Patents

Literature

53results about How to "Flexible pressure adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

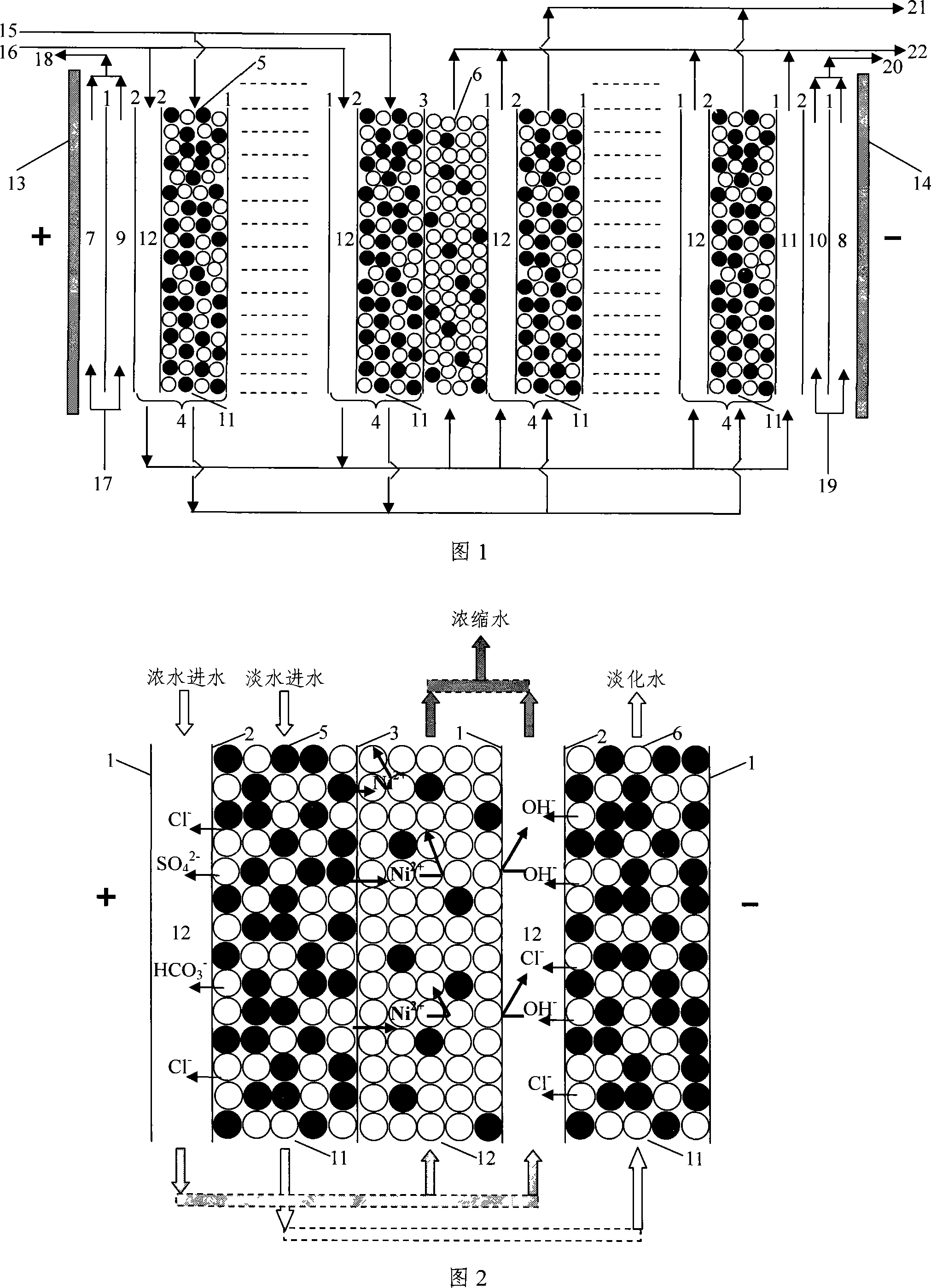

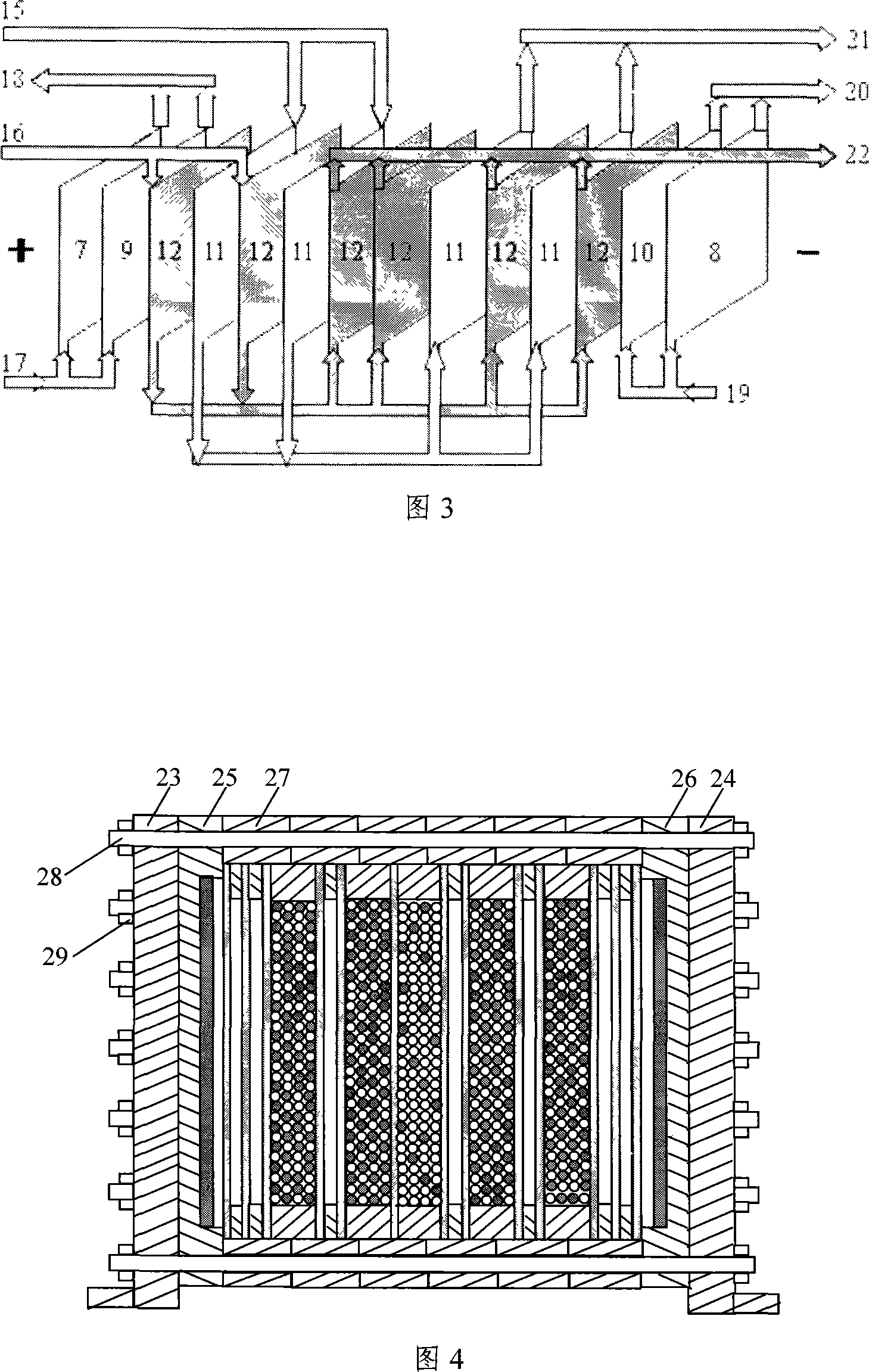

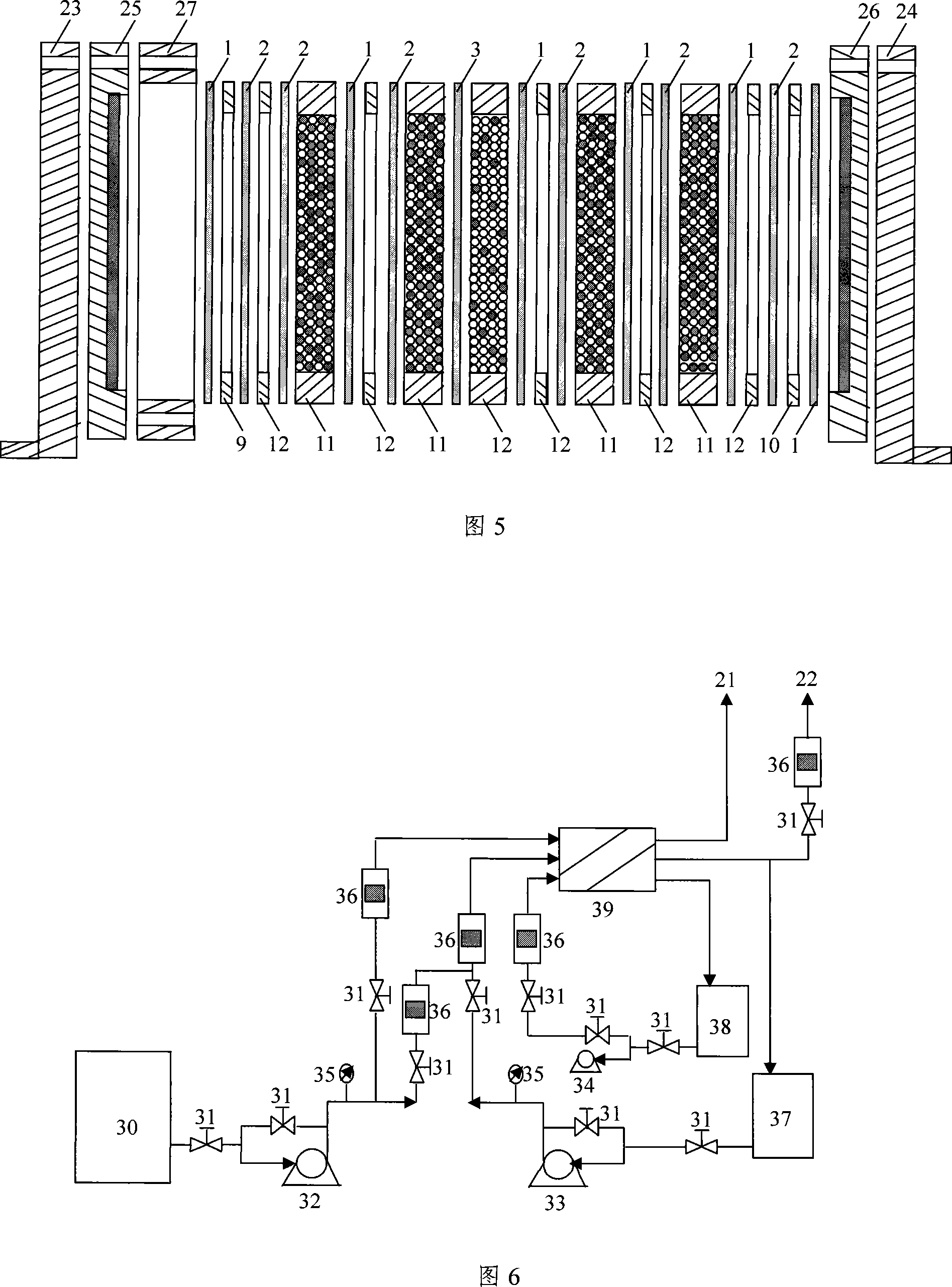

Electro-deionization method and device for synchronously concentrating and purifying heavy metal wastewater

InactiveCN101200325ALow flow resistanceImproved hydrodynamic propertiesDispersed particle separationWater/sewage treatment by ion-exchangeStrong acidsPollution

The invention relates to an electro-deionization method and device for concentrating and purifying heavy metal wastewater synchronously, belonging to a wastewater treatment technique, which adopts first-stage two-section or first-stage multi-section electro-deionization device, wherein the inner sides of the positive and negative poles are arranged with corresponding pole protection chambers, the desalting chamber is filled with large-hole strong-acid strong-base mixed bed resin with narrow particles distributed; cation exchange film is adopted as the direction-turning film, after direction-turning, two adjacent concentration chambers are arranged continuously, both are separated by cation exchange film, simultaneously after direction-turning, the first concentration chamber is filled with large-hole mixed bed resin with the volume of cathode resin more than 50 percent, the heavy metal wastewater to be treated enters the desalting chamber and the concentration chamber in two paths, the heavy metal ion and cathode in the desalted water flow are transferred into the concentration chamber so as to obtain the desalted water, the concentrated water flow is partially circulated or closely circulated so as to obtain the concentrated liquid of metal wastewater, thereby recycling valence metals and pure water resources synchronously and realizing zero emission and resource treatment of wastewater. Compared with the prior art, the wastewater treatment process has higher separation efficiency, more reliable operation, more convenient operation, continuous process operation and no secondary pollution.

Owner:NANKAI UNIV

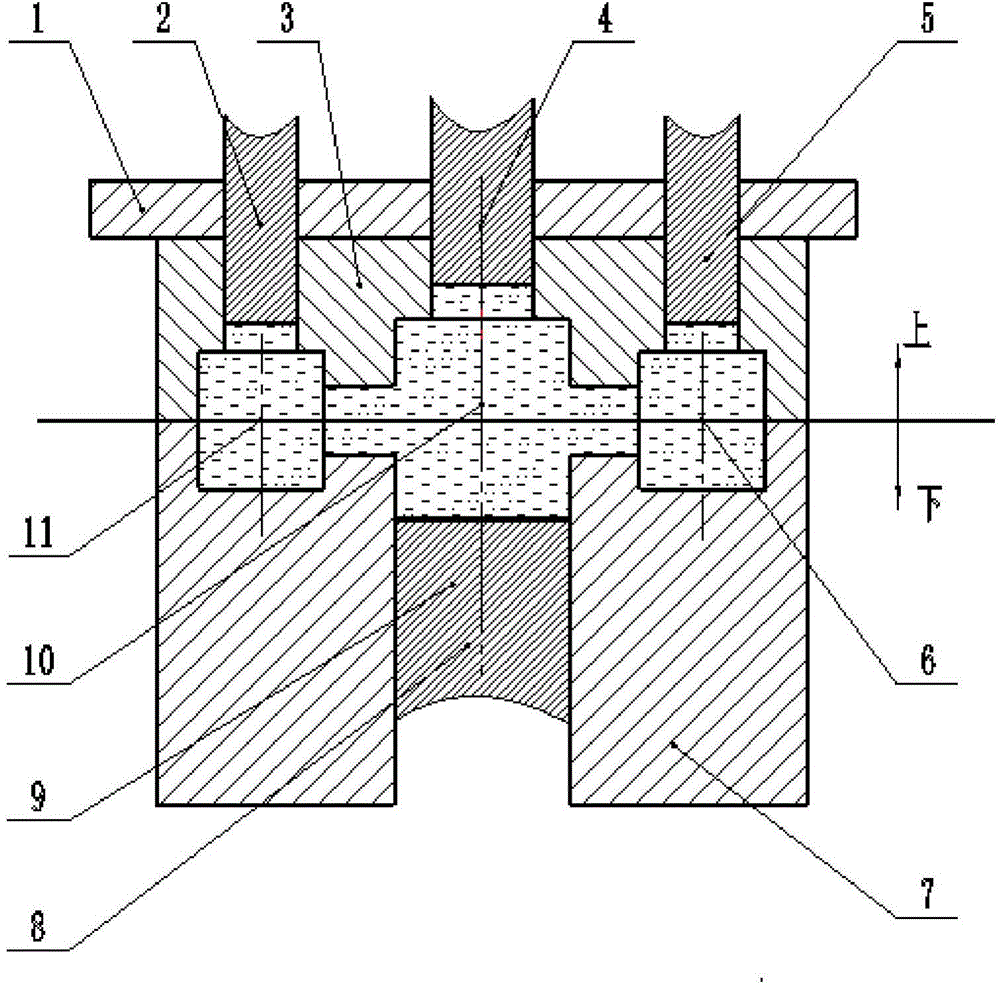

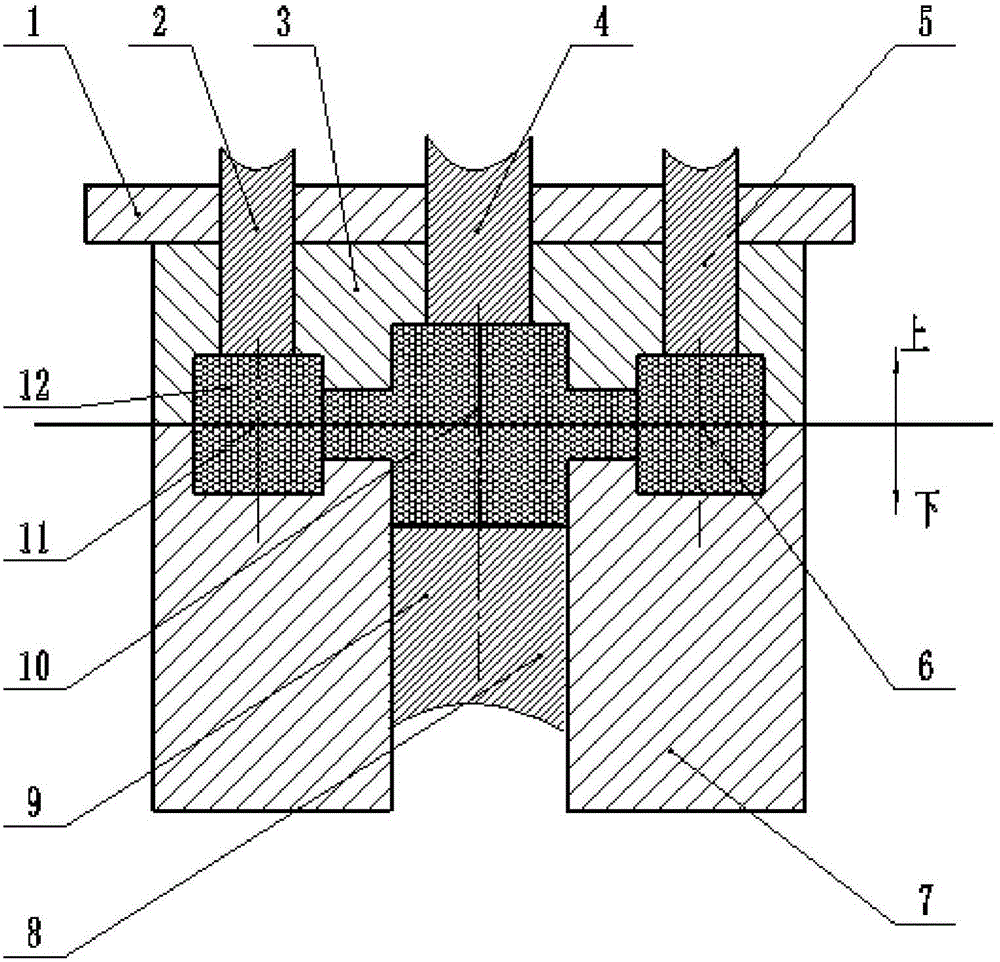

Multi-point pressurizing type hydraulic die forging method

The invention discloses a multi-point pressurizing type hydraulic die forging method. The method comprises the steps of S1, adjusting the position and travel of each feeding pressing head to make ensure the feeding pressing head is at each corresponding hot spot position of a component and the travel of each feeding head is more than the density compact compression amount of the corresponding hot spot position; S2, pouring molten liquid under a temperature exceeding the temperature of liquid phase line of alloy into a die cavity or a pressing cavity which communicates with the die cavity; S2, fast closing the die, and applying a locking force to lock the die; S4, pressurizing the molten alloy to enable flowing and filling in the whole die cavity; S5, sequentially or synchronously applying a force to each hot spot position of the component and the pressing cavity to enable the molten alloy at the hot spot position to be fast solidified and subjected to rheological feeding until completely solidifying; S6, releasing all pressures, opening the die and removing the component. With the adoption of the method, the problem of liquid forging of large complex component can be effectively solved; the method has the advantages of being small in investment, free of shrinkage defect in the component, stable in product quality, and wide in applicable scope.

