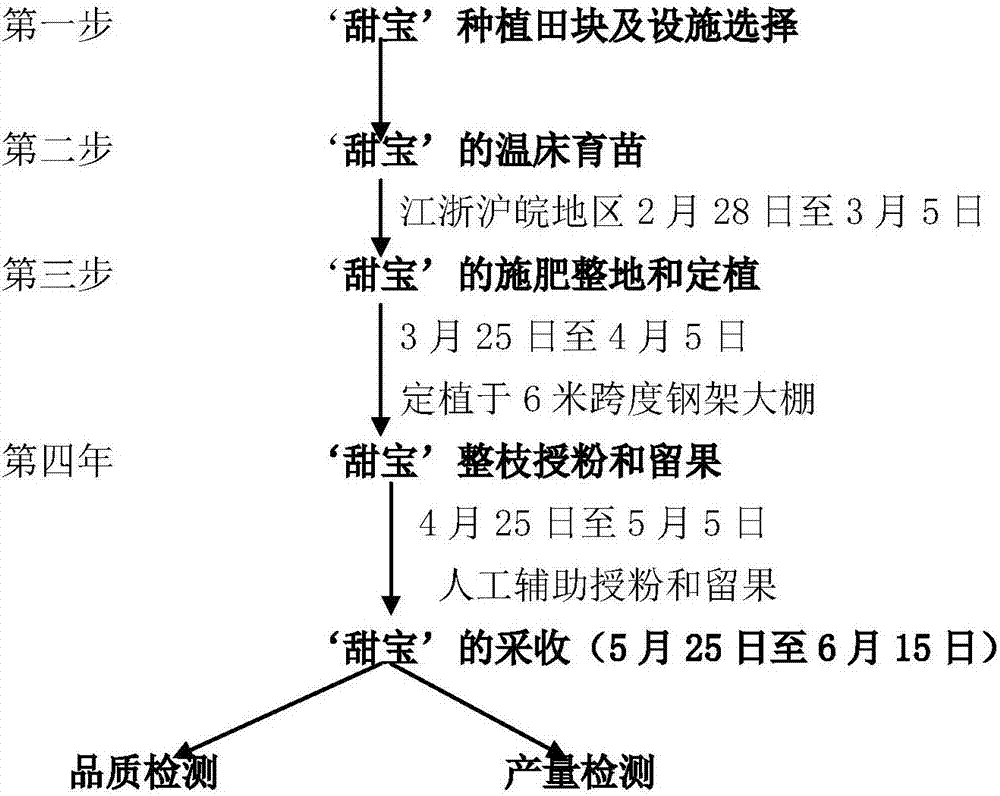

Good-quality high-yield cultivation method of muskmelons

InactiveCN106973672AAvoid Pollen DysplasiaReduce production management costsFertilising methodsPlant cultivationFlavorPruning

The invention provides a high-quality and high-yield cultivation method of muskmelon, the method comprising the following steps: (1), selection of production areas and production facilities; (2), timely sowing and seedling cultivation, and cultivating strong seedlings; (3), fertilization and land preparation; Four), timely field planting, hanging vine cultivation; (five), single vine pruning, select the remaining sub-vines to set fruit; (6), re-apply swelling melon fertilizer water, increase the application of high potassium foliar fertilizer; (7), control the temperature of the shed, Harvest in good time. The high-quality and high-yield cultivation method of muskmelon of the present invention reduces the use of chemical pesticides throughout the cultivation process, avoiding excessive pesticide residues; the base fertilizer is mainly organic fertilizers such as chicken manure, sheep manure, and vegetable cakes, which reduces the residues of nitrates and heavy metals in fruits Exceeding the standard; increasing the application of high-potassium foliar fertilizer during the melon swelling period significantly improved the taste and flavor of the fruit, and at the same time extended its production and supply period.

