Patents

Literature

37results about How to "Improve retort efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

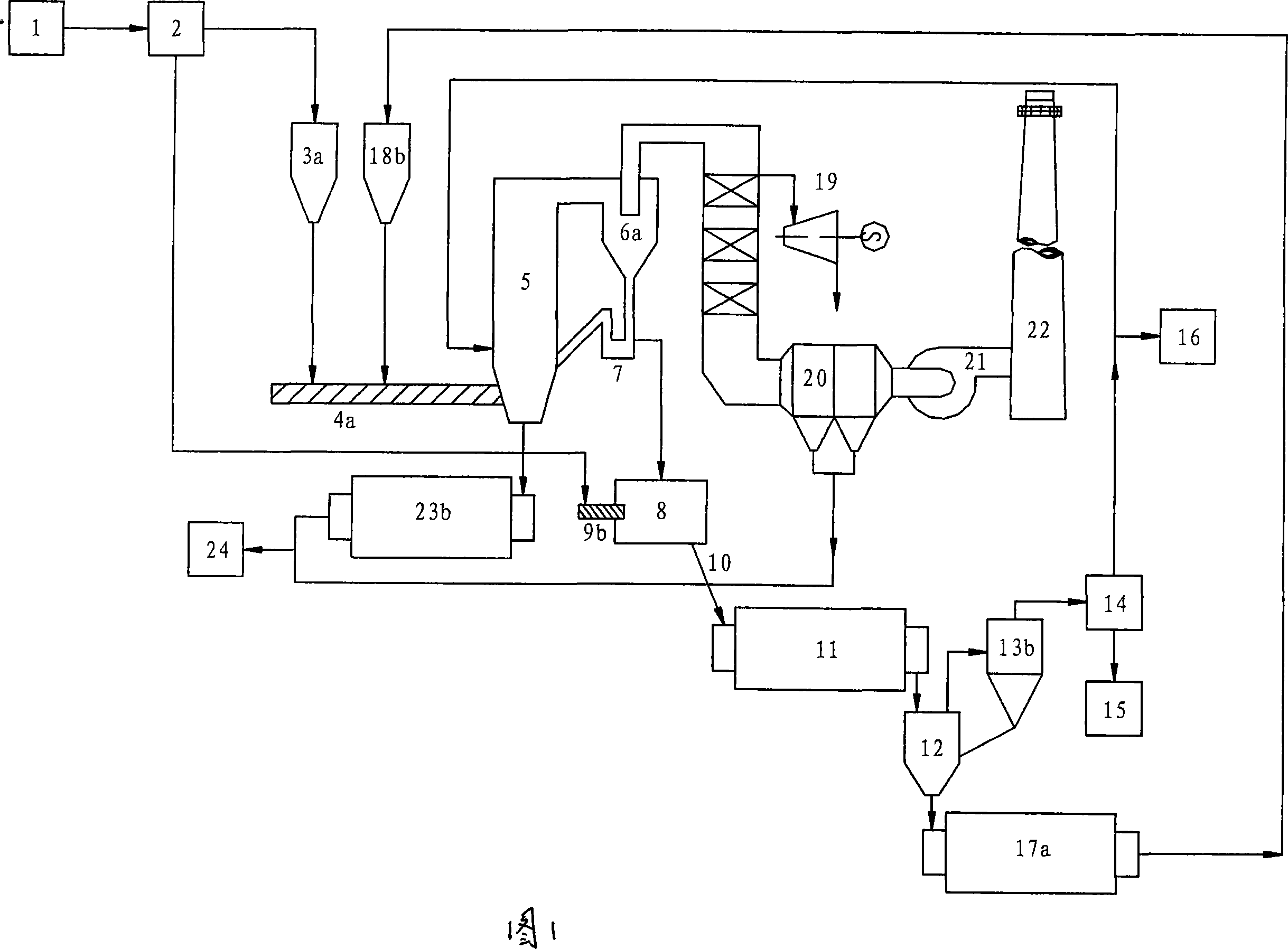

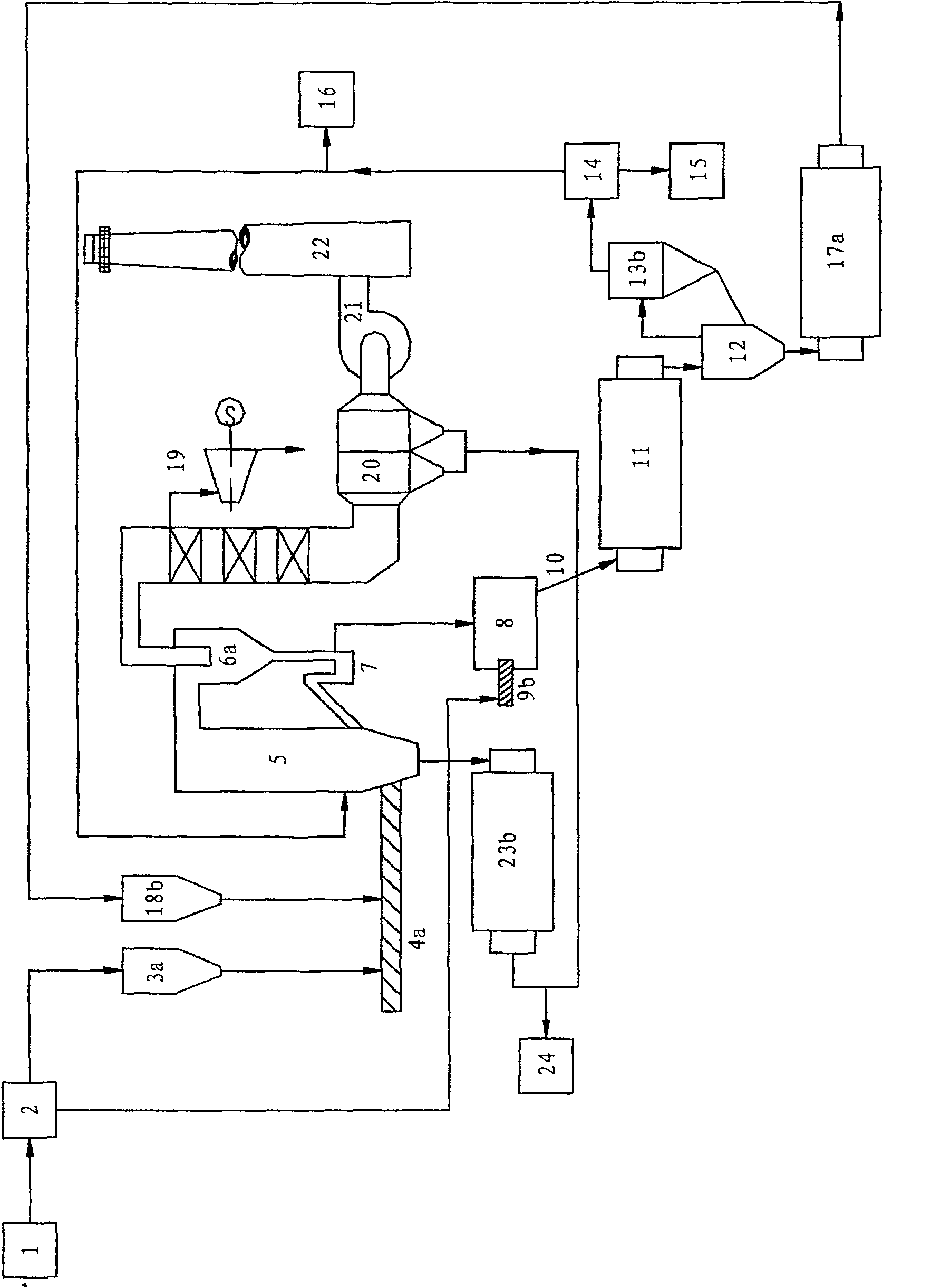

Integral process for oil shale retorting oil refining and coal-char combustion power generation

InactiveCN101117584AGood heat transfer effectImprove heat utilizationInternal combustion piston enginesPowdered engine fuelsHeat carrierCirculating fluidized bed boiler

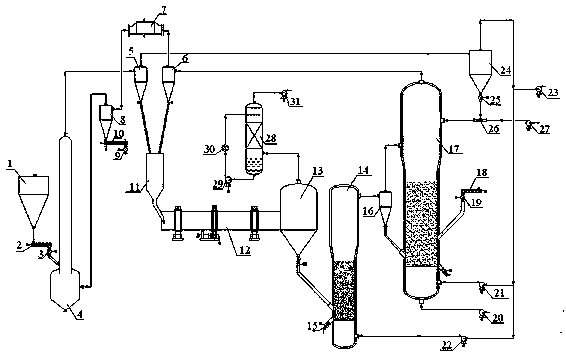

The present invention discloses an oil shale carbonization oil refining, carbocoal burning electricity generating integrated technology. The present invention is characterized in that green ore oil shale is crushed into 0 to 15mm grains by a crusher, through that circulating fluid bed boiler circulating ash is used as a solid heat carrier, the mixture of the oil shale and the circulating ash is fed into a roller retort to form oil shale oil refining, carbocoal and the oil shale are mixed, fluidized and burned to generate electricity as a whole, separated non-condensation carbonization coal gas is fed into the circulating fluid bed boiler and the both are burned with the carbocoal and the oil shale together or is fed into a gas engine for direct-fired power generation; the carbon content of the clinker after burned on the circulating fluid bed is less than 2 percent, thus no further roasting is necessary, and the present invention can be directly used as building raw material; the thermal value of produced carbonization coal gas which can be directly used as fuel to feed into the boiler for burning is high, the quantity of heat released through burning can be transferred to the water through the heated surface of the boiler, the water is heated into a overheat steam to be used as out-supplied working substance and / or to be fed into a steam turbine for power and electricity generating. The present invention has the advantages that the comprehensive utilization degree is high, the cost is low, the technology is scientific and reasonable, etc.

Owner:NORTHEAST DIANLI UNIVERSITY +1

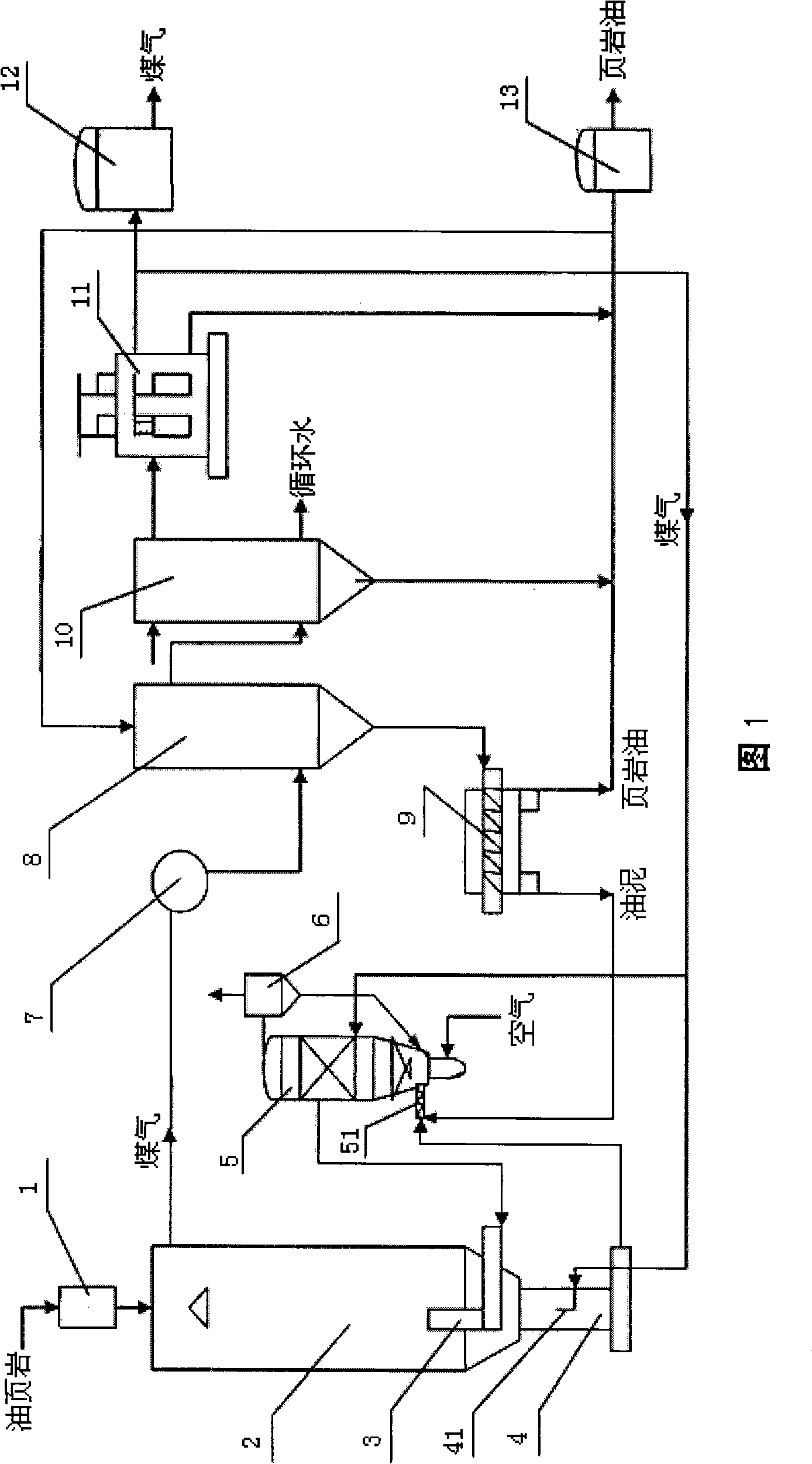

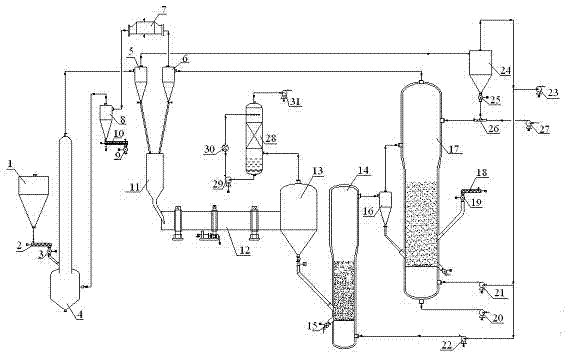

Full cycle dry distillation process and system for producing shale oil from oil shale (coal)

InactiveCN101280201AHigh calorific valueAchieve separationSpecial form destructive distillationDistillationOil sludge

The invention provides a full cycle dry distillation process and a system which use oil shale (coal) to produce shale oil; the technological process includes that the distillation of the oil shale is processed in an oil shale distillation system which is composed of an oil shale input storage tank, a non-oxygen coal-gas heating retort and a semi-coke discharge device to generate pyrogenous coal gas and the semi-coke; the pyrogenous coal gas is separated and purified by a pyrogenous coal gas multi-stage purifying system composed of a coal gas collecting pipe, an oil-washing tower, an intercooling tower and an electrical oil trap; the obtained coal gas is preheated by a coal gas preheating system composed of a fluidized bed combustion furnace, a spiral feeder and a duster collector and then is fed into the non-oxygen coal-gas heating retort for the dry distillation of the oil shale; the oil product separated from the oil-washing tower, the intercooling tower and the electrical oil trap is purified and collected through an oil product purifying and collecting system so that the shale oil product is obtained; the semi-coke and the sludge generated during the dry distillation and purification process are used as the materials for the preheating of the coal gas. The dry distillation process in the invention can effectively realize the functions of dry distillation, dust separation and combusting the semi-coke and sludge generated during the process of dry distillation for the preheating of the coal gas; thereby, the sources is utilized sufficiently and the environmental protection requirement is fulfilled.