Owner:BEIJING JIAOTONG UNIV

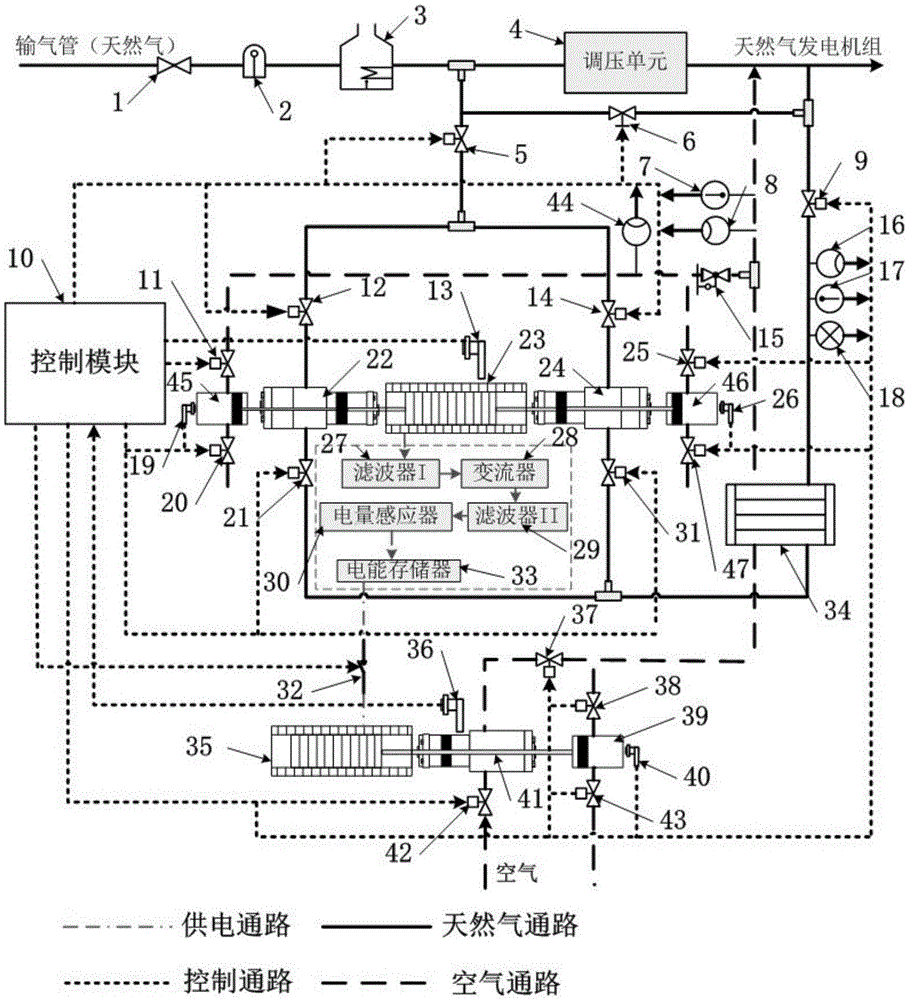

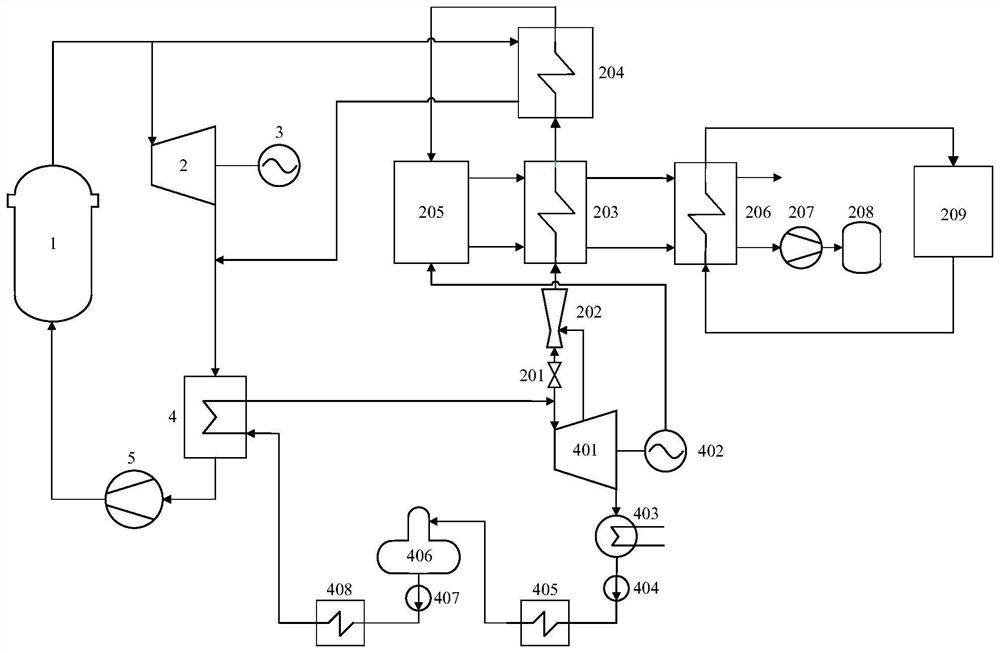

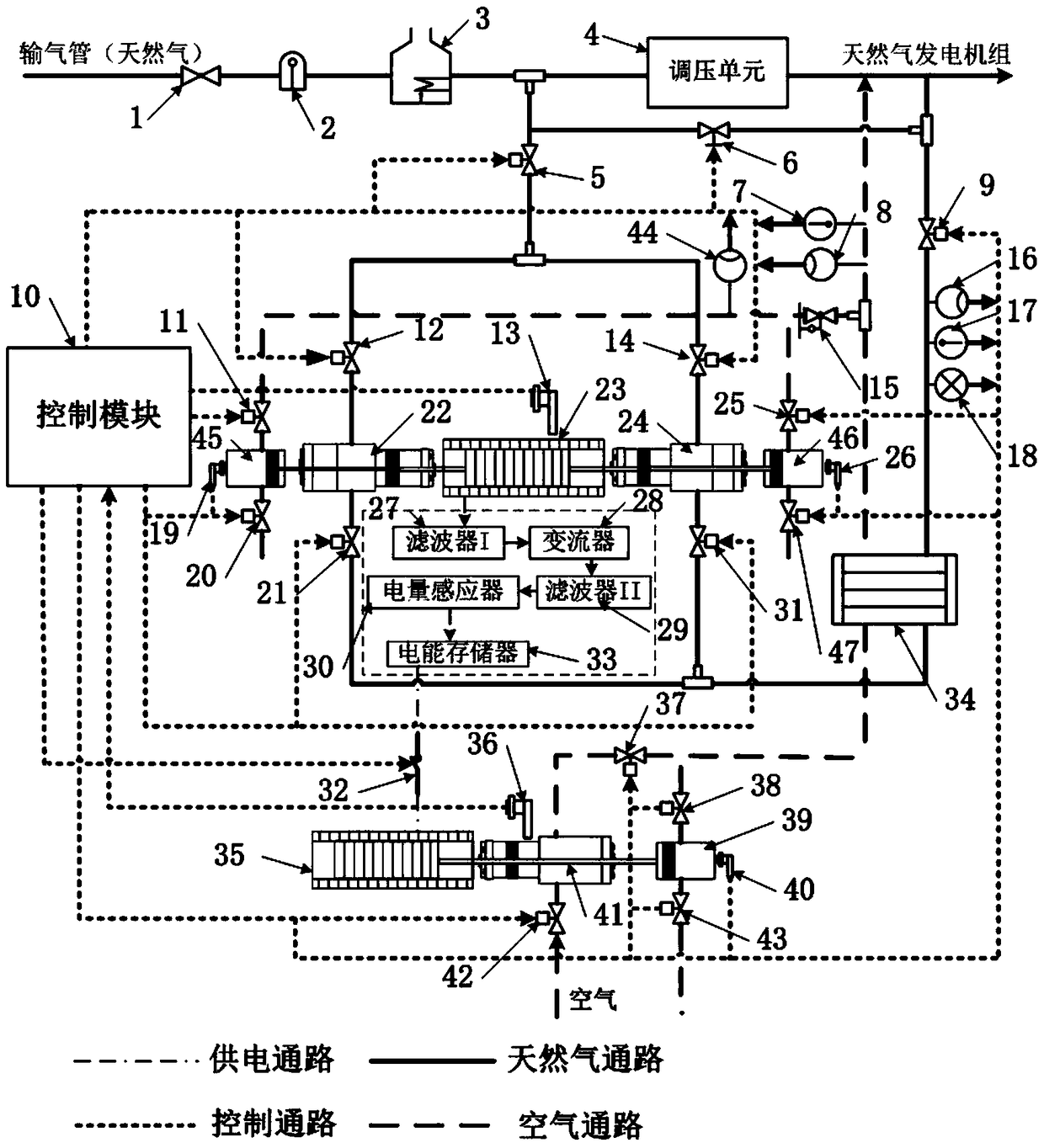

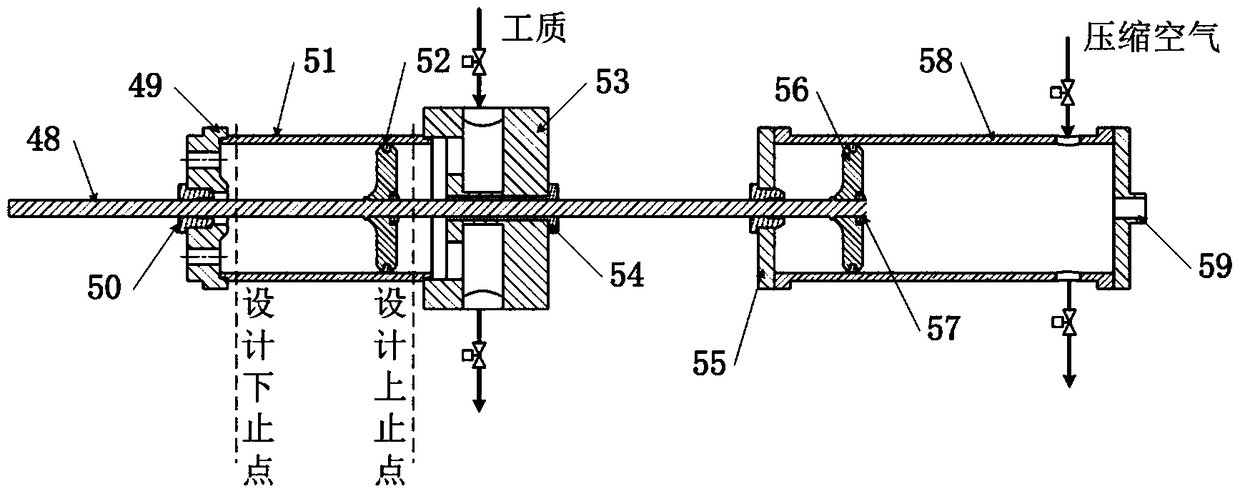

Pressurization system based on free piston expansion/compressor-linear motor

InactiveCN105422182ACompact structureHigh degree of mechatronicsMachines/enginesSafety/regulatory devicesPressure.driveCircuit switching

The invention discloses a pressurization system based on free piston expansion / compressor-linear motor. The system mainly consists of four parts, including an excess pressure recycling system, a circuit switching system, a pressurization system and a control system. The pressurization system disclosed by the invention can be used for transforming excess pressure energy in a gas conveying pipeline of a natural gas driven generator set into electric energy and storing the electric energy, simultaneously driving a free piston expansion / compressor to compress air and then respectively supplying the compressed air to a gas charging system of the natural gas driven generator set and a pressure regulation system of the free piston expansion / compressor. In comparison with a current excess pressure driven power generation system which adopts a turbine type machinery as an acting unit, the excess pressure driven power generation system has the advantages of being reliable in work, high in system energy utilization rate and mechanical and electrical integration degree and flexible in regulation on pressure fluctuation of natural gas or pressurized air at the outlet of the expansion / compressor.

