Internal and external heating type medium and low temperature powdered coal temperature division dry distillation system and method

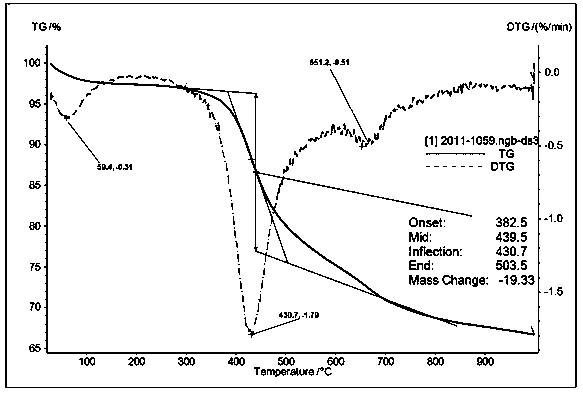

A pulverized coal temperature and dry distillation technology, applied in the field of coal pyrolysis and dry distillation, can solve the problems of inability to obtain calorific value, not fully considering the characteristics of weight loss at different temperatures, and limiting the industrial application of raw coal dry distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

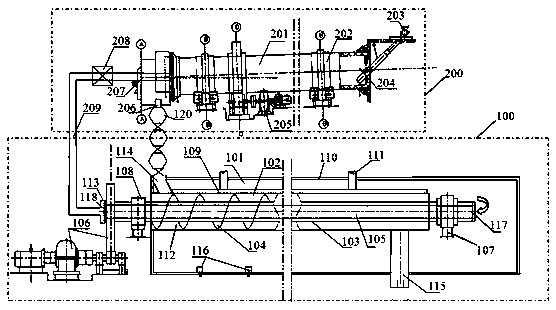

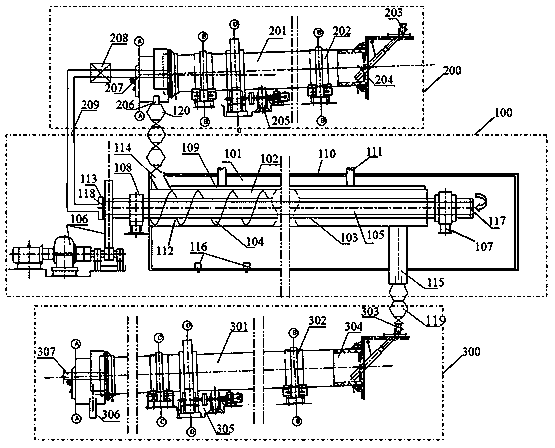

[0061] As the second preferred embodiment of the present invention, the internal and external heating type medium and low temperature pulverized coal temperature fractionation dry distillation system, as attached image 3 and 4 shown in the above appended figure 2 On the basis of the medium-low temperature external heating type screw pusher retort device 100 and the low temperature internal heating type rotary kiln retort device 200 in the first preferred embodiment shown, it further includes a medium temperature internal heat type rotary kiln retort device 300 , the medium temperature internal heat type rotary kiln retort device 300 The kiln retort device 300 is connected to the medium and low temperature external heating type screw pusher retort device 100, the composition structure and working of the medium and low temperature external heat type screw retort device 100 and the low temperature internal heat type rotary kiln retort device 200 in the second preferred embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com