Owner:ZHUHAI TOP ENERGY TECH

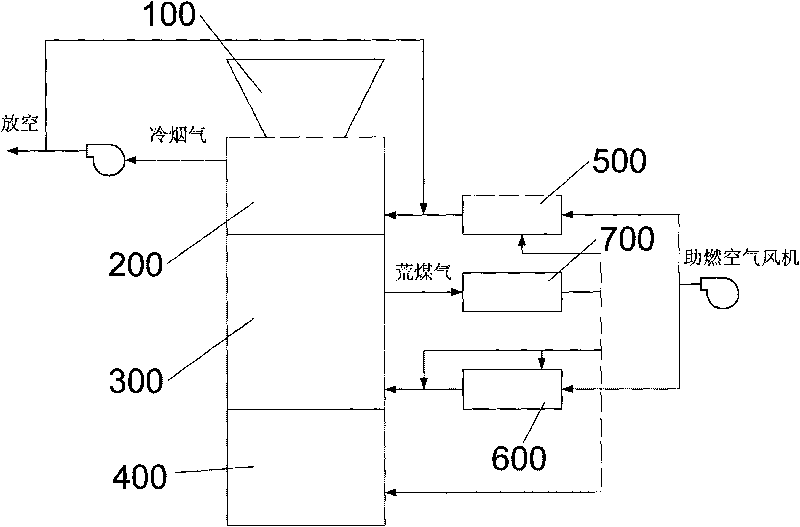

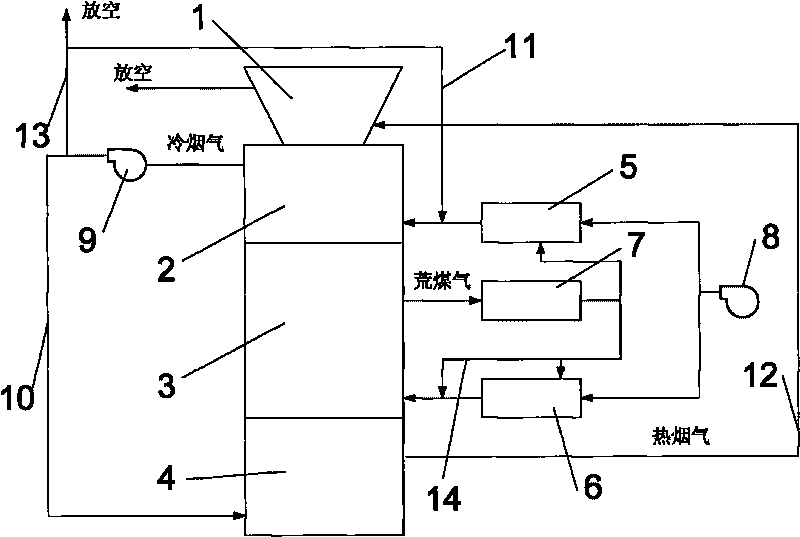

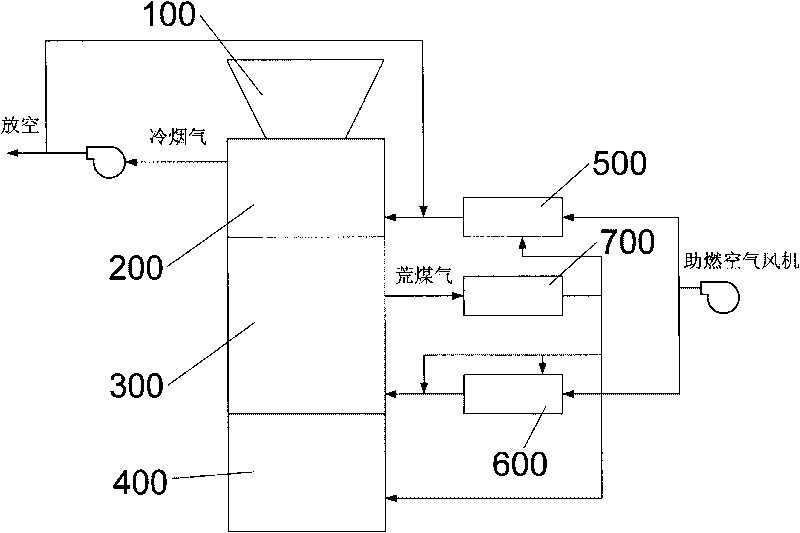

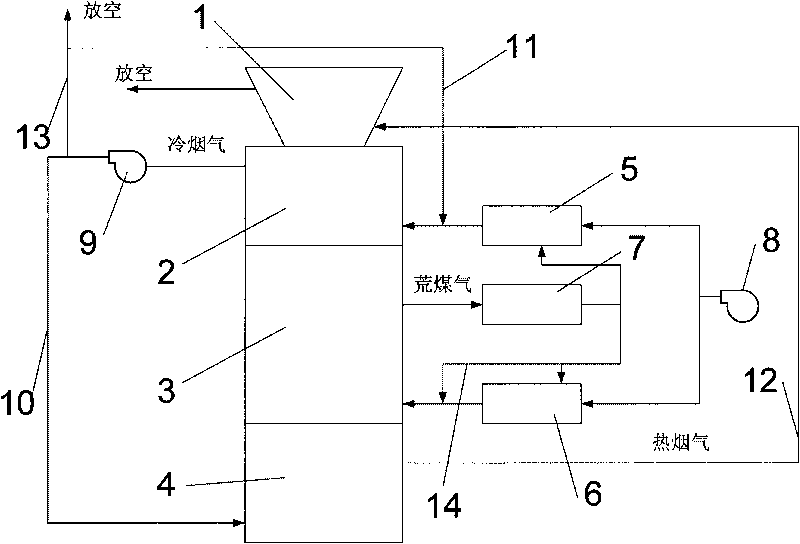

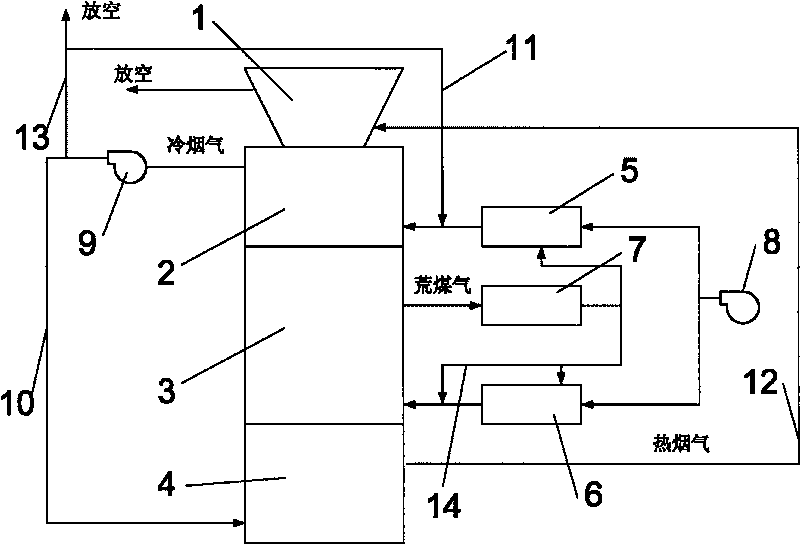

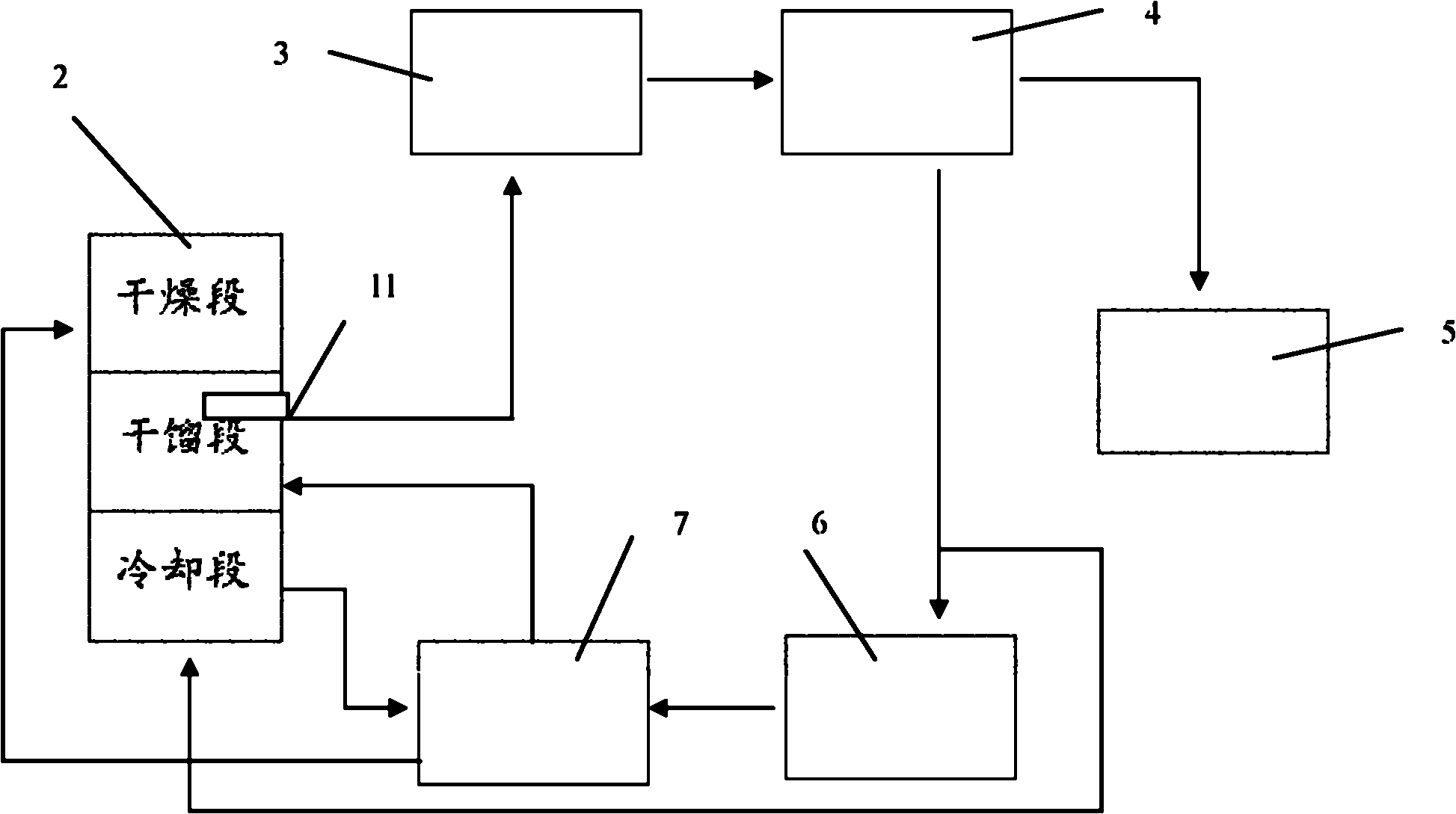

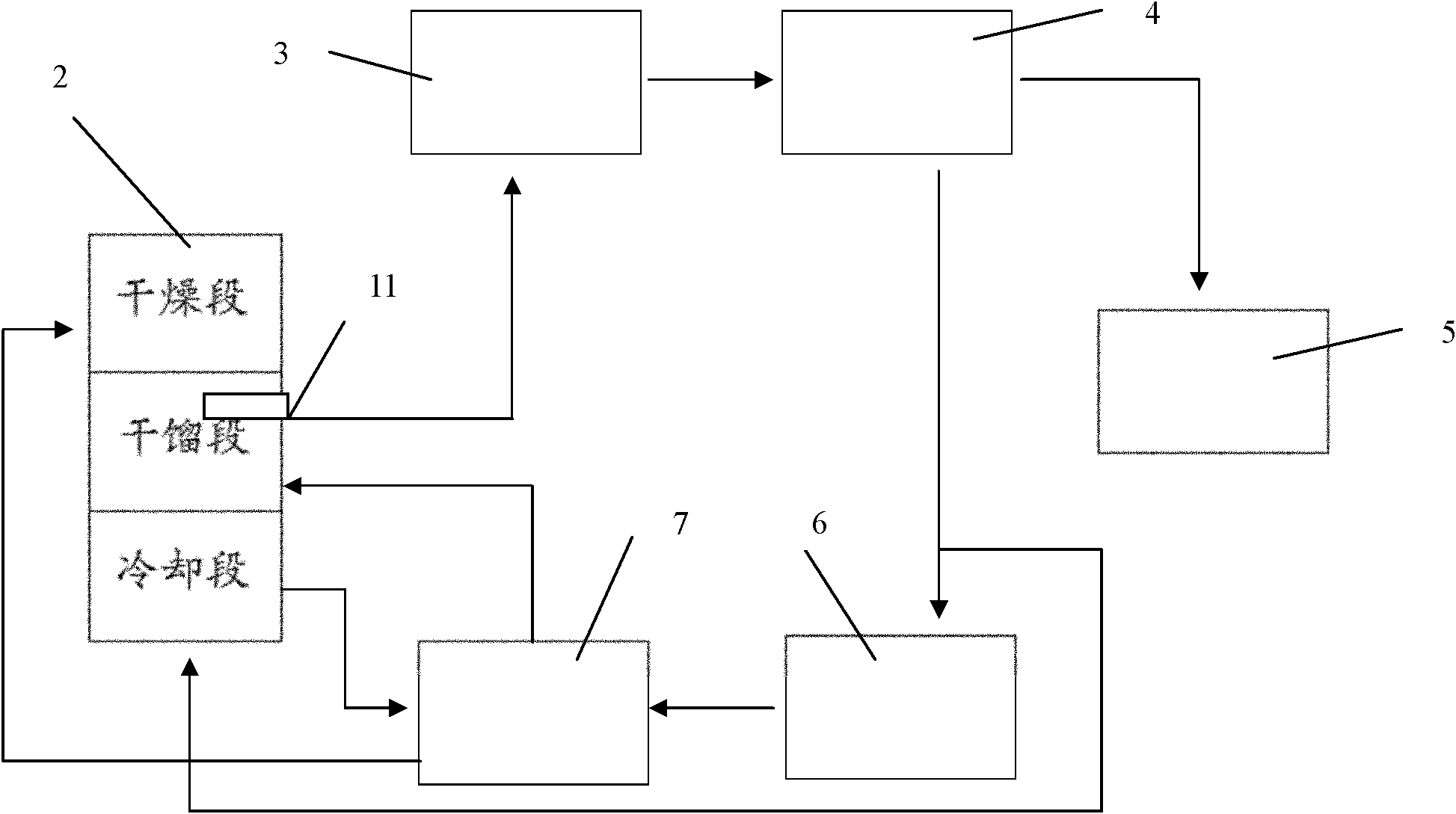

External combustion internally heated coal carbonization furnace

ActiveCN101691493AImprove retort efficiencyRealize energy saving and environmental protectionDirect heating destructive distillationIndirect heating destructive distillationProcess engineeringCoal

The invention relates to an external combustion internally heated coal carbonization furnace which comprises a drying section, a carbonization section, a cooling section and a cold smoke pipe which are arranged sequentially from top to bottom, wherein the drying section is used for drying the raw material coal and simultaneously obtaining cold smoke in the drying process; the carbonization section is used for carbonizing the raw material coal after the drying process and forming a carbonization product after the raw material coal is carbonized; the cooling section is used for cooling the carbonization product produced in the carbonization section by introducing the cold smoke; and the cold smoke pipe is used for conducting the cold smoke generated by the drying section to the cooling section. The external combustion internally heated coal carbonization furnace of the invention fully utilizes the cold smoke generated in the technical process to cool the carbonization product, thereby improving the overall carbonization efficiency; and a large amount of sulfur in the smoke is removed simultaneously when the carbonization product is cooled, thereby realizing the purposes of energy saving and environment protection.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +1

Coal carbonization technology

InactiveCN101691492AImprove retort efficiencyRealize energy saving and environmental protectionCoke quenchingSpecial form destructive distillationSulfurProcess engineering

The invention relates to a coal carbonization technology which comprises the following steps: a. drying raw material coal, and simultaneously obtaining cold smoke; b. carbonizing the coal after the drying process to form a carbonization product; and c. introducing the cold smoke generated in step a into the carbonization product generated after the carbonization, and cooling the carbonization product. The carbonization technology of the invention fully utilizes the cold smoke generated in the technical process to cool the carbonization product, thereby improving the overall carbonization efficiency; and a large amount of sulfur in the smoke is removed simultaneously when the carbonization product is cooled, thereby realizing the purposes of energy saving and environment protection.

Owner:XILINHOT NAT ENERGY TECH +1

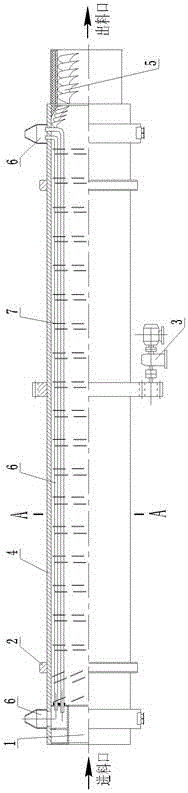

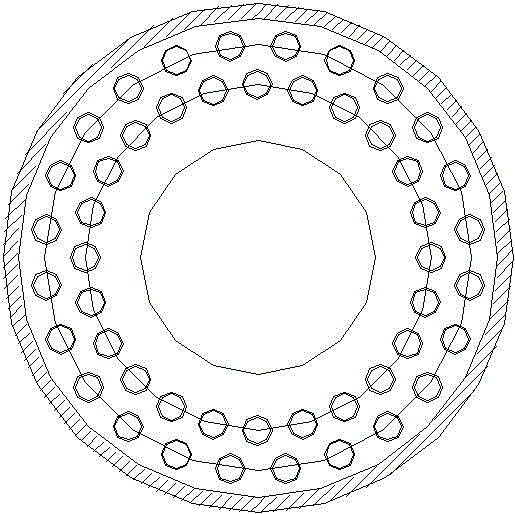

Internal heat rotary kiln coal dry distillation device

InactiveCN104910939AAvoid pollutionSolve pollutionIndirect heating destructive distillationSpecial form destructive distillationThermodynamicsProcess engineering

The invention discloses an internal heat rotary kiln coal dry distillation device comprising a kiln body (4) with a feeding device (1) and a discharge device (5) respectively arranged on the two ends. The kiln body (4) has a sealed structure. A heating device (6), a rotation stabilization device (2) and a transmission device (3) are respectively arranged on the kiln body (4). The kiln body (4) is cylindrical. A pipe rack spiral plate (7) and a heating device (6) are arranged in the kiln body (4). The kiln body (4) is inclined towards the end provided with the discharge device (5), such that the kiln body end with the feeding device (1) is higher than the end with the discharge device (5). The internal heat rotary kiln coal dry distillation device provided by the invention has a simple and fully sealed structure. With the device, continuous production can be realized, and no dust, coal gas or pollutant is discharged to the surrounding environment during a dry distillation process. With the device, the production efficiency is greatly higher than that of prior arts.