Owner:BEIJING UNIV OF TECH

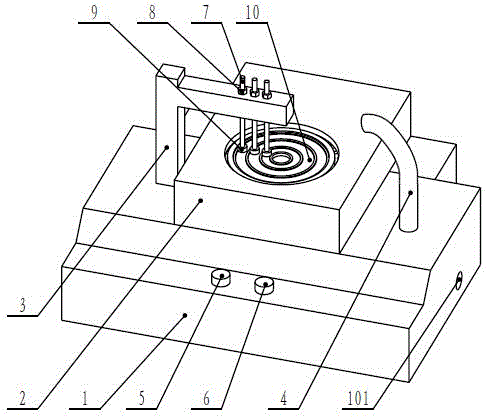

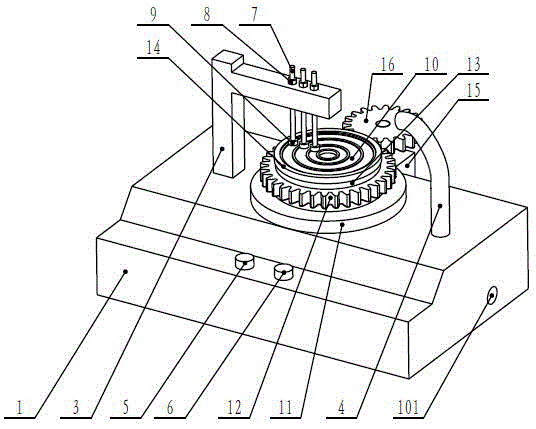

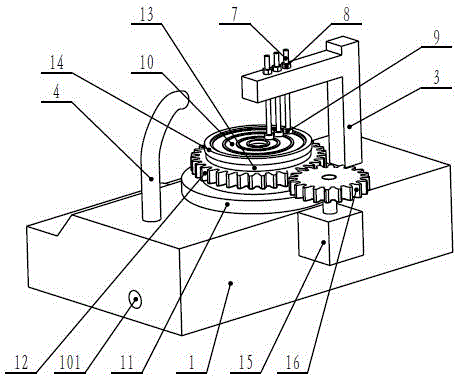

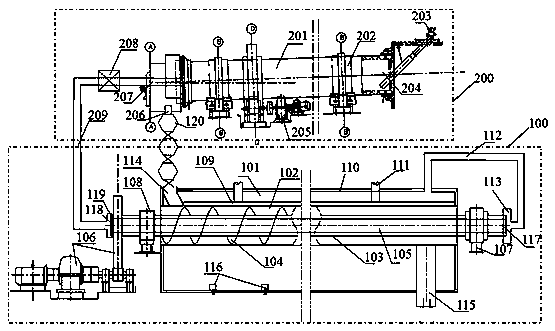

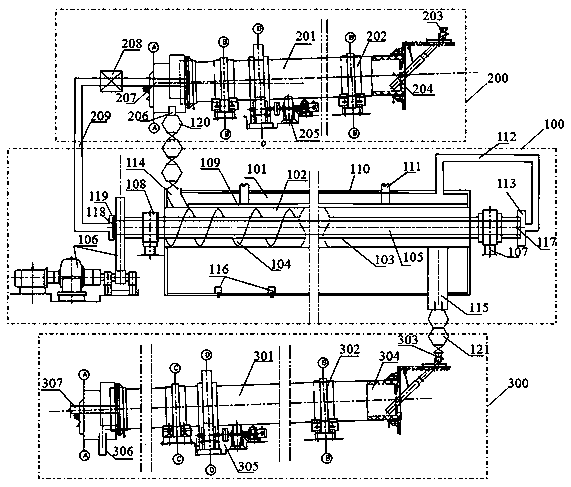

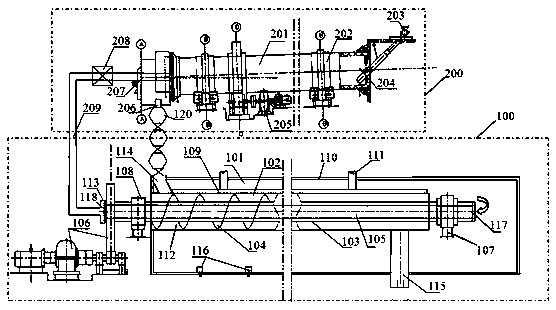

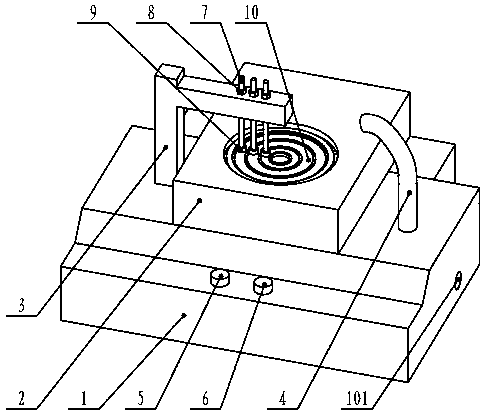

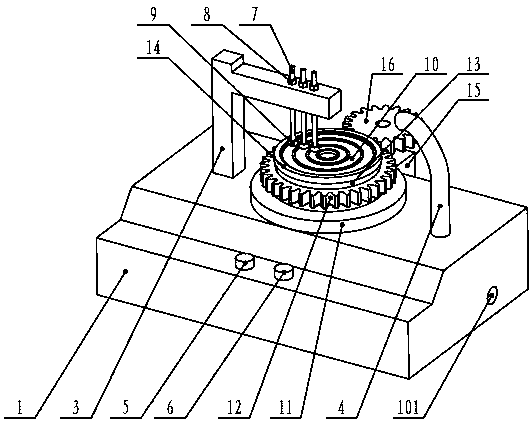

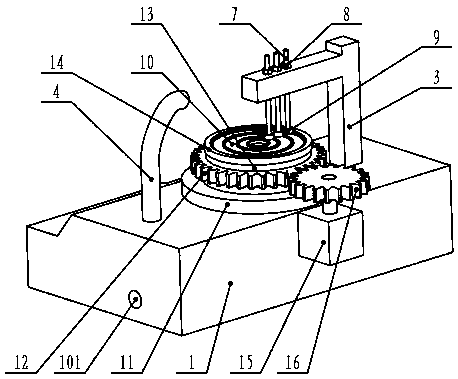

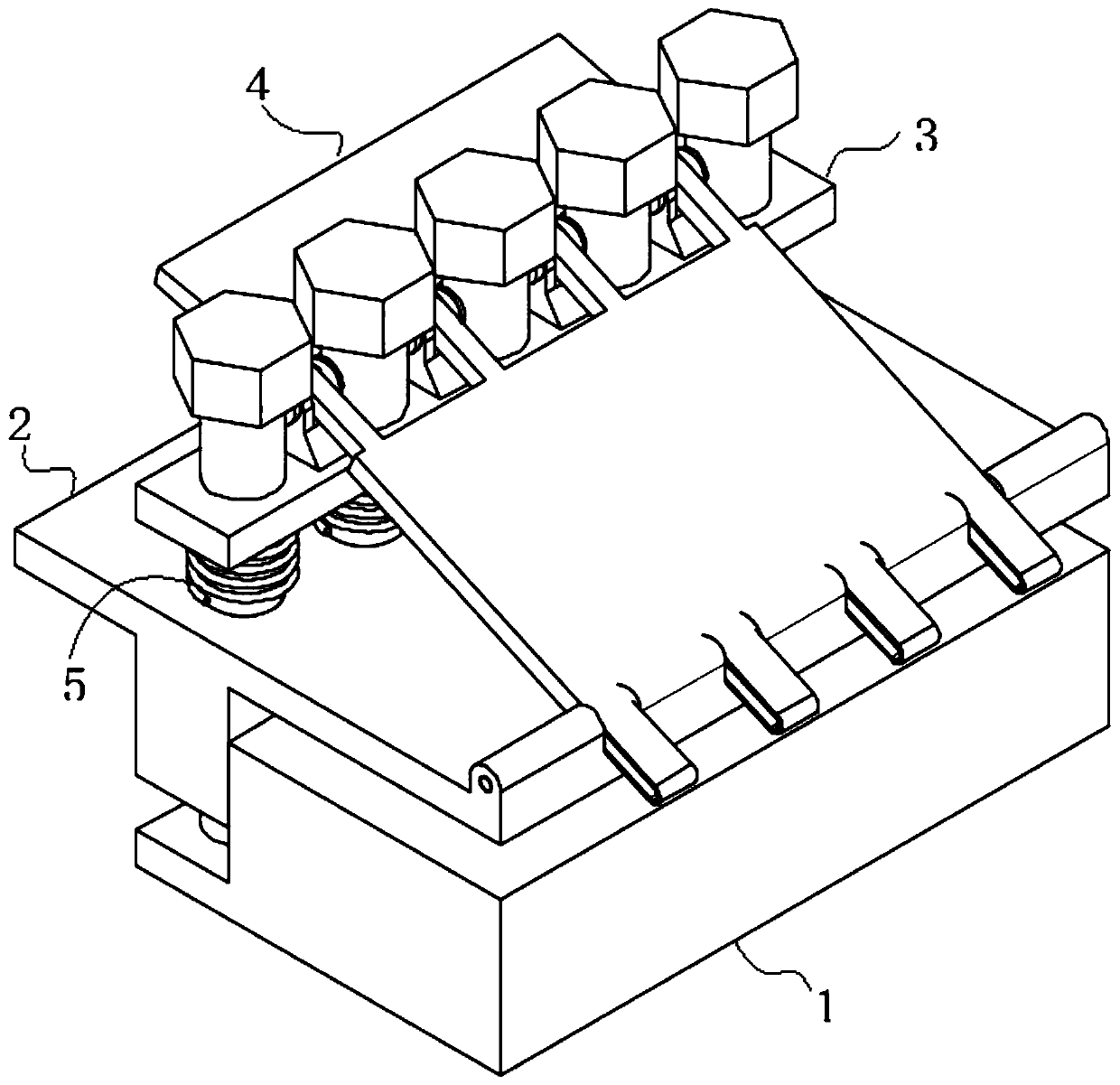

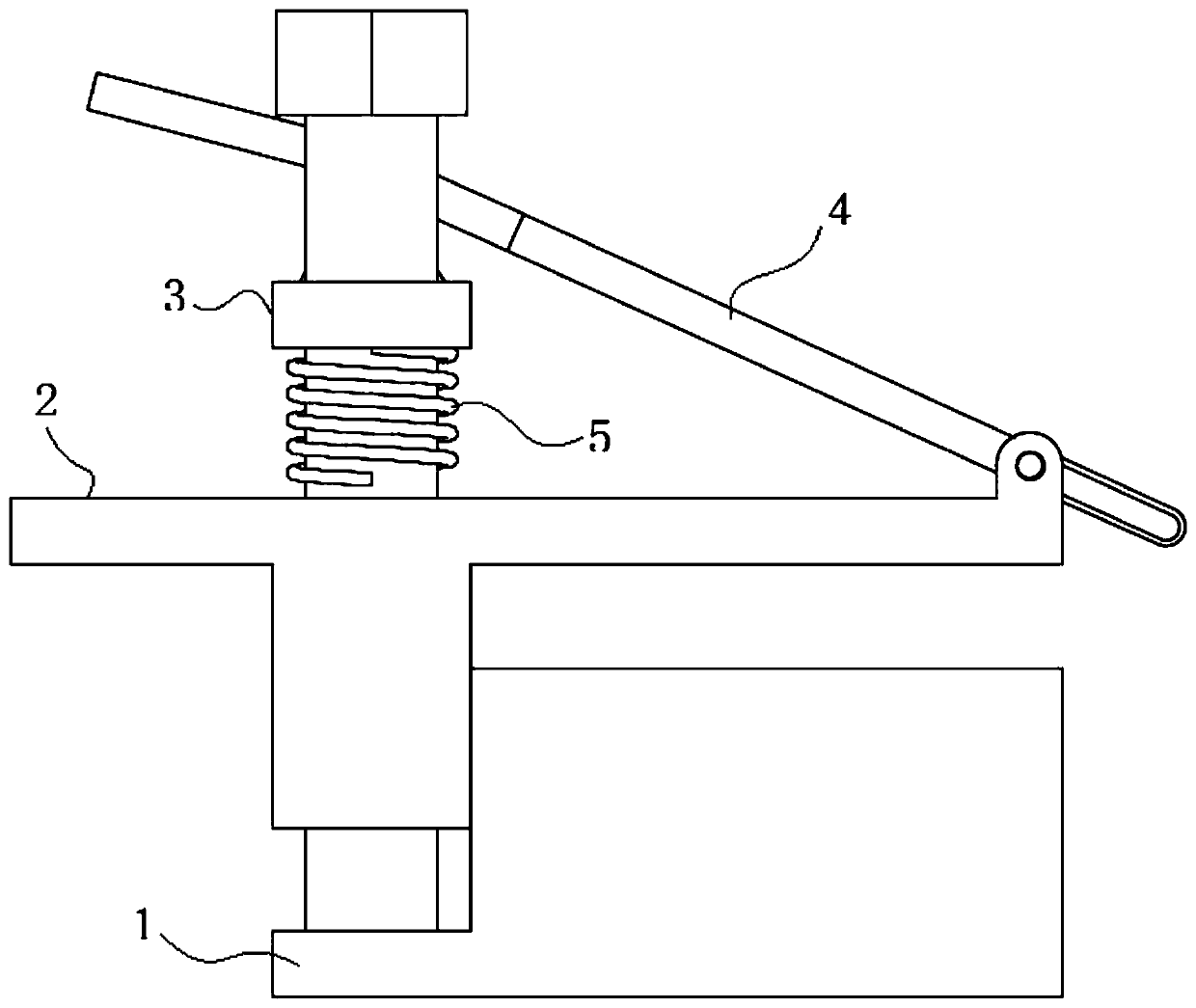

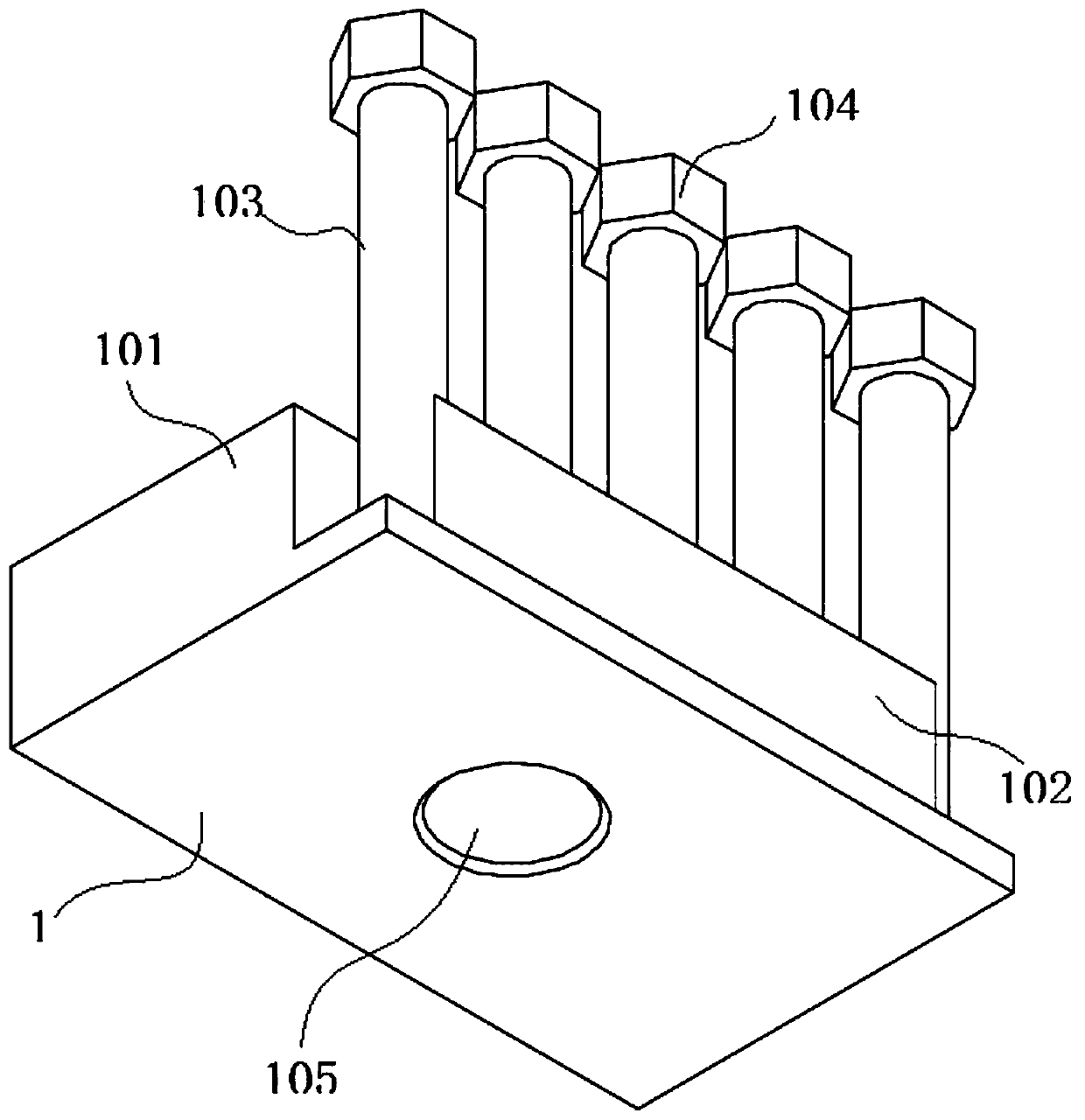

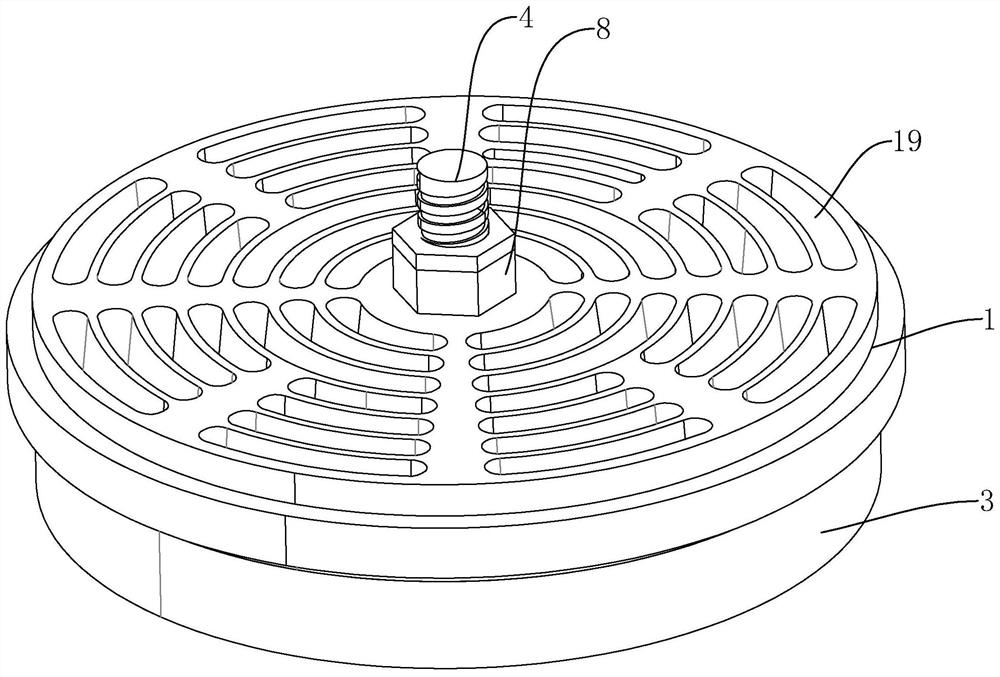

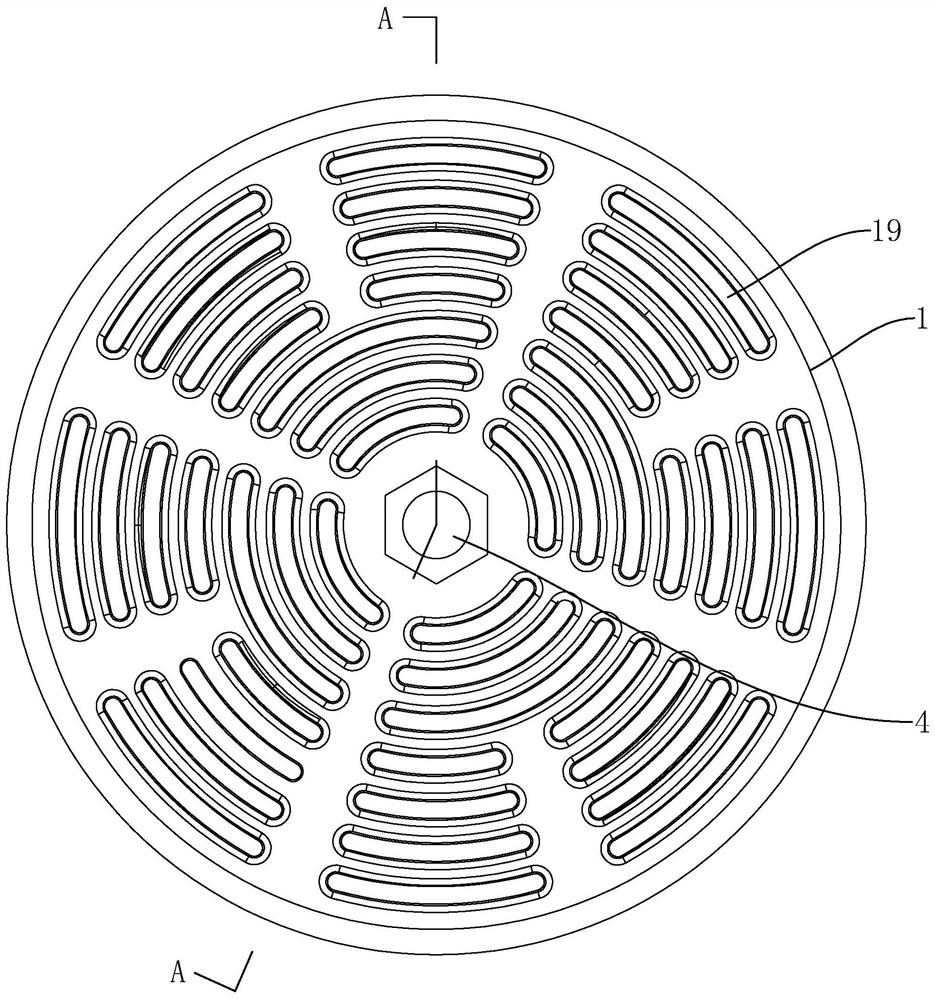

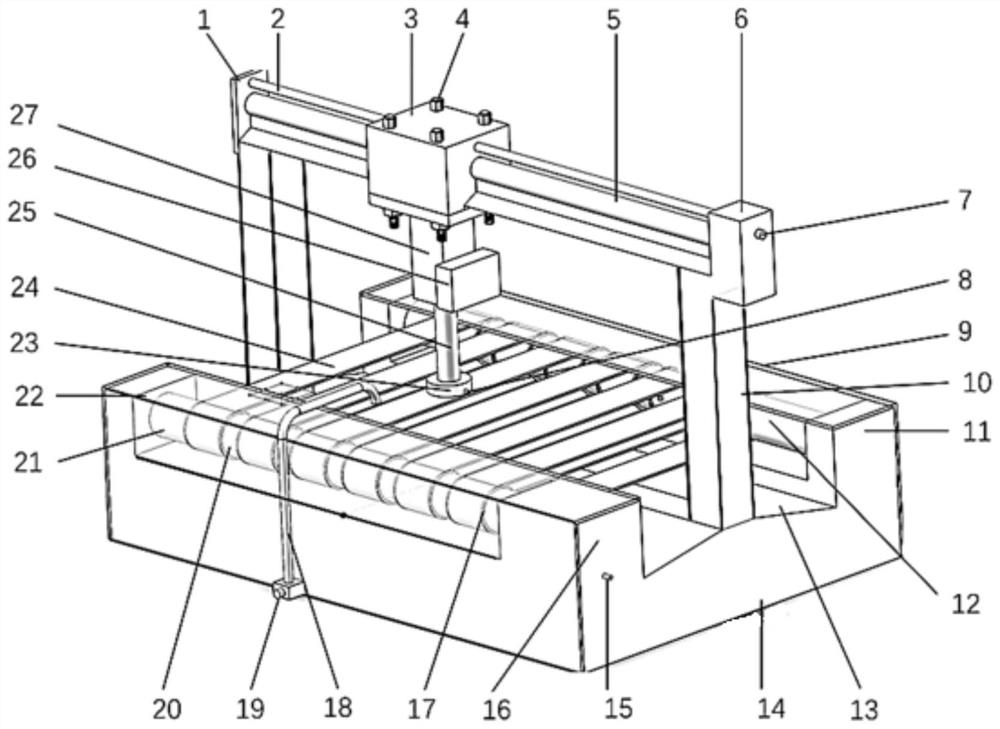

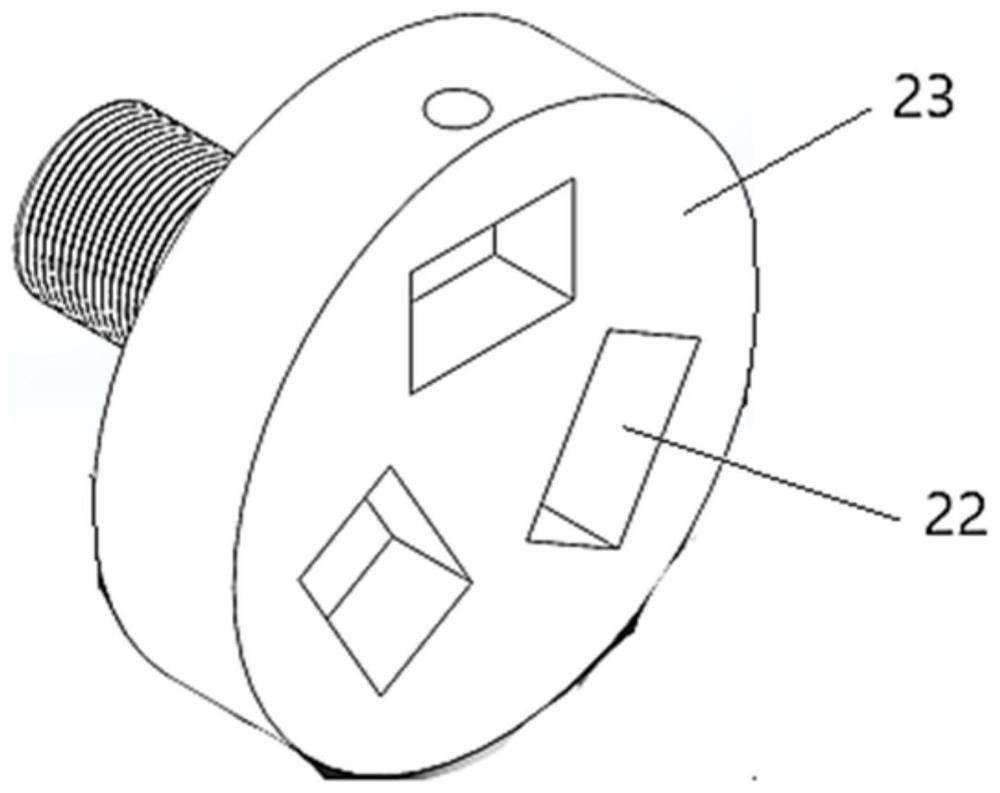

Automatic grinding machine for metallographic specimens

ActiveCN105547781AImprove work efficiencyFlexible pressure adjustmentPreparing sample for investigationEngineeringDrive motor

The invention discloses an automatic grinding machine for metallographic specimens, which comprises a basal body, an automatic adjusting stand, a spray pipe, a swivel bearing, a driving motor, a driving gear, a driven gear, a rotating disk and a sandpaper pad, wherein the swivel bearing is fixedly mounted on the basal body, the driven gear is fixedly mounted on the swivel bearing, the driven gear is engaged with the driving gear mounted on a spindle of the driving motor, and the driving motor is fixedly mounted at the back side position of the basal body. The rotating disk is fixedly mounted at the upper part of the driven gear, and the sandpaper pad is fixedly mounted above the rotating disk. The automatic adjusting stand is vertically mounted at the upper part of the basal body, adjustable pressing rods are arranged on a crossbeam of the automatic adjusting stand, and adjustable pressing blocks are mounted at the lower parts of the adjustable pressing rods. The spray pipe is fixedly mounted on the basal body. By arranging the multi-layer annular sandpaper pad and the adjustable pressing blocks, the working efficiency of the automatic grinding machine is increased, and moreover, the pressure between a metallographic specimen and sandpaper can be flexibly adjusted to meet different grinding requirements; the structure of the automatic grinding machine for metallographic specimens is simple, the design is reasonable, and the cost is low.

Owner:遵化市新宝实业有限公司

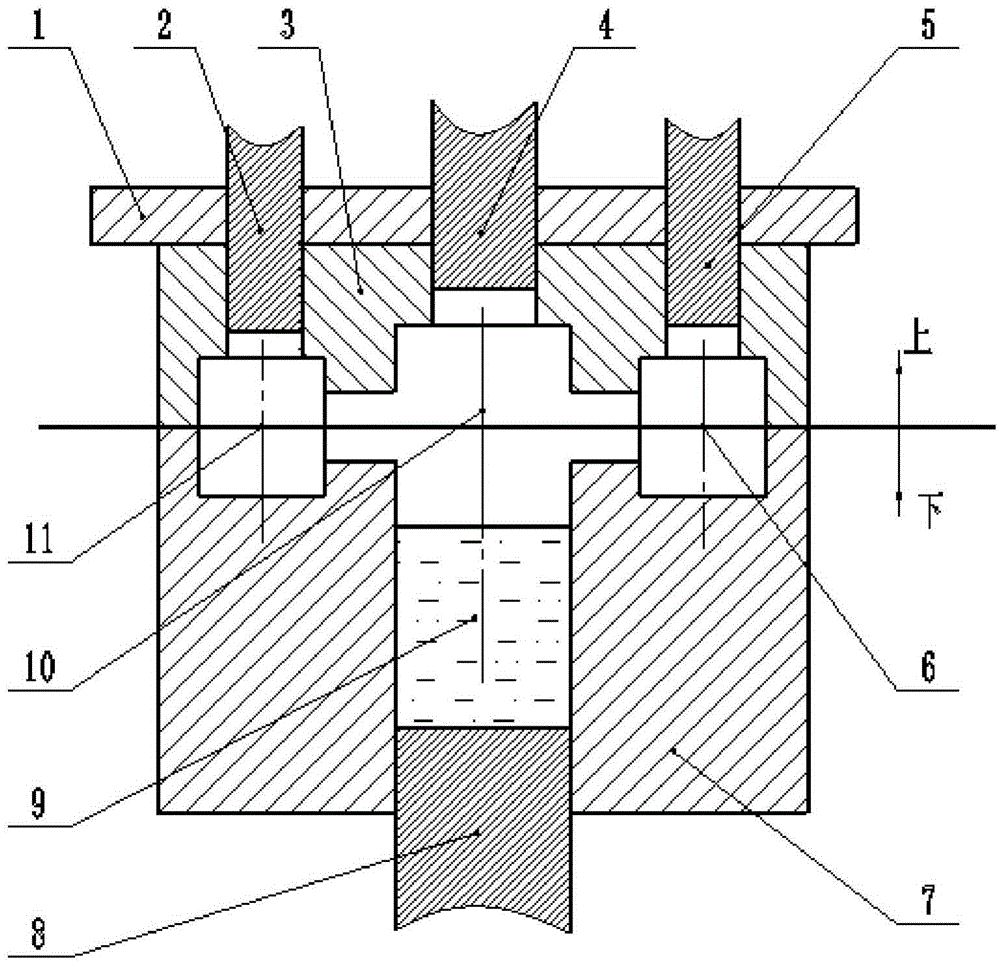

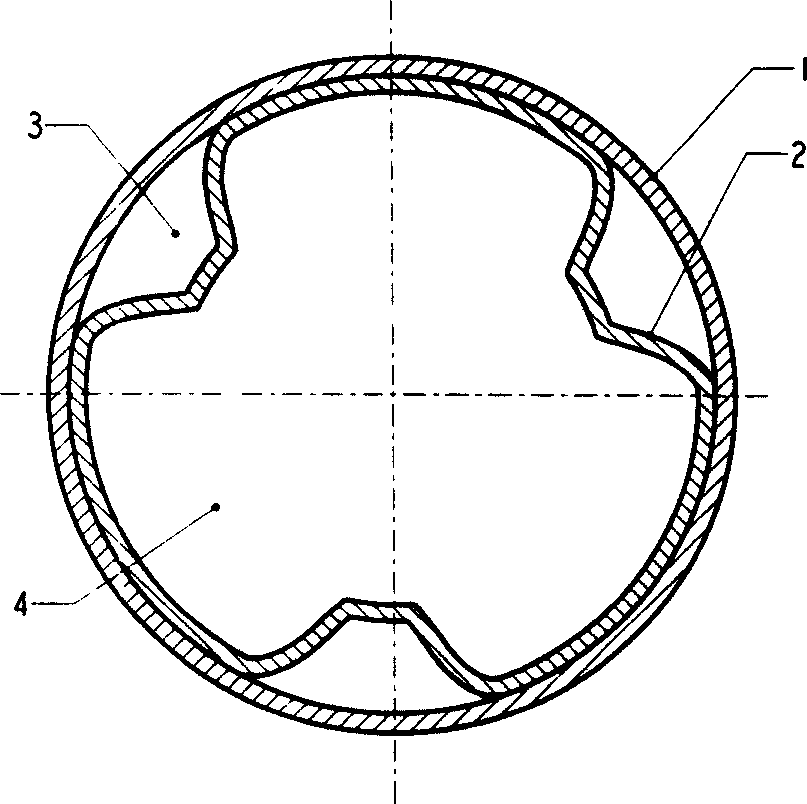

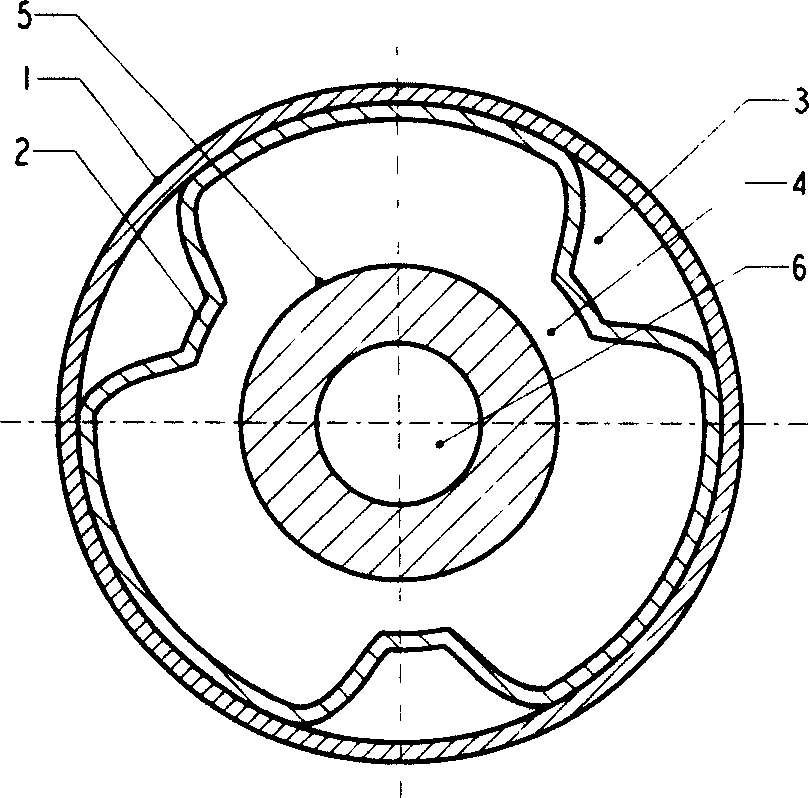

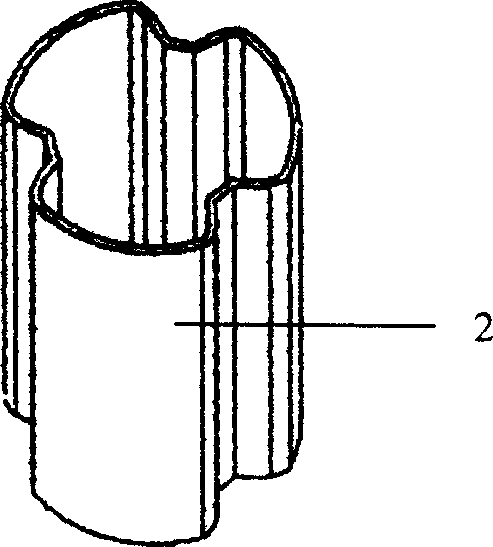

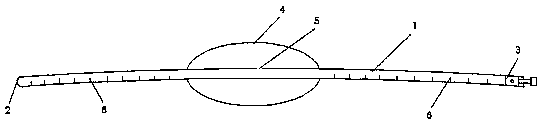

Permanent double layer well body structure for realizing gas well continuous circulation

A permanent double-layer wellbore structure for realizing continuous circulation of oil and gas wells, comprising a cemented casing (1), a thin-walled inner tube (2) added to the casing (1), and the inner tube (2) It can be a shaped tube or a circular tube, so that an annular flow channel (3) is formed between the inner tube (2) and the casing (1), and an inner flow channel (4) is also formed in the inner tube (2). When there is no operating string in the well, the flow channel (3) and the inner flow channel (4) form a circulation loop; and when there is a drill string (5) in the well, the flow channels (3), (4) and the drill string (5) ) The hollow runner (6) forms a circulation loop. In this way, regardless of whether there is a working string in the well, the continuous circulation of drilling fluid can be realized to ensure the safety of drilling operations, especially when the drill string is disconnected due to man-made or fault, the immersed oil and gas can be removed in time to prevent gas accumulation and damage lead to a blowout. The invention is suitable for operations such as well drilling, workover, and well completion, and is especially important for underbalanced drilling, high-pressure, large-volume wells, deep wells, and high-H2S oil-gas wells.