Owner:SHANGHAI CITY JINSHAN DISTRICT AGRI TECH PROMOTION CENT

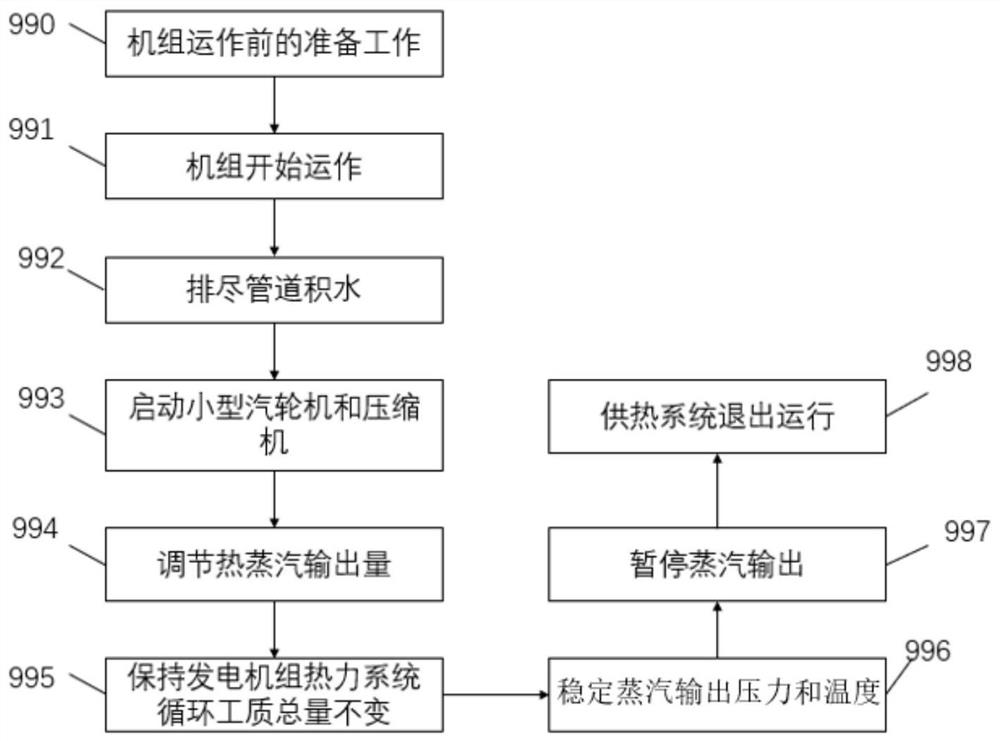

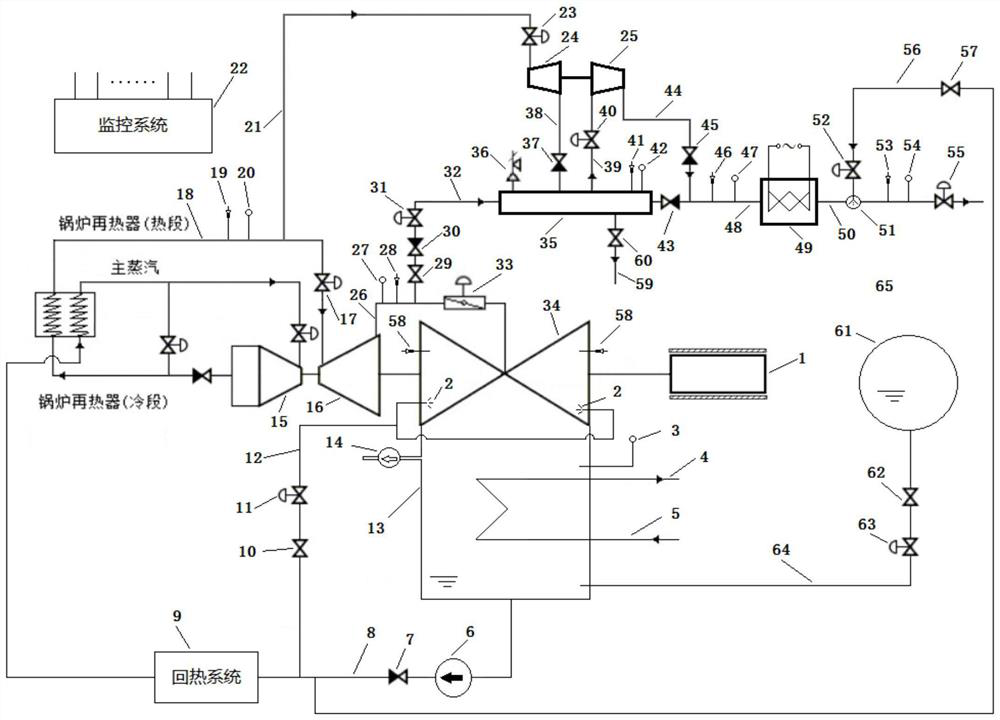

Low-pressure steam source boosting heat supply method for combined heat and power generation unit