Owner:SANMENXIA CHEM MACHINERY

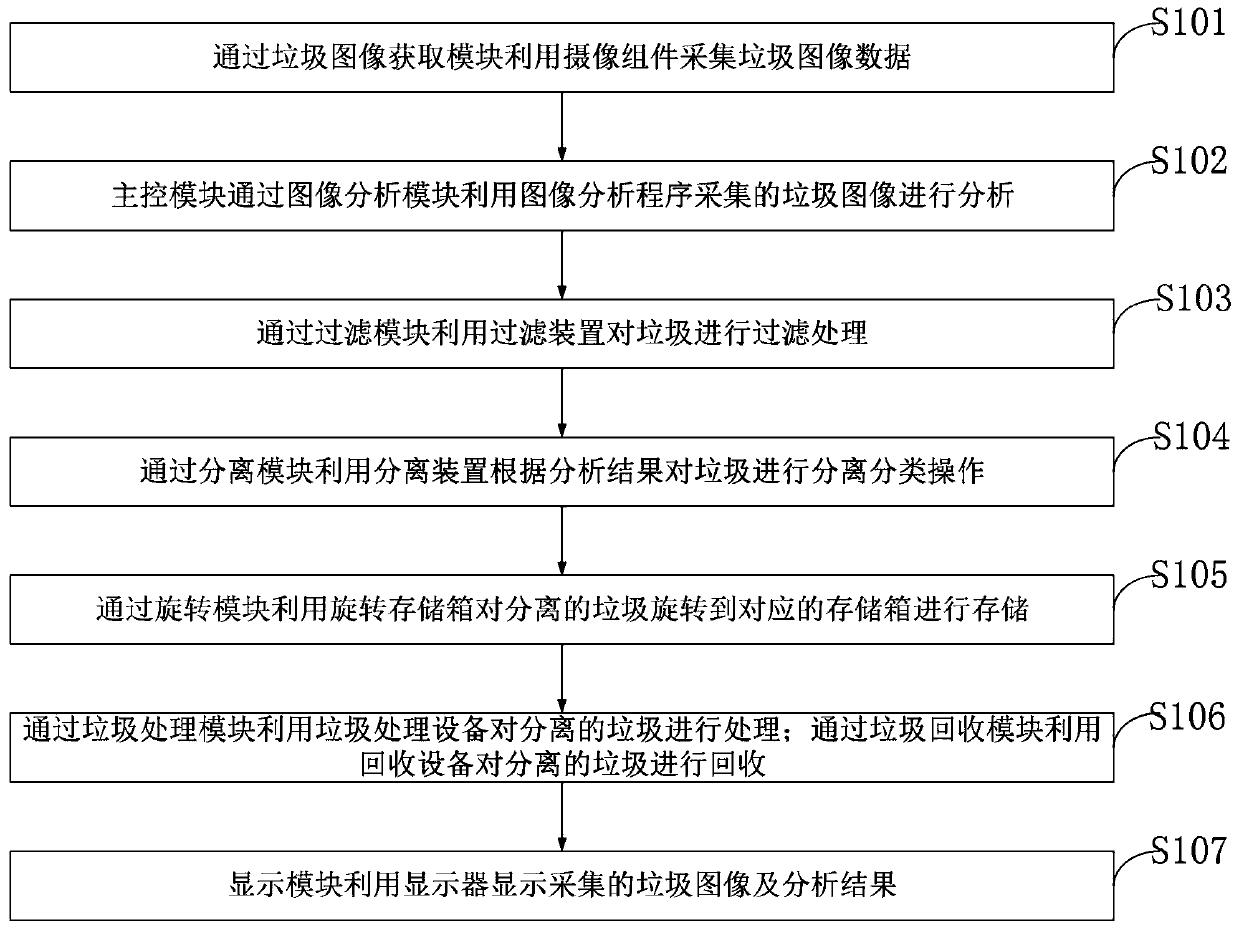

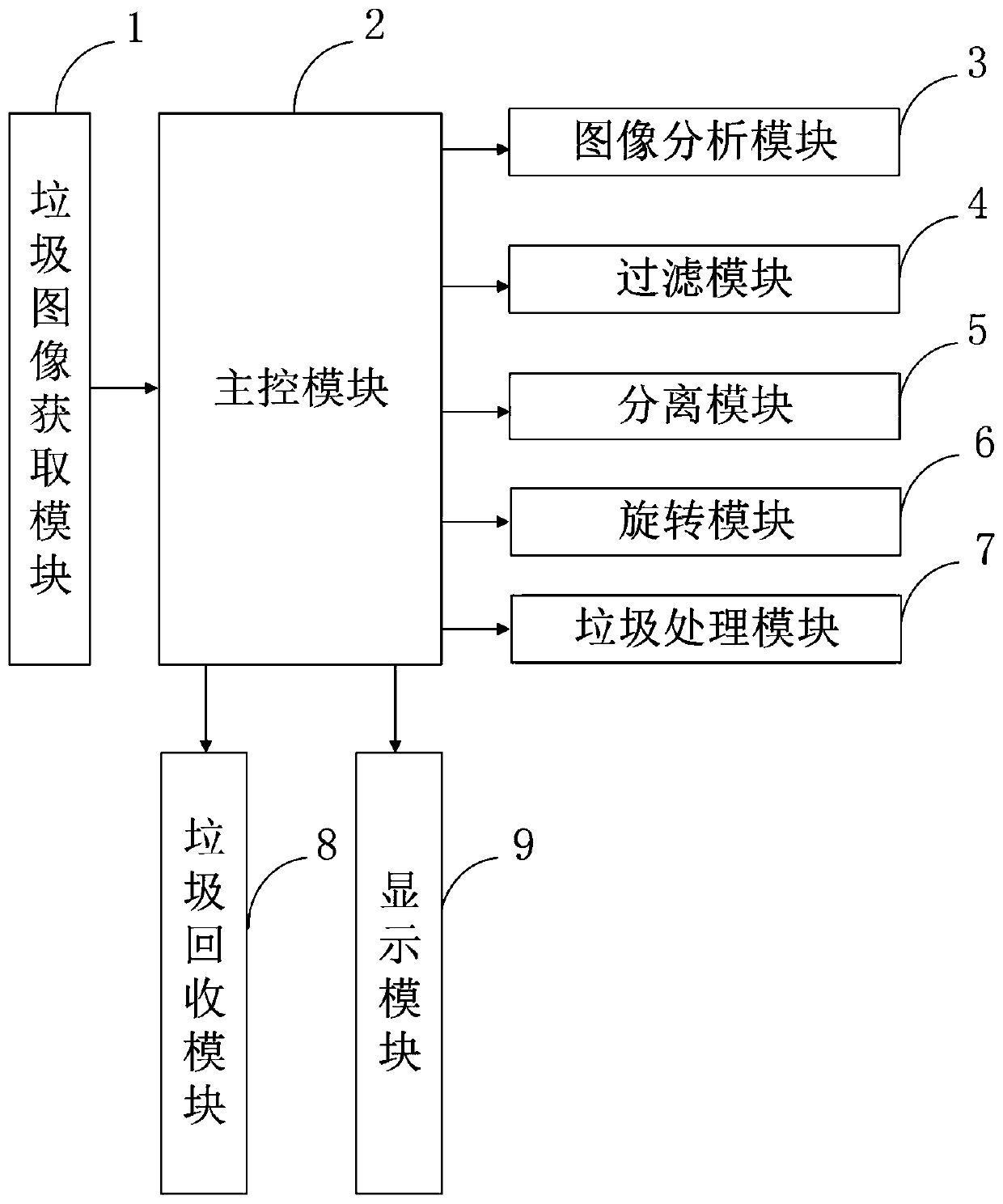

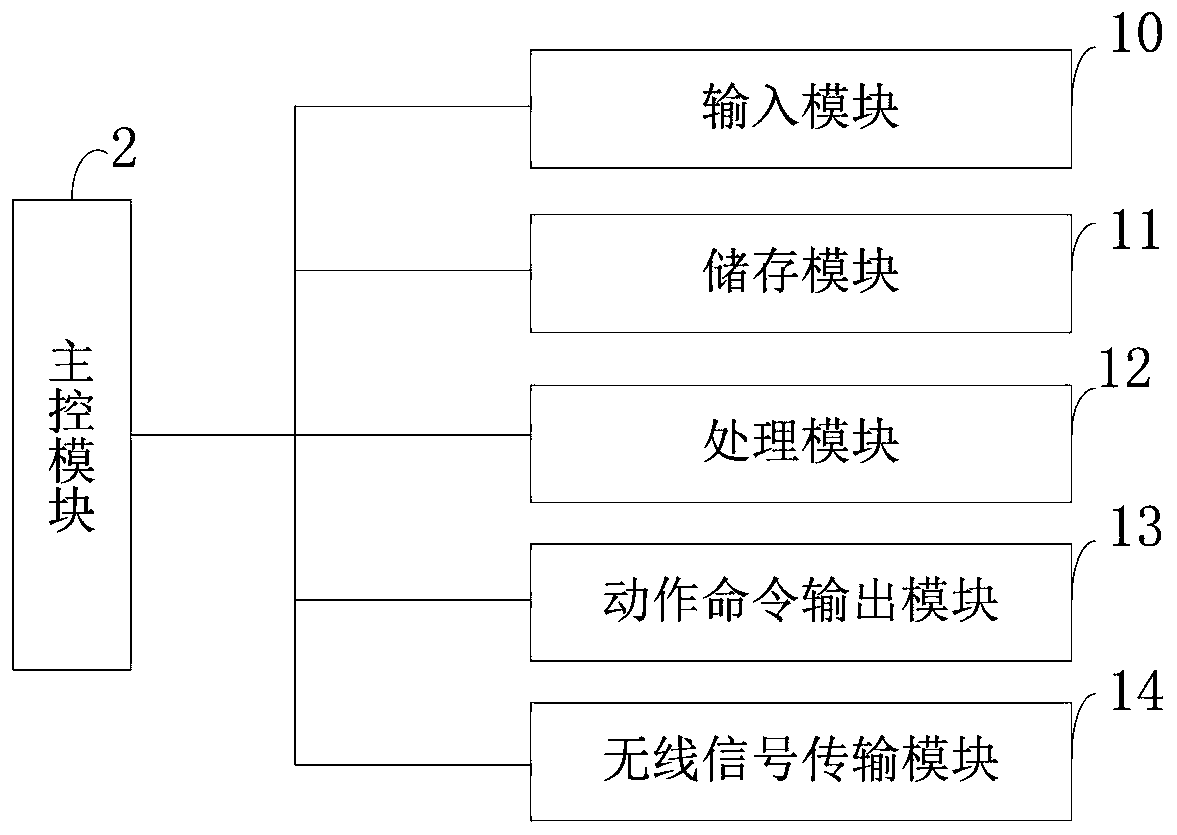

Cloud-based garbage sorting system and method, information processing terminal and storage medium

PendingCN111027639AImprove retort efficiencyImprove energy utilizationCharacter and pattern recognitionMagnetic separationInformation processingRefuse Disposals

The invention belongs to the technical field of garbage sorting, and discloses a cloud-based garbage sorting system and method, an information processing terminal and a storage medium. The cloud-basedgarbage sorting system comprises a garbage image acquisition module, a main control module, an image analysis module, a filtering module, a separation module, a rotating module, a garbage processingmodule, a garbage recycling module and a display module; the garbage image acquisition module acquires garbage image data; the main control module controls each module to work normally; the image analysis module analyzes the collected garbage images; and the separation module separates and classifies the garbage. A complex oil-gas separation system in a traditional garbage pyrolysis process is omitted through the garbage treatment module, and the garbage treatment method is simple, low in cost and easy to operate; and through the garbage recycling module, the garbage treatment and recycling efficiency is improved, resource waste is reduced, the garbage harmless treatment difficulty is reduced, and the influence on the environment is weakened.

Owner:BEIHUA UNIV

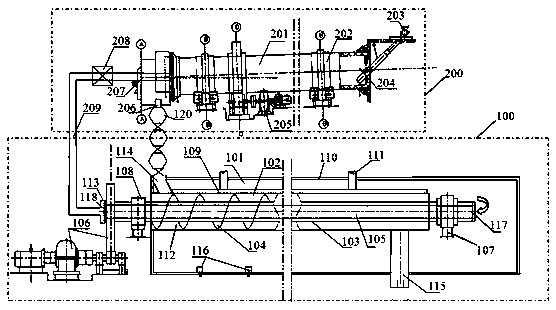

Efficient internal thermal type oil extraction device for powder oil shale and extraction method thereof

InactiveCN102161899ASufficient heat exchangeImprove thermal efficiencyDirect heating destructive distillationSpecial form destructive distillationHeating oilHeat carrier

The invention relates to an efficient internal thermal type oil extraction device for powder oil shale and an extraction method thereof. The device consists of a gas uniform distributer, a dry distillation furnace, a whirlwind clamping sleeve, a water-cooling electrical tar precipitator, an oil storage tank, a burner and a metal beehive-type heat exchanger. A dry distillation section in the dry distillation furnace is provided with the gas uniform distributer, thereby realizing the direct heat exchange between powder materials and a gas heat carrier and greatly improving heat efficiency; a multi-layer uniform wind distribution technique is used to ensure the complete dry distillation of the oil shale; and no extra energy is supplied to the whole system, thereby achieving self-sufficiency of energy. In the novel efficient internal thermal type oil extraction process for the powder oil shale, an internal thermal method is adopted, namely, the oil shale is heated by directly by gas, and the oil shale is decomposed by heating so as to generate dry distillation oil gas; and then as the dry distillation oil gas is condensed and collect to obtain high-quality crude oil and gassy mashgas.The novel process has high heat efficiency, is stable and safe, simple and reliable, and the like; and by using the novel process, the production cost of the oil extraction of the powder oil shale isgreatly reduced, and oil yield is significantly improved, thereby improving the comprehensive utilization of the oil shale.

Owner:唐山雷浩能源技术装备有限公司 +2

Heat carrier destructive distillation system for coal and method thereof

ActiveCN103409156AIncrease profitReduce oxygen contentDirect heating destructive distillationEnergy inputCooling towerHeat carrier

The invention relates to a heat carrier destructive distillation system for coal, which comprises a raw coal cabin, a flash dryer, and a circulating fluidized bed air heating furnace, wherein a spiral metering conveyor I is arranged at the bottom of the raw coal cabin; a flash dryer is connected with a drying primary separator and an air heating furnace twice cyclone separator; the drying primary separator is connected with a drying secondary separator and a mixer; the air heating furnace twice cyclone separator is connected with a cooling paddle machine and a waste heat boiler; the waste heat boiler is connected with an air heating furnace once cyclone separator connected with the mixer and the circulating fluidized bed air heating furnace; the mixer is connected with an internal thermal rotary gas retort; a separator is connected with a cooling tower and a fluidized bed grading cooler; the cooling tower is connected with a coal gas air blower and a tar oil cooler; the fluidized bed grading cooler is connected with a semi-coke delivery pipe, the drying secondary separator and a grading cyclone separator; the circulating fluidized bed air heating furnace is connected with the grading cyclone separator. In addition, the invention further discloses an application method of the system. The heat carrier destructive distillation system is low in investment and easy to implement, and has high overall efficiency and excellent safety.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

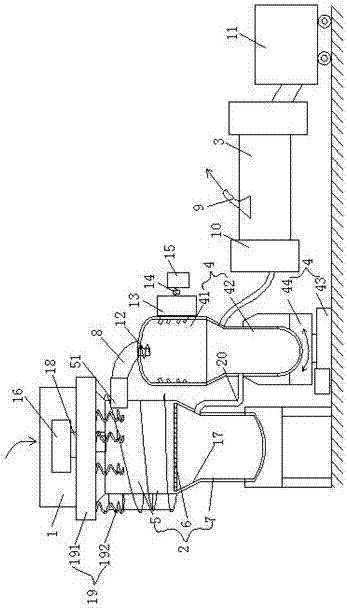

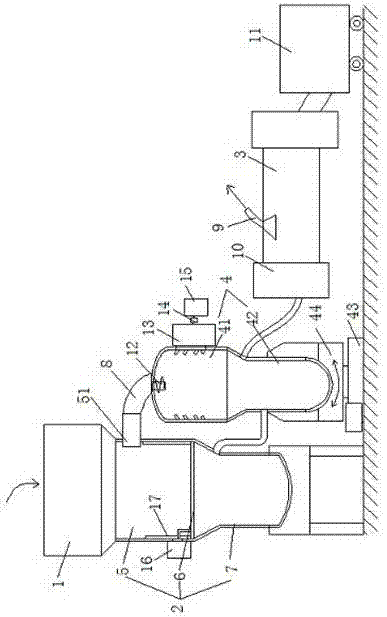

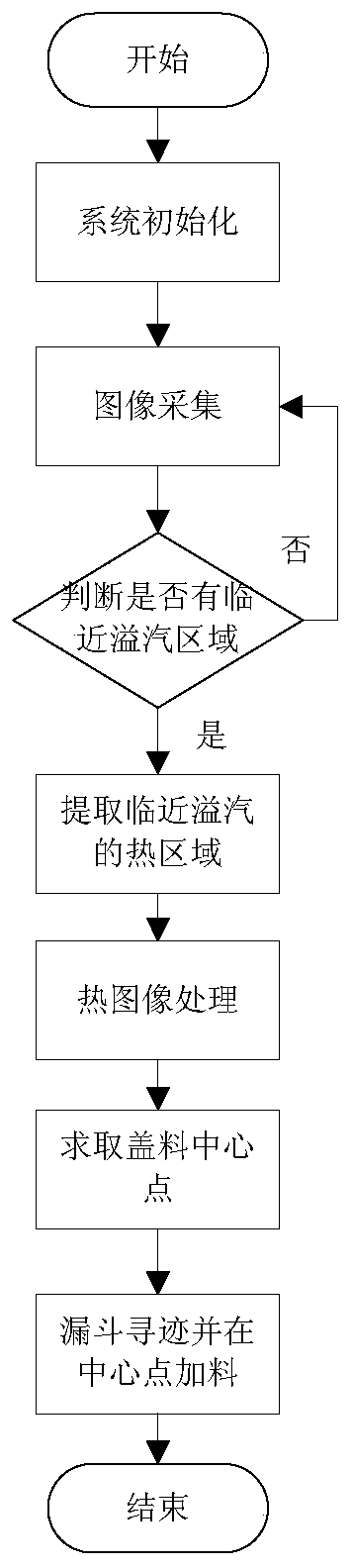

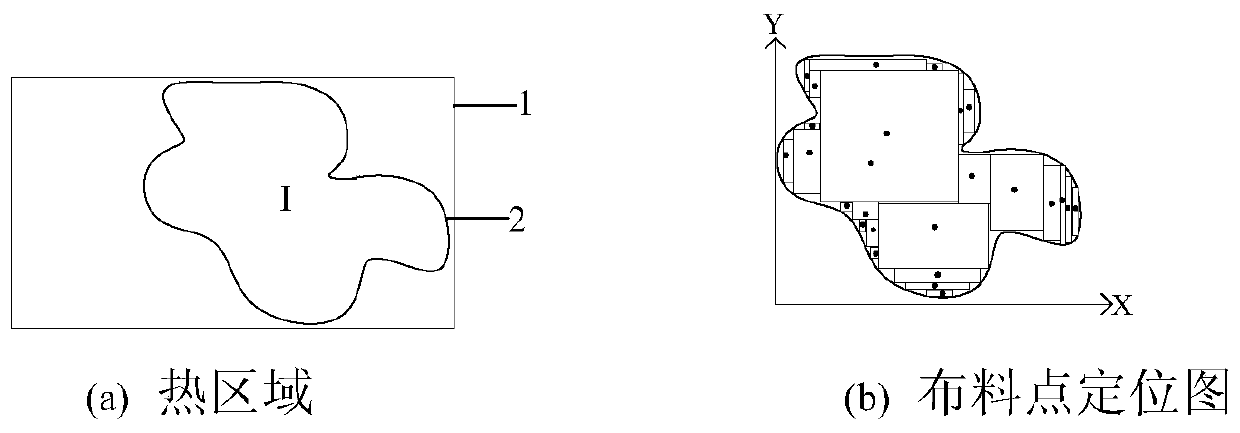

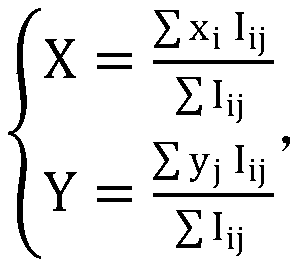

Method for controlling material distilling in liquor brewing distillation technology by use of images

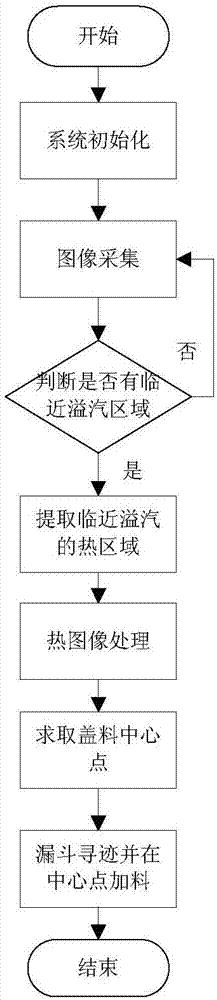

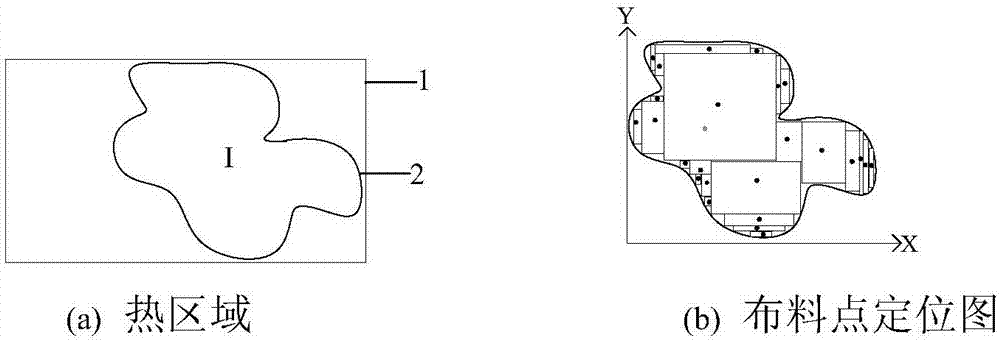

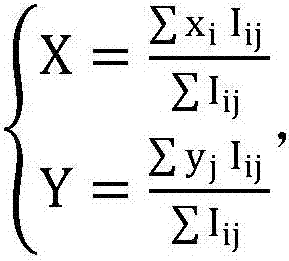

ActiveCN107168117AImprove productivityImprove retort efficiencyProgramme control in sequence/logic controllersCyclic testDistillation

The invention discloses a method for controlling material distilling in liquor brewing distillation technology by use of images. The method comprises steps of step 1, initializing a system; step 2, image acquiring: acquiring infrared thermal images; step 3, carrying out circulation test on the infrared thermal images; step 4, extracting pixel regions meeting the condition that the pixel value G is between G1 and G2 in the infrared thermal images as heat regions; step 5, processing the heat region images; and step 6, solving the position of the center point of covering materials, and charging materials in the center point to the boundary position of a covering material region, thereby finishing material charging. According to the invention, a thermal imaging camera is used for acquiring images so as to search the heat regions, so the position of an overflow critical point of the liquor steam is intelligently recognized; the coordinate of the center of mass is solved, so the material distribution center is rapidly determined in real time and through a hopper, tracking is automatically performed and specific spiral type material distribution to the boundary of the covering material region is performed; and efficiency of material distilling and yield of liquor during a distillation process are greatly improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