Owner:SOUTHWEST PETROLEUM UNIV

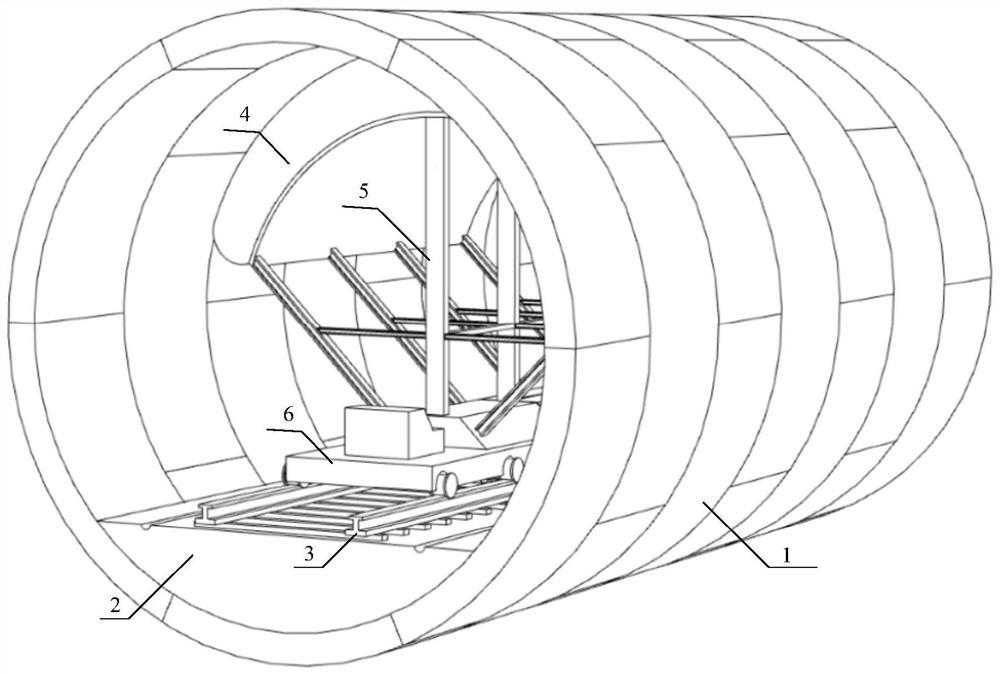

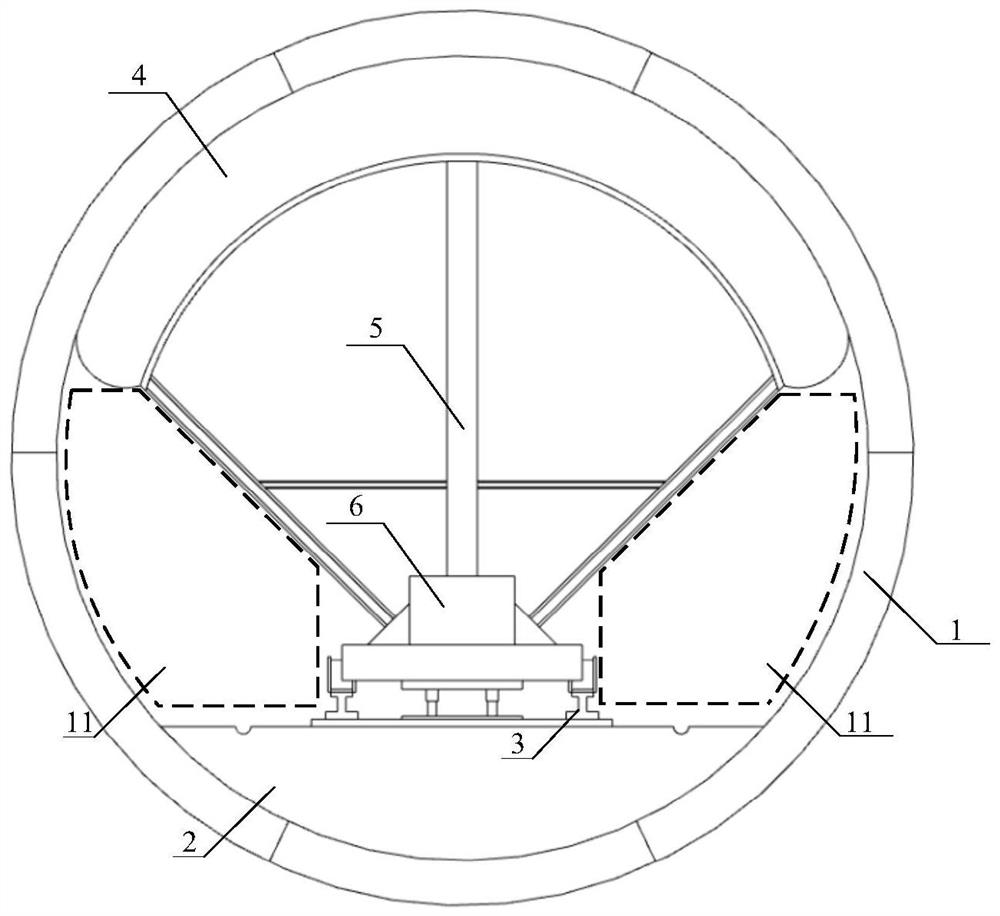

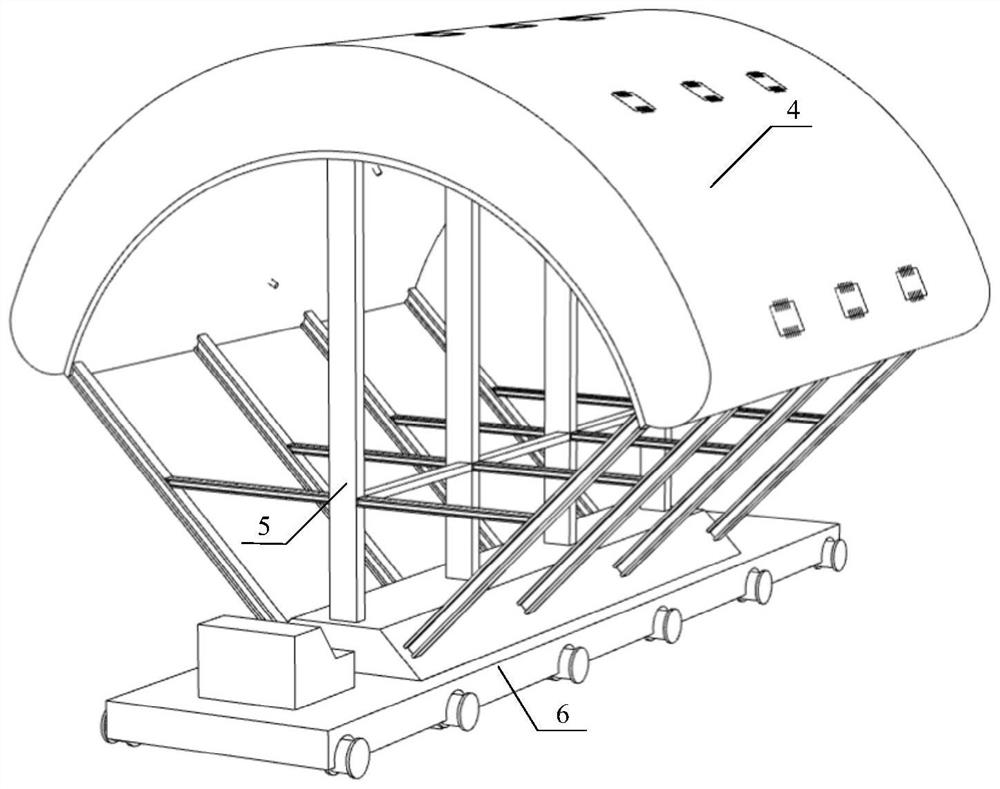

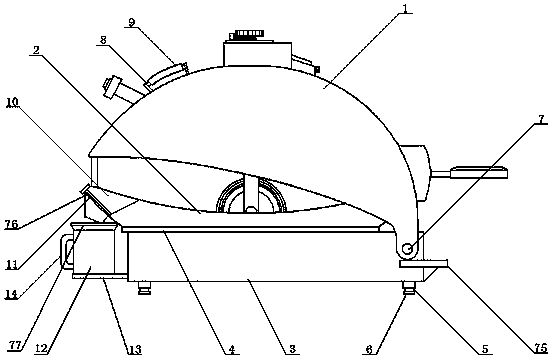

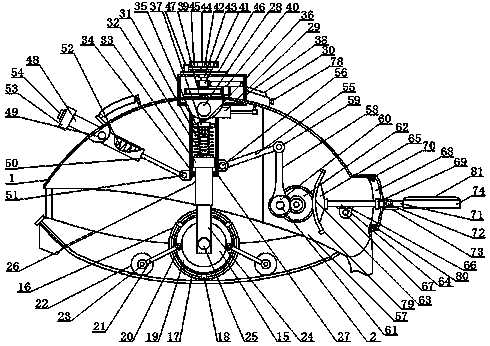

Movable shield tunnel temporary reinforcing platform

InactiveCN112523787AImprove maneuverabilityIncrease flexibilityProtective coversStructural deformationTrackway

The invention discloses a movable shield tunnel temporary reinforcing platform. The movable shield tunnel temporary reinforcing platform comprises an air bag with the top used for pushing a tunnel structure, an umbrella-shaped support arranged below the air bag and used for supporting the air bag, and a trolley connected to the bottom of the umbrella-shaped support and capable of moving on a track, wherein the trolley can be switched between a traveling state and a parking state. The movable shield tunnel temporary reinforcing platform can be rapidly positioned to the ellipse-change-area tunnel needing to be repaired along the track, the air bag is rapidly pressurized for pushing the tunnel structure, personnel can be prevented from being exposed in the risk tunnel without protective measures for a long time for operation while deformation of the tunnel structure is recovered, sufficient operation space is reserved for permanent reinforcement of the two sides of the tunnel, and a new thought is provided for shield tunnel emergency repair; and besides, when the tunnel is affected by external operation, the platform can reinforce the tunnel in the affected area in advance, the reinforcing position can be flexibly adjusted to adapt to the change of the external operation, and the influence of the external operation on the tunnel structure safety is reduced.

Owner:SOUTH CHINA UNIV OF TECH

TCM pharmacy manual grinding device

The invention relates to a TCM pharmacy manual grinding device, and belongs to the technical field of medical instruments. The TCM pharmacy manual grinding device comprises a machine body, an arc grinding groove is formed in the lower side of the machine body, a grinding fixed base is arranged on the lower side of the arc grinding groove, a powder outlet is formed in the left side of the arc grinding groove, a powder filter sieve is arranged in the powder outlet, a moving roller is arranged in the machine body, an annular grinding wheel is arranged on the outer side of the moving roller, a wheel body fixed frame is arranged on the upper side of the moving roller, a pressing telescopic arm is arranged on the upper side of the wheel body fixed frame, a pressing fixed casing pipe is arrangedon the upper side of the pressing telescopic arm, a grinding counter is arranged on the right side of a grinding fixed rotating shaft, a grinding reset device is arranged on the left side of the pressing fixed casing pipe, a grinding drive guide rod is arranged on the right side of the pressing fixed casing pipe, a swing driver is arranged on the right side of the grinding drive guide rod, and a swing arm is arranged in the swing driver. The device is simple in structure and convenient to use, when traditional Chinese medicines are manually ground in the traditional TCM pharmacy, grinding pressure can be flexibly adjusted, operation is easy, convenient and labor-saving, the grinding effect is good, and the device can be applied and popularized in the traditional TCM pharmacy.

Owner:王寿梅 +1

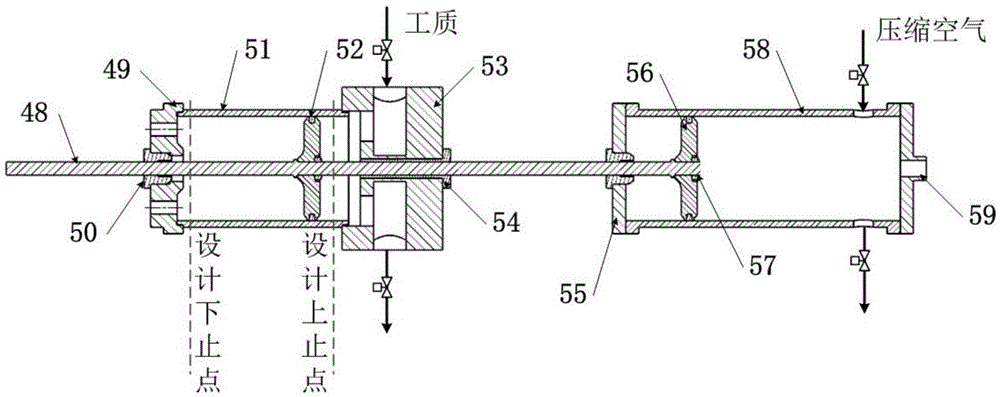

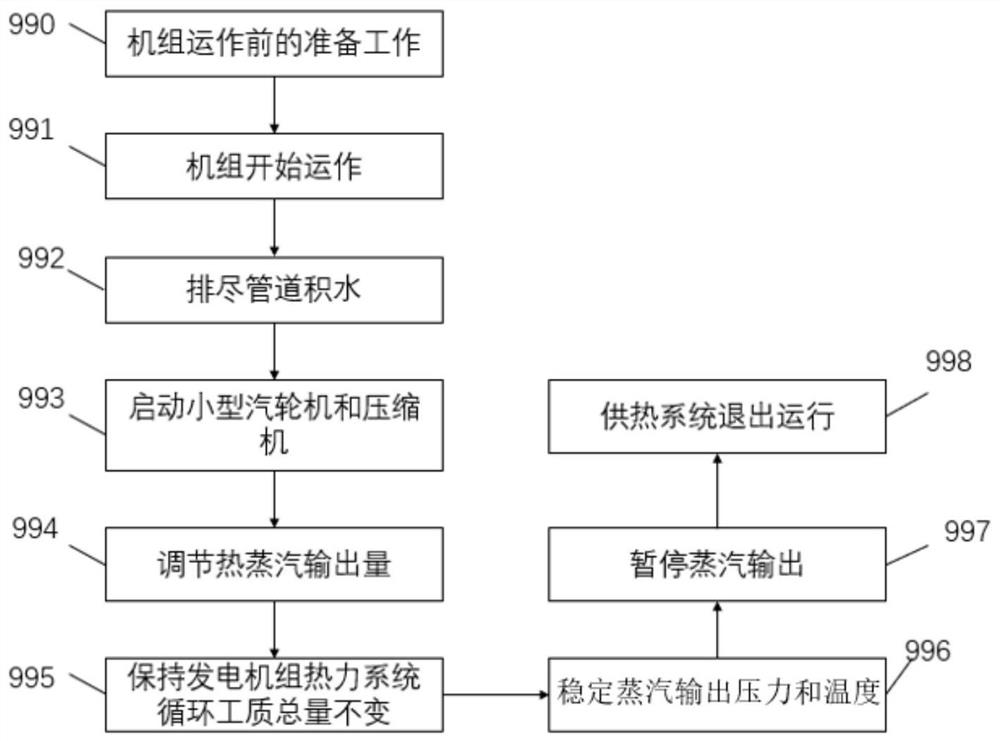

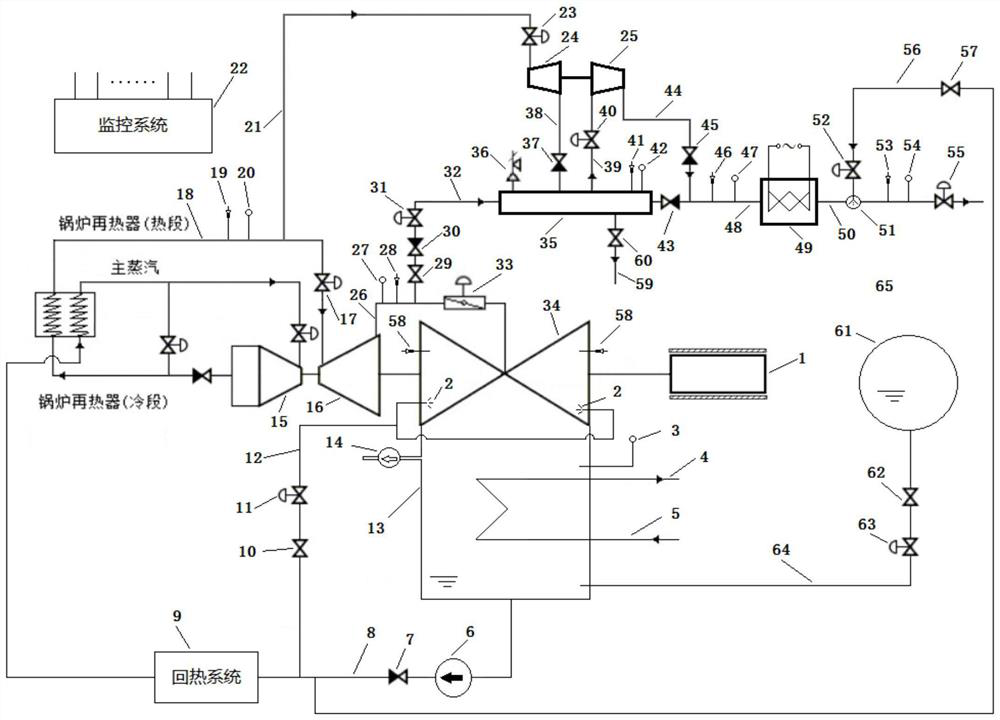

Low-pressure steam source boosting heat supply method for combined heat and power generation unit

ActiveCN112344413AFlexible pressure adjustmentFlexible temperature adjustmentSuperheating controlSteam useSteam pressureWorking fluid

The invention discloses a low-pressure steam source boosting heat supply method for a combined heat and power generation unit. The low-pressure steam source boosting heat supply method for the combined heat and power generation unit comprises the following steps that S101, preparation work before unit operation is conducted; S102, the unit starts to operate; S103, accumulated water in a pipeline is drained as much as possible; S104, a small steam turbine and a compressor are started; S105, the output quantity of hot steam is adjusted; S106, the total amount of cycle working fluid of a thermalpower system of a generator set is kept unchanged; S107, the steam output pressure and temperature are stabilized; S108, the steam output is paused; and S109, a heat supply system quits operation. Themethod can effectively solve the problem that heat supply steam pressure and temperature are flexibly adjusted under the condition that parameters such as through-flow steam pressure and temperatureof a turbine bleed point cannot meet user requirements, so that the heat supply steam parameters meet the requirements of heat consumers, the method does not excessively depend on the method of increasing the electric power of the generator set to increase the steam flow of the steam turbine in order to enhance the steam supply capacity of the unit, and the flexibility of greatly adjusting the electric power of the generator is also improved.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

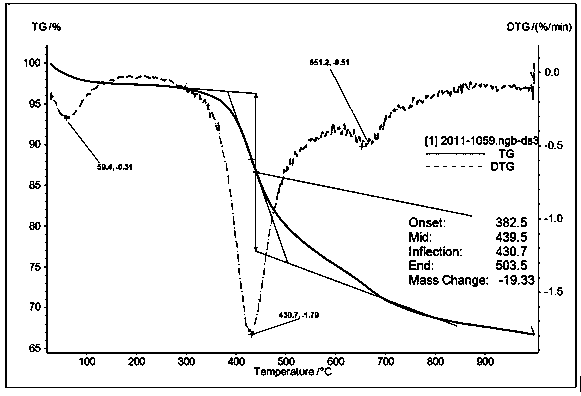

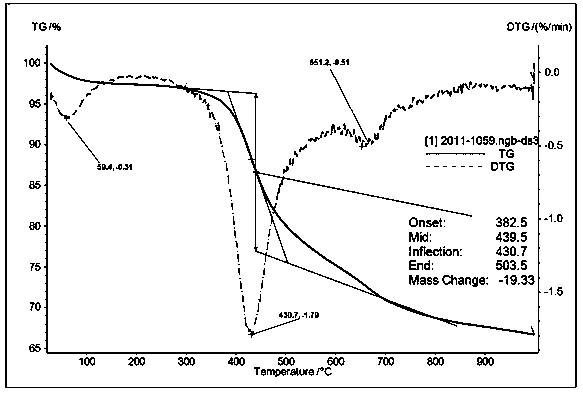

Medium and low coal temperature separate dry distillation system and method

ActiveCN105505421AEfficient dehydrationImprove thermal distillation efficiencySpecial form destructive distillationThermodynamicsCombustion chamber

The invention provides a medium and low coal temperature separate dry distillation system and method. The dry distillation system comprises a spiral pushing medium and low temperature external heating dry distillation device and a low temperature internal heating rotary kiln dry distillation device. A spiral pushing dry distillation chamber in the spiral pushing medium and low temperature external heating dry distillation device is arranged in a combustion chamber of the spiral pushing medium and low temperature external heating dry distillation device, burned smoke in the combustion chamber is circulated back into a rotary kiln cylinder, and solid-state materials in the rotary kiln cylinder are supplied into the spiral pushing dry distillation chamber. For the first time, dry distillation of coal is divided into two or more stages according to temperature, an internal heating rotary kiln and the external heating type spiral pushing dry distillation device are combined organically to achieve dry distillation; the rotary kiln is used for performing winnowing dust removal, preheating drying and dehydration on raw coal, and the external heating type spiral pushing dry distillation device realizes a high-efficiency medium and low temperature dry distillation process and precipitation of high calorific value raw gas and a tar product; the advantages of internal and external heating dry distillation equipment are fully combined, dry distillation efficiency, heat utilization efficiency and dry distillation product quality are greatly improved in a brand new mode, and the market popularization prospect is broad.

Owner:王崇峰

Internal and external heating type medium and low temperature powdered coal temperature division dry distillation system and method

ActiveCN105505422AEfficient dehydrationImprove thermal distillation efficiencyIndirect and direct heating destructive distillationSpecial form destructive distillationProcess engineeringCombustion chamber

The invention discloses an internal and external heating type medium and low temperature powdered coal temperature division dry distillation system and method. The system comprises a spiral pushing medium and low temperature external heating dry distillation device and a low temperature internal heating rotary kiln dry distillation device, wherein a spiral pushing dry distillation chamber in the spiral pushing medium and low temperature external heating dry distillation device is arranged in a combustion chamber of the spiral pushing medium and low temperature external heating dry distillation device, combustion smoke in the combustion chamber is directly supplied to the interior of a rotary kiln cylinder, and solid materials in the rotary kiln cylinder are supplied to the interior of the spiral pushing dry distillation chamber. Dry distillation of coal is divided into two or more phases according to temperature and is achieved through organic combination of the internal heating rotary kiln dry distillation device and the spiral pushing external heating dry distillation device, winnowing and dust removal, preheating and drying and dehydration are conducted on raw coal by means of a rotary kiln, high-efficiency medium and low temperature dry distillation and high-calorific-value raw gas and tar product precipitation are achieved by means of the spiral pushing external heating dry distillation device, the advantages of the internal heating dry distillation device and the external heating dry distillation are fully combined, dry distillation efficiency, heat utilization efficiency and the quality of dry distillation products are improved greatly, and marketing prospects are broad.