ActiveCN112344413AFlexible pressure adjustmentFlexible temperature adjustmentSuperheating controlSteam useSteam pressureWorking fluid

The invention discloses a low-pressure steam source boosting heat supply method for a combined heat and power generation unit. The low-pressure steam source boosting heat supply method for the combined heat and power generation unit comprises the following steps that S101, preparation work before unit operation is conducted; S102, the unit starts to operate; S103, accumulated water in a pipeline is drained as much as possible; S104, a small steam turbine and a compressor are started; S105, the output quantity of hot steam is adjusted; S106, the total amount of cycle working fluid of a thermalpower system of a generator set is kept unchanged; S107, the steam output pressure and temperature are stabilized; S108, the steam output is paused; and S109, a heat supply system quits operation. Themethod can effectively solve the problem that heat supply steam pressure and temperature are flexibly adjusted under the condition that parameters such as through-flow steam pressure and temperatureof a turbine bleed point cannot meet user requirements, so that the heat supply steam parameters meet the requirements of heat consumers, the method does not excessively depend on the method of increasing the electric power of the generator set to increase the steam flow of the steam turbine in order to enhance the steam supply capacity of the unit, and the flexibility of greatly adjusting the electric power of the generator is also improved.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

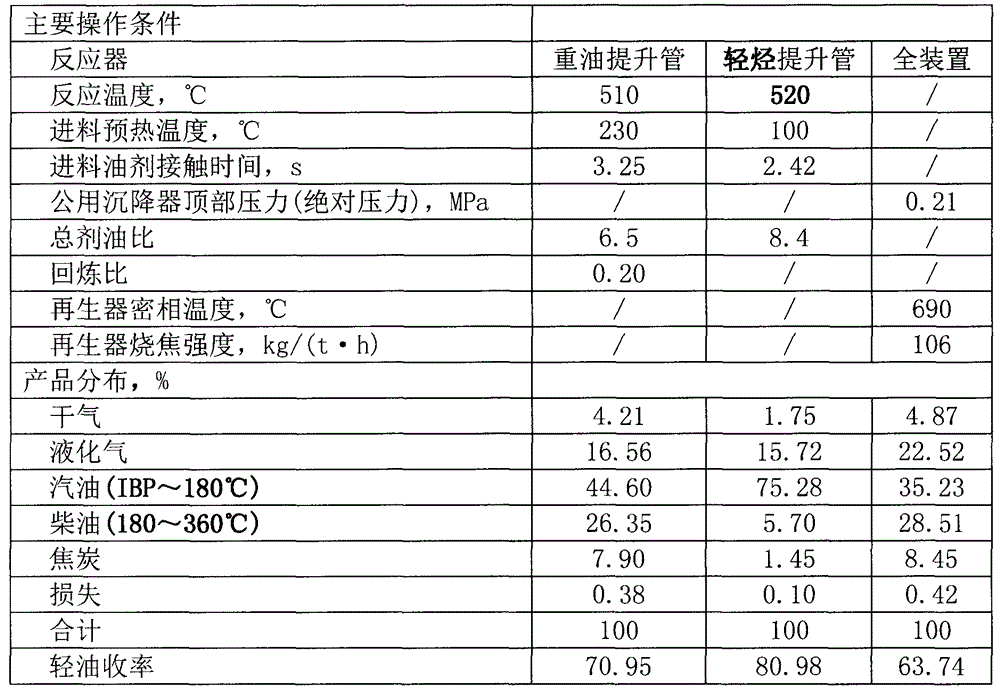

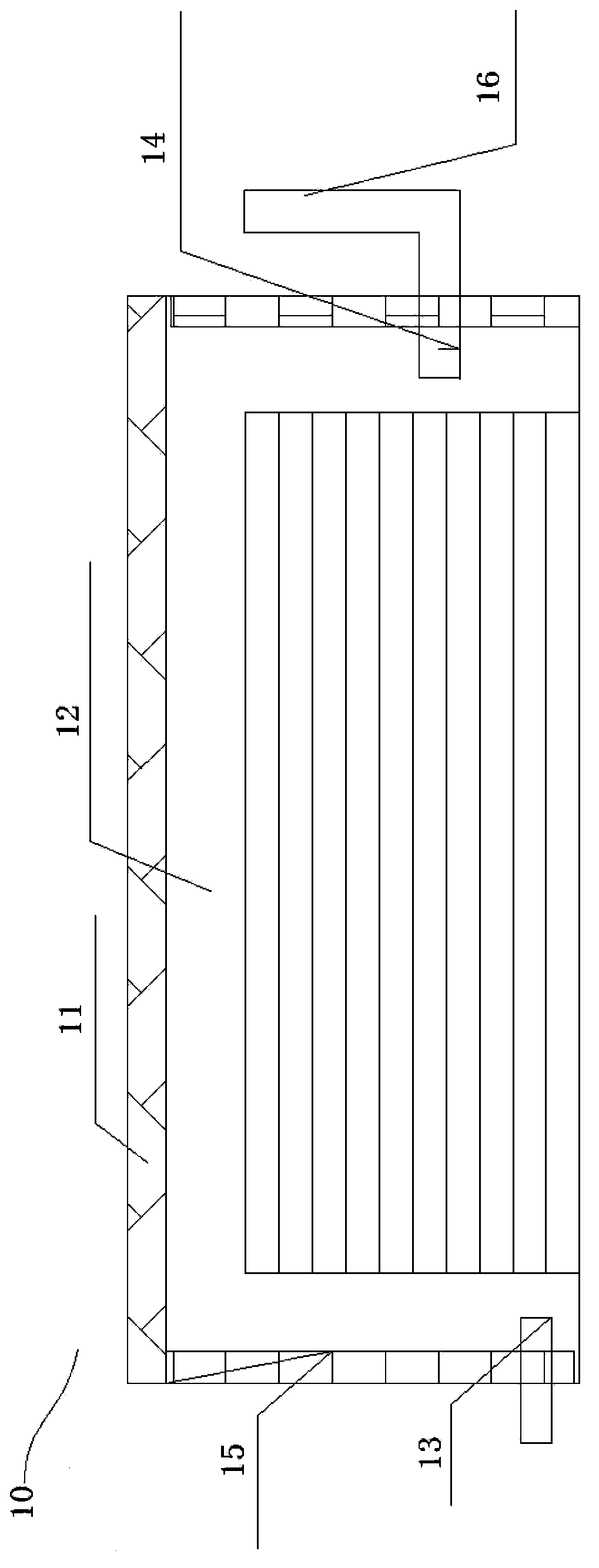

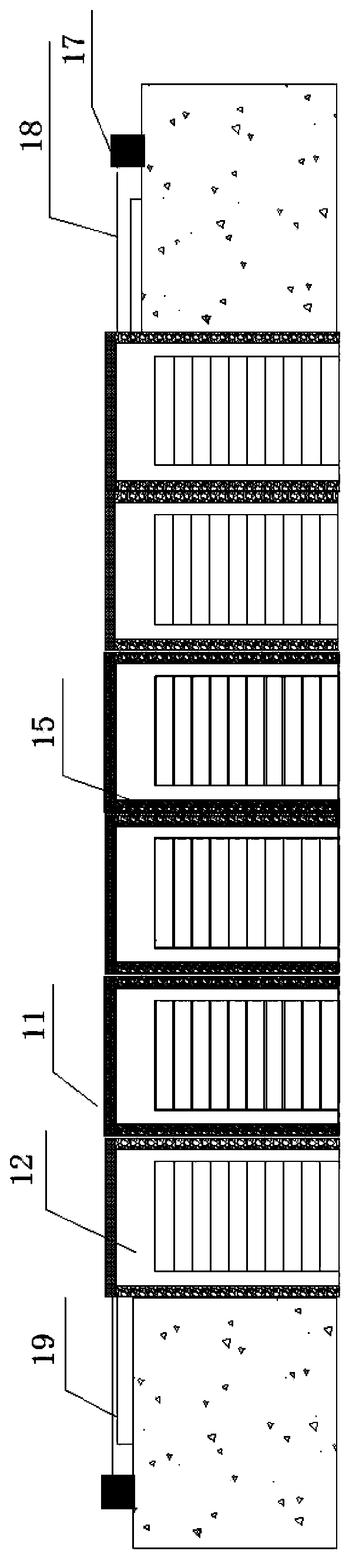

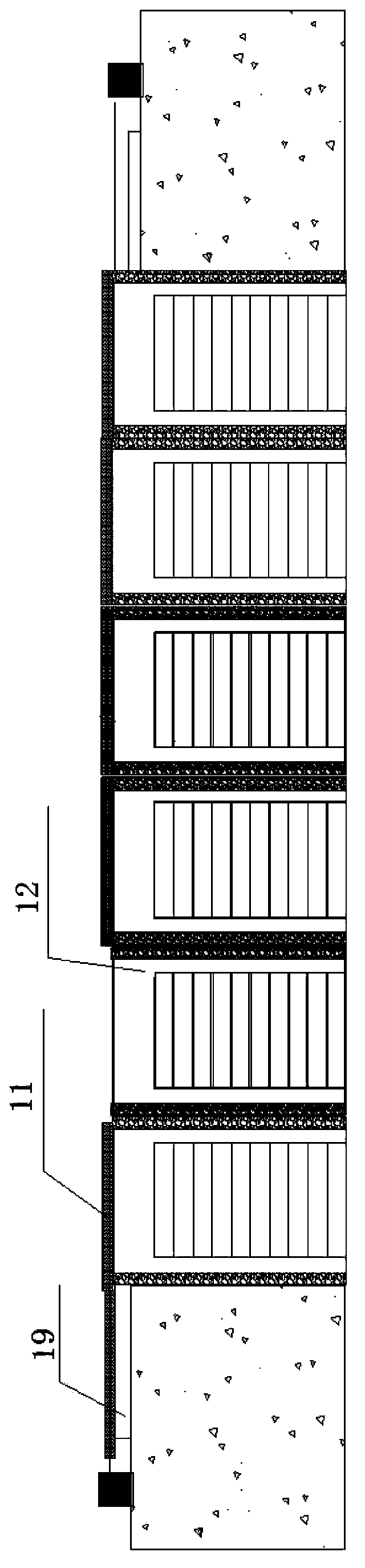

Double-lifted pipe catalytic cracking device and method thereof

ActiveCN105885941AReduce contact timeImprove distributionTreatment with plural parallel stages onlyChemical/physical processesContact timeFuel oil

The invention discloses a double-lifted pipe catalytic cracking device. The double-lifted pipe catalytic cracking device mainly comprises a heavy oil lifting pipe, a light hydrocarbon lifting pipe, a settlement device, regenerators and a catalyst cooler. The regenerators comprise a baffle plate regenerator and a turbulent bed regenerator, the baffle plate regenerator, the turbulent bed regenerator, and the catalyst cooler are coaxially arranged from top to down, the baffle plate regenerator is composed of an outer tube and an inner tube; a top of a circle bench-type cylindrical shell of the catalyst cooler is taken as a main wind outlet of the catalyst cooler for connecting with the bottom of a prevulcanization segment of the inner tube of the baffle plate regenerator; the bottom of the settlement device is communicated to a spent catalyst of the baffle plate regenerator, and the bottom of the catalyst cooler is respectively communicated to the bottom of the heavy oil lifting pipe and the light hydrocarbon lifting pipe through pipelines. By adopting the device disclosed by the invention, various heavy oil feed stocks and light hydrocarbon feed stocks are processed, a relatively short oiling agent contact time can be achieved, and the product quality is improved.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

Slab burial pit with adjustable cooling speed

The invention discloses a slab burial pit with an adjustable cooling speed. The slab burial pit comprises a pit body, a pit cover, a pit wall, a heating burner, an air door and a chimney, wherein the pit body is encircled by the pit wall, and buried under the ground; the pit cover is covered on the top; the heating burner is arranged at one side; the air door and the chimney are arranged at the other opposite side; the opening of the air door is adjustable. By adopting the technical scheme disclosed by the invention, the slab temperature can be flexibly adjusted according to the production rhythms of the upper and lower procedures, the slab is prevented from generating a stress crack, meanwhile, the capability of simultaneously slowly cooling large quantities of slabs is provided, and the problem of rapid cooling of the slab in fact caused by ambient cold air also can be avoided in the process of storing the slab. Meanwhile, normal logistics above the ground is not affected under the condition that the large quantities of slabs are simultaneously slowly cooled by the pit body arranged below the horizontal plane, and the slow cooling requirements of the slab are completely met.

Owner:BAOSTEEL STAINLESS STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com