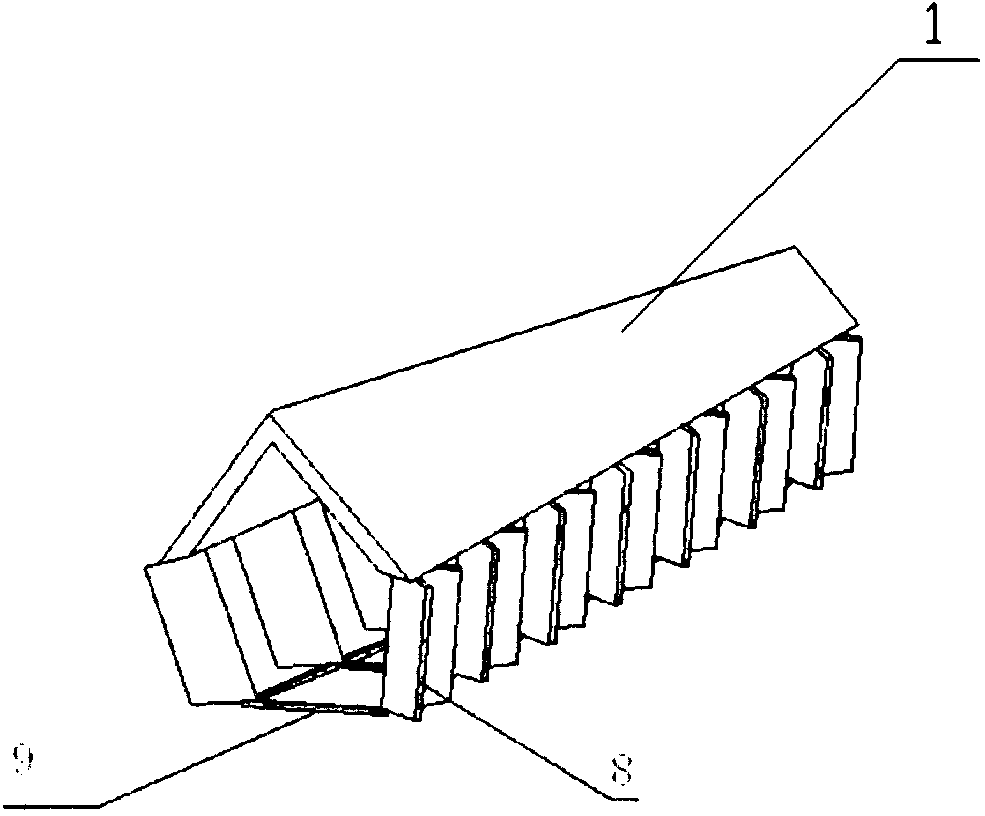

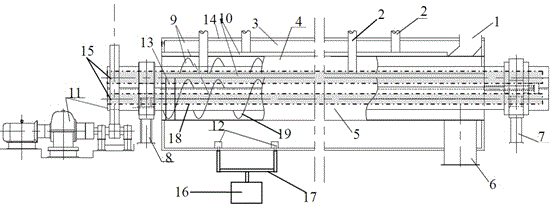

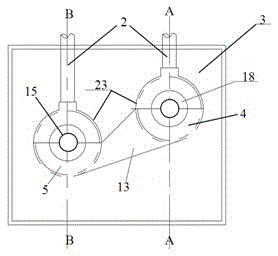

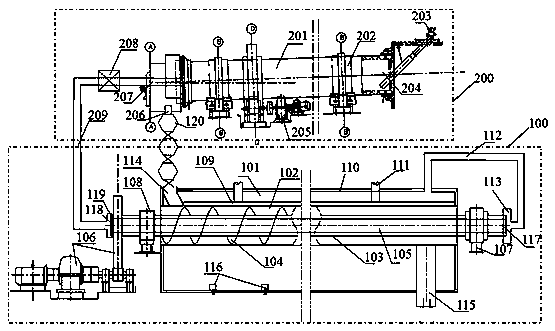

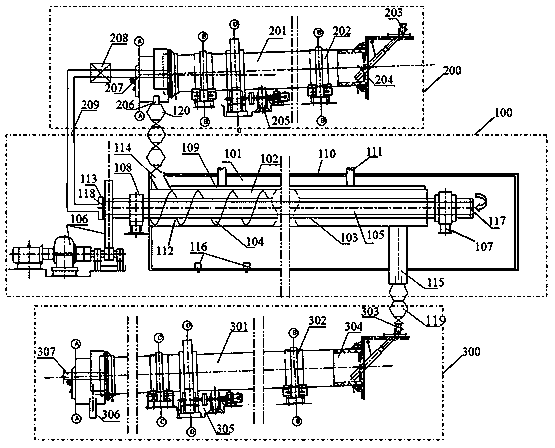

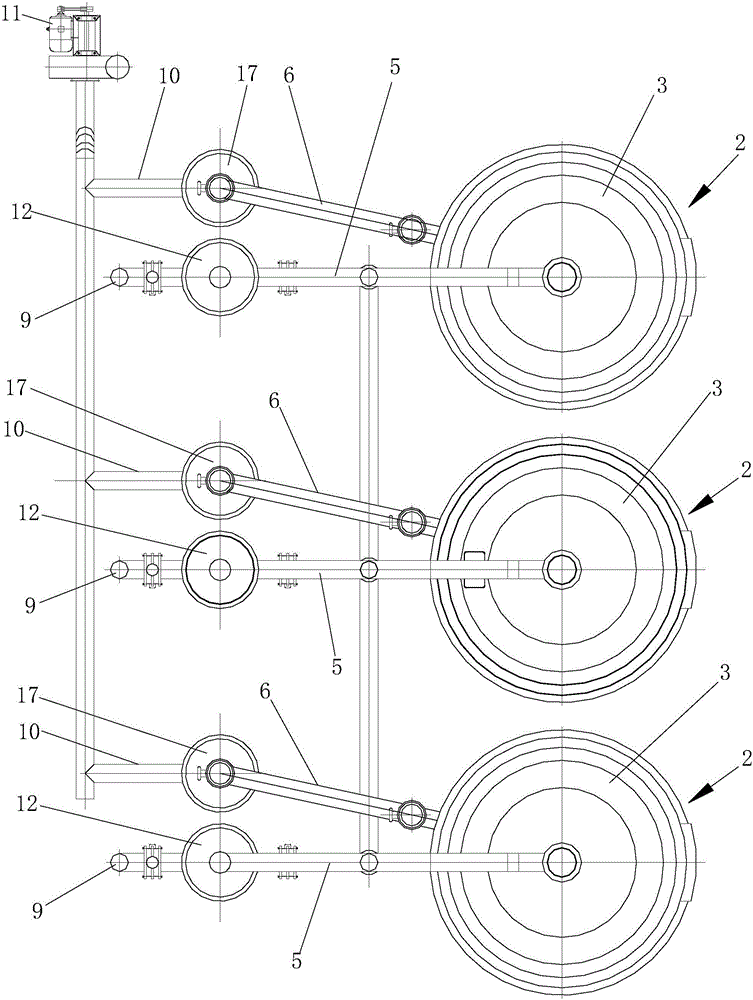

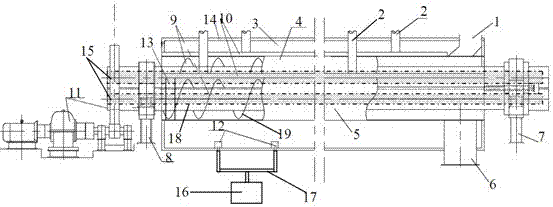

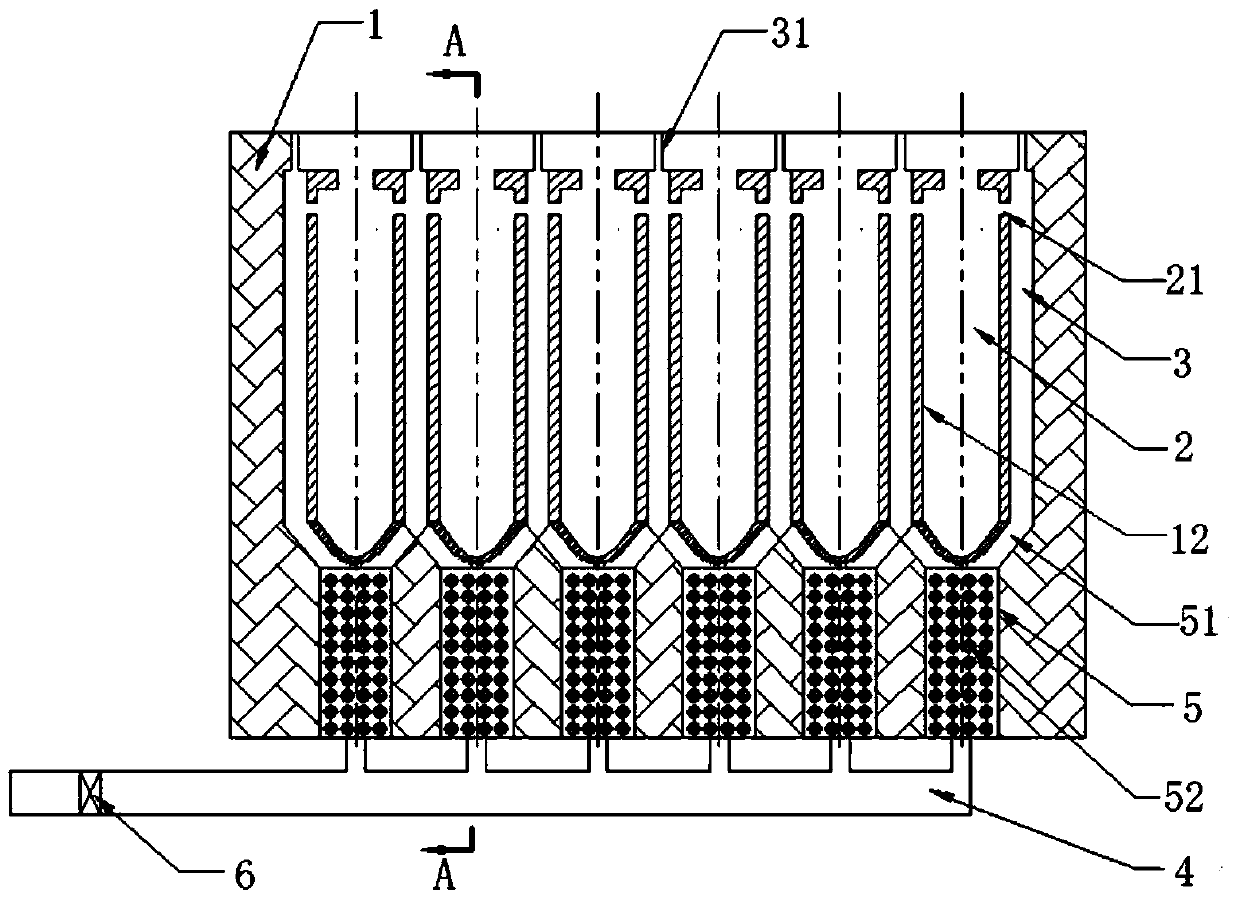

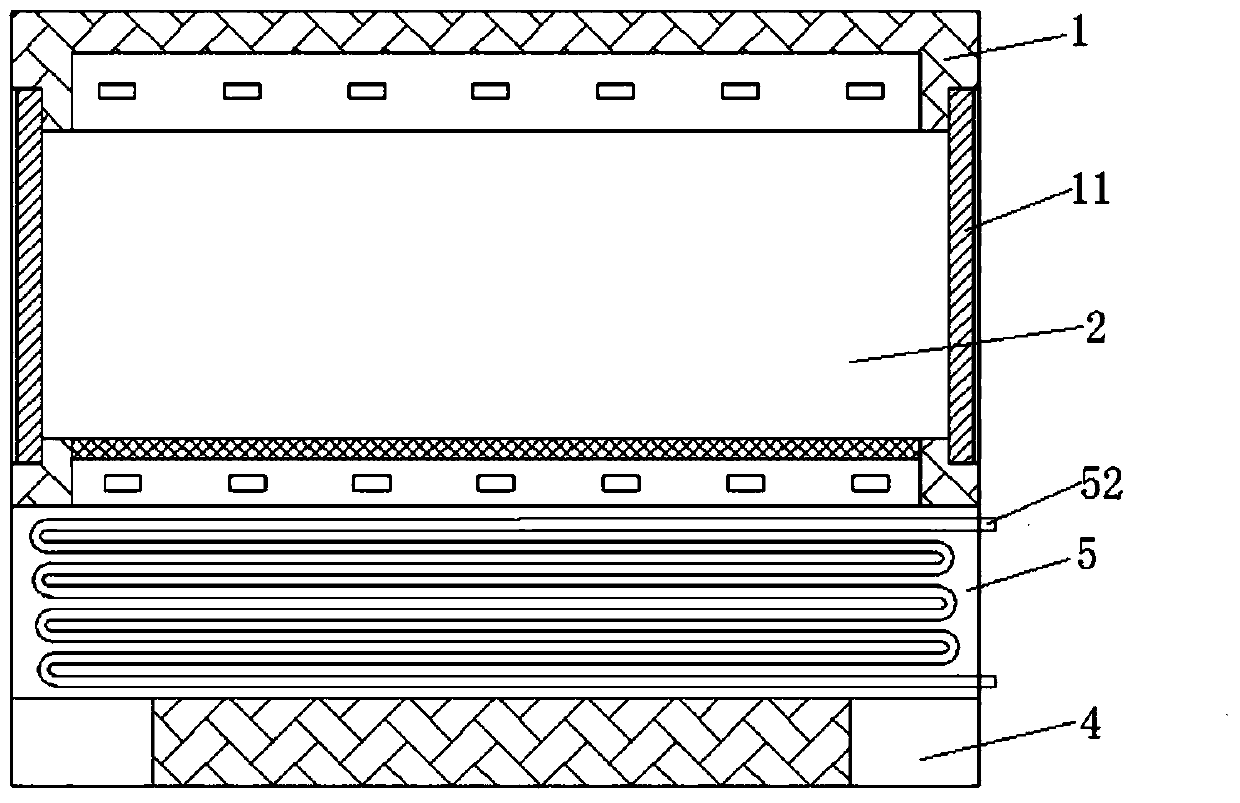

Screw-propelling external-heating type coal dry distillation device

ActiveCN105482841ABroad market prospectImprove retort efficiencyLiquid hydrocarbon mixture productionIndirect heating destructive distillationTarProcess engineering

The invention provides a screw-propelling external-heating type coal dry distillation device. The device comprises a heating chamber, dry distillation chambers, a spiral conveying device, a pyrolysis gas collection device, a bearing supporting base, a material feeding and discharging mechanism and a drive device, wherein the pyrolysis gas collection device is communicated with the dry distillation chambers , the heated part of each dry distillation chamber is located in the heating chamber, the dry distillation chambers are isolated from the heating chamber, the material feeding and discharging mechanism is connected with the dry distillation chambers, the spiral conveying device is arranged in the dry distillation chambers, the end of the spiral conveying device is supported by the bearing supporting base, the drive device is connected to the end of the spiral conveying device, a smoke exhaust channel is arranged in the spiral conveying device, and the heating chamber is communicated with the smoke exhaust channel. A spiral propelling mechanism is adopted for propelling of raw coal, multiple dry distillation chambers are connected in the same sealed heating chamber in parallel, combustion smoke is introduced into a raw material propelling device to realize recycling of heat energy, the raw coal propelling problem in dry distillation of coal is solved, the dry distillation heating efficiency is improved, and the device has the advantages that coal is uniformly heated in the dry distillation process, the heating efficiency is high, the yield of tar is high and the like.

Owner:王崇峰

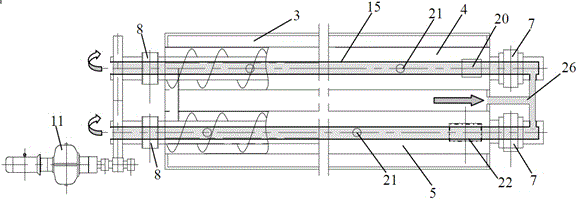

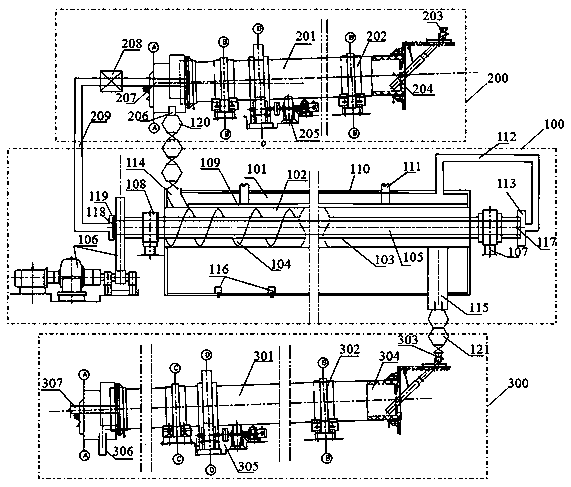

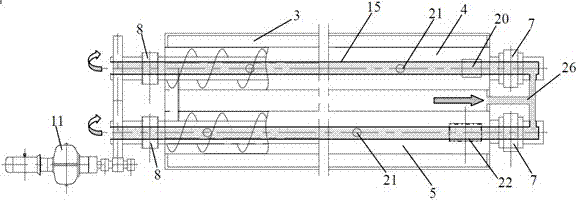

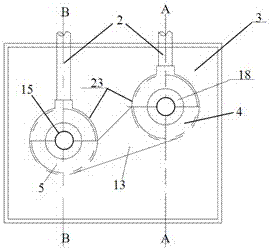

Medium and low coal temperature separate dry distillation system and method

ActiveCN105505421AEfficient dehydrationImprove thermal distillation efficiencySpecial form destructive distillationThermodynamicsCombustion chamber

The invention provides a medium and low coal temperature separate dry distillation system and method. The dry distillation system comprises a spiral pushing medium and low temperature external heating dry distillation device and a low temperature internal heating rotary kiln dry distillation device. A spiral pushing dry distillation chamber in the spiral pushing medium and low temperature external heating dry distillation device is arranged in a combustion chamber of the spiral pushing medium and low temperature external heating dry distillation device, burned smoke in the combustion chamber is circulated back into a rotary kiln cylinder, and solid-state materials in the rotary kiln cylinder are supplied into the spiral pushing dry distillation chamber. For the first time, dry distillation of coal is divided into two or more stages according to temperature, an internal heating rotary kiln and the external heating type spiral pushing dry distillation device are combined organically to achieve dry distillation; the rotary kiln is used for performing winnowing dust removal, preheating drying and dehydration on raw coal, and the external heating type spiral pushing dry distillation device realizes a high-efficiency medium and low temperature dry distillation process and precipitation of high calorific value raw gas and a tar product; the advantages of internal and external heating dry distillation equipment are fully combined, dry distillation efficiency, heat utilization efficiency and dry distillation product quality are greatly improved in a brand new mode, and the market popularization prospect is broad.

Owner:王崇峰

Internal and external heating type medium and low temperature powdered coal temperature division dry distillation system and method

ActiveCN105505422AEfficient dehydrationImprove thermal distillation efficiencyIndirect and direct heating destructive distillationSpecial form destructive distillationProcess engineeringCombustion chamber

The invention discloses an internal and external heating type medium and low temperature powdered coal temperature division dry distillation system and method. The system comprises a spiral pushing medium and low temperature external heating dry distillation device and a low temperature internal heating rotary kiln dry distillation device, wherein a spiral pushing dry distillation chamber in the spiral pushing medium and low temperature external heating dry distillation device is arranged in a combustion chamber of the spiral pushing medium and low temperature external heating dry distillation device, combustion smoke in the combustion chamber is directly supplied to the interior of a rotary kiln cylinder, and solid materials in the rotary kiln cylinder are supplied to the interior of the spiral pushing dry distillation chamber. Dry distillation of coal is divided into two or more phases according to temperature and is achieved through organic combination of the internal heating rotary kiln dry distillation device and the spiral pushing external heating dry distillation device, winnowing and dust removal, preheating and drying and dehydration are conducted on raw coal by means of a rotary kiln, high-efficiency medium and low temperature dry distillation and high-calorific-value raw gas and tar product precipitation are achieved by means of the spiral pushing external heating dry distillation device, the advantages of the internal heating dry distillation device and the external heating dry distillation are fully combined, dry distillation efficiency, heat utilization efficiency and the quality of dry distillation products are improved greatly, and marketing prospects are broad.

Owner:王崇峰

Compression calcining type oil shale dry-distillation system

PendingCN107298982AImprove retort efficiencyImprove oil recoveryIndirect heating destructive distillationSpecial form destructive distillationSand blastingHeat energy

The invention discloses a compression calcining type oil shale dry distillation system, which comprises a crushing device, a compression classification device, a sandblasting dry distillation device, a filter, an oil gas separation device, an oil gas dust collector, and an oil collection device connected in sequence, wherein: compression classification The device includes sequentially connected capsule-type grading compression chambers, fixed mesh screens, and first-stage dry distillation and calcining chambers. The capsule-type grading compression chambers are equipped with vertically telescopic power sources, telescopic sleeves, and automatic recovery devices. The outlet of small grains of oil shale passes through The conveying pipe transports the small particle oil shale to the sandblasting and retorting device, and the sandblasting and retorting device includes a vertical sandblasting section and a secondary calcining device; the primary retorting and calcining chamber is also connected to the secondary calcining device. The dry distillation system of the present invention compresses and grades oil shale according to particle size, and is accompanied by sandblasting in the second stage of calcination, and heat energy can be shared between the two stages of calcination. It is a highly efficient, low-loss graded dry distillation system for calcination.

Owner:JIANGSU PENGFEI GROUP

Carbonization furnace used for destructive distillation

InactiveCN105950189AImprove retort efficiencyEffective separationBiofuelsIndirect heating destructive distillationCombustionMetallurgy

The invention discloses a carbonization furnace used for destructive distillation. The carbonization furnace comprises a base, a furnace body arranged on the base and a furnace pipe arranged in the furnace body in a hoisting way, wherein the upper end of the furnace pipe is hermetically connected with the upper end of the furnace body; a combustion heating device used for heating the furnace pipe is arranged below the furnace pipe; the base is provided with an air inlet used for providing the combustion heating device with air and an adjusting door used for controlling the opening degree of the air inlet; a heating gap is left between the furnace pipe and the furnace body; the furnace body is provided with a smoke exhaust port used for exhausting heating smoke; and the upper end of the furnace pipe is provided with a destructive distillation gas outlet used for discharging destructive distillation gas. The carbonization furnace used for destructive distillation employs a manner of direct heating of the furnace pipe; the heating of the furnace pipe is carried out in the furnace body; charging, cooling, discharging and other procedures are carried out out of the furnace body; and after heating of one furnace pipe is completed, another furnace pipe can be hoisted for heating, so destructive distillation efficiency is greatly improved.

Owner:咸阳盘州现代农业有限公司

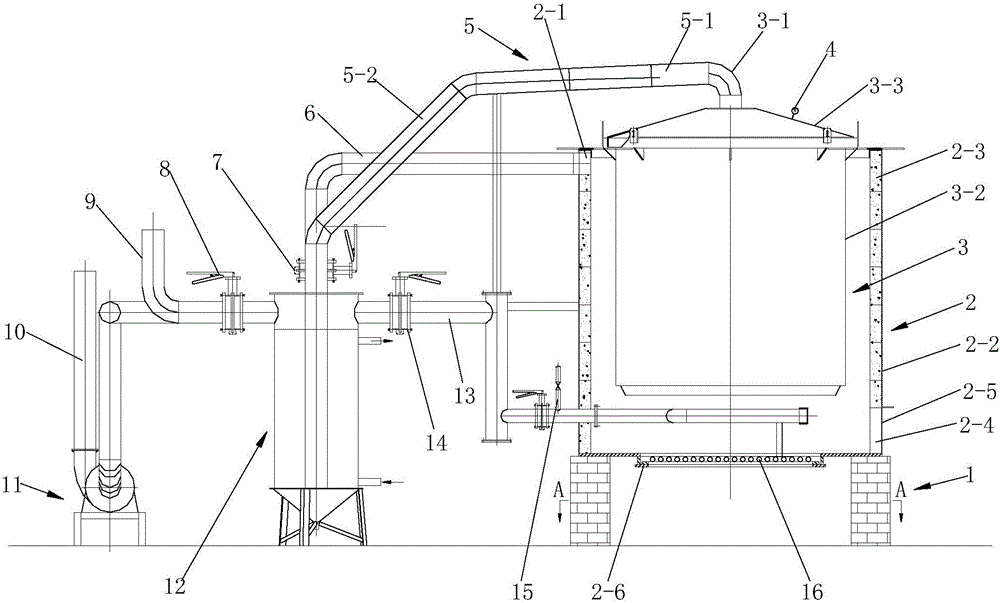

Dry deslagging and dry distillation furnace for small oil shale grains

PendingCN110903838ARetortTo achieve the purpose of dry distillationIndirect and direct heating destructive distillationLiquid hydrocarbon mixture productionSlagWater jacket

The invention discloses a dry deslagging and dry distillation furnace for small oil shale grains, and belongs to the technical field of dry distillation furnaces. The dry deslagging and dry distillation furnace comprises a furnace body, a gas collecting umbrella, a gas eduction tube, a high-temperature radiation heat exchange small ring tube, a high-temperature radiation heat exchange large ring tube, a cone grate, a flue gas heat exchange guide tube, a slag scraping plate, an in-furnace slag discharging transmission device, an air and saturated steam mixed furnace inlet, a slag discharging box, a water jacket cooling spiral conveyor and a steam sealing heat exchange inlet. A 5-13 mm or 5-20 mm oil shale raw material is subjected to dry distillation oil refining; a dry deslagging mode is adopted, the height of the slag scraping plate in the furnace is set, and the rotating speed of a motor is adjusted through an adjustable frequency converter in the in-furnace slag discharging transmission device to control the deslagging amount; after ash is discharged, steam with a certain pressure is used for blocking the gas in the furnace from overflowing, and a part of steam exchanges heat with high-temperature ash and is pumped into the furnace, so the heat efficiency of the dry distillation furnace is improved; and the ash slag is cooled with the steam, and then passes through the waterjacket cooling spiral conveyer, and ash slag semicoke is conveyed out of the furnace.