Owner:王崇峰

Efficient nuclear energy comprehensive utilization system capable of realizing flexible peak regulation of nuclear power station

ActiveCN113503192AImprove utilization efficiencyFlexible adjustment of power generation loadCellsEnergy inputNuclear powerWater vapor

The invention discloses an efficient nuclear energy comprehensive utilization system capable of realizing flexible peak regulation of a nuclear power station. The nuclear energy comprehensive utilization system comprises a helium-steam combined power generation system, a high-temperature solid oxide water electrolysis hydrogen production system and a seawater desalination system; and the helium-steam combined power generation system is used for generating power through a high-temperature helium Brayton cycle and a steam Rankine cycle and outputting steam to the high-temperature solid oxide water electrolysis hydrogen production system, and the high-temperature solid oxide water electrolysis hydrogen production system is used for electrolyzing the steam to generate hydrogen, oxygen and water vapour and inputting the hydrogen, the oxygen and the water vapour into the seawater desalination system for heat recovery and utilization. According to a principle of gradient utilization of energy, the power generation system, the high-temperature solid oxide water electrolysis hydrogen production system and the seawater desalination system are coupled, flexible adjustment of power generation loads can be achieved, and the high efficiency and flexibility of the whole unit are improved.

Owner:SOUTH CHINA UNIV OF TECH

An automatic grinding machine for metallographic samples

ActiveCN105547781BImprove work efficiencyFlexible pressure adjustmentPreparing sample for investigationEngineeringDrive motor

The invention discloses an automatic grinding machine for metallographic specimens, which comprises a basal body, an automatic adjusting stand, a spray pipe, a swivel bearing, a driving motor, a driving gear, a driven gear, a rotating disk and a sandpaper pad, wherein the swivel bearing is fixedly mounted on the basal body, the driven gear is fixedly mounted on the swivel bearing, the driven gear is engaged with the driving gear mounted on a spindle of the driving motor, and the driving motor is fixedly mounted at the back side position of the basal body. The rotating disk is fixedly mounted at the upper part of the driven gear, and the sandpaper pad is fixedly mounted above the rotating disk. The automatic adjusting stand is vertically mounted at the upper part of the basal body, adjustable pressing rods are arranged on a crossbeam of the automatic adjusting stand, and adjustable pressing blocks are mounted at the lower parts of the adjustable pressing rods. The spray pipe is fixedly mounted on the basal body. By arranging the multi-layer annular sandpaper pad and the adjustable pressing blocks, the working efficiency of the automatic grinding machine is increased, and moreover, the pressure between a metallographic specimen and sandpaper can be flexibly adjusted to meet different grinding requirements; the structure of the automatic grinding machine for metallographic specimens is simple, the design is reasonable, and the cost is low.

Owner:遵化市新宝实业有限公司

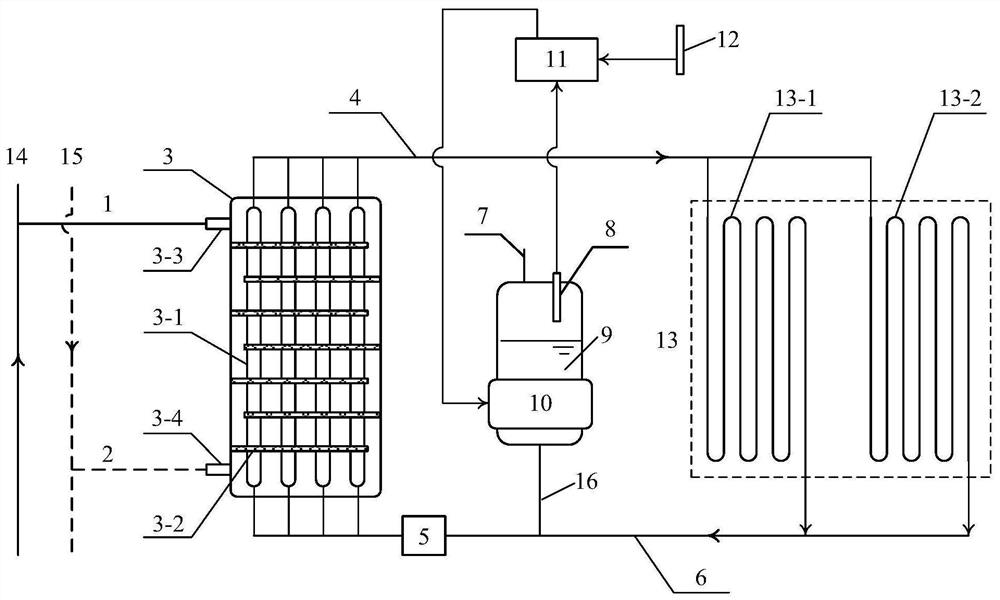

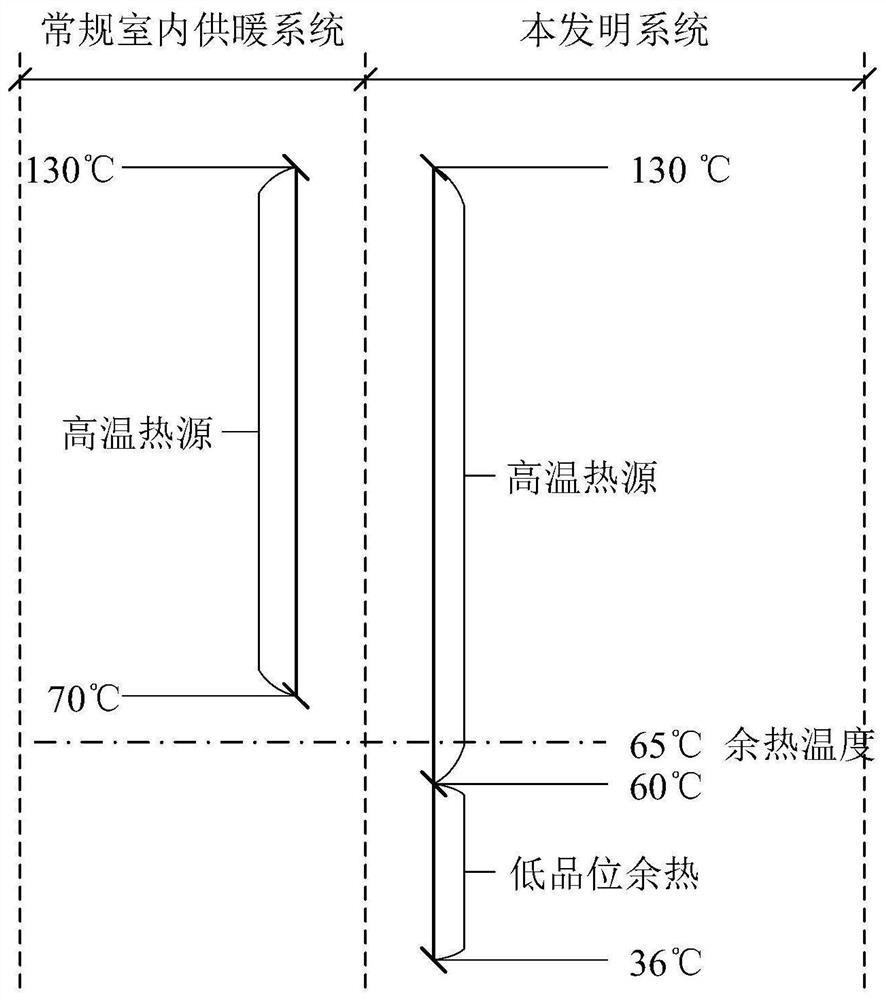

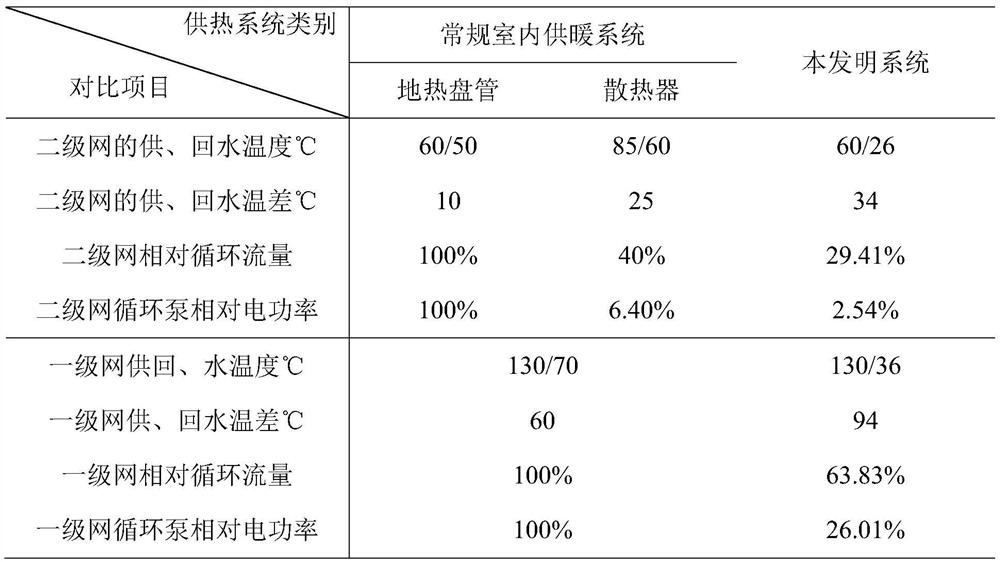

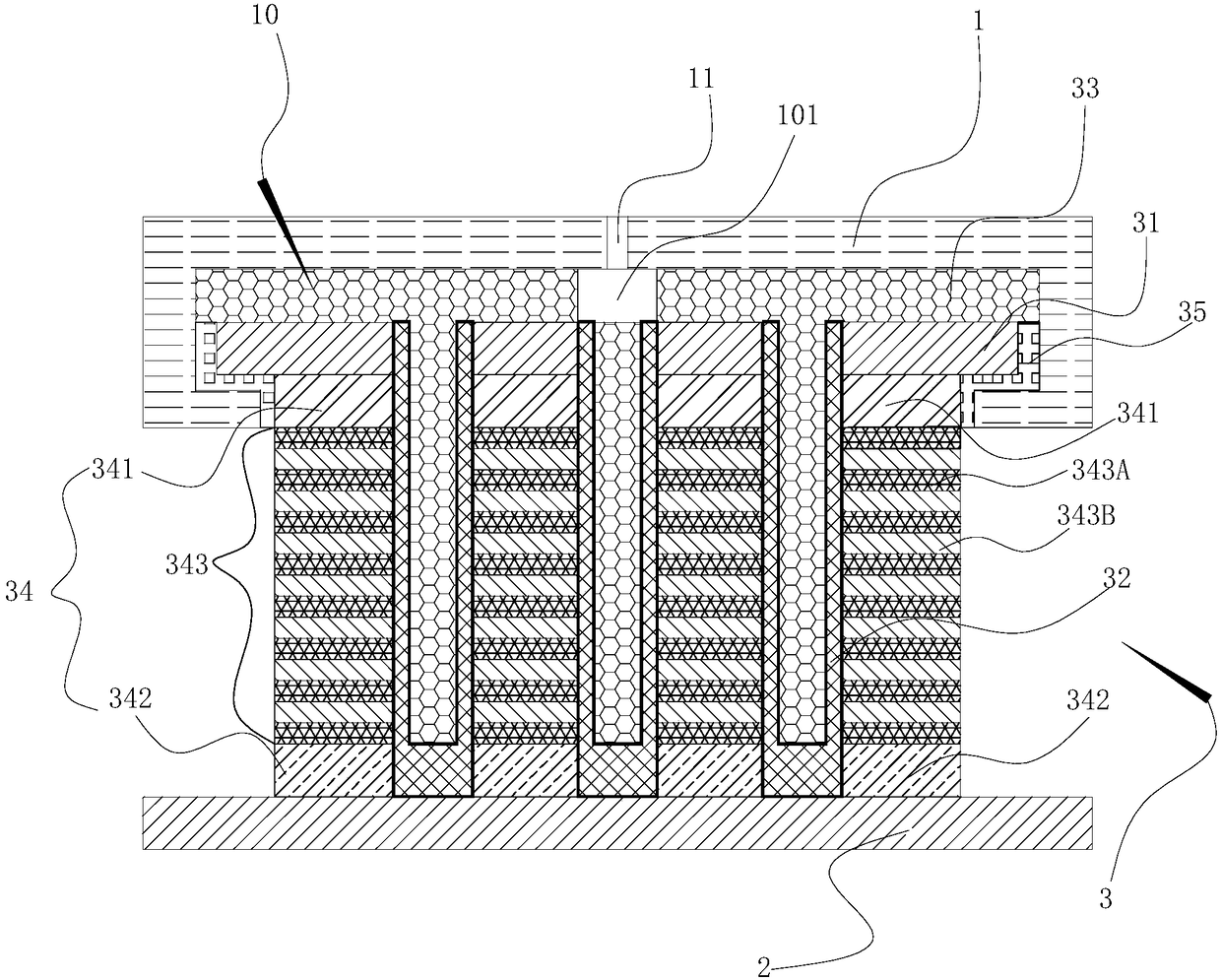

Efficient indoor heating system for capillary pump

ActiveCN111765505ALower return water temperatureIncrease return water temperatureEfficient regulation technologiesSpace heating and ventilation detailsCirculator pumpEngineering

The invention discloses an efficient indoor heating system for a capillary pump. The efficient indoor heating system for the capillary pump comprises a secondary network indoor water supply transversepipe, a secondary network indoor return water transverse pipe, an evaporator, a steam conveying pipeline, a gas-liquid isolator, a liquid conveying pipeline, a pressure sensor, a pressure regulatingstorage device, an electric heating device, a programmable controller, an outdoor temperature sensor and a condenser. The evaporator is provided with a heating medium inflow port and a heating mediumoutflow port, and a plurality of capillary liquid absorbing cores are arranged in the evaporator in parallel. The system can significantly reduce the return water temperature of a secondary network, thereby increasing the supply and return water temperature difference of the secondary network and reducing the circulation pump flow and electric energy consumption of the secondary network; and meanwhile, the primary network return water temperature is reduced, the supply and return water temperature difference of a primary network is increased, the circulation pump flow rate and electric energyconsumption of the primary network are reduced, and energy-saving operation of a transportation and distribution system is realized.

Owner:HEBEI UNIV OF TECH

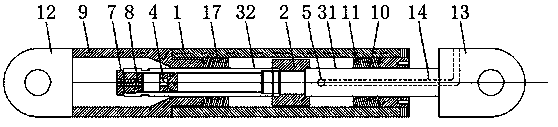

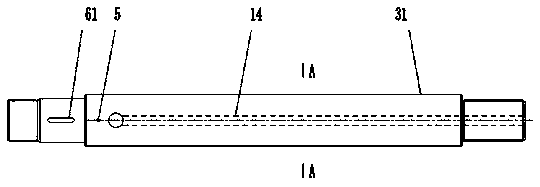

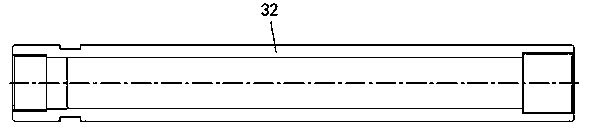

Vibration isolation device

PendingCN108396786AIncrease vertical stiffnessReduce the overall heightProtective foundationEngineeringVibration isolation

The invention relates to a vibration isolation device. The vibration isolation device comprises an upper connection plate (1), a lower connection plate (2) and a vibration reduction and isolation matching assembly (3); the vibration reduction and isolation matching assembly (3) is arranged between the upper connection plate (1) and the lower connection plate (2); the vibration reduction and isolation matching assembly (3) comprises a middle connection plate (31) and a hollow cylindrical supporting piece (32); the middle connection plate (31) is in sealing connection with the upper connection plate (1); a cavity (10) is formed between the middle connection plate (31) and the upper connection plate (1); the cylindrical supporting piece (32) is vertically arranged in the vibration reduction and isolation matching assembly (3); the open end of the cylindrical supporting piece (32) communicates with the cavity (10), so that the interior of the cylindrical supporting piece communicates withthe cavity (10); and the cavity (10) and the cylindrical supporting piece (32) are inflated with compressed gas. Compared with the prior art, the vibration isolation device has a good vibration isolation effect.

Owner:NINGBO UNIV

Clamping-installing type quick clamping mechanism and installation method thereof

ActiveCN109866132AFlexible pressure adjustmentWide range of applicationsWork holdersEngineeringMechanical engineering

Owner:安徽华中机械配套工程有限公司

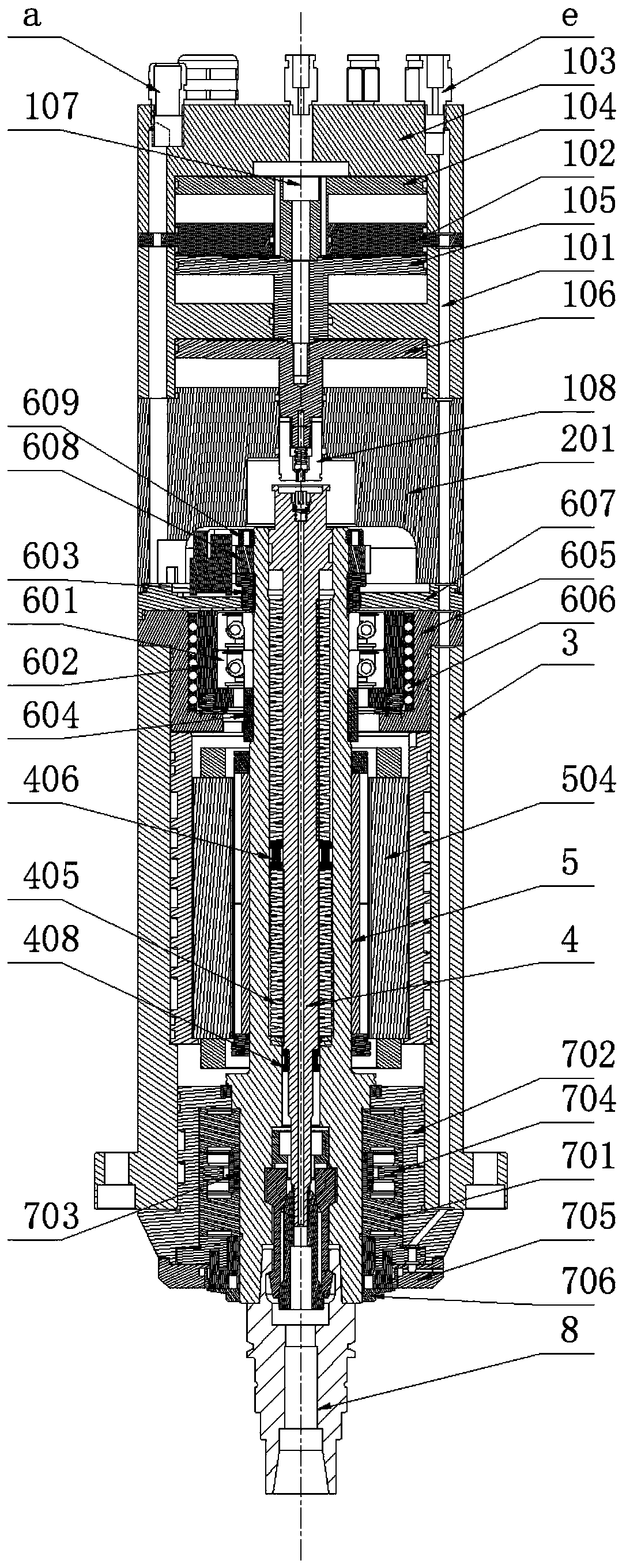

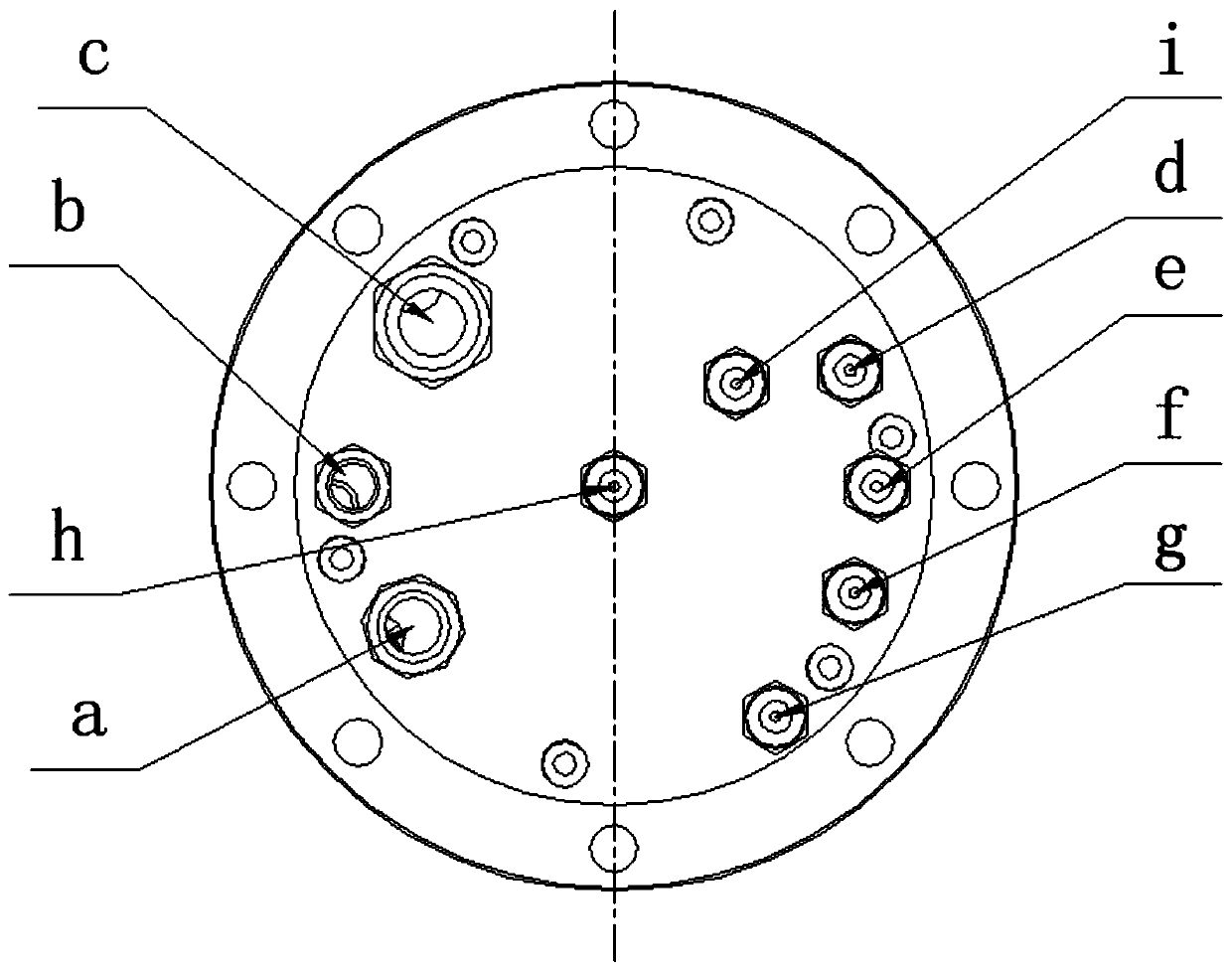

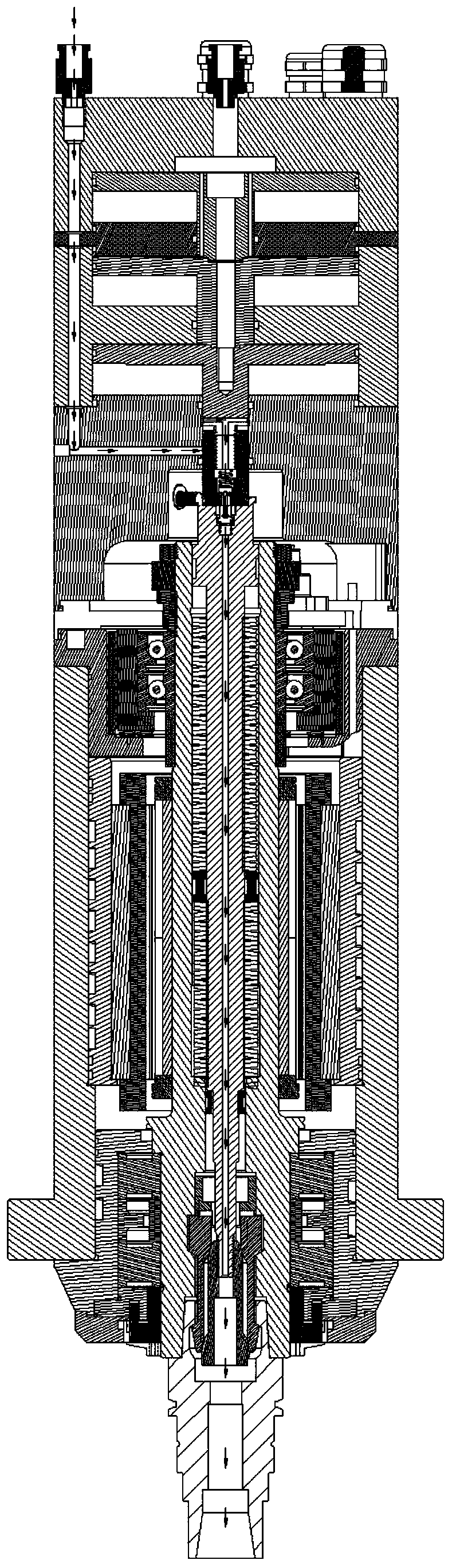

Electric spindle structure of high-speed finish engraving machine

The invention relates to the technical field of processing center equipment and discloses an electric spindle structure of a high-speed finish engraving machine. The electric spindle structure comprises an air cylinder assembly, a back cover detecting assembly, a steel cylinder, a pull rod assembly, a rotor assembly, a rear bearing assembly, a front bearing assembly and a knife handle, wherein theair cylinder assembly comprises a first air cylinder and an air cylinder shim; the air cylinder shim is positioned in an upper chamber of the first air cylinder and divides the upper chamber of the first air cylinder into two chambers; and an air passage independent of the air chamber of the air cylinder assembly is formed in the edge of the air cylinder assembly, passes through the edge and thecenter shaft of the back cover detecting assembly and then penetrates through the center shaft of the pull rod assembly to reach the inner conical surface end of the knife handle. The air cylinder shim is additionally mounted in the air cylinder assembly and is mounted between the first air cylinder and an air cylinder cover; compared with the structure that the air cylinder cover is directly connected with the first air cylinder, a piston chamber is additionally formed; and the space occupied by the entire air cylinder assembly is slightly increased, so that larger knife loosening force can be provided for the spindle within a limited space.

Owner:深圳市爱贝科精密工业股份有限公司

Battery module heating device and battery module heating shape-maintaining monitoring system

ActiveCN112827780AGuaranteed qualifiedFit tightlyMeasurement of fluid loss/gain ratePretreated surfacesThermodynamicsMonitoring system

The invention discloses a battery module heating device and a battery module heating shape-maintaining monitoring system. The battery module heating device comprises a supporting base, a bottom heating assembly, a module supporting assembly and a side heating assembly. The bottom heating assembly comprises a bottom heating plate which is arranged on the supporting base in an up-down moving manner. The module supporting assembly comprises module supporting blocks symmetrically arranged at the two sides of the bottom heating assembly. The side heating assembly comprises heating side plates symmetrically arranged at the two sides of the module supporting assembly, airflow channels are formed in the heating side plates in the length direction of the bottom heating assembly, and air outlets communicating with the airflow channels are formed in heat conduction type soft bonding material pieces on the inner side faces of the heating side plates. Air inlets of the airflow channels communicate with an air source through air inlet channels. By arranging pressure measuring elements in the air inlet channels, the air pressure in the airflow channels can be effectively monitored during heating, and whether a battery module is heated uniformly or not is monitored, so that the heating and curing quality is effectively ensured.

Owner:SHANGHAI SK SPECIAL MACHINERY CO LTD

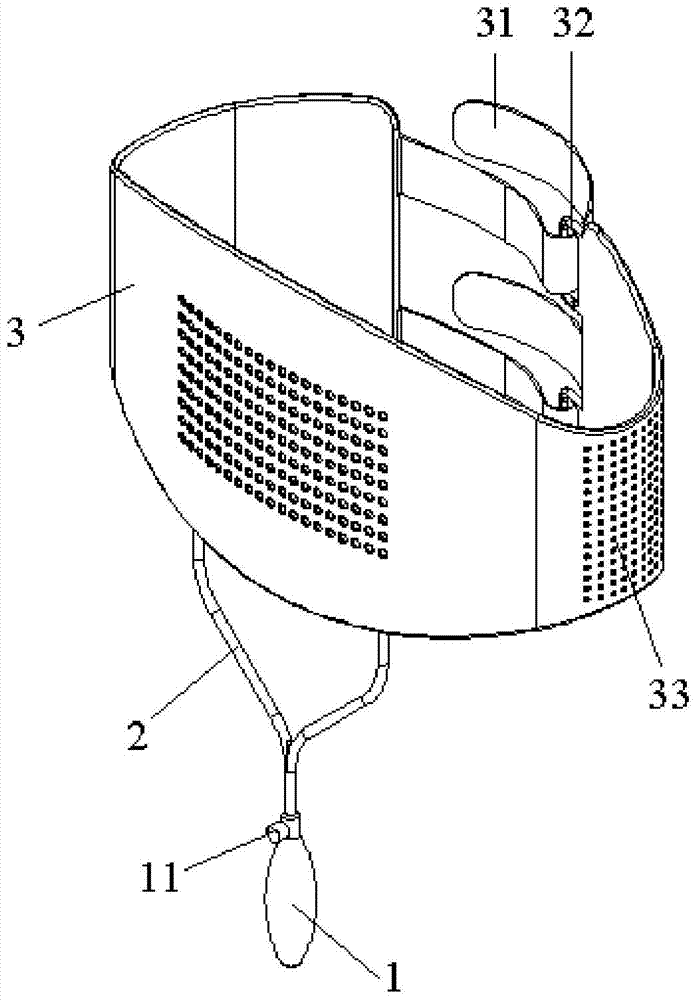

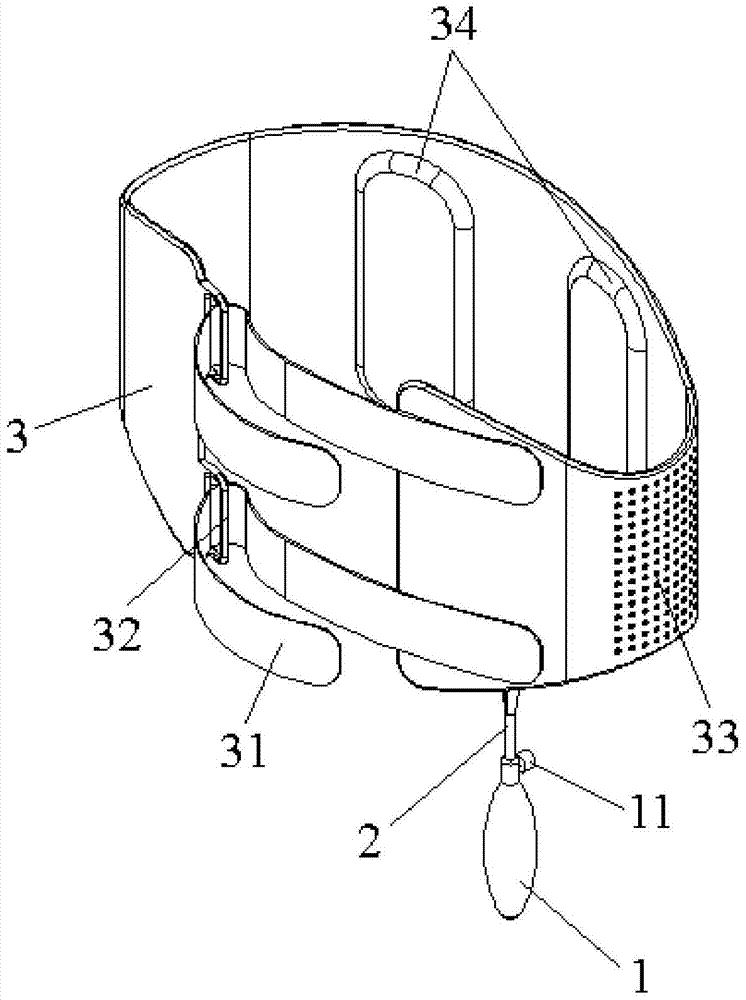

A corset for auxiliary use in stereotaxic radiotherapy

ActiveCN105214216BReduce displacementPrecise positioningRadiation therapyStereotactic radiotherapyStereotactic surgery

The invention relates to a corset for auxiliary use in stereotaxic radiotherapy, which is provided with an air bag, a balloon catheter and a corset; one end of the corset is provided with a fixing belt, and the other end is provided with a restraining ring of the fixing belt. The corset belt is provided with two auxiliary brake airbags; the two auxiliary brake airbags are connected with the airbags through the airbag catheter, and correspond to the patient's abdomen in use, and are symmetrical with respect to the sagittal plane of the human body; The corset belt is provided with ventilation holes; the fixing belt is a self-adhesive belt; the connection between the air bag and the air bag catheter is provided with an air bag regulating valve. The corset belt used in auxiliary stereotactic radiotherapy of the present invention has a good fixing effect on organs, is easy to use and operate, has a simple structure, and is low in cost. Comprehensive therapeutic effect of surgery.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

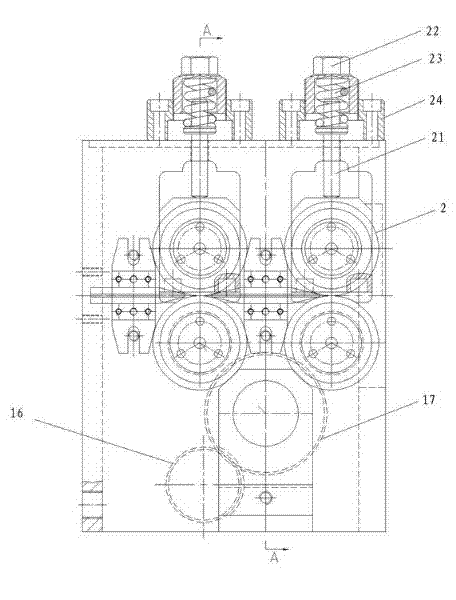

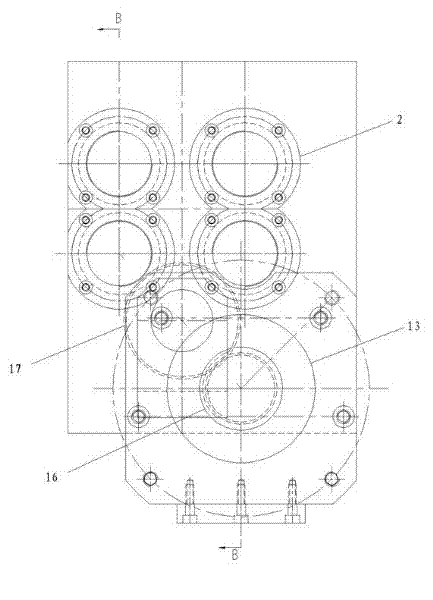

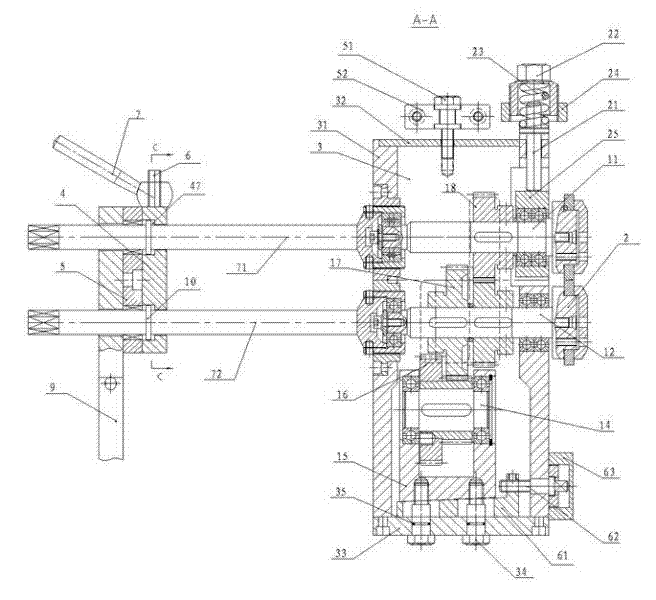

Wire feeding reduction gearbox

Owner:ZHEJIANG OMNIPOTENT SPRING MACHINE

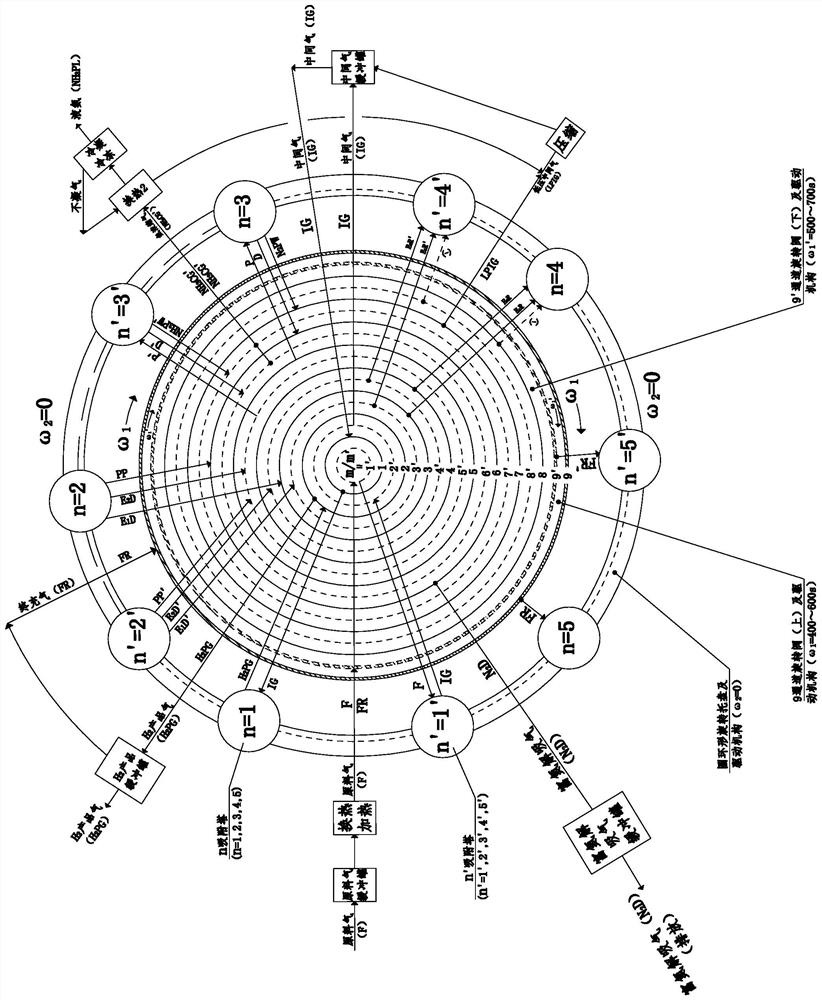

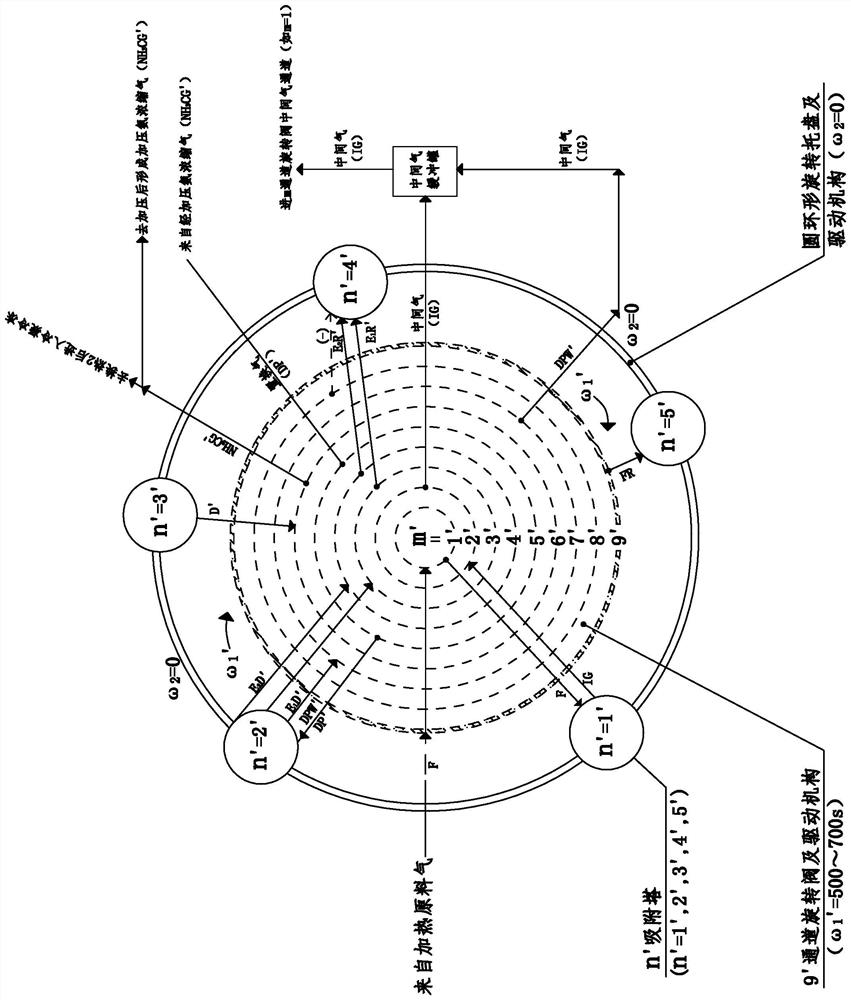

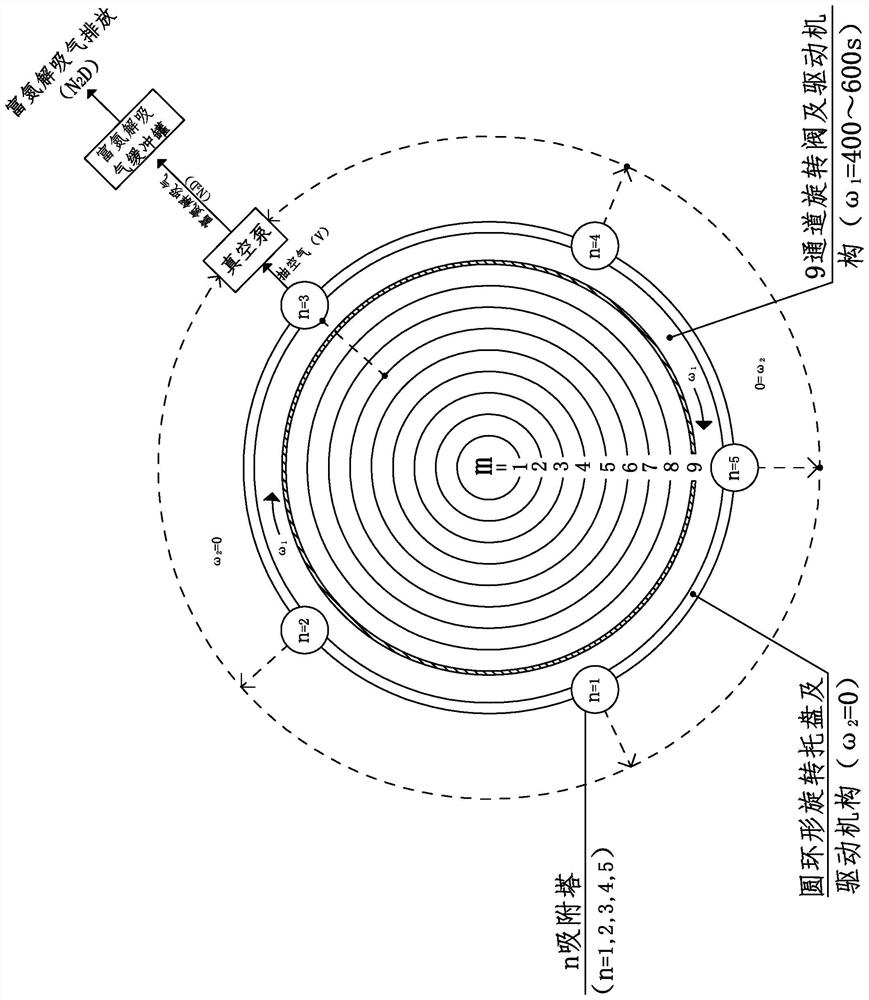

Full-temperature-range simulated rotating moving bed pressure swing adsorption process for extracting H2 and NH3 from synthetic ammonia purge gas

PendingCN114588749AReduce manufacturing complexity and costImprove efficiencyHydrogen separation using solid contactDispersed particle separationAmmonia productionRotary valve

The invention discloses a full-temperature-range simulated rotating moving bed pressure swing adsorption (FTrSRMPSA) process for extracting H2 and NH3 from synthetic ammonia purge gas. The middle-high temperature pressure swing adsorption ammonia concentration system and the middle gas pressure swing adsorption hydrogen extraction system are formed by a plurality of axial flow fixed bed adsorption towers and a rotating speed mechanism, wherein the axial flow fixed bed adsorption towers are arranged in the center of an upper multi-channel rotating valve and a lower multi-channel rotating valve, and are arranged on a circular ring-shaped rotating tray around the multi-channel rotating valve; gas flowing through a rotary valve channel, pipelines at the inlet and outlet ends of the adsorption towers and the adsorption bed layers can complete mass transfer of respective adsorption and desorption steps at the inlet and outlet positions of each adsorption tower and at each adsorption bed layer while rotating, so that a pressure swing adsorption process of simulating a rotary moving bed is formed; according to the invention, a simulated rotating moving bed pressure swing adsorption process on the basis of axial flow fixed bed pressure swing adsorption is realized, and H2 and NH3 products are obtained with high purity and high yield and are returned to a synthetic ammonia production process for recycling.