Owner:北京龙源宏达科技发展有限公司

Lightweight oil shale hierarchical destructive distillation equipment

PendingCN107227166AGuaranteed stabilityImprove retort efficiencyIndirect heating destructive distillationSpecial form destructive distillationReciprocating motionOil shale gas

The invention discloses lightweight oil shale hierarchical destructive distillation equipment. The lightweight oil shale hierarchical destructive distillation equipment comprises a crushing device, a compression grading device, an oil-gas separation device, a sandblasting destructive distillation device, a filter, an oil-gas dust collector and an oil receiving device, wherein the compression grading device comprises a compression grading chamber, a mesh screen capable of moving up and down and a primary destructive distillation calcining chamber which are sequentially connected, and the diameter of the compression grading chamber is larger than that of the primary destructive distillation calcining chamber; a power source is moved up and down to drive the mesh screen capable of moving up and down to perform reciprocating motion up and down in the compression grading chamber to screen oil shale particles; a small particle oil shale outlet is further formed in the position, close to the top, of the compression grading chamber and conveys small-particle oil shale to the sandblasting destructive distillation device through a conveying pipe, and the sandblasting destructive distillation device comprises a vertical sandblasting segment and a secondary calcining device; and the primary destructive distillation calcining chamber is also connected with the secondary calcining device. According to the lightweight oil shale hierarchical destructive distillation equipment, equipment is simplified, the cost is lowered and the oil receiving rate of oil shale is improved.

Owner:JIANGSU PENGFEI GROUP

A kind of spiral propelling material external heating coal dry distillation device

ActiveCN105482841BSlow advance and even heatingSolve problems that limit pyrolysis yieldIndirect heating destructive distillationLiquid hydrocarbon mixture productionCombustionProcess engineering

The invention provides a screw-propelling external-heating type coal dry distillation device. The device comprises a heating chamber, dry distillation chambers, a spiral conveying device, a pyrolysis gas collection device, a bearing supporting base, a material feeding and discharging mechanism and a drive device, wherein the pyrolysis gas collection device is communicated with the dry distillation chambers , the heated part of each dry distillation chamber is located in the heating chamber, the dry distillation chambers are isolated from the heating chamber, the material feeding and discharging mechanism is connected with the dry distillation chambers, the spiral conveying device is arranged in the dry distillation chambers, the end of the spiral conveying device is supported by the bearing supporting base, the drive device is connected to the end of the spiral conveying device, a smoke exhaust channel is arranged in the spiral conveying device, and the heating chamber is communicated with the smoke exhaust channel. A spiral propelling mechanism is adopted for propelling of raw coal, multiple dry distillation chambers are connected in the same sealed heating chamber in parallel, combustion smoke is introduced into a raw material propelling device to realize recycling of heat energy, the raw coal propelling problem in dry distillation of coal is solved, the dry distillation heating efficiency is improved, and the device has the advantages that coal is uniformly heated in the dry distillation process, the heating efficiency is high, the yield of tar is high and the like.

Owner:王崇峰

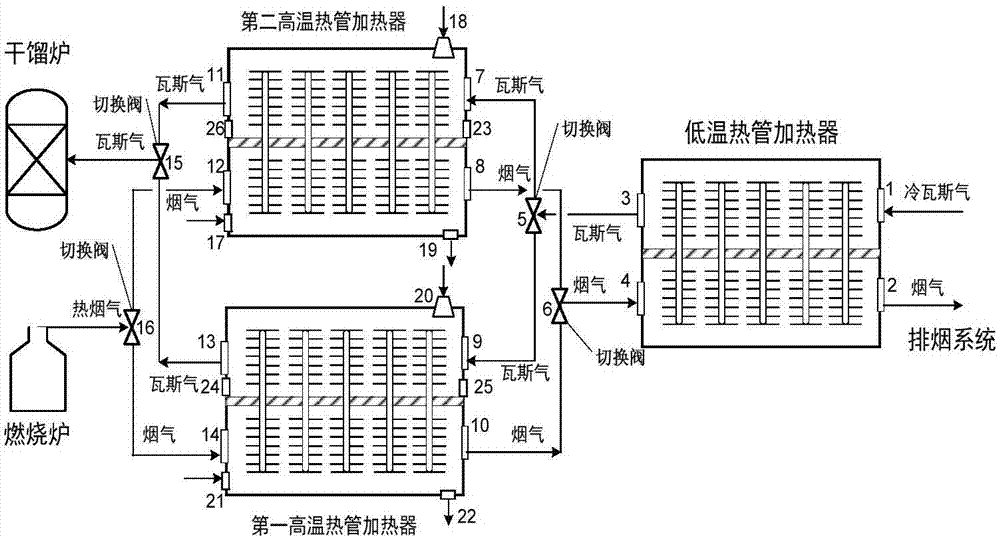

Gas distillation process employing heat pipe heating oil shale

ActiveCN104498074AAffect heating efficiencyAvoid intractableLiquid hydrocarbon mixture productionSpecial form destructive distillationDistillationCarbon deposit

The invention discloses a gas distillation process employing a heat pipe heating oil shale. The gas distillation process is characterized by comprising a circulating gas heating process, a high-temperature flue gas cooling process, treatment of carbon deposit and treatment of soot formation, wherein the circulating gas heating process is alternately switched first circulating gas heating process or second circulating gas heating process; a high-temperature circulating gas subjected to heat treatment is conveyed to a dry distillation furnace; the high-temperature flue gas cooling process is alternately switched first high-temperature flue gas cooling process or second high-temperature flue gas cooling process; the flue gas, which is subjected to cooling treatment, of a high-temperature flue gas of a combustion furnace is discharged into a smoke extraction system; and carbon deposit treatment and soot formation treatment are carried out on a high-temperature heat pipe heater in an alternately switching manner, so that the gas distillation process has the advantages of being reasonable in technological process, convenient to operate, low in fault rate, high in oil shale distillation efficiency and the like.

Owner:NORTHEAST DIANLI UNIVERSITY

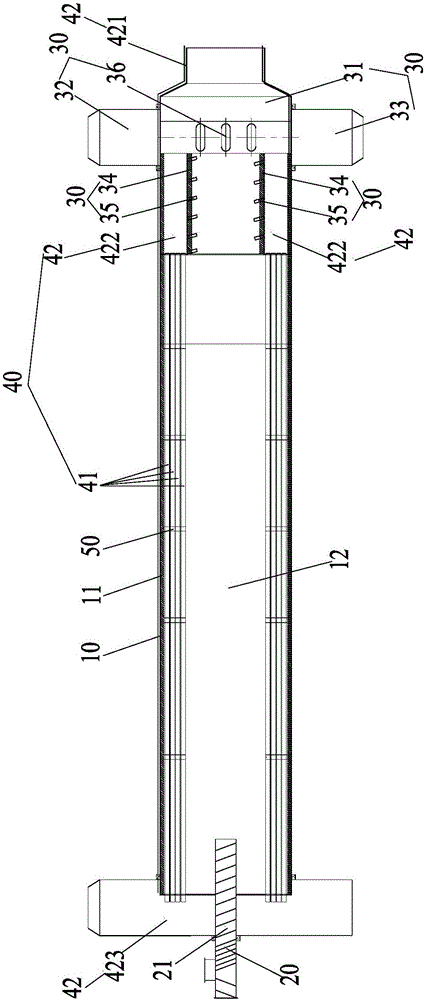

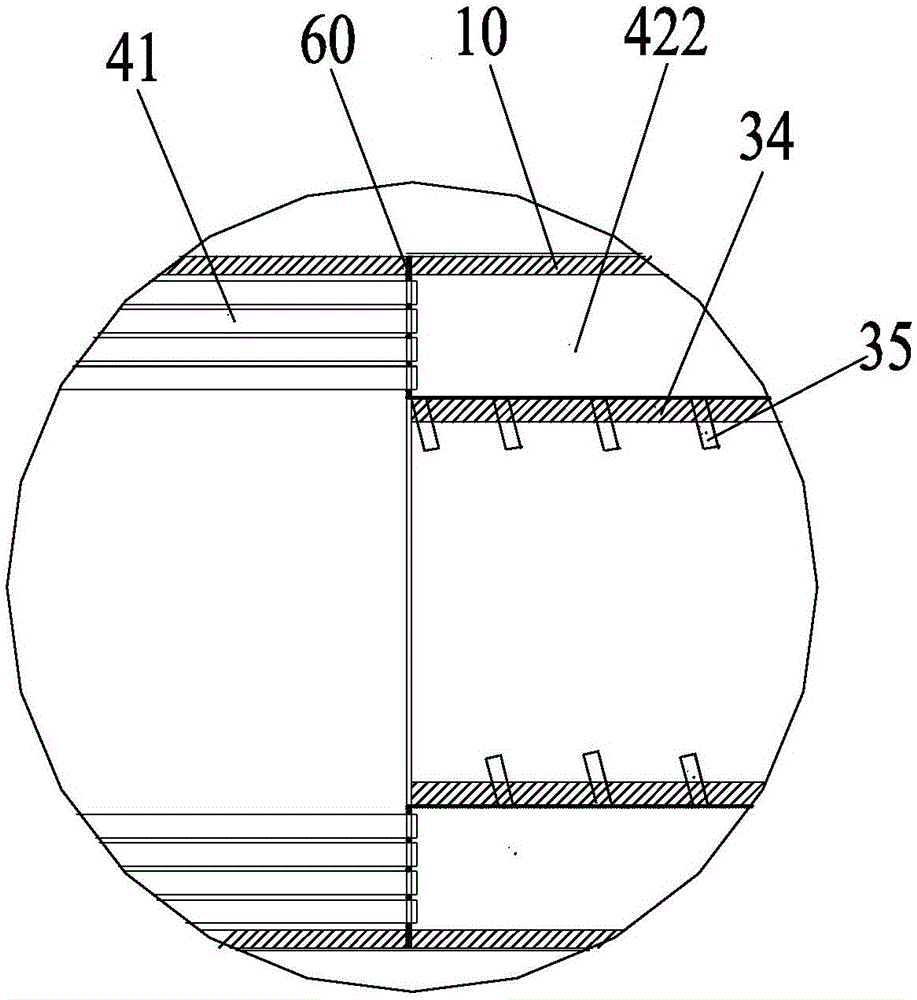

Rotary radiation bed

PendingCN106281382AImprove retort efficiencySolve low work efficiencySpecial form destructive distillationCoke ovens heatingSlagEngineering

The invention provides a rotary radiation bed. The rotary radiation bed comprises a radiation bed cylinder and a heating device, wherein the radiation bed cylinder is arranged rotationally around the axis of the radiation bed, a feeding device is arranged at one end of the radiation bed cylinder, and a discharging device is arranged at the other end of the radiation bed cylinder; at least part of the heating device is arranged in the radiation bed cylinder and used for heating a raw material entering the radiation bed cylinder. With the adoption of the rotary radiation bed of the technical scheme, continuous feeding into the radiation bed cylinder can be performed through the feeding device, slack coal is evenly heated and dry-distilled by the heating device in the radiation bed cylinder, dry-distilled gas and coal slag are discharged continuously by the discharging device, and accordingly, the dry distilling efficiency of the slack coal is effectively improved, and the problem of lower work efficiency of raw coal dry distilling equipment in the prior art is solved.

Owner:新疆广汇煤炭清洁炼化有限责任公司

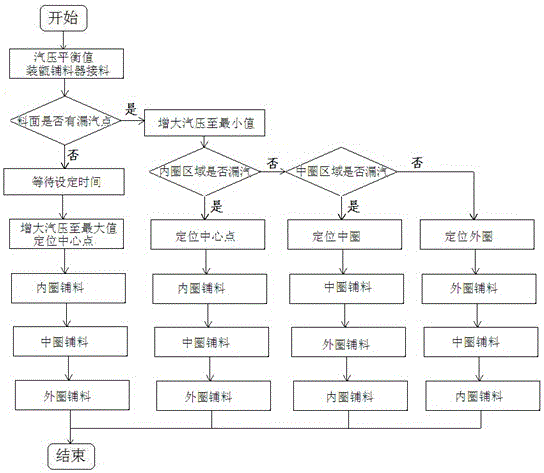

Intelligent steamer filling control method for wine making process

InactiveCN106118951ARealize automatic adjustmentReduce consumptionAlcoholic beverage preparationSteam pressureConservation energy

The invention discloses an intelligent steamer filling control method for a wine making process; the intelligent steamer filling control is achieved by controlling the initial position of a steamer filling and material spreading point in accordance with a charge level steam leakage point in a steamer barrel which is captured by virtue of an infrared thermal imager and by controlling a steamer filling steam pressure in real time by virtue of a steam electromagnetic valve; the method comprises the following steps: after receiving materials by virtue of a steamer filling and material spreading device, detecting whether a steam leakage point exists in a charge level in the steamer barrel by virtue of the thermal imager; if not, increasing the steam pressure to a maximum value, making the steamer filling and material spreading device enter the steamer barrel after a preset waiting time and beginning to sequentially implement steamer filling operations of locating a central point, spreading materials on an inner ring, spreading materials on a middle ring and spreading materials on an outer ring; if so, reducing the steam pressure to a minimum value, making the steamer filling and material spreading device enter the steamer barrel to spread the materials from the region of the steam leakage points and then paving materials in other regions, after a steamer filling action, returning to a material receiving position and regulating the steam pressure to a balanced value. By virtue of the intelligent steamer filling control method, a 'steam expelling' effect is finally achieved, so that an automatic and intelligent steamer filling process is achieved, energy consumption is reduced and steamer filling efficiency is improved.

Owner:JIANGSU KINGS LUCK BREWERY

Efficient internal thermal type oil extraction device for powder oil shale and extraction method thereof

InactiveCN102161899BSufficient heat exchangeImprove thermal efficiencyDirect heating destructive distillationSpecial form destructive distillationHeating oilHeat carrier

The invention relates to an efficient internal thermal type oil extraction device for powder oil shale and an extraction method thereof. The device consists of a gas uniform distributer, a dry distillation furnace, a whirlwind clamping sleeve, a water-cooling electrical tar precipitator, an oil storage tank, a burner and a metal beehive-type heat exchanger. A dry distillation section in the dry distillation furnace is provided with the gas uniform distributer, thereby realizing the direct heat exchange between powder materials and a gas heat carrier and greatly improving heat efficiency; a multi-layer uniform wind distribution technique is used to ensure the complete dry distillation of the oil shale; and no extra energy is supplied to the whole system, thereby achieving self-sufficiency of energy. In the novel efficient internal thermal type oil extraction process for the powder oil shale, an internal thermal method is adopted, namely, the oil shale is heated by directly by gas, and the oil shale is decomposed by heating so as to generate dry distillation oil gas; and then as the dry distillation oil gas is condensed and collect to obtain high-quality crude oil and gassy mashgas.The novel process has high heat efficiency, is stable and safe, simple and reliable, and the like; and by using the novel process, the production cost of the oil extraction of the powder oil shale isgreatly reduced, and oil yield is significantly improved, thereby improving the comprehensive utilization of the oil shale.

Owner:唐山雷浩能源技术装备有限公司 +2

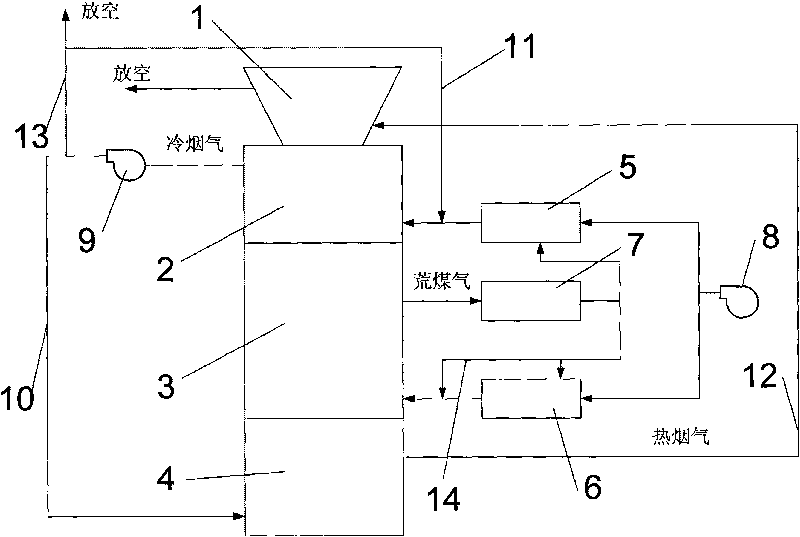

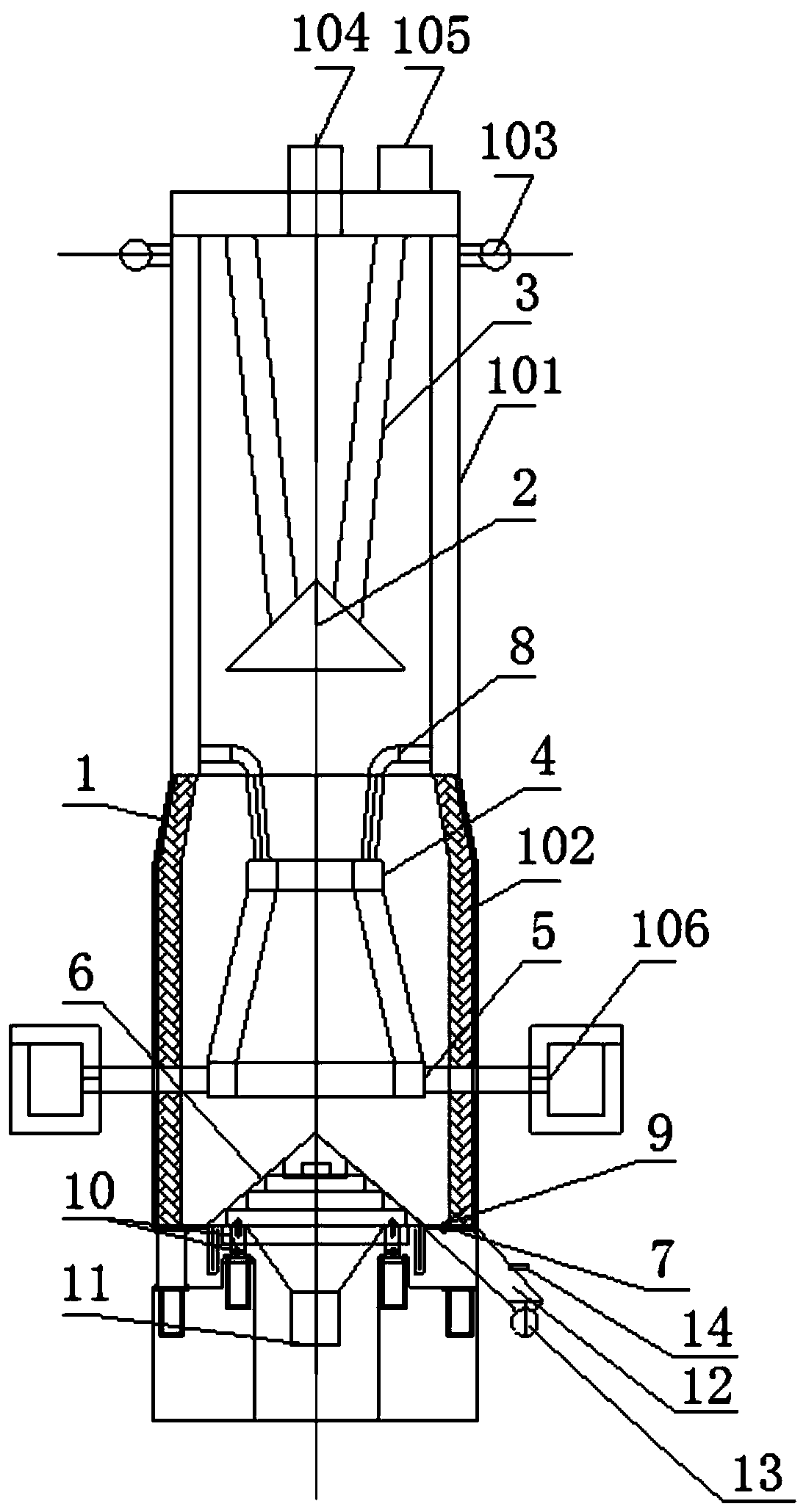

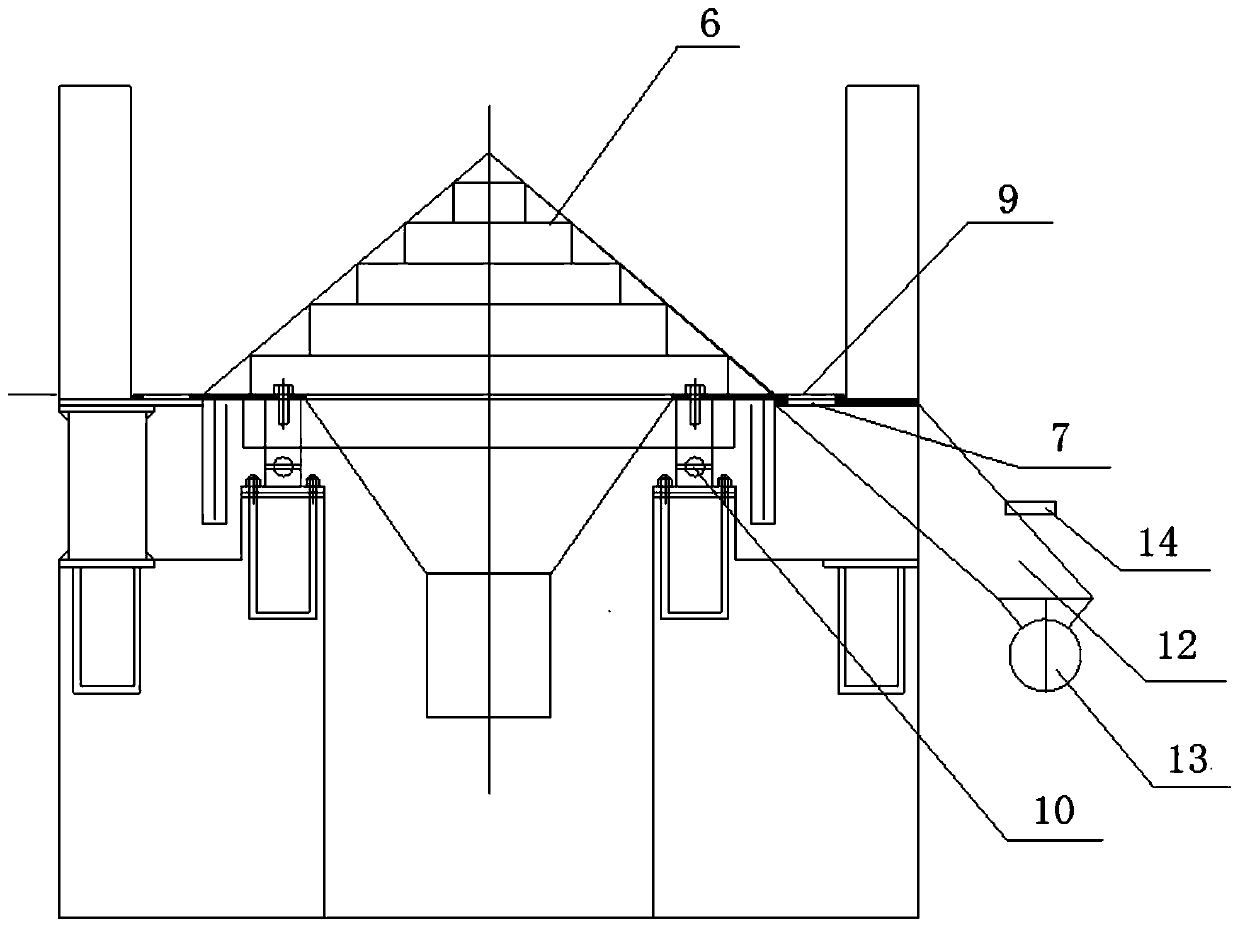

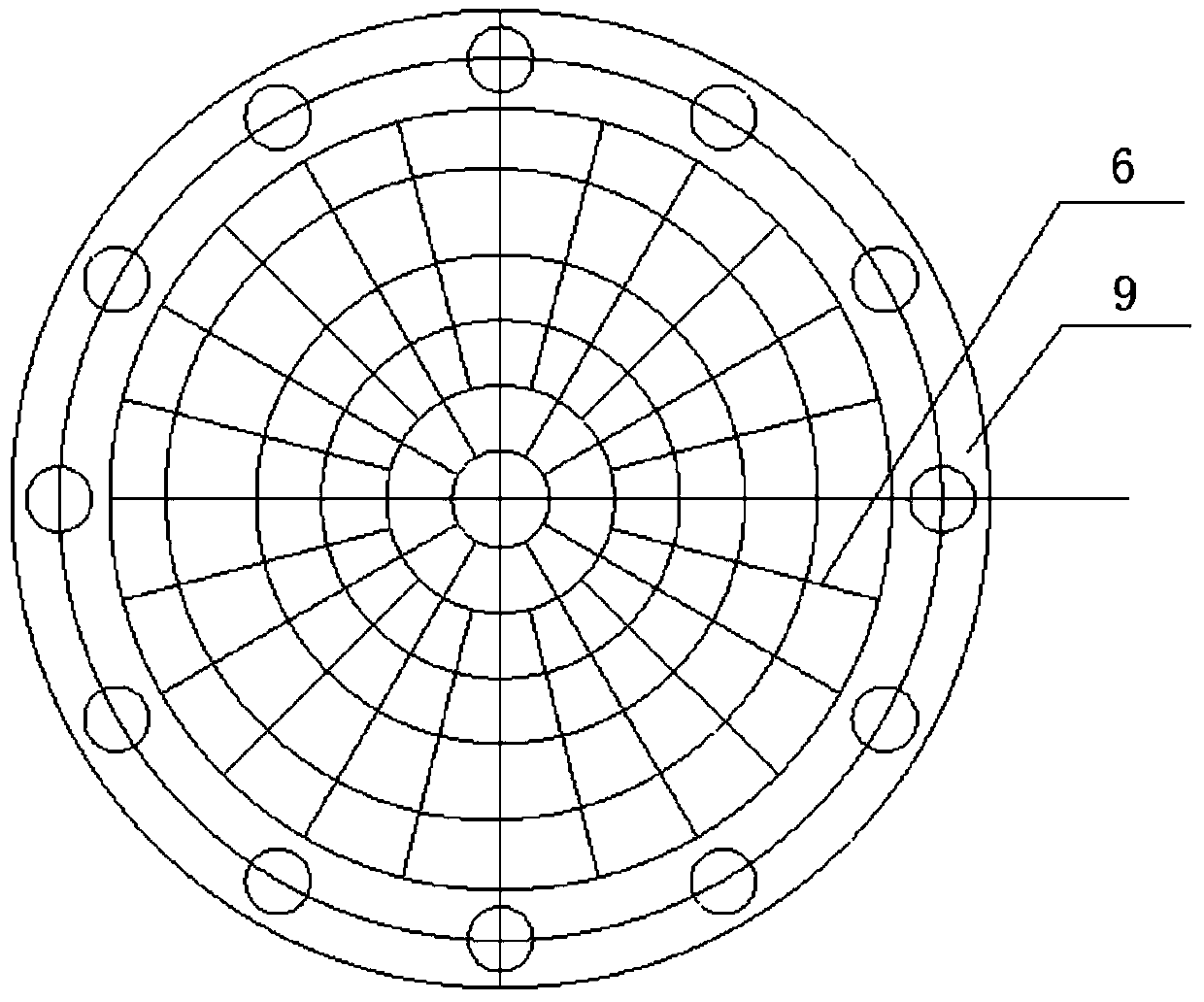

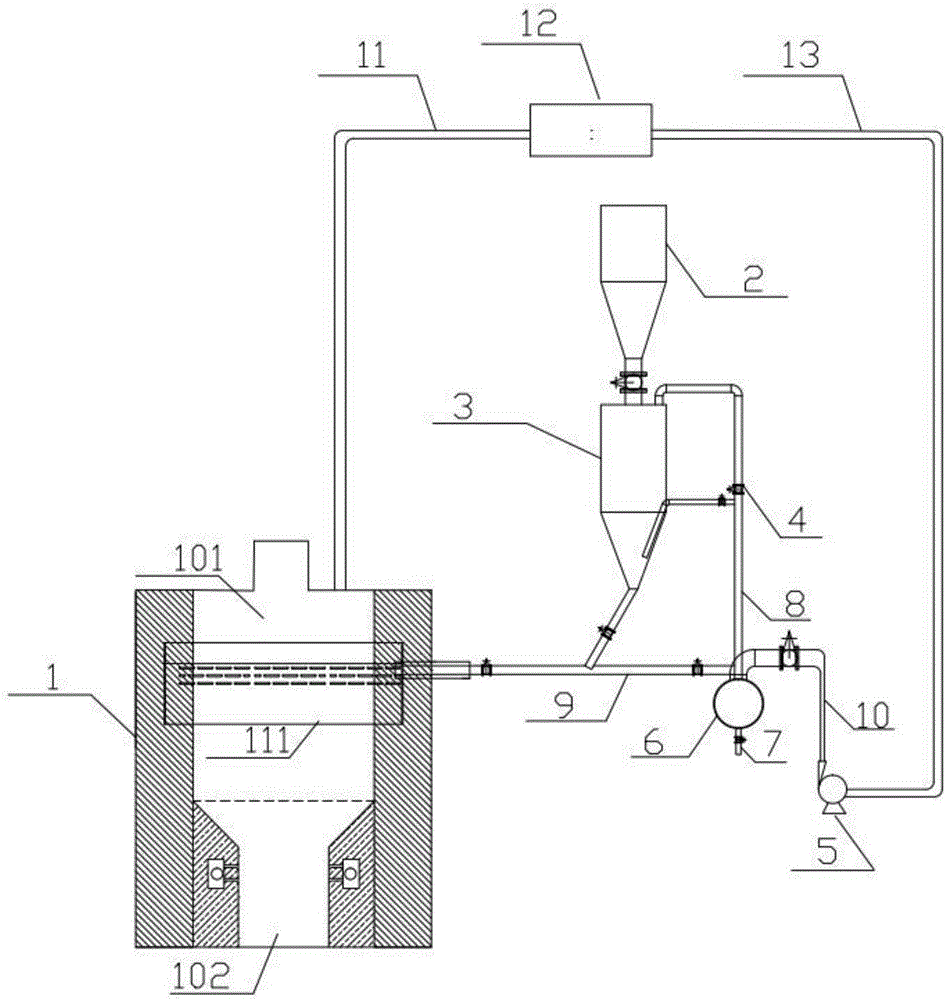

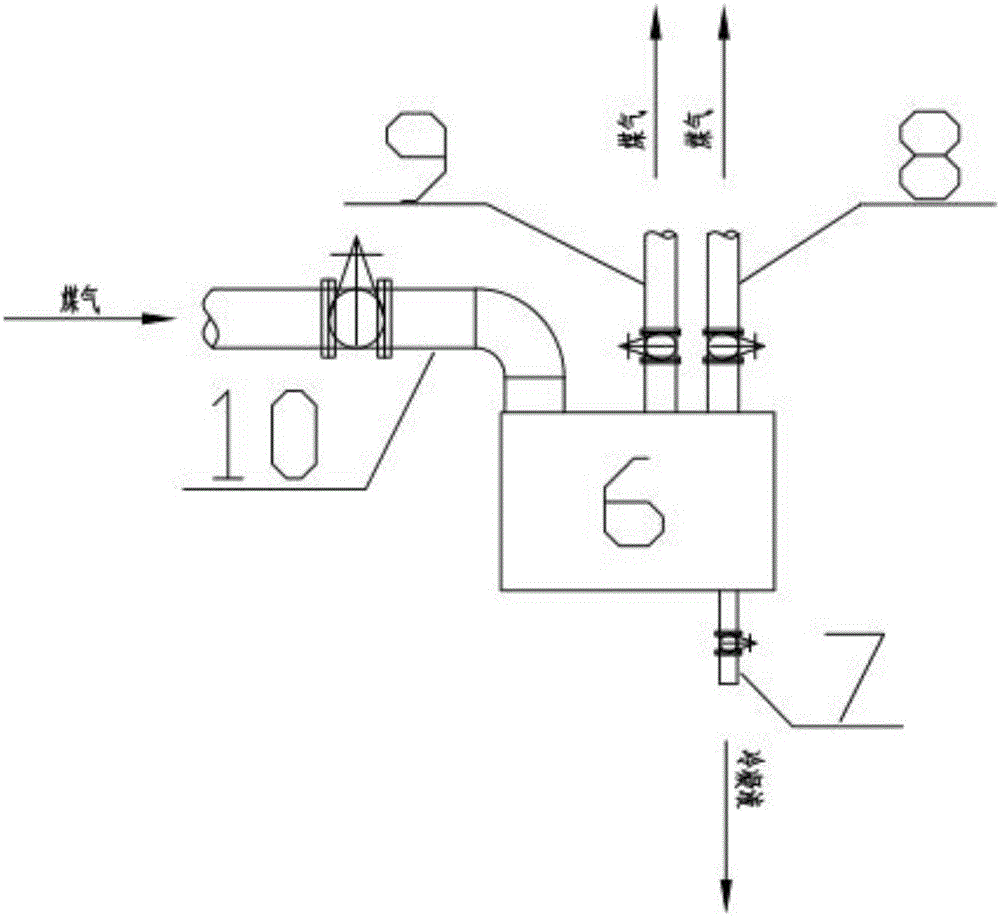

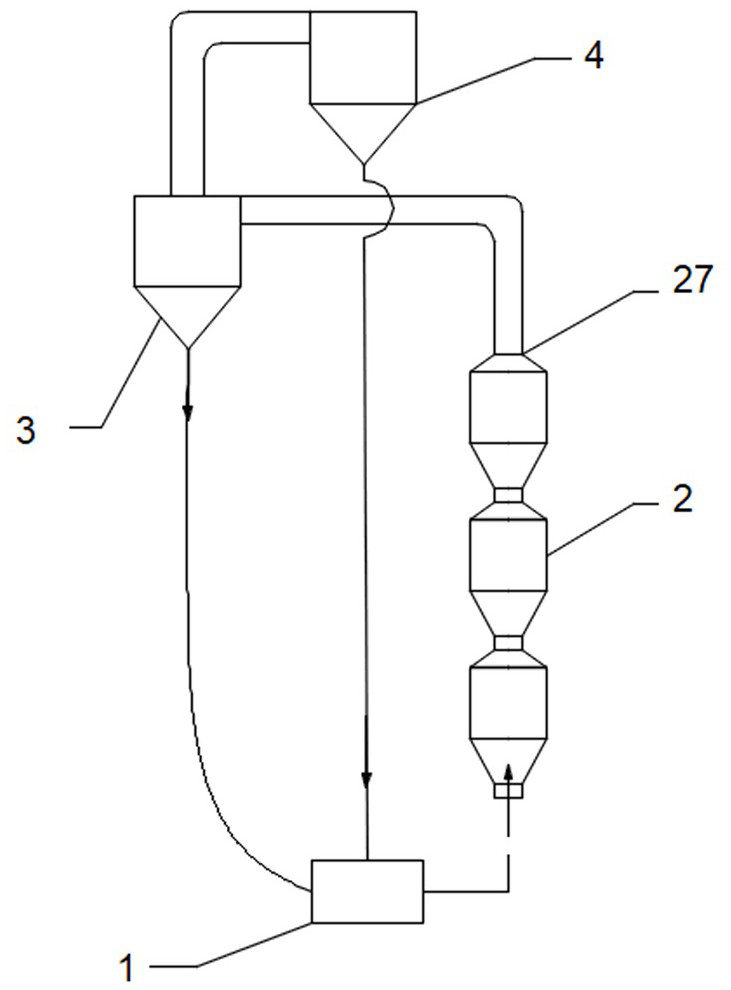

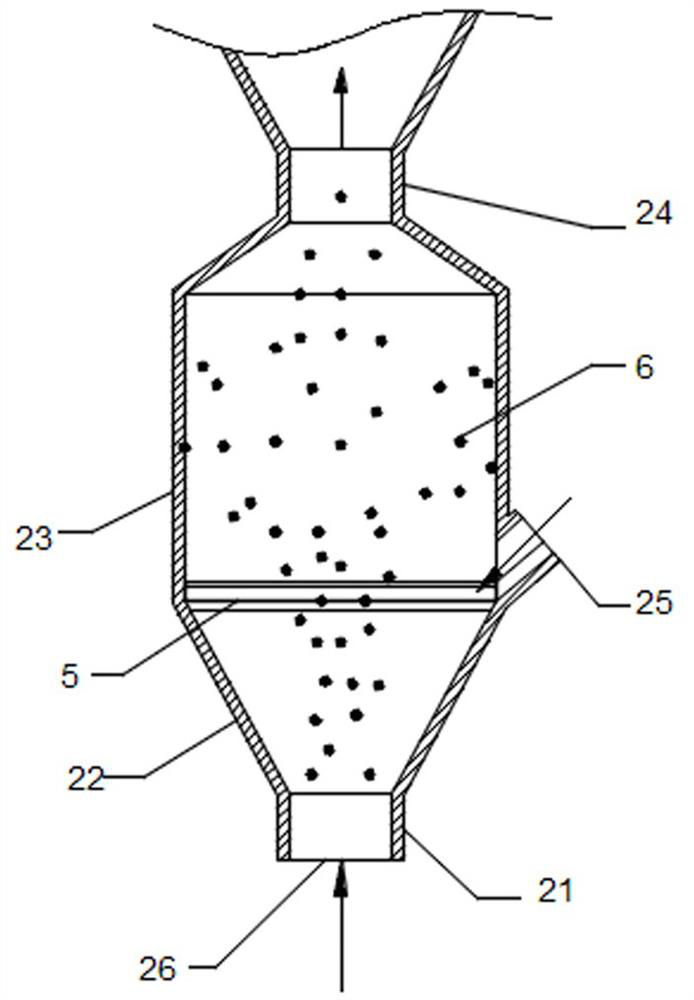

Pulverized coal low temperature carbonization system and method and coal low temperature carbonization system

PendingCN106833702AEfficient use ofHigh yieldSpecial form destructive distillationThermodynamicsCarbonization

The invention discloses a pulverized coal low temperature carbonization system, comprising a pulverized coal feeding device, a low temperature carbonization furnace (1) and a coal gas circulation system, wherein the low temperature carbonization furnace (1) comprises a carbonization section (101) and a cooling section (102) arranged at the lower end of the carbonization section (101), the top of the low temperature carbonization furnace (1) is connected with the coal gas circulation system, the coal gas circulation system is connected with the pulverized coal feeding device, and the coal gas circulation system and the pulverized coal feeding device are connected with the carbonization section (101) of the low temperature carbonization furnace (1) through an ejector (9). The invention also discloses a coal low temperature carbonization system comprising the low temperature carbonization furnace (1) and the coal gas circulation system. The invention also discloses a pulverized coal low temperature carbonization method. The pulverized coal low temperature carbonization system and method and the coal low temperature carbonization system, provided by the invention, have the following beneficial effects: (1) the feeding amount of pulverized coal can be controlled, and the pulverized coal is ejected to a position, with high temperature, of the carbonization section of the low temperature carbonization furnace, so as to realize effective carbonization and high carbonization efficiency; (2) the phenomenon that during pulverized coal carbonization, the pulverized coal is discharged out of the furnace along with raw coke oven gas, resulting in waste and pollution, is avoided, the pulverized coal is fully and effectively utilized, so as to increase the productive rate of raw coal and the pulverized coal thereof during carbonization, thereby obtaining good economic benefit.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM

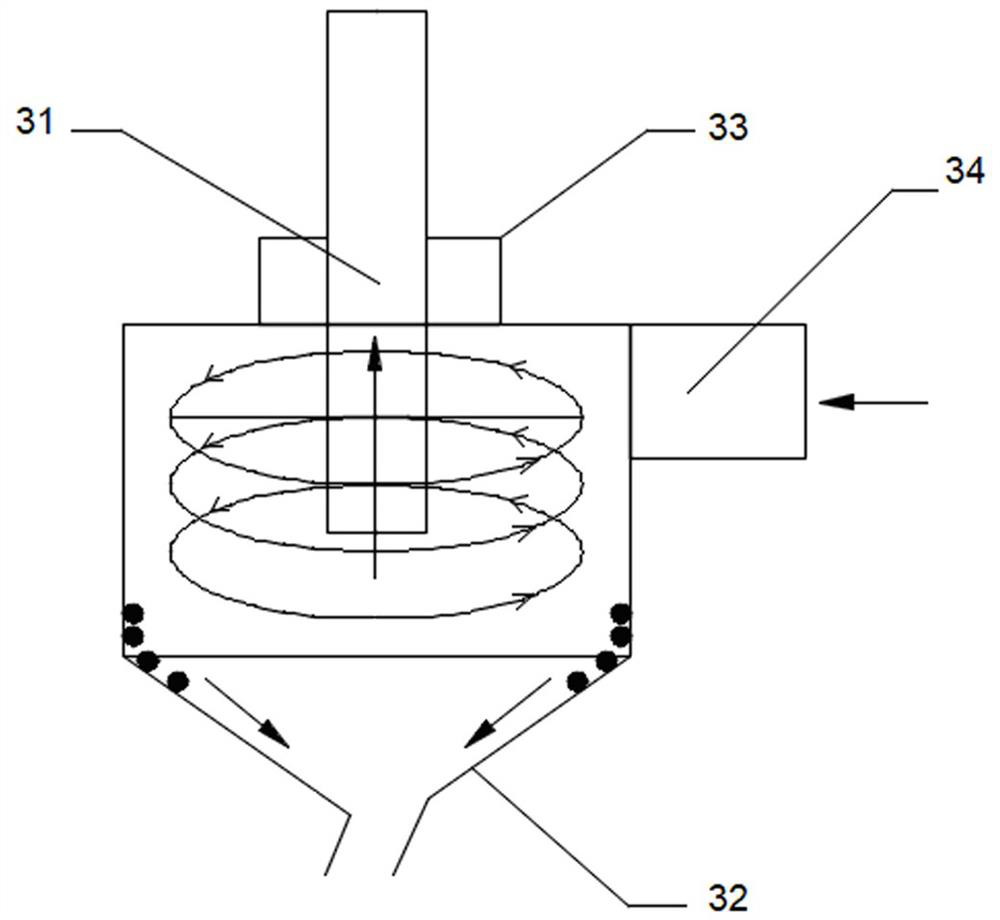

Spouting furnace system for semicoke destructive distillation of oil shale or shale semicoke and destructive distillation method thereof

ActiveCN113528168AImprove retort efficiencyImprove oil yieldSpecial form destructive distillationThermodynamicsDestructive distillation

The invention discloses a spouting furnace system for semicoke destructive distillation of oil shale or shale. The spouting furnace system comprises a spouting furnace and a cyclone dust collector, the spouting furnace comprises a furnace body unit composed of a lower necking opening, a circular truncated cone-shaped conical shell and a cylindrical shell from bottom to top, the spouting furnace is formed by combining one to four furnace body units, a feeding port is formed in the bottom of a cylindrical shell of the lowermost furnace body unit of the spouting furnace, a hot air inlet is further communicated with a lower necking opening of the lowermost furnace body unit, and an oil gas outlet is formed in a connector in the top of a cylindrical shell of the uppermost furnace body unit of the spouting furnace; and the spouting furnace further comprises the cyclone dust collector, a gas inlet of the cyclone dust collector is communicated with an oil gas outlet of the spouting furnace, and the primary cyclone dust collector comprises a conical outlet. According to the invention, the oil shale particles are circulated in the spouting furnace for heat exchange by using the spouting furnace until shale oil and shale gas are completely released, so that the oil yield is improved, and meanwhile, the pollution of destructive distillation products and the pollution to the environment in the destructive distillation process are reduced.

Owner:润鑫杭州新材料科技有限公司

Integral process for oil shale retorting oil refining and coal-char combustion power generation

InactiveCN100594228CHeating Oil Shale FastShort retort timeInternal combustion piston enginesPowdered engine fuelsHeat carrierInternal combustion engine

The present invention discloses an oil shale carbonization oil refining, carbocoal burning electricity generating integrated technology. The present invention is characterized in that green ore oil shale is crushed into 0 to 15mm grains by a crusher, through that circulating fluid bed boiler circulating ash is used as a solid heat carrier, the mixture of the oil shale and the circulating ash is fed into a roller retort to form oil shale oil refining, carbocoal and the oil shale are mixed, fluidized and burned to generate electricity as a whole, separated non-condensation carbonization coal gasis fed into the circulating fluid bed boiler and the both are burned with the carbocoal and the oil shale together or is fed into a gas engine for direct-fired power generation; the carbon content ofthe clinker after burned on the circulating fluid bed is less than 2 percent, thus no further roasting is necessary, and the present invention can be directly used as building raw material; the thermal value of produced carbonization coal gas which can be directly used as fuel to feed into the boiler for burning is high, the quantity of heat released through burning can be transferred to the water through the heated surface of the boiler, the water is heated into a overheat steam to be used as out-supplied working substance and / or to be fed into a steam turbine for power and electricity generating. The present invention has the advantages that the comprehensive utilization degree is high, the cost is low, the technology is scientific and reasonable, etc.

Owner:NORTHEAST DIANLI UNIVERSITY +1

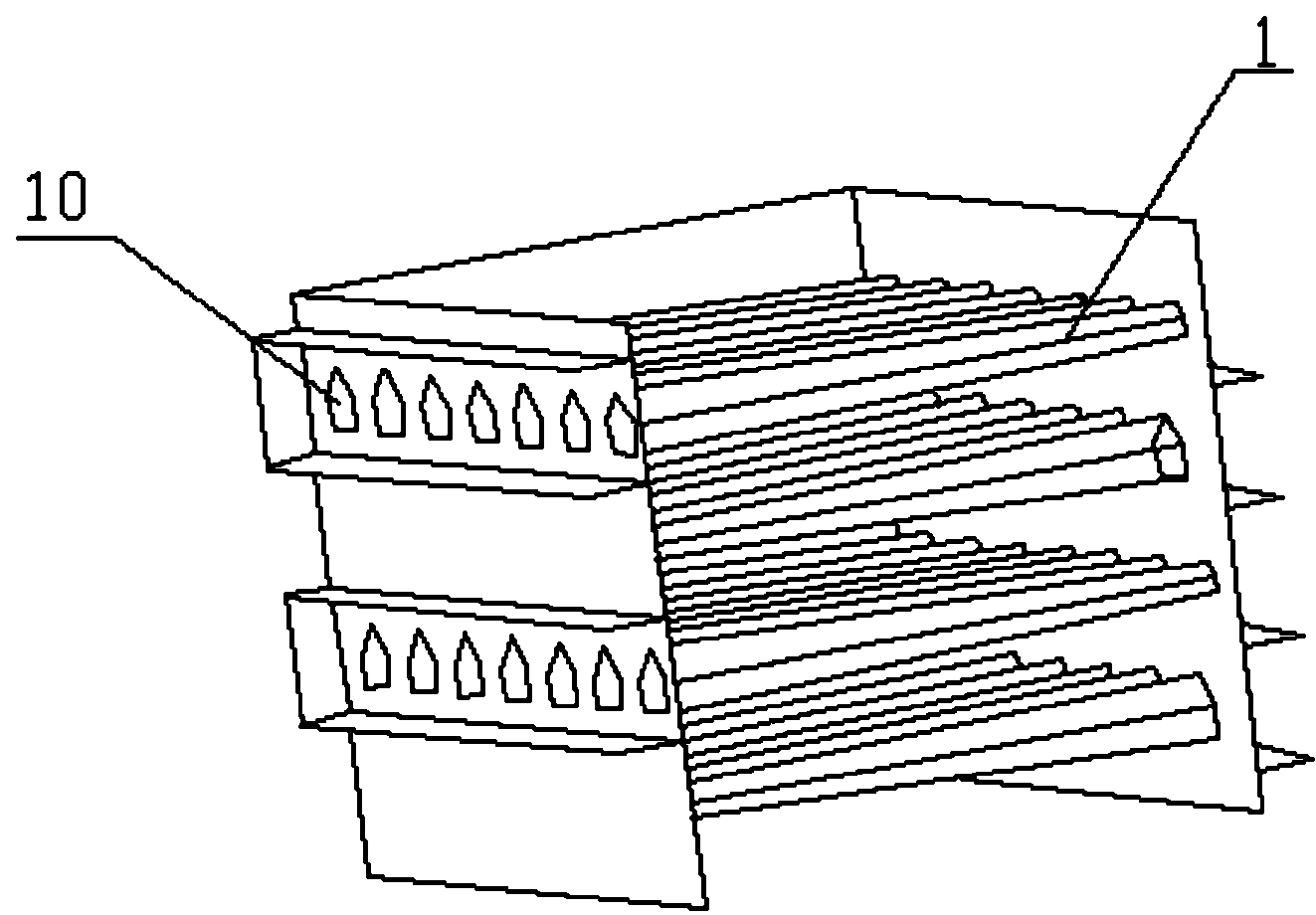

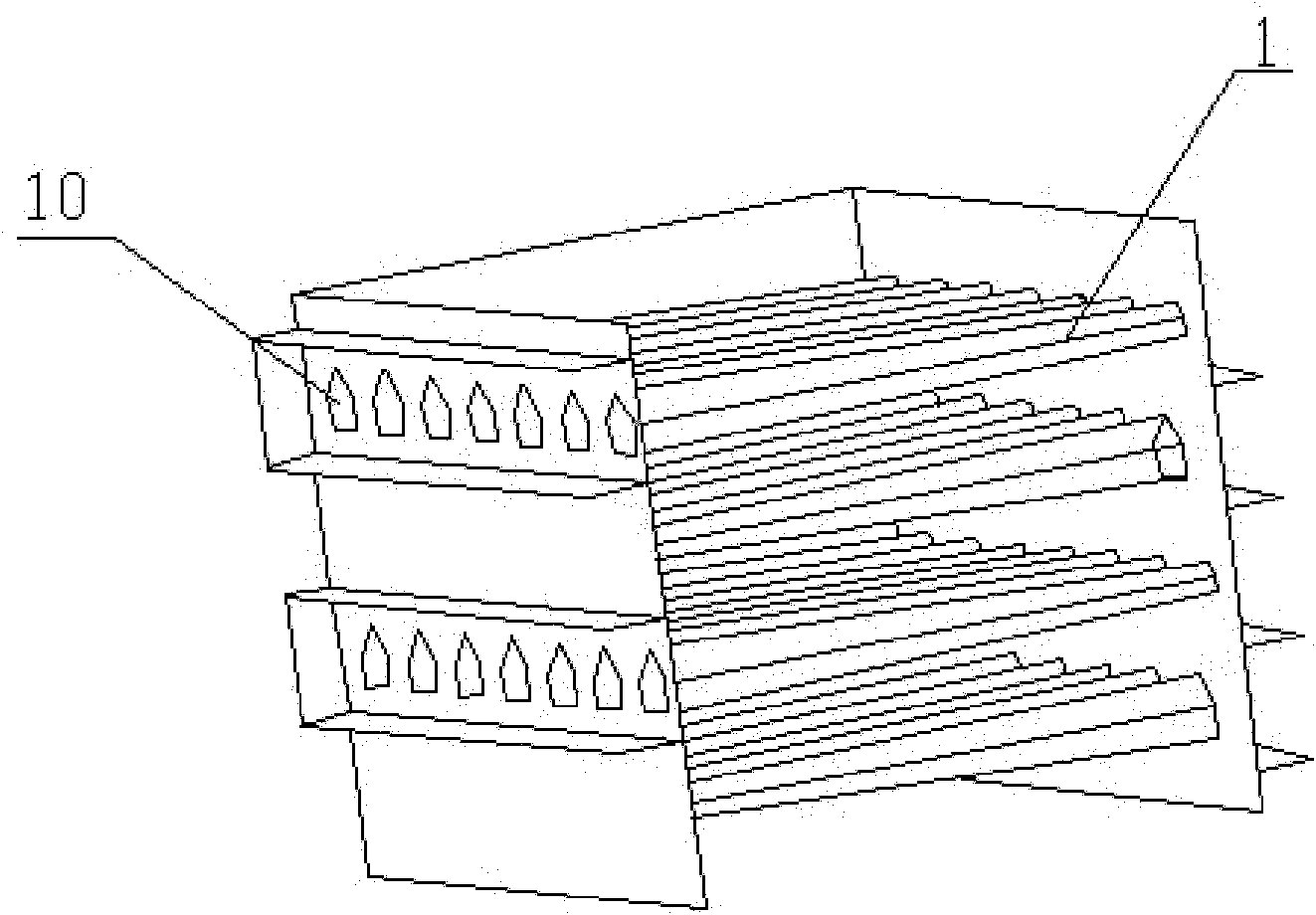

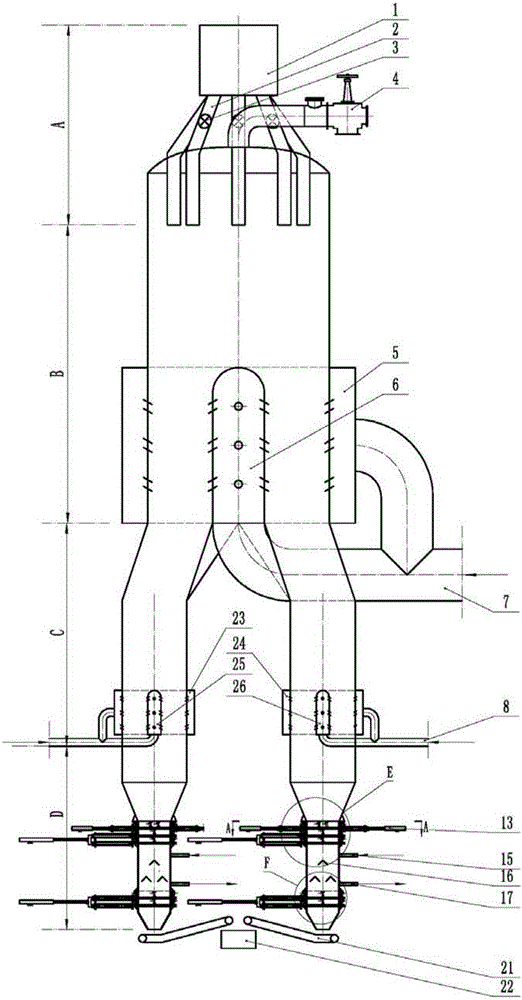

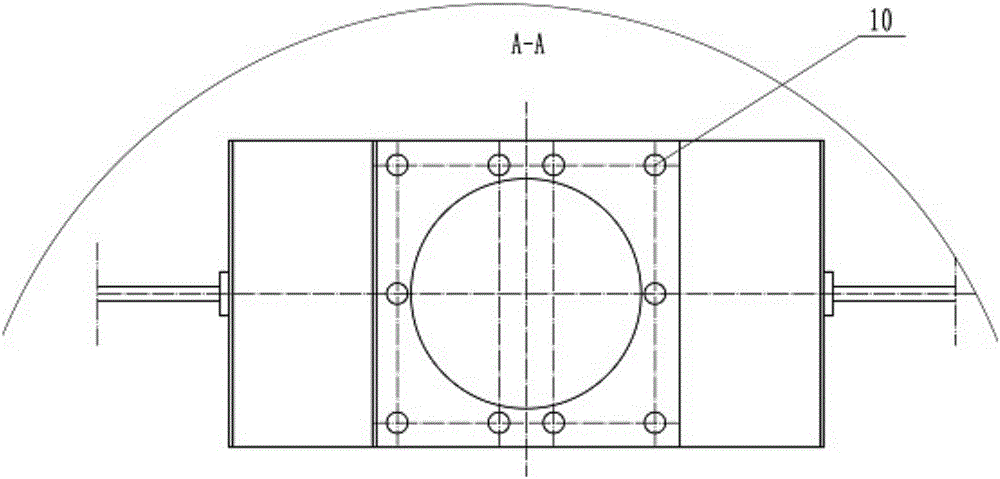

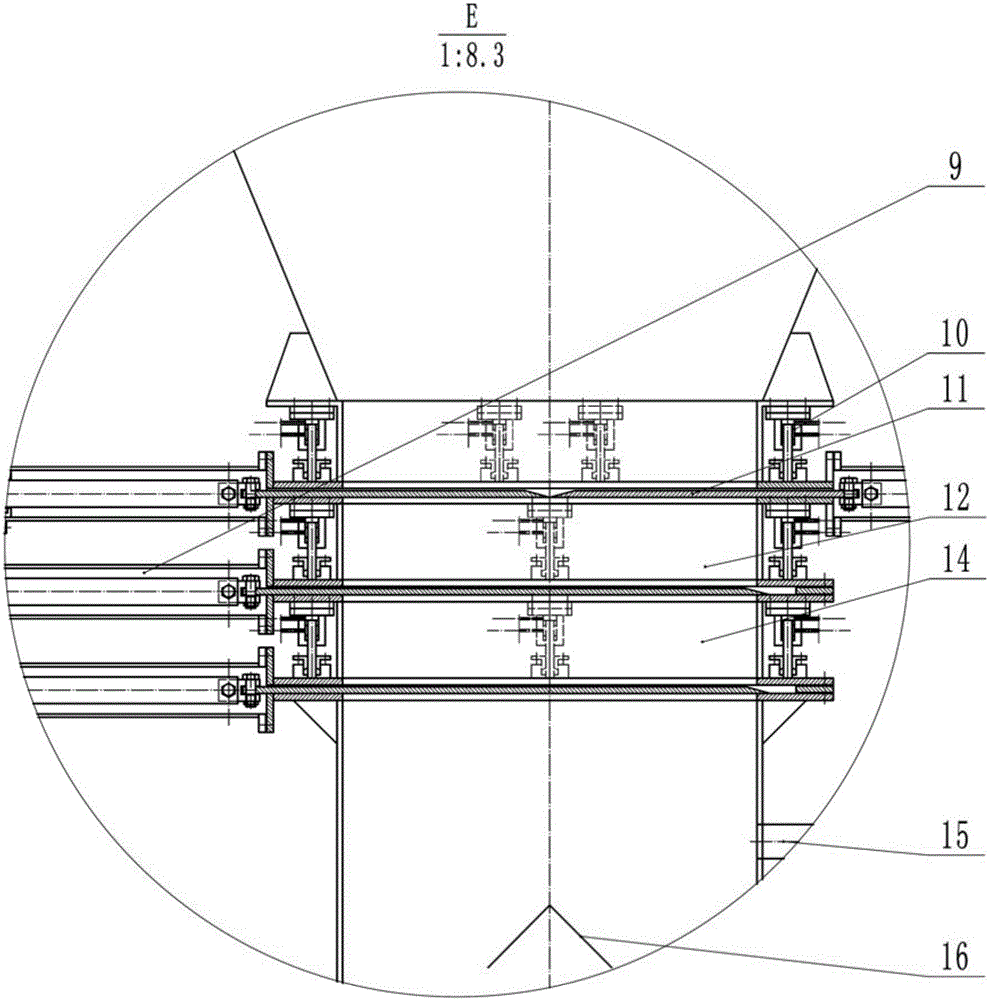

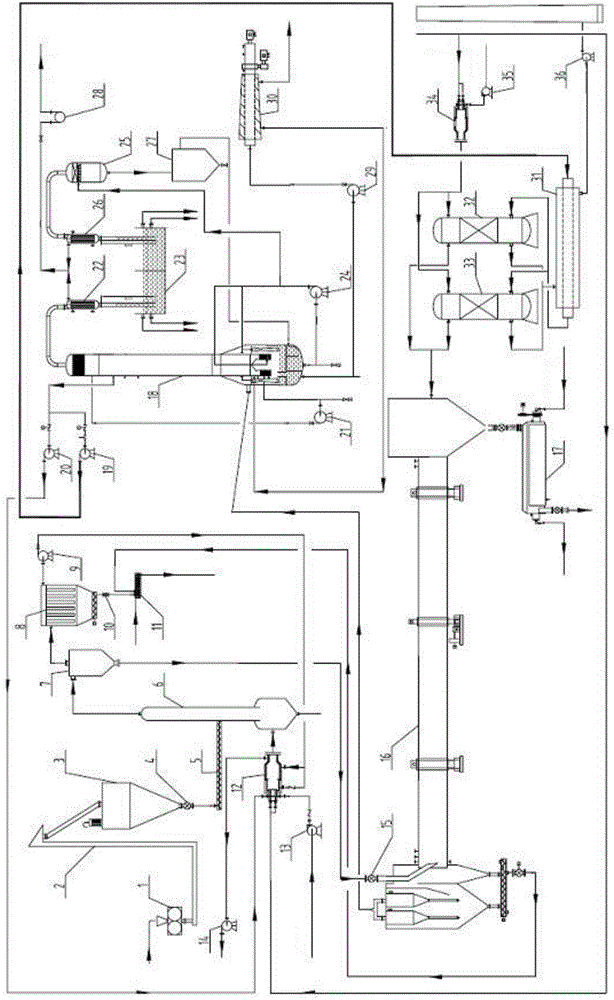

An oil shale gas heat carrier carbonization furnace that is easy to be enlarged

ActiveCN104479705BEvenly heatedSmooth dischargeDirect heating destructive distillationSpecial form destructive distillationHeat carrierSlag

The invention discloses a dry distillation furnace for oil shale gas heat carriers easy for enlargement. The dry distillation furnace is characterized by comprising the following steps: feeding crushed oil shale materials in required particle sizes into a dry distillation segment at the constant speed under the control of a feeding controller; ensuring that the hot mine gas of 600-700 DEG C pumped in can be in intensive mixing dry distillation with the materials under the combined action of a gas distribution bellow and a cap-type gas distribution device in the dry distillation segment; arranging a gas distribution bellow and a cap-type gas distribution device in a cooling segment as well, guaranteeing that the cold mine gas of 20-40 DEG C pumped in can be in intensive mixing with carbocoal to be cooled, and cooling carbocoal to below 300 DEG C; in a dry slag discharge system, adopting a labyrinth sealing plate structure and a cold mine gas circulation system in a carbocoal discharge chamber to guarantee that carbocoal is discharged smoothly, and that outside air is prevented from entering a furnace body meanwhile; meanwhile, array umbrellas are arranged in the carbocoal discharge chamber to prevent carbocoal from impacting a lower sealing plate in the falling process; after being discharged, carbocoal is conveyed into a crush machine through a sealing belt conveyor for crushing treatment.