Owner:ZHEJIANG TIANCAIYUNJI TECH CO LTD

Assembled pressure self-balancing magneto-rheological damper

InactiveCN110848312AAvoid the case of all individual piecesReduce manufacturing costSpringsNon-rotating vibration suppressionMagnetoEngineering

The invention discloses an assembled pressure self-balancing magneto-rheological damper. A piston rod adopts a two-section split type structure, a main piston is arranged at the joint of a first piston rod and a second piston rod, the main piston divides a main cylinder barrel into left and right sealing chambers, a magnetorheological damping liquid is filled in the two sealing cavities, a cavityis formed inside the second piston rod, an auxiliary piston inside the cavity divides the cavity inside the second piston rod into two sealed cavities, and the auxiliary piston can freely move along the inner wall of the piston rod under the action of the two sides. On the one hand, the assembled pressure self-balancing magneto-rheological damper can prevent the output of the damper from being toolarge under the extreme working condition while the damping force can be adjusted, and moreover, the damage of the damper itself can be avoided; on the other hand, the energy consumption performanceof the damper can be adjusted by disassembling and replacing the piston, the piston rod and coils, the production cost is effectively reduced, and the industrial production and storage of product parts are facilitated.

Owner:南通装配式建筑与智能结构研究院 +1

Intermediate type nasopharynx expanding and bleeding-stopping bag and use method thereof

The invention discloses an intermediate type nasopharynx expanding and bleeding-stopping bag and a use method thereof. The intermediate type nasopharynx expanding and bleeding-stopping bag comprises a flexible rubber hose, wherein a blind tube is arranged at one end of the flexible rubber hose while a valve is arranged at the other end of the flexible rubber hose; a soft rubber bag is fixedly arranged at the middle position of the flexible rubber hose; the flexible rubber hose runs through the soft rubber bag; the soft rubber bag and the flexible rubber hose are sealed to form an integral structure; and the flexible rubber hose in the soft rubber bag is provided with a small hole serving as a channel which allows air and a liquid to flow in and out. The intermediate type nasopharynx expanding and bleeding-stopping bag, disclosed by the invention, has a simple structure, is easy to process and produce, has a low cost, can protect the surface of a wound of the nasopharynx part safely, can stop bleeding and prevent infection efficiently and can prevent adhesion and bleeding of the nasopharynx part after an operation.

Owner:GENERAL HOSPITAL OF PLA

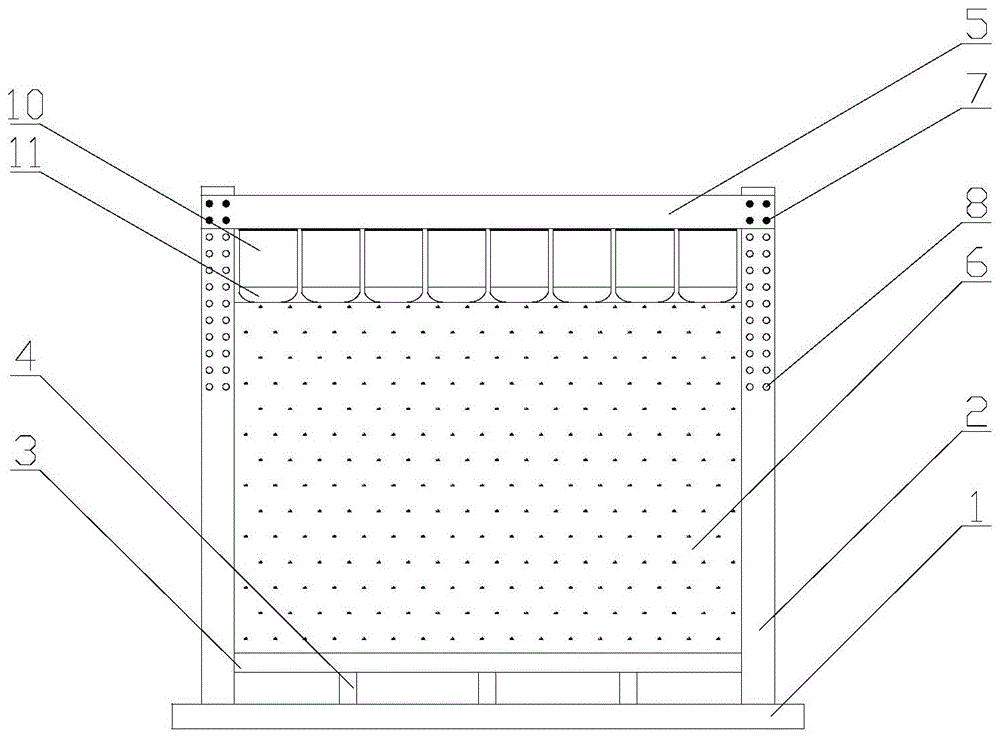

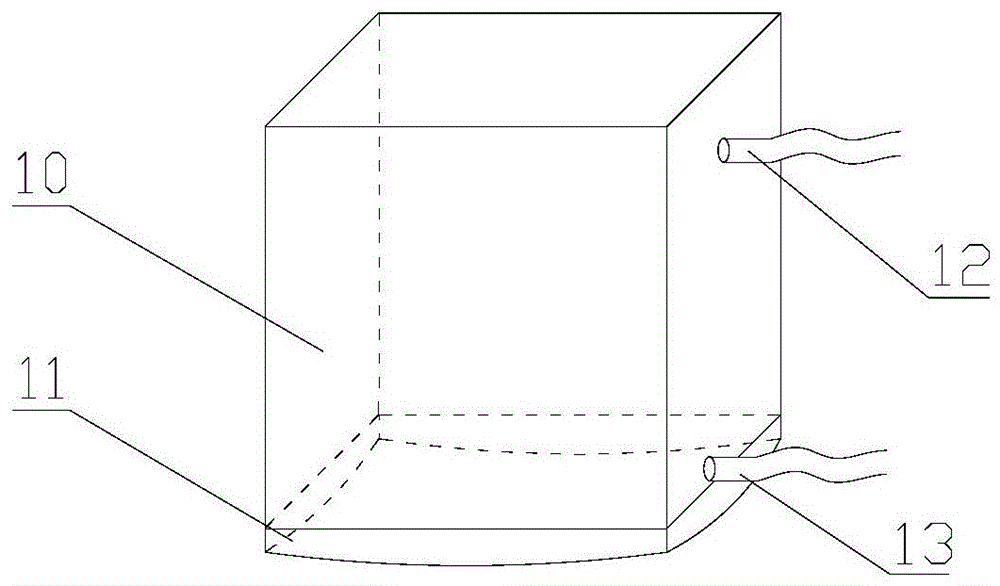

A similar material simulation semi-flexible loading experimental device and its experimental method

ActiveCN104297067BFlexible and easy pressureUniform pressureMaterial strength using tensile/compressive forcesExperimental methodsDevice form

The invention discloses a similar material simulation semi-flexible loading experimental facility and an experimental method thereof. A loading device formed by a plurality of semi-flexible loading units is adopted on the basis of the prior art, the semi-flexible loading unit adopts a hexahedral structure form of which the bottom surface is only elastically deformed and other surfaces are made of rigid materials, and adopts a hydraulic oil transmission stress loading mode; connecting parts are arranged at two ends of a top beam and are fixed on a vertical column by bolts to realize detachable connection; a plurality of locating holes are formed in different height positions of the vertical column respectively, the top beam can be locked at the positions in different heights of the vertical column through the connecting parts by the bolts or hinge pins according to different experiment demands, and the problems that the sample model loading stress is non-uniform, the system error is caused, the adjustment is inconvenient and the operation is time-saving and labor-saving and the like are solved.

Owner:SHANDONG UNIV OF SCI & TECH

Adjustable air compressor air inlet valve

ActiveCN111677875AFlexible pressure adjustmentGuaranteed to workPositive displacement pump componentsPositive-displacement liquid enginesInlet valveEngineering

The invention relates to air compressor air inlet valves, in particular to an adjustable air compressor air inlet valve. The adjustable air compressor air inlet valve comprises a valve rod; the valverod is sequentially sleeved with a first valve seat, a valve plate and a second valve seat from top to bottom; a plurality of vertically-through internal threaded holes are formed in the end face, facing the valve plate, of the second valve seat; the multiple internal threaded holes are evenly distributed in the surface of the second valve seat; and an adjusting sleeve is connected into each innerthreaded hole through threads, a spring is arranged in each inner threaded hole, the upper portion of each spring extends out of the corresponding inner threaded hole, and the lower portion of each spring extends into the corresponding adjusting sleeve and makes contact with the bottom end face of the corresponding adjusting sleeve. According to the adjustable air compressor air inlet valve, thepressure of the springs on the valve plate can be flexibly adjusted according to actual use requirements, the air inlet stability is improved, and normal work of an air compressor is guaranteed.

Owner:YUYAO DALONG AIR COMPRESSOR PARTS CO LTD

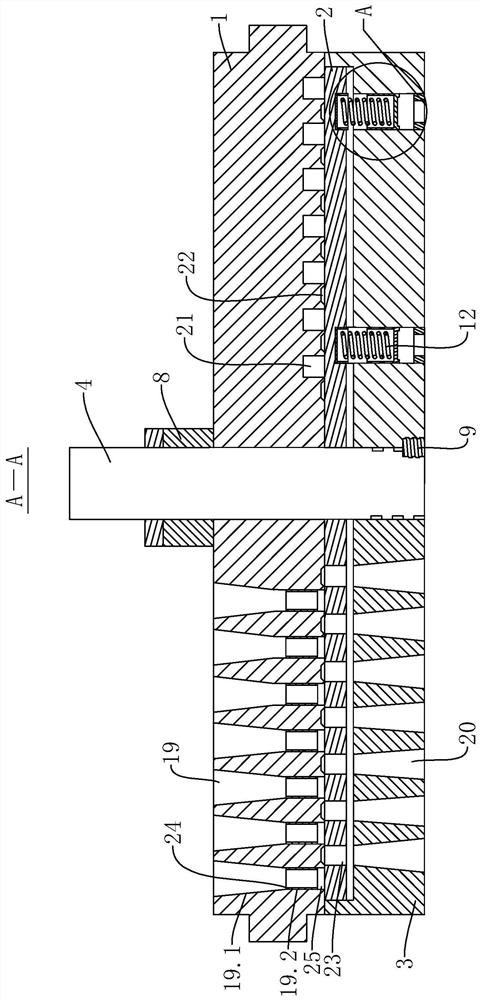

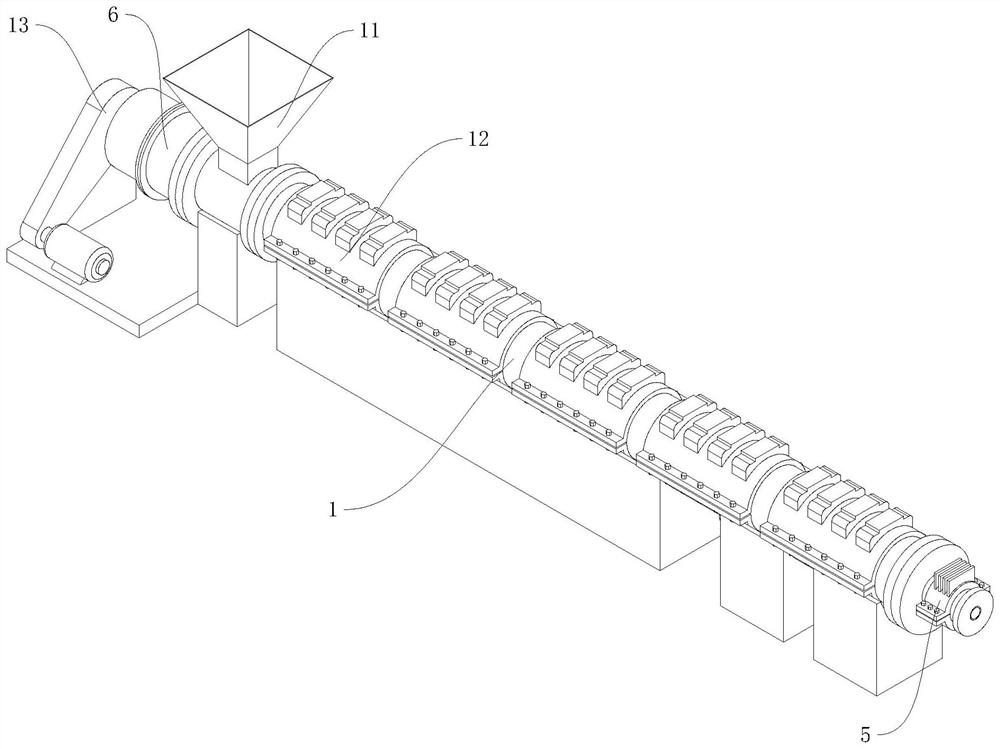

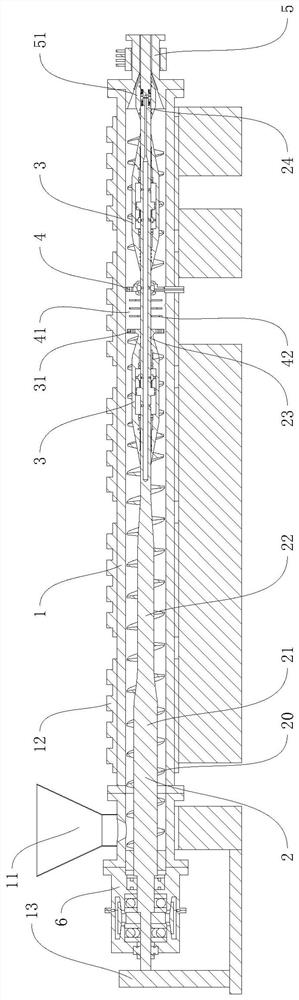

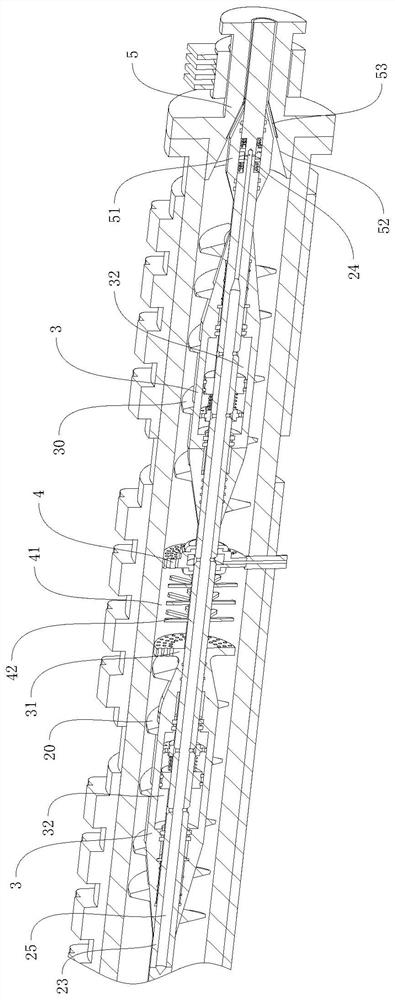

Pressure stabilizing mechanism

The invention discloses a pressure stabilizing mechanism, relates to the technical field of extrusion equipment, and aims to solve the problem of unstable pressure of a plastic extruder. The pressurestabilizing mechanism of the technical scheme is characterized by comprising two pressure stabilizing sliding sleeves sleeving the outer portion of a screw rod of the extruder, each pressure stabilizing sliding sleeve is of a conical structure with a cylindrical middle part and two gradually reduced ends, the pressure stabilizing sliding sleeves can axially move relative to the screw rod and are circumferentially linked, and a size-adjustable balance cavity is formed between the two pressure stabilizing sliding sleeves. According to the pressure balancing mechanism, balance adjustment can be carried out on the pressure in the extruder, so that the operation stability of the extruder is improved.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

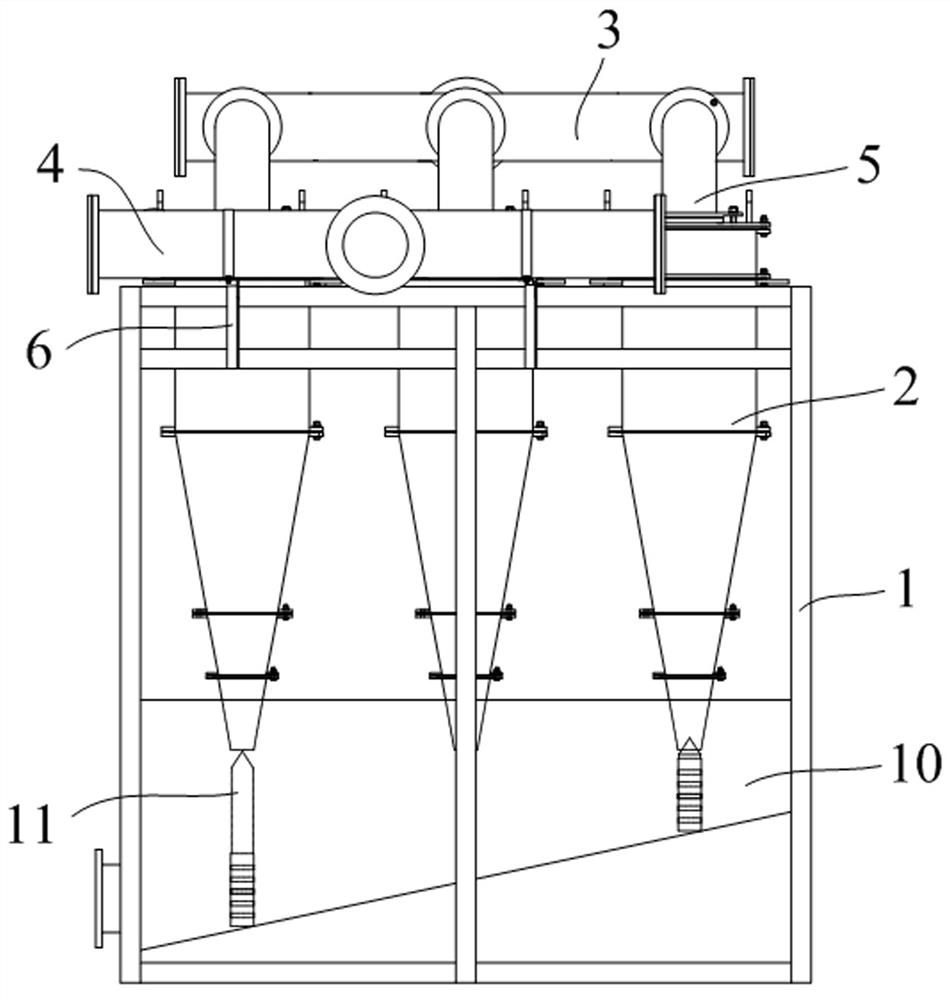

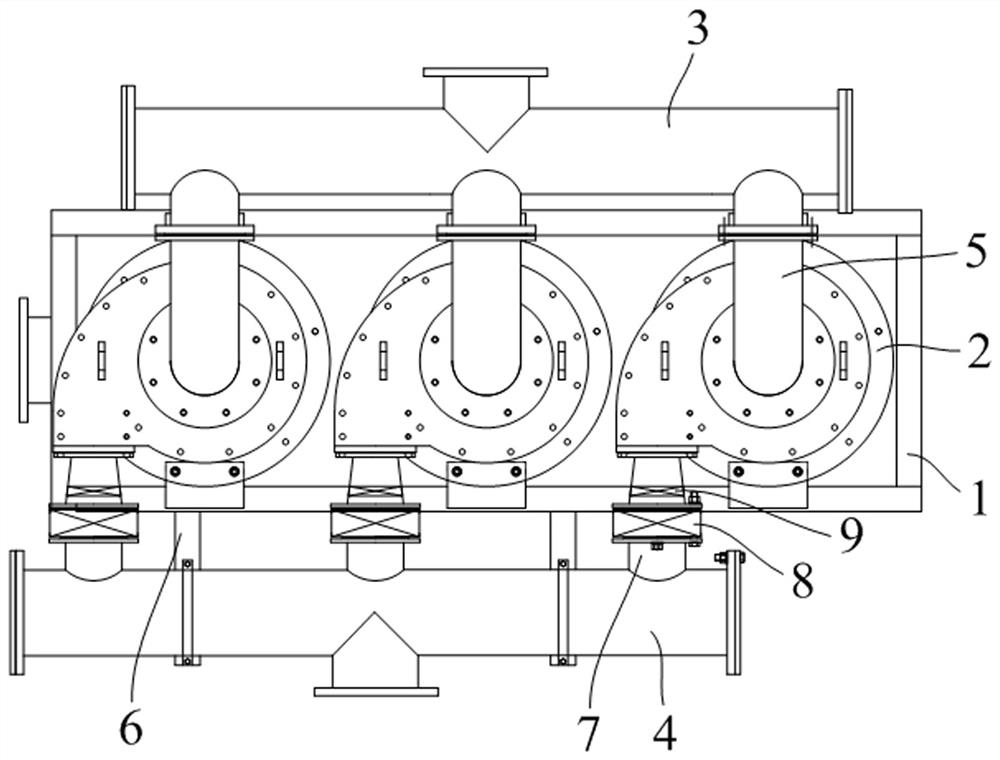

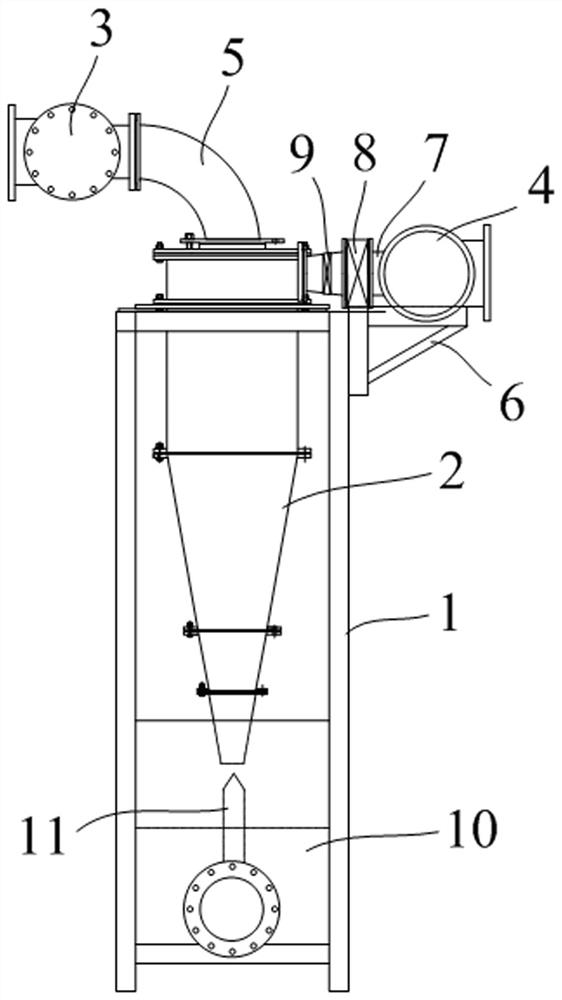

A cyclone for mineral processing

ActiveCN111760688BEnhance centrifugal sedimentationEasy to separateReversed direction vortexCycloneConical tube

The invention relates to a cyclone for ore dressing, which includes a frame and a plurality of cyclones, and the plurality of cyclones are arranged on the frame; an overflow pipe and a feeding pipe are arranged on the frame, and the overflow pipe Placed above a plurality of cyclones, the overflow pipe communicates with the tops of the plurality of cyclones through a plurality of arc-shaped tubes; a bracket is provided on one side of the upper end of the frame; the feed pipe is fixed on the bracket On the top, the feed pipe communicates with the upper ends of multiple cyclones through a plurality of conical pipes; each conical pipe is fixed with a non-gap gate valve and a pressure regulating valve; the pressure regulating valve includes a valve seat And two valve plates, the valve seat is fixed on the conical pipe, and there is a guide channel in the valve seat; there are two installation grooves in the valve seat; the two valve plates are respectively movable and placed in the two installation grooves ; Both valve plates are provided with magnet blocks, and the two magnet blocks are magnetically attracted to each other. Compared with the prior art, the present invention regulates the pressure of incoming raw materials to improve the separation effect of raw materials.