Owner:NORTHEAST DIANLI UNIVERSITY

Coal heat carrier dry distillation system and method thereof

ActiveCN103409156BIncrease profitReduce oxygen contentDirect heating destructive distillationEnergy inputCooling towerHeat carrier

The invention relates to a heat carrier destructive distillation system for coal, which comprises a raw coal cabin, a flash dryer, and a circulating fluidized bed air heating furnace, wherein a spiral metering conveyor I is arranged at the bottom of the raw coal cabin; a flash dryer is connected with a drying primary separator and an air heating furnace twice cyclone separator; the drying primary separator is connected with a drying secondary separator and a mixer; the air heating furnace twice cyclone separator is connected with a cooling paddle machine and a waste heat boiler; the waste heat boiler is connected with an air heating furnace once cyclone separator connected with the mixer and the circulating fluidized bed air heating furnace; the mixer is connected with an internal thermal rotary gas retort; a separator is connected with a cooling tower and a fluidized bed grading cooler; the cooling tower is connected with a coal gas air blower and a tar oil cooler; the fluidized bed grading cooler is connected with a semi-coke delivery pipe, the drying secondary separator and a grading cyclone separator; the circulating fluidized bed air heating furnace is connected with the grading cyclone separator. In addition, the invention further discloses an application method of the system. The heat carrier destructive distillation system is low in investment and easy to implement, and has high overall efficiency and excellent safety.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

A method for controlling the retort of brewing and distillation process by using images

ActiveCN107168117BImprove productivityImprove retort efficiencyProgramme control in sequence/logic controllersDistillationMaterial distribution

The invention discloses a method for controlling material distilling in liquor brewing distillation technology by use of images. The method comprises steps of step 1, initializing a system; step 2, image acquiring: acquiring infrared thermal images; step 3, carrying out circulation test on the infrared thermal images; step 4, extracting pixel regions meeting the condition that the pixel value G is between G1 and G2 in the infrared thermal images as heat regions; step 5, processing the heat region images; and step 6, solving the position of the center point of covering materials, and charging materials in the center point to the boundary position of a covering material region, thereby finishing material charging. According to the invention, a thermal imaging camera is used for acquiring images so as to search the heat regions, so the position of an overflow critical point of the liquor steam is intelligently recognized; the coordinate of the center of mass is solved, so the material distribution center is rapidly determined in real time and through a hopper, tracking is automatically performed and specific spiral type material distribution to the boundary of the covering material region is performed; and efficiency of material distilling and yield of liquor during a distillation process are greatly improved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

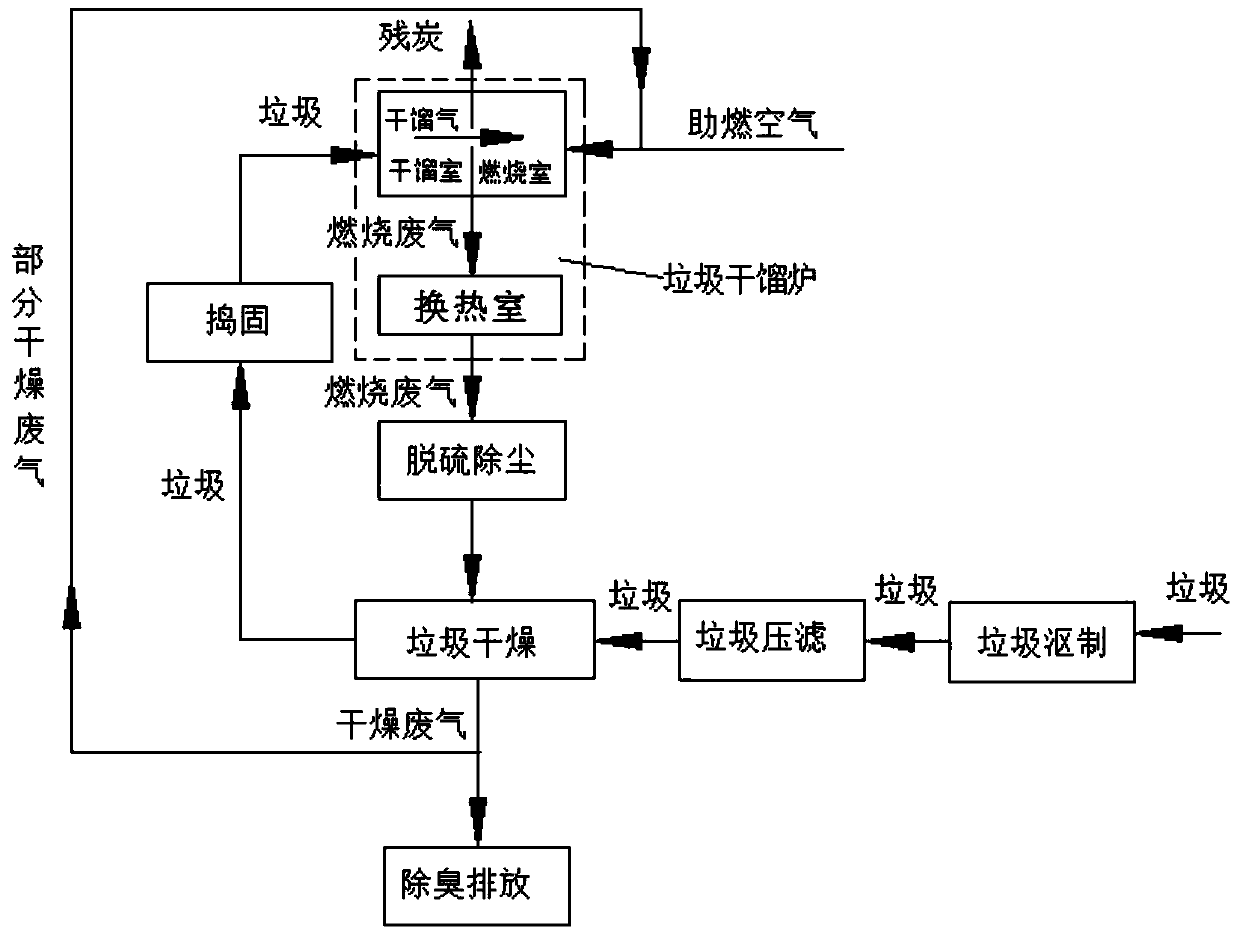

A garbage disposal method and garbage dry distillation furnace

ActiveCN105333441BDisposal method is environmentally friendlySimple processing methodIncinerator apparatusCombustion chamberHeat exchanger

The invention relates to the technical field of garbage treatment, in particular to a garbage treatment method and a garbage carbonization furnace. The garbage treatment method includes the following steps: S1, preliminary dehydration of the garbage to be treated; S2, drying of the preliminary dehydrated garbage; S3, tamping of the dried garbage; S4, drying of the garbage carbonization furnace , making the temperature in the retort chamber of the garbage retort furnace reach the set temperature; S5, importing the tamped garbage into the retort chamber of the garbage retort furnace, and performing retort distillation to obtain retort gas; S6, the retort gas obtained in step S5 is guided through the retort gas The outlet is introduced into the combustion chamber of the garbage carbonization furnace for combustion; S7, the combustion waste gas generated by the combustion in step S6 is passed into the heat exchange chamber for heat exchange. The garbage treatment method provided by the invention can improve the efficiency of garbage dry distillation, improve the energy utilization rate in the garbage treatment process, and make the garbage treatment method more environmentally friendly.

Owner:SHENWU TECH GRP CO LTD

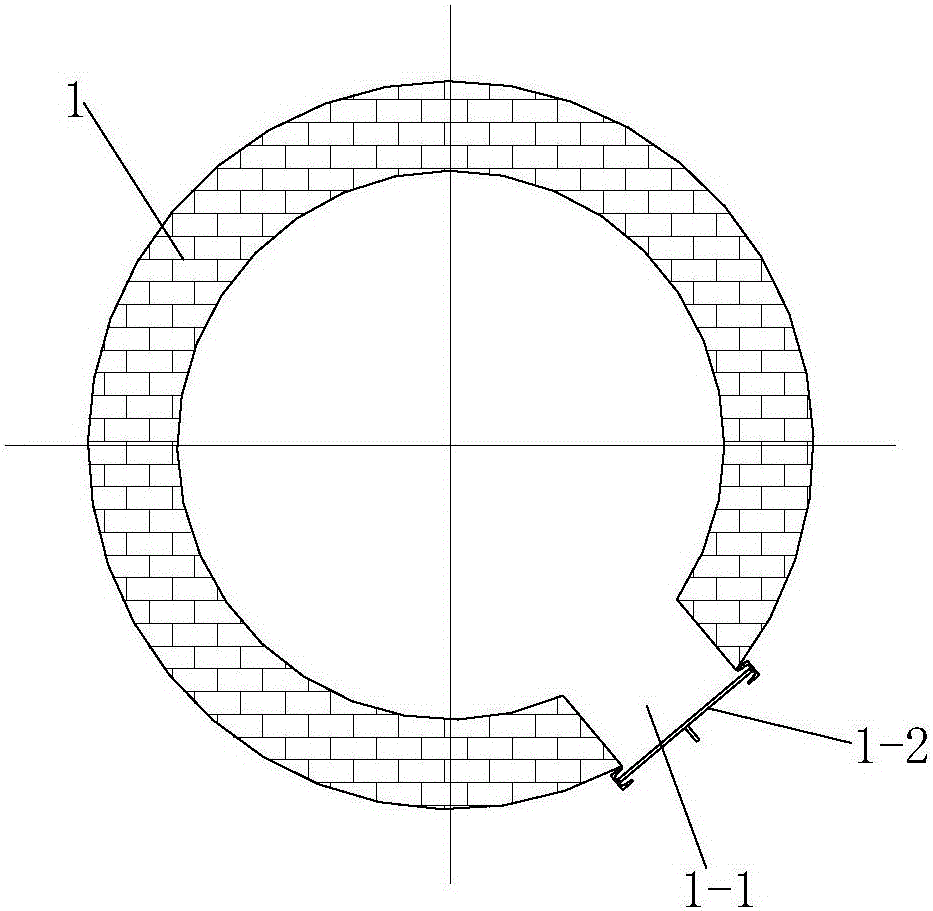

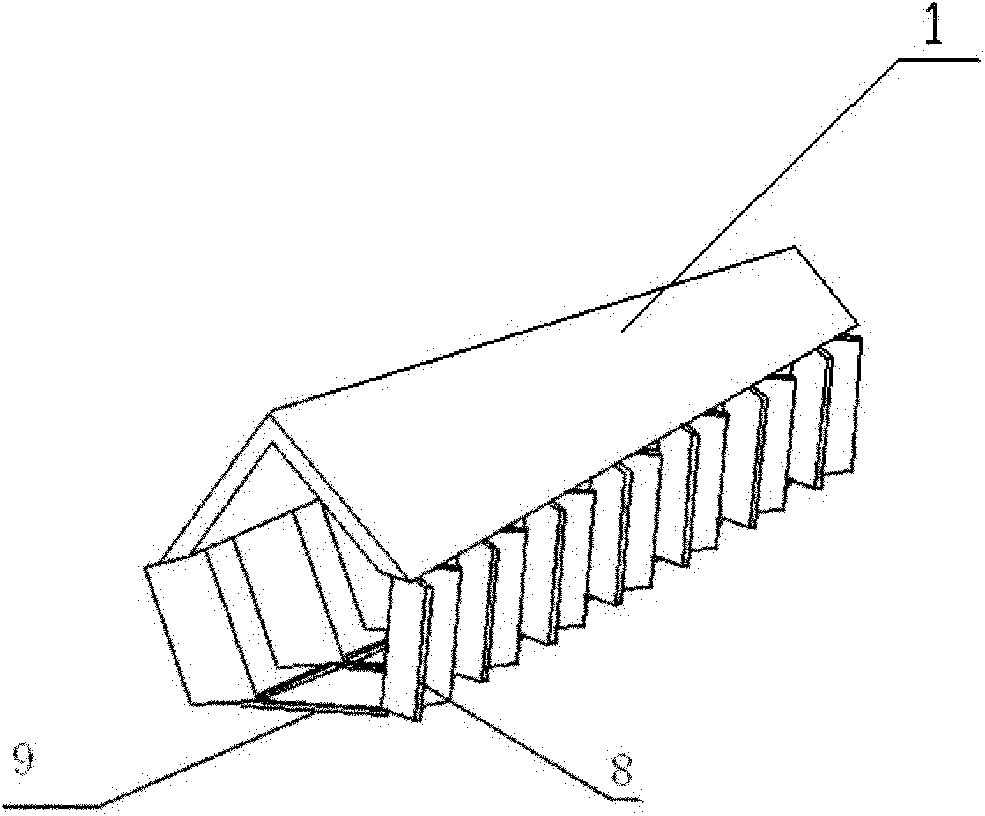

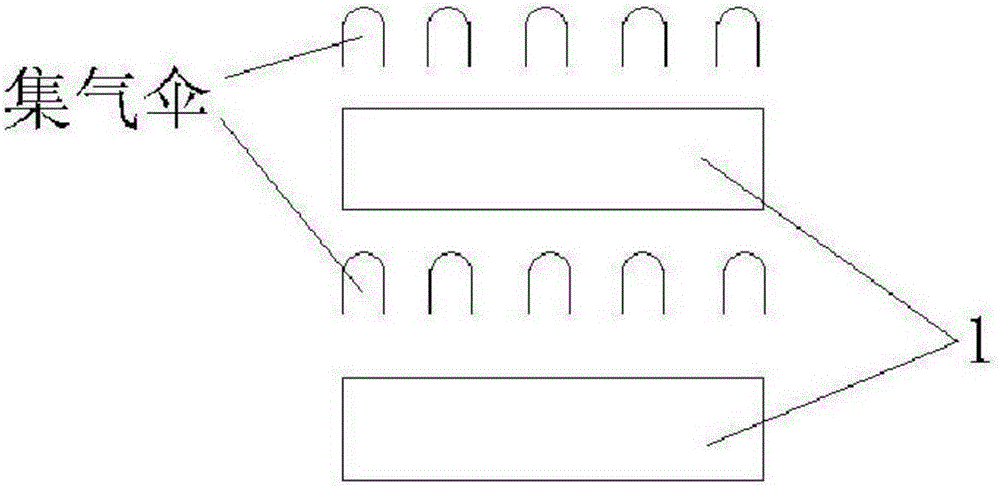

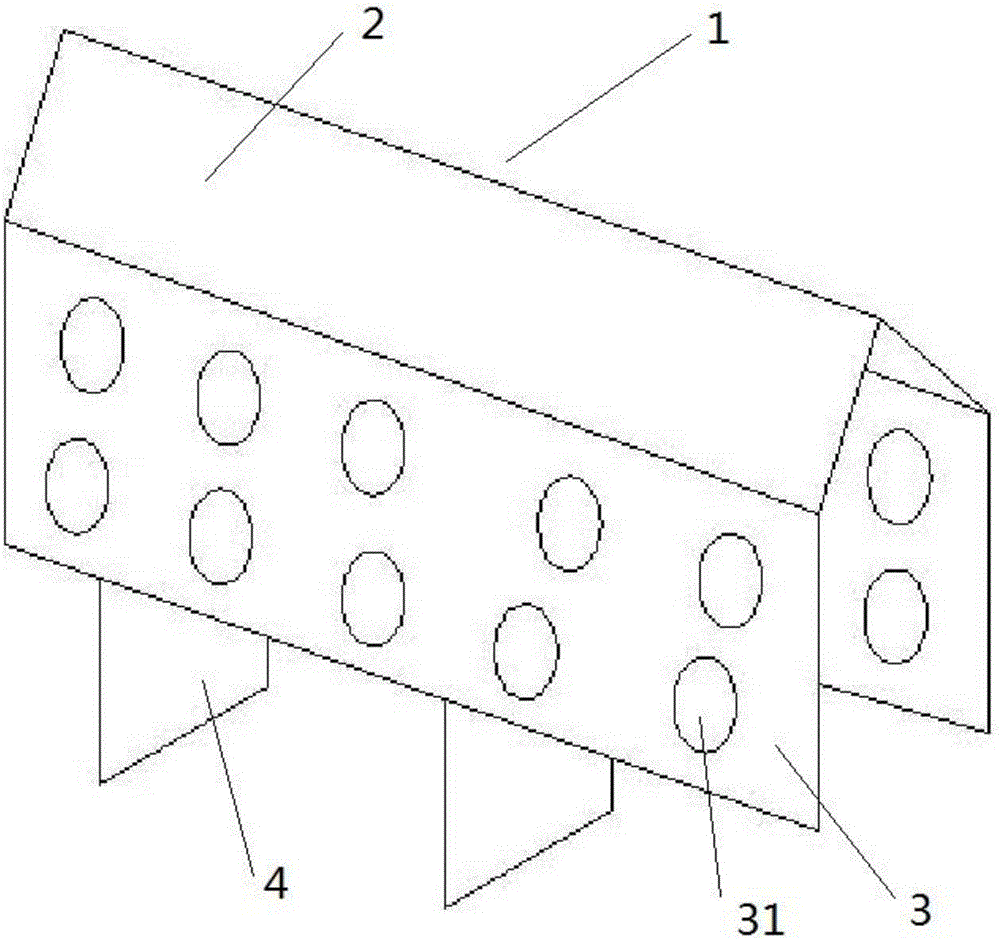

Gas guide system and method

InactiveCN106010609AReduce blow-byImprove retort efficiencySpecial form destructive distillationDistillation gas withdrawalCombustionProcess engineering

The invention discloses a gas guide system. The gas guide system is characterized by comprising at least one gas guide device (1) fixedly connected in a semicoke low-temperature dry distillation furnace; each gas guide device (1) comprises a device top (2) and connecting baffles (3), wherein the two ends of the device top (2) are fixedly connected with the connecting baffles (3), each connecting baffle (3) is provided with one or more gas nozzles (31), and at least one airflow baffle (4) is arranged on the upper portion in the device top (2). The gas guide system has the advantages that dry distillation can be carried out on raw coal with the particle size smaller than 30 mm through the semicoke low-temperature dry distillation furnace, and air distribution in the dry distillation furnace can be more uniform; in the process of carrying out dry distillation on the raw coal with the particle size smaller than 30 mm, the resistance of raw coal combustion gas can be reduced, the gas can be guided out of the dry distillation furnace more smoothly, and thus equipment loss is reduced.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM

Coal low temperature dry distillation method

InactiveCN104017594BHigh calorific valueAvoid cloggingSpecial form destructive distillationGas purification by liquid washingOil sludgeHeating furnace

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com