Owner:吉安县学海矿业有限公司

A Booster System Based on Free Piston Expansion/Compressor-Linear Motor

InactiveCN105422182BCompact structureHigh degree of mechatronicsMachines/enginesSafety/regulatory devicesCircuit switchingPiston

The invention discloses a pressurization system based on free piston expansion / compressor-linear motor. The system mainly consists of four parts, including an excess pressure recycling system, a circuit switching system, a pressurization system and a control system. The pressurization system disclosed by the invention can be used for transforming excess pressure energy in a gas conveying pipeline of a natural gas driven generator set into electric energy and storing the electric energy, simultaneously driving a free piston expansion / compressor to compress air and then respectively supplying the compressed air to a gas charging system of the natural gas driven generator set and a pressure regulation system of the free piston expansion / compressor. In comparison with a current excess pressure driven power generation system which adopts a turbine type machinery as an acting unit, the excess pressure driven power generation system has the advantages of being reliable in work, high in system energy utilization rate and mechanical and electrical integration degree and flexible in regulation on pressure fluctuation of natural gas or pressurized air at the outlet of the expansion / compressor.

Owner:BEIJING UNIV OF TECH

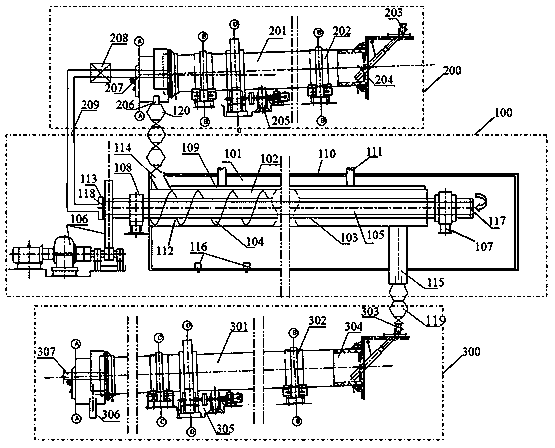

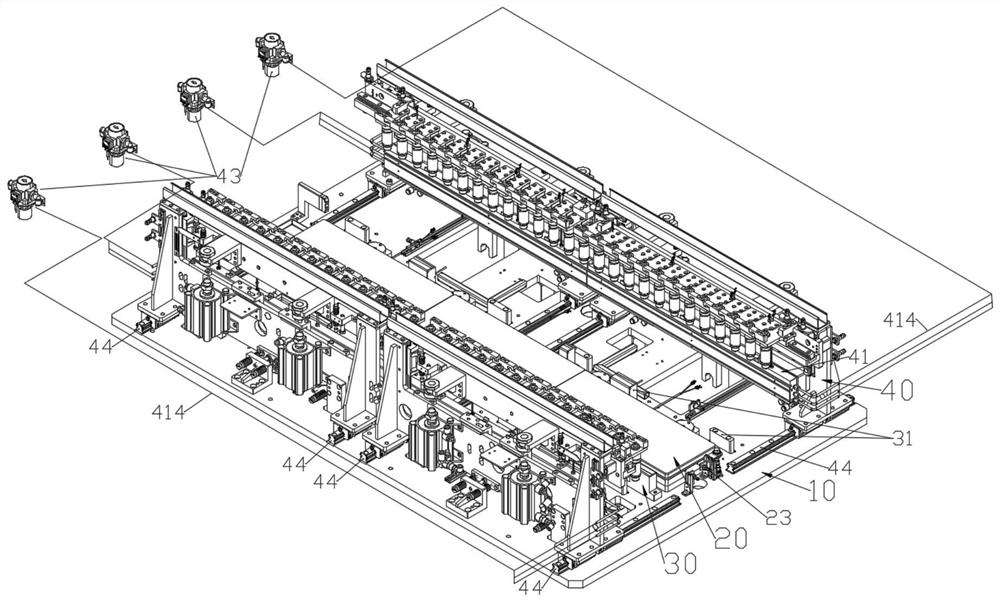

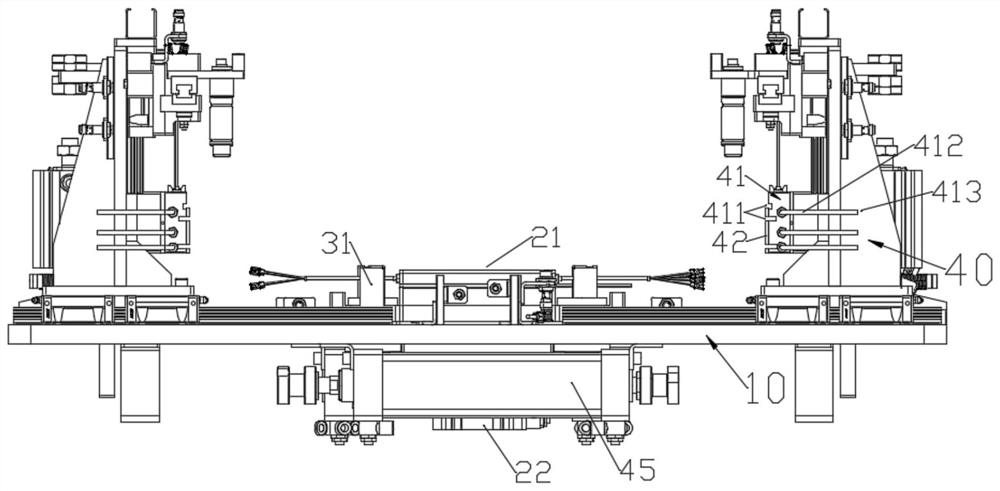

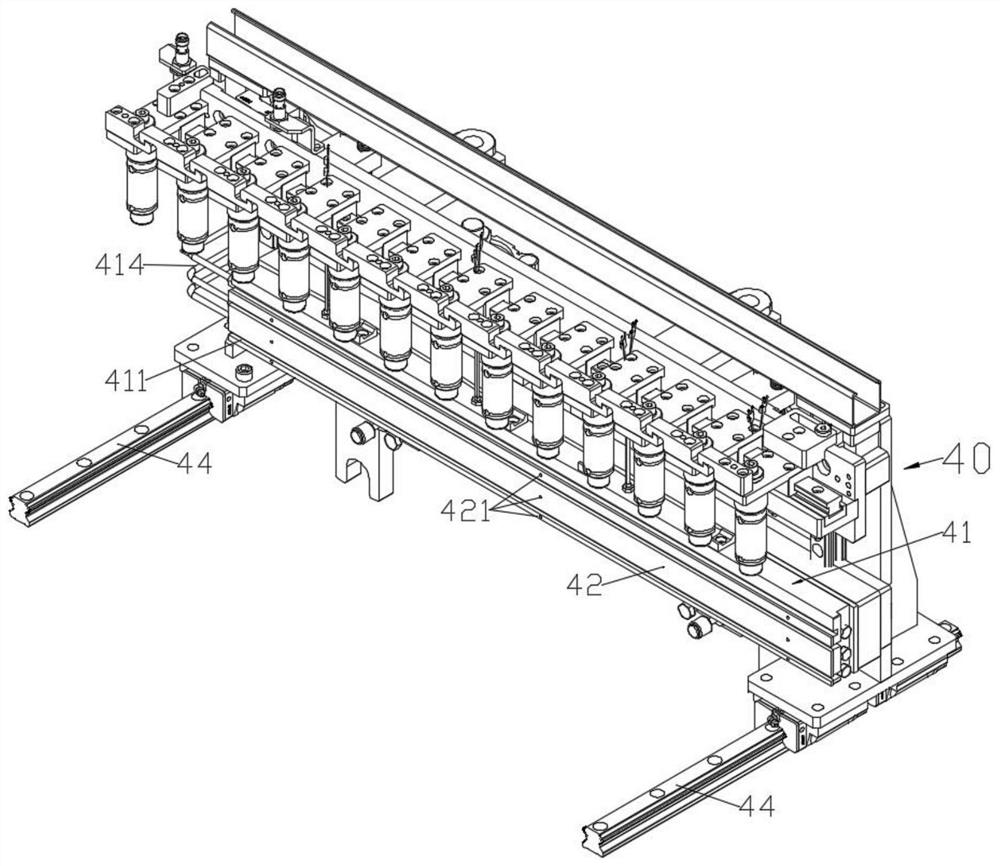

Portable metallographic phase automatic sample grinding device

PendingCN112798382AImprove work efficiencyFlexible pressure adjustmentPreparing sample for investigationDrive shaftElectric machinery

The invention relates to a portable metallographic phase automatic sample grinding device. The device comprises a base body, a supporting unit, a sample grinding unit, a pressing unit, a cleaning unit and a control unit; the top of the base body is provided with a sunken machining face; a power transmission unit is installed between two opposite installation edges of the base body; the supporting unit comprises a guide rail frame and supporting frames, and the guide rail frame is erected over the power transmission unit through the supporting frames at the two ends; the sample grinding unit comprises a transmission shaft driving motor protection box, a transmission shaft driving motor, a main transmission shaft, an auxiliary transmission shaft and a plurality of groups of sample grinding conveyor belt assemblies arranged between the main transmission shaft and the auxiliary transmission shaft side by side; the pressing unit comprises a horizontal position adjusting device, a height adjusting device and a sample pressing block; the cleaning unit comprises a water spraying pipe base, a water spraying pipe and a water outflow switch; and the control unit comprises a controller, at least one first control switch and at least one second control switch. The portable metallographic phase automatic sample grinding device, automatic grinding and station changing work of a metallographic specimen are achieved by multiple pieces of belt type abrasive paper and the height adjusting device. The automatic grinding device is simple in structure, rapid, efficient and low in cost.

Owner:ZHEJIANG UNIV OF TECH

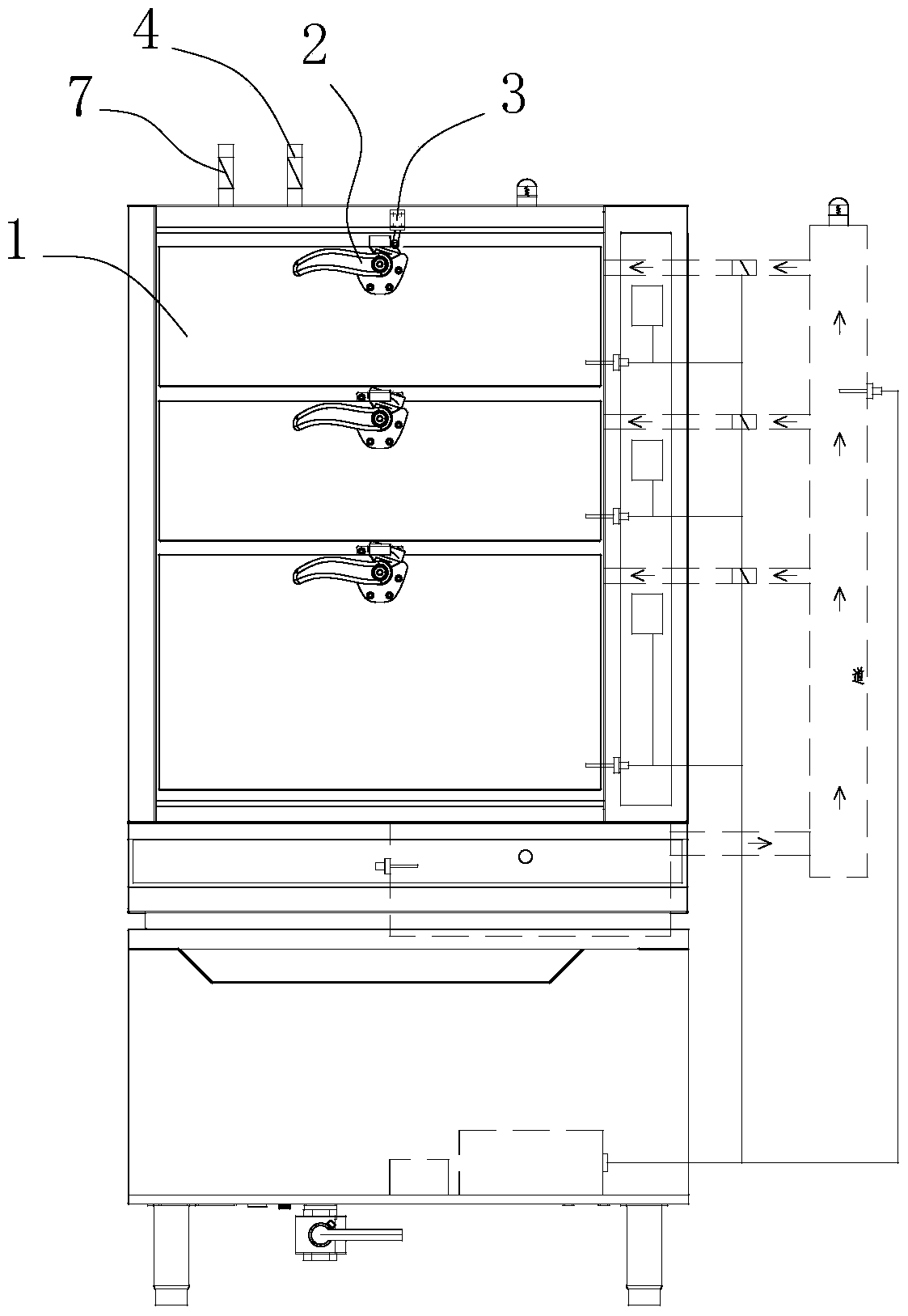

A multi-level combined protection steam cabinet and a multi-level combined protection method

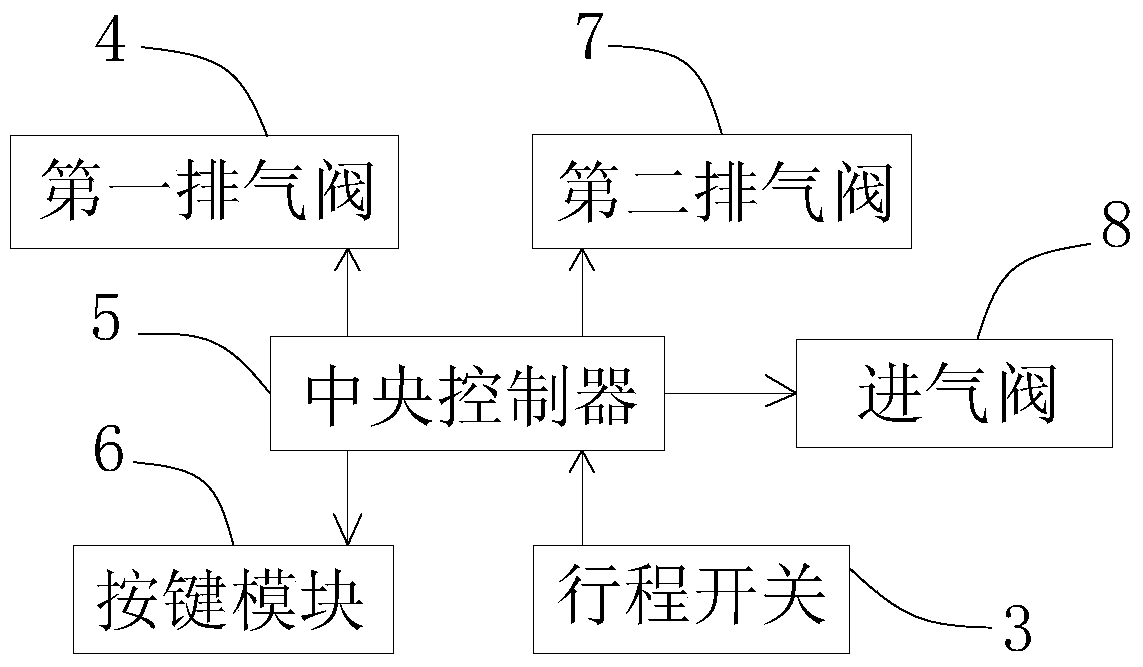

ActiveCN105768854BGuarantee the safety of useImprove securityProgramme controlComputer controlElectricityExhaust valve

The invention discloses a multi-level combined protection steaming cabinet, wherein: when the steaming cabinet is powered on, the central controller controls the closing of the second exhaust valve; after the user inputs an instruction through a button module, the central controller executes the instruction and Control the opening or closing of the intake valve and the first exhaust valve to control the heating process of the steamer; when the travel switch is off, it means that the door is open, and the central controller controls the opening of the first exhaust valve; when the travel switch is closed , indicating that the door is closed, and the central controller controls the heating process of the steamer by controlling the on-off of the intake valve and the first exhaust valve. The above-mentioned multi-level joint protection steam cabinet forms a combination of active and passive, normal and abnormal, mechanical and electronic through the joint action of the button module, the first exhaust valve, the second exhaust valve, the travel switch and the handle-type door lock. The multi-level joint protection method achieves better safety and more flexible pressure regulation, effectively ensuring the safety of the steamer.

Owner:广东易爱云厨科技股份有限公司

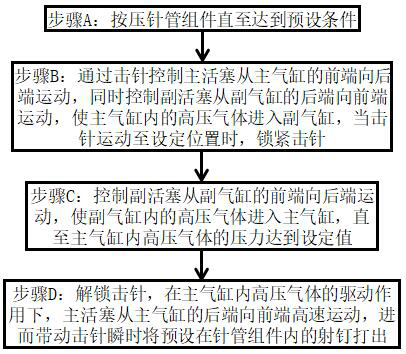

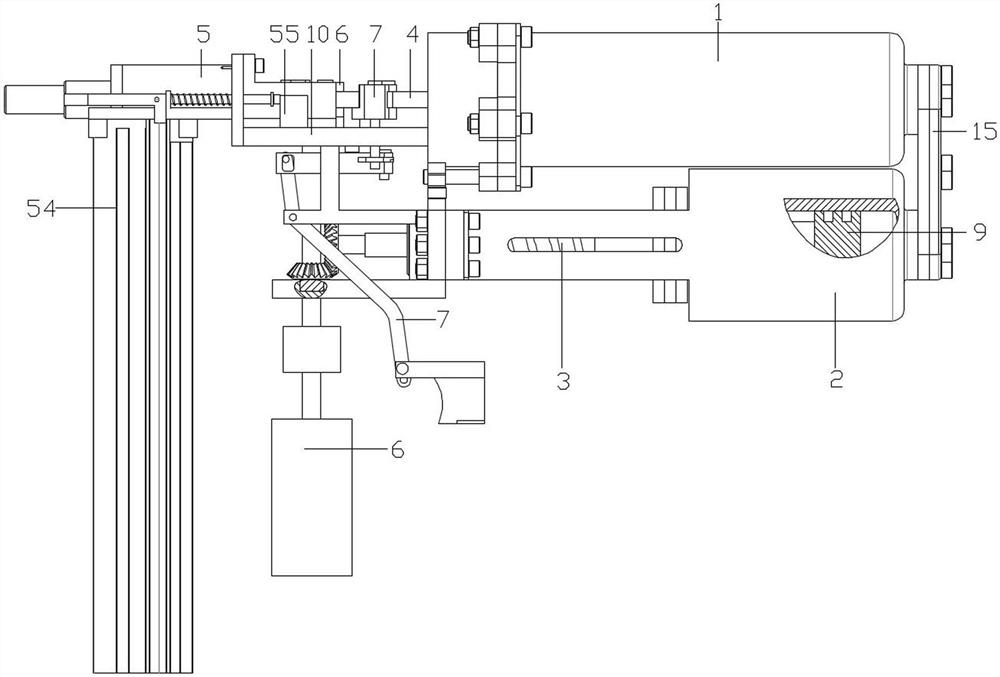

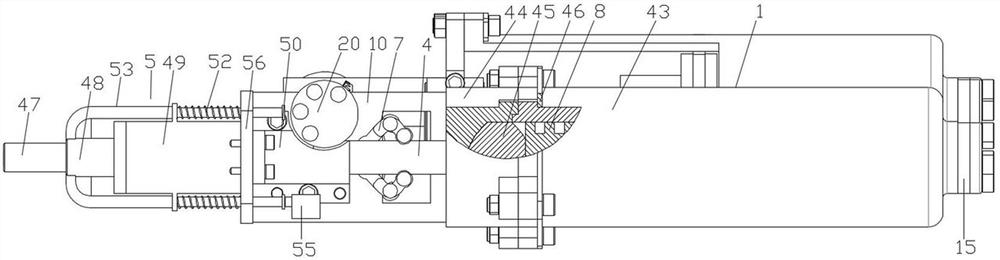

Double-cylinder nailing method

The invention discloses a double-air-cylinder nailing method. The method comprises the steps that A, a needle tube assembly is pressed till a preset condition is met; b, driving a main piston to move from the front end to the rear end of the main air cylinder through the firing pin, meanwhile, moving an auxiliary piston from the rear end to the front end of the auxiliary air cylinder, enabling high-pressure gas in the main air cylinder to enter the auxiliary air cylinder, and enabling the firing pin to enter a limiting state when the firing pin moves to a set position; c, the auxiliary piston moves from the front end of the auxiliary air cylinder to the rear end of the auxiliary air cylinder, so that the high-pressure gas in the auxiliary air cylinder enters the main air cylinder till the pressure of the high-pressure gas in the main air cylinder reaches a set value; and D, limiting of the firing pin is relieved, the main piston moves at a high speed from the rear end of the main air cylinder to the front end of the main air cylinder under the driving effect of the high-pressure gas in the main air cylinder, and the firing pin is driven to instantly shoot out the shoot nail preset in the needle tube assembly. According to the method, the nailing power can be automatically adjusted according to needs, and the micro-leakage amount can be automatically compensated when gas in a cylinder is subjected to micro-leakage, so that the better nailing power is ensured; and meanwhile, the product structure is simplified, and the size is reduced.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com